Bennett Read Pacific 1000 User Manual

Bennett Pacific Series

1000 Series Remote Dispensers

Electronic Service Manual

READ THIS BOOK This book has important information for

safely servicing of this equipment. Read and understand this

book before attempting troubleshooting. Keep this book and tell

all service personnel to read this book. If you do not follow the

instructions, you can cause bodily injury, death or damage to the

equipment.

For new books, FAX to:

BENNETT MARKETING SERVICES

(231)799-6202

Or visit our web page at:

http://www.BennettPump.com

111661 Rev B 02/09

Bennett 1218 E. Pontaluna Road Spring Lake, MI 49456

USA 800-235-7618 Outside USA 231-798-1310 sales@bennettpump.com

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

www.bennettpump.com

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

Table of Contents

SECTION A

SECTION B

INTRODUCTION

SERVICE SAFETY INSTRUCTIONS

BASIC SYSTEM THEORY OF OPERATION

THE POWER DISTRIBUTION BOARD

Part Number B-1

Board Functions B-1

Theory of Operation B-2

Battery Backup B-3

Description Of Controls B-4

Switch 2 (On/Off) B-4

Switch 1 (Battery Kill) B-4

PAD Jumpers B-5

Relays B-5

Fuses B-6

Standard B-6

Pico B-6

Light Emitting Diodes (LED’s) B-6

System Battery B-6

Powering Down the Dispenser for Service B-6

Turning the Dispenser On B-6

Taking Voltage Readings B-7

AC Voltage Reference B-7

DC Voltage Reference B-7

Voltage Tolerances B-7

Testing Fuses B-7

Incoming Power B-8

Neutral to Ground Reading B-8

Terminal Strips, Connectors and Pinouts B-9

TS1 - Input Power B-9

TS2 - Motor Power products A and B B-9

TS3 - Motor Power products C and D B-9

TS4 - Card Reader Communication B-9

TS5 - Dispenser Communication B-10

J1 - DC Voltages to the CPU Board B-10

J2 - Battery Charging Circuit B-10

J4 - DC Voltages to the Power Distribution Boards B-10

J3 - Dispenser, Card Reader Communications and Motors B-11

J5 - Filtered AC Connection B-11

Power Supply B-12

Part Number B-12

Board Functions B-12

Description of Controls B-12

LED’s B-12

Fuses B-12

Voltage Adjustments B-12

Taking Voltage Readings B-13

Color Coding B-13

+24 Volts B-13

+12 Volts B-13

+ 5 Volts B-13

A-1

A-2

A-3

111661 Rev B 02/09

i

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

Table of Contents

SECTION C

SECTION D

SECTION E

SECTION F

THE CPU BOARD

Part Number C-1

Board Functions C-1

Theory of Operation C-2

Communication with the Point of Sale C-3

Communication with the Card Reader System C-4

Communication with the Handle Switches C-4

Communication with the Pulsers C-4

System Software C-4

System Memory C-5

On Board Battery C-5

Communication with the Product Select Panel C-5

Communication with the Local Preset C-6

Local Preset Troubleshooting C-6

Power Fail Circuit C-6

Power On Self Test C-6

Light Emitting Diodes C-7

Communication LED’s C-7

Test Points C-8

RAM Clear Procedure C-9

Terminal Strips, Connectors and Pinouts C-10

J1,J2 - Internal Local Area Network C-10

J7 - DC Voltages from the Power Distribution Board C-11

J8 - Communication Ribbon Cable C-11

J9,J10 - Intrinsically Safe Barrier Board Connections C-12

CPU Jumpers C-13

Valve Control

Proportional Valve Control C-14

Mixer Valve C-15

Electronic Calibration Switch Board C-16

THE PRODUCT SELECT / AUXILIARY BACKLIGHT DISPLAY BOARD

Part Number D-1

Theory of Operation D-1

Block Diagram D-2

How to Prepare the Dispenser for Programming D-3

The Electromechanical Totalizers D-4

THE DISPLAY BOARDS

Main Display Part Number E-1

Main Display Theory of Operation E-1

Main Display Terminal Strips, Connectors and Pinouts E-2

Auxiliary Display Part Number E-2

Auxiliary Display Theory of Operation E-3

THE BACKLIGHT BOARD

Part Number F-1

Theory of Operation F-1

Description of Controls F-1

LED’s F-1

Test Points F-1

Terminal Strips, Connectors and Pinouts F-1

111661 Rev B 02/09

ii

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

Table of Contents

SECTION G

SECTION H

SECTION I

SECTION J

SECTION K

THE INTRINSICALLY SAFE BARRIER BOARD

Part Number G-1

Theory of Operation G-2

Description of Controls G-2

LED’s G-2

Test Points G-2

Terminal Strips, Connectors and Pinouts G-2

J1, connector to the CPU G-2

J2, Pulser Ribbon Cable Connection G-3

J3, Pump Handle Cable Connection G-3

Pulser Board Part Number G-4

Theory of Operation - Pulsers G-4

Error Checking G-4

J2, Ribbon Cable on Pulser Connection G-5

J3, Ribbon Cable to Next Pulser Connection G-5

Connecting Pulsers G-6

Test Points G-6

LED’s G-6

Handle Switch Circuit Part Number G-7

Theory of Operation - Handle Switches G-7

Handle Switch Location G-8

Setting the Jumper on the Handle Switch Board G-8

Test Points G-9

Connecting the Handle Switches G-10

LED’s for the Handles G-11

SECURE PUMP PAY

Serial Numbers H-1

Diagnostics H-2

Keypad H-4

Printer H-4

Display H-4

Card Reader H-5

Dukpt Encryption H-5

Menu2 Option H-6

Ping H-6

Error Codes H-7

Preventive Maintenance Tips H-8

LCD Display Contrast H-8

Troubleshooting Chart H-9

VIB2 Board H-12

Part Number H-12

Description Controls H-12

LED’s H-12

Connectors & Pinouts H-13

ERROR CODES

List of Error Codes I-1

Clearing Error Messages I-1

TROUBLESHOOTING BREAKDOWN

DIAGNOSTICS

J-1

K-1

111661 Rev B 02/09

iii

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

This manual covers service information for the electronic components of Bennett pumps. It covers the

Pacific Series with 708 electronics. Information is correct at time of publication. For more information,

please contact the Bennett Customer Response Department at Bennett Pump in Spring Lake, Michigan.

UNAUTHORIZED ALTERATION OF BENNETT PRODUCTS

Bennett Pump Company products are designed to meet or exceed the standards of UL, FCC and the

National Institute of Standards and Technology. These standards protect the operator and the

consumer from personal injury and insure an accurate delivery of product. Any deviation from the use of

authorized replacement parts or alteration of a designed product configuration may cause personal

injury, death or the revocation of one or all of the above approvals.

The most frequently abused design alteration of Bennett products is the conversion of a self-contained

model (pumping unit in the dispenser cabinet) to a remote dispenser (submerged pump in the storage

tank). This field practice has mainly occurred in an effort to overcome the problem of vapor lock.

Bennett Pump Company does not condone nor offer a kit or instructions for this type of conversion.

Bennett Pump Company strongly opposes this type of conversion. Safety standards required by the

agencies above are violated when unauthorized conversions are performed. Bennett Pump Company

recommends the replacement of a self-contained model with a remote dispenser model to overcome the

problem of vapor lock. The Pacific Series does not offer a self-contained model.

Bennett Pump Company will not assume responsibility or liability for any consequential injury or damage

caused by the unauthorized alteration of its products.

NOTE: Before performing any type of service to the dispensers, be sure to shut off all

electrical supplies and secure them in the OFF position. Close all valves in

incoming piping. Also, to prevent the risk of electrical shock from sub pump feedback, make sure you disconnect the field wiring from the power distribution board

by using the quick disconnect terminals provided at the bottom of the power distribution board. Maintenance must be performed by trained personnel ONLY.

Introduction

BEFORE SERVICING A BENNETT DISPENSER, CHECK THE FOLLOWING:

1. Make sure all dispensers are correctly grounded with 12 gauge wire.

2. Make sure input voltages are within operating level: 120VAC (96 to 135VAC) or 240VAC

(192 to 276VAC).

3. There are no more than two units operating on a clean and dedicated 120/240VAC voltage

sources.

4. There are RC networks installed across the coil of the motor relay and contacts of remote

submerged pumps.

IF ANY DEVIATION FROM THE ABOVE IS FOUND,

CORRECT THE PROBLEM BEFORE PROCEEDING.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-1

Safety Instructions

WARNING ADVERTISSEMENT ADVERTENCIA

For the safe installation of this equipment, read and understand all warning and cautions. Look for these

warnings:

“DANGER” means: If you do not follow the instructions, severe injury or death will occur.

“WARNING” means: If you do not follow the instructions, severe i njury or death can occur.

“CAUTION” means: If you do not follow the instructions, damage can occur to the equipment.

DANGER: Fire, explosion, injury or death will

occur if fuel filters are changed by untrained

personnel. Make sure only trained personnel

change filters.

DANGER: To prevent injury to you from vehicles

and onlookers, always place a barrier around this

equipment before performing service or

maintenance.

DANGER: Gasoline is flammable. NO

SMOKING OR OPEN FLAME.

DANGER: Disconnect all power to this

equipment and associated submerged

pump(s) during installation, service or any

maintenance, i.e., changing filters.

WARNING: You must have training in the

installation, service or maintenance of this

equipment (dispenser, pump, console, control

box or submerged pump) before working on it.

Maintenance repairs must be done by authorized

personnel only. Warranty work may only be

performed by Bennett certified technicians.

WARNING: To prevent electric shock, keep the

electrical parts of the dispenser dry.

WARNING: Electronic components are static

sensitive. Use proper static precautions (static

straps) before working on the equipment.

WARNING: The emergency shut-off valve (also

called the fire valve, shear valve or impact valve)

must be closed when service or maintenance is

performed on this equipment.

WARNING: You must have training in the

operation and programming of this dispenser

before using it. READ THE OPERATORS

MANUAL.

WARNING: Make sure this equipment is

correctly grounded. Failure to do will cause

injury or damage equipment or improper

operation. Improper grounding voids the

warranty.

WARNING: When anchoring the dispenser,

always level the dispenser with shims before

bolting to the island. DO NOT shim just the

middle of the dispenser and bolt down.

CAUTION: Do not drill holes in fuel dispensers.

Holes can cause failure of the electronic

equipment. The warranty will become void. Use

only adhesive backed sign mounting brackets.

READ AND UNDERSTAND ALL WARNING LABELS ATTACHED TO THE DISPENSER

NOTICE

This device complies with part 15 of the FCC rules. Operation is subject to the following 2 co nditions:

(1) This device may not cause harmful interference and (2) th is device must accept interference received,

including interference that may cause undesired operation.

111661 Rev B 02/09

A-2

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

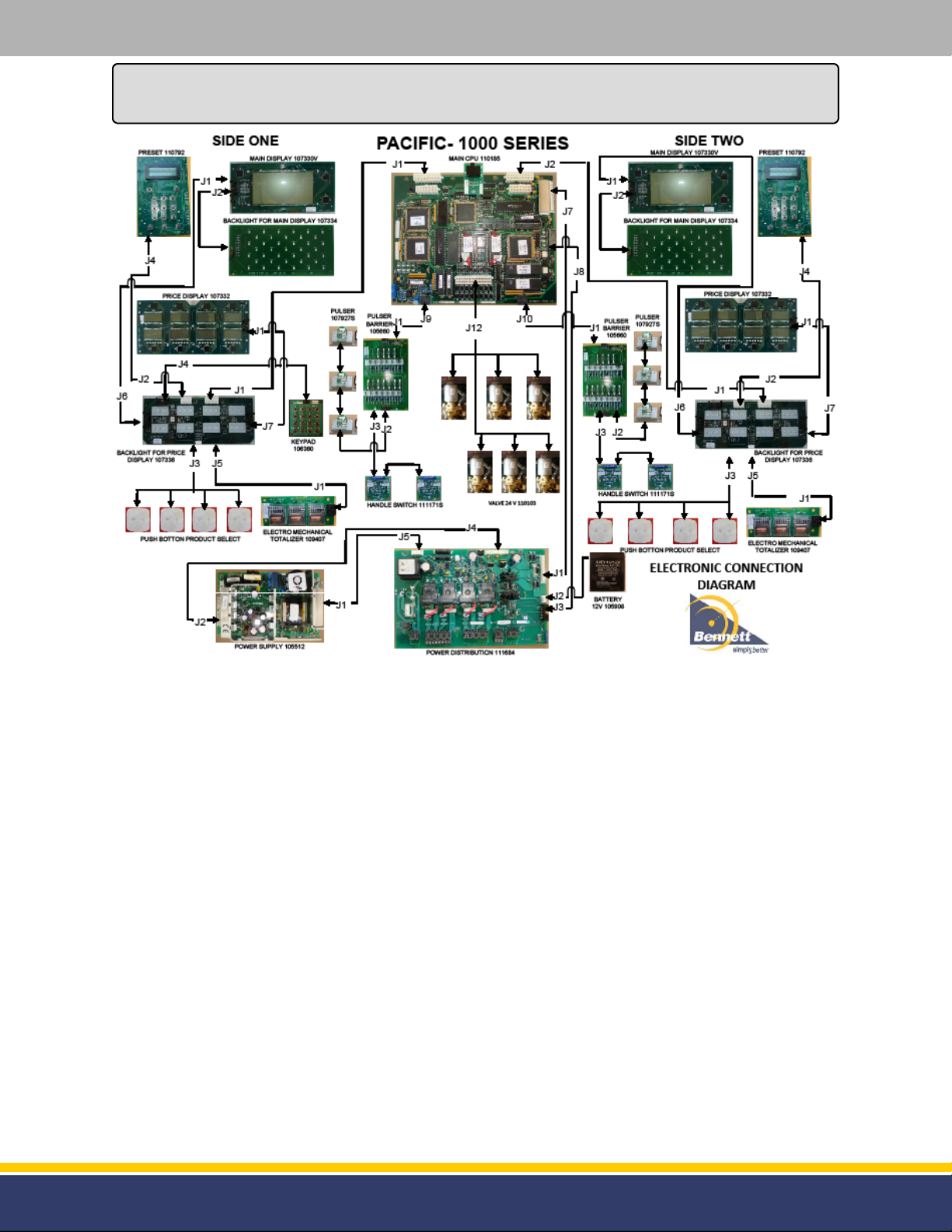

Overview of 708 Electronic Components

Basic System Theory of Operation

110– 230 Volts A.C. 50 or 60 cycle power comes into the dispenser through field wiring to the bottom of

the Power Distribution Board terminal strip (TS1). Power then passes through a 3 amp fuse and then is

filtered for noise. Any electrical noise is dampened out by this filter FIL1. The power is then passed from

the Power Distribution Board to the Power Supply (through connector J5) for Direct Current (D.C.) conversion. There is only one Power Distribution Board and one Power Supply for the dispenser.

Power comes into the Power Supply assembly on connector J1. This power supply creates various D.C.

Voltages for use throughout the system. Specifically, the power supply takes the 110– 230volt A.C. input

to create the following voltages:

1) +24 Volts DC

2) +12 Volts DC

3) +5 Volts DC

These voltages have tolerances of +/- 5%. There are no adjustments for any of these voltages but there

are test points.

The DC voltages are fed back to the Power Distribution board connector J4 through a multi-pin conductor connected to J2 of the Power Supply. There is fuse protection on the Power Distribution Board for

both power coming into the system and also fuse protection for power traveling internal to the system.

From there the DC voltages are sent over to the CPU board through another multi-pin conductor from

connector J1 of the Power Distribution Board to connector J7 on the CPU board. From this point the

voltages are distributed to all other parts of the system.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-3

Battery Backup— A separate rechargeable +12volt battery is connected to the Power Distribution

Board. When the dispenser is in normal operation the battery is not used and is charged by the +14 volt

D.C. battery charging circuit located on the Power Distribution Board. When main incoming power is removed from the system or when the system incoming AC voltage drops below 74 volts AC, the CPU

detects this and the dispenser goes into “Power Fail” condition. At this point the battery supplies +12

volts DC for 30 seconds to the system or unless you use the magnet provided to close the battery kill

reed-switch. This battery kill switch allows the technician to eliminate the 30 second wait if he has to service the equipment. The battery itself is connected at the factory but requires several hours to charge.

This battery has nothing to do with maintaining system programming in the event of a power outage.

The Power distribution board has other functions as well. This board houses four solid state relays that

are used to route incoming power as Motor “Out” signals to turn on remote submerged pump relays.

These relays are controlled by +12 volt DC signals from the CPU board. When the CPU board wants to

turn on a submerged pump, it sends a +12 volt dc signal to the proper relay pulling in the coil and routing

the power to the proper terminal on the terminal strips located at the bottom of the Power Distribution

Board. When the CPU wants to turn “Off” a motor, it removes the +12volt dc signal which opens that

relay. In the case of blended products, more than one relay is activated at one time.

Dispenser communication with a Point of Sale and Card Reader communication is also routed through

the power distribution board. Dispenser communication comes in from the mod el 515 box to the power

distribution board terminal strip TS5. This is the current loop communication signal that passes through

the Power Distribution Board on connector J3 through a ribbon cable to the CPU board connector J8.

Card reader communication also is routed through the power distribution bo ard. Card reader information

comes from the IC Box through twisted pair wiring (3 wires) and connects to terminal strip TS4. This is

RS485 protocol. This information follows the same path through the power distribution board as the dispenser communication, that is, it exits the power distribution board through the same ribbon ca ble over

to the CPU on connector J8.

The CPU board— The CPU board is the heart of the system. It runs the software, has the memory,

communicates with Point of Sale, sends control signals to the solid state relays, sends display signals to

the display boards, communicates with the product select touch panel, interfaces with the handles and

pulsers through the Intrinsically Safe Barrier Boards, controls the proportional valves through a wiring

harness. It performs the blending functions, and stores historical data for sales and diagnostics. It receives power from the Power Distribution Board. It also routes power to the card reader system. It also

communicates with and sends signals from the Vapor Recovery system.

There is one CPU board per dispenser and it can be accessed easily by opening the electroni cs enclosure door. The CPU board is mounted vertically and has various cables and harnesses connected to it.

The CPU receives dc voltages from the power distribution board on connector J7. The wiring harn ess is

color coded and uses the following color scheme:

1) Orange - +24 volts dc Valve, printer, display and backlighting

2) Yellow- +14 volts dc Battery charging circuit

3) Red - +12 volts dc Product select, Card reader, Pulsers, Handles, Display and Solid State

Relays

4) Black - DC Ground Reference for all DC voltages

5) Violet - +5 volts dc System logic voltage used by the CPU

The CPU board is physically mounted to the Intrinsically safe barrier modules.

Overview of 708 Electronic Components

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-4

Intrinsically Safe Barrier Modules - The Intrinsically safe barrier modules provide protection to the

handle and pulser circuits located in the lower half of the dispenser in the hydraulic area. These circuits

are designed with fuses and zener diodes to prevent any potential energy from entering the hydraulic

area so that under no condition will there be enough energy to create an electrical “spark”. This way,

there can be no explosion if there are vapors. There is one ISB for side 1 and one for side 2. The boards

are identical. The fuses on these boards cannot be replaced in the field as a UL requirement. These

boards are covered with a metal cover to protect the circuits from an inadvertent short and the covers

should always be in place when the dispenser is in operation. The ISB’s do not have any discreet or

“smart” components. There are two ISB modules for a two sided dispe nser, they are identical and interchangeable.

Dual Phase Pulsers - Pacific pulsers are dual phase electronics pulsers that pulse at a rate o f 1024

pulses per gallon. These pulsers are physically mounted to the output shaft of the meter. As fuel flows

through the meter, the output shaft rotates and turns the pulser. Approximately 8 rotations of the meter

represents 1 gallon of fuel. The pulser is an optically coupled device and outputs 2 separate phases of

square wave pulses through a ribbon cable connection, in a daisy chain fashion whe re it con nects

through the “flame deck” to the ISB for that side. The pulsers operate off a regulated +5volt dc signal

that was created from a +12volt supply. When the valves are closed and there is no fuel flow, there

should be no pulses output from the pulser. The pulser only generates pulses a s it is turning. As it turns

and generates pulses, it sends these pulses to the CPU board through the ISB for that side. The CPU

counts the pulses and performs the mathematical computations to covert this information to a display

readout that shows the volume and it’s computed currency value on the main display. The CPU and the

pulser works in conjunction with one and another. For example, when the CPU receives it’s first 9

pulses, it opens up the proportional valves. At this point it is making sure that both phases are working. If

one of the phases of the pulser is not working, the dispenser will never come out of slow flow. Generally, a retail dispenser in fast flow puts out a maximum of 10-12 gallons per minute maximum due to

state and federal regulations. There is one pulser for every meter.

Error checking - The dual phase pulsers allow for error checking. One phase is used to check the

other. For example, after pumping 1 gallon of fuel the CPU should see approximately 1024 pulses from

each phase. There is a built in diagnostic where if the CPU sees more than 26 consecutive missing

pulses from one or the other of the phases it will stop the sale and post an error message on the display

of the side of the dispenser with the error. Also, on the blended product, if one or the other product going

into the mix is dispensing too slowly, an error will result. Errors are stored in a diagnostic history file and

any error that occurs can be cleared by removing and replacing the nozzle from the nozzle boot, or lifting and lowering the lever if it is set up in the Lever Option (see page G-8).

Nozzle Boot - Handle switches allow the system to know what product the customer wants to dispense

and signals the CPU to turn on the proper pump motor. The handle switch uses a magnetic proximity

switch to signal when the nozzle has been removed from the boot and the lever lifted. On the nozzle

boot there is a spring loaded lever. Attached to the lever is a magnetic. When the nozzle is removed

from the nozzle boot and the lever rises (auto on) or the lever is lifted (lift to start) it moves the magnet

away from the proximity switch on the handle circuit board. When this happens, the switch is opened

and sends a signal to the CPU. The CPU reads this signal and determines if it is handle A or B and then

turns on the appropriate relay to turn on the remote motor. When the handle is returned to the nozzle

boot this signals that the sale is complete and the CPU sends this information to the Point of Sale device

(if there is one). There is a handle switch for every nozzle boot.

Proportional Valve control - The CPU also controls the valves. The valves are there to control product flowing through a hose. They prevent the unauthorized dispensing from a ho se that isn’t authorized.

They are also used to slow down the flow towards the end of a pre-pay or preset sale. These proportional valve operates off +24 volts dc. The CPU pulses or “modulates” the valve with pulses based on

the rate of what is programmed in for the blend ratio through the dispenser programming. For example,

if the dispenser is set for a 60/40 blend, it will modulate the first product for a 60% mixture and the second product to produce 40%. It checks the output pulses of the respective meters to see if it is blending

Overview of 708 Electronic Components

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-5

properly or if it has to “modulate” one or the other valve more or less. If the mixture does not meet the

blend ratio setting within a programmable tolerance, then an error will result and the sale will stop. The

maximum blend ratio that can be set is 95/5 or 5/95. The error tolerance can be set from 1 % to 99 %.

We recommend setting this for 10%.

Outlet Manifold - The outlet manifold for the right hose contains a check valve for each product being

delivered. The same check valves are used here and in the inlet manifold. The left hose is only used for

the non-blended fuel which does not require a check valve.

System Memory - A +3.3 volt dc on board battery is provided on the CPU board for maintaining system programming in the Random Access Memory (RAM) during a power outage or anytime the system

is turned off. This battery is not replaceable. This battery is designed to outlast the longest of power outages.

System software - The dispenser “operating program” is provided by use of two 32 pin EPROMS.

These EPROMS determine the functions that are available on the dispenser.

Product Select - The product select board is where the customer can either press a “start” button or

select an octane or “grade” at the beginning of the fuel transaction. The product select is similar to a

standard keypad but is not a standard dry contact type keypad. Instead, the keys on this board are activated using the principle of capacitance. The customer removes the nozzle and makes either a grade

selection or presses a “start” key on the product select. The customer should hear a “beep” when pressing any key.

The product select is activated by human touch. There are diagnostics built in to test these keys on the

product select board. The product select is connected to the CPU by means of a wiring harness. This

wiring harness is also used for the CPU to send power and talk to other components such as the display

board and backlight board farther down the line.

The product select board includes the Price Per Volume Displays.

Main Display - The main display is used for the customer to view the currency and volume amount of

the sale. The display gets its information from the CPU through the product select board.

Electromechanical Totalizer Board - The dispenser is equipped with an Electro-mechanical totalizer

for each hose which records the volume dispensed for each sale. The volume recorded is an accumulative total that cannot be reset. The total is cumulative and reads in whole unit (gallon or liter) increments.

Main Display Backlighting Board - The dispenser does not use lights or ballasts. To light the display it

uses a backlight board using a series of 1.5 volt Light Emitting Diodes (LED’s). By using this type of

lighting it eliminates the need to replace burnt out light bulbs and ballasts. These LED’s are powered

from 24 volts it receives from the main display.

Local Preset Option - Another option that is available is the Local Preset. This option is generally for

attended fueling sites where the attendant can select the money or volume of the transaction. The dispenser stops at the preset amount. A receipt printer is available.

The local preset electronics is mounted the same place that the card reader would be mounted in the

dispenser electronics. Therefore, the local preset and the card reader system ca nnot co-exist in the

same dispenser.

The local preset is programmed using a standard PC ASCII keyboard with an OS2 connection. There

are 2 languages to choose from. You can also program receipt header/footer informatio n.

Overview of 708 Electronic Components

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-6

Normal fueling transaction at the dispenser - When a customer wants fuel they lift the nozzl e from

the nozzle boot. That signals the CPU that the customer wants fuel. They are then prompted by the display to select a grade or octane. Once the product is selected, and if the dispenser is in “stand alone”

the dispenser shows all 8888’s in the display (segment check) sends out the appropriate motor control

signal. If the dispenser is in “Console” control, it waits until authorization has been received from the

console. Then, the appropriate valve is opened after the programmed delay time expires for the leak

detectors. Fuel begins to flow.

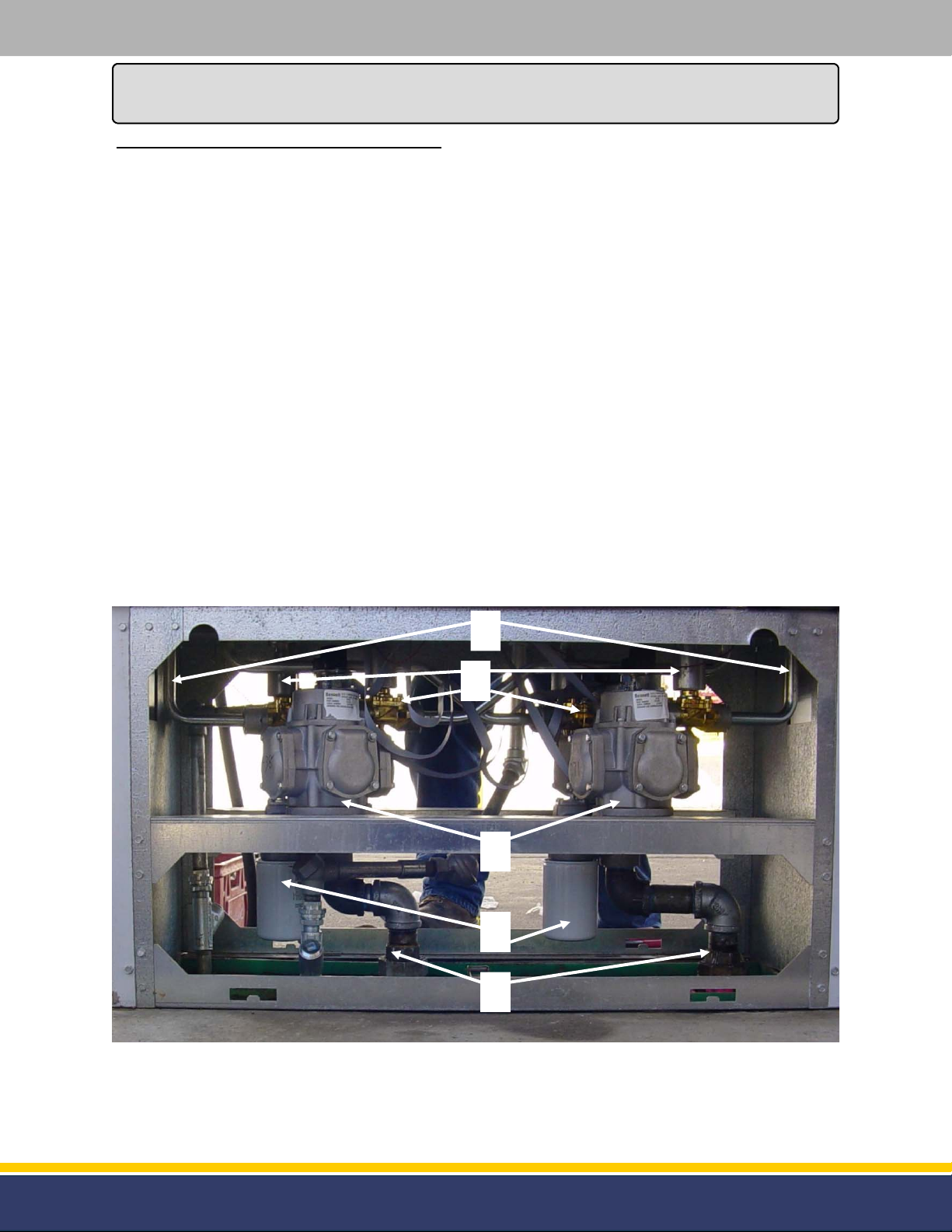

Liquid flow through the dispenser - The dispenser sends a 120vac signal to the relay used to control

the submerged pump. As the signal energizes the coil it closes the contacts sending the proper voltage

to the motor. As the motor turns on it pressurizes the product line to approximately 28 P.S.I.

Once the product begins to flow it goes through the normally opened shear valve and enters the product

inlet of the dispenser (see figure A.1). From here, the product gets purified through the filter (see figure

A.2) and then passes the check valve (not present). The check valve is located in the same manifold as

the filter, on the opposite side.

Once it goes through the check valve it enters the meter (see figure A.3). When the product leaves the

meter the flow is controlled by the proportional valve (see figure A.4). If the blended grade is selected

then the CPU Board will modulate a 24vdc signal to both valves to create the blend ratio programmed in

the dispenser. From this point the product goes through a 3/4” steel tube (see figure A.5). The product

travels through this tube at approximately 10 - 12 G.P.M. up the side of the dispenser into the outlet

manifold. From here the product is dispensed through the hose and nozzle of the dispenser.

Overview of 708 Electronic Components

Figure A

5

4

3

2

1

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-7

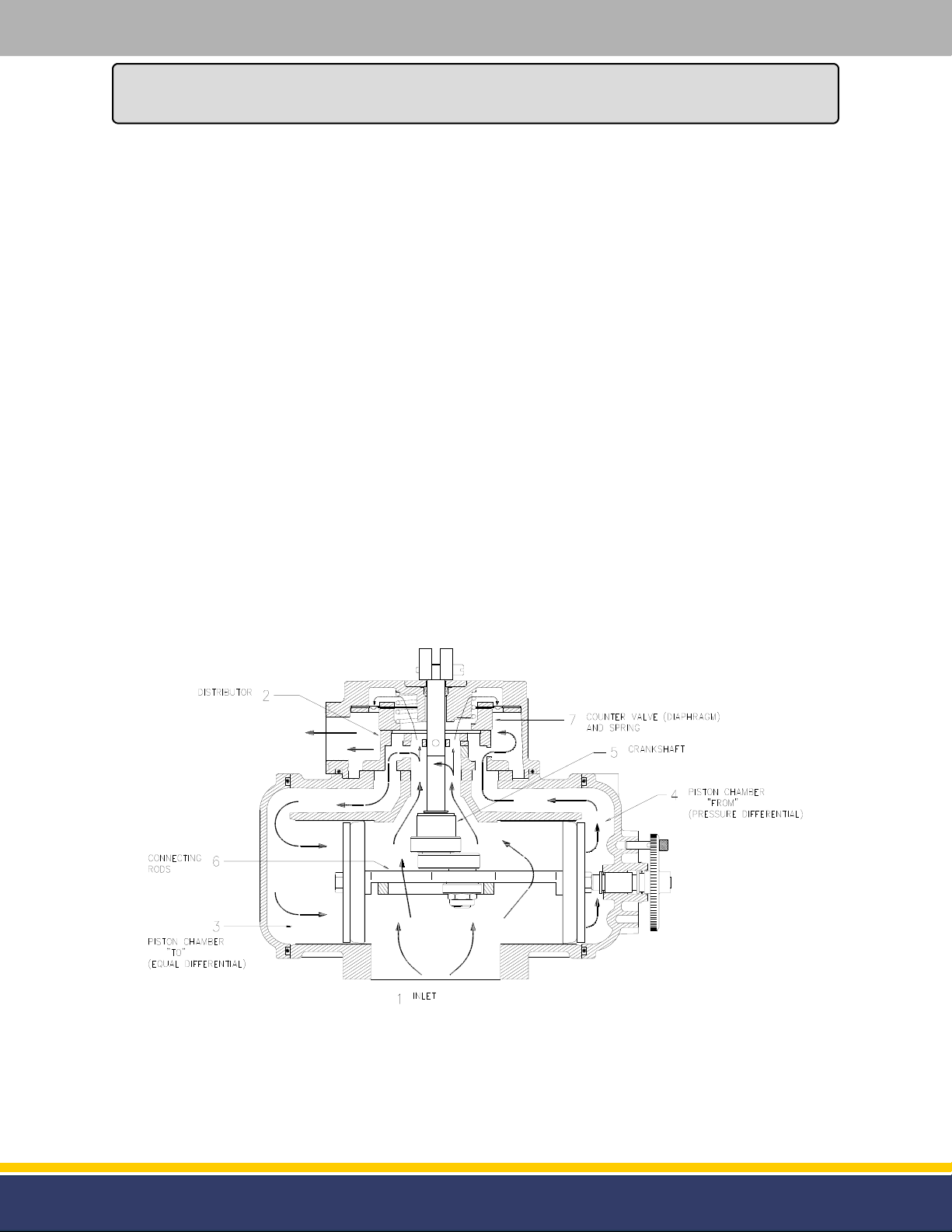

Product enters at the bottom inlet (see figure B.1) and fills the inner cavity of the meter. As the meter

body fills, product passes around the crankshaft and up to the top throat of the meter body. From the

top throat, product flows to the distributor (B.2) which either ports product “to” or “from” each of the four

piston chambers. When the distributor (see figure B.2) is in a position that allows product to be ported

“to” a piston chamber (see figure B.3), equal pressure is applied across both sides of the piston. Equal

pressure applied across a piston offers zero resistance to the crankshaft (see figure B.5) via the piston’s

connecting rod (see figure B.6). When the distributor (see figure B.2) is in a position that allows product

to be ported “from” a piston chamber (see figure B.4), there is greater product pressure applied to the

inside of the piston than to its outer side. The differential of pressure causes the piston to travel in an

outward direction. As the piston travels in an outward direction, product is ported to the meter’s top

collector and to its outlet. As a piston is forced in its outward direction, a rotational force is applied to the

crankshaft via the piston’s connecting rod. This rotational force of the crankshaft is then applied to

adjacent pistons, which offering zero resistance, allows them to be pulled in their inner direction easily.

This allows product from the distributor to fill the piston chamber. The above process is repeated by all

four pistons. A spring and pressurized countervalve (see figure B.7) employing a diaphragm imparts a

downward thrust on the rotating distributor to seal its surfaces and prevent internal leakages which

would result in unmeasured product being delivered.

Overview of 708 Electronic Components

Figure B

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-8

Notes

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

A-9

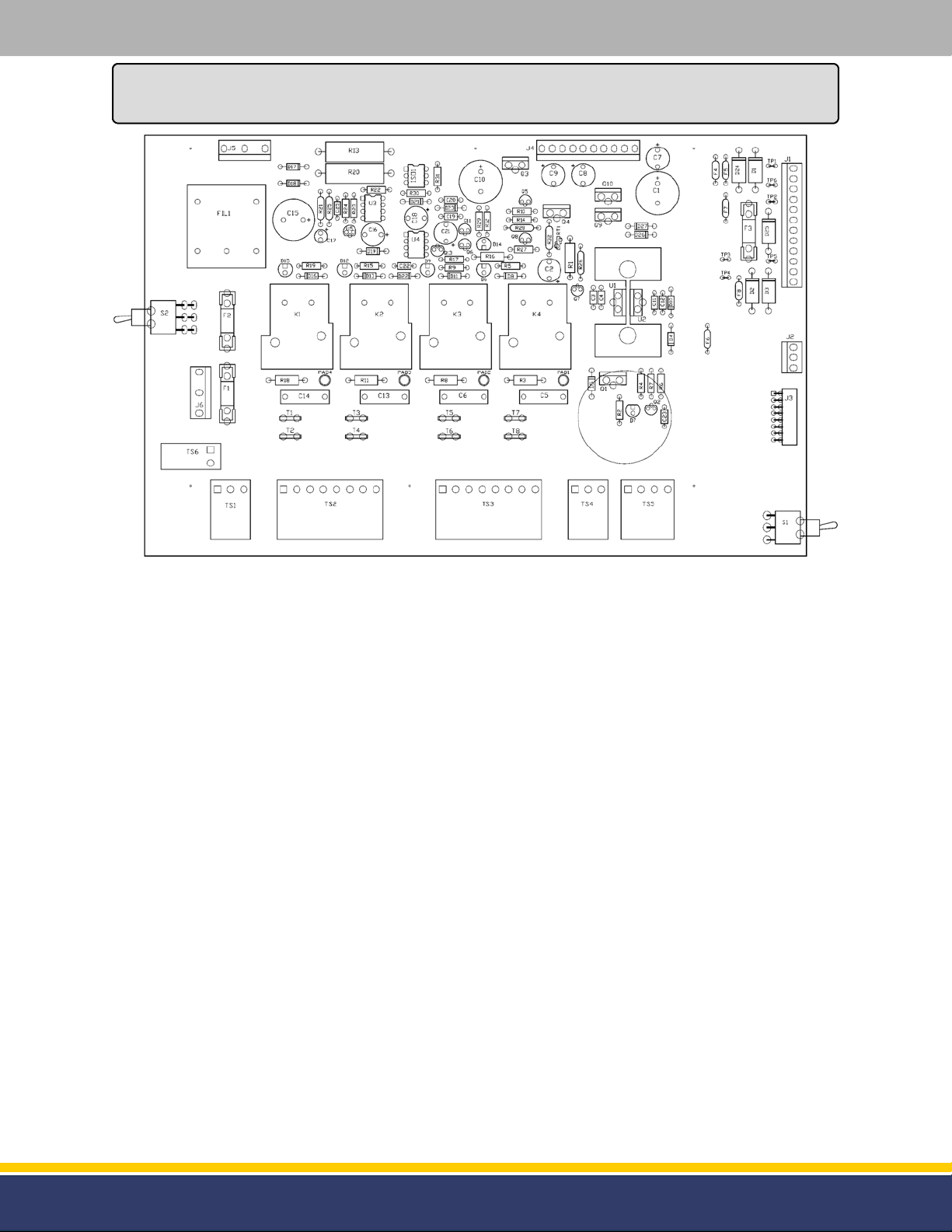

Power Distribution Board

Power Distribution Board Assembly - 110206

Board Functions:

• Incoming A.C. voltage filter (FIL1).

• Solid State Relay control for submerged pumps (K1, K2, K3, K4)

• Fuse protection for the system (F1, F2, F3, F4 -7)

• D.C. voltage distribution (J1)

• Battery charging circuit (J2)

• Connection to field wiring for motor out, card reader communication, and dispenser communi cation.

(TS2,3,4 & 5)

• Provides a switch for the main power (S2)

• Provides a switch for the battery override (S3)

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-1

Power Distribution Board

Power Distribution Board Theory of Operation-

The Power Distribution board is located in the center of the dispenser in the electronics cabinet. This board is covered by a

metal cover to protect anyone working inside the equipment from

receiving an electrical shock. This cover is removed for service. It

must also be replaced when service is complete.

WARNING - Always replace the metal cover when you have completed service. Failure to do so poses a potential for electrical

shock.

110– 230 Volts A.C. 50 or 60 cycle power comes into the dispenser through field wiring to the bottom of the Power Distribution

Board terminal strip (TS1) 1. Power then passes through a 3 amp

fuse and then is filtered for noise. Any electrical noise is dampened out by this filter FIL1. The power is then passed from the

Power Distribution Board to the Power Supply (through connector

J5) for Direct Current (D.C.) conversion.

Incoming A.C. voltage is also routed through fuse F1 (1 amp) for

submerged pump control. If power to the dispensers are “cross

phased” this fuse will blow to protect the dispenser from damage.

If this fuse blows, check for cross phasing. If a cross phasing

condition exists, correct the problem before attempting to replace

the fuse.

Power from the power distribution board comes into the Power

Supply assembly on connector J1. This power supply creates

various D.C. Voltages for use throughout the system. Specifically,

the power supply takes the 110– 230volt A.C. input to create the

following voltages:

1) +24 Volts DC

2) +12 Volts DC

3) +5 Volts DC

These voltages have tolerances of +/- 10%. There are no adjustments for any of these voltages but there are test points.

The DC voltages are fed back to the Power Distribution board

connector J4 through a multi-pin conductor connected to J2 of the

Power Supply.

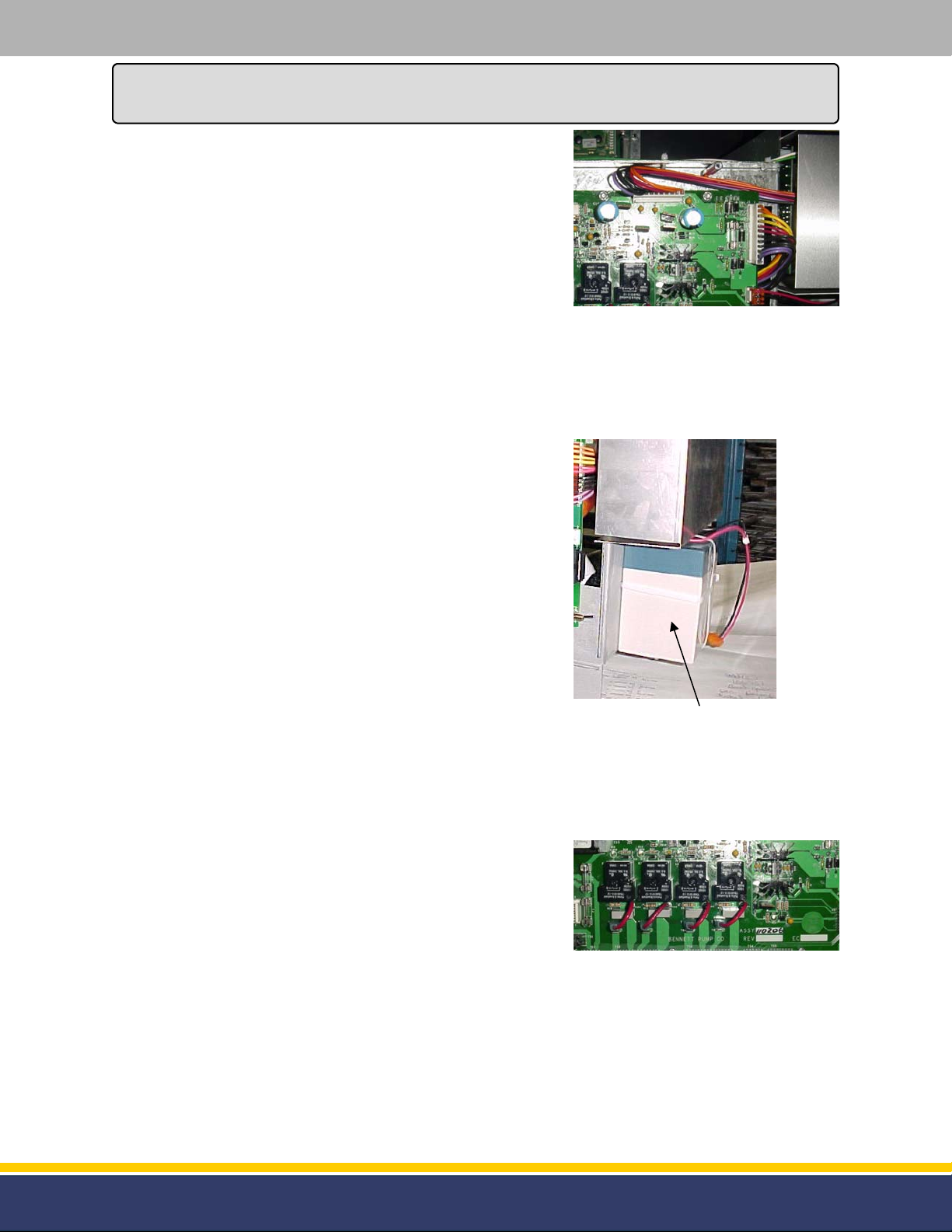

Figure 1 - Power Distribution Board

with the protective cover on.

Figure 2 - Incoming power on terminal TS1 is line voltage. It passes thru

fuse protection and a easy “Off/On”

switch. Then it is filtered and sent

over to the power supply.

Figure 3 - DC voltages returns from

the power supply to the power distribution board on connector J4.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-2

Power Distribution Board

There is fuse protection on the Power Distribution Board for both

power coming into the system and also fuse protection for power

traveling internal to the system. From there the DC voltages are

sent over to the CPU board through another multi-pin conductor

from connector J1 of the Power Distribution Board to connector

J7 on the CPU board. From this point the voltages are distributed

to all other parts of the system.

Battery Backup— A separate rechargeable +12volt battery is

connected to the Power Distribution Board. When the dispenser

is in normal operation the battery is not used and is charged by

the +14 volt D.C. battery charging circuit located on the Power

Distribution Board. When main incoming power is removed from

the system or when the system incoming AC voltage drops below

74 volts AC, the CPU detects this and the dispenser goes into

“Power Fail” condition. At this point the battery supplies +12 volts

DC for 30 seconds to the system or unless the battery override

switch is closed. This battery over-ride switch allows the technician to eliminate the 30 second wait if he has to service the

equipment. The battery itself is connected at the factory but requires several hours to charge. This battery has nothing to do

with maintaining system programming in the event of a power

outage. Make sure the battery is connected because the battery

will eliminate the effect of momentary power sags thus making

the dispenser more reliable.

The Power distribution board has other functions as well. This

board houses four relays that are used to route incoming line voltage as Motor “Out” signals to turn on remote submerged pump

relays. These relays are controlled by +12 volt DC signals from

the CPU board. When the CPU board wants to turn on a submerged pump, it sends a +12 volt dc signal to the proper relay

turning it “On” and routing the line voltage the proper terminal on

the terminal strips located at the bottom of the Power Distribution

Board. This line voltage is connected to the STP relay inside the

building by field wiring. When the CPU wants to turn “Off” a motor, it removes the +12volt dc signal which opens that relay. In the

case of the blended product, more than one relay is activated at

one time.

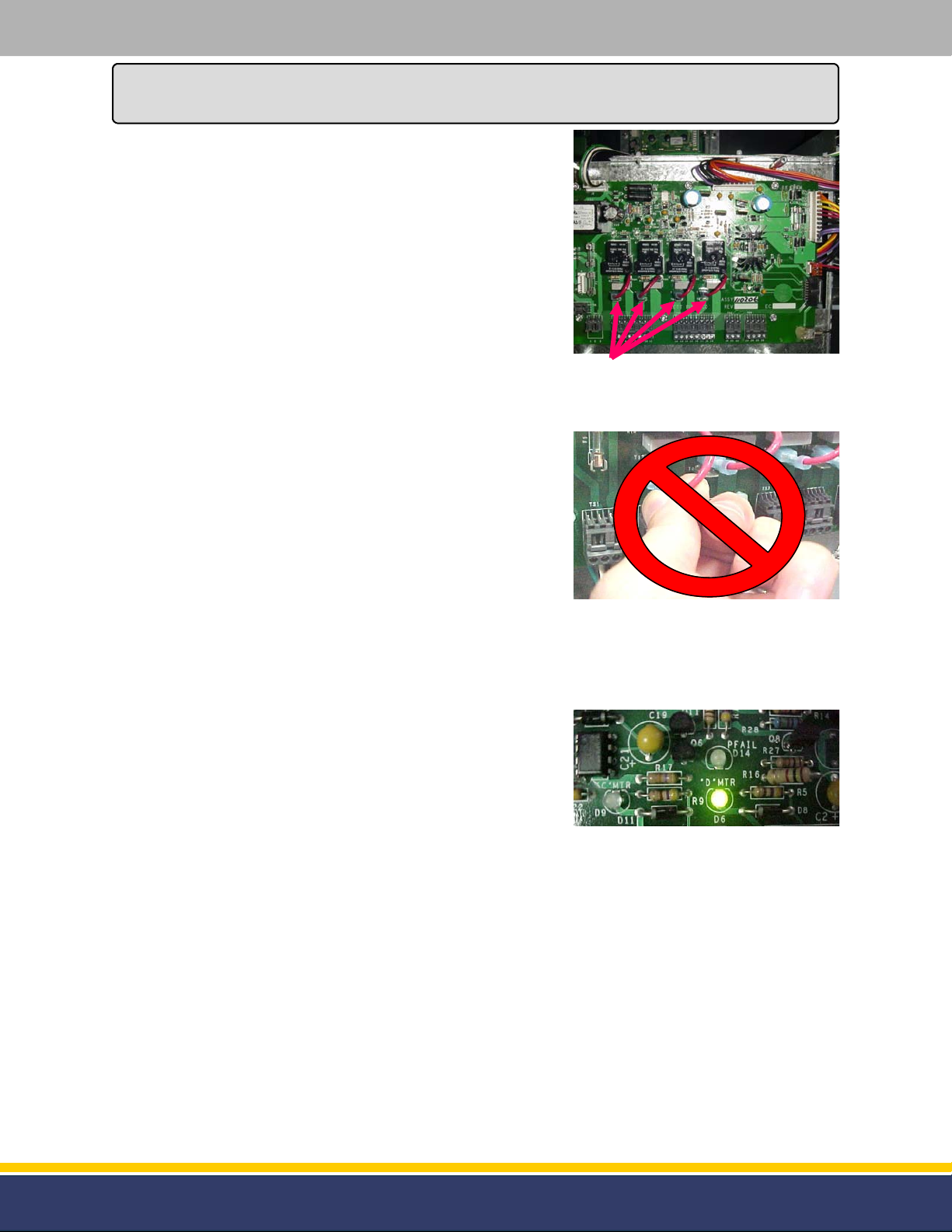

Figure 4 - Pico fuses and standard

replaceable fuses are located in the

upper right of the Power Distribution

Board . Also, connector J1 sends

power over to the CPU.

Figure 5 - External battery for maintaining display after loss of primary

power. This battery is re-chargeable

and takes several hours to charge on

a brand new dispenser.

Figure 6 - Solid state relays provide

motor control for the STP’s or the

Self Contained Motors. +12volts DC

is used to turn them on.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-3

Power Distribution Board

Dispenser communication with a Point of Sale and Card Reader

communication is also routed through the power distribution

board. Dispenser communication comes in from the model 515

box to the power distribution board terminal strip TS5. This is the

current loop communication signal that passes through the Power

Distribution Board on connector J3 through a ribbon cable to the

CPU board connector J8.

Card reader communication also is routed through the power distribution board. Card reader information comes from the IC Box

through twisted pair wiring (3 wires) and connects to terminal strip

TS4. This is RS485 protocol. This information follows the same

path through the power distribution board as the dispenser communication, that is, it exits the power distribution board through

the same ribbon cable over to the CPU on connector J8.

Description of Power Control -

Warning - The only option that you have for removing power

from the dispenser is by turning off the S2 switch from the Power

Distribution Board.

• Switch 3 (S3)- Located on the bottom right hand side of the

board is the Battery Over-ride Switch. This switch can be

used to override the 30 second battery if primary power is lost

at the dispenser or if incoming power drops below 74 volts

A.C. This switch Stays in the up position by a spring. To

“kill” the power you must press down momentarily and then

release. Once the switch is closed and the display goes

blank remove your finger from the switch. See figure 8.

Figure 7 - TS4 is the Dispenser Card

Terminal Connection to the IC Box in

the building and TS5 is the Fuel

Communication to the 515 box.

Figure 8 - S3 is a switch which is

normally opened. Always turn off the

battery when attempting to service

the Pacific dispenser.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-4

Power Distribution Board

PAD Jumpers - There are a series of PAD jumpers located be-

low the solid state relays. These PAD jumpers should not change

in the Pacific dispenser. If these PAD jumpers are not set correctly improper system operation will result and you may possibly

blow fuse F1. For proper operation connect the PAD jumpers as

follows:

For submerged pumps:

Product A - PAD 4 connected to T1

Product B - PAD 3 connected to T3

Product C - PAD 2 connected to T5

Product D - PAD 1 connected to T7

Relays - Relays are controlled with +12 volt D.C. control signals

from the CPU:

Relay K1 - Product A - LED D15

Relay K2 - Product B - LED D16

Relay K3 - Product C - LED D9

Relay K4 - Product D - LED D6

Note: Anytime you see a relay LED “lit” you can assume the relay

is “turned on”.

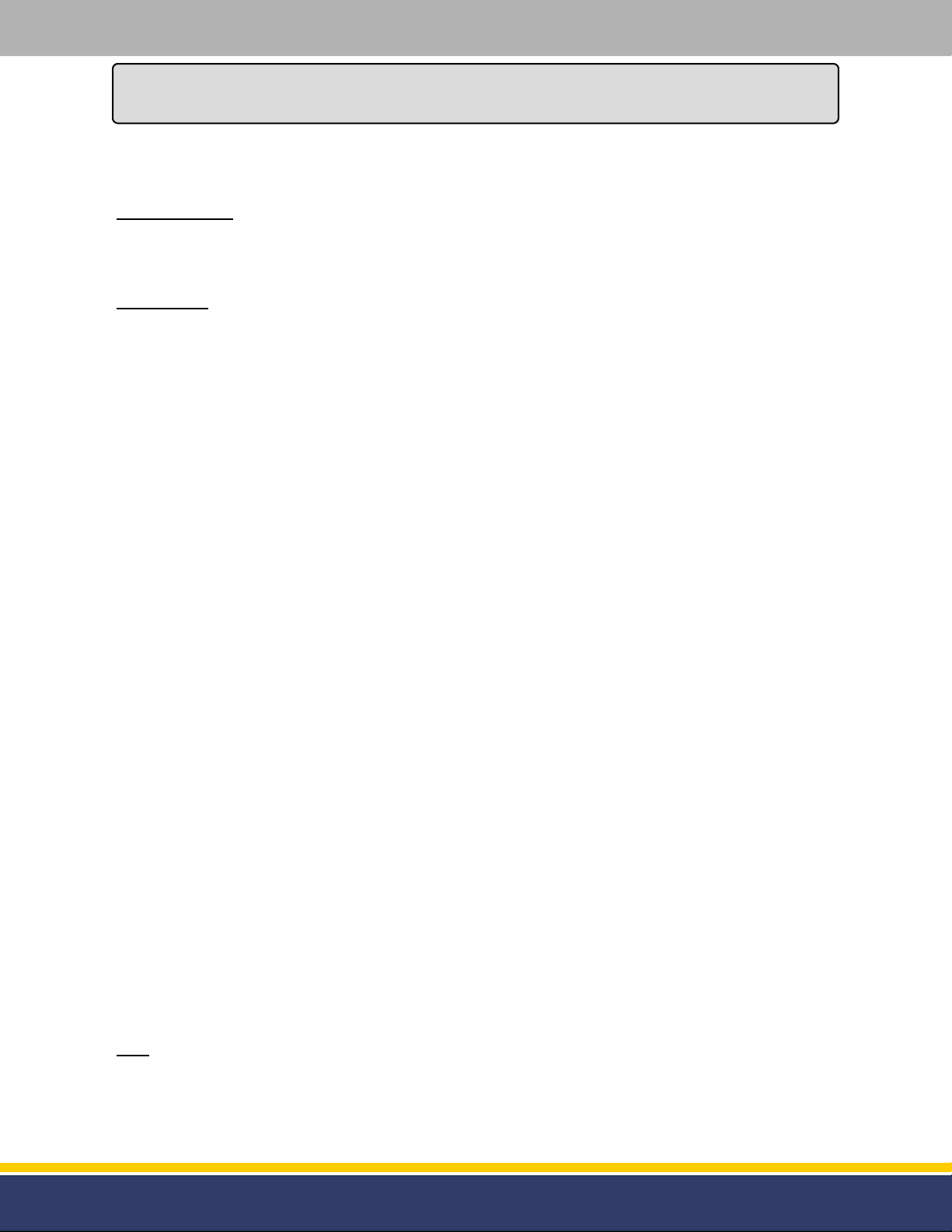

Figure 9 - PAD jumpers are set for

remote submerged pumps. They are

connected to the top row of pads.

Figure 10 - Do Not Change the PAD

jumper. This is for Self Contained

pumps, which is Not an option with

the Pacific dispenser.

Figure 11 - LED “Lit” means the CPU

is telling the relay to turn on.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-5

Power Distribution Board

Fuses - A series of fuses are located on the Power Distribution Board. There are two types, standard

and Pico. The standard fuses are located in standard fuse mounts whereas the Pico fuses are soldered

onto the board. The fuses are used as follows:

Standard Fuses

F1 - 3 amp standard blow for system power

F2 - 1 amp standard blow for submerged pump control

F3 - 1 amp for battery charging circuit.

Pico Fuses -

F4 - F5 - (3.25 amp) +24 volt D.C. circuit side 1 and side 2

F6 - (3.25 amp) +14 volt D.C. battery charging circuit

F7 - (3.25 amp) +12 volt D.C. circuit side 1 and side 2

F8 - (3.25 amp) +5 volt D.C. logic power

Note - Contact Technical Support before replacing a Pico fuse.

Light Emitting Diodes - There are several LED’s located on this board. They are described as follows:

LED D15 - Motor “A” power. If illuminated means the solid state relay for the “A” submerged

pump motor is energized.

LED D12 - Motor “B” power. If illuminated means the solid state relay for the “B” submerged

pump motor is energized.

LED D 9 - Motor “C” power. If illuminated means the solid state relay for the “C” submerged

pump motor is energized.

LED D 6 - Motor “D” power. If illuminated means the solid state relay for the “D” submerged

pump motor is energized.

LED D 7 - Recall. If illuminated means that the Recall button has been activated.

LED D14 - Power Fail. If illuminated means that the system has lost primary power or that in-

coming power has dropped below 75 volts A.C.

System Battery (P/N 105908)- A +12 volt rechargeable battery is supplied with the dispenser. The bat-

tery has a charging circuit and must be charged for several hours before it has a full charge. The battery

is used to supply DC voltage (+12volt D.C.) to the dispenser if the dispenser looses primary power or if

primary power drops below 75 volts D.C. The battery, when in use, provides power for 30 seconds and

then times out. The battery override switch is located on the right hand side of the Power Distribution

board. It is used to bypass the 30 second battery “On” time. If the system is on battery and you want to

override it, push down on switch F1. It will disconnect the battery circuit. Note - Always make sure the

battery has been bypassed when servicing the equipment.

Powering down the dispenser for Service - To remove power from the dispenser for service follow

this procedure - Power down the dispenser by turning off S2 from the Power Distribution board. The

display lights should go off and a message on the display should read “PFAIL”. This message will blink

for 30 seconds OR until the battery override switch is closed (S3 on the Power Distribution Board).

Turning the dispenser back on - Turn on S2 from the Power Distribution Board.

Note

: Always replace the metal cover for the Power Distribution Board after finishing your service work.

This will help protect any un-trained store personnel from voltages if they open the electronic head of the

dispenser.

111661 Rev B 02/09

B-6

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

Power Distribution Board

Taking Voltage Readings -

When taking voltage readings it is important to have a good voltage “reference”. Without a good reference, the voltage reading

that you measure may be wrong. There is a difference between

an AC voltage reference and a DC voltage reference.

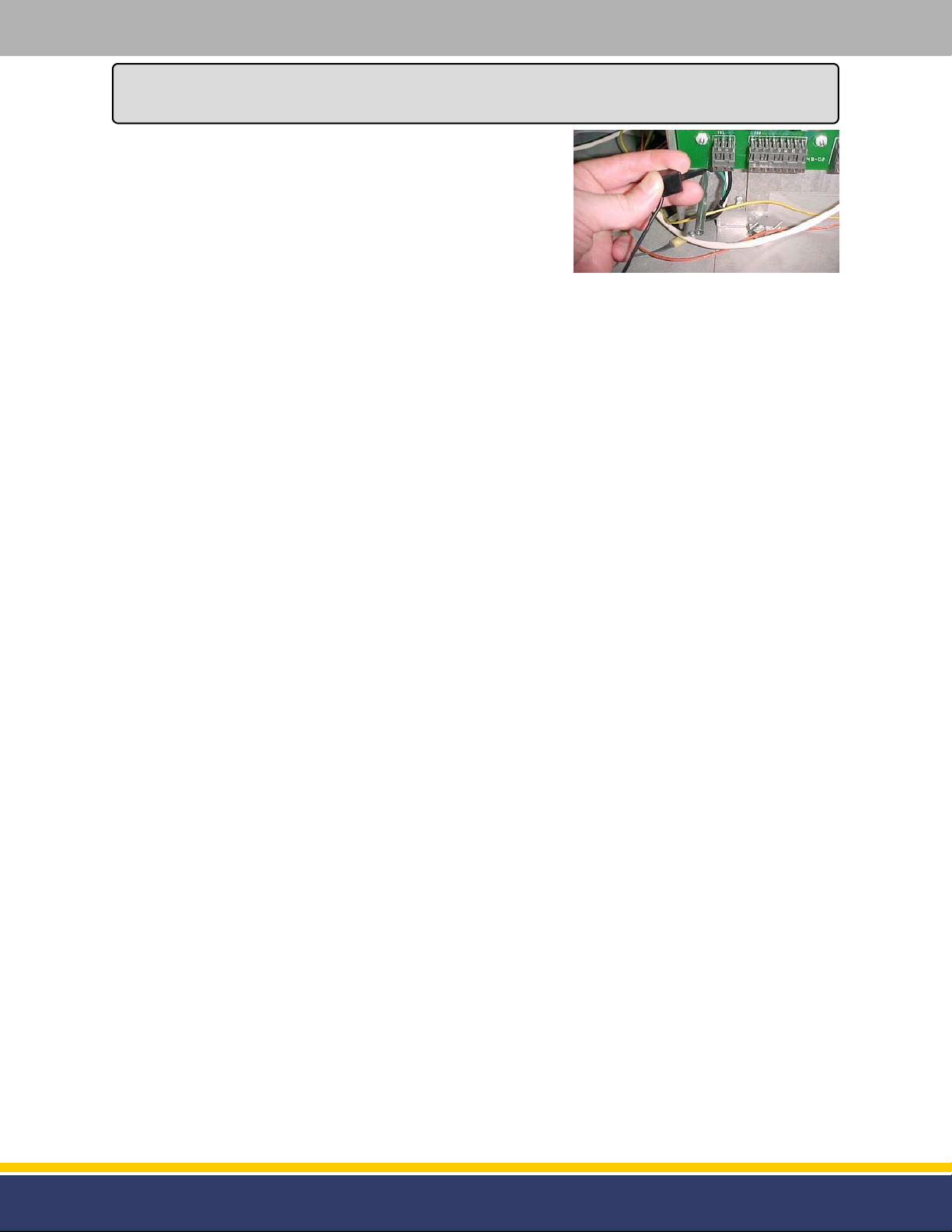

AC Voltage reference - When measuring an A.C. voltage the

best voltage reference that you can use is the incoming ground

wire connected to terminal one on TS1 on the lower left edge of

the Power Distribution Board on side 1 of the dispenser (see figure 12).

DC Voltage reference - When measuring D.C. Voltages rather

than looking to hook your test lead up to a board component, a

good place to put your black lead on any black wire connection

on the multi-pin, multi-colored connector J3 on the upper right

side of the Power Distribution Board.

Voltage Tolerances - When taking voltage readings the (+/-) tolerance of any reading is (+/-) 5%. There are no adjustments that

can be made on any voltages from the Power Supply. If the voltage is out of range, replace the power supply.

Measuring fuses - There are two ways to see if a fuse is good.

Either visually or by measuring it using a multi meter. To measure

the fuse put your meter on the “ohms” scale or “continuity”. If the

fuse is good you should hear a “beep” when you put your leads

across the fuse. This means the fuse is good. If it reads anything

other than 0 ohms or “continuity” the fuse is probably bad and

needs to be replaced. This test works for replaceable fuses and

Pico fuses as well.

Note: Always measure fuses with the dispenser power off.

Note: When replacing a fuse always replace with the same type

and size. The rating of the fuse is written on the fuse. If in doubt

about the rating of any fuse in the system call Bennett Technical

Support.

Figure 12 – Using incoming ground

for measuring AC voltages.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-7

Power Distribution Board

Important voltage tests - A couple of important voltage tests

that our Technical Support Department may want to have you

check are as follows:

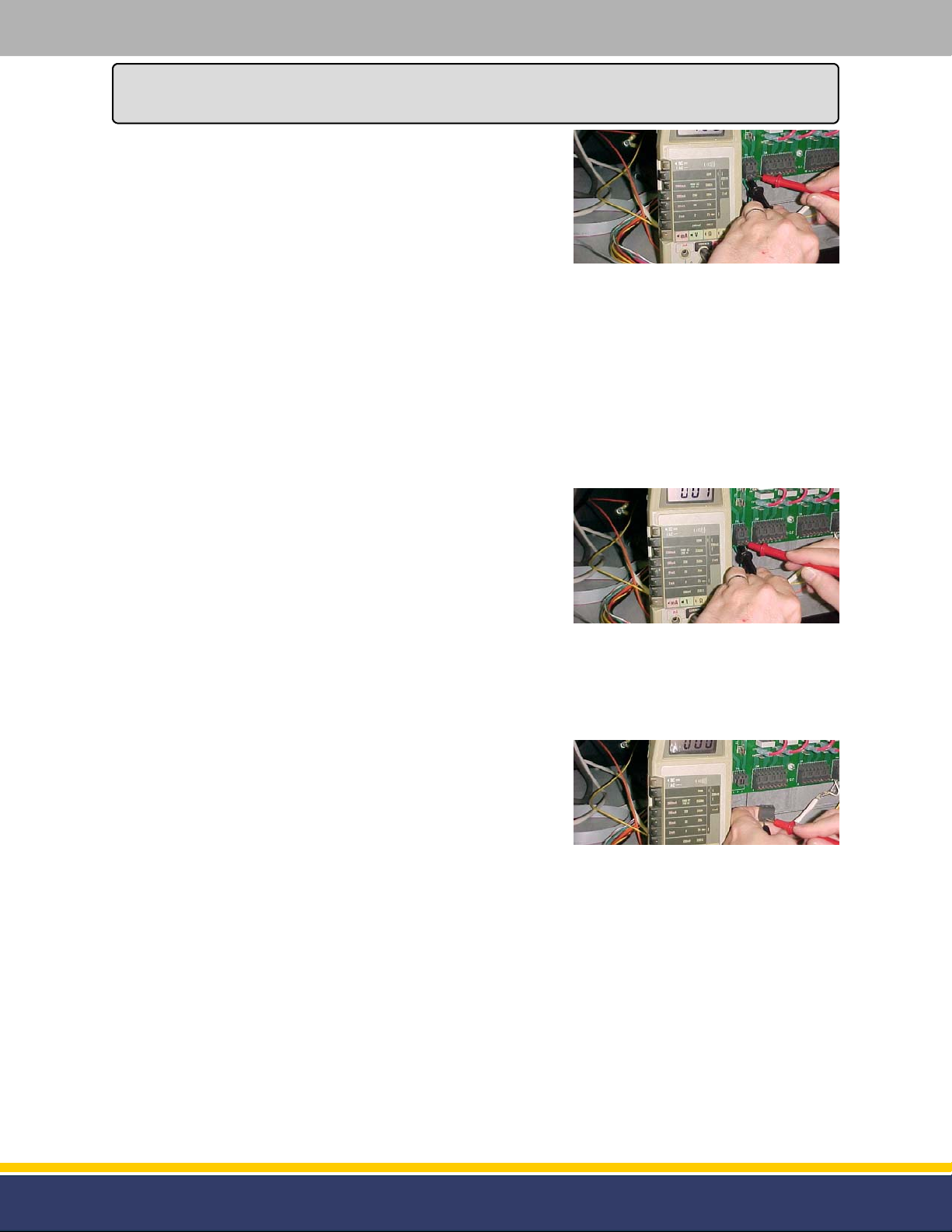

Incoming power - Measure for A.C. Voltage between terminal 3

and terminal 2 (Hot to Neutral). The measurement should be recorded before calling Technical Support (see figure 13).

Also measure between the ground and the neutral with your meter on the A.C. scale. You should see approximately zero volts

(see figure 14).

Neutral to Ground - Also, an important reading is to make sure

that the resistance from the neutral to the ground is less than 1

ohm. Take this measurement with the multi-meter on the ohms

scale and with the field wires disconnected from the board. Notice that the field wires connect to quick “disconnect” type terminals (see figure 15).

Note: Make sure the dispenser power circuit (Breaker Panel) has

been turned “off” before taking this measurement.

It is important to mark this measurement down on your Audit Report for each installation.

Figure 13 - This example shows

measuring incoming power of 120

volts A.C. to the dispenser.

Figure 14 - Measuring for “stray”

voltage between Neutral and

Ground. Should be zero volts.

Figure 15 - With the field wires disconnected from the board measure

the resistance between neutral and

ground. It should be 1 ohm or less.

This means that the neutral and the

ground are at the same potential.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-8

Power Distribution Board

Terminal Strips, Connectors and Pinouts - The following is a description of the connections to the

terminal strips, and pinouts of all the connections on the Power Distribution Board.

Note: Voltage readings can be taken right on the terminal strip connector pins.

Terminal Strip 1 (TS1) - Dispenser Input Power

• Pin 1 - Earth Ground

• Pin 2 - Neutral

• Pin 3 - Incoming Line Voltage (110v - 230 v AC @ 50 or 60 Hz)

Terminal Strip 2 (TS2) - Motor Power Products “A” and “B”-

• Pin 4 - Not used

• Pin 5 - Not used

• Pin 6 - Not used

• Pin 7 - Submerged pump relay control product “A”

• Pin 8 - Not used

• Pin 9 - Not used

• Pin 10 - Not used

• Pin 11 - Submerged pump relay control product “B”

Terminal Strip 3 (TS3) - Motor Power Products “C” -

• Pin 12 - Not used

• Pin 13 - Not used

• Pin 14 - Not used

• Pin 15 - Submerged pump relay control product “C”

• Pin 16 - Not used

• Pin 17 - Not used

• Pin 18 - Not used

• Pin 19 - Not used

Terminal Strip 4 (TS4) - Dispenser Card Reader Terminal (DCT)- RS 485 Communication

• Pin 20 - (+)Data (RS485) for card reader terminal from dispenser to IC Box (+) terminal

• Pin 21 - Data Common from dispenser to IC Box Common terminal

• Pin 22 - (-) Data (RS485) for card reader terminal from dispenser to IC Box (-) terminal

Terminal Strip 5 (TS5) - Dispenser Communication Current Loop Signals - There are 2 Current

Loop wires per SIDE of a dispenser. On a two sided dispenser side 1 communication is on terminals 23

and 24 and side 2 communication is on terminals 25 and 26. These wires are pulled from the model 515

box inside the building and are connected to the dispenser here. Pay attention to polarity. Make sure to

connect the (+) in the dispenser to the (+) in the 515 etc. Notice that the first terminal in the dispenser is

data (-) for side 1.

• Pin 23 - (-)Data side 1 out to model 515 box (-) for the first Fueling Point

• Pin 24 - (+)Data side 1 out to model 515 box (+) for the first Fueling Point

• Pin 25 - (-)Data side 2 out to model 515 box (-) for the second Fueling Point

• Pin 26 - (+)Data side 2 out to model 515 box (+) for the Second Fueling Point

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-9

Power Distribution Board

Terminal Strip 6 (TS6) - Constant 120 AC Connection—Note that this is a constant 120vac.

• Pin 1 — Neutral (top)

• Pin 2 — Incoming Line Voltage (110v - 230 v AC @ 50 or 60 Hz)

J1 - DC voltages from the Power Distribution Board to the CPU board - Multi colored cable

• Pin 1 - 24 Volts d.c.. Used for Backlights, Printer and Valve Control side 1. Orange wire.

• Pin 2 - 24 Volts d.c.. Used for Baclkights, Printer and Valve Control side 2. Orange wire.

• Pin 3 - Standby. (14.5 volts d.c. battery backup) side 1. Yellow wire.

• Pin 4 - Standby. (14.5 volts d.c. battery backup) side 2. Yellow wire.

• Pin 5 - 12 Volts d.c. Used for display board, operator interface board, local preset side 1. Red wire.

• Pin 6 - 12 Volts d.c. Used for display board, operator interface board, local preset side 2. Red wire.

• Pin 7 - DCC - Direct Current Common or Ground Reference. Black wire.

• Pin 8 - DCC - Direct Current Common or Ground Reference. Black wire.

• Pin 9 - DCC - Direct Current Common or Ground Reference. Black wire

• Pin 11 - +5 Volts d.c. CPU logic power - Violet wire side 1.

• Pin 12 - +5 Volts d.c. CPU logic power - Violet wire side 2.

J2 - Battery Charging Circuit - When main powe r is on the battery charging circuit provides +14.1

Volts d.c. to charge the battery. When the battery is “On” the battery supplies +12.6 volts d.c. for the system.

• Pin 1 - +14.1 volts battery charging. +12.6 volts battery on.

• Pin 2 - Direct Current Common (DCC)or ground reference

J3 - Grey ribbon cable that connects the CPU to the Power Distribution Board. This cable mainly handles the card reader communication and dispenser communication from the CPU to the Power Distribution Board.

• Pin 1 - (identified by the red tracer) Suicide signal. The CPU uses this signal to turn off the battery

after 30 seconds in case of power failure. Normal reading is +5 volts d.c.

• Pin 2 - RS 485 (-) - Card Reader communication with console (-)

• Pin 3 - Recall - Used by the CPU / Product Select Keypad to turn on dispenser buttons to read to-

tals. Normal reading is +5volts d.c.

• Pin 4 - RS485 Common - Card Reader communication with consol e common

• Pin 5 - Power Fail - Signal from power distribution board indicating loss of power or less than 75

volts A.C. Normal reading is +5 volts d.c.

• Pin 6 - RS485 (+) - Card Reader communication with console (+)

• Pin 7 - Ground

• Pin 8 - Ground

• Pin 9 - Motor “A” - Motor relay control signal. +12vdc represents “motor on”. Ovdc represents “motor off”.

• Pin 10 - Current Loop (+) side 2. Fuel channel communication with the 515 interface box.

• Pin 11 - Motor “B” - Motor relay control signal. +12vdc represents “motor on”. Ovdc represents “motor off”.

• Pin 12 - Current Loop (-) side 2. Fuel channel communication with the 515 interface box.

• Pin 13 - Motor “C” - Motor relay control signal. +12vdc represents “motor on”. Ovdc represents “motor off”.

• Pin 14 - Current Loop (+) side 1. Fuel channel communication with the 515 interface box.

• Pin 15 - Motor “C” - Motor relay control signal. +12vdc represents “motor on”. Ovdc represents “motor off”.

• Pin 16 - Current Loop (-) side 1. Fuel channel communication with the 515 interface box.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-10

Power Distribution Board

J4 - D.C. Voltages created by the Power Supply and sent to the Power Distribution Board

• Pin 1 - 5 volts d.c. Logic Power for the CPU. Violet wire.

• Pin 2 - 5 volts d.c. Logic Power for the CPU. Violet wire.

• Pins 3-6 - Direct Current Common (DCC) Ground Reference. Black wires.

• Pin 7 - +12 volts d.c. Power for display board, operator interface board, local preset side 1. Red wire.

• Pin 8 - +12 volts d.c. Power for display board, operator interface board, local preset side 2. Red wire.

• Pin 9 - +24 Volts d.c.. Used for Backlights, Printer and Valve Control side 1. Orange wire.

• Pin 10 - +24 Volts d.c.. Used for Backlights, Printer and Valve Control side 2. Orange wire.

J5 - Filtered A.C. 110 - 230 volts A.C. 50/60 cycle from power distribution board from Power distribution to the Power Supply

• Pin 1 - Earth Ground. Green wire.

• Pin 3 - Neutral. White wire

• Pin 5 - 110 - 230 volts A.C. 50/60 cycle. Black wire.

J6—Non-filtered A.C. 110-230 volts A.C. 50/60 cycle. Note that this is switched.

• Pin 1 - Earth Ground.

• Pin 2 - Neutral.

• Pin 3 - Hot (top).

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-11

Power Supply

Power Supply Assembly

Power Supply Assembly Part Number—105512

Board Functions -

• Creates Direct Current (DC) voltages from Alternating Current (AC) voltages

Power Supply Assembly Theory of Operation -

AC power 110– 230 volts AC 50/60 cycle comes from the Power Distribution board on Power Supply

Assembly connector J1.

The purpose of the power supply is to take incoming AC and convert it to various DC voltages for use

throughout the system. After creating these voltages it sends them to the Power Distribution Board for

distribution throughout the system. The DC voltages created are:

• +24 volts DC for use with the valves, the receipt printer power, the display and the backlighting

• +12 volts DC for use with the Product select board, Card Reader power, Pulser and Handle circuitry

and the solid state relays.

• +5 volts DC for the CPU logic voltage.

Description of Controls - There are no controls on the Power Supply Assembly

LED’s - There are no LED’s on this assembly

Fuses - There are no fuses on this assembly

Voltage Adjustments - There are no voltage adjustments on this assembly. If the output voltages are

not within (+/-) 10% of the rated voltage, replace the power supply.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-12

Power Supply

Taking voltage readings (Continued)— Next, you can measure power from the Power Distribution

Board to the CPU board. You can measure using the same technique.

Note - Color Coding - In the 708 electronics, most of the voltages and wires are color coded, but not

always. In most cases the colors are as follows Orange- +24 Volts DC

Red - 12 Volts DC

Violet - +5 Volts DC

Black - DC Common

With the dispenser power on locate connector J1 on the top right (vertical) of the Power Distribution

Board.

+24 volts - Putting your black (negative) lead on any of the black wires and your red (positive) lead on

either of the orange wires, measure for +24 volts dc. There are 2 orange wires, one for side 1 and one

for side 2. Both should have +24 volts (+/- 5%).

+14 volts - Putting your black (negative) lead on any of the black wires and your red (positive) lead on

either of the yellow wires, measure for +14 volts dc. There are 2 yellow wires, one for side 1 and one for

side 2. Both should have +14 volts (+/- 5%).

+12 volts - Putting your black (negative) lead on any of the black wires and your red (positive) lead on

either of the red wires, measure for +12 volts dc. There are 2 red wires, one for side 1 and one for side

2. Both should have +12 volts (+/- 5%).

+5 volts - Putting your black (negative) lead on any of the black wires and your red (positive) lead on the

violet wire, measure for +5 volts dc. There is 1 violet wire. It should read +5 volts (+/- 5%).

If any of these voltages are out of range, you may experience erratic performance and it may be necessary to replace the Power Supply. Call Technical Support for assistance 1-800-423-6638.

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-13

Notes

111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

B-14

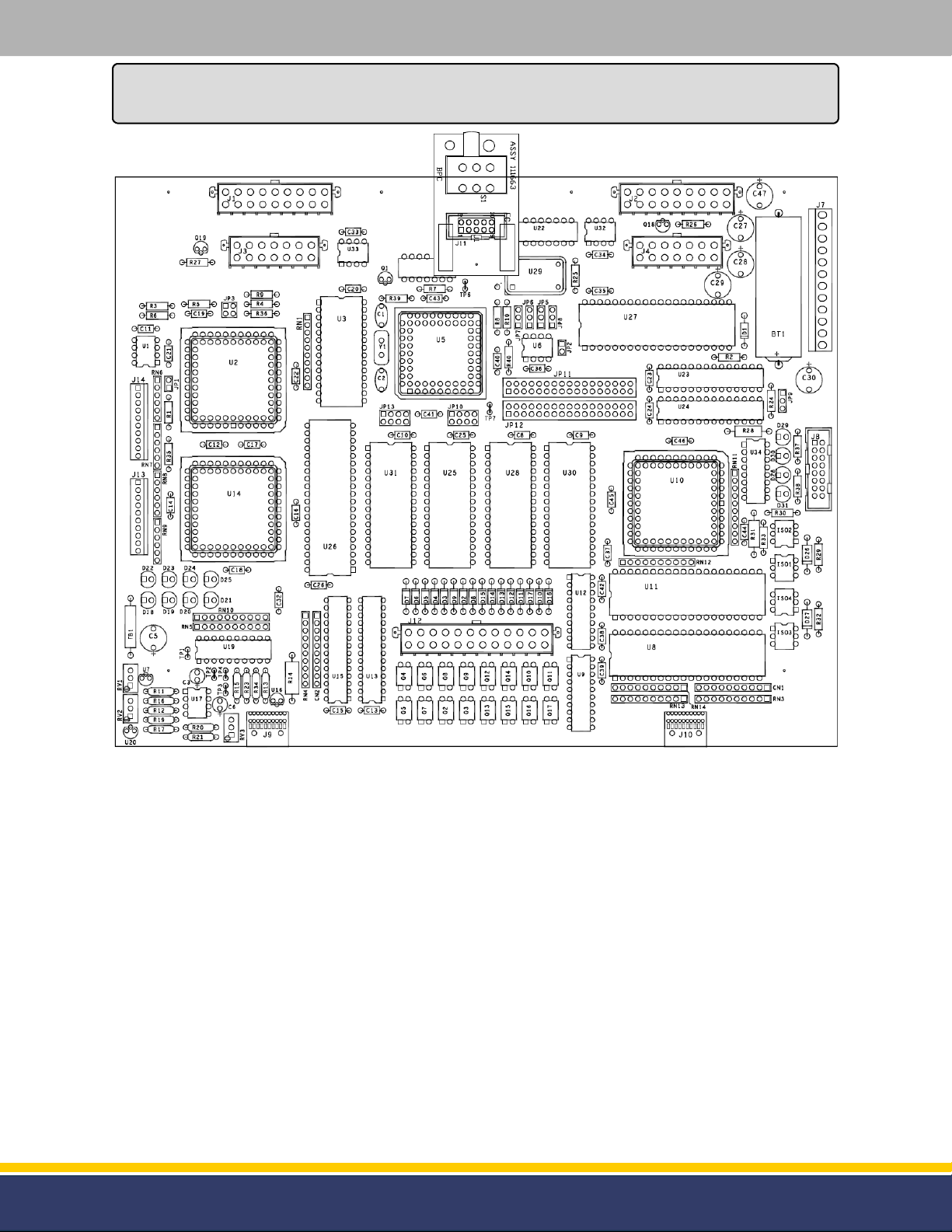

CPU Board

CPU Board Assembly Part Number - 110185

Board Functions:

• Runs Software

• Contains Memory (RAM)

• Communicates with the Point of Sale

• Controls the Solid State Relays

• Sends display signals to the Display Board

• Interfaces with the Handles and Pulsers

• Controls all the Blending Functions

• Valve Control

• Stores historical data for sales and diagnostics

• Contains back up battery for programming information

C-1 111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

CPU Board

Theory of Operation— The CPU board is the heart of the sys-

tem. It runs the software, has the memory, communicates with

Point of Sale, sends control signals to the solid state relays,

sends display signals to the display boards, communicates with

the touch pad, interfaces with the handles and pulsers through

the Intrinsically Safe Barrier Boards, controls the blend valves

through a wiring harness. It performs the blending functions, and

stores historical data for sales and diagnostics. It receives power

from the Power Distribution Board and also routes power to the

card reader system. It also communicates with and sends and

receives signals from the Vapor Recovery system. It also contains backup battery for maintaining programming in the RAM

during power outages.

There is one CPU board per dispenser. The CPU board is

mounted vertically and has various cables and harnesses connected to it.

The CPU board receives dc voltages from the power distribution

board on connector J7. The wiring harness is color coded and

uses the following color scheme:

1) Orange - +24vdc - Valve, printer, display and backlighting

2) Yellow- +14vdc - Battery charging circuit

3) Red - +12 - Product select, Card reader, Pulsers, Handles

and Solid State Relays

4) Black - dcc - Reference for all DC voltages

5) Violet - +5vdc - System logic voltage used by the CPU

The CPU board is physically mounted to the Intrinsically safe barrier modules. The CPU must be removed to remove either of the

Intrinsically Safe Barriers.

Figure 2– CPU Board plugged in.

Figure 3 - The DC power comes from

the Power Distribution board to connector J7 of the CPU.

Figure 1 - CPU Board

C-2 111661 Rev B 02/09

© 2002 BENNETT PRINTED IN U.S.A. 105894 Rev. D, 04/06

Loading...

Loading...