Page 1

BenQ Rev 1.0

1

BenQ March (D72)/Amethyst

LT Mobile Phone

Service Manual

BenQ Inc.

Wireless Business Unit

Customer Service Dep.

Tel : +886-(0)2-2799-8800 ext 6687

E-Mail : Roychen@acercm.com.tw

Page 2

BenQ Rev 1.0

2

Contents

l Preface…………………………………………………..……………1

l Theory of Operation

1.GSM system Description…………………………………………7

2.Baseband function description…………………………………12

3.Radio Frequency function description ………………………..44

l Download

1.System requirements and setup ………………………………59

2.Function descriptions……………………………………………61

3.FAQ… ……………….……………….……………………………67

l Disassembly (Level1~Level2)………….………………………….69

l Troubleshooting

Level 1~level 2 repair………………………………………………73

Level 3~level 4 repair………………………………………………74

l Replacement parts

Exploded View (fig1~fig3)………………………………………….95

Spare parts list………………………………………………….…..98

l Service Manual Feedback Form……..…………………………….99

Page 3

BenQ Rev 1.0

3

Preface

This service manual is for the customers who purchase of Acer

March handset . It has several main parts of our handset that include

hardware/software and simple disassembly/assembly procedure

introduction. If you don’t understand some of these sections or any

query about it please kindly use our service manual feedback form and

send it back to our Customer Service Department and we’ll response

your query as soon as possible.

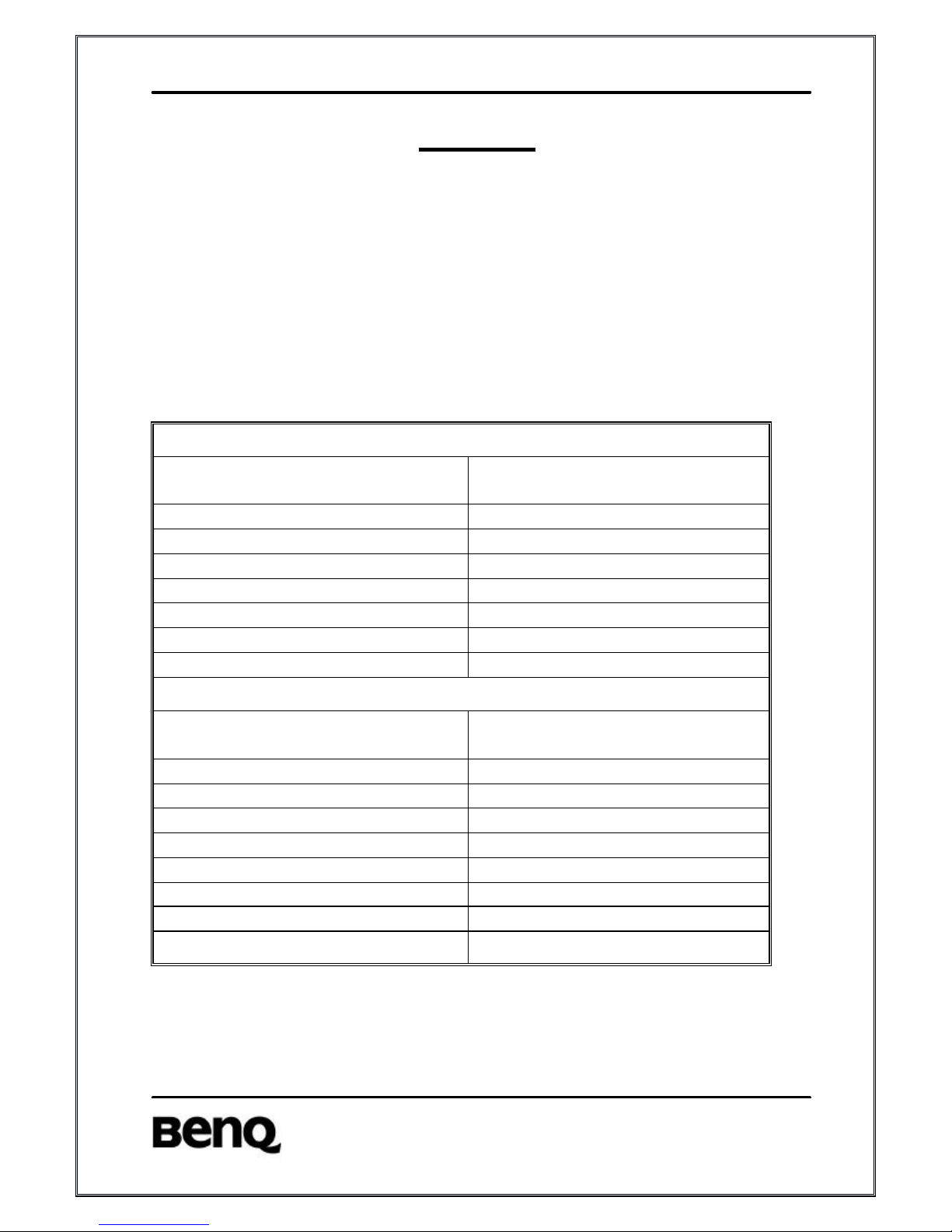

Specifications

Table 1: Radio Frequency

Radio Frequency (900 MHz)

Frequency Range TX 880-915 MHz; RX 925-

960

MHz

Channel Spacing 200 KHz

Number of Channels 174 Carriers x 8 (TDMA)

Modulation GMSK

Duplex Spacing 45 MHz

Frequency Stability +/- 0.1 ppm (Uplink TX)

Power Output 33 dBM Class 4 (2 W peak)

Receiver Level < -102 dBm (Wireless)

Radio Frequency (1800 MHz)

Frequency Range TX 1710-1785 MHz; RX

1805-1880 MHz

Channel Spacing 200 KHz

Number of Channels 374 Carriers x 8 (TDMA)

Modulation GMSK

Duplex Spacing 95 MHz

Frequency Stability +/- 0.1 ppm (Uplink TX)

Power Output 30 dBM – 0 dBM

Receiver Level < -102 dBm (Wireless)

Operating Temperature Range -10 to +55 °C

Page 4

BenQ Rev 1.0

4

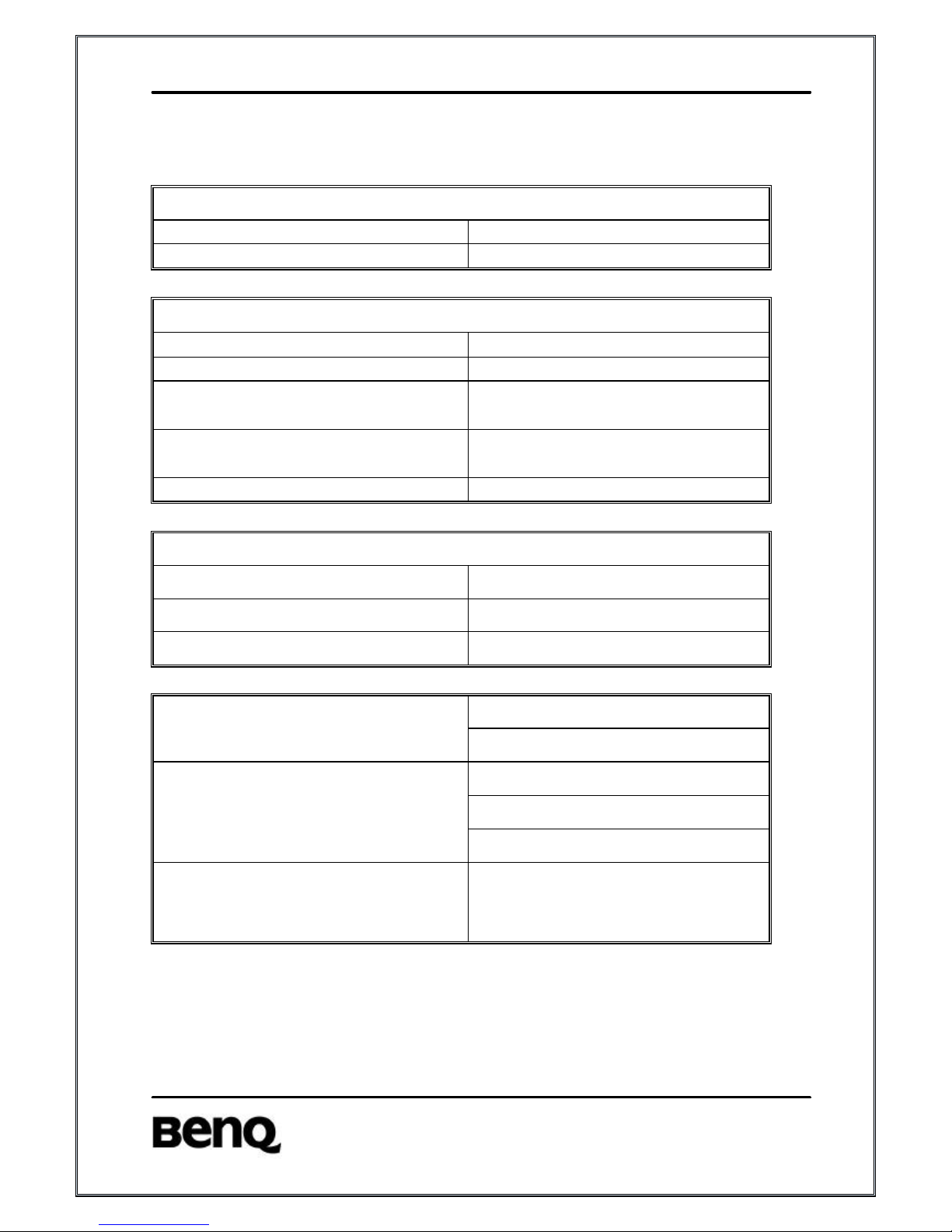

Table 2: Voltage Operation

Voltage Operation

Li-ion Battery DC 3.3-4.2 V

Ni-MH Battery DC 3.3-4.2 V

Table 3: Power Consumption

Power Consumption

Working Current Average < 270 mAH

Standby Current 6 +/-0.2 mAH

Talking Time* 120 ~300 min (With Ni-

MH 550

mAH)

Standby Time* 50~120 hours (With Ni-

MH 550

mAH)

DTX / DTR Yes

Table 4: Appearance

Handset Appearance

Dimensions 106 x 40 x 16 mm

Volume 68 c.c.

Handset Weight 99 g

Table 5: Basic Services

Telephony (Speech)

Tele Service

Emergency Call

Delivery Report

Short Message Service MT/MO

Short Message Service

Cell Broadcast

Bearer Service

Data circuit duplex

asynchronous up to 14400

bit/sec

Page 5

BenQ Rev 1.0

5

Scope of Manual

This manual is intended for use by experienced technicians

familiar with similar types of equipment. It is intended primarily to

support electrical and mechanical repairs. Repairs not covered in the

scope of this manual should be forwarded to Motorola’s regional

Cellular Subscriber Support Centers.

Page 6

BenQ Rev 1.0

7

Theory of Operation

△ GSM System Description

General Cellular Concept

The cellular systems are used to provide radiotelephone service in

the frequency range 890-960 MHz. A cellular system provides higher

call handling capacity and system availability than would be possible

with conventional radiotelephone systems (those which require total

system area coverage on every operating channel) by dividing the

system coverage area into several adjoining sub-areas or cells.

Each cell contains a base station (cell site) which provides

transmitting and receiving facilities, for an allocated set of duplex

frequency pairs (channels). Since each cell is a relatively small area,

both the cell site and the radiotelephone that it supports can operate at

lower power levels than would be used in conventional systems.

Using this technique, radiation on a given channel is virtually

contained in the cell operating on that channel and, to some extent,

those cells directly adjacent to that cell.

Since the coverage area of a cell on a given channel is limited to a

small area (relative to the total system coverage area), a channel may

be reused in another cell outside the coverage area of the first. By this

means, several subscribers may operate within the same geographic

area, without interference with each other, on a single channel.

GSM Description

Unlike previous cellular systems, GSM uses digital radio

techniques. The GSM system has the following advantages over

previous analogue systems:

♦International Roaming - Due to international harmonization and

standardization, it will be possible to make and receive calls in any

Page 7

BenQ Rev 1.0

8

country which supports a GSM system.

♦Digital Air Interface - The GSM phone will provide an entirely digital

link between the telephone and the base station, which is, in turn,

digitally linked into the switching subsystems and on into the PSTN.

♦ISDN Compatibility - ISDN is a digital communications standard that

many countries are committed to implementing. It is designed to carry

digital voice and data over existing copper telephone cables. The GSM

phone will be able to offer similar features to the ISDN telephone.

♦Security and Confidentiality – Telephone calls on analogue systems

can very easily be overheard by the use of a suitable radio receiver.

GSM offers vastly improved confidentiality because of the way in which

data is digitally encrypted and transmitted.

♦Better Call Quality - Co-channel interference, handover breaks, and

fading will be dealt with more effectively in the digital system. The call

quality is also enhanced by error correction, which reconstructs lost

information.

♦Efficiency - The GSM system will be able to use spectral resources

in a much more efficient way than previous analogue

Systems

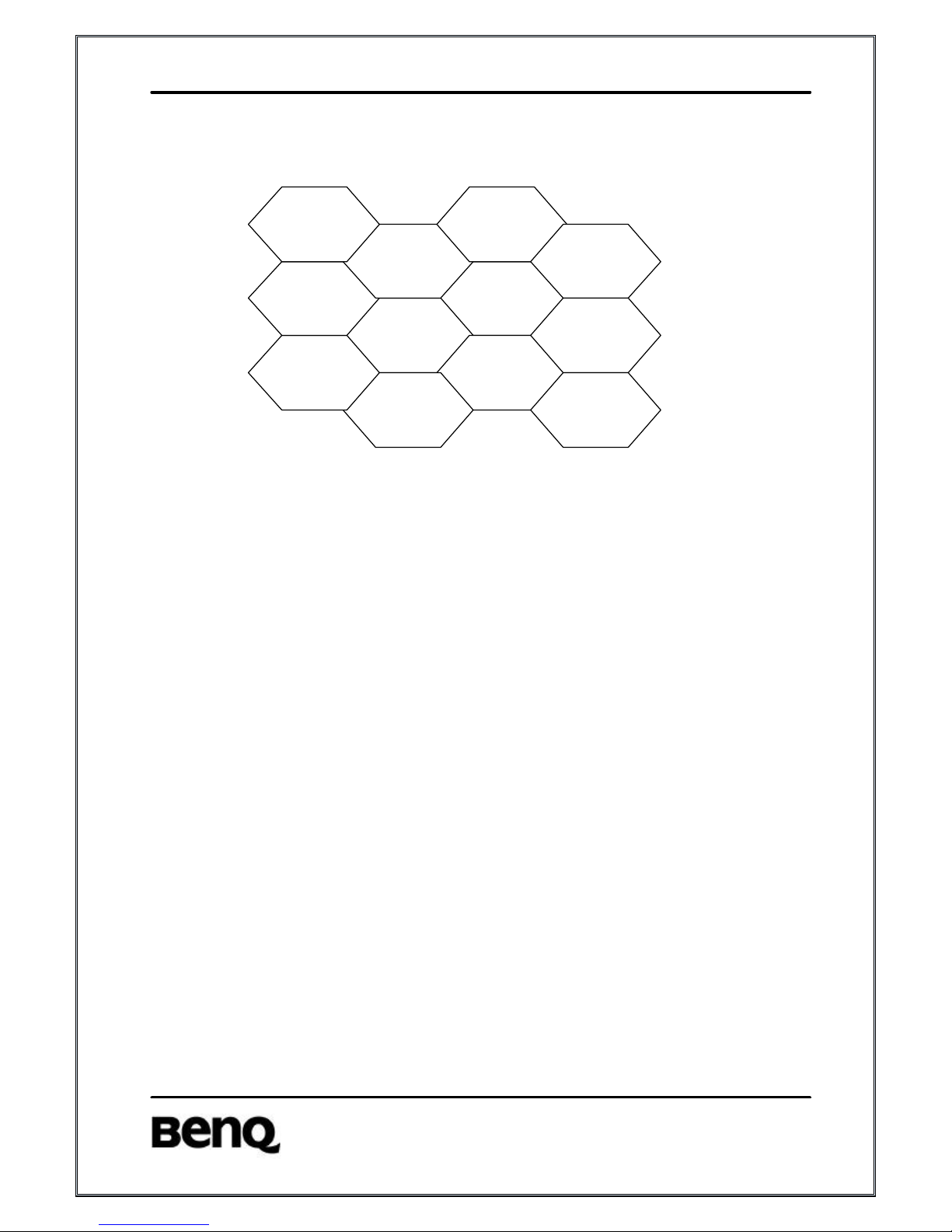

In the figure below, the area bounded by bold lines represents the

total coverage area of a hypothetical system. This area is divided into

several cells, each containing a cell site (base station) operating on a

given set of channels which interfaces radiotele- phone subscribers to

the telephone switching system.

Page 8

BenQ Rev 1.0

9

The radiotelephones themselves are capable of operation on any

channel in the system, allowing them to operate in any cell. Due to the

low power requirements for communications between radiotelephones

in a particular cell and the cell site, operating channels may be

repeated in cells which are outside the coverage area of each other.

For example, presume that cell A operates on channels arbitrarily

numbered 1 through 8, cell B operates on channels 9 through 16, cell C

operates on channels 17 through 24 and cell D operates on channels 1

through 8 (repeating the usage of those channels used by cell A). In

this system, subscribers in cell A and subscribers in cell D could

simultaneously operate on channels 1 through 8.

The implementation of frequency re-use increases the call

handling capability of the system, without increasing the number of

available channels. When re-using identical frequencies in a small area,

co-channel interference can be a problem. The GSM system can

tolerate higher levels of co-channel interference than analogue systems,

by incorporating digital modulation, forward error correction and

equalization. This means that cells using identical frequencies can be

CELL A

CHANNELS

1-8

CELL B

CHANNELS

9-16

CELL C

CHANNELS

17-24

CELL D

CHANNELS

1-8

CELL F

CHANNELS

17-24

CELL E

CHANNELS

9-16

Figure 2: Hypothetical

Page 9

BenQ Rev 1.0

10

physically closer, than similar cells in analogue systems. Therefore the

advantage of frequency re-use can be further enhanced in a GSM

system, allowing greater traffic handling in high use areas.

By incorporating Time Division Multiple Access (TDMA) several

calls can share the same carrier. The carrier is divided into a

continuous stream of TDMA frames, each frame is split into eight time

slots. When a connection is required the system allocates the

subscriber a dedicated time slot within each TDMA frame. User data

(speech/data) for transmission is digitized and sectioned into blocks.

The user data blocks are sent as information bursts in the allocated

time slot of each TDMA frame.

The data blocks are modulated onto the carrier using Gaussian

Minimum Shift Keying (GMSK), a very efficient method of

phase modulation.

Each time an information burst is transmitted, it may be transmitted

on a different frequency. This process is known as frequency hopping.

Frequency hopping reduces the effects of fading, and enhances the

security and confidentiality of the link. A GSM radiotelephone is only

required to transmit for one burst in each frame, and not continually,

thus enabling the unit to be more power efficient.

Each radiotelephone must be able to move from one cell to

another, with minimal inconvenience to the user. The mobile itself

carries out signal strength measurements on adjacent cells, and the

quality of the traffic channel is measured by both the mobile and the

base station. The handover criteria can thus be much more accurately

determined, and the handover made before the channel quality

deteriorates to the point that the subscriber notices.

When a radiotelephone is well within a cell, the signal strength

measured will be high. As the radiotelephone moves towards the edge

of the cell, the signal strength and quality measurement decreases.

Signal information provides an indication of the subscriber’s

Page 10

BenQ Rev 1.0

11

distance from the base station. As the radiotelephone moves from cell

to cell, its control is handed from one base station to another in the new

cell.

This change is handled by the radiotele-phone and base stations,

and is completely transparent to the user.

Service Area

The area within which calls can be placed and received is defined

by the system operators. (Because this is a radio system, there is no

exact boundary that can be drawn on a map.) If the telephone is

outside a coverage area, the (no service) indicator will illuminate and

calls will be unable to be placed or received. If this happens during a

conversation, the call will be lost. There may also besmall areas within

a particular service area where communications may be lost.

The radiotelephone’s identity information is held by its local GSM

system in its Home Location Register (HLR) and Visitor Location

Register (VLR). The VLR contains identity information on all local active

radiotelephones. Should you roam to another area, system or country

the radiotelephones identity information is sent to the VLR in the new

system. The new system will then check the radiotelephones details

with your home system for authenticity. If everything is in order it will be

possible to initiate and receive calls whilst in the new area.

Page 11

BenQ Rev 1.0

12

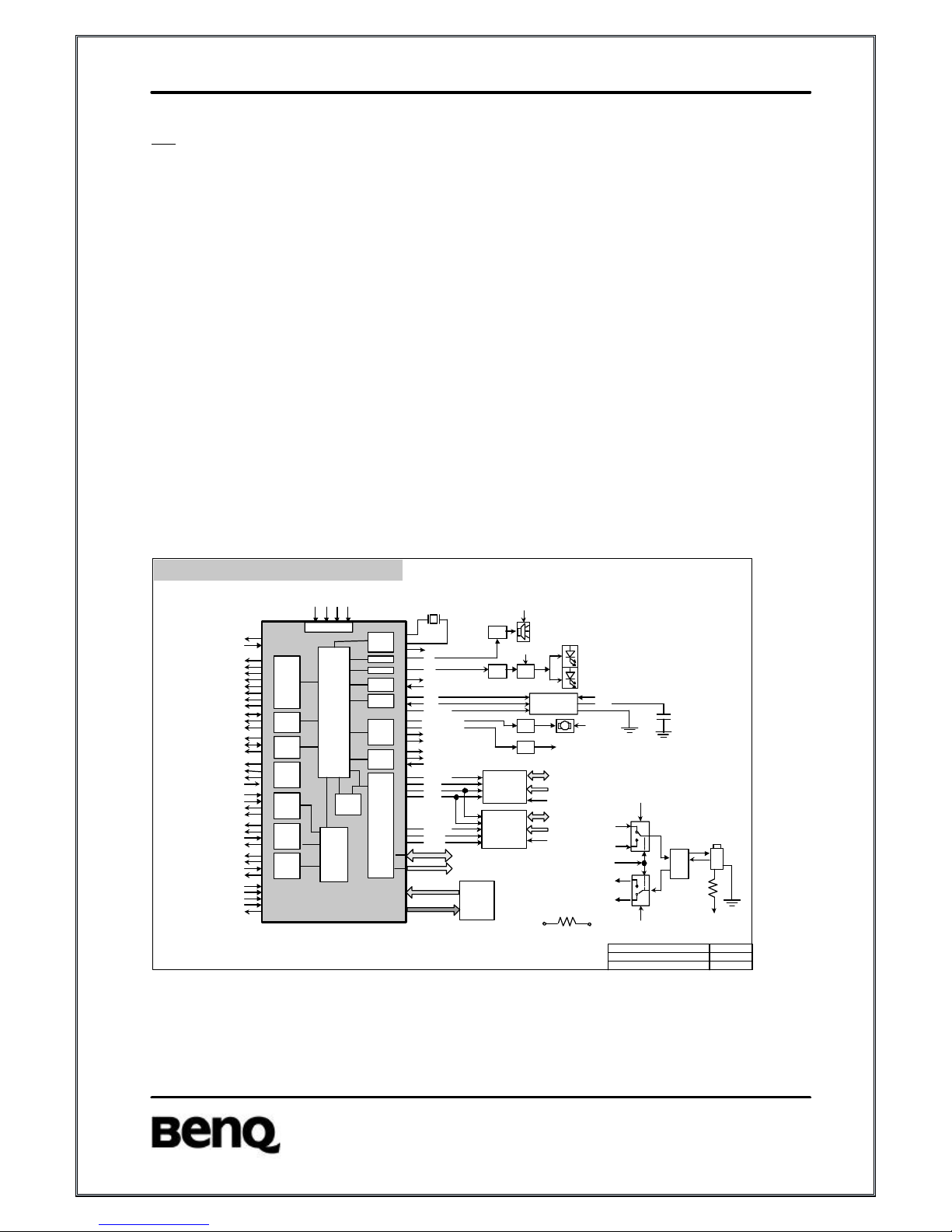

△ Baseband function Descriptions

1. Introduction:

March(T191) utilizes TI’s chipsets (Ulysse and Nausica) as

base-band solution. Base-band is composed with two potions:

Logic and Analog/Codec. Ulysse is a GSM digital base-band logic

solution included microprocessor, DSP, and peripherals. Nausica is

a combination of analog/codec solution and power management

which contain base-band codec, voice-band codec, several voltage

regulators and SIM level shifter etc. In addition, 56D66 integrates

with other features such as LED backlight, LCD display, vibration,

buzzer and charging etc. The following sections will present the

operation theory with circuitry and descriptions respectively.

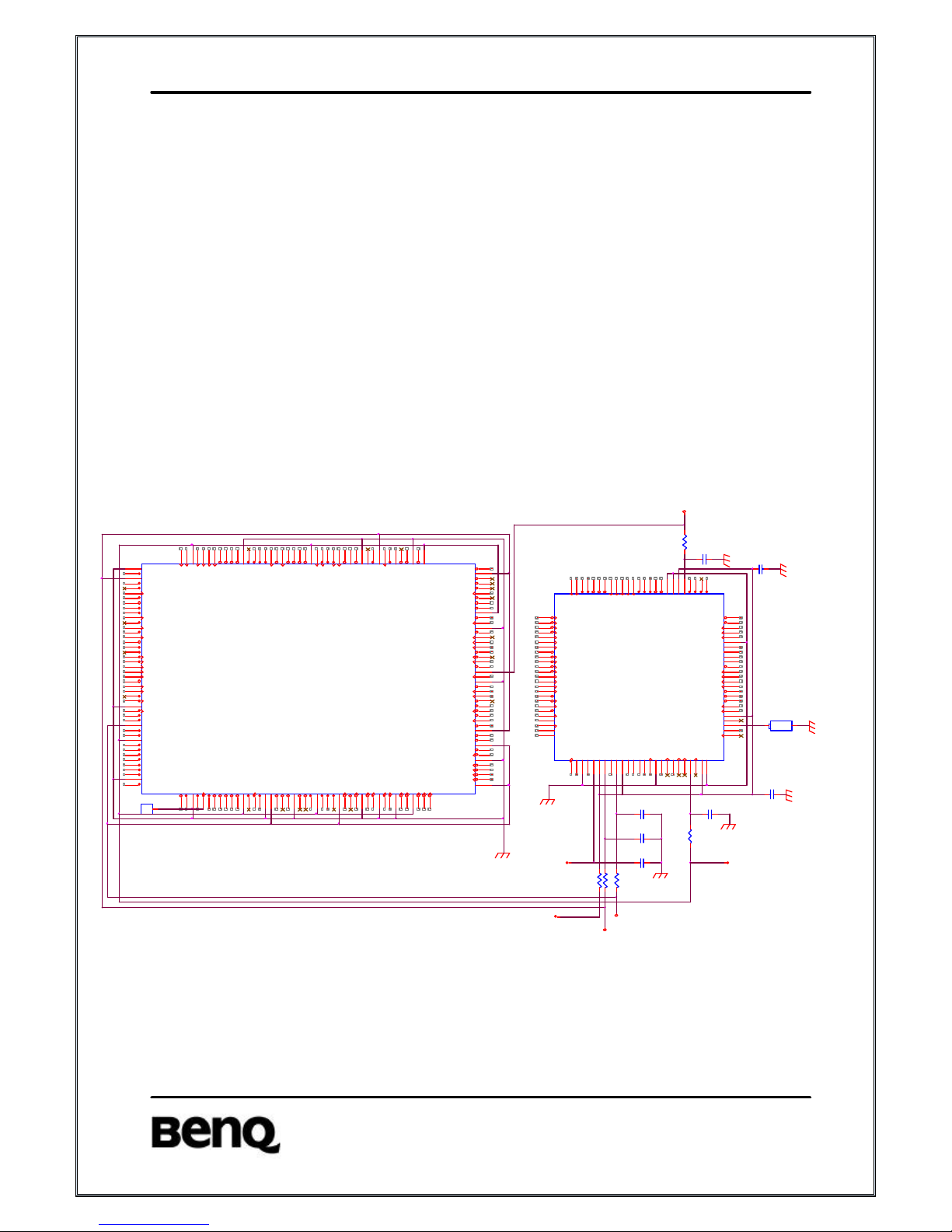

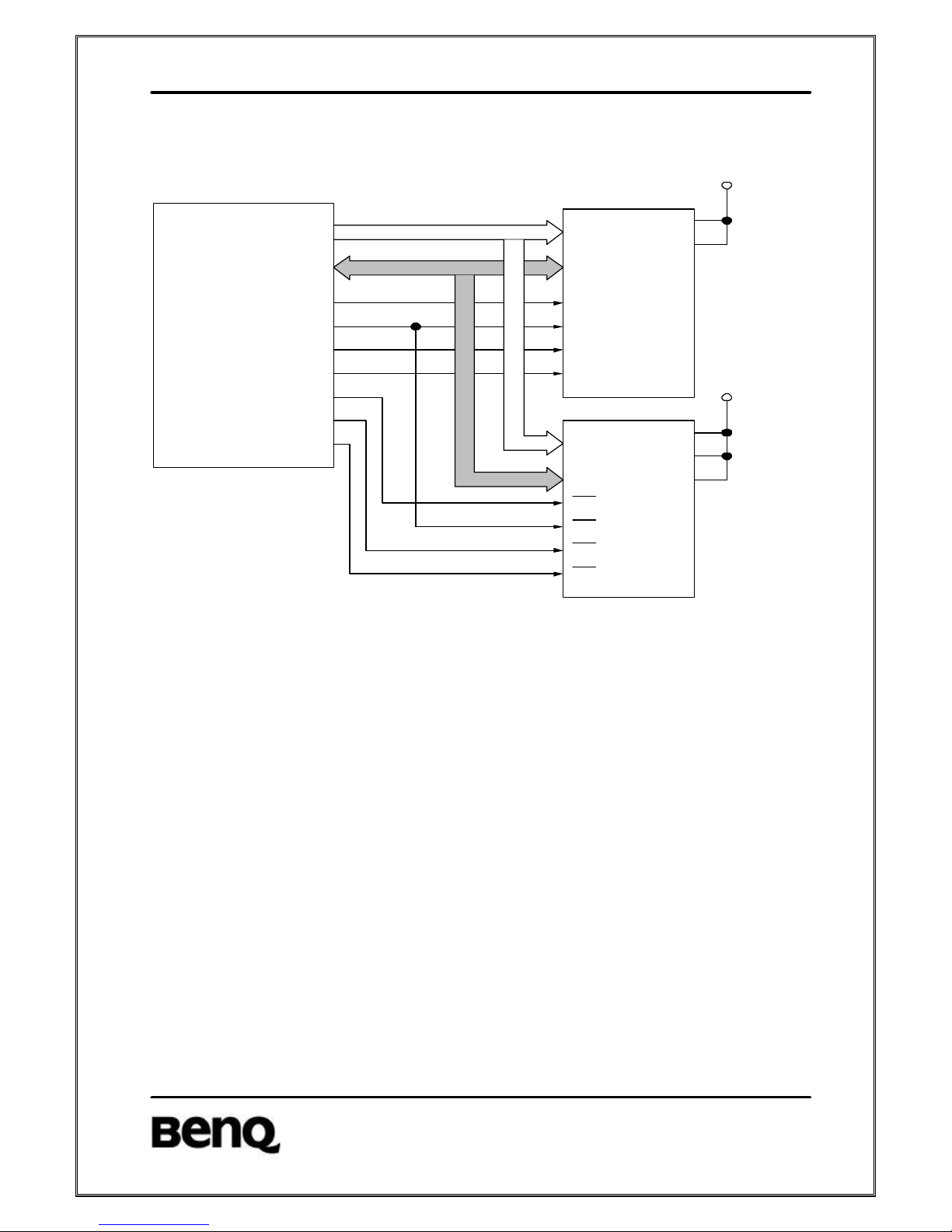

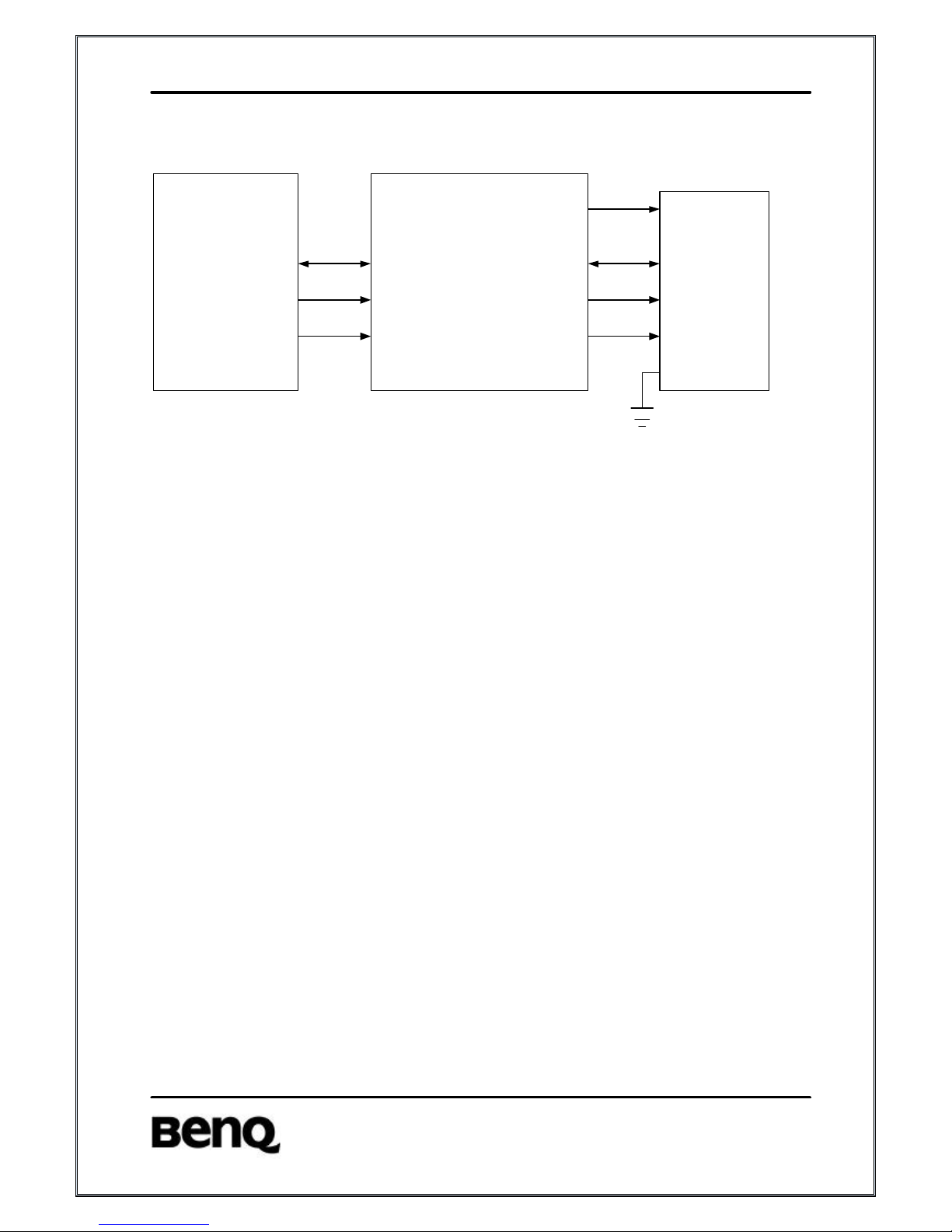

2. Block Diagram

2.1 Ulysse (Hercules)

JAMES WANG, WEN-SHIH LIU PAGE 1 OF 2

DUAL BAND AMETHYST

BASEBAND BLOCK DIAGRAM REV 1.0

DUAL BAND AMETHYST

SRAM

1Mbit

G5

A2

B5

A1

B2

Flash

Memory

32Mbit

D7

B4

B3

D8

ARM7

RTC

PWT

PWL

UART

I2C

SPI

MEM.

INTF.

GPIO

ACT

TSP

SIM

JTAG

RIF

Voice-

band

INTF

DAI

DSP

2M

SRAM

E10

A11

B6

C2

B1

D2

D3

F4

C4

K11

J1

J3

M6

A7

C7

C8

A8

P6

M9

N8

L8

P7

K8

K7

C6

E6

E9

B11

D11

B12

B13

H10

D14

E14

D13

J14

J13

K14

G1

H1

H3

H2

F12

F13

F14

G13

G11

H12

H13

H11

D8

D9

B9

A9

NROMCS1

FDP

RNW

NFOE

NRAMCS

NBLE

NBHE

MCUEN

MCUDO

MCUDI

IO3DATA_HP_SEL

IO13ACCIN

IO0VIBRATOR

IO1BATID_DET

SCL

SDA

NRSTOUT

TXD0

RXD0

BU

BL

RTCINT

H3

D7

G3

G14

H14

VR1 VR2 VR2B VR3

RX_ON

TX_ON

DCS_T/R

GSM_T/R

BS2

PC

BS1

LE

DATA

CLK

TSPEN0

S_CLK

S_IO

S_RST

TCK

TMS

TDO

TDI

BFSR

BDR

BFSX

BDX

VCLKRX

VDX

VDR

VFSRX

DAI_RST

DAI_CLK

DAI_DI

DAI_DO

TO / FROM

OMEGA

{

TO / FROM

OMEGA

{

JTAG

TO / FROM

OMEGA

{

DAI INTF

{

DATA BUS

DATA BUS

ADDRESS BUS

VR2

DATA BUS

ADDRESS BUS

VR2

}

TO / FROM ULYSSE

LCM

CONT.

4

5

6

7 , 8

1

2 , 3

VR2

VLCD

C34

}

TO EARPHONE JACK

BQ3

BUZZER

U7 BQ2

LCM BACKLIGHT

KEYPAD BACKLIGHT

BQ4 M

U15 BATID

EXTIRQ

EXTFIQ

NRESET

13MHZ

13MOUT

FROM

OMEGA

FROM U61

KEYPAD

POWER

FROM OMEGA

ULYSSE

U1

VIBRATOR

X1 32.768KHZ

E11

D6

TCXOEN

ON_OFF

{

{

{

TO RF BLOCK

TO RF BLOCK

{

TO / FROM

OMEGA

ROW0~ROW3

COL0~COL4

ADDRESS BUS

VBAT

VBATBB

VBAT

U5

U6

TO OMEGA

TO U84,U90

FROM OMEGA

TO OMEGA

TO OMEGA

U9

3

4

2

1

R72

EARPHONE JACK

TXDO

AUXI

IO3DATA_HP_SEL

IO13ACCIN

RXDO

AUXOP

U8

U10

VR2BSW

VR2BSW

MIC

SPK

VR2BSWVR2B

{

U13

M1

Page 12

BenQ Rev 1.0

13

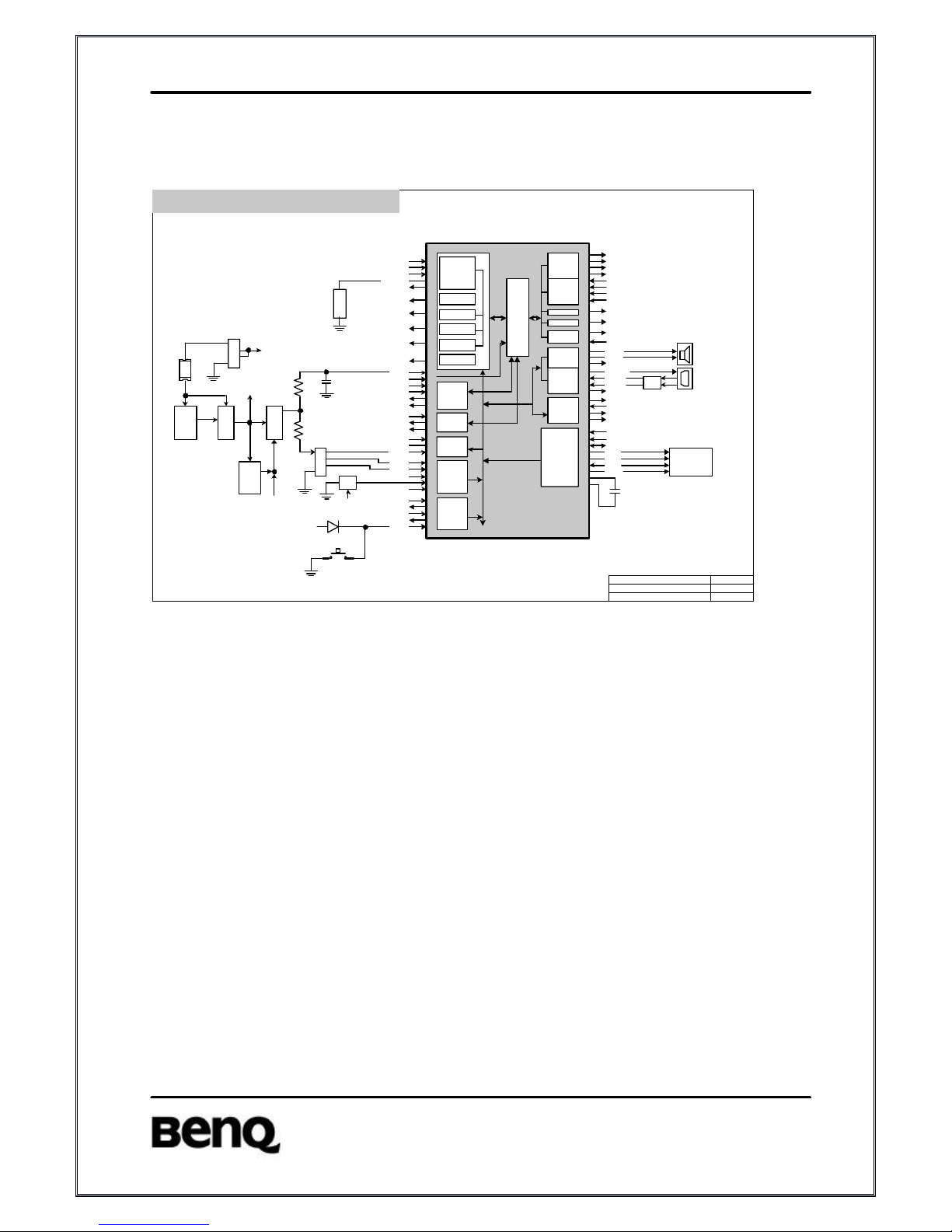

2.2 Nausica (Omega)

IBIC

BUS

CONT.

C4

B3

B2

B4

B5

D4

A2

A1

B1

BSP

K5

J 5

H5

G5

SPI

BCI

ADC

VRPC

F5

K6

J 6

E3

E4

E5

B5

A5

E6

D6

C6

F7

F6

D7

D10

B10

BACKUP

VR1B

2.0V@50mA

VR2B

2.9V@50mA

VR2

2.9V@120mA

VR1

1.8V@120mA

VR3

2.9V@80mA

VREG

B/B

U/L

C9

C10

D8

D9

B/B

D/L

E7

E8

E9

E10

AFC

APC

TSP

VOICE

D/L

VOICE

U/L

USP

SIM REG.

3/5V

SHIFTER

F8

F9

J 4

K4

H8

H9

J 9

K9

J 8

K8

H7

H6

G6

G7

K7

K3

D2

G9

J3

C3

C1

D1

E1

H1

H10

F1

A4

TXIP

TXIN

TXQP

TXQN

RXIP

RXIN

RXQP

RXQN

AFC

RAMP

SMADA

TPENQ

AUXOP

MICBIAS

MICIN

MICIP

AUXI

VCLKRX

VDR

VDSRX

VDX

S_CLK

S_RST

S_IO

CLK

RST

I/O

VSIM

C8

BDX

BFSX

BDR

BFSR

MCUEN0

MCUDO

MCUDI

ICTL

VCHG

VBAT

BATID

TBAT

HWID

EXTFIQ

NRESET

RTCINT

ON_OFF

PWON

VCC1

VCC2

VCC3

VBACKUP

UPR

VR1B

VR2B

VR2

VR1

VR3

OSCAS

EXTIRQ

EARPHONE_IN

SIM

SOCKET

1

3

2

4

}

TO / FROM

ULYSSE

}

}

TO U61

}

FROM U61

TR1

ROW4

S19

EARN

EARP

SPEAKER

MICROPHONE

TO U85

TO U74

}

TO/FROM ULYSSE

{

TO / FROM

ULYSSE

{

TO / FROM

ULYSSE

{

FROM

BATBB

OMEGA

POWER JACK

BATTERY

CONNECTOR

U3

COIN LI-ION

BATTERY

TO / FROM

ULYSSE

1

2

3

4

4

3

2

1

ICTL

VCHG

MANTEST

FUSE

F1

+

_

U4

U14

FROM ULYSSE

C22

TO / FROM

ULYSSE

{

D1

S1

G2

D2

G1

S2

U17

U17

JAMES WANG, WEN-SHIH LIU PAGE 2 OF 2

DUAL BAND AMETHYST

BASEBAND BLOCK DIAGRAM REV 1.0

DUAL BAND AMETHYST

U18

U16

D1

D2

D1

D2

J 1

R21

R24

VR3

VBBATBB

3. Theory:

3.1 Ulysse

ULYSSE (HERCROM200) is a chip implementing the digital

base-band processor of a GSM mobile phone. This chip combines a

DSP M16L80 mega-module (LEAD2 CPU) with its program and data

memories, a Micro-Controller core with emulation facilities

(ARM7TDMIE) and an internal 2M-bit RAM memory, a clock squarer

cell, several compiled single-port or 2-ports RAM and 120K

equivalent CMOS gates.

Major functions of this chip are as follows:

3.1.1 Real Time Clock (RTC)

3.1.2 Pulse Width Tones (PWT)

The function of the PWT is to generate a modulated frequency

signal for the external buzzer.

3.1.3 Pulse Width Light (PWL)

This module allows the control of the backlight of LCD and keypad

by employing a 4096 bit random sequence.

Page 13

BenQ Rev 1.0

14

3.1.4 MODEM-UART

3.1.5 I2C master serial interface (I2C)

In 56D66, we employ I2C bus to control LCD module.

I2C_SCL: programmed to the fast transmission mode (400KHz)

I2C_SDA: the serial bi-directional data of the LCM controller

3.1.6 General Purposes I/O (GPIO)

Ulysse provides 16 GPIOs configurable in read or write mode by

internal registers. In 56D66, we utilize 5 of them as follows:

IO0 : to control vibrator; ‘L’: idle, ‘H’: activate vibrator

IO1 : to identify legal NiMH battery

IO3 : to control phone jack configuration; ‘L’: data cable, ‘H’:

hands-free

IO8 : to support one-wire protocol for Li-Ion battery

IO13 : to detect accessory plug-in at phone jack; ‘H’: idle, ‘L’: plug-in

3.1.7 Serial Port Interface (SPI)

3.1.8 Memory Interface and internal Static RAM

A 2Mbit SRAM is embedded on the die and memory mapped on the

chip-select CS6 of the memory interface.

3.1.9 SIM Interface

3.1.10 JTAG

3.1.11 Time Serial Port (TSP)

3.1.12 TSP Parallel interface (ACT)

In 56D66, we employ 8 of them to control RF activity.

TSPACT1: Band selection 1 (BS1)

TSPACT2: Power control enable (PC)

TSPACT3: Band selection 2 (BS2)

TSPACT4: GSM TR switch on/off (GSM_TR)

TSPACT5: DCS TR switch on/off (DCS_TR)

TSPACT8: RX VCO on/off (RX_ON)

TSPACT9: TX VCO on/off (TX_ON)

TSPACT10: Latch enable (LE)

3.1.13 Radio Interface (RIF)

3.2 Nausica (Omega)

Together with a digital base-band device (Ulysse), OMEGA is part

of a TI DSP solution intended for digital cellular telephone applications

including GSM 900, DCS 1800 and PCS 1900 standards (dual band

Page 14

BenQ Rev 1.0

15

capability).

It includes a complete set of base-band functions to perform the

interface and processing of voice signals, base-band in-phase (I) and

quadrature (Q) signals which support single-slot and multi-slot mode,

associated auxiliary RF control features, supply voltage regulation,

battery charging control and switch ON/OFF system analysis.

OMEGA interfaces with the digital base-band device through a set

of digital interfaces dedicated to the main functions of Ulysse, a

base-band serial port (BSP) and a voice-band serial port (VSP) to

communicate with the DSP core (LEAD), a micro-controller serial port

to communicate with the micro-controller core and a time serial port

(TSP) to communicate with the time processing unit (TPU) for real time

control.

OMEGA includes also on chip voltage reference, under voltage

detection and power-on reset circuits.

Major functions of this chip are as follows:

3.2.1 Baseband Codec (BBC)

3.2.2 Automatic Frequency control (AFC)

3.2.3 Automatic Power Control (APC)

3.2.4 Time serial port (TSP)

3.2.5 Voice band Codec (VBC)

3.2.6 Micro-controller serial port (USP)

3.2.7 SIM card shifters (SIMS)

3.2.8 Voltage Regulation (VREG)

Linear-regulation performed by several low dropout (LDO) regulators

to supply analog and digital baseband circuits.

(1) LDO R1 generates the supply voltage (2.5V, 1.8V, 1.4V and 1.2V)

for the digital core of Ulysse. In 56D66, it is programmed to 1.8V.

This regulator takes power from the battery voltage and it has a

backup through BBS system.

(2) LDO R1B generates the supply voltage 2.0V for the digital core of

OMEGA. It is supplied by the battery.

(3) LDO R2B generates the supply voltage 2.9V for the digital I/O’s of

Ulysse and Omega. It is supplied from battery voltage and has a

backup through BBS system.

Page 15

BenQ Rev 1.0

16

(4) LDO R2 generates the supply voltages 2.9V for Ulysse memory

interfaces I/O’s. It has a backup through BBS system.

(5) LDO R3 generates the supply voltage 2.9V for the analog

functions of OMEGA.

The backup battery switch (BBS) generates at its output an

uninterrupted power rail (UPR) of which purpose is to supply

continuously the minimum necessary circuitry of the power-control

functions either from the main battery of from the backup battery

3.2.9 Baseband Serial Port (BSP)

3.2.10 Battery charger Interface (BCI)

3.2.11 Monitoring ADC (MADC)

3.2.12 Reference Voltage / Power on Control (VRPC)

3.2.13 Internal bus and interrupt controller (IBIC)

3.3 Power Supply circuit

BGND

BGND

VR3

BGND

BGND

BGND

VR2B

BGND

BGND

BGND

VR2

VBATBB

VR1VR1B

TPL16

1

U1

ULYSSE_uBGA179

B2

C2

C3

B1

C1

D3

D2

D1

F5

E4

E2

E3

E1

F4

F3

F2

F1

G5

G4

G2

G3

G1

H1

H3

H2

H4

H5

J1

J2

J3

J4

K1

K3

K2

K4

J5

L1

L2

L3

M1

N1

M3

M2

N2

P2N3P3L4M4N4P4K5L5N5P5M5K6M6P6N6L6K7L7P7N7M7M8N8P8L8K8L9N9P9M9K9M10

P10

N10

L10

K10

P11

N11

M11

L11

P12

N12

P13

N13

M13

M12

N14

M14

L12

L13

L14

K11

K13

K12

K14

J11

J12

J13

J14

H10

H11

H13

H12

H14

G14

J10

G12

G13

G11

G10

F14

F13

F12

F11

E14

E12

E13

E11

F10

D14

D13

D12

C14

B14

C12

C13

B13

A13

B12

A12

D11

C11

B11

A11

E10

D10

B10

A10

C10E9C9A9B9D9E8D8A8B8C8C7B7A7D7E7D6B6A6C6E6C5A5B5D5E5A4B4C4D4A3B3A2

P1

A14

P14

GND

BU/PWT

VDDS2

LT/PWL

SDO/INT10n

RX_MODEM

TX_MODEM

SD_IRDA/CLKOUT_DSP

DSR_MODEM/LPG

RTS_MODEM/TOUT

CTS_MODEM/XF

SCLK/INT1n

RX_IRDA

nSCS0/SCL

RXIR_IRDA/X_A1

TX_IRDA

TXIR_IRDA/X_A4

nSCS1/X_A2

nEMU1

nEMU0

nRESPWRON

TCK

TMS

TDO

TDI

nBSCAN

EN_LMM_PWR/X_IOSTRB

IO0/TPU_WAIT

GND

IO1/TPU_IDLE

ADD0

ADD1

VDDS1

ADD2

ADD3

VDD

ADD4

ADD5

ADD6

ADD7

ADD8

ADD9

ADD10

ADD11

ADD12

ADD13

GNDLMM

ADD14

IO2/IRQ4

ADD15

ADD16

ADD17

ADD18

ADD19

ADD20

VDDLMM

ADD21/CK16X_IRDA

IO3/SIM_RnW

nCS0

GND

VDDS1

nBHE/IO14

nCS1

nCS2

GNDLMM

nCS3

CS4/ADD22

RnW

VDD

nFOE/X_A3

nBLE/IO15

nFWE/X_A0

VDDS1

DATA0

FDP/nIACK

DATA1

GND

DATA2

DATA3

GND

DATA4

DATA5

GNDARM

DATA6

DATA7

VDDARM

DATA8

DATA9

DATA10

DATA11

DATA12

DATA13

DATA14

GND

DATA15

CLK13M_OUT/START_BIT

nRESET_OUT/IO7

TSPACT11/MCLK

VDDS2

SIM_RST

SIM_CD/MAS0

SIM_PWCTRL/IO5

SIM_IO

SIM_CLK

TSPACT10/nWAIT

VFSRX

VDR

VDX

GNDA1

CLKTCXO

VDDS1

VDDA1

BDX

VCLKRX

BCLKX/IO6

BFSX

BDR

BFSR

BCLKR/ARMCLK

TSPCLKX

GND

EXT_IRQ

TCXOEN

VDD

TSPDO

TSPEN0

TSPEN1

TSPDI/IO4

TSPEN2

TSPEN3/nSCS2

TSPACT0

TSPACT1

VDD

TSPACT2

GND

TSPACT3

CLK32K_OUT

GNDA2

OSC32K_OUT

OSC32K_IN

VDDS2

TSPACT4

RFEN/NOPC

GND

TSPACT5

IDDQ

MCSI_TXD/IO9

MCSI_RXD/IO10

MCSI_CLK/IO11

TSPACT6/nCS6

MCSI_FSYNCH/IO12

MCUDI

VDDLMM

MCUDO

MCUEN0

MCUEN1/IO8

MCUEN2/IO13

EXT_FIQ

TSPACT7/CLKX_SPI

ON_OFF

IT_WAKEUP/INT4n

KBC0/NFIQ

TSPACT8/nMREQ

TSPACT9/MAS1

GNDLMM

KBC1/NIRQ

KBC2/XDI_00

KBC3/XDI_01

KBC4/XDI_02

KBR0/XDI_03

KBR1/XDI_04

SDI/SDA

KBR2/XDI_05

VDDLMM

KBR3/XDI_06

KBR4/XDI_07

GND

VDDS2

VDDS1

C21 10UF

C26

0.1UF

C250.1UF

C19 2.2UF

C1710UF

C20 10UF

R22

0

R15

0

U3

OMEGA

B2B1C2C3C1D2D1D3E1E2E3E4E5F1F2F3F4G4G1G2G3H1H2J1K1

J2

K2

J3

H3

K3

J4

K4

H4

K5

J5

H5

G5

F5

K6

J6

H6

G6

G7

K7

J7

H7

K8

J8

K9

K10

A10

B10C9D8D9D10D7E7E8E9

E10F6F7F8F9

F10G8G10G9H10H8H9

J10

J9

A1

A2

B3

A3

C4

B4

A4

D4

D5

C5

B5

A5

E6

D6

C6

B6

A6

C7

A7

B7

A8

C8

B8

A9

B9

C10

SIO3

VS1

GRND2

UPR

VR1BOUT

VCC2

VR2BOUT

VR2SEL

VR2OUT

VR2IN

ICTL

VCHG

VBAT

OSCAS

TESTRESETZ

REFGND

VREF

BGTR1

IBIAS

BGTR3

BGTR2

VR1OUT

BGTR4

FDBK

GRND1

BGTR5

SWITCH

VBACKUP

COMP

VCC1

TDR

TEN

INT2

BDX

BFSX

BDR

BFSR

UEN

UDR

UDX

VCK

VDX

VFS

VDR

AGNDA1

AUXI

MICIP

MICIN

MICBIAS

BUZZOP

RPWON

PWON

BULIP

BULQP

BULQM

ONNOFF

RTC_ALARM

BDLIP

BDLIM

BDLQP

BDLQM

RESPWRONZ

INT1

AFC

APC

DAC

AUXGND

GRND3

VCC3

VR3OUT

EARN

EARP

AUXON

AUXOP

VS2

SVDD

SRST3

VAUX

SCLK3

SCLK5

CK13M

SIO5

SRST5

LCDSYNC

ADIN1

ADIN2

ADIN3

ADIN4/TSCXP

ADIN5/TSCYP

TSCXM

TSCYM

TDO

TDI

TCK

TMS

TEST1

TEST2

TEST3

TEST4

BULIM

R54

0

+-V

U4A

Back-up Battery

2 1

R160R17

0

C15 2.2UF

2.9V@80mA

Omega/Ulysse Analog part

1.8V@120mA

Ulysse Core

2.9V@120mA

Memory

2.9V@50mA

Peripherals

(From Main Battery)

2.0V@50mA

Omega Core

The phone is mainly supplied from the main battery (VBAT)

which is divided into two routes: VBAT is for RF block, vibrator and

buzzer; VBATBB is for baseband block.

The input power (VBATBB) to Nausica is divided into 4 blocks:

Page 16

BenQ Rev 1.0

17

VCC1: to provide power for DC/DC and regulator R1 (VR1)

VCC2: to provide power for regulator R1B (VR1B), R2B (VR2B) and

charger pump

VCC3: to provide power for regulator R3 (VR3)

VR2IN: to provide power for regulator R2 (VR2)

NAUSICA provides five low drop-out voltage regulators.

R1 (VR1): 1.8V@50mA; to supply ULYSSE digital core, RTC,

32KHz and the internal SRAM

R2 (VR2): 2.9V@120mA; to supply 13MHz clock, external memory

devices and LCD display

R2B (VR2B): 2.9V@50mA; to supply peripheral devices, I/O to

NAUSICA

R1B (VR1B): 2.0V@50mA; to supply the digital part of NAUSICA

R3 (VR3): 2.9V@80mA; to supply analog part of NAUSICA.

Among these 5 LDOs, only R1, R2 and R2B are support with

back-up mode.

The power of Ulysse is supplied by these LDOs:

VDD: supplied by VR1 and used for core logic

VDDS1: supplied by VR2 and used for I/Os to memory devices

VDDS2: supplied by VR2B and used for I/Os to Omega and

peripherals

VDDLMM: supplied by VR1 and used for Lead MegaModule (DSP)

VDDARM: supplied by VR1 and used for ARM

Page 17

BenQ Rev 1.0

18

3.4 System power on/off Sequence

3.4.1 Power on

There are three conditions that system can power on.

-On button pushed: A falling edge is detected on PWON pin and the

debouncing time is greater than 30ms.

-Set Alarm: A rising edge is detected on RTC_ALARM (RTCINT)

-Charger plugged: VCHG > VBAT + 0.4V is detected

When these conditions occur in the power on state, the

hardware power on sequence starts:

1. Enable local oscillator OSCAS (~ 100KHz)

2. Enable band-gap (VREF and IREF)

3. Check if Main Battery voltage is greater than 3.2V

4. Enable charge pump (VAUX ~ 5.8V)

5. Enable LDO regulators (R1, R1B, R2, R2B and R3)

6. Set ON_OFF pin to ‘H’.

7. NRESET pin is set from ‘L’ to ‘H’

8. 13MHz clock oscillator is enabled (Ulysse’s task)

3.4.2 Power off in normal mode

When system is powered off in normal mode by long pressing

power-on key, the power off sequence will be executed:

1. Start watchdog timer during 150us and disable DC/DC

2. Set ON_OFF pin to ‘L’

3. Disable all the regulators

4. Disable the band-gap

5. Disable the local oscillator OSCAS

3.4.3 Power off in emergency mode

When the main battery voltage is detected lower than 2.7V, the

following sequence is executed:

1. Set INT1 (FIQ) to ‘L’

2. Start watchdog timer during 150us and disable DC/DC

3. Set ON_OFF pin to ‘L’

4. Disable all the regulators

5. Disable the band-gap

6. Disable the local oscillator OSCAS

Page 18

BenQ Rev 1.0

19

3.5 Memory circuit

DATA BUS

U5

FLASH

U6

SRAM

ULYSSE

CE#

CE1

NROMCS1

NRAMCS

OE#

NFOE

ADDRESS BUS

RP#

WE#

FDP

RNW

OE

HB

LB

NBHE

NBLE

VCCQ

VCC

VCC

VCC

CE2

VR2

VR2

Description

Flash (U5) is a 32Mbit device, supported by VR2 and booted from

top. The total 32Mbits are divided into two sections: 24Mbits is used

for software program code and 8Mbits is used for EEPROM data. The

access time of Flash is 100ns.

SRAM (U6) is a 1Mbit device, supported by VR2. The access time of

SRAM is 70ns.

Page 19

BenQ Rev 1.0

20

3.6 Display circuit

VR2

BGND

NRSTOUT

I2C_SDA

I2C_SCL

R27

1K

C33

1UF(0603)

C32

C(0603)

J2

LCD

1

2

3

4

5

6

7

8

9

10

VLCD

VSS

VSS

SCL

SDA

/RES

VDD2,3

VDD1

X

X

C50

39PF

C51

39PF

C34

1UF(0805 Z5U 16V)

2.9V

400KHz

7.6V

From U1/Ulysse

Description

Display circuit is composed of a 98*64 resolution LCD module and

a display supply voltage bypass capacitor C34. The power of LCDM is

supplied from VR2. It is controlled by U1 via I2C bus: SCL and SDA.

The data rate of I2C is programmed to 400KHz. NRESTOUT is low

active to reset all LCD registers. The LCD Module is adopted with

COG (chip on glass) type, and default display supply voltage VLCD at

normal temperature is 7.6V. R27 is used for ESD protection and C50,

C51 are used for radiation suppression.

Page 20

BenQ Rev 1.0

21

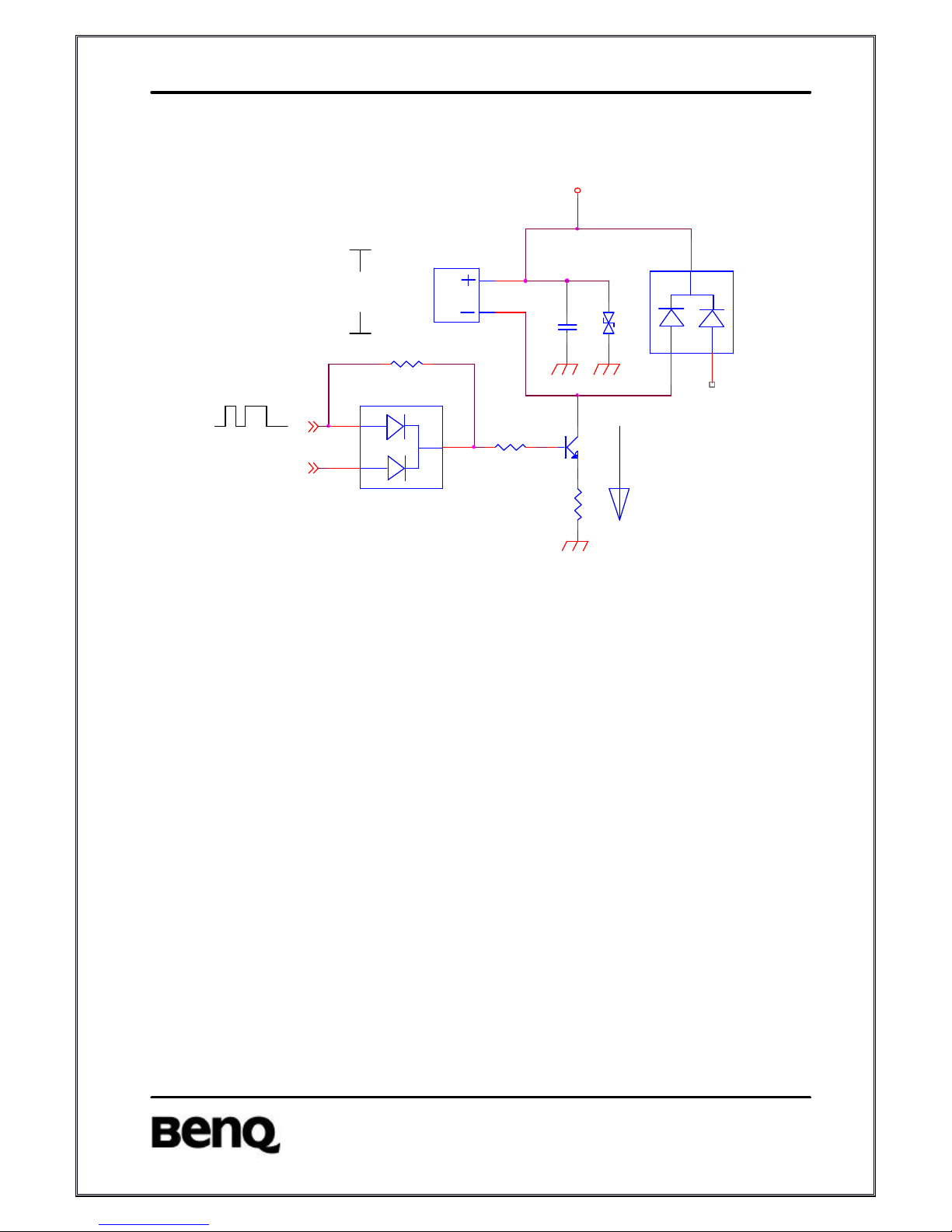

3.7 Vibrator circuit

BGND

VBAT

IO0VIBRATOR

R49

15

R46

1K

A

-

+

M1

LA4-432

12

BQ4

UMT4401

2

1

3

D14

DAN222

2

1

3

3.6V

94mA

1.2V

From U1/Ulysse

Description

To enable vibration, Ulysse sets IO0VIBRATOR to ‘H’ to activate

the motor. R46 and R49 are used to make BQ4 working in saturation

area. D14 is used to feedback EMF. Under the condition of VBAT =

3.6V, the average voltage across the motor is about 1.2V and drain

current is around 94mA.

Page 21

BenQ Rev 1.0

22

3.8 Buzzer circuit

VBAT

BGND

BGNDBGND

BU

BUZZOP

C59

8PF

D14

DAN222

2

1

3

U13

BUZZER

3

4

R48

0

R45

1K

BQ3

UMT4401

2

1

3

T10

TVS

1 2

. .

D16

DAN222(N.M.)

2

1

3

R71

0

3.6V

78mA

1.3V

From U1/Ulysse

(PWT)

(Not In Use)

Description

To alert the buzzer, Ulysse applies PWT (Pulse Width Tone) signal

at BU to drive the buzzer. R45 and R48 are used to make BQ3

working in saturation mode. D14 is used to feedback EMF. Under

the condition of VBAT = 3.6V, the average current is 78mA and terminal

voltage of buzzer is about 1.3V.

Page 22

BenQ Rev 1.0

23

3.9 LED circuit

BGND

VBATBB

BGND

BGND

BL

BQ2

UMT4403

2

1

3

D8

19-21

D7

19-21

D9

19-21

D5

19-21D619-21

R34

2K

D10

19-21

R35

24 (0805)

U7

UMH10N(SOT363)

1 6

2

3 4

5

D11

19-21

D12

19-21

D3

22-21

D13

22-21

D4

22-21

R40

39 (0805)

3.6V

From U1/Ulysse

3.35V

60mA37mA

1.9V

(PWL)

Description

56D66 employs three LEDs for LCD module backlight and eight

LEDs for keypad backlight. To light up the LEDs, Ulysse applies PWL

(Pulse Width Light) at BL to drive LEDs. U7 is used as an inverter to

enable BQ2. Under the default condition (VBAT=3.6V), the average

current of one LCD backlight LED is about 12mA and of one keypad

backlight LED is about 7.5mA. In 56D66, all the LEDs are yellow-green

color and forward voltage is 1.9V

Page 23

BenQ Rev 1.0

24

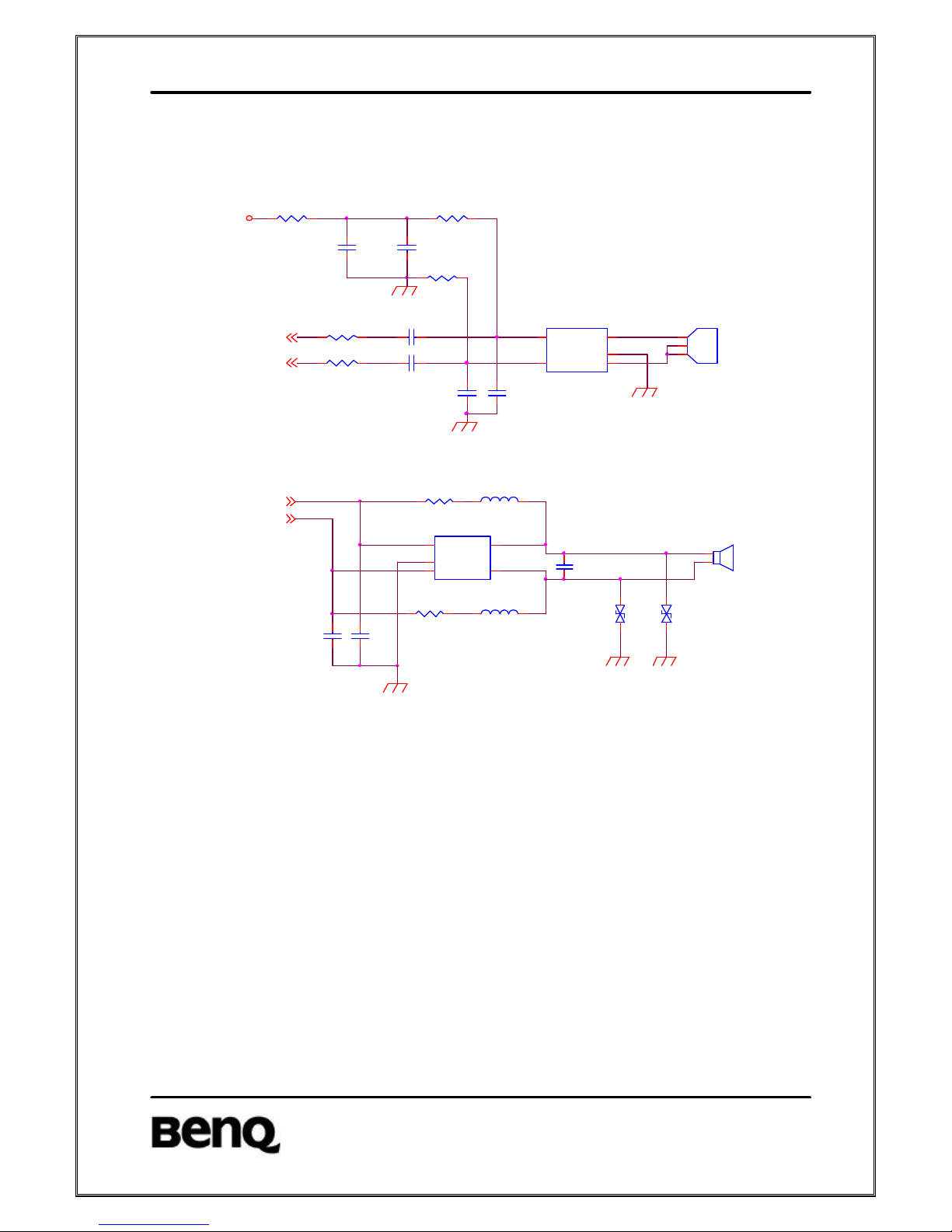

3.10 Audio circuit

Uplink:

MICIP

MICIN

BGND

MICBIAS

BGND

BGND

C43

4.7UF(0805)

R43

1K

C44 1UF(0603)

X2

Microphone

1

2

3

1

2

3

C54

47PF

R44

4.3K

C42

0.1UF

C45 1UF(0603)

R47

4.3K

U14

EMIF01-10005W5

1

2

34

5

I1

GND

I2O2

O1

R50 0

C53

47PF

R51 0

2.5V

From U3/Omega

To U3/Omega

To U3/Omega

Downlink:

EARN

EARP

BGND BGND

BGND

C39

100PF

BL2 0

BL3 0

R74

10

LS1

SPEAKER_0

C41

150PF

U12

EMIF01-10005W5 (N.M.)

1

2

3 4

5

I1

GND

I2 O2

O1

C40

150PF

R73

10

T4

TVS

1 2

. .

T3

TVS

1 2

. .

From U3/Omega

From U3/Omega

Description

The audio circuit is divided into two parts, uplink and downlink.

For uplink path, the analog voice signals are fed into NAUSICA

from the microphone differential input and then transmitted to Ulysse

DSP via the voice-band series port (VSP). After being modulated, the

signals go through the uplink I/Q path to the RF transceiver and

transmitted from the antenna.

The microphone circuit is biased from Nausica MICBIAS (2.5V).

The bias circuit R43, R44, R47 mainly provides the optimal operation

point for the microphone signals, MICP and MICN.

For downlink path, the signals received from the antenna are

down-converted to I/Q signals and then transmitted to Ulysse DSP.

After being demodulated, the signals are fed to NAUSICA via

voice-band interface and then amplified to drive the receiver.

Page 24

BenQ Rev 1.0

25

3.11 Charging circuit

BGND

BGND

BGND

VBATBB

VBAT

VR3

BGND

BGND

BGND

BGND

BGND

BGND

BGND

BGND

BGND

CHARGERIN

TBAT

VCHG

BATID_NIMH

IO8ONEWIRE

ICTL

G1

S2 G2

D2S1D1

U17

FDC6506P

1 6

3 4

52

C28

C

C31

0.1UF

G1

S2

G2

D2

S1

D1

U18

FDG6303N

1 6

3 4

52

R70 0

R66

3.9M

R67

200K

C48

4.7UF(0805)

R68 0

D15

RB520S-30

1 2

G1

S2

G2

D2

S1

D1

U16FDG6303N

1 6

3 4

52

R65

43K (1%)

R63

470K

R62

470K (1%)

R60

6.2K

F1

FUSE(1A 0603)

C49

1K

T1

TVS

12

..

T5

TVS

12

..

J1

Power Jack

1

2

3

4

V+

SW

SW

GND

J5

0

1

2

3

C56

10UF(0805)

R24

0.2(1%) 0805

D1

CRS03

1 2

C30

100PF

R25

47K

JP1

BATTERY CONN

4

3

2

1

C29

10UF(0805)

C47

0.1UF

C57

1000PF

C55

0.1UF

R64

100K

C58

1000PF

Trigger Charging Circuit

Charger Over-voltage Protection Circuit

Main Charging Route

To U3/Omega To U3/Omega

Description

The charging circuit of 56D66 is composed of charger over-voltage

protection circuit, 3-sec trigger charging circuit and main charging

circuit that are controlled by Omega (U3). 56D66’s charging devices

are standard linear 3.6V/600mA charger and switching VPA (cigarette

charger) with 6V/400mA output.

The group of R62, R65, R63 R64, R70, C47 and U16 compose the

charger over-voltage protection circuit. The cut-off voltage is 8V.

While the charger voltage is over 8V, the circuit will turn off U17 by

latching U17.G1 to stop charging.

The group of D15, R66, C48, R67 and U18 compose the 3-sec

trigger charging circuit. At the very beginning of charging, the circuit will

force to turn on U17 to full charger the battery which can prevent from

long charging wake-up for deep discharge battery. After around 3

seconds, software will take over the charging task by controlling ICTL.

Page 25

BenQ Rev 1.0

26

F1 is a 1A fuse to assure charging current under limit.

The normal charging operation theory is that Omega monitors

charger voltage via VCHG pin to decide whether charger plug in or out,

and control power P-MOSFET (U17) via ICTL pin. If phone enters into

charging mode, Ulysse will follow the charging algorithm to control

charging circuit and monitor charging current by detecting the terminal

voltage of R24 (0.2 ohm). Omega control procedure is classified into

two parts according to whether battery voltage is higher than 3.2V.

Omega will execute trickle charge with 20mA to charge battery via

VCHG pin if battery voltage is lower than 3.2V. On the other hand, the

phone will proceed normal charging task following by the charging

algorithm.

Page 26

BenQ Rev 1.0

27

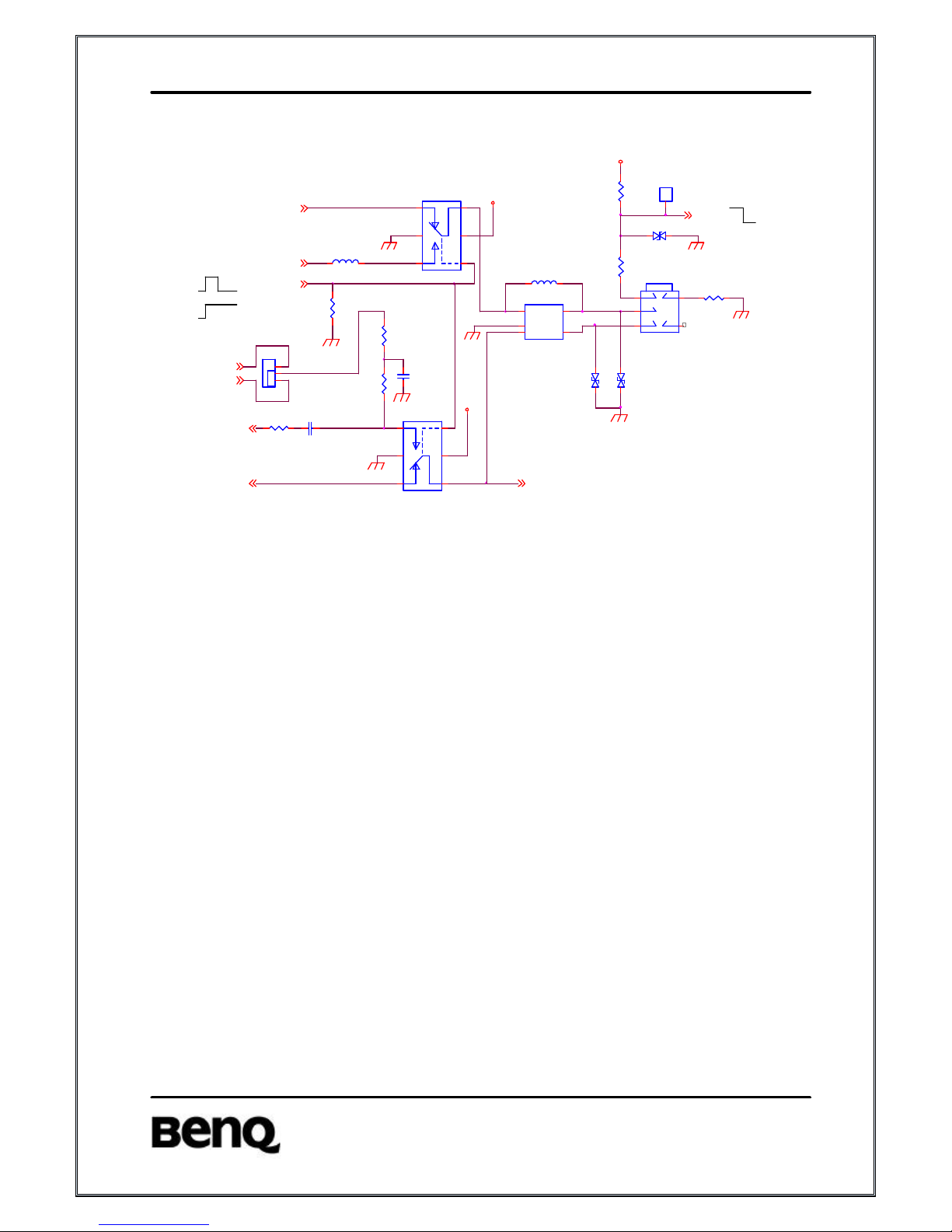

3.12 Earphone jack circuit

IO3DATA_HP_SEL

VR3

IO13ACCIN

AUXI

EARPHONE_INRXD0

MICBIAS

TXD0

AUXOP

BGND

BGND

BGND

BGND

BGND

VR3

VR2B_SW

BGND

BGND

VR2B_SW

BGND

T9

TVS

1 2

. .

T8

T

1 2

. .

R76

0

U8

NC7SB3157

1

3

2

4

5

6

B1

B0

GndAVcc

S

BL1

BEAD(0603)

R36

10K

T2

TVS

1 2

. .

C37

4.7UF(0805)

R72

1K

J3

Audio Jack

12

3

4 5

GNDSW

SPK

MIC MIC

R37

2K

R38

1K

R41

2K

U9

EMIF01-10005W5

1

2

3 4

5

I1

GND

I2 O2

O1

U10

NC7SB3157

1

3

2

4

5

6

B1

B0

GndAVcc

S

C38

1UF(0603)

BL4

22

J4

0

1

2

3

TP33

1

R32

100K

L: Download

H: Earpiece

active

Plug-In

2.9V

2.9V

V= 1.0 ~ 2.4 => Hands-free

V= 2.6 ~ 2.8 => Data Cable

(To U3/Omega)

2.9V

(Not In Use)

For Data Cable

For Hands-Free

(From U1/Ulysse)

Description

The earphone Jack circuit is used either for the headset or the data

service. The IO13ACCIN will be pulled to low level when headset or

data cable is plugged in. Here, U8 and U10 are used as the switch

between headset using or data service using which is controlled by the

IO3DATA_HP_SEL. When IO13ACCIN is detected as low level,

IO3DATA_HP_SEL is switched from low to high level to identify whether

the headset or the data cable is plug-in by reading the voltage at

EARPHONE_IN. If the voltage at EARPHONE_IN is in the range of

1.0V to 2.4V, the phone recognizes headset is plugged in and

IO3DATA_HP_SEL stays at high to keep U8 and U10 as auxiliary audio

path. If the voltage at EARPHONE_IN is in the range of 2.6V to 2.8V,

the phone identifies data cable plugged in and IO IO3DATA_HP_SEL

switches back to low to keep U8 and U10 as data service path.

Page 27

BenQ Rev 1.0

28

3.13 Rader circuit

OMEGA

SCLK5

SIO5

SRST5

SVDD

RST

CLK

VCC/VPP

GND

I/OSIO3

SCLK3

SRST3

SIM_IO

SIM_CLK

SIM_RST

ULYSSE

SIM

SOCKET

Description

The SIM follows the GSM and ISO specifications and works in 3

volts or in 5 volts with a minimum external logic.

SIM_IO(I/O): Data

SIM_RST(O): Reset signal

SIM_CLK(O): Clock (1.6MHz/3.2MHz)

The SIM card digital interface insures the translation of logic levels

between ULYSSE and SIM card. There is a level shifter embedded in

Omega to support 5V SIM card.

Page 28

BenQ Rev 1.0

29

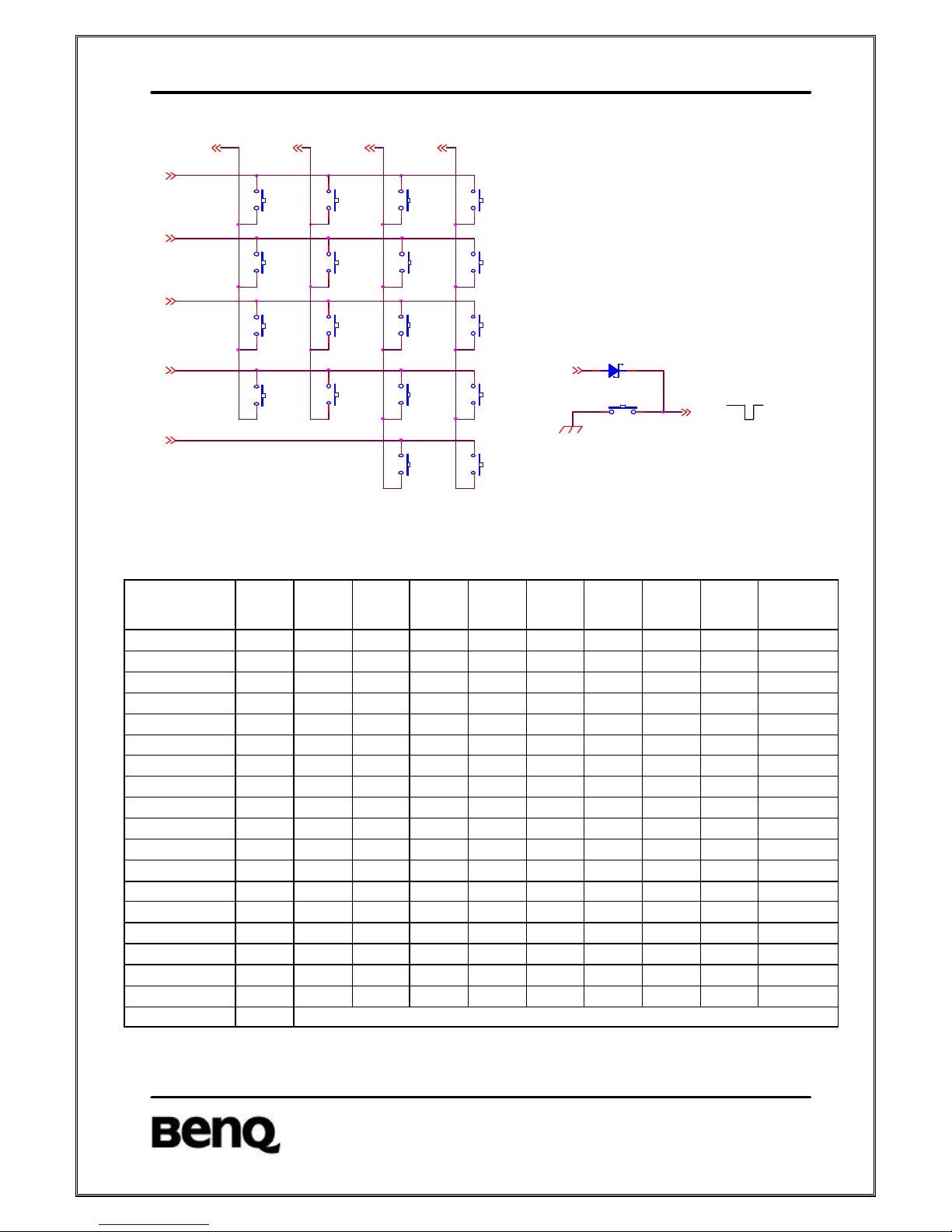

3.14 Keyboard circuit

BGND

ROW2

COL2

COL3

COL1

ROW4

ROW3ROW0

COL4

ROW1

COL0

PWON

S1

KSW

[3]

S7

KSW

[4]

S2

KSW

[2]

S16

KSW

[#]

S10

KSW

[7]

S3

KSW

[1]

S9

KSW

[8]

S6

KSW

[5]

S5

KSW

[6]

S4

KSW

[Down]

D2

RB520S-30

1 2

S13

KSW

[0]

S15

KSW

[menu]

S19

KSW

[NO]

[PWR]

S14

KSW

[*]

S8

KSW

[SEL]

S17

KSW

[Send]

S12

KSW

[9]

S18

KSW

[QUIT]

S11

KSW

[Up]

To U3/Omega

Description

1. The keypad is made of a 5 Column x 4 Row matrixes.

2. The keypad matrix is as follows:

Function Key

COL0 COL1 COL2 COL3 COL4 RO

W0 ROW1 ROW2

ROW3

3 S1 0 0

2 S2 0 0

1 S3 0 0

DOWN S4 0 0

6 S5 0 0

5 S6 0 0

4 S7 0 0

SEL S8 0 0

8 S9 0 0

7 S10 0 0

UP S11 0 0

9 S12 0 0

0 S13 0 0

* S14 0 0

MENU S15 0 0

# S16 0 0

SEND S17 0 0

QUIT S18 0 0

NO/PWR S19

Reference Drawing:

Page 29

BenQ Rev 1.0

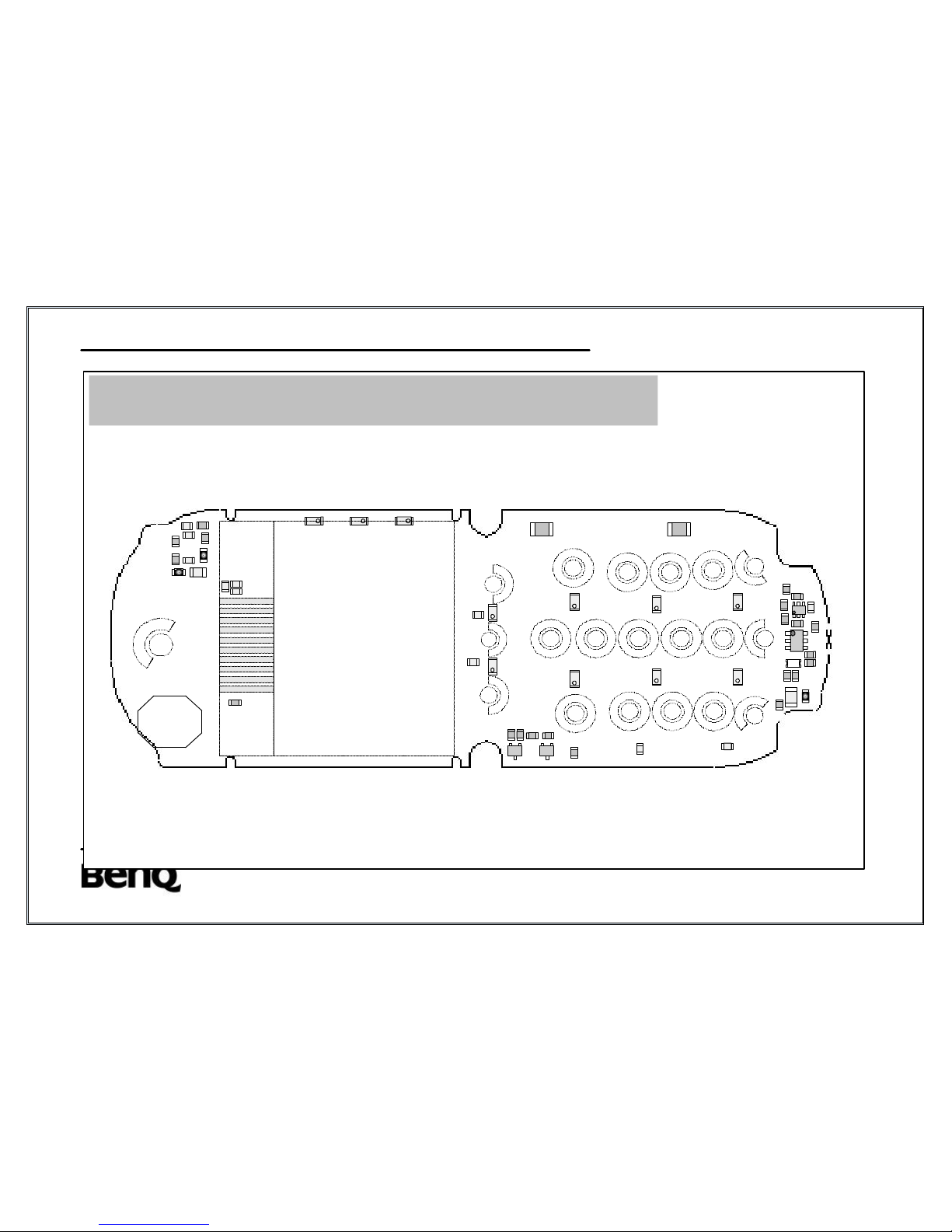

31

56D72 Side 1 Layout

U2

RN4

RN2

RN1

RN3

D2

R1

R26

C1

C2

R56

R52

R59

R58

R57

RN5 RN6

C13

R14

U7

BQ2 U14

C35

R34

C54

C53

C44

C45

C55

T1

R51

R50

R44

C43

C48 U18

D15

D1

R24

C29 C56

R66

R67

R25

C36

C42

TR1

R43

R47

R19

C4

C5

R5 R8

R7

R9

C7

R6

R28 R29 R13

R15

R17

R18

R16

C9

R21

C24 R20

C25

C18

C6

R77

C22

R4

R23

C46

C23

C8

C19 C20

C21

C17

C15

R41

R22

C12

C11

C26

R54

C37

R37

R38

U8

U10

C38

R33

R36

R32

U9

JP1

R11

C3

R2

J1

X2

U6

U5

U1

U3

X1

RF

BLOCK

D14

T10

J3

T8

T9 T2

R72

R76

C27

R3

C16

U15

Page 30

BenQ Rev 1.0

32

56D72 Side 2 Layout

LCD Module

D5

D7

D9

D11

D6

D8

D10

D12

D3

D4

D13

C57

T3

C34

T4

BL2

BL3 R74

C41

R73

C39

C40

R40

R35

C50

C51

C33R27

BQ3

BQ4

R48

R45

R71

R49

R46

C31

C30

T5

R60

F1

R75

R68

U17

R64

R70

R65

R63

R62

C49

C47

U16

U4

R61C10

R80

C58

Page 31

BenQ Rev 1.0

33

56D72 ULYSSE

RN4

RN2

RN5

RN3

C1

C2

R56

C52

R2

C3

DATA

TCXOEN

CLK

TSPDO

TCXOEN

TSPCLKX

CLKTCXO

13MHZ

OSC32KOUT

GANDA2

OSC32KIN

KBR4

KBR3

KBR1

KBR2

KBR0

RXMODEM

RX_IRDA

VR2B

SDI

SCL

ULYSSE

U1

X1 CRYSTAL 32.768KHz

Page 32

BenQ Rev 1.0

34

56D72 OMEGA

R

N

5

R

N

6

R6R9

C7

TR1

R5

C46

R11

R18

U15

R58 R57

R14

C12

C11

R59

ADIN2

CK13M

ADIN4

ACCID

ADIN5

PWON

RPWON

ONNOFF

ADIN1

EARPHONIN

VR3

13MOUT

IO1BATID_DET

VR2

TBAT

VR3

OMEGA

RESPWRONZ

U3

Page 33

BenQ Rev 1.0

35

VAUX

VR2

VR1B

VR2B

SVDD

VR3

VBAT

VBATBB

UPR

U3 Omega

C21

C20C19

C23

C15

C17

R24

C9

C18

1.8V

2.9V

2.9V

2.0V

2.9V

VBACKUP

C25

LCD

Flash & SRAM

Ulysse

SIM

SOCKET

VR1

Lower side

R15

R16

R17

R20

R22

R54

U1

U5,U6

J2

1.8V

1.8V

U4A

U2

2.9V

2.9V

2.9V

2.9V

5.8V

3.0V/5.0V

56D72 Power Supply Circuit

3.2V

On Side 2

On Side 2

Page 34

BenQ Rev 1.0

36

A

B

C

D

E

F

1 2 3 4 5 6

7 8

ADD

DATA

DATA

ADD

A

B

C

D

E

F

1 2 3 4 5 6

G

H

DATA

DATA

ADD

DATA

DATA

ADD

R28 R29

R30

C35

C36

VR2

2.9V

U1.J12

IO5FLASH_WP#

U1.P6

NROMCS1

U1.M9

FDP

U1.N8

RNW

U1.L8

NFOE

U1.P7

NRAMCS

U1.K7

NBHE

NBLE

U1.K8

U5

FLASH

U6

SRAM

2.9V

2.9V

56D72 Memory Circuit

Page 35

BenQ Rev 1.0

37

Receiver

EARN

EARP

U3.H8

U3.H9

T3

T4

BL2

BL3

R74

C40 C41

R73

C39

U12

U3.K9

U3.K8

U3.J8

R43

R44

C42

C43

R50

R51

C44

C45

C53

C54

U14

R47

2.5V

56D72 Audio Driver

MICBIAS

Microphone

MICP

MICN

Page 36

BenQ Rev 1.0

38

56D72 Earphone Jack

VR2B

BL1

R36

R37

R38

C37

C38

R41

BL4

U9

U8 U10

J3

R72

R32

T2

T8

T9 R76

EARPHONE_IN

VR3

IO13ACCIN

AUXI

AUXOP

TXD0

RXD0

IO3DATA_HP_SEL

R33

J4

VR3

Upper side

2.9V

V

earphone_in

= 1~2.4V for earphone

V

earphone_in

= 2.6~2.8V for data cable

2.9V

L: plug-in

H: idle

U1.A7

U3.H10

U3.D1

U1.M6

U3.J9

U3.H7

U3.H10

U1.D3

U1.D2

2.9V

L: Data Cable

H: Earphone

R6

Page 37

BenQ Rev 1.0

39

56D72 Charging Circuit

J1

U16

U18

R62

R65

R64 R70

R68

D1

R24

R25

R66

D15

C29

C49

C31

R63

U17

C47

C48

C30

C10

T1

C55

T5

R60

Charger In

R69

C28

JP1

C56

R67

VBAT

VBATBB

F1

VCHG

VR3

U3 Omega

ICTL

On Side 1

Page 38

BenQ Rev 1.0

40

56D72 Vibrator & Buzzer

D14

T10

BQ4

R49

R46

On Side 2

IOVIBRATOR

R71

R45

BQ3

On Side 2

D14

T10

BU

U1.C2

U1.J3

VBAT

VBAT

Page 39

BenQ Rev 1.0

41

GND

VPP

I / O

VCC

RST

CLK

U3.D5

R4

U3.A2

U3.D4

C6

U2

R3U3.B4

C4R7

R8

C5

3V/5V

SIO5

SCLK5

SVDD

SRST5

1.6/3.2MHz

56D72 SIM Circuit

1.6/3.2MHz

Page 40

BenQ Rev 1.0

42

56D72 Keypad and LEDs

D5

D6

D7

D8

D9 D10

D11

D12

ROW0

U1.A4

ROW1

U1.B4

ROW2

U1.D4

U1.B3

ROW3

U1.A6

COL0

U1.A5

COL1

COL2

U1.B5

COL3

U1.D5

COL4

U1.E5

ROW4

U1.A2

D2

PWON

U3.B10

D3

D4

D13

R40

R35

BQ2

U7.6

R34

VBATBB

1.9V

LCD

Backlight

1.9V

On Side 1

On Side 1

Page 41

BenQ Rev 1.0

43

56D72 LCD Circuit

VR2

I2C_SCL

C32

R27

C34

C50

C33

C51

NRSTOUT

I2C_SDA

U1.K11

10 9 8 7

6

5 4

3

2 1

RN3.1 / U1.C4

RN3.2 / U1.F4

2.9V

7.6V

2.9V

400KHz

J2

Page 42

BenQ Rev 1.0

44

△ Radio Frequency function Descriptions (Top Side)

Page 43

BenQ Rev 1.0

45

Bottom Side

Page 44

BenQ Rev 1.0

46

Tx Flow Chart

T/R Switch For TX

EGSM:880.2∼914.8MHz

DCS:1712.2∼1786.8MHz

(LMC33-07A0533A)

DCS:3604.4~3753.6 MHz

GSM:3700.8~3839.2 MHz

RFVCO

(UCVE4X307)

Dual Band PA

Tx

EGSM:880.2∼914.8MHz

DCS:1712.2∼1786.8MHz

(CX77301)

RF Synthesizer

(HD 155141TF)

Mixer with RF

(HD155141TF)

Loop

Filter

Phase

Dectector

I/Q

Modulator

I

Q

DCS: 360/368MHz

GSM: 360/368MHz

IFVCO

(HD155141TF)

IF Synthesizer

(HD 155141TF)

DCS/4=90/92MHz

EGSM/8=45/46MHz

TX VCO

EGSM: 880.2∼914.8 MHz

DCS:1712.2~1786.8 MHz

(ENFVF382S12)

HD155141TF

Page 45

BenQ Rev 1.0

47

Rx Flow Chart

T/R Switch For RX

EGSM:925.2∼959.8MHz

DCS:1805.2∼1879.8MHz

(LMC33-07A0533A)

DCS:3610.4~3759.6 MHz

EGSM:3700.8~3839.2 MHz

RFVCO

(UCVE4X307)

DUAL SAW FILTER

EGSM:925.2∼959.8MHz

(B7710)

DCS:1805.2∼1879.8MHz

(SAFSD1G84CB0T00)

Mixer with RF

(HD155141TF)

DC Offset

Cancellation

(HD155141TF)

I

Q

LNA

(HD155141TF)

RF Synthesizer

(HD 155141TF)

Page 46

BenQ Rev 1.0

48

Tx Block Diagram

Dual Band PA

T/R

Switch

Charge

Pump

PFD

2

QTxP

QTxN

ITxP

ITxN

EGSM : 45 MHz

DCS : 90 MHz

TX EGSM : 880.2~ 914.8 MHz

DCS : 1712.2~1786.8 MHz

Loop Filter

2

DCS:3604.4~3753.6 MHz

EGSM:3700.8~3839.2 MHz

RFVCO

RF

Synth

IFVCO

I&Q Mod

90

0

Shift(1/2)

IF

Synth

2

2

DCS

EGSM

DCS

EGSM

DCS:1802.2~1876.8 MHz

EGSM: 925.2~959.8 MHz

DCS:360/368 MHz

EGSM: 360/368 MHz

DCS : 90/92 MHz

EGSM : 45/46 MHz

Page 47

BenQ Rev 1.0

49

Rx Block Diagram

T/R

Switch

90

0

90

0

90

0

90

0

QRxP

QRxN

IRxP

IRxN

EGSM LNA

DCS LNA

EGSM: 925.2~959.8 MHz

DCS:1805.2~1879.8 MHz

2

DCS:3610.4~3759.6 MHz

EGSM:3700.8~3839.2 MHz

RFVCO

Shift(1/2)

Shift(1/2)

ADC/DAC & Control Logic for DC Offset Cancellation

RF

Synth

DCS:

1805.2~1879.8 MHz

EGSM:

1850.4~1919.6 MHz

Page 48

BenQ Rev 1.0

50

U75

U73

U67

U66

U71

C704

D

3

U61

U65

U85

U63

U64

U74

RF circuit element placement

Page 49

BenQ Rev 1.0

51

U75

U73

U67

U66

U71

C704

D

3

U61

U65

U85

U63

U64

U74

EGSM 900 Receive Signal Path Diagram

U72

CW Wave

CH 62 947.46MHz

-50dBm

-53dBm

-54dBm

-63dBm

-63dBm

Phone setting

+:continuous RX mode

ARFCN:62

BB PGC Gain value:3

IF PGC Gain value:60

LNA turned off:n

Legend:

chip inductor

chip capacitor

chip resistor

Vpp = 0.9V for

RFin=-60dBm

-3dBm

1.66V

2.84V

Page 50

BenQ Rev 1.0

52

U75

U73

U67

U66

U71

C704

D

3

U61

U65

U85

U63

U64

U74

CW Wave

CH 700

1842.86MHz

-50dBm

-53dBm

-56dBm

-63dBm

-63dBm

Phone setting

+:continuous RX

modeARFCN:700

BB PGC Gain value:3

IF PGC Gain value: 60

LNA turned off :n

Legend:

chip inductor

chip capacitor

chip resistor

Vpp = 0.7V for

RFin = -60dBm

-3dBm

1.18V

2.84V

DCS 1800 Receive Signal Path Diagram

Page 51

BenQ Rev 1.0

53

U75

U73

U67

U66

U71

C704

D

3

U61

U65

U85

U63

U64

U74

DCS 1800 Transmit Signal Path Diagram

U72

CH 700

1747.8MHz

27dBm

C806

0V

L606

C622

DC 1.18V

AC 0.46Vpp

1747.8

MHz

1747.8MHz

6dBm

C714

3675.6MHz

-1dBm

0V

1.1V

0V

2.8V

0V

2.8V

C621

26MHz

C709

1748.8MHz

24dBm

1747.8MHz

28dBm

1.6V

0V

1.4V

360MHz

-4dBm

DC 1.18V

AC 0.46Vpp

DC 1.18V

AC 0.46Vpp

1.8V

1.4V

Phone setting

RF toolkit mode

CH 700 : ARFCN

Power Supply Setting : 3.8V

Spectrum Analyzer Trace : Max Hold Mode

800 : scaling factor

6 : Data pattern =>random data=>TSC=5

Legend:

chip inductor

chip capacitor

chip resistor

3.8V

Page 52

BenQ Rev 1.0

54

U75

U73

U67

U66

U71

C704

D

3

U61

U65

U85

U63

U64

U74

EGSM 900 Transmit Signal Path Diagram

U72

CH 62

902.4MHz

31dBm

C806

0V

L606

C622

DC 1.18V

AC 0.46Vpp

902.4MHz

5dBm

C715

3693.6MHz

-2dBm

0V

1.6V

0V

2.8V

0V

2.8V

C621

26MHz

C709

902.4MHz

27dBm

1.6V

0V

1.3V

368MHz

-5dBm

DC 1.18V

AC 0.46Vpp

DC 1.4V

AC 0.7Vpp

2V

1.9V

902.4MHz

28dBm

6.5dBm

Phone setting

RF toolkit mode

CH 62 : ARFCN

Power Supply Setting : 3.8V

Spectrum Analyzer Trace : Max Hold Mode

Legend:

chip inductor

chip capacitor

chip resistor

800 : scaling factor

6 : Data pattern =>random data=>TSC=5

3.8V

Page 53

BenQ Rev 1.0

55

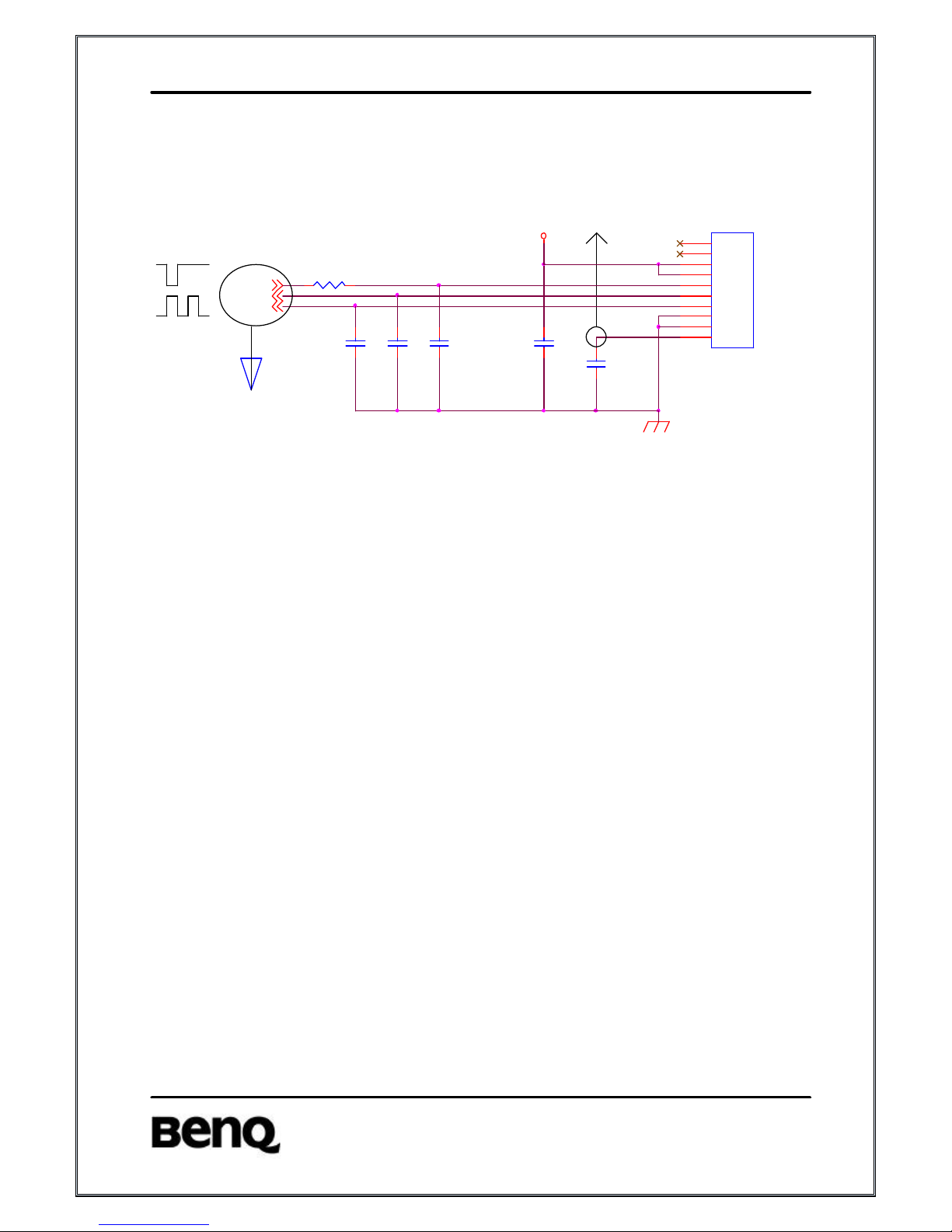

1.T/R switch:

U75 is a front-end switch device for GSM/DCS.

These devices include 1 diplexer + 2 switches + 2 LPFs. The below

table shows the three operating mode.

Mode Vc1 (pin 2) Vc2 (pin 11)

GSM TX L H

DCS TX H L

GSM Rx and DCS

Rx

L L

These four control signals are generated from U73 Dual Buffer, which

controlled by GSM_T/R(U1 Pin B10) DCS_T/R(U1 pin E9).

2.PA and power control circuit:

PA (U71) is control by signal BS and APC (U74 Pin7). APC is

generated from U74 (Operational Amplifier), which controlled by RAMP

signal (U3 pin 47). The power control loop is a current sensor. U74

works as the error amplifier. It can compare the RAMP signal and

feedback signal from R702 then amplify the error part to drive PA. U86

is a switch for power saving. Please refer to TX signal path chart for

detailed signal waveform. Please refer to TX signal path chart for

detailed signal waveform.

3.Transceiver:

U61 is the transceiver.

A>.Receiver Operation

The receiver employs a direct-conversion architecture. The

incoming RF signals pass via a suitable front-end filter into the

balanced LNA and a pair of Gilbert Cell mixers. The mixers convert the

RF signal directly down to baseband frequencies. The I/Q local

oscillator signals for the mixers are derived from a 3.6~3.84GHz RFLO,

divided down by high-speed BiCMOS flip-flops. The receiver has 2

separate front-end blocks, optimized for 900MHz and 1.8GHz operation

respectively. Each front-end block has 3 discrete gain settings. These

settings allow the signal levels in the receiver to be optimized,

particularly under high signal conditions. The I/Q baseband lowpass

filters and programmable gain amplifiers follow the mixer. The

Page 54

BenQ Rev 1.0

56

baseband filtering is distributed in the PGA and comprises a single R/C

low-pass section and 2 second order Butterworth filters. The majority of

the baseband filtering is implemented on-chip. Each 3 stage PGA is DC

coupled and has a gain range. The base-band PGA has 2dB gain steps

and 90dB control range. The baseband PGA includes a DC offset

cancellation system.

The signal is then down converted by a demodulator to I and Q.

B>.Transmitter Operation

The transmitter chain converts differential IQ baseband signals to a

suitable format for transmission by a power amplifier.

The common mode voltage range of the modulator inputs is 0.9V to

1.4V and they have 1.25V differential swing. The modulator circuit uses

double-balanced mixer for the I and Q paths. The Local signals are

generated by dividing the IFLO signals by 8 for GSM, and dividing IFLO

signals by 4 for DCS, and then passed to the modulator through a

phase splitter / shifter. The IF signals generated are then summed to

produce a single modulated IF signal which is amplified and fed into the

offset PLL block.

Within the offset PLL block there are a down converter, a phase

comparator and a VCO driver. The down converter mixes the first local

signal and the TXVCO (U65) signal to create a reference local signal

for use in the offset PLL circuit. The phase comparator and the VCO

driver generate an error current, which is proportional to the phase

differential between the reference IF and the modulated IF signals. This

current is used in a second order loop filter to generate a voltage, which

in turn modulates the TXVCO.

4. Synthesizer:

A>.TCVCXO

U85 is a TCVCXO module which providing RF system clock (26

MHz). The 13MHz generated by dividing the 26 MHz by 2 provide

Baseband system clock. U3 (Pin F8) can fine tune the clock frequency

by AFC signal (U85 Pin1).

B>.RF VCO

Page 55

BenQ Rev 1.0

57

U63 is a RF VCO module. The frequency band is 3610∼3840 MHz

for GSM / DCS TX / RX. The output frequency can be controlled by

U61 pin 43,44.

C>.IF VCO

IF VCO consists of U61 pin 32、33, D601、D602(varactor) and other

RLCs. The operating frequency is 360 MHz, and 368MHz. The output

frequency is controlled by U61 pin 34.

5.Regulator

U90 is the Dual regulator for RF circuit. The first regulator (pin 1)

provides transceiver 2.85V and TXVCO (U65) 2.85V through Q700

pin6 which is a switch for power saving. The second regulator (pin 6)

provides synthesizer of transmitter and RFVCO (2.85V) through Q700

pin3. All the Dual regulators can be shut down simultaneously by set

TCXOEN signal (U1 pin E11).

Table A

Receiver Troubleshooting and Repair Chart

Rx Symptom Probable Cause

Verification and Remedy

1. Portable

telephone

exhibits poor

reception

and/or erratic

operation

(such as calls

a) Antenna

assembly is

defective.

1. Check to make sure that

the antenna is properly

touched to the telephone

Main Board pad. If not,

substitute a known good

antenna assembly.

2. If the fault is still present,

proceed to b.

Page 56

BenQ Rev 1.0

58

frequently

dropping,

weak and/or

distorted

audio, etc.).

b) Defective or

misplaced

telephone Main

Board.

1. Check for appropriate

frequencies and power

level gains/losses in the Rx

path.

2. Replace malfunctioning

components if listed in

parts list. Likely fail

components are:U75,

C608, C609, L601, L602,

L603, and L604.

3. If parts replacement

doesn’t correct the fault,

replace the SAW filter U66,

U67, or transceiver U61.

Table B

Transmitter Troubleshooting and Repair Chart

Tx Symptom Probable Cause Verification and Remedy

a) Microphone

connections to

Main Board

defective.

1. Check connections and

if OK, proceed to b.

1.Transmit audio

is weak,

(usually

indicated by

called parties

complaining of

difficulty in

hearing voice

from portable

phone).

b) Microphone

defective.

1. Substitute a known

good microphone.

2. Place a call and Verify

improvement in portable

transmit signal as heard

by called party. If good,

re-assemble portable

with new microphone

3. If microphone is not at

fault, re-install original

microphone and

proceed to c.

Page 57

BenQ Rev 1.0

59

c) Main Board

assembly

defective.

1. Replace Main Board

Assembly.

2. If Main Board Assembly

is at fault, examine for

improper solder and

connections.

Download

Introduction:

This document describes all the functions in service DMtool.

△ System requirements and setup:

A. Minimum requirement:

Operation system: Win95/ Win98 / WinNT / Win2000.

CPU: Pentium 233 Mhz or higher.

Hard Disk: Free 10MB space.

Memory: 64MB RAM.

Input Device: Keyboard and mouse

B. Calibration requirement:

1.Instrument for calibration Hp8922M GSM/DCS/PCS MS Test Set

Hp8960 GSM/DCS/PCS RF Interface

2.GPIB interface card and cable For RF calibration

3.Power Supplies:

HpE3631,Hp66332A,Hp66311,Hp66111,Hp66309

4.Communication cables Rs232 and Acer Downloader

5.RF Cable 50 ohm cable for RF calibration.

6.Dummy battery For RF and battery calibration.

C. Setup in Windows:

Page 58

BenQ Rev 1.0

60

In Windows 95/98/NT/2000, extract the Dmtool compress files to

any temporary directory. It will create DISK1 this subdirectory. Please

go into the DISK1 and double click the setup.exe. The Install shield

will auto setup the Dmtool in your operating system.

Some necessary files are listed below :

Fixed Items:

===============================

(1) DMtool.exe (main application )

(2) DL.dll (the dll for download)

(3) CALDL.dll (the dll for calibration)

(4) E2pMmi.dll (the dll for read/write e2p and mmitest)

(5) AtStCom.dll (the dll for animation and melody download)

(6) r_flash_xx.mot (Rs232 boot code file)

(7) dmtool.hlp, dmtool.cnt (dmtool help file)

(8) AutocalMarch.cfg (auto-calibration parameter reference file)

Volatile Items:

===============================

The files you gotten may differ from the files listed below as the

result of software upgraded for handsets. When the software of

handsets release, you will get a handset program file and an eeprom

database file.

(9) mh1060.bin (eeprom database file, its file extension name must

be “bin”

(10) mh106010.mot (handset program file, its file extension name

must be “mot”

Page 59

BenQ Rev 1.0

61

△ Function descriptions:

There are several windows (views) in the DMtool application.

Each view performs a special function.

A. Download:

Before you start a RS232 download, you must select a flash-load

program file by pressing down the “Flash File” button or “Set Flash

File” submenu button in “File” menu. Then you must select the

correct com port in “Option” menu. When the Dmtool application

setup completed, the default boot code will be assigned. You don’t

need to change the boot code yourself. You can change boot code

by “Boot File” button or “Set Boot Code File” submenu button in

“File” menu. If you assigned incorrect flash or boot code file, you

may still encounter errors.

Before press “Download” button to start a RS232 download

process, you must power off the handset. When the string “Wait for

target ready” appears, power on the handset. Then the download

process starts. It will take about 5 minutes for completing the

download.

After undergoing a completed download process, the Dmtool will

auto trigger a Set E2P Default dialog to execute set e2p default.

There are two option, “Set E2P Default” or “Set E2P Default and

Phone Book Initialize” in this dialog. You must select “Set E2p

Default and Phone Book Initialize” and click the “OK” button. After

the “Wait for target ready” message appears, power on the handset.

If the handset receive the set e2p command form dmtool, it will start

to execute set e2p command and send the ack message to dmtool.

When the dmtool received the ack from handset it will display the

message “Waiting for target Acknowledgment …”. If the handset

complete the set e2p command, it send the ack to dmtool. When the

dmtool receive the ack message, it will display “Set e2p command

success” message.

Remark:

1. It must be emphasized that never stop or remove the power

supply (battery) when your handset is downloading the block 0

Page 60

BenQ Rev 1.0

62

and block 1 program codes . It is writing critical boot codes at

this time. If you terminate the download process at this moment,

this handset not only can’t power on but also can’t re-download

again. In this case , the only solution is using a special “Jtag

interface and cable” to do a low-level download.

2. When the new vendor flash used in handset, the boot code

r_flash_xxx.mot need upgrade to new version which support

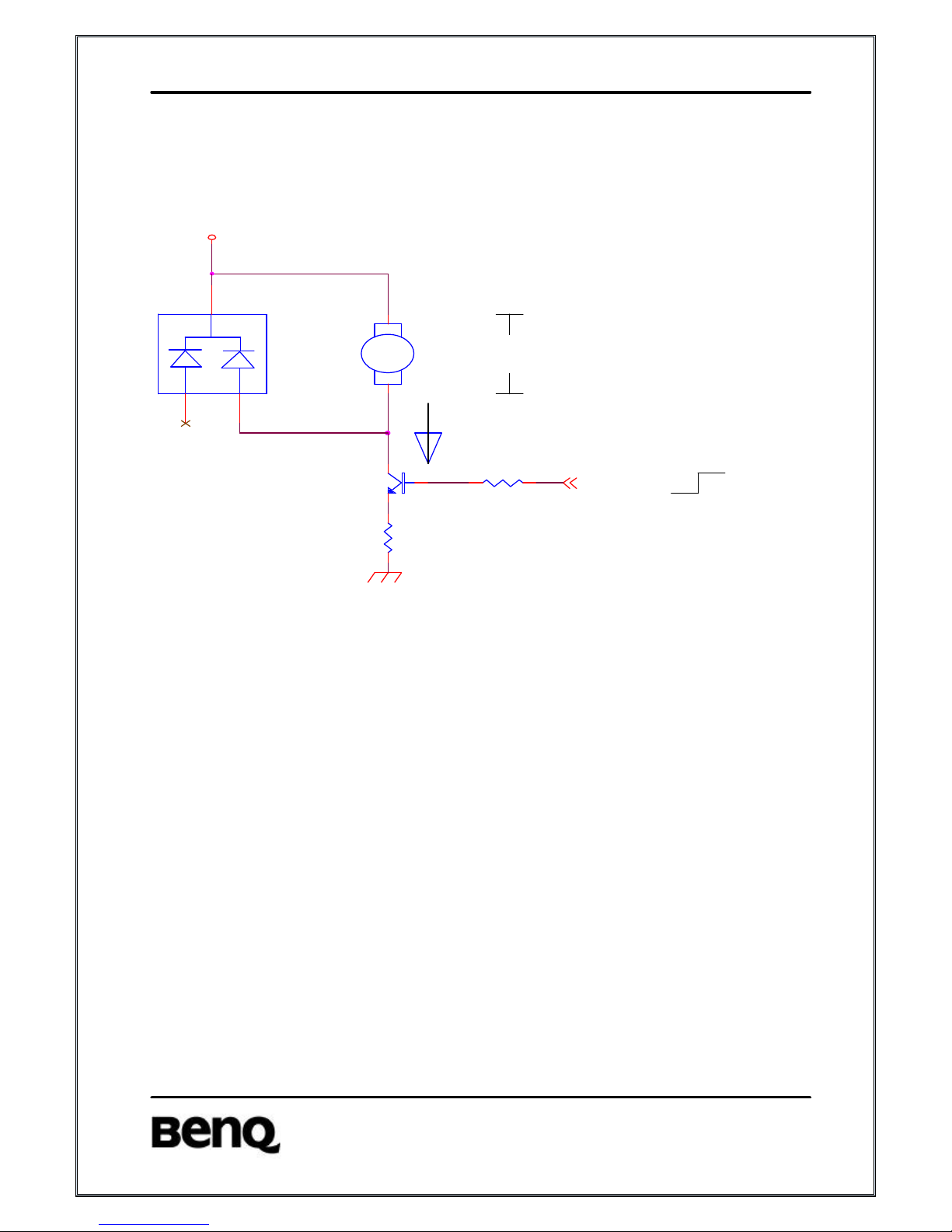

new vendor flash.

B. Set E2P:

There are several sub-options for this function. You can select these

option from “Set E2p Mode” submenu in “Option” menu. You can see

which set e2p mode you select current in the status bar (in the

right-bottom) of the window. To execute those options, first power off

the handset and click this “Set E2p” button. After the “Wait for target

ready” message appears, power on the handset. Details for each

sub-options are listed below.

(1).Set EEPROM default will set a part of contents in EERPOM to

factory default value. Phone books and calibration data won’t be

reset in this operation.

(2).Set EEPROM Default Phone books initialize is similar to Set

EEPROM default, but this option will erase all phone book data in

EEPROM.

C. Read/Write FlexOption:

”Flex option” is used for modifying the handset’s flex option settings.

Changing those options are straightforward, just click the individual

enable/disable check button of every tree-item. The procedure to

Read/Write FlexOption is:

(1).Set baud rate 115200 and select com port then connect RS232

communication.

(2).Turn on the handset.

(3).Check the database file are the same as software version. You

can assign database file from menu “File” à “Set Database

File”. You can verify software version by keypress “*#300#” in

handset.

(4).Click “Read Flex Option” to read flex option from handset.

Page 61

BenQ Rev 1.0

63

(5).Select the feature you want enable/disable by click check button

in option tree-item.

(6).Click “Write Flex Option” to write flex option to handset.

D. Calibration:

(1).calibration connect cable:

PS:

1. In some calibration instrument, the RF output of GSM and

DCS are different, so you must calibrate GSM and DCS each

other.

2. If you have no connector with power supply and Acer

downloader, you can get a travel charger and cut it, then

divide the positive and negative electrode to connect into

power supply.

(2). Calibration Item:

2-1.Configuration file:

The auto-calibration configure file contents some

optimal value for some object in handset and some

parameters dependent on calibration device and handset.

u

v

Calibration

Instrument

PC

RF output

Power

Supply

Acer

downloader

GPIB

Com

GPIB

GPIB

Rs232

RF Cable

Power lines

Downloader cable

Dummy battery

u w x

GSM I/O

Power

Handset

Page 62

BenQ Rev 1.0

64

2-2.Auto-Power-Control:

If the flag is TRUE and the power supply is a supported

type (please refer to System Requirement

) , the calibration

will start automatically, or you must operate it manually.

2-3.Set Ramping Default:

Some measurement instruments do not support ramping

calibration, you can set the ramping table by default values.

2-4.HW Version:

The hardware version of the target handset. It combined

with major and minor hardware version. The major hardware

version is indicates the type of PA, and the minor hardware

version indicates the type of baseband or others.

Major version 1.x – Conexant PA

Major version 2.x -- Hitachi PA

2-5.PA Type Selection:

There are two kinds of PA, Conexant PA and Hitachi

PA. Before you start to calibrate, you must select the correct

PA type.

2-6.Auto-calibration selection:

Choose the items that you want to calibrate when

running auto-calibration function.

AFC: Frequency. (Before calibrate AFC, you must select

AGC Item)

AGC: RxGain

APC: TxPower