Page 1

Bendix® SR-5™ Trailer Spring Brake Valve

PRESSURE

PROTECTION

VALVE

™

VALVE

SR-5

IDENTIFICATION

HOLE

COVER*

1/4” NPT TRAILER

SUPPLY

1/4” NPT TRAILER

SERVICE

FIGURE 1 - BENDIX

®

SR-5™ TRAILER SPRING BRAKE VALVE (*SHOWN WITH OPTIONAL ANTI-COMPOUNDING COVER)

3/8” NPT

DELIVERY (4)

EXHAUST

SD-03-4516

1/4” NPT

SERVICE

RESERVOIR

(2)

1/2” OR 3/4” NPT

SPRING BRAKE

RESERVOIR

DESCRIPTION

The Bendix® SR-5™ valve is a reservoir-mounted trailer

valve that can control up to four spring brake actuators

during parking or emergency applications. It has the

following capabilities:

• Automatically applies trailer spring brakes in the event

of a breakaway or trailer supply line failure.

• Protects trailer reservoir(s) air pressure in the event of

a breakaway or trailer supply line failure.

• Allows no automatic trailer spring brake application

with air pressure loss in trailer reservoir(s).

• Allows the trailer spring brakes to be applied and released

repeatedly with a failed trailer reservoir(s):

• Optional anti-compounding-prevents an overriding

service brake signal while the trailer supply line is at

atmospheric pressure.

• Does not allow service system charging if a failure occurs

in the parking brake circuit.

PORTS

1 - 1/2" or 3/4" NPT Spring Brake Reservoir Mounting

(SPR BK RES)

1 - 1/4"-18 NPT Trailer Supply (TRL SUP)

1 - 1/4"-18 NPT Trailer Service (TRL SER)

4 - 3/8"-18 NPT Delivery (DEL)

2 - 1/4"-18 Service Reservoir (SERV RES)

1 - Exhaust (EXH)

The SR-5™ valve appears very similar to the Bendix® SR-2™

valve. Both valves consist of a die-cast aluminum body and

cover, pressure protection valve, and reservoir-mounting

nipple. However, Figure 1 notes the distinguishing

characteristic of the SR-5™ valve–a hole drilled into the

fl at surface between the pressure protection valve and

the body.

1

Page 2

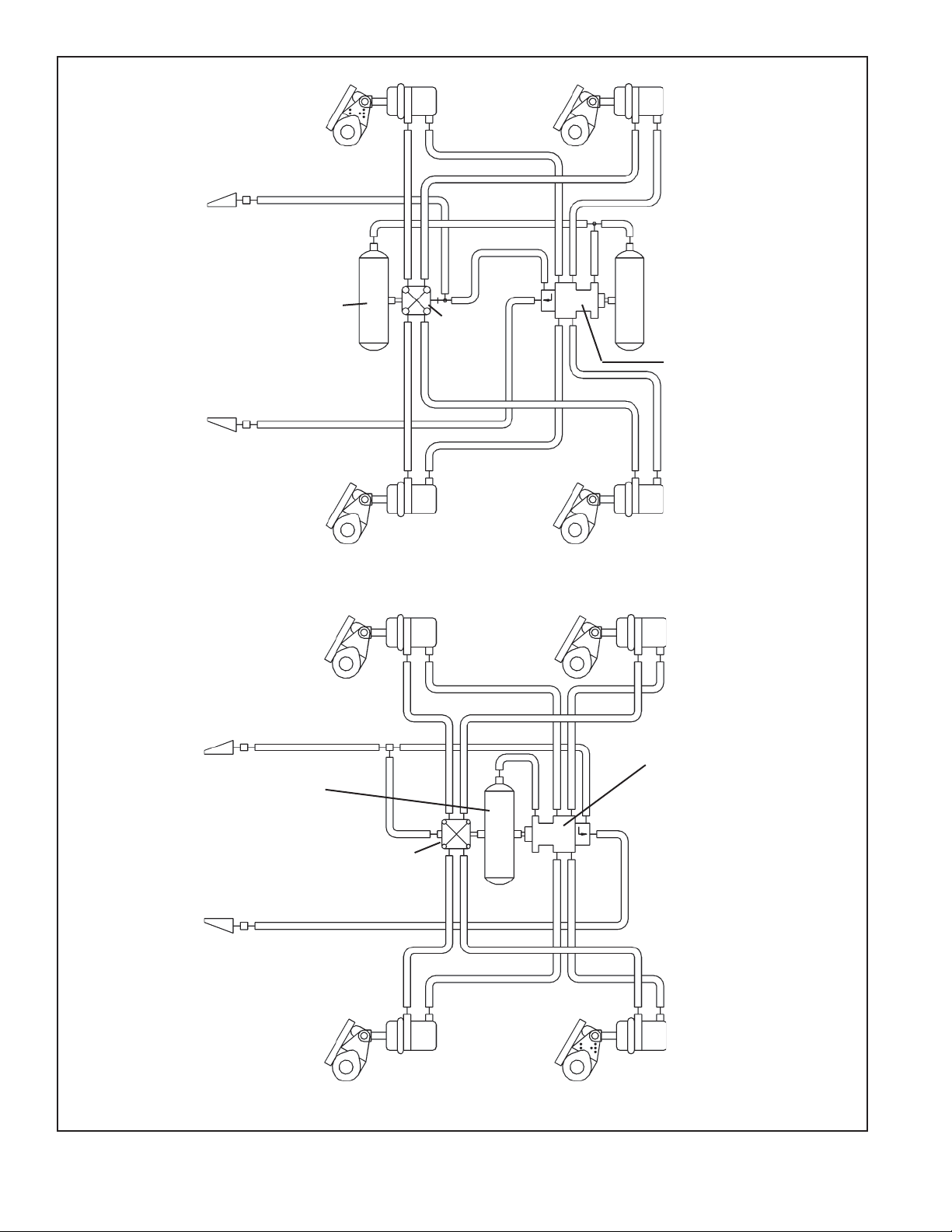

TRAILER SERVICE

SERVICE/SPRING BRAKE

RESERVOIR

TRAILER SUPPLY

SERVICE

RELAY

VALVE

TWO-TANK SYSTEM

SERVICE/

SPRING BRAKE

RESERVOIR

™

SR-5

VALVE

TRAILER SERVICE

™

SERVICE/SPRING BRAKE

RESERVOIR

SR-5

VALVE

SERVICE

RELAY

VALVE

TRAILER SUPPLY

ONE-TANK SYSTEM

FIGURE 2 - TYPICAL SYSTEM SCHEMATICS WITH BENDIX® SR-5™ TRAILER SPRING BRAKE VALVE

2

Page 3

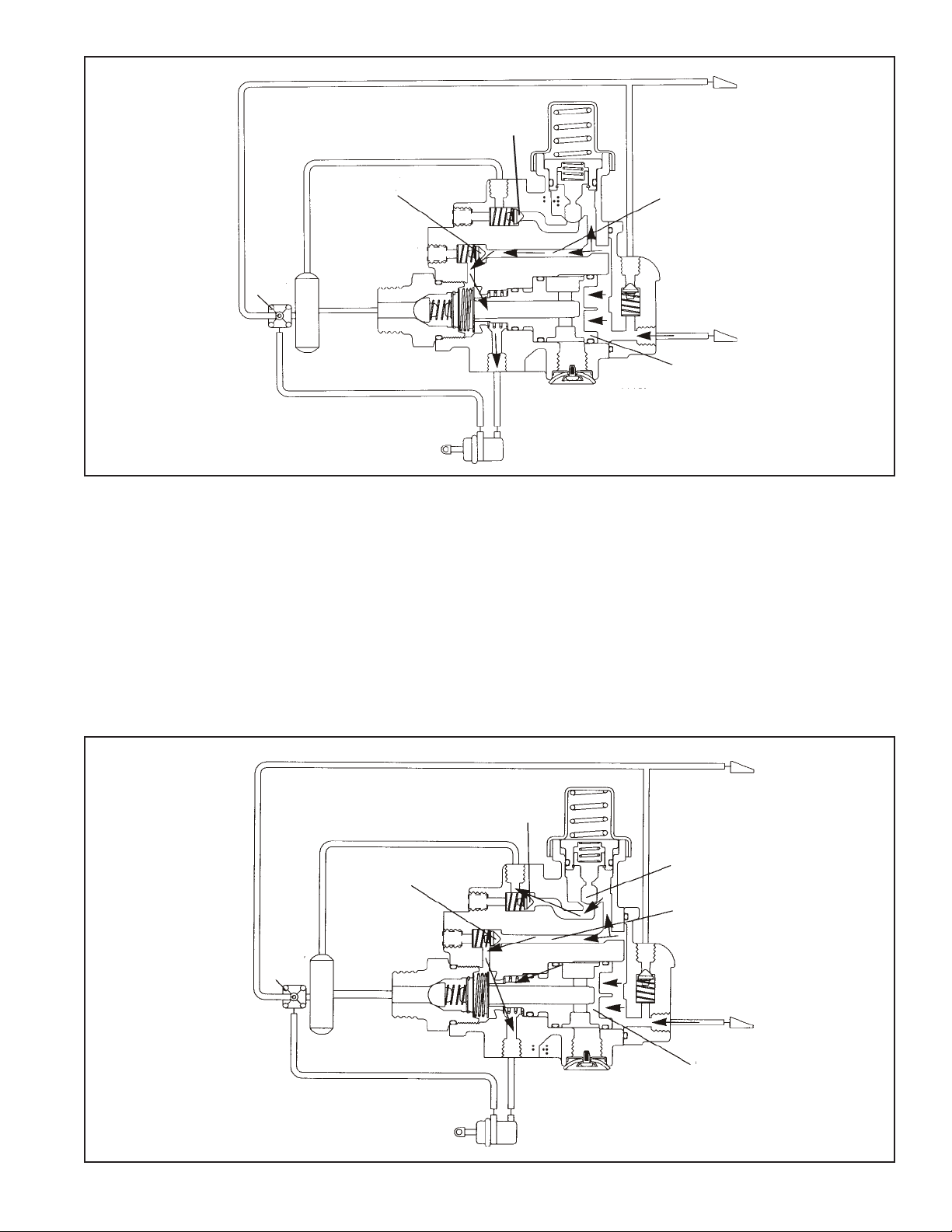

SERVICE

SPRING BRAKE

RELAY

VALVE

FIGURE 3 - CHARGING BELOW 70 PSI

TRAILER SERVICE RES.

CHECK

VALVE

B

SERVICE/

RESERVOIR

CONNECTION

CHECK

VALVE

D

DELIVERY

SPRING

BRAKE

CHAMBER

TRAILER SERVICE

PASSAGE A

TRAILER SUPPLY

CONTROL PISTON

EXHAUST

OPERATION

CHARGING BELOW 70 PSI (SEE FIGURE 3)

Air fl ows through the trailer supply line, enters the Bendix

SR-5™ valve trailer supply port, and moves the control

piston. The control piston contacts the control inlet/exhaust

valve, sealing off the piston’s exhaust passage.

As piston travel continues, the control inlet valve opens. Air

acting on the control piston also fl ows through passage A,

unseating check valve B, and fl owing past the open control

TRAILER SERVICE RES.

CHECK

VALVE B

SERVICE/

SPRING BRAKE

SERVICE

RELAY

VALVE

RESERVOIR

CONNECTION

®

inlet valve. This air fl ows into the spring brake cavities,

releasing the spring brakes.

CHARGING ABOVE 85 PSI (SEE FIGURE 4)

Air pressure acting on the control piston and fl owing

through passage A also acts on pressure protection valve

C. At approximately 85 psi, valve C opens. This allows

the air to fl ow past check valve D and charge the trailer

reservoir(s). The trailer braking system is now in the normal

run mode. Service braking occurs through the trailer

service relay valve.

TRAILER SERVICE

CHECK

VALVE D

PRESSURE

PROTECTION

VALVE C

PASSAGE A

FIGURE 4 - CHARGING ABOVE 85 PSI

DELIVERY

SPRING

BRAKE

CHAMBER

EXHAUST

CONTROL PISTON

3

Page 4

TRAILER SERVICE RES.

CHECK

VALVE D

CHECK

VALVE B

SERVICE/

SERVICE

RELAY

VALVE

FIGURE 5 - P ARK APPLICA TION

SPRING BRAKE

RESERVOIR

CONNECTION

PARK APPLICATION (SEE FIGURE 5)

To park the trailer, either the trailer air supply valve or the

system park control valve (in the tractor) is actuated. This

vents the trailer supply line. The control piston, no longer

under supply pressure, is moved by air pressure on its

delivery side. This allows the control piston to move to the

exhaust position. The control inlet valve closes and the

exhaust valve opens, allowing air from the spring brakes

to exhaust through the passage in the control piston and

apply the brakes. Check valves B and D close, preventing

trailer reservoir air pressure loss through passage A.

TRAILER SERVICE

PRESSURE

PROTECTION

VALVE C

PASSAGE A

TRAILER SUPPLY

CONTROL PISTON

EXHAUST

SPRING

BRAKE

CHAMBER

PARK RELEASE WITH TRAILER CHARGED

(SEE FIGURE 6)

To release a park application with the trailer charged, the

trailer supply valve (in the cab) is actuated. Air fl ows through

the trailer supply line and enters the Bendix® SR-5™ valve

trailer supply port. With a minimum of 55 psi on the control

piston, the piston will move, sealing its exhaust passage.

As piston travel continues, the inlet valve opens. Reservoir

air (approx. 1 10 psi) then fl ows through check valve F , past

the open inlet, and out to the spring brake chambers to

release the brakes.

TRAILER SERVICE RES.

CHECK

SERVICE/

SPRING

SERVICE

RELAY

VALVE

FIGURE 6 - PARK RELEASE WITH TRAILER CHARGED

4

BRAKE

RESERVOIR

CONNECTION

VALVE F

SPRING

BRAKE

CHAMBER

TRAILER SERVICE

CHECK

VALVE D

CHECK

VALVE B

TRAILER SUPPLY

CONTROL PISTON

EXHAUST

PASSAGE

Page 5

TRAILER SERVICE

CHECK

VALVE F

SERVICE/

SPRING BRAKE

SERVICE

RELAY

VALVE

FIGURE 7 - OPTIONAL ANTI-COMPOUNDING

RESERVOIR

CONNECTION

Note that pressure protection valve C will open if trailer

supply air is greater than 70 psi. But check valves B and

D will not open unless release pressure from the tractor

exceeds trailer reservoir pressure.

ANTI-COMPOUNDING (SEE FIGURE 7)

ANTI-COMPOUNDING

LINE

CHECK

VALVE E

TRAILER SUPPLY

EXHAUST

DELIVERY

SPRING BRAKE

CHAMBER

The Bendix® SR-5™ valve has an optional anti-compounding

feature. (See Figure 7.) A single check valve in the SR-5™

valve cover prevents brake compounding (simultaneous

spring brake and service brake application), which creates

extra load on foundation brake components.

If a trailer service application is being made and at the

same instant a park application is made, air in the service

line fl ows through single check valve E in the SR-5™ valve

cover. Pressure is maintained on the control piston, while

air also fl ows out the trailer supply line and exhausts

through the tractor protection control. Future compounding

is prevented by the closed tractor protection valve.

5

Page 6

TRAILER SERVICE

TRAILER SERVICE RESERVOIR

CHECK

VALVE B

SERVICE/

SERVICE

RELAY

VALVE

FIGURE 8 - FAILED TRAILER RESERVOIR

SPRING BRAKE

RESERVOIR

CONNECTION

CHAMBER

FAILED TRAILER RESERVOIR (SEE FIGURE 8)

Should trailer reservoir pressure be lost, trailer service

braking is no longer available. Pressure protection valve

C will close at approximately 70 psi (minimum), retaining

air pressure in the trailer supply line.

The air held by the pressure protection valve will continue to

hold the control piston’s inlet valve open, supplying air to the

spring brakes. Thus, no automatic spring brake application

occurs. However, trailer supply line air can be used to apply

and release the trailer spring brakes repeatedly.

PRESSURE

PROTECTION

VALVE C

TRAILER SUPPLY

EXHAUST

SPRING

BRAKE

SERVICE CHECKS

1. Remove any accumulated contaminants. Visually

inspect the valve’s exterior for excessive corrosion

or physical damage. Repair/replace the valve as

necessary.

2. Inspect all air lines connected to the valve for signs of

wear or physical damage. Repair/replace as necessary .

3. Test air line fi ttings for excessive leakage and tighten

or replace as necessary.

OPERATIONAL AND LEAKAGE TESTS

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions, as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum, the

Bendix® SR-5™ valve should be inspected every 6 months

or 1500 operating hours, whichever comes fi rst, for proper

operation. Should the SR-5™ valve not meet the elements

of the operational tests noted in this document, further

investigation and service of the valve may be required.

6

Check the tractor dash gauge against a gauge known to

be accurate before performing these tests. Connect the

tractor air lines to the trailer on which the SR-5™ valve is to

be tested. Block all wheels or hold the vehicles by means

other than air brakes.

1. Install a gauge in the trailer reservoir(s). Build tractor

and trailer to full system pressure by placing the

park control valve and the trailer air supply valve in

the charge position. As system pressure reaches

approximately 75-95 psi, the trailer spring brakes

should also build up to approximately 75- 95 psi before

the reservoir(s) begin to charge.

2. When full system pressure is reached, and the spring

brakes are fully released, apply a soap solution to the

SR-5™ valve exhaust port and the vent. A 1" bubble in

5 seconds is permissible.

Page 7

3. Place the trailer air supply valve in the exhaust position.

The spring brakes should apply . Disconnect the trailer

supply line and apply a soap solution to check for leaks.

A 1" bubble in 5 seconds is permissible.

4. Reconnect the trailer supply hose coupling and

recharge the trailer system. The spring brakes should

release. Shut off the engine. Open the trailer reservoir

drain cock. The tractor air system should bleed down to

approximately 70 psi. The trailer spring brakes should

remain released. After the system is stabilized, leakage

at the open drain cock should not exceed a 1" bubble

in 5 seconds.

5. If the Bendix® SR-5™ valve does not function as

described; or if leakage is excessive, repair the valve,

or replace with a genuine Bendix service replacement

valve.

REMOVAL

1. Identify and mark or label all air lines and their

connections on the SR-5™ valve. Then disconnect the

air lines.

2. Remove the SR-5™ valve from the reservoir.

INSTALLATION

1. Install the SR-5™ valve on the reservoir.

2. Reconnect all air lines to the valve using the

identifi cation made in REMOVAL step 1.

3. Perform OPERA TIONAL AND LEAKAGE TESTS before

placing the vehicle back in service.

DISASSEMBLY

The following procedure is for reference only. Always

have the appropriate maintenance kit on hand, and use its

instructions in lieu of those presented here. Refer to Figure

9 throughout the procedure.

7

Page 8

6

7

11

9

18

17

PIPE PLUG

12

10

4

5

VALVE BODY

25

24

8

23

2

1

FIGURE 9 - EXPLODED VIEW

16

15

18

17

3

14

PIPE PLUG

13

19

20

21

22

8

Page 9

1. Remove the four screws (1) that secure the spring

retainer (2) to the valve body. Note that the retainer is

spring-loaded. Remove the screws while holding the

retainer against its spring load. Then slowly remove the

retainer.

2. Remove spring (3) and piston assembly (4).

3. Remove piston o-ring (5). Do not remove the retaining

ring and stem from the piston. The piston is serviced

as an assembly.

4. Note and mark the position of control piston cover (7).

Then remove the four screws (6) that secure the cover

to the body.

5. Remove cover (7) and sealing ring (8), control piston

(9), and spring (10).

6. Remove o-rings (11 & 12) from piston assembly.

7. Remove reservoir fi tting (13) and o-ring (14).

8. Remove spring (15) and inlet/exhaust valve (16).

9. Remove the pipe plugs that retain the three single check

valves. Two check valves are in the body, and one is

in the cover (7).

10. Remove check valve springs (17) and rubber check

valves (18).

11. With a pair of I.D. snap ring pliers, remove the snap

ring (19) in the end of the reservoir fi tting check valve

assembly. Remove spring seat (20), spring (21), and

check valve (22).

12. Remove screw (23), washer (24), and diaphragm (25)

from the exhaust port.

CLEANING AND INSPECTION

1. Inspect all parts for excessive wear or deterioration.

Inspect valve seats for nicks or burrs. Check the springs

for cracks or corrosion.

2. Inspect the bores of the valve housing for deep scuffi ng

or gouges.

Replace all non-metallic parts and any part not found to be

serviceable during inspection, using only genuine Bendix

replacement parts.

ASSEMBLY

Before assembling the Bendix

o-rings, o-ring grooves, piston bores, and metal-to-metal

moving surfaces with Bendix silicone lubricant BW-650-M

piece number 291126.

®

SR-5™ valve, lubricate all

1. Twist the springs (17) on each of the check valves (18).

Drop the assemblies into their respective bores in the

valve body and install the pipe plugs. Torque the plugs

to 140-170 inch pounds.

2. Place reservoir fi tting (13) upright, pipe threads down.

Drop check valve (22) into place. Install check valve

spring (21), spring seat (20), and snap ring (19). Install

o-ring (14) into fi tting.

3. Install inlet/exhaust valve (16) into valve body. NOTE:

The side with four protruding ears rests against the seat

in the body.

4. Place spring (15) in position on the inlet/exhaust valve.

Make sure the spring rests evenly on the four ears of

the inlet/exhaust valve and the rubber protrusion on

the valve fi ts into the spring’s inner diameter.

5. Properly align the inlet/exhaust valve springboard in

the recess at the end of the reservoir port fi tting (13).

Install the fi tting into the valve body . Torque to 200-300

inch pounds.

6. Install o-rings (1 1 & 12) into their respective grooves in

the control piston (9).

7. Drop and position the spring (10) into the valve body.

8. Make sure all parts are properly aligned, and install the

control piston (9) into the valve body.

9. Install sealing ring (8) in the cover (7), and install

cover onto valve body, using the identifi cation made

in DISASSEMBL Y step 4. Torque screws (6) to 40-60

inch pounds.

10. Install o-ring (5) in its groove in the pressure protection

piston (4). Install the piston assembly into the valve

body.

1 1. Position the spring (3) and spring retainer (2) on top of

the pressure protection piston assembly , and secure it

with the four screws (1). Torque to 20-30 inch pounds.

12. Install diaphragm (25), washer (24) and screw (23) into

the exhaust port. Torque screw to 15-25 inch pounds.

NOTE: BEFORE PLACING THE VEHICLE BACK INTO

SERVICE, PERFORM “OPERATIONAL AND

LEAKAGE TESTS,” LISTED IN THIS MANUAL.

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to not allow

the sealant to get into the valve itself. Apply the

sealant beginning with the second thread back

from the end.

BW1680 © 2011 Bendix Commercial Vehicle Systems LLC. All rights reserved. 4/2011 Printed in U.S.A.

9

Loading...

Loading...