Page 1

®

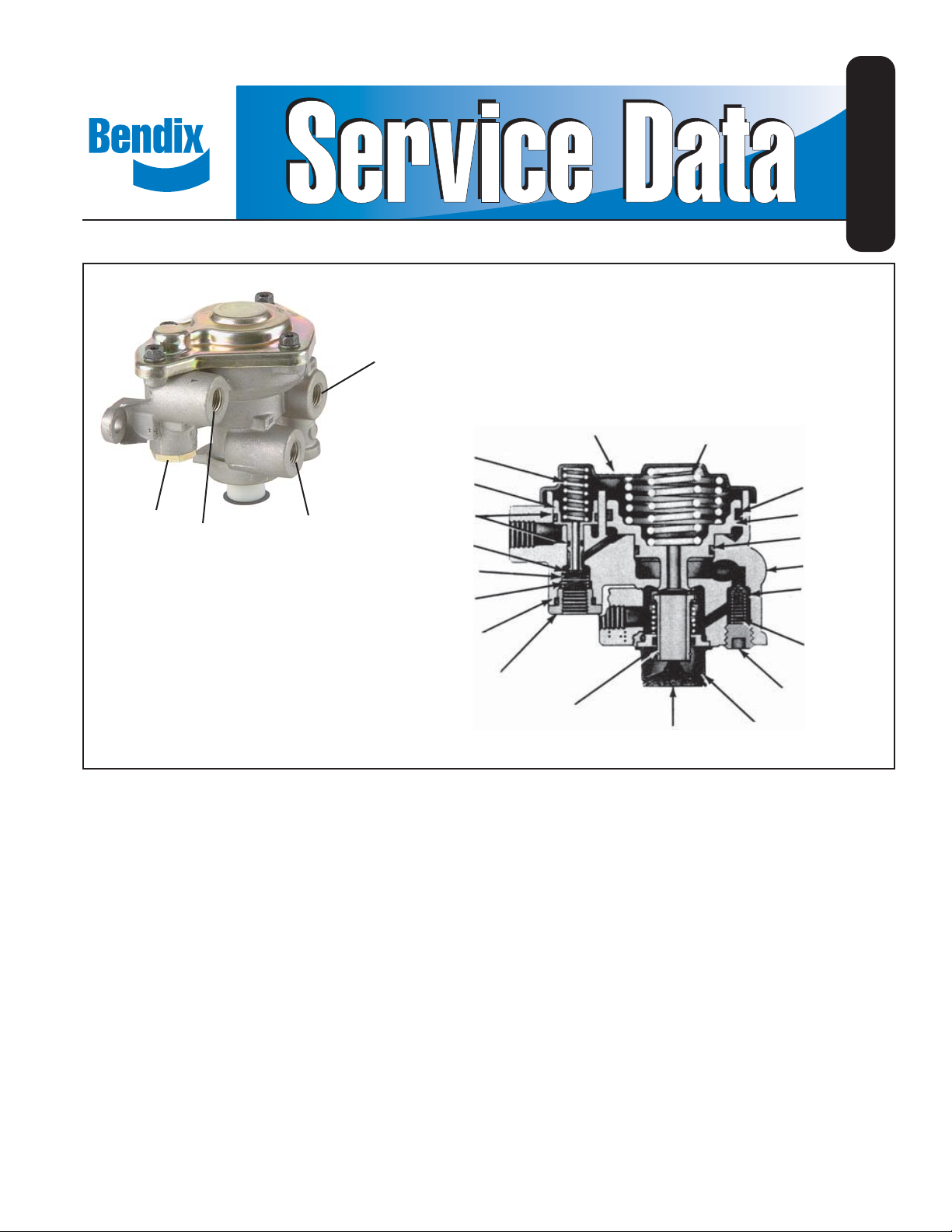

Bendix® SR-1™ Spring Brake Valve

1/4 P.T.

DELIVERY

SD-03-4508

PISTON SPRING

(14)

PISTON (15)

1/4 P.T.

CONTROL

1/4 P.T.

RES. #1

FIGURE 1 - BENDIX

1/4 P.T.

SUPPLY

®

SR-1™ VALVE EXTERIOR AND SECTIONAL VIEW

PISTON O-RINGS

(16)

VALVE (12)

VALVE SPRING (11)

VALVE STOP (10)

O-RING (9)

CAP NUT (8)

DESCRIPTION:

The Bendix® SR-1™ spring brake valve is used in dual

or “split” air brake systems equipped with spring brake

actuators. The function of the SR-1 valve is to supply a

specifi c, limited hold-off pressure to the spring brakes, and

in the event of the loss of No. 1 service air pressure, to

modulate the spring brakes through the use of the service

brake valve.

The valve has four identifi ed 1/4" N.P.T.F. ports and a

diaphragm protected exhaust port. Two 5/16" diameter

holes are provided in the integral mounting bracket of the

valve body. The SR-1 valve must be mounted with the

exhaust port down toward the road surface.

COVER (13)

INLET &

EXHAUST

VALVE (7)

PISTON SPRINGS

DIAPHRAGM

(6)

(14)

O-RING

(LARGE)

(18)

PISTON (17)

O-RING

(SMALL) (19)

BODY

CHECK

VALVE (4)

CHECK

VALVE SPRING (2)

PIPE PLUG

(1)

EXHAUST

COVER (5)

OPERATION - INITIAL AIR SYSTEM CHARGE

Air fl owing from the No. 1 reservoir only enters the reservoir

port of the SR-1 valve. This air remains under piston A as

system pressure builds. With No. 1 reservoir pressure

below approximately 55 P.S.I. the spring above piston A

forces it into contact with inlet and exhaust valve A causing

the exhaust to seal and the inlet to open. Refer to Figure 3.

With air system pressure above approximately 55 P.S.I. in

No. 1 & 2 service reservoirs, piston A has moved against

the force of the spring above it, allowing the inlet of valve A

to close and opening the hollow exhaust passage through

piston A. Refer to Figure 4.

1

Page 2

BRAKE

CHAMBER

BRAKE

VALVE

PARK

CONTROL

VALVE

SLACK

ADJUSTER

SPRING

BRAKE

QUICK

RELEASE

VALVE

MODULATOR

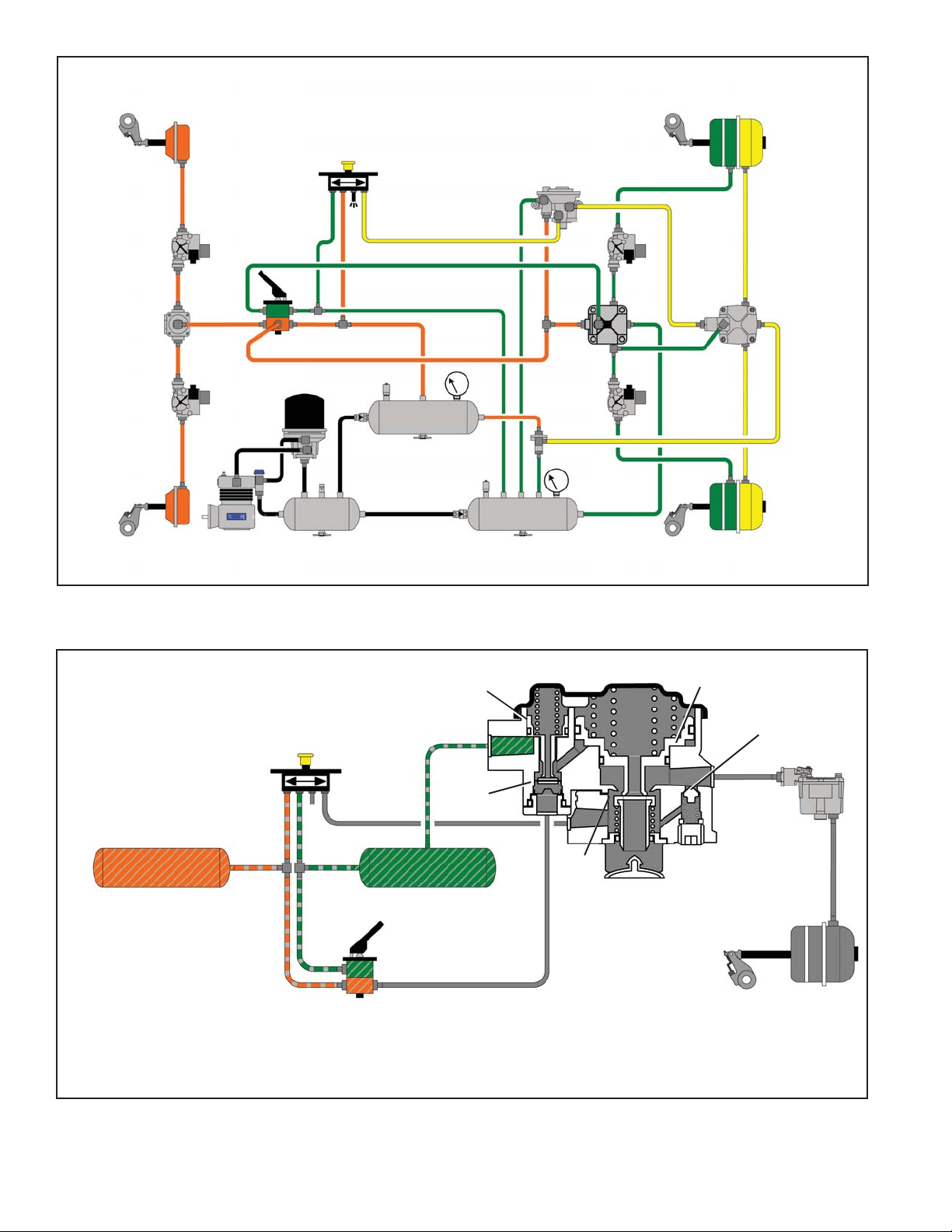

FIGURE 2 - SYSTEM SCHEMATIC

PARK

CONTROL

VALVE

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

SUPPLY

DOUBLE

CHECK VALVE

#2 SERVICE

RESERVOIR

#1 SERVICE

RESERVOIR

PISTON A

INLET &

EXHAUST A

#1 SERVICE

RESERVOIR

™

R-8

VALVE

INLET

&

EXHAUST

B

EXHAUST

®

R-14

RELAY

VALVE

PISTON B

CHECK VALVE

®

R-14

RELAY

VALVE

BRAKE

VALVE

FIGURE 3 - RESERVOIRS CHARGING - BELOW 55 P.S.I.

2

SPRING

BRAKE

Page 3

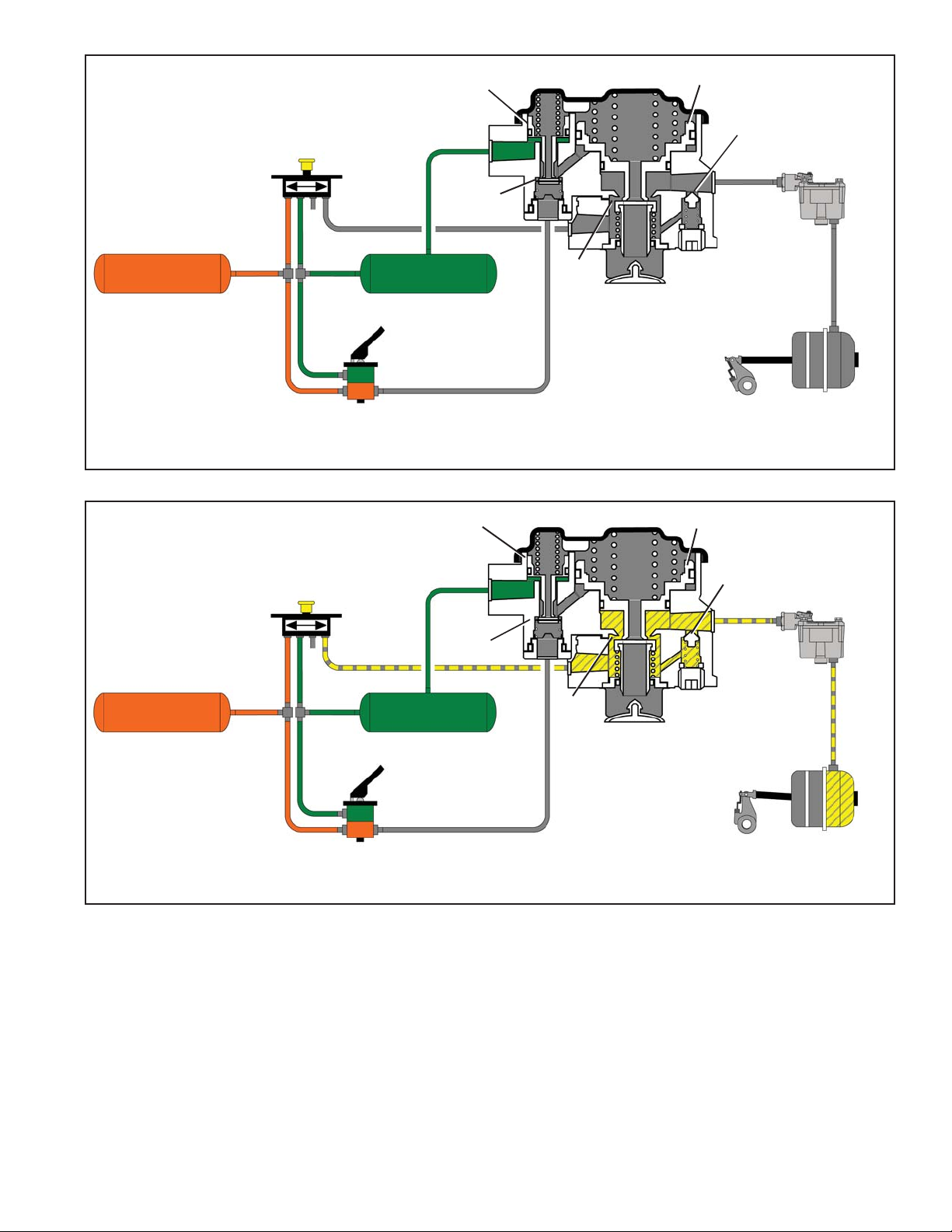

PARK

CONTROL

VALVE

PISTON A

INLET &

EXHAUST A

PISTON B

CHECK VALVE

R-14

RELAY

VALVE

®

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

FIGURE 4 - RESERVOIRS CHARGING - ABOVE 55 P.S.I.

PARK

CONTROL

VALVE

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

#1 SERVICE

RESERVOIR

EXHAUST A

#1 SERVICE

RESERVOIR

PISTON A

INLET &

INLET

&

EXHAUST

B

INLET

&

EXHAUST

B

EXHAUST

EXHAUST

PISTON B

CHECK VALVE

R-14

RELAY

VALVE

SPRING

BRAKE

®

BRAKE

VALVE

FIGURE 5 - PARKING BRAKE SUPPLY DELIVERY LESS THAN 95 P.S.I.

OPERATION - CHARGING SPRING BRAKE

ACTUATORS LESS THAN 95 PSI

With the air brake system charged and the dash valve

pushed in, air enters the Bendix

Air entering the supply port fl ows past inlet and exhaust

valve B to the underside of piston B and out the delivery

port of the SR-1 valve to the Bendix® R-14® parking relay

valve then to the emergency air connection at the spring

brake actuator. Note that the springs above piston B force

it into contact with inlet and exhaust valve B. In the position

®

SR-1™ valve supply port.

OPERATION - CHARGING SPRING BRAKE

ACTUATORS ABOVE 95 PSI

When air pressure beneath piston B is approximately

95* P.S.I., piston B rises slightly, against the force of the

springs above it, allowing the inlet of valve B to close. The

exhaust through valve B remains closed. The closing of

the inlet portion of valve B retains approximately 95* P.S.I.

in the hold- off cavity of the spring brake actuators while

allowing full air system pressure to build elsewhere. Refer

to Figures 5 and 6.

shown the exhaust is closed and the inlet is open.

SPRING

BRAKE

3

Page 4

PISTON A

PISTON B

PARK

CONTROL

VALVE

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

FIGURE 6 - PARKING BRAKE SUPPLY DELIVERY EQUAL TO OR GREATER THAN 95 P.S.I.

PARK

CONTROL

VALVE

#1 SERVICE

RESERVOIR

BRAKE

VALVE

INLET &

EXHAUST A

PISTON A

INLET &

EXHAUST A

INLET

&

EXHAUST

B

EXHAUST

PISTON B

CHECK VALVE

®

R-14

RELAY

VALVE

SPRING

BRAKE

CHECK VALVE

®

R-14

RELAY

VALVE

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

FIGURE 7 - NORMAL SERVICE APPLICATION

#1 SERVICE

RESERVOIR

BRAKE

VALVE

*Note: Other spring brake hold-off pressures are

supplied according to the vehicle manufacturer’s

specifi cations. 95 P.S.I. was chosen only for the

purpose of explanation.

OPERATION - NORMAL SERVICE RESERVOIRS

1 & 2 CHARGED

When a service application is made by actuating the dual

brake valve, air from the No. 2 delivery circuit is delivered

from the brake valve to the control port, and is stopped at

the closed inlet of valve A. No movement of the internal

components of the Bendix

Air from the No. 1 delivery circuit of the dual brake valve

actuates the service section of the spring brake actuators.

Refer to Figure 7.

®

SR-1™ valve takes place.

INLET

&

EXHAUST

B

EXHAUST

SPRING

BRAKE

OPERA TION - SERVICE APPLICA TION WITH LOSS

OF NO. 2 RESERVOIR PRESSURE

In the event air pressure is lost in the No. 2 reservoir,

the No. 1 reservoir and the parking control valve will be

protected via the double and single check valves in the

air system. A service application of the foot brake valve

in this situation results in little or no air being delivered

from the No. 2 delivery circuit to the control port of the

SR-1 valve. No movement of the SR-1 valve internal

components takes place. Braking is assured because the

No. 1 service reservoir is protected by a check valve and

the No. 1 delivery circuit of the dual brake valve will apply

the service section of the spring brake actuators.

4

Page 5

PARK

CONTROL

VALVE

PISTON A

INLET &

EXHAUST A

PISTON B

CHECK VALVE

®

R-14

RELAY

VALVE

#2 SERVICE

RESERVOIR

FIGURE 8 - SERVICE APPLICATION - LOSS OF #2 RESERVOIR

#2 SERVICE

RESERVOIR

DOUBLE

CHECK

VALVE

PARK

CONTROL

VALVE

DOUBLE

CHECK

VALVE

#1 SERVICE

RESERVOIR

PISTON A

INLET &

EXHAUST A

#1 SERVICE

RESERVOIR

INLET

&

EXHAUST

B

INLET

&

EXHAUST

B

EXHAUST

EXHAUST

PISTON B

CHECK VALVE

R-14

RELAY

VALVE

SPRING

BRAKE

®

FIGURE 9 - SERVICE APPLICATION - LOSS OF #1 RESERVOIR

OPERA TION - SERVICE APPLICA TION WITH LOSS

OF NO. 1 RESERVOIR PRESSURE

If air pressure in the No. 1 service reservoir falls below

approximately 55 P.S.I., the pressure beneath piston A is

insuffi cient to resist the spring force above and piston A moves

into contact with valve A. Initial contact between piston A

and valve A closes the hollow exhaust passage of piston A.

Continued movement of the piston opens the inlet of valve A.

The No. 2 service reservoir and the park control valve are

protected from pressure loss by the action of the double

check valve.

SPRING

BRAKE

When a service application of the dual brake valve is

made, air delivered from the No. 2 delivery circuit of the

dual brake valve enters the Bendix

®

SR-1™ valve control

port. Air entering the control port moves past the inlet of

valve A and is conducted through a passage in the body to

the underside of piston B. The air pressure moves piston

B up, opening the exhaust of valve B. When the exhaust

of valve B opens, air pressure trapped in the emergency

section of the spring brake actuator is allowed to escape,

resulting in an emergency brake application. The air

pressure released from the spring brake is proportional

to the air pressure delivered to the control port of the

SR-1 valve by the No. 2 delivery of the dual brake valve.

5

Page 6

PISTON A

PISTON B

PARK

CONTROL

VALVE

INLET &

EXHAUST A

#2 SERVICE

RESERVOIR

FIGURE 10 - P ARK APPLICA TION

DOUBLE

CHECK

VALVE

#1 SERVICE

RESERVOIR

OPERATION - PARKING

If both systems #1 and #2 are intact and the park control

valve is placed in the “park” or exhaust position, the Bendix

SR-1™ valve supply of air pressure and the air pressure in

the spring brake actuator cavities is exhausted. The single

check valve in the SR-1 valve assists this exhaust of air

pressure by allowing the air below piston B to fl ow back

out the open exhaust of the park control valve. When air

pressure below piston B has dropped suffi ciently , piston

B moves down, opening the inlet of valve B and providing

an additional exhaust passage for air exhausting through

the SR-1 valve from the spring brakes.

®

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions, as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum,

the SR-1 valve should be inspected every 6 months or

1500 operating hours, whichever comes fi rst, for proper

operation. Should the SR-1 valve not meet the elements

of the operational tests noted in this document, further

investigation and service of the valve may be required.

CHECK VALVE

®

R-14

RELAY

VALVE

INLET

&

EXHAUST

EXHAUST

B

SPRING

BRAKE

1. Place parking control valve in the “park” position.

Observe that the spring brake actuators apply promptly .

In the delivery port of the valve install a test gauge

known to be accurate. Place the parking control valve

in the “release” position. Observe that the spring brake

actuators release fully.

2. With the parking control valve in the “release” position,

note the gauge pressure reading. (Check the vehicle

manual for the correct spring brake actuator hold-off

pressure.) If the pressure reading is incorrect, the valve

must be repaired or replaced.

3. Place the parking control valve in the “park” position,

the gauge reading should drop to zero promptly . A slow

release of pressure may indicate faulty operation of the

single check valve (within the modulating valve.)

4. Place the parking control valve in the “release” position.

Locate the number one service reservoir and drain it

completely.

Apply the foot brake valve several times and note that

the pressure reading on the gauge decreases each

time the foot brake valve is applied. After several

applications, pressure on the gauge will drop to the

point where release of the spring brake actuators will

no longer occur.

SERVICE CHECKS

OPERATING CHECKS

Block all wheels and hold by means other than vehicle

brakes. Charge air brake system to governor cut-out

pressure.

6

Page 7

LEAKAGE CHECK

With the air system fully charged and the parking control

valve in the “release” position, coat the exhaust port and

around the valve corner with a soap solution. Slight leakage

is permitted.

®

If the Bendix

as described previously, or leakage is excessive, it is

recommended that it be repaired or replaced with a genuine

Bendix service replacement valve.

Note: A maintenance kit for the SR-1 spring brake valve is

available from any authorized Bendix outlet. All parts

necessary for minor repair are included.

SR-1™ spring brake valve does not function

REMOVAL

1. Prior to removing the SR-1 valve, apply the parking

brakes and drain all the vehicle reservoirs.

2. Identify all air lines before disconnecting.

3. Remove the two mounting bolts from the SR-1 valve

and remove the valve.

DISASSEMBLY (REFER TO FIGURE 1)

1. Remove the socket head pipe plug (1).

2. Remove the check valve spring (2) and the check valve

(4).

3. Remove the two phillips head screws and remove the

exhaust cover (5).

4. Separate the exhaust diaphragm (6) from the cover.

5. Remove the inlet and exhaust valve assembly (7).

6. Remove the inlet and exhaust valve cap nut (8) and

separate the cap nut o-ring (9).

7. Remove the valve stop (10) valve spring (11) and inlet

and exhaust valve (12).

8. Remove the four phillips head screws and lockwashers

that secure the cover to the body . Caution: the cover is

under a spring load, and should be held while removing

the screws.

9. Remove the cover (13) and the three piston springs

(14). Note: Some SR-1 valve piece numbers have one

large piston spring.

10. Remove the small piston (15) and the small and large

o-rings (16).

11. Remove the large piston (17). Remove piston o-rings

(18) & (19).

CLEANING & INSPECTION

1. Inspect all parts for excessive wear or deterioration.

2. Inspect the valve seats for nicks or burrs.

3. Check the springs for cracks or corrosion.

4. Replace all rubber parts and any part not found to be

serviceable during inspection. Use only genuine Bendix

replacement parts.

ASSEMBLY (REFER TO FIGURE 2)

Prior to assembly of the SR-1 spring brake valve, lubricate

all o-rings, o-ring grooves, and piston bores with Bendix

silicone lubricant BW-650-M piece number 291126.

Note: All torques specifi ed in this manual are assembly

torques and can be expected to fall off, after

assembly is accomplished. Do not retorque after

initial assembly torques fall.

1. Assemble the check valve (4), and valve spring (2) and

install in body.

2. Apply pipe sealant to the socket head pipe plug (1)

and install in the body . T ighten to 130-170 inch pounds

torque.

3. Install inlet and exhaust valve assembly (7) in valve

body.

4. Secure the exhaust cover (5) with two 10-24 phillips

head screws and lockwashers. Tighten to 20-30 inch

pounds torque.

5. Install exhaust diaphragm (6) into the exhaust cover.

6. Place inlet exhaust valve (12) in the body. Install the

valve spring (11) and valve stop (10).

7. Install o-ring (9) on cap nut and install cap nut (8) in

body. Tighten to 100-125 inch pounds torque.

8. Install the small and large o-rings (16) on the small

diameter piston (15) and install piston in the body.

9. Install large o-ring (18) and small o-ring (19) on the

large diameter piston and install piston in the body.

10. Install the piston springs (14) in their respective pistons.

11. Secure the cover to body using four 1/4"-20 phillips

head screws and lockwashers. Tighten to 50-80 inch

pounds torque.

TESTING THE REBUILT BENDIX® SR-1™ SPRING

BRAKE VALVE

Test the rebuilt SR-1 spring brake valve by performing the

operation and leakage test outlined in the “Service Checks”

section of this manual.

7

Page 8

BW1589 © 2012 Bendix Commercial Vehicle Systems Company LLC, a member of the Knorr-Bremse Group • 5/2012 • All Rights Reserved

8

Loading...

Loading...