Page 1

®

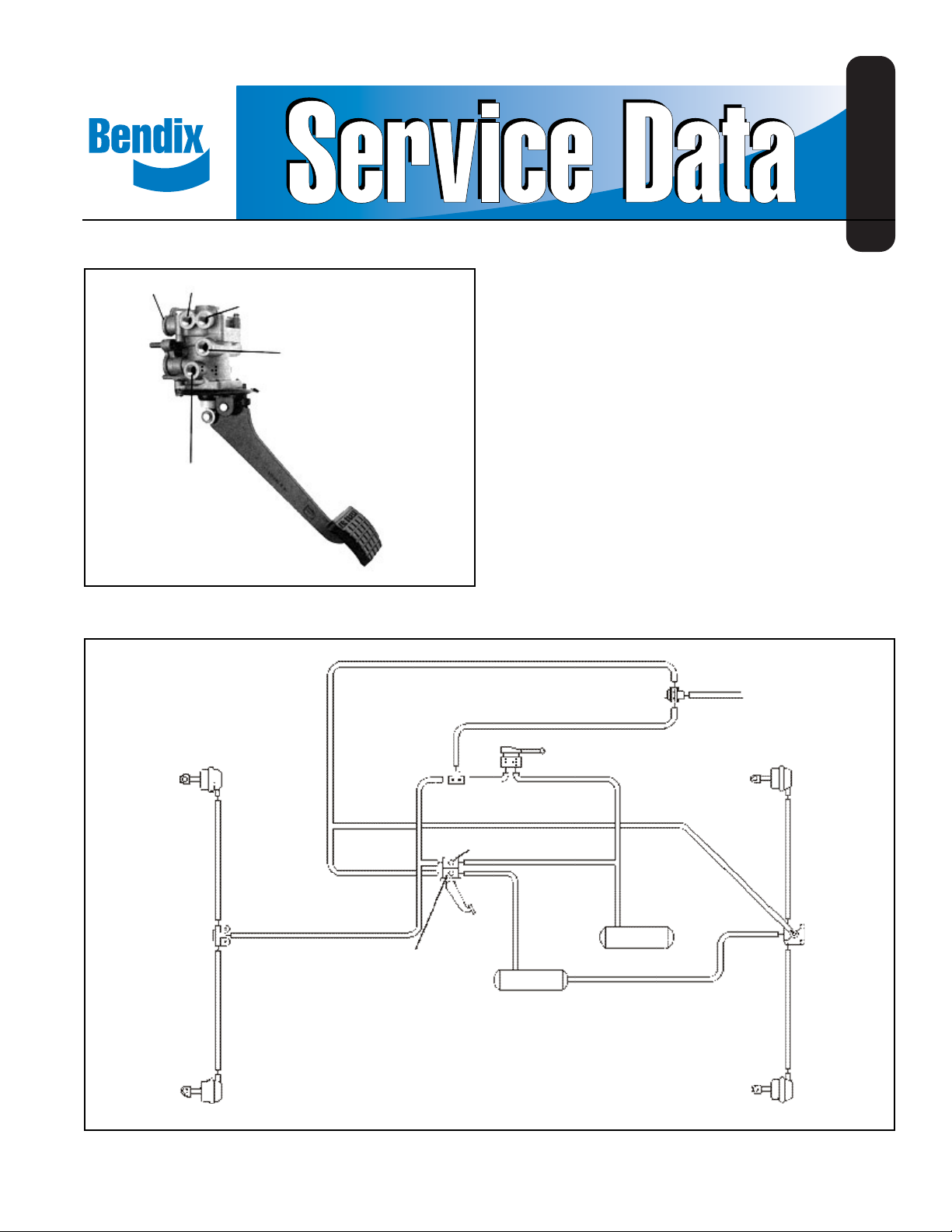

Bendix® E-14™ Dual Brake Valve

EXHAUST

FIGURE 1 - E-14

SECONDARY DELIVERY

SECONDARY SUPPLY

PRIMARY

SUPPLY

™

DUAL BRAKE V ALVE

PRIMARY

DELIVERY

SD-03-828

DESCRIPTION

The E-14™ dual brake valve is a suspended-pedal foot valve

with two separate supply and delivery circuits. The valve

provides the driver with graduated control for applying and

releasing the vehicle brakes.

The circuits in the E-14™ dual brake valve are identified as

follows: The number one (primary) circuit is the portion of

the valve between the primary piston and the secondary

piston. The number two (secondary) circuit consists of the

area between the secondary piston and the exhaust cavity .

The supply , delivery , and exhaust ports of the E-14™ brake

valve are identified by designations cast into the valve body

next to the port. (See Figure 1). The primary supply and

delivery ports are located in the valve’s primary body, and

the secondary supply and delivery ports are located in the

secondary body.

QUICK RELEASE

VALVE

FRONT SERVICE

BRAKE CHAMBER

PRIMARY

CIRCUIT

DOUBLE CHECK

VALVE

SECONDARY

CIRCUIT

™

E-14

DUAL

BRAKE

VALVE

SERVICE RESERVOIR

CONTROL

REAR AXLE

TRAILER

VALVE

FRONT AXLE

SERVICE RESERVOIR

TO TRACTOR

PROTECTION

DOUBLE CHECK

AND

STOP LIGHT SWITCH

REAR AXLE

SERVICE RELAY

VALVE

REAR SERVICE

BRAKE CHAMBER

FIGURE 2 - TYPICAL PIPING SCHEMA TIC

1

Page 2

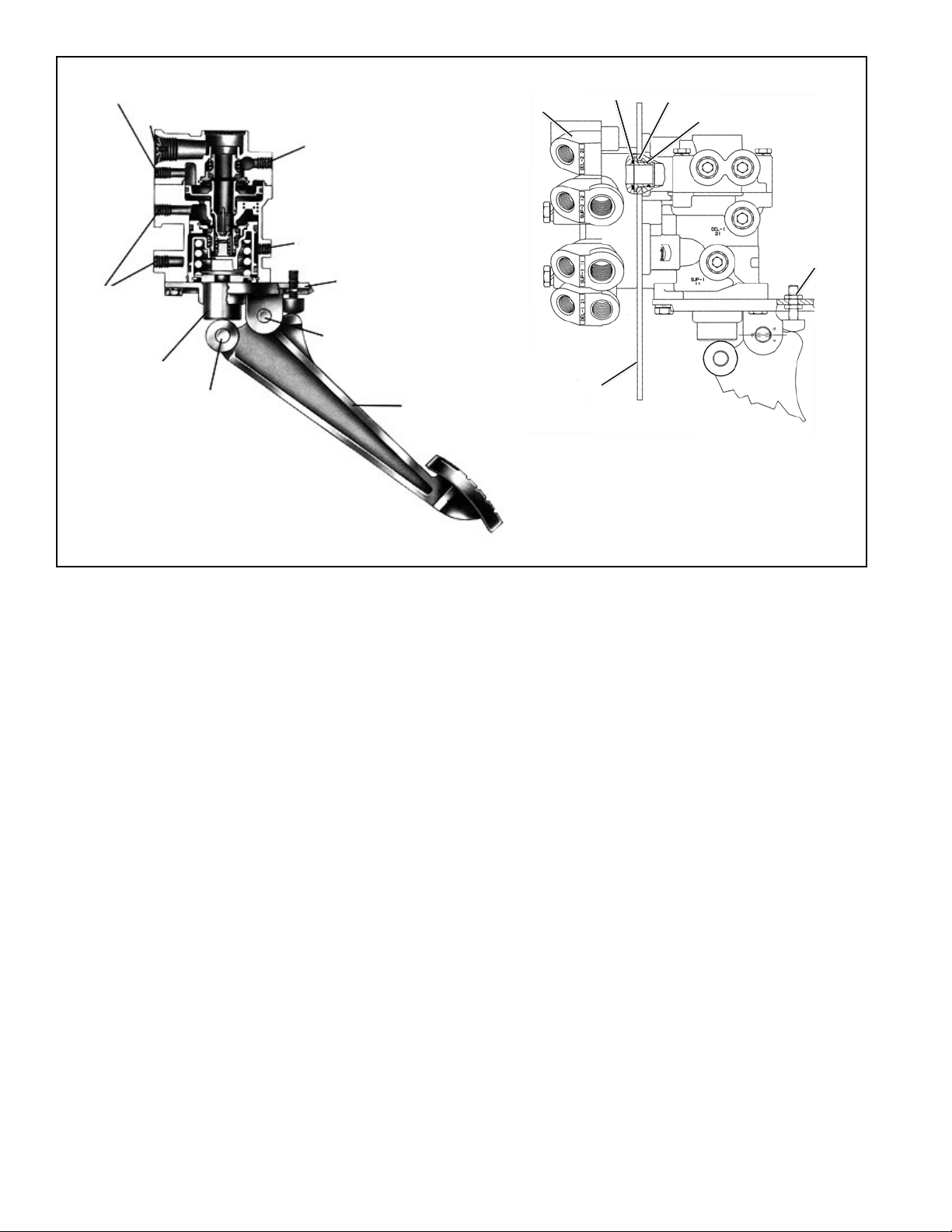

SECONDARY DELIVERY (#2)

EXHAUST

PRIMARY

DELIVERY (#1)

PLUNGER

ROLLER

SECONDARY SUPPLY

(#2)

PRIMARY

SUPPLY (#1)

MOUNTING PLATE

PIVOT PIN

PEDAL

MANIFOLD

SEALING

RING

MOUNTING

PLATE

(FIREWALL)

ADAPTER SLEEVE

O-RING

MOUNTING

PLATE (PEDAL)

A

E-14™ DUAL

BRAKE VALVE

FIGURE 3 - E-14™ DUAL BRAKE V ALVE CROSS SECTIONAL VIEW

The primary circuit operates similar to a standard single

circuit air brake valve, and under normal operating

conditions the secondary circuit operates similar to a relay

valve.

Both the primary and secondary circuits use a common

exhaust, protected by an exhaust diaphragm.

OPERATION

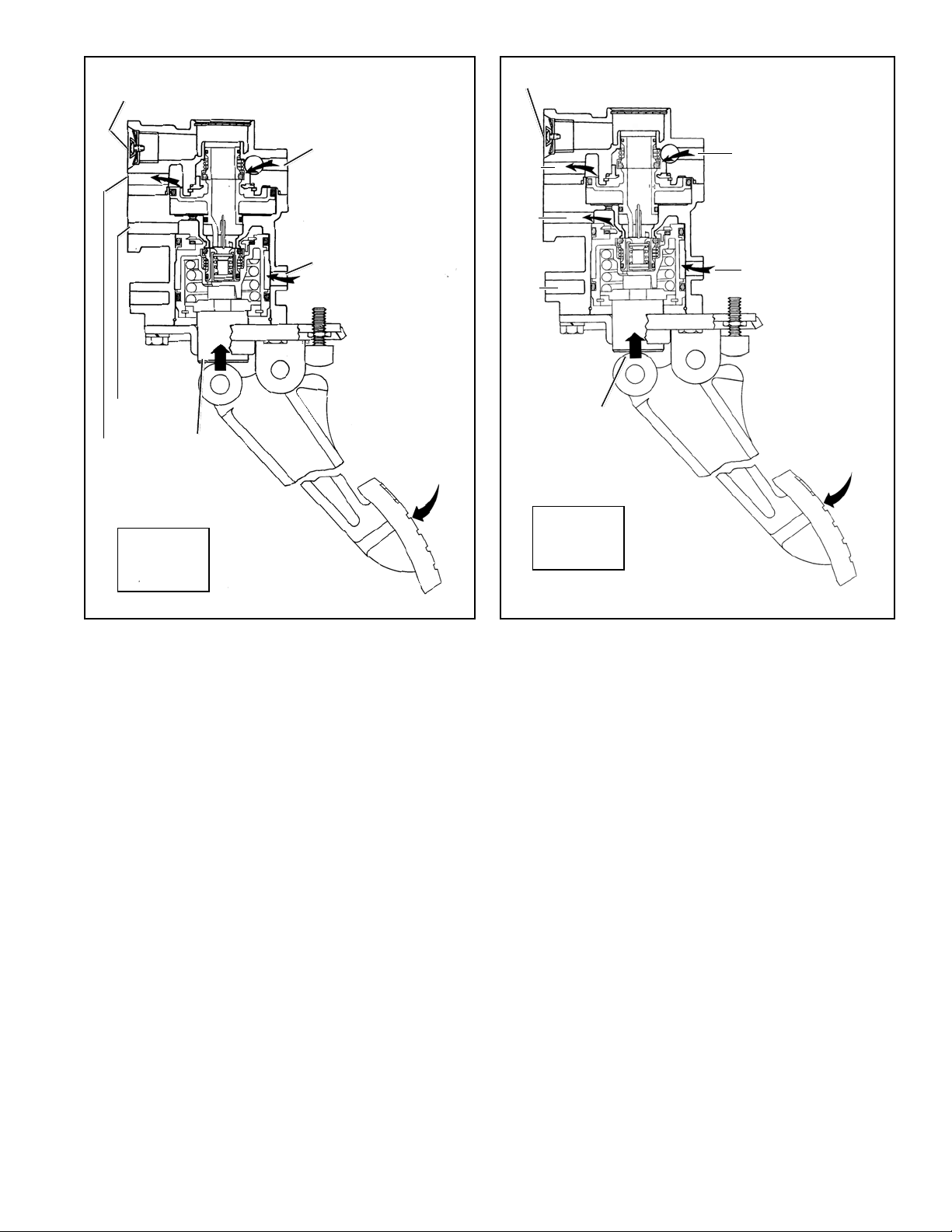

APPL YING: NORMAL OPERA TION-PRIMARY CIRCUIT

When the brake pedal is depressed, the plunger exerts a

force on the spring retainer(7), graduating spring(8), and

primary piston(2). The primary piston, which contains the

exhaust valve seat, closes the primary circuit exhaust valve.

As the exhaust valve closes, the inlet valve for the primary

circuit moves off its seat, allowing air from the primary

circuit supply port to flow out the delivery port.

APPLYING: NORMAL OPERATION-SECONDARY

CIRCUIT

The secondary piston(18) moves with the primary piston

and closes the secondary circuit exhaust. When the inlet

valve in the primary portion of the valve is moved off its

B

E-14™ DUAL BRAKE

VALVE WITH MANIFOLD

seat, air passes through the bleed passage in the secondary

portion of the primary body and enters the secondary piston

cavity . The air moves the secondary piston and opens the

secondary inlet valve, allowing the air from the secondary

supply to flow out the delivery port.

APPL YING: LOSS OF AIR IN THE PRIMAR Y CIRCUIT

If the brake pedal is depressed and no air pressure is

present in the primary circuit, the primary piston will

mechanically move the secondary piston, closing the

secondary exhaust and opening the secondary inlet,

allowing air flow from the secondary supply to its delivery

port.

APPL YING: LOSS OF AIR IN THE SECONDARY CIRCUIT

If the air is lost in the secondary circuit, the primary circuit

will function normally, as described in “Normal Operation:

Primary Circuit.”

BALANCED: PRIMARY CIRCUIT

When the primary delivery pressure acting upon the primary

piston equals the mechanical force of the brake pedal

application, the primary piston will close, preventing further

2

Page 3

EXHAUST

EXHAUST

DEL-2

DEL-1

AIR FLOW

PLUNGER

FORCE

á

SUP-2

SUP-1

DEL-2

SUP-2

DEL-1

SUP-1

DEL-1

PLUNGER

FORCE

PEDAL FORCE

PEDAL FORCE

á

AIR FLOW

FIGURE 4 - APPL YING - NORMAL OPERATION

air flow from the supply port to the delivery port. The exhaust

valve remains closed, preventing the escape of air through

the exhaust port.

BALANCED: SECONDARY CIRCUIT

When air pressure on both sides of the secondary piston

approach each other, the piston moves, closing the

secondary inlet valve and preventing further air flow from

the supply line through the valve. The exhaust remains closed

as the secondary delivery pressure balances the primary

delivery pressure.

RELEASING: PRIMARY CIRCUIT

When the force on the brake pedal is released, mechanical

force is removed from the graduating spring and the primary

piston. Air pressure in the delivery circuit moves the primary

piston and opens the primary exhaust valve, allowing air

pressure in the primary circuit to exit through the exhaust

port.

FIGURE 5 - APPL YING - F AILURE IN THE PRIMARY CIRCUIT

RELEASING: SECONDARY CIRCUIT

When the brake pedal is released, air is exhausted from the

primary circuit side of the secondary piston through the bleed

passage. Air pressure in the delivery side of the secondary

circuit moves the piston and opens the secondary exhaust

valve, allowing air pressure in the secondary delivery line to

exit through the exhaust port.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

Because no two vehicles operate under identical conditions,

maintenance and maintenance intervals will vary . Experience

is a valuable guide in determining the best maintenance

interval for any one particular operation.

Visually check for physical damage to the brake valve such

as broken air lines and broken or missing parts.

3

Page 4

EXHAUST

DEL-2

SUP-2

EXHAUST

SUP-2

DEL-2

DEL-1

SUP-1

DEL-1

PLUNGER

FORCE

PEDAL

FORCE

á

AIR FLOW

FIGURE 6 - APPL YING-F AILURE IN THE SECONDAR Y CIRCUIT

DEL-1

DEL-1

PLUNGER

FORCE

á

AIR FLOW

FIGURE 7 - BALANCED POSITION

SUP-1

PEDAL

FORCE

EVERY 3 MONTHS, 25,000 MILES OR 900 OPERATING

HOURS

1. Remove any accumulated contaminants such as dirt

and gravel from the heel of the pedal, plunger, plunger

boot, and mounting plate.

2. Using a light oil, lubricate the pedal roller, roller pin, and

hinge pin.

3. Inspect the plunger boot for cracks, holes, or

deterioration. Replace if necessary. Also check mounting

plate and pedal for wear and corrosion. Repair or replace

as necessary .

4. Apply 2 to 4 drops of oil between plunger and mounting

plate - DO NOT OVER OIL!

5. Check for excessive leakage as described in the

“OPERATIONAL & LEAKAGE TEST” section of this

manual.

EVERY YEAR, 100,000 MILES, OR 3,600 OPERATING

HOURS

1. Perform steps 1 through 4 above.

2. Perform the checks in the “OPERA TION & LEAKAGE

TEST” section of this manual.

4

OPERATIONAL & LEAKAGE TESTS

GENERAL

A change in vehicle braking characteristics or a low pressure

warning may indicate a malfunction in one of the brake

circuits. Although the air brake system may continue to

function, the vehicle should not be operated until the

necessary repairs have been made and both braking circuits,

including the pneumatic and mechanical devices, are

operating normally .

If the brake valve does not function as described above or if

leakage is excessive, it is recommended that it be replaced

with a new or remanufactured unit, available at Bendix outlets.

Always check the vehicle brake system for proper operation

after performing brake work and before returning the vehicle

to service.

OPERATIONAL TEST

Check the delivery pressure of both circuits, using test

gauges known to be accurate. Note: The pedal will not be in

a “normal” released position until the air brake system is

pressurized. The pedal will rise to its normal release position

as the brake system is pressurized from 0 psi. Depress the

pedal to several positions between the fully released and

fully applied positions and check the delivered pressure on

the test gauges to see that it varies equally and proportionally

with the movement of the brake pedal.

Page 5

EXHAUST

SUP-2

SUP-1

DEL-1

DEL-1

DEL-2

PLUNGER

FORCE

FIGURE 8 - RELEASED MODE

PEDAL FORCE

After a full application is released, the reading on the test

gauges should fall off to zero promptly . NOTE: the number

one circuit delivery pressure will be about four psi greater

than the number two circuit delivery pressure with both supply

reservoirs at the same pressure. This is normal for the E-14

brake valve.

LEAKAGE TEST

Make and hold a high pressure application (80 psi). Coat

the exhaust port and body of the brake valve with a soap

solution. Leakage permitted is a 1" bubble in 3 seconds in

both the applied and released positions. No leakage is

permitted anywhere else.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

™

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

V AL VE REMOVAL

1. Identify and mark or label all air lines and their respective

connections on the brake valve to facilitate ease of

installation. Disconnect all air lines.

2. Remove the valve from its mounting on the vehicle. For

manifold-type valves, remove the brake valve and manifold,

in tact, from the vehicle.

DISASSEMBLY (SEE FIGURE 9)

The following disassembly and assembly procedure is

presented for reference purposes only. Always have the

appropriate maintenance kit on hand, and use its instructions

in lieu of those presented here. Refer to Figure nine

throughout the procedure.

™

5

Page 6

CAUTION: The brake valve may be light clamped in a bench

vise, but overclamping may damage the valve and

cause leakage and/or malfunction. If a vise is used,

clamp on the supply and delivery ports on opposing

sides of the valve’s primary body .

1. Remove all air line fittings and plugs.

2. On valves that have a manifold on the engine

compartment side, remove the bolts that secure the

manifold to the valve. Separate the valve and manifold

and remove the sealing rings and adapter sleeves. (See

Figure 2.)

3. Remove the four cap screws(16) that secure the primary

body to the secondary body. Separate the two body

halves and remove and discard o-ring(17).

4. Pull secondary piston(18) out of the primary body and

remove and discard o-rings(19 & 20).

5. Remove and discard snap ring(10) from the secondary

body while manually holding and compressing valve

seat(1 1) in place.

6. Slowly release valve seat(11), allowing it to rise out of

the body . Remove the valve seat, then remove and discard

o-ring(12).

7. Remove and discard valve assembly(13) along with its

o-ring(15) from the secondary body . Remove the valve

assembly return spring(14).

8. Carefully remove and discard exhaust diaphragm

screw(24), diaphragm washer(25), diaphragm(26), and

diaphragm retainer(27) from the secondary body . NOTE:

Some E-14™ brake valves have a threaded exhaust port

instead of items 24-27.

9. Using light force, push piston(2) into the primary body

until piston retaining ring(1) is fully visible. Remove piston

retaining ring(1), taking care not to damage the piston

bore in the body.

10.Gently tap the primary body on a soft surface to remove

piston(2). Remove and discard o-rings(3 & 5) and both

wear rings(4) from piston(2).

11. Place the piston on a flat surface. Using finger force,

depress and hold spring retainer(7), then remove and

discard retaining ring(6) from piston(2).

12.Gently release spring retainer(7), allowing it to rise out

of the piston. Remove spring retainer(7) and graduating

spring(8) from piston(2).

13. Remove and discard rubber spring(9) from the interior of

piston(2).

14.Remove and discard snap ring(10) from piston(2) while

manually holding and compressing valve seat(11) in

place.

15.Slowly release valve seat(11), allowing it to rise out of

piston(2). Remove valve seat(1 1), then remove and discard

o-ring(12).

16.Remove and discard valve assembly(13) along with its

o-ring(15) from piston(2). Remove valve assembly return

spring(14).

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts.

2. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting, or cracks.

Superficial corrosion and/or pitting on the exterior portion

of the secondary and primary bodies is acceptable.

3. Inspect the bores of both bodies for deep scuffing or

gouges.

4. If primary piston(2) is reused, make certain that vents

“A & B” are open and free of obstructions. (See Figure

2.)

5. Make certain vent “C” is open in the primary body of the

valve. (See Figure 2.)

6. Inspect the pipe threads in both bodies. Make certain

they are clean and free of thread sealant.

7. Inspect pedal assembly and mounting plate. Make certain

the pedal roller turns freely and is lightly lubricated.

Note: Some pedal assemblies, not furnished by Bendix,

do not employ a roller. In this case, make certain the

mechanism in use moves across the plunger smoothly ,

without binding or sticking. Inspect plunger for excessive

scuffing or wear. Check the plunger bore in the mounting

plate for excessive wear, shown by “egg shaping” (bell

mouthing). Inspect mounting plate for severe corrosion,

paying particular attention to the area around the pivot

pin bores.

8. If the brake valve uses a rubber boot between the plunger

and mounting plate, inspect the boot for deterioration

or cracking.

9. Inspect all air line fittings and plugs for corrosion Clean

all old thread sealant from the pipe threads.

Any valve or pedal assembly component that does not meet

the inspection criteria listed above should be discarded and

replaced before proceeding.

ASSEMBL Y (SEE FIGURE 9)

1. Using silicone lubricant (650-M), lightly coat all o-rings,

o-ring bores, and grooves, except for the secondary

piston o-rings(19 and 20). Lightly lubricate primary

piston(2) bore into which graduating spring(8) is installed.

With the 328-M lubricant, lightly coat o-rings (19 and

20) and o-ring grooves on secondary piston(18).

6

Page 7

24

25 26

16

10

11

12

27

13

14

15

15

14

17

18

19

13

10

12

11

22

20

23

5

4

2

4

3

8

9

21

1

7

6

FIGURE 9 - EXPLODED VIEW

MOUNTING PLATE

PLUNGER

PEDAL ASSEMBLY

7

Page 8

2. Place primary piston(2) on a flat surface and install rubber

spring(9) and metal graduating spring(8).

3. Install graduating spring retainer(7) on top of graduating

spring(8), making certain that the side with the high

circular protrusion is away from the spring.

4. Manually depress and hold spring retainer(7) in piston(2),

then install snap ring(6), making certain it is completely

seated in its groove in piston(2).

5. Install o-rings(15) on both valve assemblies(13).

6. Install valve spring(14) in piston(2), then install valve

assembly(13) in the spring.

7. Install o-ring(12) into the o-ring groove of piston(2), then

install valve seat(11) on valve assembly(13). Gently

depress and hold the valve seat in piston(2) while

installing retaining ring(10).

8. Install o-rings(3 and 5) on primary piston(2), then install

wear rings(4) in the o-ring grooves next to the o-rings.

Make certain that one flange of the wear ring(4) is in the

o-ring groove, while the opposite flange extends away

from the end of piston(2) and toward the center. The

wear ring flange MUST NOT COVER OR OVERLAP

EITHER O-RING . (See Figure 10.)

9. Carefully insert the assembled primary piston(2), valve

end first, into the primary valve body until the piston

retaining ring groove in the body is visible. Make certain

o-rings(3 and 5) and wear rings(4) are not damaged in

the process. Do not force the piston. If substantial

resistance is encountered, check for proper installation

of the wear rings.

10. Install piston retaining ring(1) in its groove in the

secondary body , making certain it is fully seated in the

groove.

1 1. Install plunger(21) in its return spring(22). Install the spring

and plunger on secondary piston(18). While manually

depressing and holding the plunger and spring on the

piston, slide plunger and spring retainer(23) into place

so that it secures both the plunger and spring to the

piston. Make certain the retainer flanges are securely

around piston lip and plunger groove.

12.Install o-rings(19 and 20) on secondary piston(18).

13. Install diaphragm retainer(27), diaphragm(26), diaphragm

washer(25). and screw(24) in the exhaust port. Torque

screw to 15-25 in. lbs. NOTE: Some E-14™ brake valves

have threaded exhaust ports instead of items 24-27.

14. Install valve spring(14) in the secondary body, then install

valve assembly(13) in the spring.

15.Install o-ring(12) into the o-ring groove of piston(2), then

install valve seat(11) on valve assembly(13). Gently

depress and hold the valve seat in the secondary body

while installing retaining ring(10).

PRIMARY PISTON

➋

DEL-1

21

O-RING

➎

WEAR RINGS

➍

SUP-1

11

FIGURE 10

O-RING

➌

16. Install the assembled secondary piston(18) in the primary

body, making certain that o-rings(19 and 20) are not

damaged.

17. Install o-ring(17) on the secondary body. Join the

assembled secondary and primary bodies. Secure the

bodies using the four cap screws(16), and torque to 30

to 60 in. lbs.

18. Install the pedal mounting plate on the basic brake valve,

noting the relationship marked during V AL VE REMOVAL

step 2. Secure the mounting plate to the valve using the

three cap screws and torque to 80 to 120 in. lbs.

19.If using a manifold-type valve, install the sealing rings

and adapter sleeves that connect the valve to the

manifold. Install the manifold on the valve, and secure

with its bolts. Torque to 80 to 120 in. lbs.

20. Install all air line fittings and plugs, making certain thread

sealant material does not enter the valve.

V ALVE INST ALLATION

1. Install the assembled brake valve on the vehicle.

2. Reconnect all air lines to the valve using the identification

made during V AL VE REMOVAL step 1.

3. After installing the brake valve assembly, perform the

“OPERA TIONAL & LEAKAGE CHECKS” before placing

the vehicle in service.

8

BW1666 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

Loading...

Loading...