Page 1

®

Bendix® M-12™ & M-12R™ AntiLock Modulator

4 PIN

CONNECTOR

SUPPLY

PORT DELIVERY

PORTS

2 VERTICAL

2 HORIZONTAL

CONTROL

PORT

COVER

PLATE

DELIVERY

PORTS

4 VERTICAL

WIRE

HARNESS

3 PIN

CONNECTOR

SD-13-4772

SUPPLY

PORT

CONTROL

PORT

M-12™ Modulator

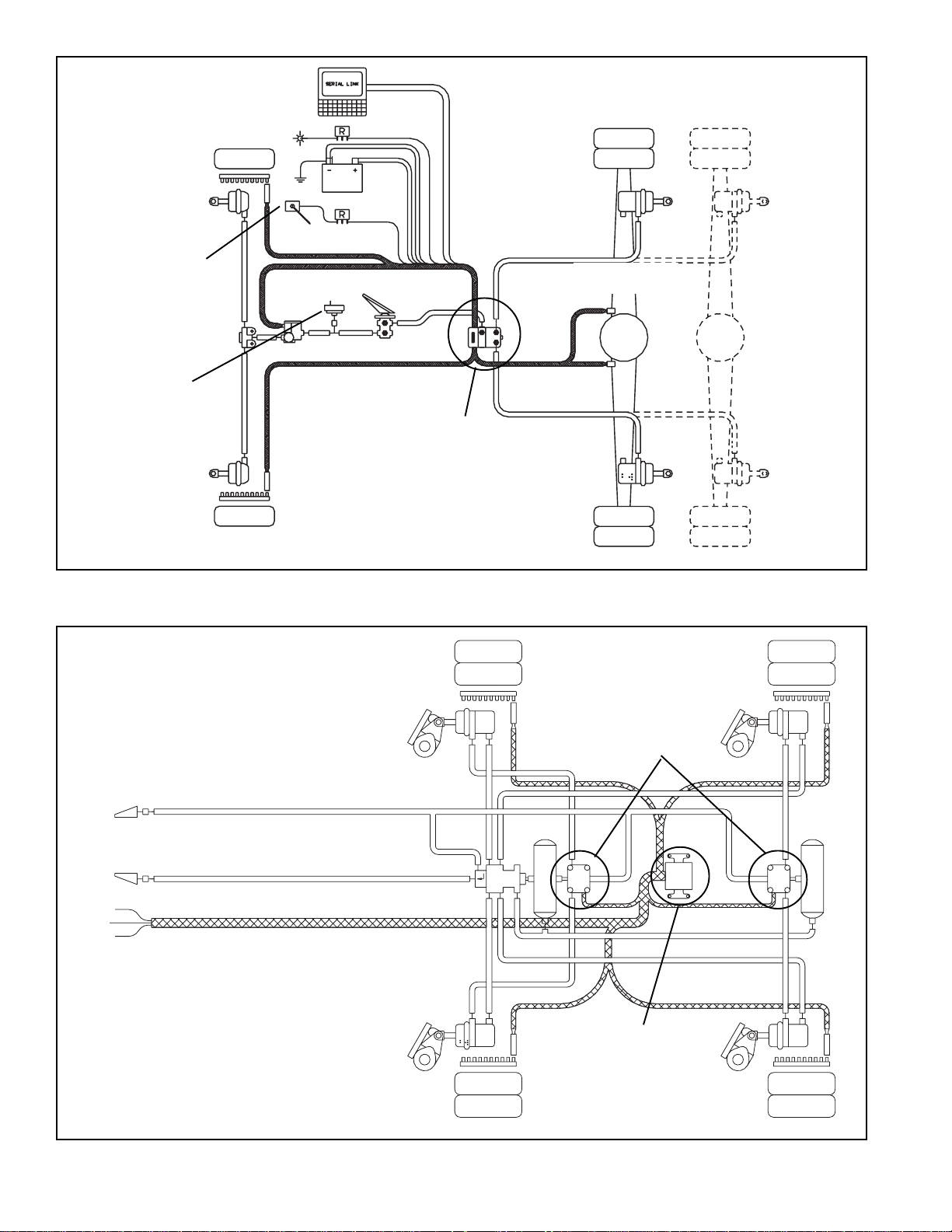

FIGURE 1 M-12™ AND M-12R™ MODULATORS

DESCRIPTION

The M-12™ antilock modulator is a standard component in

Bendix antilock systems. It is comprised of two components:

solenoids, which rapidly apply and exhaust air during an

antilock stop, and a standard relay valve.

During normal, non-antilock operation, the M-12™ modulator

serves as a relay valve that speeds the application and release

of the service brakes. If wheel lock up is impending, a antilock

controller commands the solenoids to modulate brake

chamber pressure on the axle(s) on which the system is

installed.

The M-12™ modulator is offered in two configurations as

illustrated in figure 1. The M-12™ modulator permits direct

attachment of an antilock controller, and it accepts electronic

commands from the controller through a four pin connector

(see Figure 1). The M-12R™ modulator is designed for remote

mounting on a vehicle frame rail or cross member. It accepts

electronic commands from a remote mounted controller

through a wire harness assembly that has a four pin

connector at one end and a three pin connector at the other

(see Figure 1). The M-12™ modulator and M-12R™ modulator

differ from each other only in that the M-12™ modulator is

M-12R™ Modulator

designed for direct controller mounting while the M-12R

modulator uses a cover plate where the controller would

normally mount and a wire harness is attached to the

M-12R™ modulator in order to connect it to the antilock

controller. Two body styles are available; one with four

vertical delivery ports and another with two vertical and two

horizontal delivery ports.

The M-12™/M-12R™ modulator is normally mounted close

to the service actuators it serves, and it can be nipple

mounted to a reservoir or secured to the frame rail.

The M-12™ modulator air connections are as follows:

M-12™/M-12R™ Modulator Embossed

Air Connection Identification

Supply (to reservoir) SUP

Delivery (to brake actuator) DEL

(can have 2 horizontal & 2

vertical deliveries or

4 vertical deliveries)

Control CON

(to rear service brake valve delivery)

The standard M-12™ and M-12R™ modulator is offered with

a 4 psi crack pressure. The internal components are

interchangeable with R-12™ and R-14™ relay valves therefore,

the same maintenance kit is used to service all.

™

1

Page 2

SERVICE

BRAKE

DASH

LAMP

SERIAL LINK

RELAY

SPRING

BRAKES

RETARDER

™

DISABLE

M-21

/M-22

™

MODULATOR

BRAKE VALVE

STOP LIGHT

SWITCH

M-12

MODULATOR

WITH ANTILOCK

CONTROLLER

MOUNTED

NOTCHED HUB

™

WHEEL

WS-20

SPEED SENSOR

EXCITER

FRONT AXLE

FIGURE 2A FULL VEHICLE AXLE CONTROL - TRUCK/TRACTOR

NOTCHED HUB

EXCITER

IN-AXLE WHEEL

SPEED SENSOR

™

REAR AXLE (S)

SPRING

BRAKES

™

WS-20

SPEED SENSOR

WHEEL

M-12R

™

MODULATOR

SR-5™ TRAILER

SPRING BRAKE

VALVE

FIGURE 2B TANDEM SPREAD AXLE TRAILER - AXLE CONTROL SYSTEM

2

REMOTE MOUNT

ANTILOCK

CONTROLLER

Page 3

EXHAUST

SOLENOID

DOUBLE

CHECK

TRAILER

CONTROL

BRAKE

VALVE

SUPPLY

SOLENOID

RESERVOIR

SUPPLY

EXHAUST

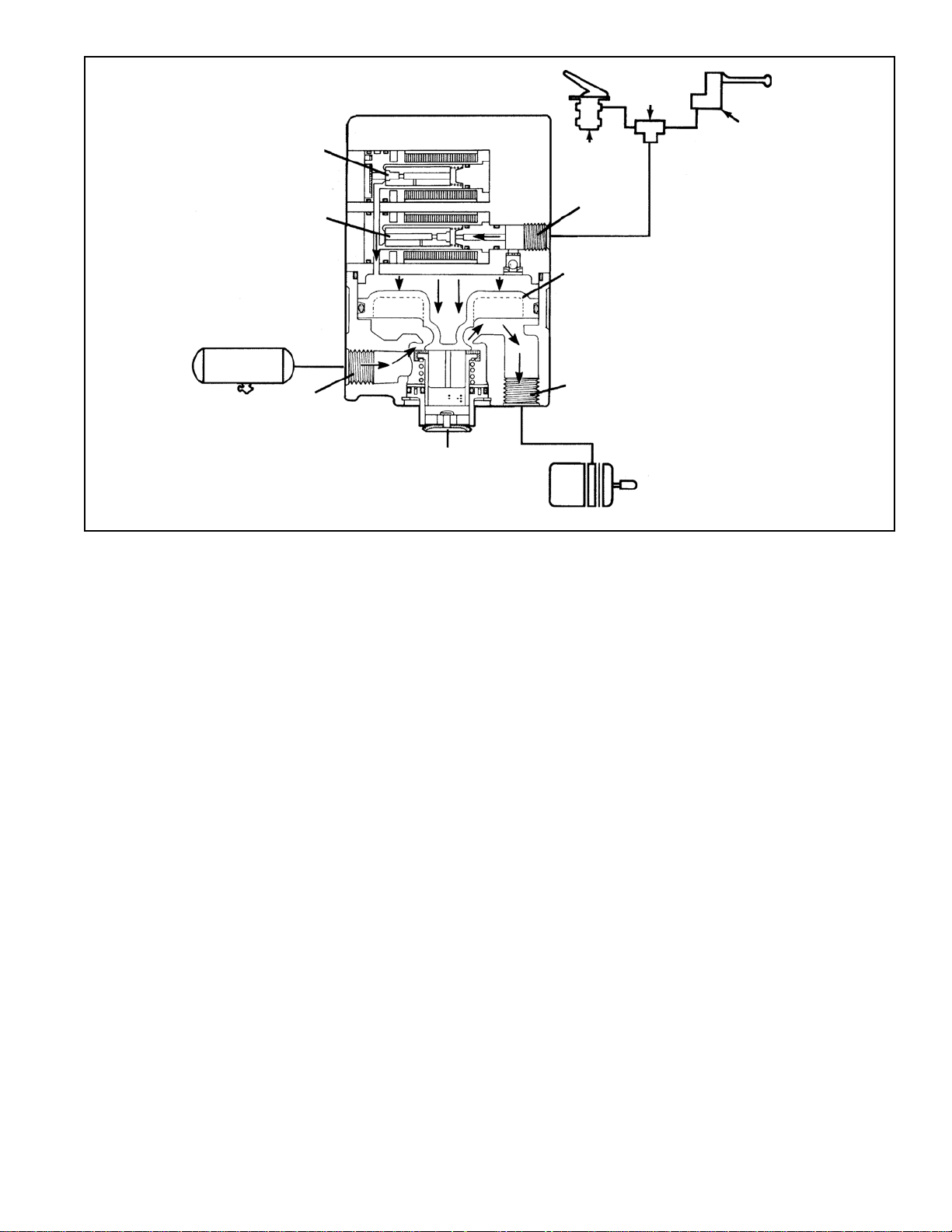

FIGURE 3 APPLYING: NORMAL SERVICE APPLICATION

Figure 2 shows two antilock systems in which the M-12

and M-12R™ modulator can be used. Figure 2A is a typical

schematic for a full vehicle axle control system, and Figure

2B is a typical trailer installation using the M-12R

modulator. With the attachment of different controllers, the

M-12™ or M-12R™ modulator can adapt to either system.

OPERATION

APPLYING: NORMAL SERVICE APPLICATION

When a normal service brake application is made, and the

antilock wheel sensors do not sense impending wheel lock

up, service air pressure enters the modulator control port.

Air passes through the normally-open supply solenoid and

into the relay valve portion of the modulator. (The normallyclosed exhaust solenoid remains closed.)

Air acts on the relay piston closing the exhaust and opening

the inlet. Supply air pressure flows to the delivery ports and

out to the service brake chambers.

BALANCED POSITION: NORMAL SERVICE

APPLICATION

The relay valve portion of the modulator reaches a balanced

position when service delivery pressure acting on the

underside of the relay piston approaches that of the control

air acting on the top side of the piston. The piston moves

allowing the inlet valve to close, while the exhaust remains

closed. This prevents the valve from delivering or exhausting

air.

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

™

EXHAUSTING: NORMAL SERVICE

APPLICATION

When a service application is released, air at the modulator

™

control port returns to the application valve. Control pressure

above the relay piston exhausts through the supply solenoid

and the check valve in the solenoid housing out to the exhaust

port of the valve that sent the control signal. Relay piston

movement opens the modulator's exhaust, allowing air from

the piston's underside (and from the service brake chambers)

to exhaust through the modulator exhaust port.

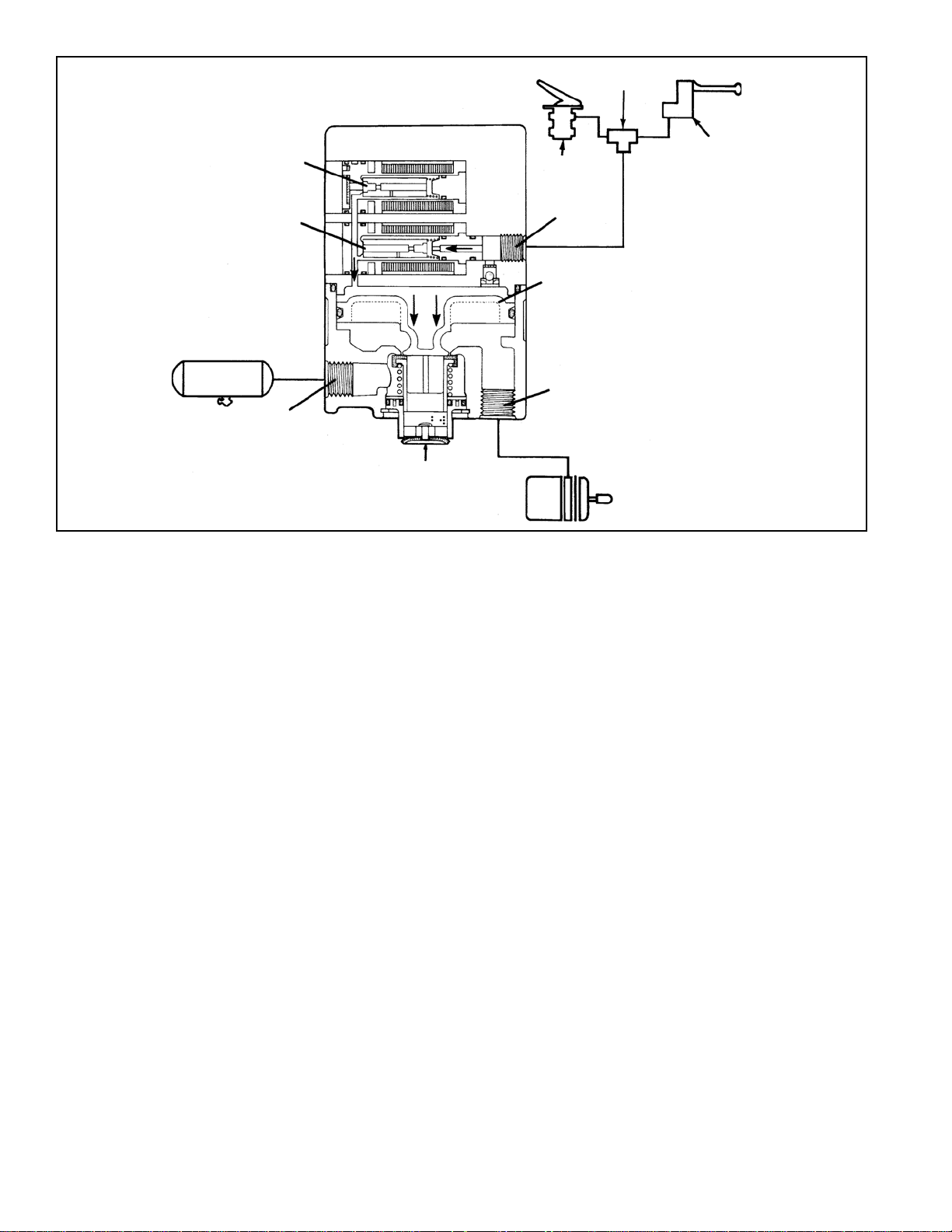

ANTILOCK MODE: SOLENOIDS ACTIVATED

If a service application is made and the antilock controller

senses impending wheel lockup, it commands the M-12™/

M-12R™ modulator to modify the service brake application

pressure. When activated by the controller, the M-12™/

M-12R™ modulator solenoids alter application by exhausting

and applying control air pressure above the relay piston.

The supply solenoid closes, preventing control line pressure

from entering the modulator. Then the exhaust solenoid

opens, allowing control pressure to exhaust from the top

side of the piston through the exhaust port of the solenoid

assembly. This activity occurs in a pulsating manner,

simulating "pumping the brakes."

3

Page 4

DOUBLE

CHECK

EXHAUST

SOLENOID

SUPPLY

SOLENOID

RESERVOIR

SUPPLY

EXHAUST

FIGURE 4 BALANCED POSITION

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

TRAILER

BRAKE

VALVE

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

CONTROL

2. Inspect all air lines connected to the M-12™/M-12R

modulator for signs of wear or physical damage. Replace

as necessary.

3. Test air line fittings for excessive leakage and tighten or

replace as necessary.

™

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable guide

in determining the best maintenance interval for a vehicle.

GENERAL

Perform the following tests and inspections at the prescribed

intervals. If the M-12™/M-12R™ modulator fails to function as

described, or if leakage is excessive, repair the valve or obtain

a replacement from any authorized Bendix parts outlet.

EVERY THREE MONTHS, 25,000 MILES, 900 OPERATING

HOURS, OR DURING THE VEHICLE CHASSIS

LUBRICATION INTERVAL, MAKE THE VISUAL

INSPECTIONS IN THE SERVICE CHECKS

EVERY YEAR, 100,000 MILES, OR 3,600 OPERATING

HOURS, PERFORM THE OPERATIONAL AND LEAKAGE

TESTS

SERVICE CHECKS

1. Remove any contaminants and visually inspect the valve's

exterior for excessive corrosion or physical damage.

OPERATIONAL AND LEAKAGE TEST

OPERATIONAL TEST

1. Apply and release the brakes several times and check

for prompt application and release at each wheel. If the

response at the wheels is "sluggish," check for a kinked

or obstructed air line leading to or from the M-12™/

M-12R™ modulator.

2. Road test the vehicle to determine proper modulator

operation. The system can be tested by making an

aggressive stop from a vehicle speed of 20 mph. When

an aggressive stop is made, solenoid pulsation creates

an audible burst of air, which can be heard from outside

the vehicle.

LEAKAGE TEST

1. Build air system pressure to governor cut out. With the

service brakes fully applied, coat the exhaust port with

a soap solution. A 1" bubble in 3 seconds is permitted.

Coat the outside of the modulator body to check for seal

ring leakage. No leakage is permitted.

4

Page 5

EXHAUST

SOLENOID

DOUBLE

CHECK

TRAILER

CONTROL

BRAKE

VALVE

SUPPLY

SOLENOID

RESERVOIR

SUPPLY

EXHAUST

FIGURE 6 ANTILOCK MODE: SOLENOIDS ACTIVATED

2. With the service brakes released, coat the exhaust port

and the area around the retaining ring with a soap solution.

A 1" bubble in 3 seconds is permitted.

3. If leakage is excessive around the supply and exhaust

solenoids, replace the M-12™/M-12R™ modulator. If

excessive leakage is detected where the solenoid

assembly and body meet, replace the M-12™/M-12R

modulator. If excessive leakage is detected at the exhaust

port, before replacing the M-12™/M-12R™ modulator,

perform the following test. Place the vehicle in park by

exhausting the air pressure from the emergency side of

the spring brake. Perform the leakage check.

ELECTRICAL TESTS

1. Before testing the solenoid assembly of a "suspect"

modulator, its location on the vehicle should be confirmed

using the Trouble Shooting or Start-Up procedure for the

specific antilock controller in use. (See the Service Data

Sheet for the antilock controller for this procedure.)

2. Proceed to the modulator in question and identify it as

an M-12™ or M-12R™ modulator and inspect its wiring

connector. In the case of an M-12™ modulator it will be

necessary to remove the four cap screws that secure

the controller to the modulator. The M-12R™ modulator

has an external connector that can be tested without

removing the cover. Disconnect the connector and test

the resistance between the pins on the modulator. Refer

to figure 7.

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

For the FOUR pin connector test as follows

A. Black to Black: Read 9 to 12 OHMS

B. White to White: Read 9 to 12 OHMS

For the THREE pin connector on the M-12R test as

follows

™

A. Red to Black: Read 9 to 12 OHMS

B. Red to White: Read 9 to 12 OHMS

Note: If the resistance readings for the three pin connector

are NOT as shown, the wire harness leading to the to

the under side of the modulator cover may require repair

or replacement. Remove the cover (as discussed

elsewhere in this manual) and disconnect the four pin

connector and perform the tests shown for the FOUR

pin connector. If the resistance is correct at the four pin

connector the short wire harness between the four and

three pin connectors is at fault.

3. If the resistance values are NOT AS SHOWN, replace

the modulator.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

5

Page 6

EXHAUST

SOLENOID

DOUBLE

CHECK

TRAILER

CONTROL

BRAKE

VALVE

SUPPLY

SOLENOID

RESERVOIR

SUPPLY

EXHAUST

FIGURE 6 ANTILOCK MODE: SOLENOIDS ACTIVATED

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

CONTROL

PISTON

DELIVERY

SERVICE BRAKE

CHAMBER

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

MODULATOR REMOVAL

1. Identify, mark, or label all air lines and wiring cables and

™

their respective connections on the modulator (M-12R™)

or modulator/controller assembly (M-12™).

2. Disconnect all air lines and wiring.

3. Remove the modulator (M-12R™) or modulator/controller

assembly (M-12™) from the vehicle.

MODULATOR INSTALLATION

1. Install all air line fittings and plugs. Make certain no thread

sealing material enters the modulator.

2. Install the assembled modulator (M-12R™) or modulator/

controller assembly (M-12™) on the vehicle.

6

Page 7

FOUR PIN

CONNECTOR

SHORT WIRE

HARNESS

BETWEEN THREE

AND FOUR PIN

CONNECTOR

MODULATOR

™

(M-12R

ONLY)

THREE PIN

CONNECTOR

TYPICAL M-12R™ MODULATORTYPICAL M-12™ MODULATOR

EXHAUST

Black

White

FIGURE 7 M-12™/M-12R™ MODULATOR CONNECTORS & WIRE HARNESS

WHITE BLACK

3. Reconnect all air lines and wiring cables to the modulator

or modulator/controller assembly using the identification

made in MODULATOR REMOVAL, step 1.

4. Test all air fittings for excessive leakage and tighten as

necessary.

3. Remove and retain the four cap screws that hold the

DISASSEMBLY - REFER TO FIGURE 8

The following disassembly and assembly procedure is

presented for reference purposes only. A complete

disassembly and assembly is described in detail, and it is

assumed that the appropriate maintenance kit(s) is on hand.

Several replacement parts and maintenance kits are

available which do not require full disassembly. The

instructions provided with these parts and kits should be

followed in place of the instructions presented here.

CAUTION: The M-12™/M-12R™ may be lightly clamped in a

bench vise during disassembly. However, over clamping will

result in damage, leakage, and/or malfunction. If a vise is to

be used, position the M-12™/M-12R™ so the jaws bear on

the flat area of the supply port and its opposing side of the

body.

1. Remove all air fittings and plugs from the valve.

2. Mark the relationship of the electronic controller and

solenoid assembly to the body.

Note: Only the M-12™ modulator will have a controller

installed directly on the solenoid assembly. The M-12R

4. Remove retaining ring(14), then remove the exhaust

5. Remove spring(10) and inlet/exhaust assembly(8).

™

COMMON

SHORT WIRE HARNESS USED ON THE M-12R™ MODULATOR

modulator will only have a cover plate enclosing the

solenoid assembly.

If a mounting bracket was used, mark the position of the

bracket on the unit.

controller (M-12™ modulator) or cover plate (M-12R

modulator) to the solenoid assembly. Then carefully lift

the controller or cover plate from the solenoid

assembly(3). The controller will be attached to the

modulator by a four pin connector. Press the lock tab on

the side of the connector and pull the connector from its

socket in the controller. Now separate the controller or

cover plate from the modulator. Remove the gasket(1)

that seals the controller or cover plate to the solenoid

assembly(3).

Remove the four cap screws(2) that secure the solenoid

assembly(3) to the valve body(7). Separate the solenoid

assembly from the valve body, and remove sealing ring(4)

from the protrusion on the bottom of the solenoid

assembly.

assembly(13). Remove o-ring(11) and o-ring(12) from the

O.D. and l.D., respectively, of the exhaust assembly(13).

Remove the spring seat(9) from the inlet exhaust

assembly.

HOLD

™

7

Page 8

CAP SCREW (4)

COVER PLATE

USED ON THE

M-12R

™

MODULATOR

1

2

3

CAP SCREW (4)

ANTILOCK

CONTROLLER

USED ON M-12

MODULATOR

™

1

4

5

6

7

8

9

10

11

FIGURE 8 M-12™/M-12R™ MODULATOR COMPONENTS

8

12

13

14

Page 9

6. Using thumb force on the piston stem, push the piston(6)

out the opposite end of the body(7). Remove o-ring(5)

from the piston.

7. Discard all items that have replacement parts in the

maintenance kit.

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all parts. Do not allow mineral spirits to

come into contact with the wiring connectors or

solenoids.

2. Inspect the interior and exterior of all parts that will be

reused for severe corrosion, pitting or cracks. Superficial

corrosion and/or pitting on the exterior portion of the body

is acceptable.

3. Inspect bores for deep scuffing or gouges.

4. Inspect pipe threads in the body. Make certain they are

clean and free of thread sealant.

5. Inspect all air line fittings and plugs for corrosion. Clean

all old thread sealant from pipe threads.

6. Any component exhibiting a condition described in

inspection steps 2 to 5 should be discarded and replaced

before proceeding.

ASSEMBLY - REFER TO FIGURE 8

1. Using a lubricant (Bendix Pc. No. 291126) lightly coat

all o-rings, seals, pistons, and body bores.

2. Install spring seat(9) onto inlet exhaust valve(8) so that

it covers the rubber seat of the inlet exhaust valve. Place

inlet/exhaust valve, large diameter first, into the body(7)

bore.

3. Install spring(10) over the barrel of the inlet exhaust

valve(8) so that one end of the spring rests on the spring

seat(9).

4. Install o-rings(11 and 12) into the respective grooves of

the outside and inside diameter of the exhaust

assembly(13). Place the large diameter of the exhaust

assembly against the spring(10) and compress the spring

until the exhaust assembly enters the bore of the body(7)

and o-ring(11) seals against the wall of the bore. Make

certain not to cut or pinch the o-ring.

5. Depress the exhaust assembly into the bore until it

exposes the groove for snap ring(14). Install snap ring(14)

into its groove. Make sure it is fully seated.

6. Install o-ring(5) into its groove in piston(6). Install piston(6)

into the M-12 body. The piston stem fits into the small

hole in the center of the body.

7. Install o-ring(4) onto the protrusion on the bottom of the

solenoid assembly(3). Install the solenoid assembly(3)

onto the body(7). The solenoid assembly will fit on the

body(7) in any of four orientations, 90 degrees apart

however it should be installed in the position marked in

step 2 of the Disassembly instructions. Secure the

solenoid assembly to the body with the four cap

screws(2). Torque to 120 to 150 in. lbs.

8. Install gasket(1) onto the controller or cover plate.

A. If installing a controller, connect the four pin connec-

tor on the solenoid assembly(3) to the corresponding

connector on the controller making certain the connector halves snap and lock.

B. If installing a cover plate, make certain the “pinch”

grommet on the short wire harness is in one of the

two “notches” in the solenoid assembly(3) so that

when the cover plate is installed the wire harness

will not be pinched.

Note the relationship mark made in step 2 of the

disassembly, then secure the controller or cover plate

to the solenoid assembly(3) using the four cap screws.

Torque to 30 60 in. lbs.

9. Install all air line fittings and plugs. Make certain no thread

sealing material enters the valve.

10. Install the antilock assembly on the vehicle. Perform the

"OPERATIONAL AND LEAKAGE TESTS" before

returning the vehicle to service.

9

Page 10

101112

Page 11

Page 12

BW1669 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 4/2004 Printed in U.S.A.

Loading...

Loading...