Page 1

®

Bendix® ADB22X™, ADB22X-V™ Air Disc Brakes

SD-23-7541

SECTION ONE: AIR DISC BRAKE OVERVIEW

1.1 DESCRIPTION

Bendix® ADB22X™ and ADB22X-V™ Air Disc Brakes

(ADB) use a fl oating caliper design to provide foundation

braking on all axles of heavy commercial vehicles, buses

and trailers. Bendix Air Disc Brakes provide safety and

performance as well as ease of service.

The ADB22X disc brakes mount to the axle's anchor plate

(torque plate) using fasteners that are installed parallel

to the axle, while the anchor-plate fasteners used for the

Bendix

to the axle.

Available with or without a combination spring brake unit,

these brakes may also include optional wear sensors and

wear diagnostic equipment.

®

ADB22X-V™ air disc brakes install at right angles

Sections in this Document

Section Page

1 Overview . . . . . . . . . . 1-5

2 Preventive Maintenance and

Wheel-on Inspections . . . . . . 6-8

3 Troubleshooting Flowchart . . . . . 9

4 Wheel-off Maintenance Inspections . 10-15

5 Maintenance Kits and Procedures. . 16-37

Full Index - see Page 38

1.2 Air Disc Brake Identifi cation

Locate the identifi cation label near the guide pin housing.

See below for information about the label fi elds used.

FIGURE 1 - BENDIX® ADB22X™ AIR DISC BRAKES

FIGURE 2 - TYPICAL PART NUMBER LABEL LOCATION

Bendix Part Number

Serial No.

Customer Part Number

FIGURE 3 - PART NUMBER LABEL INFORMATION

Section One

Section Page

1.1 Description . . . . . . . . . . 1

1.2 Air Disc Brake Identifi cation. . . . . 1

1.3 Rotor Identifi cation . . . . . . . 3

1.4 Wear Sensor Identifi cation . . . . . 3

1.5 Operation . . . . . . . . . . 3

1.5.1 Brake Release and Adjustment . . . 3

1

Page 2

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND

FOLLOW THESE INSTRUCTIONS

TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

guidelines should be observed AT ALL TIMES:

▲ Park the vehicle on a level surface, apply the parking

brakes and always block the wheels. Always wear

personal protection equipment.

▲ Stop the engine and remove the ignition key when

working under or around the vehicle. When working

in the engine compartment, the engine should be shut

off and the ignition key should be removed. Where

circumstances require that the engine be in operation,

EXTREME CAUTION should be used to prevent personal

injury resulting from contact with moving, rotating,

leaking, heated or electrically-charged components.

▲ Do not attempt to install, remove, disassemble or

assemble a component until you have read, and

thoroughly understand, the recommended procedures.

Use only the proper tools and observe all precautions

pertaining to use of those tools.

▲ If the work is being performed on the vehicle’s air brake

system, or any auxiliary pressurized air systems, make

certain to drain the air pressure from all reservoirs

before beginning AN Y wo rk on the vehicle. If the vehicle

is equipped with a Bendix

Bendix

AD-9si™ air dryer, be sure to drain the purge reser voir.

▲

Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a manner

that safely removes all electrical power from the vehicle

▲ Never exceed manufacturer’s recommended pressures.

▲ Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has

been depleted.

▲ Use only genuine Bendix

components and kits. Replacement hardware, tubing,

hose, fi ttings, etc. must be of equivalent size, type

and strength as original equipment and be designed

specifi cally for such applications and systems.

▲ Components with stripped threads or damaged parts

should be replaced rather than repaired. Do not

attempt repairs requiring machining or welding unless

specifi cally stated and approved by the vehicle and

component manufacturer.

▲ Prior to returning the vehicle to ser vice, make certain all

components and systems are restored to their proper

operating condition.

▲ For vehicles with Automatic Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive axle

are lifted off the ground and moving.

▲ The power MUST be temporarily disconnected

from the radar sensor whenever any tests USING A

DYNAMOMETER are conducted on a Bendix

Advanced

▲ You should consult the vehicle manufacturer's

operating and service manuals, and any related

literature, in conjunction with the Guidelines above.

®

DRM™ dryer reservoir module, or a Bendix

™

-equipped vehicle.

®

AD-IS® air dryer system, a

®

brand replacement parts,

®

Wingman®

WARNING: Not all wheels and valve stems

are compatible with Bendix Air Disc Brakes. Use

only wheels and valve stems approved by the

vehicle manufacturer to avoid the risk of valve

stem shear and other compatibility issues.

WARNING: AVOID CREATING

DUST. POSSIBLE CANCER AND LUNG

DISEASE HAZARD.

While Bendix Spicer Foundation Brake LLC does not

offer asbestos brake linings, the long-term affects of

some non-asbestos fi bers have not been determined.

Current OSHA Regulations cover exposure levels to

some components of non-asbestos linings, but not

all. The following precautions must be used when

handling these materials.

• Avoid creating dust. Compressed air or dry

brushing must never be used for cleaning brake

assemblies or the work area.

• Bendix recommends that workers doing brake

work must take steps to minimize exposure

to airborne brake lining particles. Proper

procedures to reduce exposure include working

in a well-ventilated area, segregation of areas

®

.

where brake work is done, use of local fi ltered

ventilation systems or use of enclosed cells with

fi ltered vacuums. Respirators approved by the

Mine Safety and Health Administration (MSHA)

or National Institute for Occupational Safety and

Health (NIOSH) should be worn at all times during

brake servicing.

• Workers must wash before eating, drinking or

smoking; shower after working, and should not

wear work clothes home. Work clothes should

be vacuumed and laundered separately without

shaking.

• OSHA Regulations regarding testing, disposal

of waste and methods of reducing exposure

for asbestos are set forth in 29 Code of Federal

Regulations §1910.001. These Regulations

provide valuable information which can be utilized

to reduce exposure to airborne particles.

• Material Safety Data Sheets on this product, as

required by OSHA, are available from Bendix.

Call 1-800-247-2725 and speak to the Tech Team

or e-mail techteam@bendix.com

2

Page 3

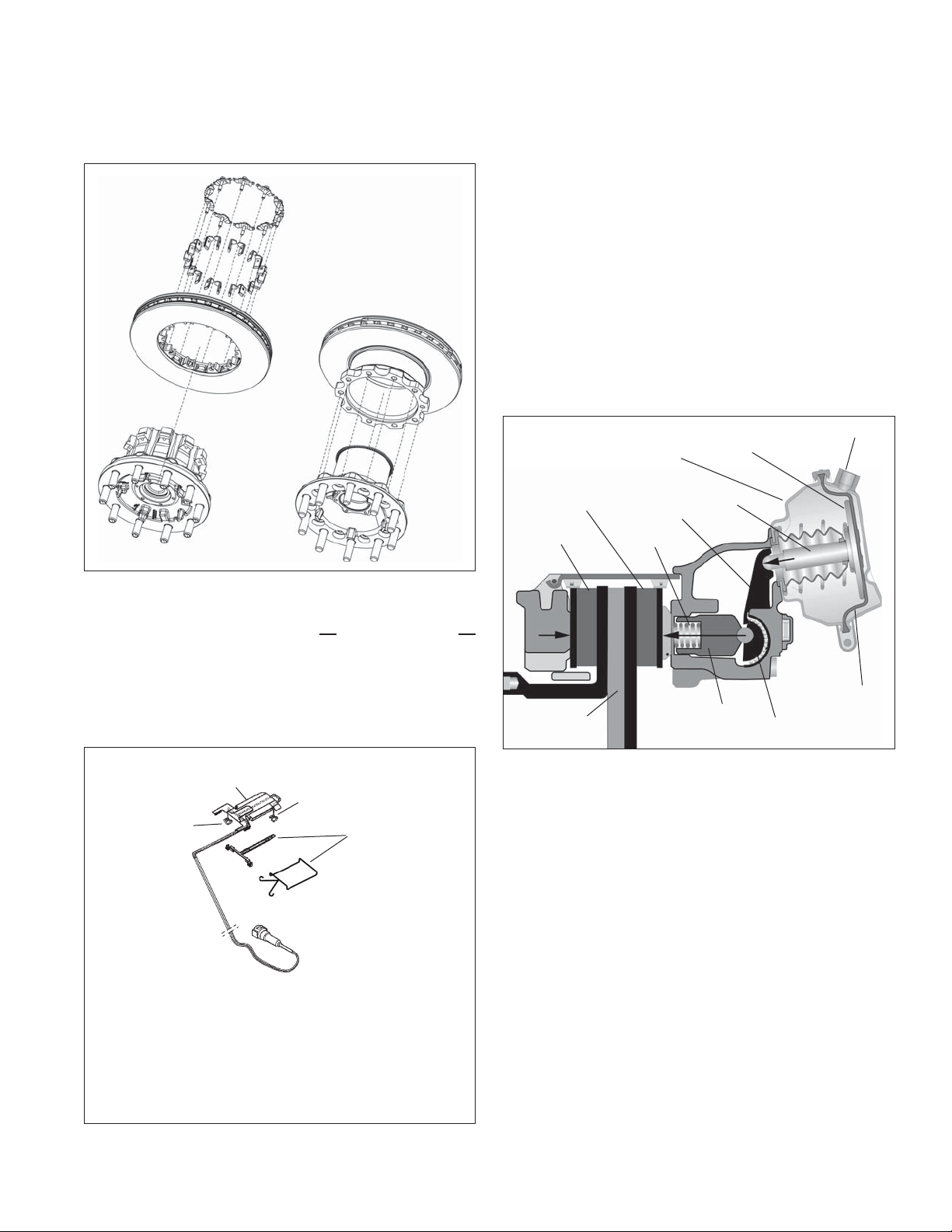

1.3 Rotor Identifi cation

See Figure 4 to help you identify which type of rotor is used

on the axle being inspected. Note that the maintenance

inspection procedure will depend on the type of rotor

installed.

®

Splined

Bendix

Disc® Rotor

Conventional

Rotor

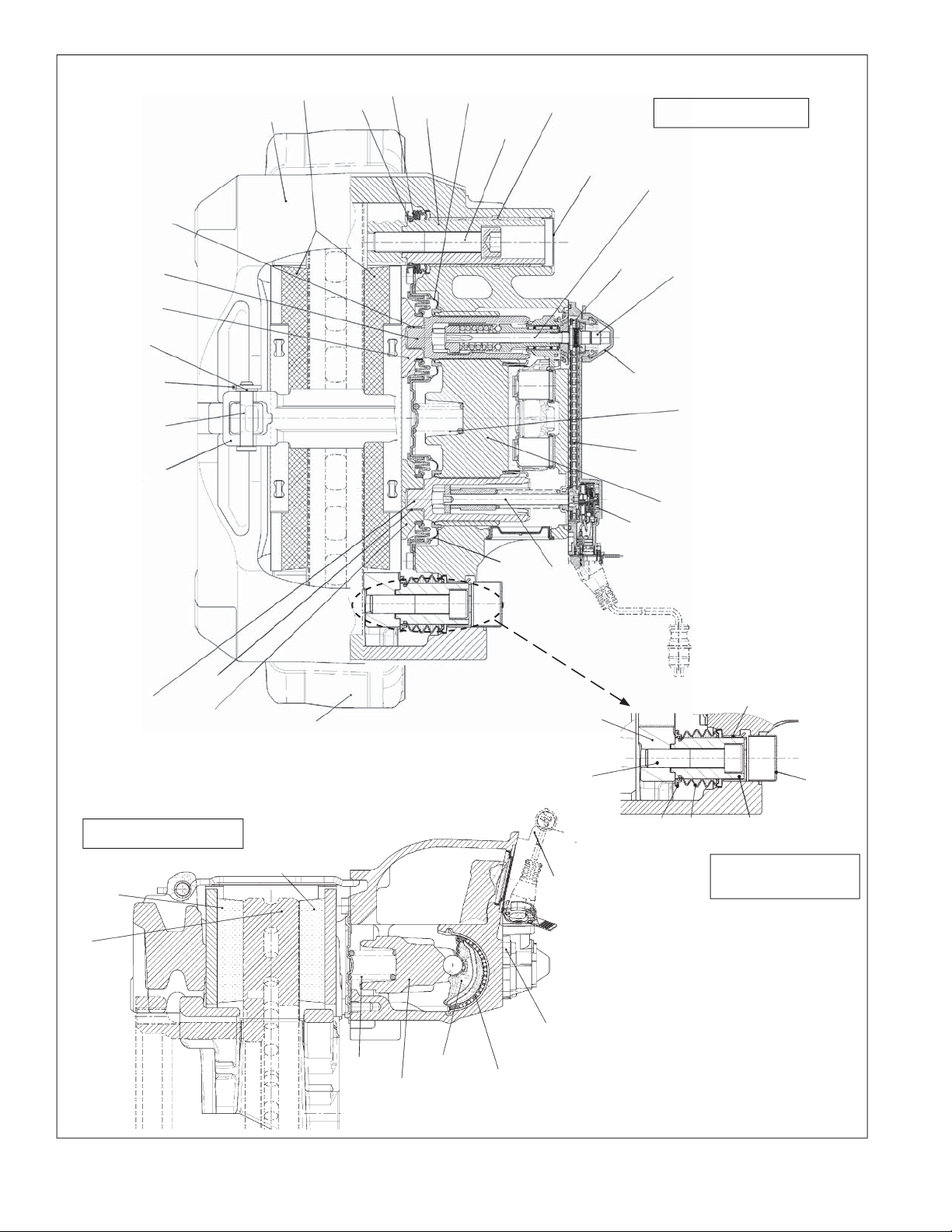

1.5 Operation

Bendix air disc brakes convert air pressure into braking

force. (See Figure 6.) When the vehicle brakes are

applied, air enters the service brake chamber through

the supply port, applying pressure within the diaphragm.

The pressure expands the diaphragm — applying force

to, and moving, the pressure plate and push rod forward.

The push rod acts against a cup in the internal lever which

pivots on an eccentric bearing moving the bridge. Moving

against a return spring, the bridge transfers the motion to

two threaded tubes and tappets, which move the inner

brake pad. The inner brake pad (from its normal position

of having a running clearance between it and the rotor)

moves into contact with the brake rotor. Further movement

of the bridge forces the caliper — sliding on two stationary

guide pins — away from the rotor. That, in turn, pulls the

outer brake pad into the rotor. The clamping action of the

brake pads on the rotor applies braking force to the wheel.

FIGURE 4 - ROTOR IDENTIFICATION

CAUTION: Rotors may not be mixed on a single axle:

axles are only permitted to have all conventional or all

splined disc rotors.

1.4 Wear Sensor Identifi cation

See Figure 5 for the electronic wear sensor that may be

present.

104

Cable Protection

Plate

101

Sensor

103

Cable to Electrical

Supply

Sensor . . . . . . . . . . . . . . . . . . . . .101

Cable to Electrical Supply. . . . . . .103

Cable Protection Plate . . . . . . . . .104

Cable Guide (two designs). . . . . . 105

Consult the instruction sheet included with wear

indicator kits for installation information.

101

Sensor

105

Cable Guide

(2 alternate

designs used)

Pressure

Service Brake

Chamber

Inner Brake Pad

Outer Brake

Pad

Rotor

FIGURE 6 - CROSS-SECTION VIEW SHOWING BRAKE

OPERATION

Lever

Return Spring

Plate

Push Rod

Bridge

Eccentric Bearing

Supply Port

Diaphragm

1.5.1 Brake Release and Adjustment

When the vehicle brakes are released, the air pressure

in the service brake chamber is exhausted and the return

springs in the chamber and the bridge return the air disc

brake to a neutral, non-braked position. To maintain the

running clearance gap between the rotor and the brake

pads over time, the non-braked position is mechanically

adjusted by a mechanism in the caliper. The adjustment

mechanism operates automatically whenever the brakes

are activated, to compensate for rotor and brake pad wear

and to keep the running clearance constant. During pad

or rotor maintenance, the technician manually sets the

system’s initial non-braked position. The total running

clearance (the sum of clearances on both sides of the

rotor) should be between 0.024 to 0.043 in. (0.6 to 1.1 mm).

FIGURE 5 - ELECTRONIC WEAR INDICATOR COMPONENTS

3

Page 4

161

Tappet Bushing

1

Caliper

12

Pad

Assembly

58

Ring

9

Inner Boot

Guide Pin

5

22

Inner Seal

Caliper Bolt

Brass Bushing

40

7

Top Sectional View

10

Cap

23

Adjuster Unit

16

Threaded Tube

13

Tappet and Boot

Assembly

45 Washer

26

Spring Clip

44

Pad Retainer Pin

11

Pad Retainer

16

Threaded Tube

161

Tappet

Bushing

13

Tappet and

Boot Assembly

2

Carrier

22

Inner

Seal

24

Turning

Device

2

Carrier

32

Chain Wheel

37

Adjuster Cap

30

Chain

33

Wear Sensor

61

Shear Adapter

27 Spring

17

Bridge

6 Guide Sleeve

Side Sectional View

12

Pad

Assembly

46

Rotor

FIGURE 7 - SECTIONAL VIEWS

4

Pad Assembly 12

27

Spring

17

Bridge

19

Lever

20

Eccentric

Bearing

39

Caliper Bolt

18/1 Spring Brake or

18/2

Brake Chamber

43

Bolt

58

Ring

9

Inner

Boot

4

Guide Pin

Short Caliper Bolt

Sectional View

68

Cap

Page 5

Type A

(Fixed pin)

Wheel Rotation

(typically right hand)

Shield

Kit

(Drive or

Steer)

(Rotor Shield for Trailers)

U-shaped

Rotor

Fasteners

(Wheel turns toward

Type B

fi xed pin side of

Wheel Rotation

(typically left hand)

161

Tappet Bushing

13 Tappet

and Boot

Assembly

U-shaped Rotor

ADB)

Pad Retainer Pin

Washer

22

Inner Seal

45

Ring

58

44

Actuator

Hardware

Inner Boot

11 Pad Retainer

26 Spring Clip

12/2 Pad Holder Spring

9

12/1 Pad

35 Double-Diaphragm Style

Spring Brake Chamber

(Pad Assembly

consists of

12/1 plus 12/2)

7

Brass

5

Guide

Pin

40

Caliper

Bolt

Bushing

37*

61

Shear

Adapter

1

Caliper

(or Caliper Kit)

2A

Bendix

ADB22X

Carrier

10

Cap

4 Guide Pin

6 Guide Sleeve

Carrier

Mounting

Hardware

Bendix

Anchor Plate

®

™

18/1 Spring Brake

Actuator

68

Cap

39 Caliper Bolt

®

ADB22X™

18/2

Service

Actuator

*37 Adjuster

Caps (2 styles

supplied in kits)

2B

®

Bendix

ADB22X-V

™

Carrier

Drive Hub

Splined Disc® Rotor

Hardware

SD-1, -2, -3

See Section 5.2 for

exploded view of electronic

Splined Disc

(SD)

®

Rotor

SD-3

Steer Hub

FIGURE 8 - EXPLODED VIEW - BENDIX® ADB22X™ AND ADB22X-V™ AIR DISC BRAKES

INDEX TO FIGURES 7 & 8

Adjuster Caps. . . . . . . . . . 37

Adjuster Unit. . . . . . . . . . . 23

Bolt . . . . . . . . . . . . . . . . . . 43

Brass Bushing . . . . . . . . . .7

Bridge. . . . . . . . . . . . . . . . 17

Caliper . . . . . . . . . . . . . . . . 1

Caliper Bolt. . . . . . . . . 39, 40

Cap. . . . . . . . . . . . . . . . . . 68

Carrier. . . . . . . . . . 2 (A or B)

Chain . . . . . . . . . . . . . . . . 30

Chain Wheel. . . . . . . . . . . 32

Cap. . . . . . . . . . . . . . . . . . 10

Eccentric Bearing . . . . . . . 20

Guide Pins . . . . . . . . . . . 4, 5

Guide Sleeve . . . . . . . . . . . 6

Inner Boot. . . . . . . . . . . . . . 9

Inner Seal. . . . . . . . . . . . . 22

Lever. . . . . . . . . . . . . . . . . 19

Pad. . . . . . . . . . . . . . . . 12/1

Pad Holder Spring . . . . 12/2

Pad Assembly. . . . . . . . . . 12

Pad Retainer. . . . . . . . . . . 11

Pad Retainer Pin . . . . . . .44

Ring . . . . . . . . . . . . . . . . . 58

Service Actuator. . . . . . 18/2

Shear Adapter. . . . . . . . . .61

Splined Disc Hardware

. . . . . .SD-1, SD-2 and SD-3

Spring. . . . . . . . . . . . . . . . 27

Spring Brake Actuator. . 18/1

SD-1

SD-2

wear indicator.

®

Bendix

ADB22X-V™

Anchor Plate

Carrier

Mounting

Hardware

Spring Brake Actuator (Double-

Diaphragm style) . . . . . . .35

Spring Clip . . . . . . . . . . . . 26

Tappet and Boot

Assembly . . . . . . . . . . . 13

Tappet Bushing. . . . . . . . 161

Threaded Tube. . . . . . . . . 16

Turning Device . . . . . . . . . 24

Washer. . . . . . . . . . . . . . . 45

Wear Sensor. . . . . . . . . . . 33

5

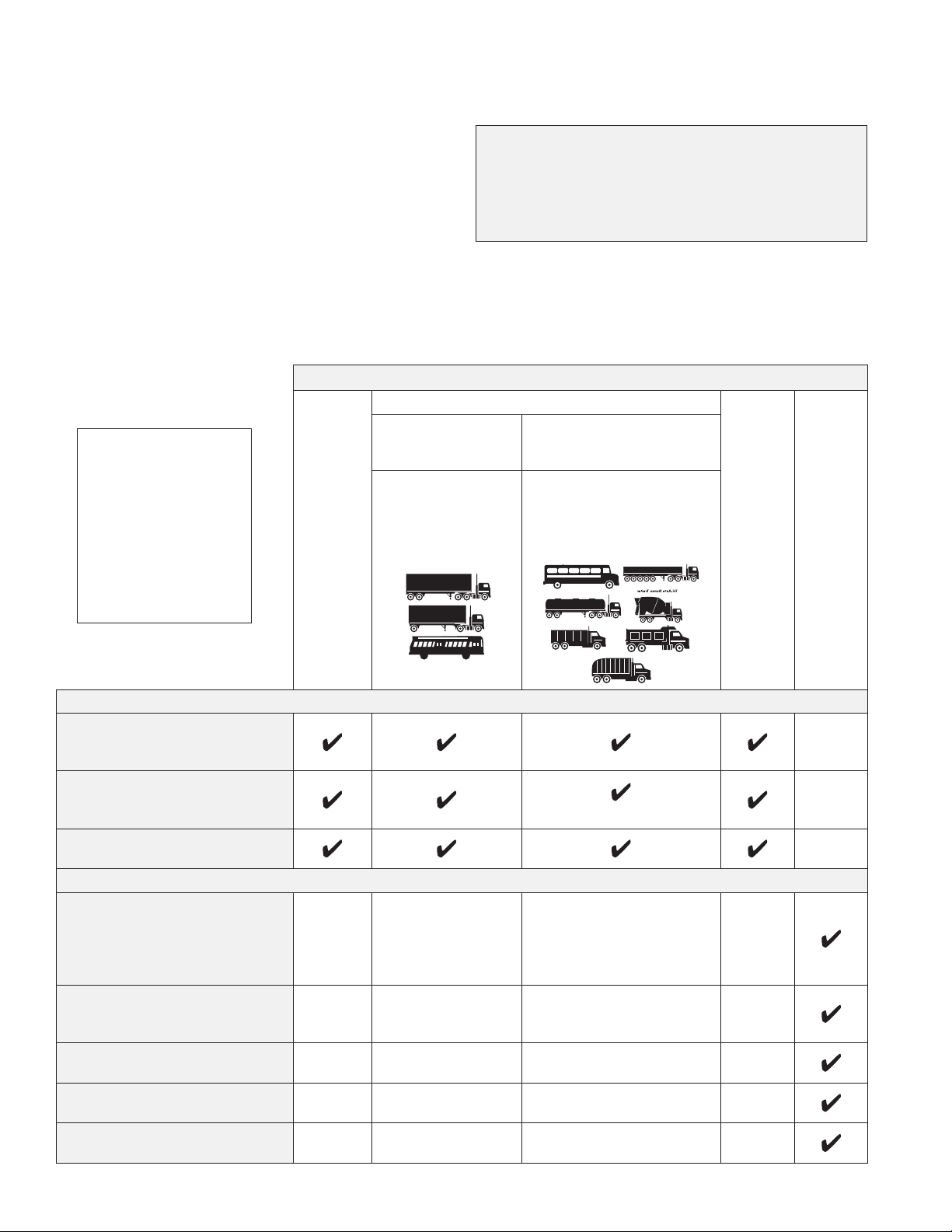

Page 6

SECTION TWO: PREVENTIVE MAINTENANCE SCHEDULE AND WHEEL-ON INSPECTIONS

2.0 PREVENTIVE MAINTENANCE

Regular inspection and maintenance of air disc brake

components is an important part of vehicle maintenance.

The maintenance practices outlined here are recommended

in addition to all standard industry practices (including

daily pre-trip inspections.) Also, see the vehicle's manual

for recommendations. Keep track of the results of your

maintenance inspections to assist you in determining the

ideal maintenance intervals for the vehicle.

Use the table below for a guide to maintenance interval

planning, however, depending on the particular vehicle's

use, more frequent checks of the components may be

necessary.

(4 to 5 times during the pad lifetime)

About every four (4)

* For vehicles with

electronic wear

months for over-the-

road applications:

indicators, use the

dash indicator(s)

and/or the hand-held

diagnostic tool to

regularly monitor the

pad wear.

See Section 5.2.

When

you

check

the tire

pressures

e.g. line haul, RV,

open-highway

coaches, etc.

Section Page

2.0 Preventive Maintenance. . . . . . 6

2.1 Brake Pad and Rotor Inspections . . . 7-8

2.2 Running Clearance Quick Inspection. . 8

Table 1: Inspection Period

About every three (3) months

for higher-duty applications:

e.g. pick-up & delivery,

off-highway, construction,

logger, concrete mixer, dump

truck, city transit bus, refuse,

school buses, etc.

Section Two

At the

very

least,

every

four (4)

months

At least

once

every

year

(and at

every

pad

replace-

ment)

Inspections with the wheel mounted (Sections 2.1 - 2.3)

Inspect the pad thickness by

checking the mechanical wear

indicators*. See Section 2.1.

Inspect the running clearances

using the quick inspection

technique. See Section 2.2.

Inspect the visible part of the rotors

for cracks, etc. See Section 2.3.

Inspect the pads and entire rotor

surfaces for cracks, etc. (Bendix

splined disc® rotors: Inspect

retaining hardware and check

torques) See Section 2.3.

Inspect the running clearances and

adjuster operation.

See Sections 2.2 and 4.2.

Inspect the caliper travel.

See Section 4.1.

Inspect the tappet and boot

assemblies. See Section 4.6.

Inspect all caps, hoses, and brake

exterior for damage etc.

6

Inspections with wheel removed (Section 4)

®

TABLE 1 - PREVENTIVE MAINTENANCE SCHEDULE

Page 7

2.1 BRAKE PAD AND ROTOR INSPECTIONS

Visual checks of the condition of the brake pad/rotor wear

can be made without removing the wheels. Where dust

guards are not used, the top of the pads and part of the

rotor are visible through the opening at the top of the brake.

Other visible portions of the rotor can be inspected at the

same time.

Unless a vehicle has been stored for some time, the main

rotor surfaces that contact the pads will always appear to

be shiny . Surface rust on these surfaces would indicate a

malfunctioning brake that should be inspected immediately .

Pads are 1.181 in. (30 mm.) thick when new and must be

replaced when they reach 0.433 in. (11 mm.). Rotors are

1.77 in. (45 mm.) thick when new and must be replaced

when they reach 1.46 in. (37 mm.). See Section 4.3 for

further inspection criteria.

2.1.1 Electronic Wear Indicators

Use the dash indicator(s) and/or a hand-held diagnostic

tool to regularly monitor the pad wear. (See Section 5.2.)

2.1.2 Mechanical Wear Indicators

See Figure 9 for the location of the mechanical wear

indicators. There are two types (See Figure 10 for Style A

and Figure 11 for Style B).

Wear Indicator Style A:

Where both the carrier and caliper have an

indicator notch.

Compare the relative position of two notches cast into

the carrier and caliper. When the two notches align,

it is time to schedule a full wheel-removed inspection

of the pads and rotor.

Notch in the

caliper

Notch in the

carrier

When the notches

line up, it is time

to schedule an

inspection of the

pads and rotor

FIGURE 10 - STYLE A - WHEN BOTH CARRIER AND CALIPER

HAVE A CAST NOTCH

Quick Visual

Inspection of Pad

Thickness and Rotor

Location of Wear

Indicator Notches

(Both sides of brake)

FIGURE 9 - LOCATION OF WEAR INDICATORS

Note: These mechanical wear indicators do

not constitute “out-of-service” criteria. These

inspections only show when to schedule a full wheelremoved inspection of the brake pads and rotor.

The thicknesses of the pad and rotor will both affect

the wear indicator position at which maintenance is

actually needed.

Wear Indicator Style B:

Where only the caliper has an indicator

notch.

When the notch in the caliper aligns with the front

edge of the torque plate, it is time to schedule a full

wheel-removed inspection of the pads and rotor.

Notch in

the caliper

No notch

in the

When the

torque plate

edge lines up

with the notch,

it is time to

schedule an

inspection of

the pads and

rotor

Torque

carrier

plate

FIGURE 11 - CARRIER WEAR INDICATOR NOTCH AND BACKING

PLATE ALIGNMENT

7

Page 8

F

No action is needed

for small cracks

spread over the

surface (e.g. Area F)

Rotor

Friction

Surface

Width “f”

G

Cracks reaching

either edge of the

rotor

are not

acceptable

for either

type of

rotor

f

Area G

Area

F

Area

H

J

Circumferential

grooves, as in Area

J, are acceptable

if less than 0.06 in.

(1.5 mm) deep.

Area J

H

• For standard Bendix rotors, cracks

running in a radial direction — like

spokes of a wheel (see Area H) — less

than 0.06 in. (1.5 mm) deep or wide

are acceptable if they do not reach

either edge (see G). Cracks are only

acceptable if the length of the crack is

less than 75% of dimension “f” (the width

of the rotor contact area).

• For Bendix Splined Disc rotors, radial

cracks are only acceptable if they are

less than 0.04 in. (1.0 mm) deep or

wide and if they do not reach either edge

(see G). Crack lengths must be less

than 75% of dimension “f” (the width

of the rotor contact area).

In addition, follow the

recommendations of the

vehicle manufacturer.

Note: Axles should

have either all Bendix

Splined Disc (or all

conventional) rotors.

FIGURE 12 - EXAMPLES OF ACCEPTABLE AND NON-ACCEPTABLE ROTOR CRACKS AND GROOVES

2.1.3 Rotor Quick Inspection

See Figure 12. See the various potential rotor conditions

that you may fi nd. See the criteria below for whether the

rotor needs to be replaced and/or scheduled for a full

inspection.

2.2 RUNNING CLEARANCE QUICK

INSPECTION

CAUTION: Follow all safe maintenance practices.

On level ground, with the wheels chocked and the parking

brake temporarily released, check for movement of the

brake caliper. This small movement, less than 0.08" (2 mm)

- approximately the thickness of a nickel - in the inboard/

outboard direction indicates that the brake is moving

properly on its guide pins.

If the caliper has no movement or appears to move greater

than the distances noted above, a full wheel-removed

inspection will be necessary (See Section 4.1).

FIGURE 13 - CALIPER RUNNING CLEARANCE

(FIGURE DOES NOT SHOW WHEEL)

Push/Pull

By Hand

to Check

the Caliper

Movement

8

Page 9

SECTION THREE: TROUBLESHOOTING PROCEDURE FLOWCHART

Air Disc Brake Inspection

Follow safe maintenance practices,

chock wheels. Engage spring brakes

and cage spring. Release spring

brakes and drain air from system.

Raise axle, spin

the wheel by

hand.

Does

the wheel

turn smoothly?

YES

Check

running

clearance (4.1)

- OK?

NO

Check

Adjuster (4.2)

- OK?

NO

NO

Is

the

spring brake fully/

partially applied?

YES

Check

caliper

guidance (4.5)

- OK?

NO

YES

YES

Drain air pressure from

system. Re-start test after

caging spring brakes

YES

YES

Check

running

clearance (4.1)

- OK?

NO

Check

adjuster (4.2)

- OK?

NO

Replace caliper/

carrier assembly

(5.3)

YES

Check

Pad and rotor

wear (4.3-4.4)

- OK?

YES

NO

Replace caliper/

carrier assembly

(5.3)

FIGURE 14 - TROUBLESHOOTING BENDIX AIR DISC BRAKES

NO

Replace guide pins

(5.6) OR replace

caliper/carrier

assembly (5.3)

Tightness not due to

air disc brake. See

vehicle manual.

Replace components

as needed with

genuine Bendix parts.

Disc brake OK

9

Page 10

SECTION FOUR: WHEEL-OFF MAINTENANCE INSPECTIONS

Section Four

Section Page

4.0 Wheel-Off Inspections . . . . . . 10

4.1 Caliper Movement Test . . . . . . 10

4.2 Adjuster Mechanism Inspection . . . 11

4.3-4.4 Brake Pads and Rotors . . . . . 12-14

4.3 Inspect the Brake Pads . . . . . . 12

4.4 Inspect the Rotor . . . . . . . 13-14

4.4.3 Machining (Grinding or Turning) Rotors 14

4.5 Guide Pin Bearing Inspection . . . 14-15

4.6 Tappet & Boot Assembly Inspection . . 15

4.0 WHEEL-OFF INSPECTIONS

CAUTION: During these inspections, follow all safe

maintenance practices, including those on page

two of this service manual. Also, follow the vehicle

manufacturer’s recommendations. When working on

foundation brakes, be sure that the vehicle is on level

ground, that the vehicle is parked by other means

than the foundation brakes, and that the wheels are

chocked.

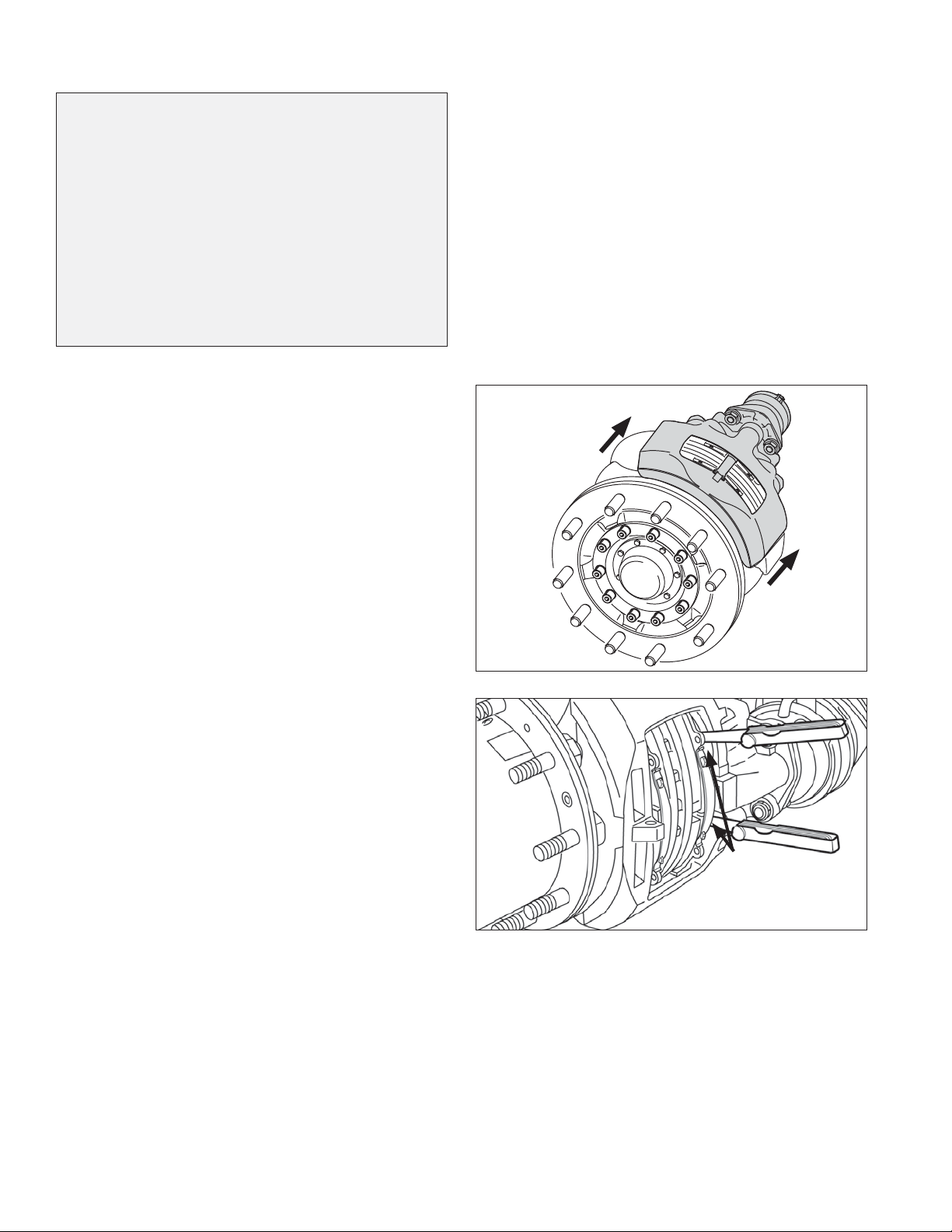

4.1 CALIPER MOVEMENT TEST

CAUTION: Follow all safe maintenance practices.

Remove the wheel. With the spring brakes released or

caged, push the caliper assembly inboard on its guide pins.

Note: To fully release the spring brakes, assure that the

air system pressure is at least 90 PSI. Using a suitable

tool (for example a large fl at-blade screwdriver), press the

inboard pad (12) away from the tappets. Check that there

is no dirt, etc. in the gap, and clean if necessary . Then use

two long-blade feeler gauges to measure over the whole

tappet surface the gap between them and the inboard pad

backplate. (See Figure 16.) The gap should be between

0.024 in. (0.6 mm) and 0.043 in. (1.1 mm). If the gap is

within the range given, the test is complete.

4.0.1 Wheel Removal and Re-Installation

Refer to the vehicle manufacturer’s recommendations for

removing the wheel.

Note: When removing the wheel, inspect fi rst to see that

there is no contact between the caliper and axle, vehicle,

chassis sections or carrier, etc. that may be impeding the

free movement of the caliper.

WARNING: Not all wheels and valve stems are

compatible with Bendix Air Disc Brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid risk of valve stem shear and

other compatibility issues. After re-installing a wheel

according to the vehicle manufacturer’s recommendations,

please ensure that there is suffi cient clearance between

the tire infl ation valve stem, the caliper and the wheel rim,

to avoid damage.

Pull

Caliper

Inboard

FIGURE 15 - PULL CALIPER INBOARD

Check the clearance at

both tappets simultaneously:

0.024 in. to 0.043 in.

(0.6 mm. to 1.1 mm.)

FIGURE 16 - RUNNING CLEARANCE CHECK

CAUTION: If the clearance is too wide, there is a

danger of brake failure. If the clearance is too small,

or if there is no gap at all, there is a danger of the brake

overheating. These conditions must be corrected

before returning the vehicle to service.

For further investigation, where there is some gap, go to

Section 4.2 and check the adjuster mechanism. Where

there is no movement at all (and so no gap to measure),

go to Section 4.5 “Guide Pin Inspection.”

10

Page 11

4.2 ADJUSTER MECHANISM INSPECTION

CAUTION: Follow all safe maintenance practices.

Aside from the normal maintenance schedule, the

adjuster mechanism inspection that follows is also

carried out when the Caliper Movement Test (4.1) fi nds

that the running clearance is too small or too large.

4.2.1 With the spring brake released (or caged), remove

the adjuster cap (37) using the tab, taking care not

to move the shear adapter (61). Note: One of two

styles of adjuster cap (stamped metal or plastic

adjuster cap) may be used.

Adjuster Cap

Location

FIGURE 20 - BACKING-OFF (INCREASING) THE RUNNING

CLEARANCE

If the shear adapter fails, you may attempt a second time

with a new (unused) shear adapter.

Note: Always double-check that the spring brake is released

(where applicable) if a shear adapter fails; if this step was

missed, the shear adapter will break off, and it may appear

that the caliper is seized.

In cases where a second failure of the shear adapter

confi rms that the adjustment mechanism is seized, the

caliper must be replaced.

FIGURE 17 - ADJUSTER CAP LOCATION

37

Cap

23 Adjuster

61 Adapter

37

Cap

Tab

FIGURE 18 - EXPLODED VIEW

OF ADJUSTER AND ADAPTER

FIGURE 19 - CAP INSTALLED:

TAB LOCATION

Tab

For illustration purposes, the exploded view (Figure 18)

shows the adjuster (23) and shear adapter (61) separated.

When using the adjuster mechanism, always have the

shear adapter installed on the adjuster.

4.2.2 Using a 10 mm. six-point box wrench, turn the Shear

Adapter (61) counter-clockwise and listen for

the sound of 3 clicks as the mechanism backs-off

(increases) the running clearance. Note: Do not

use an open-ended wrench as this may damage

the adapter. See Figure 20.

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent excessive

torque from being applied to the adjuster. The shear

adapter will fail (by breaking) if too much torque is

applied.

FIGURE 21 - APPLYING MODERATE APPLICATIONS OF THE

BRAKES: THE WRENCH MOVES CLOCKWISE AS THE RUNNING

CLEARANCE IS DIMINISHED

4.2.3 Where the adjuster mechanism is able to be backedoff normally , position a box-end wrench on the shear

adapter so that it can turn clockwise freely without

coming into contact with parts of the vehicle (See

Figure 21). Make fi ve to ten moderate applications

of the brakes [at about 30 psi (2 Bar)], and observe

that the box-end wrench or socket should turn

clockwise in small increments.

NOTE: As the number of applications increases,

the turning movement will decrease (as the brake

reaches its normal calibration point).

If the box-end wrench does not: (a) turn at all; (b) turns only

with the fi rst application; or (c) turns forward and backward

with every application, the automatic adjuster has failed and

the caliper/carrier assembly must be replaced.

After completing these wheel-off tests, Bendix recommends

installing a new adjuster cap (lightly greased using white,

lithium-based grease) when returning the brake to service.

Ensure that the tab is in the position shown in Figure 19.

11

Page 12

4.3- 4.4 BRAKE PADS AND ROTORS

CAUTION: Follow all safe maintenance practices.

If electronic wear sensors are present, see Section 5.2.

If dust covers are present, see Section 5.1.

See Figure 23. While pressing down against the pad

retaining bar (11), remove and retain the clip (26),

washer (45) and pin (44). Remove the pad retainer bar (1 1).

Bendix recommends that these items should be replaced

with new (See available kits and parts, Section 5.0).

Follow the steps in Section 4.2 for backing-off the adjuster

mechanism. Slide the caliper inboard then outboard to

permit easy removal of the brake pads.

Brake Rotor

Outboard

Brake Pad

Inboard

Brake Pad

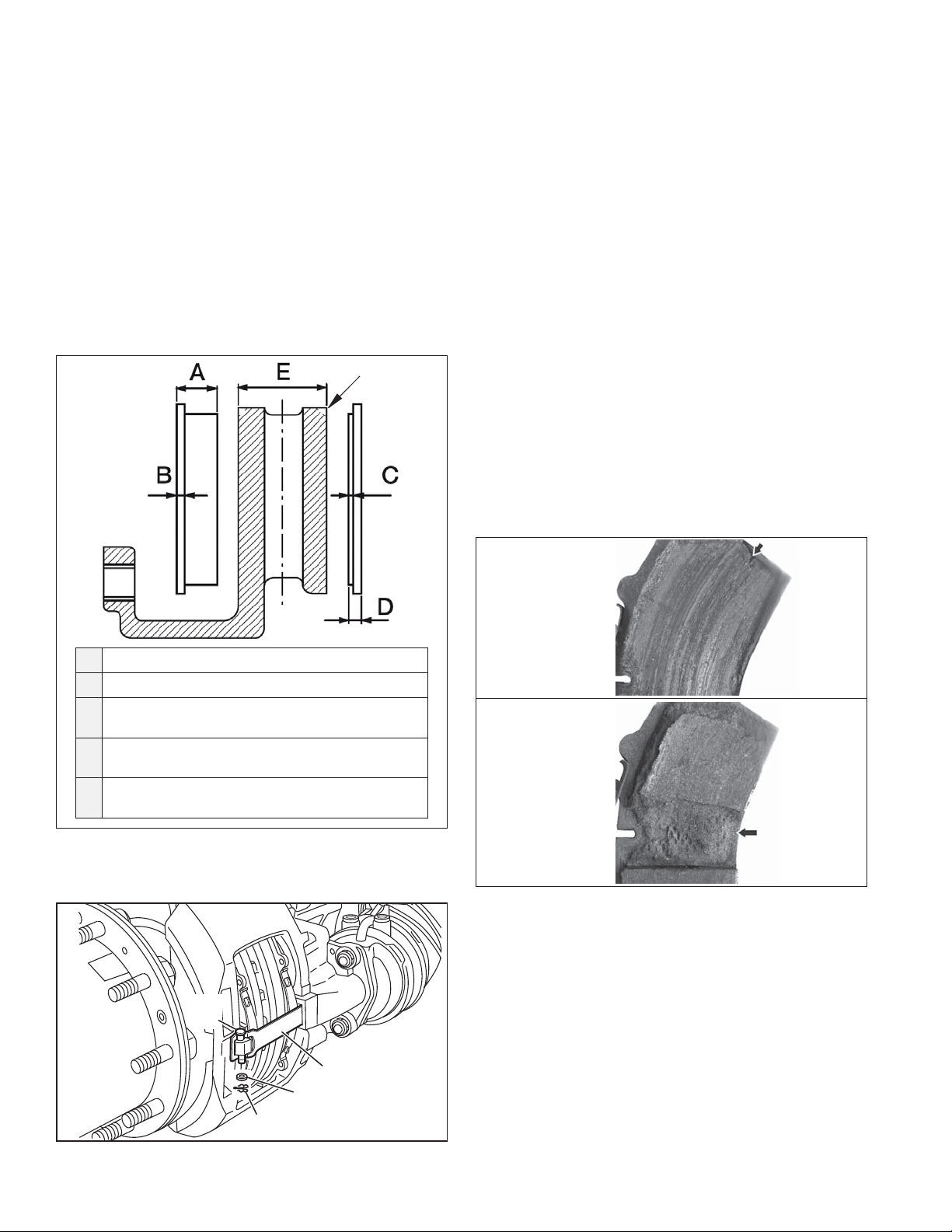

A Thickness of a new pad (1.181 in.) (30 mm.).

B Backing plate thickness (0.360 in.) (9 mm.)

C Minimum thickness of friction material (0.080 in.)

(2 mm.)

D Minimum thickness of a worn pad (0.433 in.)

(11 mm.); replace pads.

E Thickness of a new rotor (1.77 in.) (45 mm.).

Minimum rotor thickness (1.46 in.) (37 mm.)

FIGURE 22 - PAD AND ROTOR DIMENSIONS

See Figure 22 for initial brake pad and rotor dimensions,

as well as minimum acceptable dimensions.

4.3 INSPECT THE BRAKE PADS

Regular inspection of the brake pads (even for vehicles

that use an electronic wear indicator) is an important part

of vehicle maintenance.

4.3.1 See Figure 22. If the thickness of the friction

material — dimension “C” — is less than 0.080 in.

(2 mm.), the pads must be replaced.

®

Bendix

(9 mm.) backing plates, so dimension “D” (the combined

pad and backing plate thickness) must be a minimum of

0.43 in. (11 mm.).

4.3.2 Check for uneven end-to-end pad wear. If the

4.3.3 Compare the thickness of the inboard and outboard

If the results of the pad inspections are within the acceptable

range, inspect the pad surface. (See Figure 24).

FIGURE 24 - BRAKE PAD SURFACE INSPECTION

Minor damage at the edges is permitted, but replace the

pads if major damage on the surface of the pad is found.

ADB22X™, ADB22X-V™ air disc brakes use 0.35 in.

difference in wear is greater than 0.080 in. (2 mm.),

replace the brake pads and also inspect the guide

pins (See Section 4.5).

pads of each set. If the difference between the

inboard and outboard pad thickness is greater than

0.138 in. (3.5 mm.), replace the brake pads and

inspect the guide pins (See Section 4.5).

small amount

Minor Damage -

Is Acceptable

chipped from

Major Damage -

Is Not Acceptable

Section

damaged or

missing

Where a

of brake

material

the edge

44

Pin

26 Spring Clip

FIGURE 23 - RETAINER BAR REMOVAL

12

When replacing brake pads, Bendix strongly recommends

that all the brake pads on an axle be replaced at one time.

See Section 5.1 for the pad replacement procedure. Also

see the vehicle manufacturer’s recommendations found in

the operator’s manual.

11 Pad Retainer Bar

45 Washer

Page 13

Bendix air disc brakes are precision-engineered braking

mechanisms. The “friction couple” braking characteristics

have been carefully optimized — and the rotor design and

materials have been matched with special formulation

brake pads for optimal performance. In all cases, use

brake pads with the type of backing plate and lining material

originally supplied by the vehicle manufacturer.

CAUTION: When replacing brake pads and rotors,

®

use only Bendix

brand replacement pads and rotors

and/or those approved by the OEM. Non-approved

replacement disc pads or rotors can cause excess

wear to brake components, and can increase the risk

of rotors cracking, etc.

4.4 INSPECT THE ROTOR

CAUTION: Follow all safe maintenance practices.

Identify if the rotor is a Bendix® Splined Disc®, or Bendix

brand conventional rotor (See Section 1.03). Rotors should

be inspected regularly (See Section 2.0 for recommended

inspection schedule) and at each pad change.

®

4.4.1 Measure the thickness of the brake rotor at the

thinnest point (Dimension “E” in Figure 22). A void

measuring near the edge of the rotor as minor

burrs may result in inaccurate measurement. For

Bendix® brand rotors, replace the rotor when

the minimum thickness of 1.46 in. (37 mm.) is

reached. For other brands of rotors, refer to the

rotor manufacturer’s guidelines.

4.4.2 Inspect the rotor surface. See Figure 25. The type

of rotor, and also the size, depth and direction of

the imperfections, must all be considered.

NOTE: If surface wear conditions F through J are

in the permitted range, the rotor is still usable until

it reaches the minimum acceptable thickness for the

rotor manufacturer’s guidelines.

4.4.3 Machining (Grinding or Turning) Rotors

Bendix® brand rotors are normally service-free. In the case

of severe grooving of the entire friction surface, however,

CONVENTIONAL ROTORS may be turned when changing

pads, to increase the load-bearing surface.

F

No action is needed

for small cracks

spread over the

surface (e.g. Area F)

Rotor

Friction

Surface

Width “f”

G

Cracks reaching

either edge of the

rotor

are not

acceptable

for either

type of

rotor

f

Area G

Area

F

Area

H

J

Circumferential

grooves, as in Area

J, are acceptable

if less than 0.06 in.

(1.5 mm) deep.

Area J

H

• For standard Bendix® brand rotors,

cracks running in a radial direction —

like spokes of a wheel (see Area H)

— less than 0.06 in. (1.5 mm) deep or

wide are acceptable if they do not reach

either edge (see G). Cracks are only

acceptable if the length of the crack is

less than 75% of dimension “f” (the width

of the rotor contact area).

• For Bendix

®

Splined Disc rotors,

radial cracks are only acceptable if they

are less than 0.04 in. (1.0 mm) deep

or wide and if they do not reach either

edge (see G). Crack lengths must be

less than 75% of dimension “f” (the

width of the rotor contact area).

In addition, follow the

recommendations of

the vehicle and rotor

manufacturer.

Note: Axles should

have either all Bendix

Splined Disc (or all

conventional) rotors.

FIGURE 25 - EXAMPLES OF ACCEPTABLE AND NON-ACCEPTABLE ROTOR CONDITIONS

13

Page 14

MACHINING OF BENDIX® SPLINED DISC® ROTORS IS

NOT PERMITTED.

CAUTION: Always maintain air disc brake pads and rotors

within specifi cations. Excessive pad or rotor wear will

degrade braking performance.

Periodic inspection of the Bendix Splined Disc attachment

hardware is recommended to ensure optimum braking

performance. Bendix recommends verifying the torque on

the spring element fasteners whenever a brake inspection

is performed.

WARNING! AFTER MACHINING/TURNING,

THE MINIMUM ROTOR THICKNESS FOR BENDIX®

BRAND ROTORS MUST BE AT LEAST 1.535 - 1.575 IN.

(39 - 40 MM.) - FOR OTHER BRANDS, CONSULT THE

MANUFACTURER’S GUIDELINES. ALSO, CHECK THE

VEHICLE MANUFACTURER’S RECOMMENDATIONS.

FAILURE TO COMPLY MAY RESULT IN BRAKE FAILURE

AND IN SERIOUS INJURY OR DEATH. MACHINING OF

BENDIX SPLINED DISC ROTORS IS NOT PERMITTED.

4.4.4 Rotor Replacement

An axle is permitted to have only all Bendix Splined

Disc, or all conventional, rotors.

1

Caliper

9

Inner Boot

5

Guide Pin

7

Brass Bushing

10

Cap

LONG

BEARING SIDE

SHORT

BEARING SIDE

When replacing rotors, be sure to adhere to the vehicle

manufacturer’s recommendations, including bolt tightening

torques. It is recommended to install only Bendix

®

brand

rotors, and also that the pads should be replaced (as an

axle set) at the same time.

Non-Bendix

®

brand rotors. If a non-Bendix® brand rotor is

used, confi rm that it complies to the vehicle manufacturer’s

recommendations.

CAUTION: The use of non-approved brake rotors may

reduce levels of safety and invalidate the warranty.

See Section 5.7 for re-installation procedures.

4.5 GUIDE PIN BEARING INSPECTION

CAUTION: Follow all safe maintenance practices.

This guide pin inspection should be carried out if the

technician cannot move the caliper during a Caliper

Movement Test (Sections 2.2 and/or 4.1).

Measure the range of travel along the guide pin

bearings:

4.5.1 Remove the Pads (See Section 4.3). Using hand

pressure only (no tools), the caliper (1) should slide

freely along the whole length of the guide pins. This

movement should be at least 0.95 inch (25 mm)

when the pads are not present. If the movement

is less than this amount, replace the caliper/carrier

assembly.

6 Guide Sleeve

Caliper

Outboard Inboard

FIGURE 26 - GUIDE PINS

Magnetic

Dial-Gauge

Measures

Range Here

FIGURE 27 - MAGNETIC DIAL-GAUGE IN USE

Movement

39

Caliper Bolt

9 Inner Boot

12 Pad Assembly

2

Caliper

68

Cap

4 Guide Pin

1

Carrier

Measure the “play” (range of movement) in the guide

pin bearings:

4.5.2 See Figures 26 and 27. With the wheel removed,

remove the pad retainer bar (11). Temporarily

replace the pads with two new pads (12). Attach

a magnetic dial-gauge holder to the carrier (2) on

the short bearing side of the caliper (1). Use the

measuring point on the caliper (1) - see the callout

14

Page 15

in Figure 27. Press the caliper in the direction of

the carrier (2) and set the dial-gauge to zero.

4.5.3 Place a suitable tool (e.g. a large flat-blade

screwdriver) between carrier (2) and caliper (1) and

use light hand force to move the caliper away from

the carrier, until the movement stops. Read the

maximum value on the dial-gauge. See Figure 27.

If the value is greater than 0.039 in. (1.0 mm), replace

the guide pin bushings (See Section 5.6) OR replace the

caliper/carrier assembly (See Section 5.3).

Inspect the guide pin inner boots:

4.5.4 See Figures 28 and 29. With the pads removed,

slide the carrier by hand to the inboard position (See

Figure 28). By looking through the opening where

the pads are installed — and also from below —

inspect the inner boot (9) for each of the guide pins.

INSPECT FOR DAMAGE, CUTS AND CRACKS.

Replace damaged boots immediately to prevent

dirt and/or moisture affecting the movement of the

guide pins (See Section 5.4). Damaged or corroded

guide pins will impair the operation of the brake.

In addition, during installation, the boots are

compressed to minimize the amount of air trapped

within them. Observe as you move the carrier back

towards the outboard position; the boots should only

expand outwards a small amount due to trapped

air. The boots should normally (due to their ribbed

construction) contract back into place as the caliper

moves on the guide pins. The boots are not airtight and so some trapped air is normal; excess air

trapped will dissipate.

4.6 TAPPET AND BOOT ASSEMBLY

INSPECTION

4.6.1 In order to inspect the tappet and boot assembly,

remove the pads (12) (See Sections 4.3 or 5.2) and

advance the shear adapter (61) clockwise.

CAUTION: NEVER EXTEND THE TAPPET MORE THAN

1.75 in. (44.5 mm). See Figure 29. Over-extending the

tappet will result in the tappet losing engagement with

the synchronizing mechanism. Since the mechanism

can only be set at the manufacturing plant, the caliper/

carrier assembly must be replaced if this happens.

4.6.2 INSPECT THE TAPPET AND BOOT ASSEMBLIES

(13) FOR EVIDENCE OF DAMAGE, CUTS,

CRACKS, TEARS AND EVIDENCE OF

CORROSION, ETC. Damaged boots lead to the

penetration of dirt and moisture, and can lead to

corrosion and impair the operation of the brake.

Replace as necessary (See Section 5.5).

13

Extend LESS THAN

1.75 in. (44.5 mm.)

Inspect

Boot

FIGURE 28 - GUIDE PIN BOOT INSPECTION (THIS IMAGE DOES

NOT SHOW THE CARRIER)

4.5.5 Inspect the original pads (See Section 4.3) and they

may be reused if they are in good condition with

suffi cient pad thickness.

FIGURE 29 - PERMITTED TAPPET EXTENSION

Where the tappets and boots pass the inspection, retract

the tappets using the shear adapter.

When installed, the boots are compressed to minimize the

amount of air trapped within them. Observe as you move

the tappet back using the shear adapter; the boots should

only expand outwards a small amount due to trapped air.

The boots should normally (due to their ribbed construction)

contract back into place as the tappets move. Note: If the

bellows have excess air trapped, then with the tappets

retracted, remove and re-install the actuator to vent the

excess trapped air (See Section 5.4).

Follow the reinstallation steps for the brake pads (See

Section 5.2).

15

Page 16

SECTION FIVE: MAINTENANCE KITS AND PROCEDURES

Section Five

Section Page

5.0 Maintenance Kits . . . . . . . 16-18

5.1 Air Disc Brake Shield Kit . . . . . 19

5.2 Pad Replacement . . . . . . . 20

5.3 Caliper/Carrier/Actuator Assembly . 22-23

Section Page

5.4 Spring/Service Brake. . . . . . . 24

5.5 Tappet & Boot, and Tappet Inner Seal 25-28

5.6 Guide Pin and Boot Assemblies . . 29-34

®

5.7 Bendix

Splined Disc® Hub Rotor . . 35-37

Type A

(Fixed pin)

Wheel Rotation

(typically right hand)

Shield

Kit

(Drive or

Steer)

(Rotor Shield for Trailers)

U-shaped

Rotor

Fasteners

(Wheel turns toward

Type B

fi xed pin side of

Wheel Rotation

(typically left hand)

161

Tappet Bushing

13 Tappet

and Boot

Assembly

U-shaped Rotor

ADB)

Pad Retainer Pin

Washer

22

Inner Seal

45

Ring

58

44

Actuator

Hardware

Inner Boot

11 Pad Retainer

26 Spring Clip

12/2 Pad Holder Spring

9

12/1 Pad

(Pad Assembly

consists of

12/1 plus 12/2)

7

Brass

Bushing

61

Shear

Adapter

1

Caliper

(or Caliper Kit)

5

Guide

Pin

37*

40

Caliper

Bolt

2A

Bendix

ADB22X

Carrier

35

10

Cap

4 Guide Pin

6 Guide Sleeve

Carrier

Mounting

Hardware

Bendix

Anchor Plate

®

™

18/1 Spring Brake

Actuator

68

Cap

39 Caliper Bolt

®

ADB22X™

18/2

Service

Actuator

*37 Adjuster

Caps (2 styles

supplied in kits)

2B

®

Bendix

ADB22X-V

™

Carrier

Drive Hub

SD-2

Splined Disc® Rotor

SD-3

Splined Disc® Rotor

(SD)

Steer Hub

FIGURE 30 - EXPLODED VIEW - BENDIX® ADB22X™ AND ADB22X-V™ AIR DISC BRAKES

Hardware

SD-1, -2, -3

See Section 5.2 for

exploded view of electronic

16

SD-1

Bendix

ADB22X-V™

Anchor Plate

wear indicator.

®

Carrier

Mounting

Hardware

Page 17

5.0 MAINTENANCE KITS FOR BENDIX® ADB22X™ AND 22X-V™ AIR DISC BRAKES

Below is a list of some of the available kits. See Figure 30 for an exploded view showing the components listed.

Kit

Pad Kit (axle set) K070796 (11, 12/1, 12/2, 26, 37, 44, 45, 61)

Splint Kit (box of 25) 803151 (26)

Shear Adapter (box of 10) 802455 (61)

Tappet/Boot Kit (wheel end kit) K092079 (13, 22, 161)

Adjuster Cover (box of 10) 802643 (37)

Guide Pin, Seal and Boot Kit

(wheel end kit)

Guide Pin Boot Kit K023768 (9, 10, 37, 39, 40, 58, 61, 68)

Guide Pin Grease

Service Actuators

NG-3 Piston Style

Spring Brake Chambers

Double-Diaphragm Style

Spring Brake Chambers

Caliper-Carrier Assembly

(Includes 803114)

Caliper Kit

(rationalized)

Includes 803114

Carrier Kit

Hubs

Bendix

®

Splined Disc

®

Rotor Attaching Kit K037767 All Splined Disc® Rotor Applications (SD-1, SD-2, SD-3)

Piece

Number

Components Included in Kit

803114 (4, 5, 6, 7, 9, 10, 37, 39, 40, 58, 61, 68)

II14525 White (5 grams)

K021964 White (500 grams)

®

K028039 Bendix

K028226 Bendix

K028022 Bendix

K028225 Bendix

K028238 Bendix

K028252 Bendix

K027557 Bendix

K025670 Bendix

K025669 Bendix

K042457 Bendix

Type 14 Universal (9, 18/2)

®

Type 16 Universal (9, 18/2)

®

Type 18 Universal (9, 18/2)

®

Type 20 Universal (9, 18/2)

®

Type 22 Universal (9, 18/2)

®

Type 24 Universal (9, 18/2)

®

Type 18/16 Piston Style Truck/Trailer Universal (1, 18/1)

®

Type 18/24 Piston Style Truck/Trailer Universal (1, 18/1)

®

Type 20/24 Piston Style Truck/Trailer Universal (1, 18/1)

®

Type 16/24 Double Diaphragm Style (35)

K043329 Bendix® Type 18/24 Double Diaphragm Style (35)

K041960 Bendix

®

Type 20/24 Double Diaphragm Style (35)

K043148 Bendix® Type 22/24 Double Diaphragm Style (35)

K043270 Bendix

®

Type 24/24 Double Diaphragm Style (35)

K081142 12 Degree Steer and Drive Axial “A” (2A, 1)

K081143 12 Degree Steer and Drive Axial “B” (2A, 1)

802984 Zero Degree Trailer Axial “A” (2A, 1) [Zero degree dual-beam carrier.]

802985 Zero Degree Trailer Axial “B” (2A, 1)

K081256 12 Degree Steer and Drive Vertical “A” (2B, 1)

K081257 12 Degree Steer and Drive Vertical “B” (2B, 1)

K081258 12 Degree Steer and Drive Axle “A” (1)

K081259 12 Degree Steer and Drive Axle “B” (1)

K019180 Zero Degree Trailer Axle “A” (1)

K019181 Zero Degree Trailer Axle “B” (1)

K051853 Steer and Drive Axle, Axial (2A, 9, 10, 20, 39, 40, 58, 61, 68)

K043288 Trailer Axle, Axial (2A, 9, 10, 20, 39, 40, 58, 61, 68)

K056559 Steer and Drive Axle, Vertical (2B, 9, 10, 20, 39, 40, 58, 61, 68)

K020505 Splined Disc

803134 Splined Disc

802847 Splined Disc

K020514 Splined Disc

803138 Splined Disc

®

Brake - Aluminum - FF Steer, LMS Bearing Package (Steer Hub)

®

Brake - Aluminum - FL Steer, LMS Bearing Package (Steer Hub)

®

Brake - Aluminum - R Drive, LMS Bearing Package (Drive Hub)

®

Brake - Aluminum - FF Steer, Standard Bearing Package* (Steer Hub)

®

Brake - Aluminum - FL Steer, Standard Bearing Package* (Steer Hub)

802859 Splined Disc® Brake - Aluminum - R Drive, Standard Bearing Package* (Drive Hub)

K045298 Splined Disc

K045297 Splined Disc

See hub

supplier

U-shaped - Iron/Aluminum, LMS/Standard Bearing Packages

®

- Aluminum - "TN" Trailer, Standard Bearing Package* (Drive Hub)

®

- Aluminum - "TP" Trailer, Standard Bearing Package* (Drive Hub)

for these

standard

Flat - Iron/Aluminum, LMS/Standard Bearing Packages

hub

products

TABLE 2 - MAINTENANCE KITS

(CONTINUES OVER)

17

Page 18

Kit

Rotors

Shields

TABLE 2 - MAINTENANCE KITS (CONTINUED)

Piece

Number

802081 Severe Duty 138mm U-shaped Rotor and Fasteners

K038573 Heavy Duty 138mm U-shaped Rotor and Fasteners

802082 Severe Duty 150mm U-shaped Rotor and Fasteners

K038574 Heavy Duty 150mm U-shaped Rotor and Fasteners

802083 Severe-Duty Splined Disc Kit (SD-1, SD-2, SD-3, SD)

802569 Heavy-Duty Splined Disc Kit (SD-1, SD-2, SD-3, SD)

803129 (Dana) Trailer Axle Pad & Rotor Shield Kit

803130 Axial Drive Axle Pad & Rotor Shield Kit

802948 Pad Shield Kit

K032135 Vertical Drive Axle Pad & Rotor Shield Kit

k022168 Vertical Drive Axle Rotor Shield

Components Included in Kit

See the Bendix Quick Reference Catalog (BW1 1 14) for maintenance kits for other Bendix® brand Air Disc Brakes.

5.0.1 GENERAL INFORMATION ABOUT

BENDIX

When working on Bendix® Air Disc brakes, please note

the following:

• Read and follow the Safe Maintenance Practices on

• Depending on the particular axle, the technician may

• CAUTION: When using a hoist to support the air

®

AIR DISC BRAKE MAINTENANCE

page two.

need to remove the caliper/carrier to allow suffi cient

access to perform the work.

disc brake, do not attempt to use the pad retainer

bar as a bracing point as it is not designed to

support the weight of the brake. Instead use a

brace (or chain) wrapped around the entire brake

to attach the hoist.

Kit

See

Section

• When replacing bearings — or for any other

maintenance procedure where the technician needs

to remove the caliper/carrier assembly from the vehicle

to perform the maintenance — replacement caliper/

carrier bolts will be required. Please note that due

to the high torque required, the original bolts cannot

be reused. The bolts are available from the vehicle

manufacturer.

• WARNING: Not all wheels and valve stems are

compatible with Bendix Air Disc Brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid risk of valve stem shear and

other compatibility issues.

5.0.2 SERVICE DVD

Order part number BW7356 for a DVD showing the full

set of maintenance procedures included in this Service

Data sheet.

Remove

Brake Pads?

Section 5.2

Remove Caliper/

Carrier from

Vehicle?

Section 5.3

Remove

Actuator from

Caliper?

Section 5.4

Dust Shields Section 5.1 Not Typically NA NA

Pad Kit (axle set) Section 5.2 Yes No No

Caliper Kit (rationalized) Section 5.3 Yes Yes Yes

Carrier Kit Section 5.3 Yes Yes Yes

Service Actuator Section 5.4 No Not Typically Y es

Spring Brake Actuator Section 5.4 No Not Typically Yes

Tappet/Boot Kit (wheel end kit) Section 5.6 Yes Typically Typically

Guide Pin, Seal and Boot Kit (wheel end kit) Section 5.7 Yes Typically Typically

Hubs Section 5.8 Yes Yes Yes

Splined Disc

®

Rotor Attaching Kit Section 5.9 Yes Yes Yes

Rotor Section 5.10 Yes Yes Yes

TABLE 3 - OTHER REQUIRED SECTIONS FOR MAINTENANCE KITS

18

Page 19

5.1 AIR DISC BRAKE SHIELD KIT

5.1.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

Note: Most torque plates manufactured after January 1,

2007 have the required torque plate tabs to permit these

shields to be mounted.

This shield kit includes a brake pad shield, a rotor shield

and the required attaching hardware for use in Bendix

ADB22X

™

and ADB22X-V™ Air Disc Brake applications

where external contamination and excessive road debris is

a concern. Brake pad and rotor shields can greatly reduce

damage and/or premature wear of pads and rotors under

these conditions.

During installation, verify that once the shield(s) are

installed they will not come into contact with any vehicle

components, suspension, housings, etc. through the full

range of motion of the wheel. Keep in mind the particular

use of the vehicle, the orientation of the brake on the axle

and torque plate, the proximity of other axles, and/or the

wheel/tire being used.

®

5.1.2 Remove and discard the spring clip and washer

from the pad retainer pin. Remove and retain the

retainer bar and retainer pin. Position the pad shield

as shown and re-insert the retainer bar. Install

the retainer pin. Use the included spring clip and

washer to secure the retainer pin. Check that the

pad shield is held securely in place by the retainer

bar. See Figure 31 or 32.

Spring

Clip

Washer

Pad Shield

Rotor Shield

Washer

Spring

Clip

Pad Shield

Rotor Shield

Fastener

FIGURE 31 - DRIVE OR STEER AXLE EXPLODED VIEW WITH

INSET SHOWING ROTOR SHIELD INSTALLATION

Torque

Plate

Fastener

Rotor Shield

Torque

Plate

Fastener

Fastener

Lock

Washer

FIGURE 32 - TRAILER AXLE EXPLODED VIEW WITH INSET

SHOWING ROTOR SHIELD INSTALLATION

(with Washer)

Rotor

Shield

5.1.3 Drive or Steer Axle Rotor Shields (See Figure

31). Position the rotor shield between the torque

plate and the rotor. The supplied cap screws

pass through the mounting tabs in the torque plate

and install into the shield. Torque cap screws to

44 Ft. Lbs. (528 in. lbs.).

5.1.4 Trailer Axle Rotor Shields (See Figure 32).

Position the rotor shield with the torque plate

between the shield and the rotor. With one

(supplied) lock washer in place on each cap screw,

pass the screws through the shield before mounting

onto the threaded torque plate holes. Torque the

cap screws to 24 ft. lbs. (288 in. lbs.).

Note: The installation of air disc brake shields does not

eliminate the need for periodic maintenance and inspection

of the air disc brake and entire wheel end for damage and/

or wear. In addition, the truck and trailer manufacturer’s

specifi c criteria for the brake shield requirements on air

disc brakes should be consulted before either installing or

removing air disc brake shields from a wheel end(s).

19

Page 20

5.2 PAD REPLACEMENT

5.2.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

The Bendix DVD (BW7356) shows this procedure.

Important: If the vehicle is equipped with spring brakes,

cage the spring brakes on all axles to be worked on.

Consult the vehicle manufacturer’s instructions as

necessary. For Bendix piston-style, see Section 5.4.

and retain the mounting hardware for the cable

protection plate. The cable protection plate can

then be set aside while servicing the pads. Note the

position of the sensors in the brake pad channels,

and carefully remove them. In most cases you do

not need to release the cable connector in order to

move the sensors away from the pad installation

work area. Inspect the wear sensors - replace if

damaged or abraded.

5.2.4 See Figure 34. Remove and discard the pin

retention clip (26) and washer (5).

ELECTRONIC WEAR

SENSOR

(if installed)

101

Sensor

Cable to Electrical

Supply

11

104

Cable Protection

Plate

103

Outboard

101

Sensor

44

105

Cable Guide

(2 alternate

designs used)

45

26

12

44

Pin

11 Pad Retainer Bar

45 Washer

26 Spring Clip

FIGURE 34 - PAD RETAINER BAR REMOVAL

5.2.5 While pressing against the pad retainer bar , remove

the pin (11). Discard the pad retainer bar.

5.2.6 With the spring brake released (or caged), remove

the adjuster cap (37) using the tab, taking care not

2

to move the shear adapter (61). Note: Two sizes

of adjuster cap are supplied in kits; use the same

size as before in step 5.2.20.

5.2.7 Inspect the shear adapter (61). If significant

corrosion and/or damage is present, remove the

adjuster adapter using needle-nose pliers and

replace with the adapter supplied in the kit and

clean as necessary.

Inboard

37

FIGURE 33 - PAD R EP LAC EM ENT

61

5.2.2 Raise the complete axle to be worked on until the

tires clear the ground. See the vehicle maintenance

manual instructions for removing the wheels.

5.2.3 If the air disc brake is equipped with an electronic

wear sensor indicator (see top of Figure 33), remove

20

37

Cap

23 Adjuster

61 Adapter

37

Cap

Tab

FIGURE 35 - EXPLODED VIEW

OF ADJUSTER AND ADAPTER

FIGURE 36 - CAP INSTALLED:

TAB LOCATION

Tab

For illustration purposes, the exploded view (Figure 35)

shows the adjuster (23) and shear adapter (61) separated.

When using the adjuster mechanism, always have the

shear adapter installed on the adjuster.

Page 21

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent too much

torque being applied. The shear adapter will fail (by

breaking) if too much torque is used.

Note: For wheel-ends with spring brakes, if a shear adapter

fails, always double-check to verify that the spring brake

has been released (or caged). If the spring brake is applied,

release or cage the brake (assure that the air system

pressure is at least 90 PSI) and start the procedure again.

If the shear adapter fails, you may attempt a second time

with a new (unused) shear adapter. In cases where a

second failure of the shear adapter confi rms that the

adjustment mechanism is seized, the caliper must be

replaced.

5.2.8 Use a 10 mm., six-point box wrench (See Figure 37)

to turn the adjuster counterclockwise until suffi cient

space exists to remove the brake pads. A clicking

noise occurs each time the adjuster turns.

CAUTION! Avoid overloading or damaging the adjuster

shaft. Do not use an open-ended wrench since it may

damage the adjuster shaft.

Use these two inspections:

A. Check for uneven end-to-end pad wear. If

the difference in wear is greater than 0.080 in.

(2 mm.), replace the brake pads and also inspect

the guide pins (See Section 4.5).

B. Compare the thickness of the inboard and

outboard pads of each set. If the difference

between the inboard and outboard pad thickness

is greater than 0.138 in. (3.5 mm.), replace the

brake pads and inspect the guide pins (See

Section 4.5).

5.2.12 Inspect the Brake Rotor (See Section 4.4).

5.2.13 Inspect the guide pins (See Section 4.5).

Important: To maintain optimal braking, Bendix

strongly recommends that whenever brake pads

are replaced, the complete axle set be replaced

together. Use only pads which are permitted by the

vehicle manufacturer, axle manufacturer, and/or disc

brake manufacturer. Failure to comply with this may

invalidate the vehicle manufacturer’s warranty.

Before installing the brake pads, use the adjuster to

fully retract the tappets to provide adequate clearance.

FIGURE 37 - BACKING OFF THE ADJUSTER FOR PAD REMOVAL

Inboard

Outboard

Inboard Pad

FIGURE 38 - PAD REMOVAL

5.2.9 See Figure 38. Move the caliper fully inward and

remove the inboard pad, then move the caliper fully

outward and remove the outboard pad.

5.2.10 Repeat the pad removal procedure for the other

end of the axle.

5.2.11 To confi rm that the guide pins are sliding freely,

examine the pads just removed for uneven wear.

5.2.14 Clean the surfaces that will come in contact with

the brake pad.

Caution: When installing pads and retaining springs,

where appropriate, use heavy duty gloves and always

keep fi ngers away from potential pinch hazard areas.

2

12

FIGURE 39 - PAD RETAINING SPRING INSTALLATION

5.2.15 Install the pad retaining springs(2) onto the brake

pads(12) by inserting one end of the spring onto

the lug at the top of the brake pad (See Figure 39).

Carefully apply enough force to permit the second

lug to fully engage, taking care to keep fi ngers etc.

away from the spring as it seats.

5.2.16 Pull the caliper fully outward and install the outboard

pad. Move the caliper fully inward and install the

inboard pad.

5.2.17 To reinstall wear indicators (if used): Insert the

wear sensors into position in the new brake

pads. Route the sensor cable through the cable

protection plate channel and secure the plate with

the mounting hardware retained at disassembly.

(See Section 5.2.)

21

Page 22

FIGURE 40 - RUNNING CLEARANCE ADJUSTMENT

5.2.18 Using a 10 mm., six-point box wrench, turn the

Shear Adapter (61) clockwise until the pads contact

the rotor. Note: Do not use an open-ended wrench

as this may damage the adapter. (See Figure 40).

5.2.19 Using the same tool, turn the Shear Adapter (61)

counter-clockwise and listen for the sound of 3

clicks as the mechanism backs-off (increases) the

running clearance. (See Figure 37).

5.2.20 Select the correct replacement adjuster cap from

those supplied with the kit. Lightly grease adjuster

cap with Renolit HLT2 white grease (part number

14525) and install the cap.

5.2.21 Push the new pad retainer bar (11) into the groove

of the caliper. Press down on the pad retainer bar,

and insert the pad retainer pin (44), with the pin

pointing downwards, where possible. Install the

supplied washer (45) and then the spring clip (26).

(See Figure 34).

5.2.22 Apply and release the brakes. The hub should

turn easily by hand after applying and releasing the

brake.

5.3 CALIPER/CARRIER/ACTUATOR

ASSEMBLY

CAUTION: Follow all safe maintenance practices,

including those listed on page two of this document.

Park the vehicle (by other means than the foundation

brakes) on level ground and chock the wheels.

CAUTION: When using a hoist to support the air disc

brake, do not attempt to use the pad retainer bar as a

bracing point. It is not designed to support the weight

of the brake. Use instead a brace (or chain) wrapped

around the entire brake to attach the hoist.

5.3.1 In all cases check that the current hose routing

arrangement does not restrict the full travel of the

caliper before beginning work on the assembly.

5.3.2 Remove the brake pads (See Section 5.2).

5.3.3 (See Section 5.4). If the actuator used is a spring

brake, following the manufacturer’s guidelines, cage

the spring. With all air pressure drained from the

system, disconnect the air hoses from the brake

chamber.

Vertical Mounting Bolt Style

Caliper/Carrier Assembly (Showing

Spring Brake Actuator )

Alignment

Bushing

Anchor Plate/

Torque Plate

5.2.23 Re-check the running clearance. Readjust if

necessary.

5.2.24 Reinstall the wheel, following the vehicle manual

instructions.

WARNING!

The brake pads and rotor must be maintained within

the recommended wear limits. Failure to monitor wear

and replace the brake pads and rotor when required

may result in diminished brake performance.

Alignment

Bushing

Mounting Bolts

(6 total - washers

not required)

FIGURE 41 - VERTICAL MOUNT CALIPER/CARRIER

5.3.4 See Figure 41. Supporting the air disc brake by

necessary means, remove the six (6) mounting

bolts/washers and discard. Note: Bendix strongly

recommends that during re-assembly these bolts

are replaced - see your vehicle manufacturer for

replacement hardware. Lift the caliper up off the

anchor plate.

The vertical bolt assembly includes an alignment bushing.

This bushing must be saved for re-use during re-

assembly of the brake. The bushing mounts in the torque

plate and maintains the correct alignment of the brake

assembly relative to the rotor.

22

Page 23

5.3.5 If the brake assembly does not separate from the

anchor plate it may be helpful to install an M16X2.0

screw longer than 120 mm at the bushing locations

and tap the end of the bolt with a hammer to free

the brake assembly. Remove the assembly.

Caliper/Carrier

Assembly

(Actuator not

shown)

Axial Mounting Bolt Style

5.3.6 Disconnect the air hose(s) to the brake chamber.

See Figure 42. Supporting the air disc brake by

necessary means, remove the six bolts attaching

the brake to the anchor plate and remove the

caliper/carrier assembly from the vehicle.

Note: Bendix strongly recommends that during re-assembly

these bolts and washers are replaced. See your vehicle

manufacturer for replacement hardware. Remove the

assembly.

Re-installation (Both Styles)

5.3.7 Supporting the air disc brake by necessary means,

attach the brake to the anchor plate using six

(new) bolts. Torque to vehicle manufacturer’s

specifi cations. If torque values and bolts are not

specifi ed by the vehicle manufacturer, then select

a replacement bolt as shown in Table 4.

Air Disc Brake Attachment Hardware

Torque Plate Manufacturer Fastener Torque

Bendix Axial

Carrier Torque Plate

Fastener: M20 x 2.5 x 60 mm Class 10.9

Washer: Requires HARDENED 3 mm

(minimum thickness) for each bolt.

If the vehicle is using a Bendix

manufactured Axial Anchor Plate, with a

thickness of 1.14 in. (29 mm) where these

bolts are assembled, then a bolt with an

overall length of 2.36 in. (60 mm) will meet

these requirements

Anchor Plate/

Torque Plate

FIGURE 42 - AXIAL MOUNT CALIPER/CARRIER

5.3.8 Re-install the air hoses (See Section 5.4.8-9) and

check for leaks.

5.3.9 Inspect and re-install the pads (See Section 5.2).

1

Use the manufacturer’s recommendations.

If unavailable, use phosphate

and oil fi nish fastener.

Pre-Torque: 20-60 ft-lbf [27-81 N·m]

Final Torque: 350-400 ft-lbf [475-542 N·m]

Mounting Bolts

and Washers

(6 sets total)

Bendix Vertical

Carrier Torque Plate

Use the manufacturer’s recommendations.

If unavailable, use plain and oil fi nish fastener.

Torque: 200-220 ft-lbf [271-298 N·m]

Use the manufacturer’s recommendations.

If unavailable, use phosphate

and oil fi nish fastener:

Pre-Torque: 20-60 ft-lbf [27-81 N·m]

Final Torque: 350-400 ft-lbf [475-542 N·m]

Trailer Torque Plate

Fastener: M16 x 2.0 x 110 mm, Class 10.9

Washer: None required.

Fastener: M20 x 2.5 x L Class 10.9

Length determination:

L = Torque Plate (TP) thickness + Carrier

engagement + Washer thickness

= TP thickness + 24 mm + 3 mm

L

min

= TP thickness + 29 mm + 3 mm

L

max

Washer: Requires HARDENED 3 mm

(minimum thickness) for each bolt.

1

CAUTION: The washer outside diameter must be less than 1.5 in (37.5 mm).

TABLE 4 - TORQUE PLATE FASTENERS AND TORQUE RECOMMENDATIONS (SEE MANUFACTURER’S RECOMMENDATIONS)

23

Page 24

5.4 SPRING OR SERVICE BRAKE

5.4.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

5.4.2 Use the spring brake manufacturer’s recom-

mended safety practices in all cases.

Some spring brake and vehicle manufacturers

permit caging the spring brake while the spring

brake is engaged.

THE FOLLOWING INSTRUCTIONS ARE FOR BENDIX®

BRAND PISTON-STYLE ACTUATORS.

5.4.3 With the vehicle on a level surface and the wheels

properly chocked, apply air to release the spring

brakes (parking brakes) by using the dash-mounted

air control valve. Back out the release bolt (Figure

43, arrow “D”), using a maximum torque of 26 ft. lbs.

(35 N·m) to cage the air released spring force on

the push rod.

A

B

A

18/1

D

C

FIGURE 44 - SPRING BRAKE INSTALLATION

CAUTION: Do not use brake chambers with seals that

have a thickness less than 0.12 in. (3 mm). Use only

actuators which are recommended by the vehicle

manufacturer.

5.4.7 Install the brake chamber using new self-locking

nuts (EN ISO 10513). Alternately tighten both the

nuts step by step up to a fi nal torque of 133 ± 7 ft. lbs

(180 ± 10 N·m). Bendix strongly recommends

that new nuts be used.

5.4.8 Re-connect the air hose(s) and be sure that each

hose is not twisted or in contact with moving vehicle

components. The air hose routing must allow for full

caliper travel. Note that for spring brake service

chambers the ports are indicated by: “11” Service

Brake Port and “12” Spring Brake Port

B

FIGURE 43 - ACTUATOR SPRING CAGING AND REMOVAL

5.4.4 Exhaust the air from the brake chambers by using

the dash-mounted air control valve. With all air

pressure drained from the system, disconnect the

air hoses from the brake chamber. While supporting

the brake chamber in position, remove and discard

the brake chamber mounting nuts (Figure 45,

arrows marked “B”). Remove the brake chamber.

5.4.5

Re-installation. Before installing the brake chamber,

the actuator fl ange (See Figure 46, arrow “C”) must be

cleaned and inspected. Consult the vehicle manual.

The spherical cup in the lever (19) must be greased

with white grease (Part No. 14525 or K021964).

Add grease to the rubber gasket on the chamber.

CAUTION: Do not use grease containing molybdenum

disulfate.

5.4.6 The seal, as well as the push rod area, must be

clean and dry.

FIGURE 45 - PORT DESIGNATIONS

Note: Where a new spring brake chamber is being

installed, note that in some cases drain plugs are installed

(See Figure 43, arrows marked “A”). Where drain plugs

are present, after installation, remove whichever plug is

at the lowest position. The selected drain hole must be

aligned downwards (or within ±30°) when installed on the

vehicle. In the case of spring brake chambers, install the

pads before uncaging the spring.

5.4.9 Before returning vehicle to service, with the system

pressurized, using a soap solution, check for air

leakage. Minimal leakage in the area around the

diaphragm is permitted (100 SCCM), and a one-inch

bubble in one minute at the hose fi tting is acceptable.

If abnormal leakage is detected, the diaphragm must

be replaced, or fi tting adjusted, respectively.

24

Page 25

5.5 TAPPET & BOOT ASSEMBLIES, AND

TAPPET INNER SEAL REPLACEMENT

5.5.1 CAUTION: Follow all safe maintenance

practices, including those listed on page two of

this document. Park the vehicle (by other means

than the foundation brakes) on level ground and

chock the wheels.

In some cases, the technician will need to remove the caliper

carrier assembly from the vehicle. (See Section 5.3.) Note

that new bolts (available from the vehicle manufacturer)

will be needed for re-installation.

22

Inner Seal

Pad Retainer

13 Tappet

and

Boot Assy

161

Tappet

Bushing

11

44 Pad Retainer Pin

26

Spring Clip

45

Washer

12

Pad

Assembly

Important: If the vehicle is equipped with spring brakes,

cage the spring brakes on all axles requiring work.