Page 1

Technical Bulletin

Bulletin No: TCH-013-005 Effective Date: 6/26/00 Cancels: NA Page: 1 of 3

Subject:

Bendix Commercial Vehicle Systems is reinforcing the importance of following proper installation and service

guidelines for installing, routing and securing whee l speed sensors, sensor cables and wire harnesses for Bendix

Antilock Braking Systems (ABS).

Bendix has discovered that if wheel speed sensor cables are not properly routed and secured, the cable could rub

on rotating components, causing damage which, in rare circumstances, could result in a temporary exhaust of

brakes for a few seconds at low speeds. Although this issue has only been reported on a small number of straight

trucks and buses, Bendix recommends that when servicing ABS, you ensure proper routing and securing of wheel

speed sensor cables.

Wheel Speed Sensor Cables

Wheel speed sensor cables coming directly out of the wheel ends should be routed at least 1.5 inches away from

moving components at all points and be properly secured to air lines and the axle to prevent excess cable slack

and potential chafing damage. Ensure that the wheel speed sensor cables attached along the length of the service

brake hoses are secured with tie wraps at intervals of approximately six (6) inches and are securely connected to

the wiring harness. In addition the wheel speed sensor cable should be secured with a tie wrap three (3) inches

from the sensor.

Wheel Speed Sensor Cable Chafing

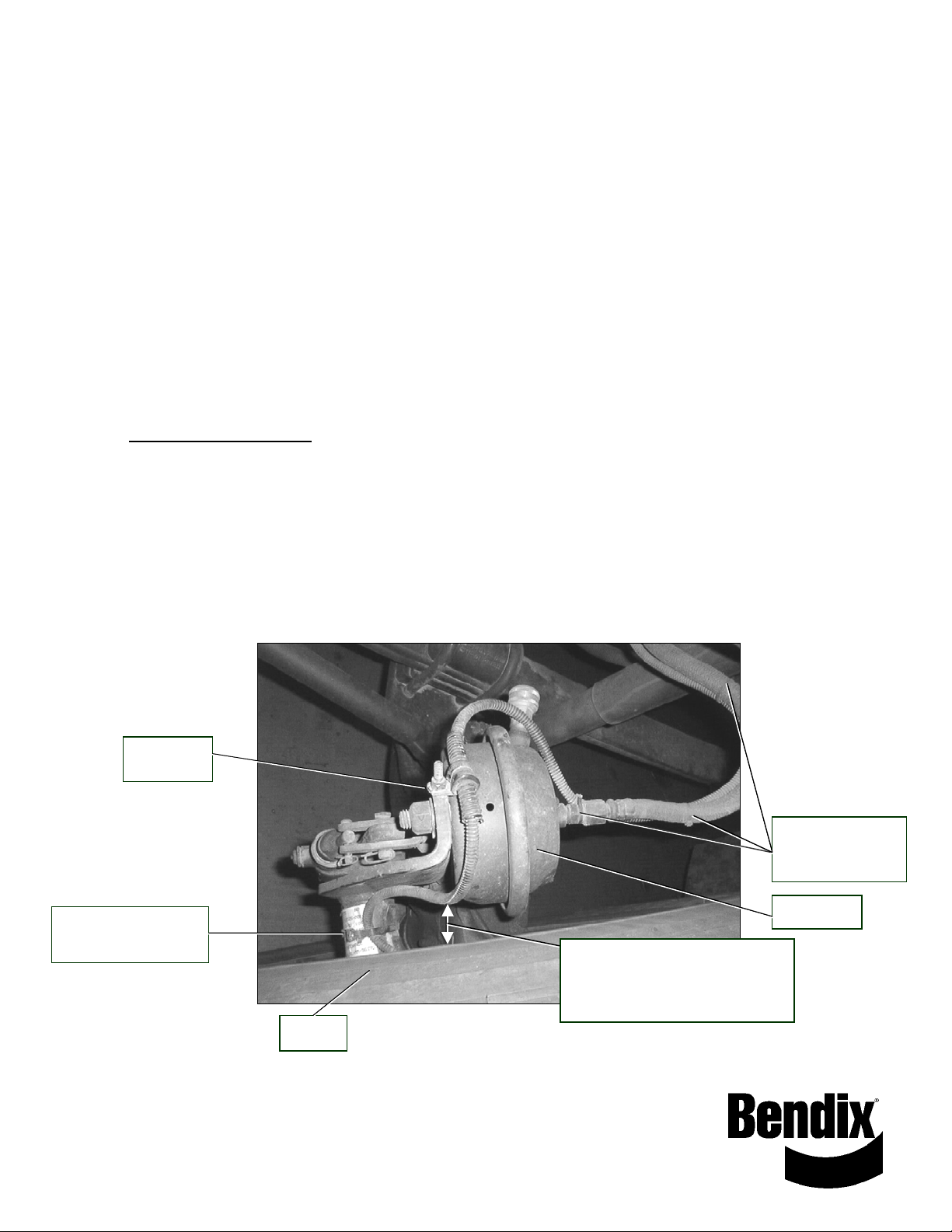

Figure 1 - Photo of typical front wheel speed sensor cable installation

(View from Top)

Clamp

Tie Wrap 3 inches

from sensor

Tie Wraps

6 inches apart

Actuator

1.5 inch clearance at all points

from wheel or rotating

components with minim al

slack in cable

Tire

Page 2

Wire Harness

Ensure all wiring routed along the frame rails is secured to frame members wherever possible. Secure every 12

inches throughout its length, preferably with non-metallic clamps or “Bow Tie” tie wraps. Route wires away

from sharp corners, heat sources, and moving or rotating components. If a harness is installed through a frame

member, grommets must be installed to prevent wire chafing. At all connectors, verify that the wires come out

straight for a minimum of three (3) inches before any bends. Be sure all connector seals are fully engaged in the

mating connector and secondary locks are snapped securely.

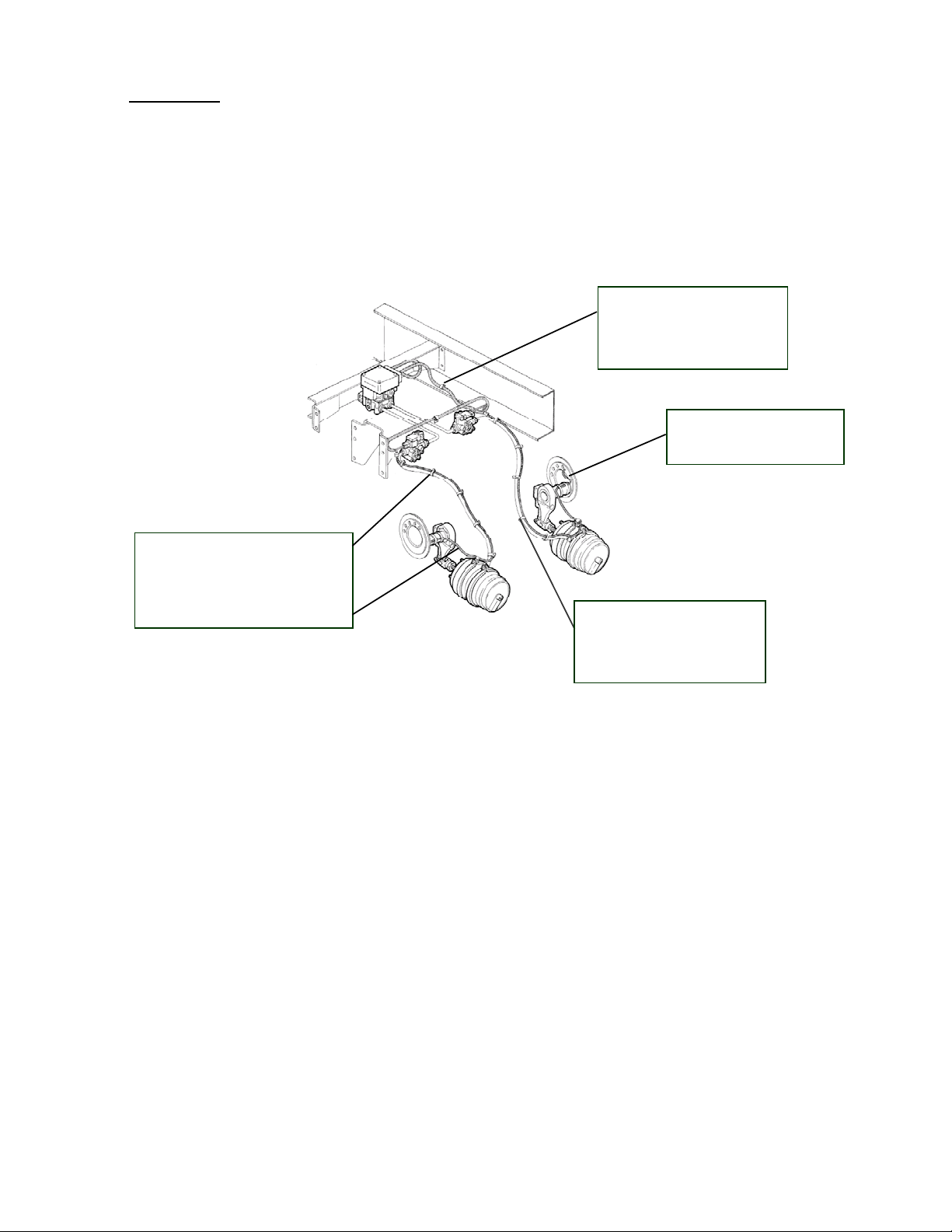

Figure 2 – Diagram of typical rear sensor routing and wire harness installation

Tie Wraps located

every 12 inches on

frame rail

Tie Wrap 3 inches

from sensor

1.5 inch clearance at all

points from wheels or

rotating components with

minimal slack in cable

Tie Wraps located

every 6 inches along

brake hose

As with all maintenance procedures before working on any vehicle follow the Safety Precautions outlined below.

IMPORTANT! PLEASE READ

When working on or around a vehicle, the following general precautions should be observed.

1. Park the vehicle on a level surface, apply the parking brakes, and always block the wheels.

2. Stop the engine when working around the vehicle.

3. If the vehicle is equipped with air brakes, make certain to drain the air pressure from all reservoirs before

beginning ANY work on the vehicle.

4. Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a manner

that removes all electrical power from the vehicle.

5. When working in the engine compartment the engine should be shut off. Where circumstances require that

the engine be in operation, EXTREME CAUTION should be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated, or electrically charged components.

6. Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has been depleted.

7. Never exceed recommended pressures and always wear safety glasses.

Page 2 of 3

Page 3

8. Do not attempt to install, remove, disassemble or assemble a component until you have read and thoroughly

understand the recommended procedures. Use only the proper tools and observe all precautions pertaining to

use of those tools.

9. Use only genuine Bendix replacement parts, components, and ki t s . Replacement hardware, tubing, hose,

fittings, etc. should be of equivalent size, type, and strength as original equipment and be designed

specifically for such applications and systems.

10. Components with stripped threads or damaged parts should be replaced rather than repaired. Repairs

requiring machining or welding should not be attempted unless specifically approved and stated by the

vehicle or component manufacturer.

11. Prior to returning the vehicle to service, make certain all components and systems are restored to their

proper operating condition.

Bendix Commercial Vehicle S ystems

901 Cleveland Street

Elyria, OH 44035

440-329-9000

Page 3 of 3

Loading...

Loading...