Page 1

®

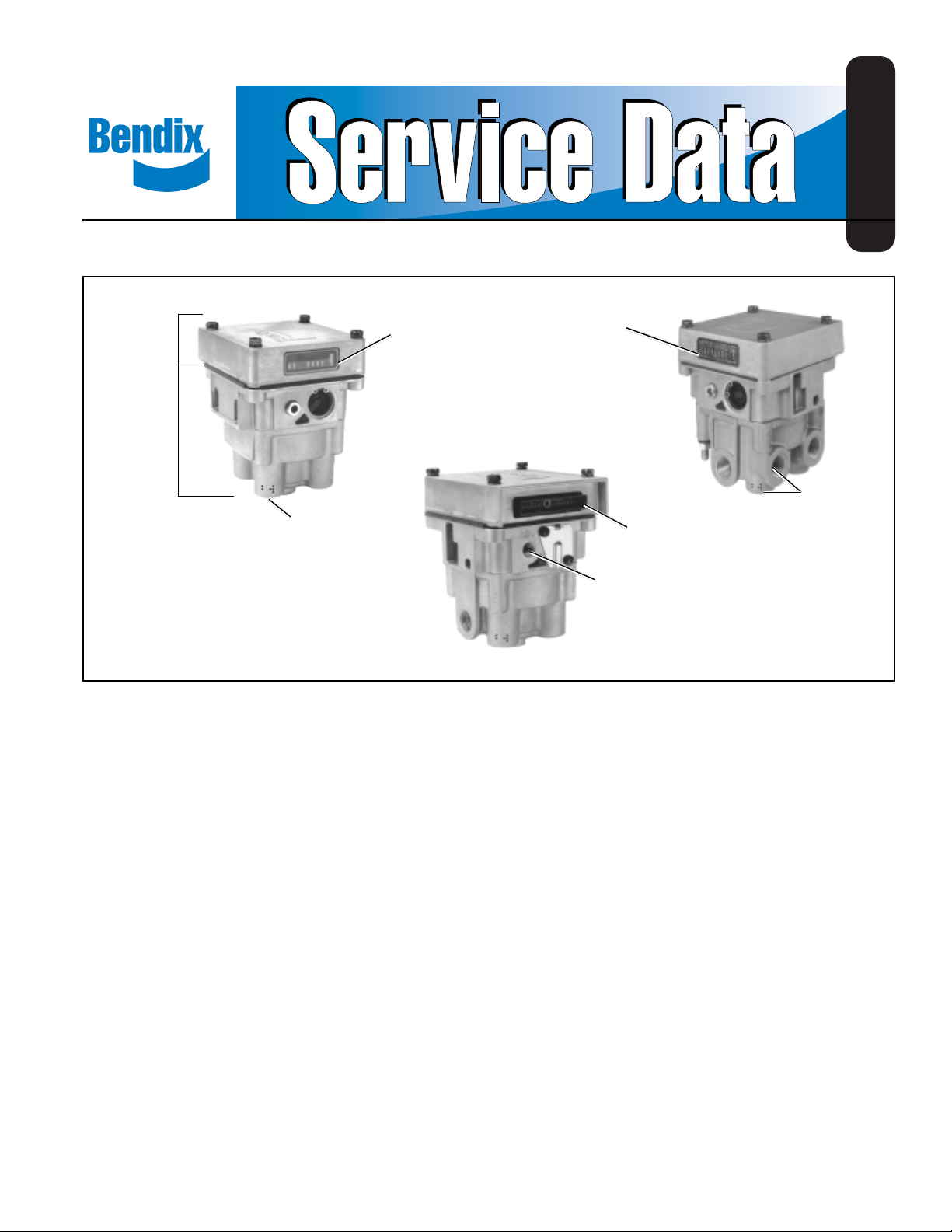

Bendix® MC-12™ Modulator Controller Assembly

SD-13-4762

™

EC-12

CONTROLLER

™

M-12

MODULATOR

DELIVERY

PORTS

(4 VERTICAL)

FIGURE 1 - MC-12™ MODULATOR CONTROLLER ASSY.

DIAGNOSTIC

DISPLAY

DESCRIPTION

The Bendix® MC-12™ modulator trailer antilock system is

designed to improve vehicle stability by reducing wheel lock

up during aggressive braking. Like Bendix's tractor antilock,

the trailer system can provide single or tandem axle control.

The main component is nipple mounted to a reservoir, so

the system requires no special trailer modifications.

The trailer antilock system consists of the following: MC-12

modulator/controller, WS-20™ wheel speed sensors,

electrical connectors and wiring. The MC-12™ modulator is

the main component. It houses the EC-12™ electronic

controller and the M-12™ modulator, which cont ains solenoids

and a standard relay valve.

The EC-12™ controller houses the electronics that regulate

the trailer antilock system and also incorporates a diagnostic

display window and a 14 pin connector.

DIAGNOSTIC

DISPLAY

DELIVERY

14 PIN

CONNECTOR

CONTROL

PORT

(2 VERTICAL

HORIZONTAL)

wheel end send wheel speed information to the EC-12

controller through the 14 pin connector. The sensors are

actually AC. generators. They house magnets, which create

a magnetic field. When the field is interrupted by an irregular

surface, such as a tone ring, AC. volt age is produced. The

frequency of voltage increases or decreases as wheel speed

increases or decreases.

During normal, non antilock operation, the M-12™ modulator's

inlet solenoid is open, and the exhaust solenoid is closed.

™

In this condition, the M-12™ modulator functions as a regular

R-12™ relay valve. It receives a control signal from the foot

valve, which passes through the open inlet solenoid and

causes the brakes to apply in proportion to the amount of

control pressure.

If wheel lock up is impending, the EC-12™ controller

commands the solenoids to modulate brake chamber

pressure on the axle(s) in which the system is installed.

PORTS

2

™

The EC-12™ controller mounts to the M-12™ modulator with

four bolts, and it is internally connected to the solenoids by

a four pin connector. The solenoids are the interface between

the EC-12™ controller electronic signals and the

pneumatically operated modulator. Sensors mounted at the

The MC-12™ modulator/controller receives its power from

the vehicle's stop light circuit (pin 4 on the standard seven

pin connector—red). The power enters the EC-12™ controller

at pin A and (optionally) pin B from the auxiliary terminal

(blue wire) of the trailer’s 7 pin connector.

1

Page 2

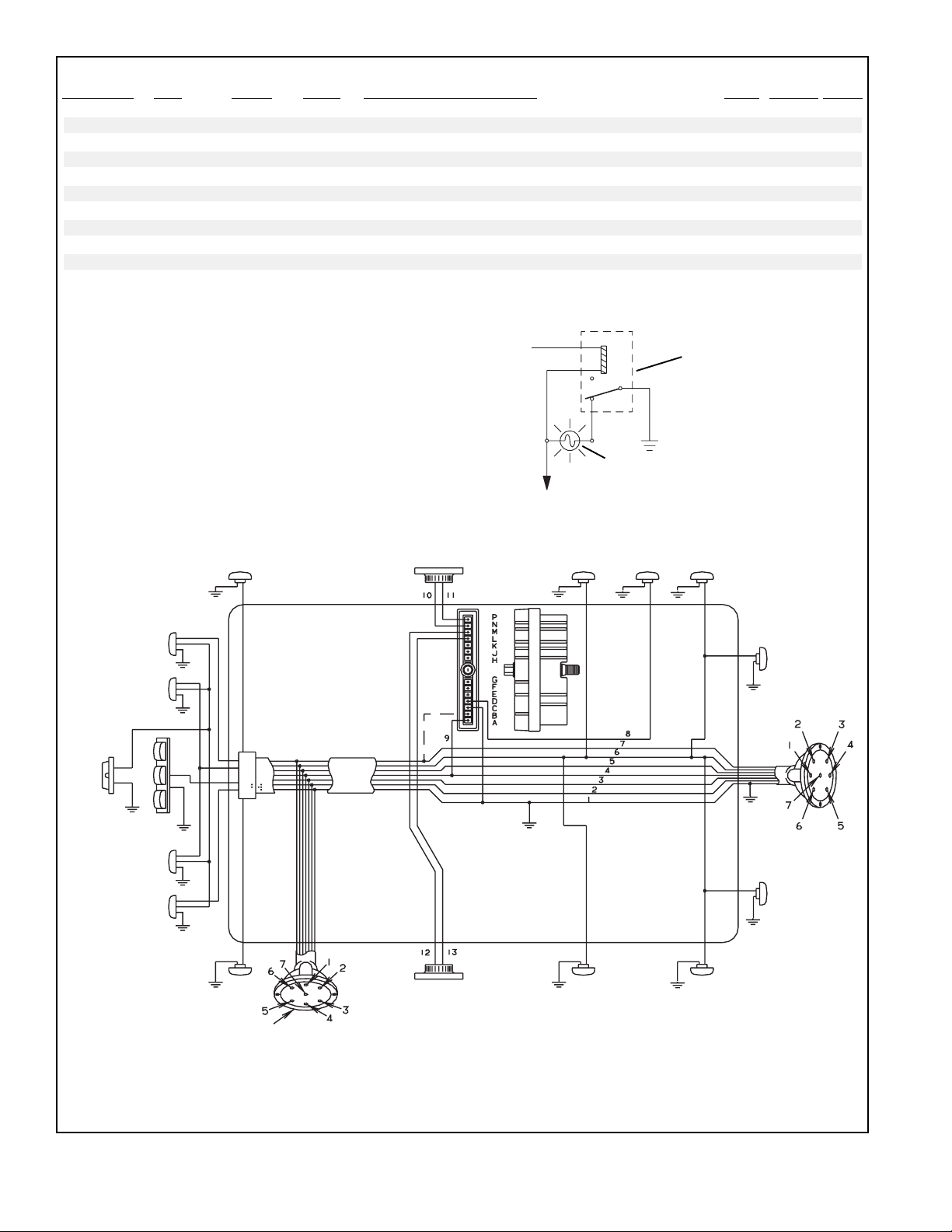

Seven Conductor Antilock Wire Gauge

Pin (Wire Connector Wire Single/

Connector No.) Letter Color Lamp and Signal Circuits Dolly Double Triple

1 1 C White Ground Return To Towing Vehicle 12 10 8

2 2 - Black Clearance, Side Marker and Identification Lamps 12 12 12

3 3 - Yellow Left Hand Turn Signal and Hazard Signal Lamps 12 12 12

4 4 - Red Stop Lamps 10 10 10

5 5 - Green Right Hand Turn Signal and Hazard Signal Lamps 12 12 12

6 6 - Brown Tail, Clearance, Side Marker and License Plate Lamps 12 12 12

7 7 B* Blue Auxiliary, Dome, Etc. or constant Antilock power 12 12 12

4 9 A Red Antilock Power From Stop Lamp 10 10 10

- 8 D Yellow Trailer Mounted Status Light 14/16 14/16 14/16

- 10/11 N/P - Wheel Speed Sensor 16/18 16/18 16/18

- 12/13 M/L - Wheel Speed Sensor 16/18 16/18 16/18

* Antilock Connector Pin B is an option and is used to provide constant power to the MC-12™ modulator during trailer operation.

CI/Directional

Stop & Tail

License Plate

The relay illustrated to the right is used when

a tractor, dash mounted status lamp for the

trailer antilock system is desired. Like the

trailer mounted status lamp, this is an option

and is not required.

Marker

MC-12

Wheel

Speed

Sensor

To Pin “G” on

™

Modulator

Connector

To Power Side of

Tractor Ignition

Tractor Electrical

Relay

Tractor Dash Mounted

Trailer Antilock Status

Lamp

Trailer

Mounted

Status

Marker Marker

Indicator

Clearance

Stop & Tail

CI/Directional

Marker

Rear 7 Pin

Connector

Plug (See

Note)

Wheel

Speed

Sensor

Note:

The rear 7 pin connector plug is for Dolly operations for Doubles & Triples

FIGURE 2 - MC-12™ MODULATOR TRAILER SYSTEM WIRING SCHEMATIC

2

Clearance

Marker Marker

Page 3

System ground (pin 1 on the seven pin connector—white)

enters the MC-12™ modulator at pin C.

Each wheel speed sensor sends the MC-12™ modulator its

AC. signal through a pair of wires. The MC-12™ modulator

pins for the sensors are L-M and N-P.

directs the driver to the problem area. A series of LEDs on

the EC-12™ controller indicate the status of power, EC-12

controller, wheel speed sensors, M-12™ modulator solenoids,

or voltage level.

™

The MC-12™ modulator can send a +12v failure signal to the

optional trailer mounted status light through pin D. The status

light indicates the condition of the trailer antilock system. In

addition, the MC-12™ modulator can send a grounding signal

through its pin J to an optional tractor, dash mounted st atus

lamp. During start up, when the trailer brakes are actuated,

trailer antilock immediately runs a self check. The status

light flashes once and then goes off. Should a problem occur ,

the antilock system disengages and returns to normal

R-12™ relay valve operation.

If the status light comes on and remains on when the trailer

brakes are actuated, a system problem has occurred. The

EC-12™ controller contains a diagnostic window, which

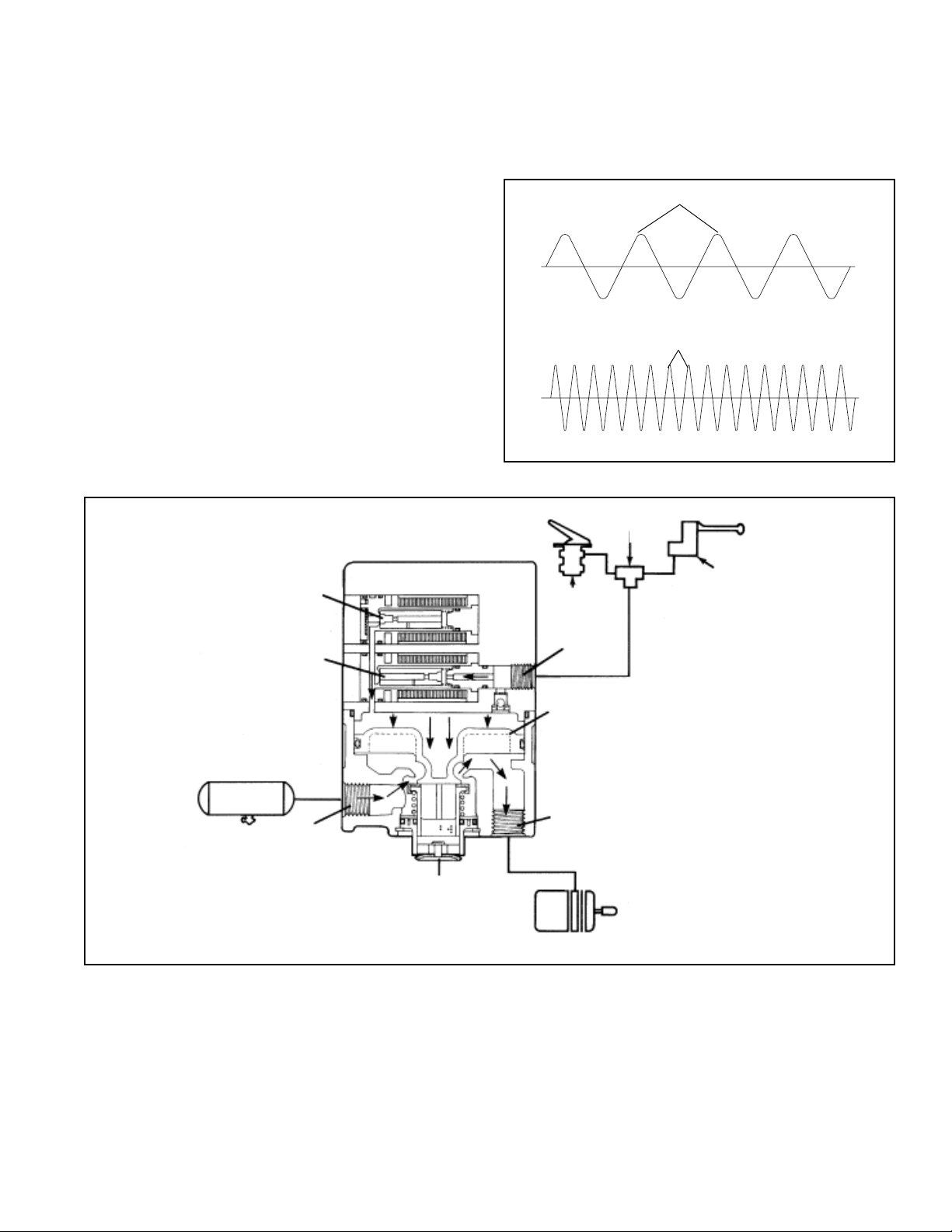

EXHAUST

SOLENOID

SUPPLY

SOLENOID

PEAK TO PEAK

LOW SPEED

PEAK TO PEAK

HIGH SPEED

FIGURE 3 - SPEED SENSOR VOL TAGE CYCLE OUTPUT

DOUBLE

CHECK

TRAILER

CONTROL

BRAKE

VALVE

CONTROL

SUPPLY

EXHAUST

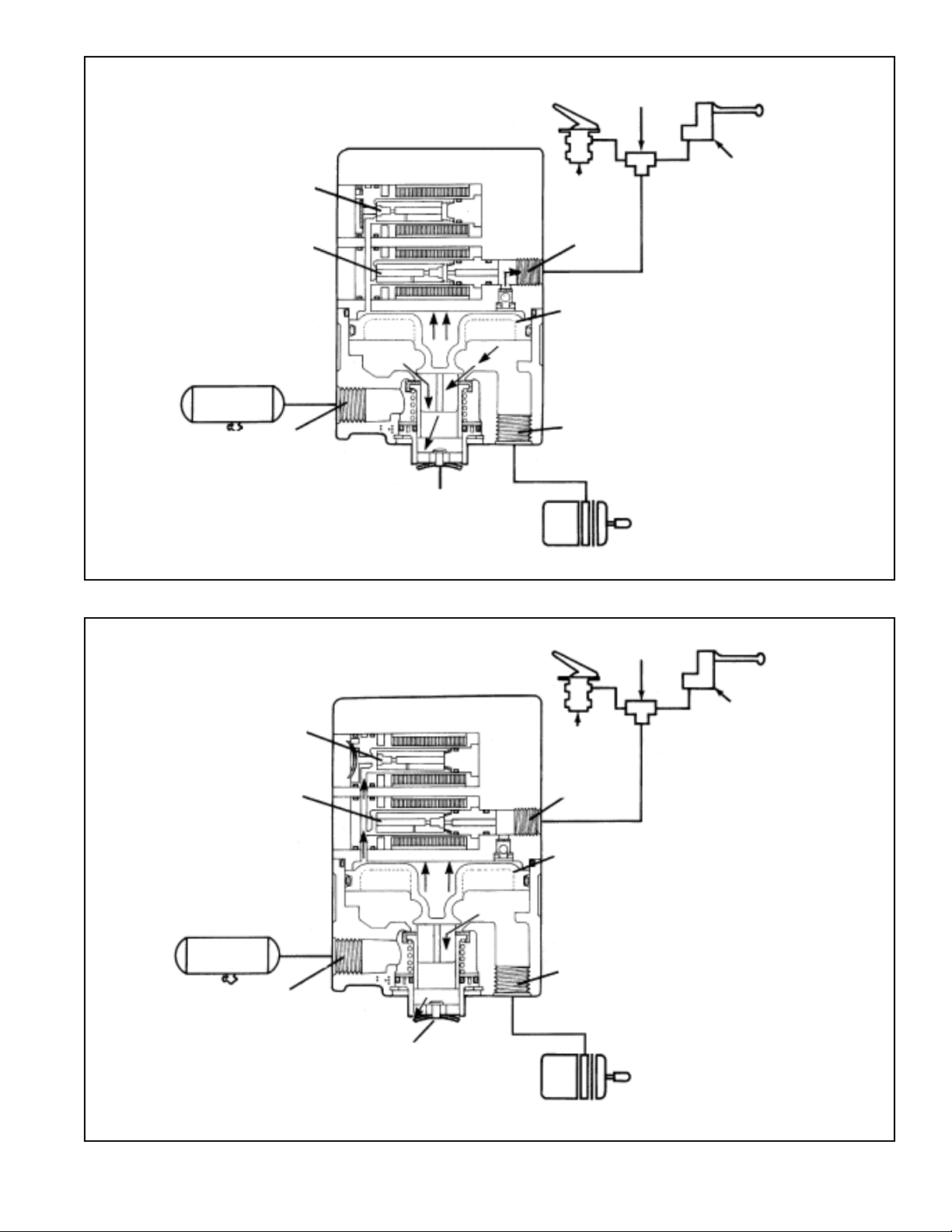

FIGURE 4 - APPLYING: NORMAL SERVICE APPLICATION

OPERATION

APPLYING: Normal Service Application

When a normal service brake application is made, and the

EC-12™ controller does not sense impending wheel lock up,

control air pressure from the brake valve enters the modulator

PISTON

DELIVERY

SERVICE

BRAKE

CHAMBER

control port. The air passes through the supply solenoid

and acts on the modulator's piston. The piston closes the

modulator exhaust and opens the inlet, delivering supply air

out the delivery ports.

3

Page 4

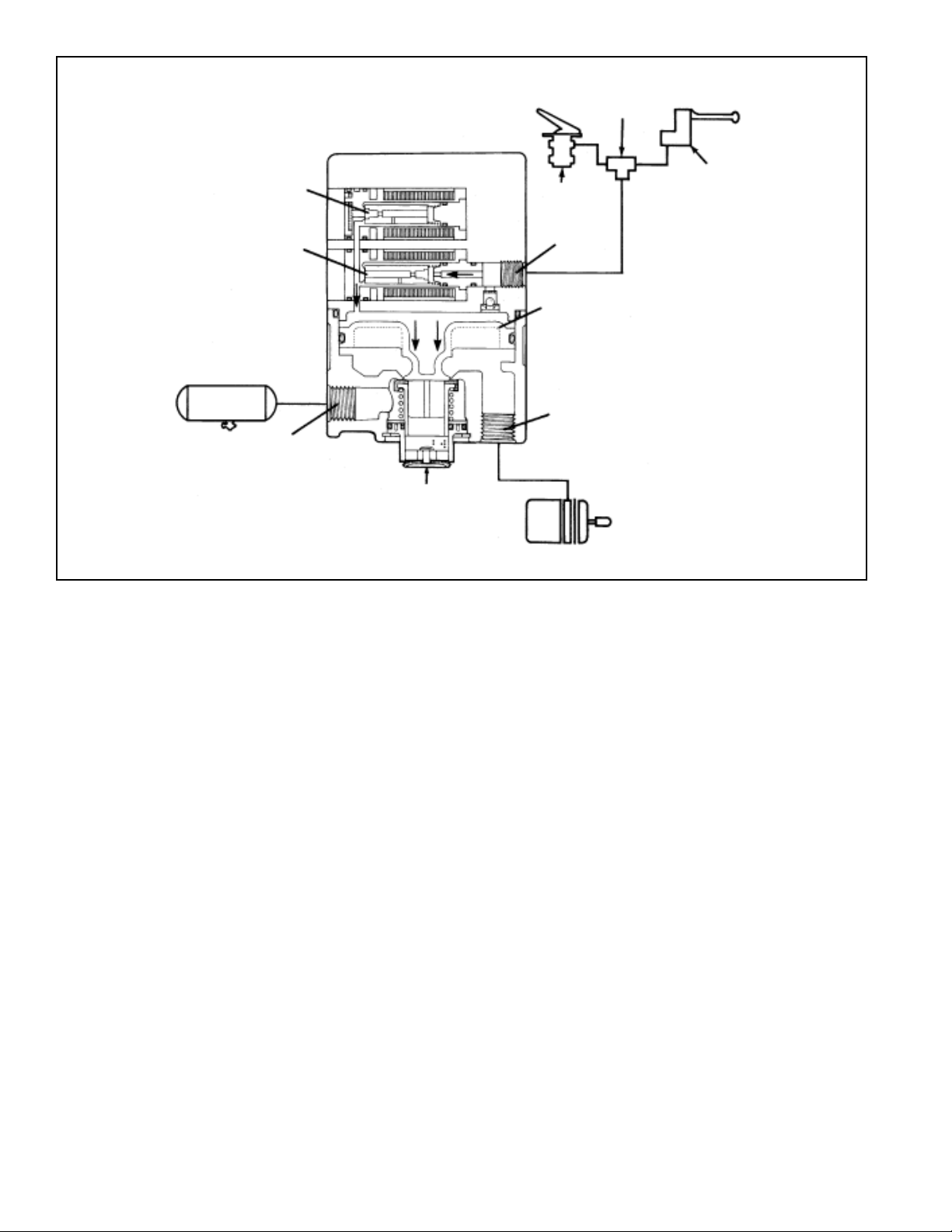

DOUBLE

CHECK

EXHAUST

SOLENOID

SUPPLY

SOLENOID

SUPPLY

EXHAUST

FIGURE 5 - BALANCED POSITION: NORMAL SERVICE APPLICATION

BRAKE

VALVE

CONTROL

PISTON

DELIVERY

TRAILER

CONTROL

SERVICE BRAKE

CHAMBER

BALANCED POSITION: Normal Service Application

The modulator reaches a balanced position when control

pressure acting upon the top side of the piston approaches

that of the air acting upon the underside of the piston. The

piston moves upward and closes the inlet valve, while the

exhaust remains closed. This prevents the modulator from

delivering or exhausting air.

EXHAUSTING: Normal Service Application

When the brake valve is released, control pressure exhausts

through the supply solenoid and the check valve in the

solenoid housing and out the exhaust port of the brake valve.

As the piston moves upward, the modulator's exhaust opens,

allowing air from the piston's underside to exhaust through

the modulator exhaust port.

ANTILOCK MODE: Solenoids Activated

If a service brake application is made and the EC-12

controller senses wheel lockup, it will command the antilock

system to alter the service brake application.

When activated, shuttles within the solenoids alter the

application and exhaust of control air pressure. The supply

solenoid closes, preventing control line pressure from entering

the modulator. Then the exhaust solenoid opens, allowing

control pressure to exhaust from the top side of the piston

through the exhaust port of the solenoid assembly. This

activity occurs in a pulsating manner, simulating "pumping

of the brakes."

PREVENTIVE MAINTENANCE

1. Every 3 months; 25,000 miles; or 900 operating hours

perform SERVICE CHECKS.

2. Every twelve months; 100,000 miles; or 3600 operating

hours, disassemble the relay valve portion of the M-12

Modulator and clean parts with mineral spirits. DO NOT

DISASSEMBLE THE SOLENOID ASSEMBL Y . Replace

all rubber parts and any parts worn or damaged. Check

™

for proper operation before placing vehicle in service.

4

Page 5

EXHAUST

SOLENOID

DOUBLE

CHECK

TRAILER

CONTROL

BRAKE

VALVE

SUPPLY

SOLENOID

SUPPLY

EXHAUST

FIGURE 6 - EXHAUSTING: NORMAL SERVICE APPLICATION

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

DOUBLE

CHECK

EXHAUST

SOLENOID

SUPPLY

SOLENOID

SUPPLY

EXHAUST

TRAILER

CONTROL

BRAKE

VALVE

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

FIGURE 7 - ANTILOCK MODE: SOLENOIDS ACTIVATED

5

Page 6

SERVICE CHECKS

Ensure that all wiring and connectors are secure and free

from visible damage. Although the MC-12™ modulator

assembly contains self check diagnostics, the LED (Light

Emitting Diode) display should be inspected to ensure that

the LEDs are functional. With the trailer brakes actuated, a

magnet (800 gauss; capable of picking up 3 ounces) held to

the LED reset area should cause all of the LEDs to illuminate.

If one or more of the LEDs DO NOT ILLUMINA TE and the

optional status light indicates proper system function, the

non illuminated LED(s) should be noted for future reference.

Although the diagnostic capabilities will be limited, the

system will continue to function as designed.

The MC-12™ modulator assembly monitors the electronics

of the system upon initial trailer brake application. However,

the vehicle should be road tested periodically to verify proper

solenoid function. The solenoids can be tested by making

an aggressive trailer stop from a speed of 20 m.p.h. When

an antilock stop is made, solenoid pulsation creates an

audible burst of air, which can be heard from the out side of

the trailer.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all

times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

®

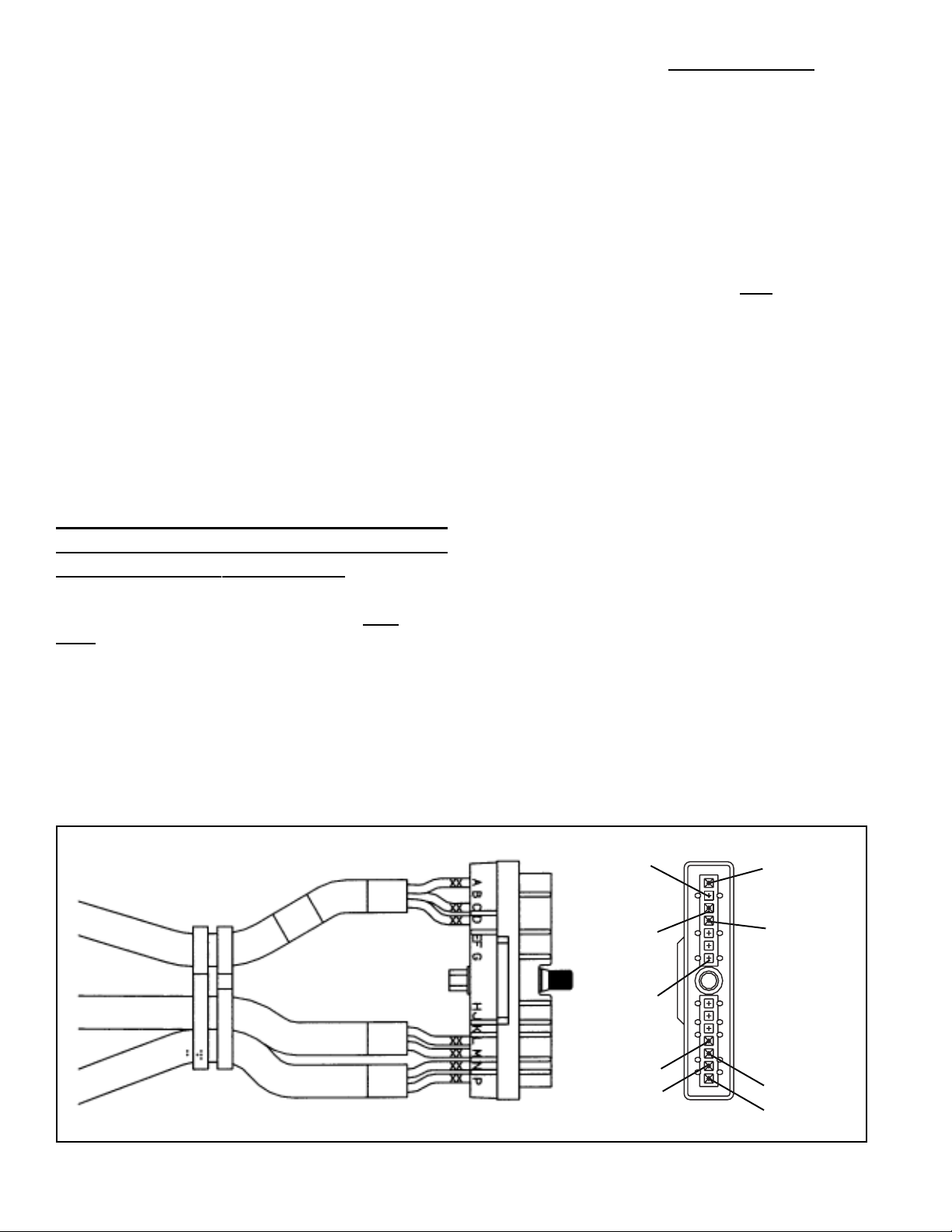

FIGURE 8 - ELECTRICAL CONNECTOR

6

OPTIONAL

CONSTANT

POWER

(TRACTOR

IGNITION)

GROUND

OPTIONAL

TRACTOR

MOUNTED

STATUS

LIGHT

SENSOR 2

SNS 2

SENSOR 1

SNS 1

A

B

C

D

E

F

G

H

J

K

L

M

N

P

STOPLIGHT

SWITCH

POWER

OPTIONAL

TRAILER

MOUNTED

STATUS

LIGHT

SENSOR 2

SNS 2

SENSOR 1

SNS 1

Page 7

REMOVAL OF THE MC-12™ MODULATOR

ASSEMBLY

1. Remove and identify all air lines connected to the unit.

2. Disconnect the 14 pin connector from the unit by

loosening its screw and pulling the connector away from

its socket.

3. Remove and save the mounting hardware connecting

the MC-12™ modulator to the vehicle.

4. Prior to disassembly, remove as much contamination

as possible from the exterior of the assembly . Be sure

to keep the contamination away from the open ports.

INSTALLATION OF THE MC-12

™

MODULA T OR ASSEMBLY

1. Replace the MC-12™ modulator assembly on the vehicle

using the hardware saved during removal. Connect the

air lines to the proper ports, as identified during removal.

Connect the 14 pin connector into the controller and

tighten the screw.

1

7

2

4

5

6

DISASSEMBLY

The following disassembly and assembly procedure is

presented for reference purposes and presupposes that a

major rebuild of the antilock valve is being undertaken. Several

replacement parts and maintenance kits are available which

do not require full disassembly. The instructions provided

with these parts and kits should be followed in lieu of the

instructions presented here.

CAUTION: The MC-12™ modulator may be lightly clamped

in a bench vise during disassembly . However, over clamping

will result in damage, leakage, and/or malfunction. If a vise

is to be used, position the MC-12™ modulator so the jaws

bear on the flat area of the supply port and its opposing side

of the body .

1. Remove the EC-12™ controller (1) from the M-12

modulator by removing the controller's four mounting

bolts.

2. Lift the controller off the M-12™ modulator and detach

the wire harness from the base of the controller by

depressing the lock tab on the side of the connector

and pulling the connector from its socket in the controller.

Remove the gasket (7) from the EC-12™ controller body.

NOTE: If replacement of the controller only is required,

proceed to Step 8 of assembly.

3. Remove sealing ring (4) from the protrusion on the bottom

of the solenoid assembly .

4. Using a pair of snap ring pliers, remove retaining ring

(14). Remove the exhaust assembly (13). Remove

o-ring (12) and o-ring (11) from the l.D. and O.D.,

respectively , of the exhaust assembly .

5. Remove spring (10). Remove the inlet/exhaust assembly

(8). Remove the spring seat (9) from the inlet/exhaust

assembly.

6. Using your thumb, press the piston stem and push the

piston (6) out the opposite end of the body. Remove

o-ring (5) from the piston.

7. Discard all items that have replacement parts in the

maintenance kit.

™

9

11

13

FIGURE 9 - EXPLODED VIEW

10

12

14

CLEANING & INSPECTION

3

8

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all parts to be reused. Do not allow mineral

spirits to come into contact with the ECU connector or

solenoids.

2. Inspect the interior and exterior of all parts that will be

reused for severe corrosion, pitting and cracks. Superficial

corrosion and/or pitting on the exterior portion of the body

is acceptable.

3. Inspect the bores for deep scuffing or gouges.

4. Inspect the pipe threads in the body. Make certain they

are clean and free of thread sealant.

7

Page 8

5. Inspect all air line fittings and plugs for corrosion. Clean

all old thread sealant from the pipe threads.

Any component exhibiting a condition described in inspection

steps 2 to 5 should be discarded and replaced before

proceeding.

ASSEMBLY—REFER TO FIG. 9

1. Using a lubricant (Bendix Pc. No. 291126) lightly coat

all o-rings and the bores of the valve body .

2. Install spring seat (9) onto the inlet/exhaust valve (8) so

that it covers the rubber seat of the inlet/exhaust valve.

Place the inlet/exhaust valve, large diameter first, into

the M-12™ modulator's bottom bore.

3. Install spring (10) over the barrel of the inlet/exhaust valve

(8) so that one end of the spring rests on the spring seat

(9).

4. Install the o-rings (1 1 8 12) into the respective grooves of

the O.D. and l.D. of the exhaust assembly (13). Place

the large diameter of the exhaust assembly against the

spring (10) and compress the spring until the exhaust

assembly enters the bore of the body and the o-ring (1 1)

seals against the wall of the bore.

5. Depress the exhaust assembly into the bore until it

exposes the groove for the snap ring (14). Install snap

ring (14) into its groove. Make sure it is fully seated.

6. Install o-ring (5) into its groove in the piston (6). Install

piston (6) into the M-12™ modulator body. The piston

stem fits into the small hole in the center of the body .

7. Install o-ring (4) onto the protrusion on the bottom of the

M-12™ modulator solenoid assembly . Install the solenoid

assembly (2) onto the valve body . The solenoid assembly

will fit on the M-12™ modulator body in any of four

orientations, 90 degrees apart. However , if clearance is

a problem, make sure the control port is not directly

above the valve's supply port, which will be nipple

mounted to a reservoir. Secure the solenoid assembly

to the valve body with the four 1/2" bolts. Torque the

bolts to 120 150 in. Ibs.

8. Install gasket (7) onto the EC-12™ controller. Inst all the

EC-12™ controller (1) as shown in Figure 9 by plugging

the electrical connector from the solenoid assembly into

the socket in the bottom of the controller. Press in until

lock tab engages. Ensure engagement by pulling the

connector lightly . Place the controller onto the solenoid

assembly and secure with the four 1/2" bolts and lock

washers. Torque to 30 60 in. Ibs.

OPERATIONAL AND LEAKAGE TEST

1. Chock wheels. Fully charge air brake system and adjust

brakes.

2. Make several trailer brake applications and check for

prompt application and release at each wheel.

3. Check for inlet valve o-ring leakage. With the trailer

service brakes released, coat the exhaust port and the

area around the retaining ring with a soap solution. A 1"

bubble in 3 seconds is permitted.

4. Check for exhaust valve leakage. With the trailer service

brakes fully applied, coat the exhaust port with a soap

solution. A 1" bubble in 3 seconds is permitted. Coat

the outside of the modulator body to check for seal ring

leakage. No leakage is permitted.

5. If leakage is excessive around the supply and exhaust

solenoids, replace the M-12™ modulator. If excessive

leakage is detected where the solenoid assembly and

M-12™ modulator body meet, replace the M-12

modulator. If excessive leakage is detected at the exhaust

™

port, before replacing the M-12

modulator perform the

following test:

Place the vehicle in park by exhausting the air pressure

from the emergency side of the spring brake. Perform the

leakage check around the exhaust. If the air continues to

leak out the exhaust replace the M-12

™

modulator. If a leak

exists between the emergency and service sides of the spring

brake, the leakage at the exhaust will cease when air pressure

is exhausted from the emergency side of the spring brake.

The air pressure will pass from the emergency side to the

service side of the chamber, out the service inlet and out the

M-12™ modulator exhaust.

ELECTRICAL TEST

If the status light remains on after the trailer brakes have

been actuated, inspect the EC-12™ controller for illuminated

LEDs. Each LED represents a specific area.

VOL T LED (red) High/Low Voltage

MOD LED (red) M-12

SNS1 LED (red) Wheel Sensor Failure

SNS2 LED (red) Wheel Sensor Failure

CONT LED (red) EC-12

PWR LED (green) EC-12

RED LEDs INDICATE FAILURE

When the EC-12™ controller senses a failure, the red LED

corresponding to the failure mode will illuminate. A failure is

stored in memory until the problem is repaired and the

EC-12™ controller is reset. NOTE: Only the voltage LED

resets itself after the condition no longer exists.

™

Modulator Failure

™

Controller Failure

™

Controller Power

™

8

Page 9

TROUBLESHOOTING INFORMATION

PREPARATION FOR TESTING

All trailer antilock testing should be performed with a tractor

connected to the trailer.

1. Connect the tractor to the trailer and build up the air

system, on both the tractor and trailer, to governor cut

out pressure.

2. Park the combination on a level surface. Apply the tractor

parking brakes then release the trailer parking brakes

only and turn off the engine.

NOTE: Some tractors may not have the ability to release

the trailer brakes while the tractor parking brakes remain

applied. In this event, chock all wheels, build the tractor

and trailer system to governor cut out and turn off the

engine without applying the parking brakes.

TROUBLESHOOTING

GENERAL

While the EC-12™ controller diagnostic display locates a

specific problem area, it is still necessary to confirm whether

the problem resides in the component itself or the wiring.

Basically the troubleshooting procedure that follows is

devoted to narrowing the problem to either the wiring or a

specific antilock component. It should be noted that ALL

TROUBLESHOOTING BEGINS BY OBSERVING THE

ANTILOCK STATUS LAMP ON THE TRAILER WHILE

PERFORMING THE "INITIAL ST ART -UP PROCEDURE" and

following the directions contained in the procedure.

Be sure to record a failure before resetting the system. Reset

by holding a magnet (capable of picking up 3 ounces) over

the reset location on the diagnostic window. If the LED(s) do

not clear during a reset, check all wiring and hardware per

the troubleshooting chart (BWS 1082). During a reset, all

LEDs will illuminate until the magnet is removed.

IMPORTANT - TROUBLESHOOTING TIPS

1. Record all findings and the action taken during the

troubleshooting process. The record sheet should be

filed in the trailer maintenance folder for future reference

and comparison.

2. No voltage or resistance tests are performed into the

EC-12™ controller . All voltage and resist ance tests are

performed by beginning at the wire harness half of the

connector and moving A WAY from the EC-12™ controller toward an antilock system component (modulator,

wheel speed sensor, etc.)

DIAGNOSTIC DISPLAY

QUICK REFERENCE

This index is presented for the benefit of personnel experienced in troubleshooting Bendix® MC-12™ trailer antilock

system. It provides a quick reference to specific sections that provide testing procedures and values.

ON

GO TO

SECTION V

NOTHING ON

GO TO

SECTION IV

GO TO

SECTION IV

NOT ON

GO

TO SECTION IV

ONE OR BOTH ON

GO TO SECTION VIA

9

Page 10

TYPICAL 7 PIN TRAILER

ELECTRICAL CONNECTOR

7 PIN TRAILER CONNECTOR

GROUND

CONSTANT POWER (IGNITION)

TYPICAL

LOCATIONS

FOR AMBER

STATUS LAMP

Troubleshooting

STOPLIGHT POWER

START HERE

AMBER STATUS LAMP

BLINKS ONCE, THEN GOES OUT

SYSTEM - OK

INITIAL START-UP PROCEDURE

WITH TRAILER CONNECTED TO

TRACTOR, TURN IGNITION ON, APPLY

TRAILER SERVICE BRAKES AND

OBSERVE STATUS LAMP MOUNTED

DID STATUS LAMP ILLUMINATE?

STATUS LAMP DOES NOT BLINK, COMES

ON AND REMAINS ILLUMINATED

ON TRAILER.

NO

YES

NO

TEST FOR POWER TO THE

TRAILER AT 7 PIN CONNECTOR

NO

ARE STOP LAMPS

ILLUMINATED

YES

GO TO SECTION I “STATUS

LAMP TESTING”

YES

GO TO SECTION II

“INSPECTION FOR

ILLUMINATED LEDS ”.

10

STATUS LAMP COMES ON, BLINKS AND

GOES OUT.

THE SYSTEM IS FUNCTIONING NORMALLY.

MAKE NOTES OF THE PARTS REPLACED OR

REPAIRED AND STEPS TAKEN .

Page 11

Troubleshooting

SECTION I

TRAILER STATUS LAMP TESTING

START HERE

POWER A & B

TRAILER STATUS

LAMP D

A B C D E F G H J K L M N P

EC-12™ CONTROLLER

WIRE HARNESS CONNECTOR

WITH TRACTOR IGNITION OFF, DISCONNECT

14 PIN WIRE HARNESS CONNECTOR FROM

EC-12™ CONTROLLER THEN TURN TRACTOR

IGNITION ON AND MAKE AND HOLD A BRAKE

APPLICATION.

USING A JUMPER WIRE CONNECT PIN A TO D THEN B

TO D. WITH THE CONNECTION IN PLACE NOTE THE

CONDITION OF TRAILER STATUS LAMP.

YES

TRAILER STATUS LAMP ON?

NO

REPLACE EC-12

CONTROLLER AND RETEST.

™

CHECK THE FOLLOWING IN THE ORDER PRESENTED AND

AFTER REPLACING OR TESTING EACH COMPONENT,

TEST THE STATUS LAMP OPERATION:

1. CHANGE TRAILER STATUS LAMP BULB

2. CHECK TRAILER STATUS LAMP WIRING-GROUND

3. CHECK CONTINUITY OF WARNING WIRE BETWEEN PIN

D ON THE 14 PIN CONNECTOR AND THE TRAILER STATUS

LAMP SOCKET

REPEAT THE “INITIAL

START-UP PROCEDURE”.

11

Page 12

START HERE

Troubleshooting

SECTION II

INSPECTION FOR ILLUMINATED LED's

WITH TRACTOR IGNITION ON AND BRAKES HELD

APPLIED, INSPECT EC-12™ CONTROLLER FOR

PRESENCE OF ILLUMINATED LEDS AND RECORD.

CHECKING

"PWR" LED

GO TO SECTION IV

“TESTING FOR POWER

TO THE EC-12

CONTROLLER”.

CHECKING

"VOLT" LED

ON?

™

IS GREEN, PWR, LED ILLUMINATED?

YES

YES

IS RED “VOLT”LED ON

NO

ARE ANY RED LED's ILLUMINATED?

NO

NO

ARE ANY RED

ILLUMINATED?

REPLACE THE EC-12

CONTROLLER

GO TO SECTION I “TRAILER STATUS

LED's

YES

NO

™

LAMP TESTING”.

GO TO SECTION IV

“TESTING FOR POWER

TO THE EC-12

CONTROLLER”.

™

12

ON?

YES

NOTE AND RECORD

THE CONDITION OF

ALL RED LEDS

GO TO SECTION III “INSPECTION

FOR ILLUMINATED LEDS ”.

RED LEDs

ANY ILLUMINATED?

Page 13

Troubleshooting

SECTION III

INSPECTION FOR ILLUMINATED LEDS

INSPECTING "CONT"

LED

ON?

TESTING "SNS1 or

SNS2" LEDs

ON?

NOTE RED “CONT” LED IN

EC-12™ CONTROLLER

DIAGNOSTICS WINDOW.

IS THIS LED ILLUMINATED?

NO

IS EITHER OR BOTH RED

"SNS1" OR "SNS2" LED

ILLUMINATED?

NO

YES

YES

START HERE

REPLACE THE EC-12

CONTROLLER.

NOTE THE ILLUMINATED LEDS

AND GO TO SECTION VI "TESTING

THE WHEEL SPEED SENSOR"

™

IS RED "MOD" LED

ILLUMINATED?

NO

IF ANY OTHER RED LEDs

ARE ILLUMINATED,

REPLACE THE EC-12

CONTROLLER AND REPEAT

THE “INITIAL START-UP

PROCEDURE”

™

YES

TESTING "MOD"

LED

GO TO SECTION V

“TESTING THE

MODULATOR”

ON?

13

Page 14

Troubleshooting

SECTION IV

TESTING FOR POWER TO THE EC-12™ CONTROLLER

START HERE

POWER A & B

A B C D E F G H J K L M N P

EC-12™ CONTROLLER

WIRE HARNESS CONNECTOR

GROUND C

TURN IGNITION OFF, DISCONNECT 14 PIN

WIRE HARNESS CONNECTOR FROM EC-12

CONTROLLER

TURN IGNITION ON, MAKE & HOLD A BRAKE

APPLICATION AND, MEASURE VOLTAGE

BETWEEN POWER AND GROUND PINS ON

WIRE HARNESS CONNECTOR

A to C

B to C

VOLTAGE SAME AS BATTERY

VOLTAGE? MUST BE

BETWEEN 8 AND 17 VOLTS.

YES

™

NO

RECONNECT CONNECTOR TO EC-12

CONTROLLER. CHECK THE VEHICLE

WIRING FOR CONTINUITY. REFER TO THE

VEHICLE SERVICE MANUAL AND CHECK

THE BATTERY VOLTAGE. REPAIR OR

REPLACE AS NECESSARY AND REPEAT

THE "INITIAL START-UP PROCEDURE"

™

RESETTING

™

EC-12

CONTROLLER

CHECKING "VOLT"

LED

MAGNET HERE

ON ?

ON?

TURN IGNITION OFF, (DO NOT APPLY BRAKES)

RECONNECT WIRE HARNESS TO EC-12™ CONTROLLER.

TURN IGNITION ON & APPLY & HOLD BRAKES ON.

PERFORM A MAGNETIC RESET BY

PASSING A MAGNET OVER THE

"RESET" IN EC-12™ CONTROLLER

DIAGNOSTIC WINDOW THEN

REMOVE MAGNET

IS THE RED, "VOLT" LED

STILL ILLUMINATED?

YES

REPLACE EC-12

CONTROLLER

™

NO

REPEAT THE

“INITIAL START-UP

PROCEDURE”.

14

Page 15

Troubleshooting

SECTION V

TESTING THE MODULATOR

M-12™ MODULATOR

4 PIN CONNECTOR

WHITE BLACK

WHITE BLACK

MAGNET HERE

RESETTING

EC-12™ CONTROLLER

TURN IGNITION OFF AND DO NOT APPLY BRAKES.

SEPARATE EC-12™ CONTROLLER FROM THE M-12

MODULATOR. DISCONNECT 4 PIN CONNECTOR

BETWEEN M-12™ MODULATOR & EC-12

CONTROLLER AND TEST RESISTANCE ON THE

MODULATOR CONNECTOR

BLACK to BLACK READ 9 to 12 OHMS

WHITE to WHITE READ 9 to 12 OHMS

ARE RESISTANCE

VALUES CORRECT?

YES

INSPECT CONNECTOR AND RECONNECT TO

EC-12™ CONTROLLER. TURN IGNITION ON &

APPLY & HOLD BRAKES ON. PASS

MAGNET OVER "RESET" ON EC-12

CONTROLLER. REMOVE MAGNET AND

NOTE REACTION OF RED LEDS.

™

NO

™

™

START HERE

REPLACE

M-12™ MODULATOR

ARE ANY RED LED's

ILLUMINATED?

YES

SAME RED LED's

ILLUMINATED?

NO

GO TO SECTION III

“INSPECTION FOR

ILLUMINATED LEDS”

AND RETEST.

NO

YES

REPEAT “INITIAL START-UP PROCEDURE”.

IF TESTING HAS RETURNED

TO THIS STEP TWICE - REPLACE THE

EC-12™ CONTROLLER.

REPLACE EC-12

CONTROLLER

IF FAILURE PERSISTS,

REPLACE THE EC-12

CONTROLLER.

™

™

15

Page 16

Troubleshooting

SECTION VI PART A

TESTING THE WHEEL SPEED SENSOR

TURN IGNITION ON & APPLY & HOLD

BRAKES ON. PASS MAGNET OVER

START HERE

MAGNET HERE

RESETTING EC-12

CONTROLLER

EC-12™ CONTROLLER WIRE

HARNESS CONNECTOR

M -SNS 2

L-SNS 2

A B C D E F G H J K L M N P

TESTING SPEED SENSOR RESISTANCE

MAGNET HERE

"RESET" ON EC-12™ CONTROLLER.

REMOVE MAGNET AND OBSERVE

™

THE LEDs.

N-SNS 1

P-SNS 1

ANY RED LED's ON?

NO

TURN IGNITION OFF, DO NOT APPLY BRAKES AND CHECK FOLLOWING:

A. REMOVE CONNECTOR FROM EC-12

RESISTANCE BETWEEN SPEED SENSOR M & L AND N & P. RESISTANCE

FOR BENDIX® WS-20™ SPEED SENSOR SHOULD BE BETWEEN 1500-2500

OHMS. REFER TO VEHICLE MAINTENANCE MANUAL IF OTHER THAN THE

™

WS-20

SPEED SENSOR IS IN USE. IF RESISTANCE NOT CORRECT,

DISCONNECT CONNECTOR AT SPEED SENSOR. INSPECT CONNECTOR,

THEN CHECK RESISTANCE BETWEEN PINS ON SENSOR. IF RESISTANCE IS

NOT CORRECT (BETWEEN 1500-2500 OHMS FOR THE BENDIX® WS-20

SPEED SENSOR), REPLACE SENSOR, OTHERWISE PROCEED TO STEP B.

B. CHECK “GAP” BETWEEN SPEED SENSOR AND EXCITER OR TONE RING.

(GAP FOR BENDIX® WS-20™ SPEED SENSOR, SPEED SENDER IS BETWEEN 0

- .015 INCHES) IF SENSOR GAP MUST BE ADJUSTED, CHECK FOR LOOSE

OR WORN WHEEL BEARINGS BEFORE RE-GAPPING SENSOR. REFER TO

VEHICLE MAINTENANCE MANUAL FOR WORN BEARINGS.

C. IF SENSOR GAP IS CORRECT CHECK WHEEL BEARING FOR FREE PLAY TO

VERIFY IT COMPLIES TO MANUFACTURER’S RECOMMENDATIONS.

D. MAKE CERTAIN EXCITER OR TONE RING IS IN PLACE AND INSPECT

CONDITION. CHECK FOR MISSING OR DAMAGED TEETH AND THAT IT RUNS

TRUE AND PERPENDICULAR TO SENSOR FACE.

E. CHECK WIRING HARNESS AND CONNECTORS THAT RUN TO SENSOR.

F. CHECK FOR DRAGGING BRAKES (OVER ADJUSTED, TRAPPED AIR IN

ACTUATOR, OUT OF ROUND DRUMS, FAULTY RETURN SPRINGS, PARKING

BRAKE SYSTEM FAULTS, ETC.) AND CORRECT AND RETEST.

YES

™

CONTROLLER AND MEASURE

GO TO SECTION VI PART B

AND BEGIN TESTING

™

16

RESETTING

EC-12™ CONTROLLER

GO TO SECTION III - "INSPECTION

FOR ILLUMINATED LEDs"

RECONNECT EC-12™ CONTROLLER CONNECTOR, TURN

IGNITION ON & APPLY & HOLD BRAKES ON. PASS

MAGNET OVER "RESET" ON EC-12™ CONTROLLER.

REMOVE MAGNET AND OBSERVE LEDs

YES

ARE ANY RED LEDs

ILLUMINATED?

NO

REPEAT THE "INITIAL START-UP

PROCEDURE

Page 17

Troubleshooting

SECTION VI PART B

TESTING THE WHEEL SPEED SENSOR

START HERE FROM

SECTION VI

EC-12™ CONTROLLER WIRE

HARNESS CONNECTOR

M -SNS 2

L-SNS 2

A B C D E F G H J K L M N P

TESTING SPEED SENSOR RESISTANCE

PART A

NO

SAME LED's ILLUMINATED?

YES

IGNITION OFF SERVICE BRAKES NOT APPLIED. REMOVE 14

PIN CONNECTOR FROM EC-12™ CONTROLLER. MEASURE

RESISTANCE BETWEEN SPEED SENSOR PINS M & L AND N & P ON

CONNECTOR. RESISTANCE FOR BENDIX® WS-20™ SPEED

SENSOR IS BETWEEN 1500-2500 OHMS. REFER TO VEHICLE

MANUAL FOR THE RESISTANCE VALUES IF OTHER THAN

WS-20™ SPEED SENSOR IS IN USE.

N-SNS 1

P-SNS 1

CORRECT RESISTANCE?

NO

DISCONNECT CONNECTOR AT SPEED SENSOR. INSPECT

THE CONNECTOR, THEN CHECK THE RESISTANCE BETWEEN

TWO PINS ON SENSOR. RESISTANCE BETWEEN 1500-2500

OHMS FOR THE BENDIX® WS-20™ SPEED SENSOR

YES

GO TO SECTION III "INSPECTION FOR ILLUMINATED LED's"

REPLACE THE EC-12

CONTROLLER

NO

REPLACE THE SENSOR

™

MAGNET HERE

RESETTING

EC-12™ CONTROLLER

YES

RECONNECT CONNECTOR AT SPEED

SENSOR AND EC-12™ CONTROLLER.

PASS MAGNET OVER "RESET" ON EC-12

CONTROLLER. REMOVE MAGNET AND

OBSERVE LEDs

ARE ANY LED's ILLUMINATED?

YES

ARE SAME RED LEDS ILLUMINATED ?

YES

REPAIR OR REPLACE SPEED

SENSOR WIRING HARNESS

AND REPEAT THE “INITIAL

START-UP PROCEDURE”.

™

NO

NO

REPEAT THE “INITIAL

START-UP PROCEDURE”.

GO TO SECTION III "INSPECTION

FOR ILLUMINATED LED's"

17

Page 18

NOTES & REFERENCES

7PIN TRAILER ELECTRICAL

CONNECTOR

CONSTANT POWER FROM

GROUND

(OPTIONAL CONNECTION)

POWER FROM

STOPLIGHTS

TRACTOR IGNITION

TRAILER

MOUNTED

STATUS LAMP

TRAILER SERVICE AIR LINE

EXCITER

RING

SPRING

BRAKE

™

MC-12

MODULATOR

CONTROLLER

ASSY.

SPEED

SENSOR

OPTIONAL

CONSTANT POWER

(TRACTOR IGNITION)

GROUND

OPTIONAL

TRACTOR

MOUNTED STATUS

LIGHT

SENSOR 2

SNS 2

SENSOR 1

SNS 1

14 PIN EC-12™ CONTROLLER

18

CONNECTOR

STOPLIGHT SWITCH

A

B

C

D

E

F

G

H

J

K

L

M

N

P

POWER

OPTIONAL

TRAILER

MOUNTED

STATUS LIGHT

SENSOR 2

SNS 2

SENSOR 1

SNS 1

VOL T LED (red) High/Low Voltage

MOD LED (red) M-12

SNS1 LED ( red) Wheel Sensor Failure

SNS2 LED ( red) Wheel Sensor Failure

CONT LED (r ed) EC-12

PWR LED (green) EC-12

EC-12™ CONTROLLER

DIAGNOSTIC WINDOW

™

Modulator Failure

™

Controller Failure

™

Controller Power

Page 19

NOTES & REFERENCES

19

Page 20

BW1667 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 4/2004 Printed in U.S.A.

Loading...

Loading...