Page 1

®

Bendix® BP-1™ Brake Proportioning Valves

SD-03-952

3/8 P.T.

SUPPLY PORT

1/8 P.T.

CONTROL PORT

3/8 P.T.

DELIVERY PORT

FIGURE 1 BP-1™ BRAKE PROPORTIONING VALVES

1.5

.340”

MOUNTING

HOLES (2)

PIECE NO.

STAMPED HERE

I.D. TAG STAMPED

BP-1 FRONT OR

BP-1 REAR

DESCRIPTION OF THE BP-1™ VALVES

The BP-1™ brake proportioning valves are incorporated into

the air brake systems to improve the controllability and

reduce the stopping distance of bobtail tractors during

braking. BP-1™, front and rear, valves reacting to the lack of

pressure in the trailer supply line reduce the braking effort

on the rear axles and increase the braking effort on the front

axle of tractors operating in the bobtail mode. Treadle

application force during bobtail operation resembles treadle

application force during normal operation with a connected

trailer.

A typical brake proportioning system is shown in Figure 6.

The system consists of a front and a rear brake proportioning

valve and a TR-3™ valve.

Caution: The BP-1™ front and BP-1™ rear valves are similar

in appearance but are NOT interchangeable. Note

identification tag attached to one of the cover

screws (Figure 1); it will be stamped ‘BP-1 Front’

or ‘BP-1 Rear’. The BP-1™ rear valve can be used

without installing a BP-1™ front valve, providing the

vehicle does not have a front axle ratio valve. If the

vehicle has a front axle ratio valve, the ratio valve

must be replaced with a BP-1™ front valve.

OPERATION

A tractor that is equipped with the BP-1™ rear brake

proportioning valve and TR-3™ valve only will respond in the

following manner. With the trailer supply valve pushed in

and a service brake application made, equal pressure (100%

of service application) will be delivered to each axle of the

tractor and trailer. When the trailer is disconnected from the

tractor and the trailer supply valve is pulled out, the front

axle of the tractor will receive 100% of the service brake

application pressure and the rear axle or axles approximately

25%. As application pressure increases, the differences

between the front axle and the rear axle(s) pressures

diminish.

1

Page 2

A tractor that is equipped with both a front and rear axle

brake proportioning valve with the trailer supply valve

activated (tractor/trailer mode) will experience 50% of service

brake application pressure on the front axle up to 40 psi.

With service applications above 40 psi the differential between

the supply and delivery diminishes until at 60 psi it is a

one-to-one ratio. The rear axles receive 100% of the service

application. With the trailer supply valve pulled out, (bobtail

mode) the front axle of the tractor will receive 100% of service

brake application and the rear axle(s) approximately 25%

during normal brake applications. As application pressure

increases, the differences between the front axle and rear

axle(s) pressures diminishes.

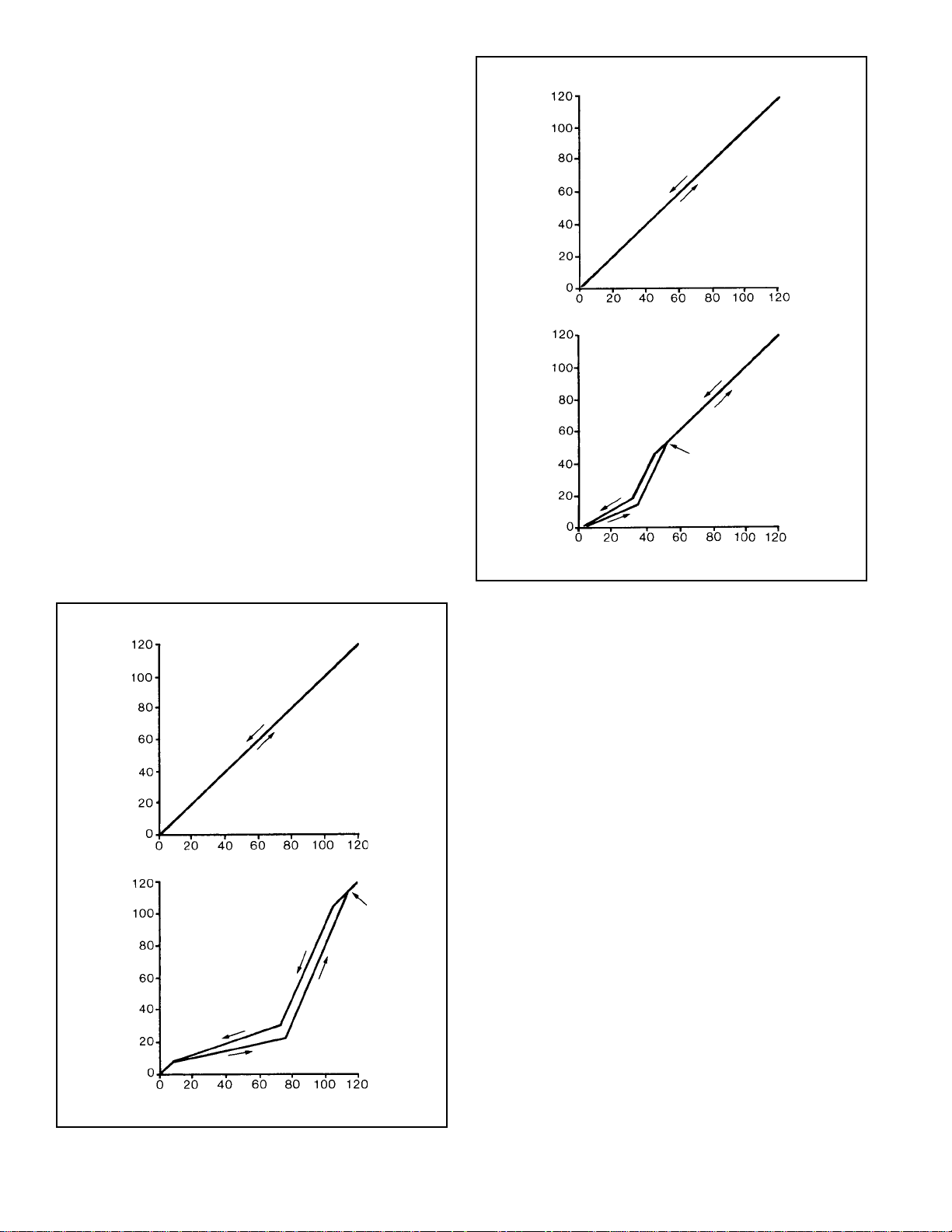

BP-1™ REAR VALVE (REFER TO FIGURE 4)

When the trailer supply valve is activated, air pressure is

delivered to the trailer via the supply line. At the same time

air is delivered to the TR-3

the air to the control port of the BP-1

application is made, air entering the supply port works upon

the total area of the upper and inner pistons and delivery

pressure equals supply pressure. See Figure 2, full delivery

mode.

™

inversion valve which exhausts

™

valve and a brake

FULL DELIVERY MODE

(NO CONTROL PRESSURE)

DELIVERY PRESSURE (PSI)

SUPPLY PRESSURE (PSI)

LIMITING MODE

(WITH CONTROL PRESSURE)

BLEND BACK

POINT

DELIVERY PRESSURE (PSI)

With the trailer supply valve released, air pressure in the

supply line to the trailer is exhausted to atmosphere. At the

same time the air pressure to the control port of the TR-3

FULL DELIVERY MODE

(NO CONTROL PRESSURE)

DELIVERY PRESSURE (PSI)

SUPPLY PRESSURE (PSI)

LIMITING MODE

(WITH CONTROL PRESSURE)

BLEND BACK

POINT

DELIVERY PRESSURE (PSI)

SUPPLY PRESSURE (PSI)

FIGURE 2 PERFORMANCE CURVE FOR NOMINAL

™

BP-1

BRAKE PROPORTIONING REAR VALVE

SUPPLY PRESSURE (PSI)

™

FIGURE 3 PERFORMANCE CURVE FOR NOMINAL

BP-1™ BRAKE PROPORTIONING FRONT VALVE

inversion valve is also exhausted. This sequence causes

full reservoir pressure to be delivered to the control port of

the BP-1™ rear valve. This air is contained on the underside

of the upper piston and when a brake application is made

the air entering the supply port of the BP-1™ rear valve can

only affect the surface of the lower and inner pistons. Due to

the reduced area of the lower and inner pistons, the valve

delivers approximately 25% of the supply pressure to the

relay valve. See Figure 2, limiting mode. In addition, spring

#8, Figure 4 causes the lower piston to be initially held open

until initial delivery pressure closes the lower piston and the

valve will limit normally. The purpose of this initial delivery is

to offset the relay valve crack pressure when the vehicle is

operating bobtailed and enhance the performance of the

proportioning system.

BP-1™ FRONT VALVE (REFER TO FIGURE 5)

When the trailer supply valve is activated air is supplied to

the trailer via the supply line at the same time air is delivered

to the TR-3™ inversion valve which exhausts the air to the

control port of the BP-1™ front brake proportioning valve.

With air pressure removed from the control port of the BP-1

valve and a brake application is made, air entering the supply

port works upon the total surface area of the upper and lower

piston. The upper piston is restricted by the piston spring

up to 40 psi; therefore, brake applications up to 40 psi can

only displace the lower piston, which due to its surface area

™

2

Page 3

2.78

COVER

3/8 P.T.

SUPPLY

8

4

UPPER

PISTON

1/8 P.T.

CONTROL

6

5

3/8 P.T.

DELIVERY

EXHAUST

Key Description Qty.

1 O-Ring 2 5 Inlet/Exhaust Valve 1

2 O-Ring 1 6 Spring 1

3 O-Ring 1 7 Sealing Ring 1

4 O-Ring 1 8 Spring 1

FIGURE 4 BP-1™ REAR BRAKE PROPORTIONING VALVE

CUTAWAY VIEW

2.78

3/8 P.T.

SUPPLY

3

UPPER

PISTON

1/8 P.T.

CONTROL

6

5

3/8 P.T.

DELIVERY

EXHAUST

Key Description Qty. 4 Spring 1

1 O-Ring 1 5 Inlet/Exhaust Valve 1

2 O-Ring 1 6 Spring 1

3 O-Ring 1 7 Sealing Ring 1

FIGURE 5 BP-1™ FRONT BRAKE PROPORTIONING VALVE

CUTAWAY VIEW

PISTON

1

LOWER

PISTON

BODY

COVER

7

1

LOWER

BODY

7

3

INNER

PISTON

2

4

2

4.34

4.34

delivers 50% of the service application to the actuators.

Service pressures above 40 psi begin to displace the upper

piston and the differential between the supply and delivery

diminishes until at 60 psi the spring force under the upper

piston is totally overcome and the valve delivers a one-to-one

ratio. See Figure 3, limiting mode.

With the trailer supply valve released, air pressure to the

trailer is exhausted to atmosphere. At the same time the air

™

pressure to the control port of the TR-3

inversion valve is

also exhausted. This sequence causes full reservoir

pressure to be delivered to the control port of the BP-1

valves. The air entering the control port of the BP-1™ front

valve acts upon the lower piston, closing the exhaust and

holding the inlet open. In this position when a service brake

application is made, 100% of the pressure received at the

supply port of the BP-1

™

front valve is delivered to the

actuators on the front axle. See Figure 3, full delivery mode.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

EXTREME CAUTION should

™

™

3

Page 4

KEY

C-CONTROL

D-DELIVERY

S-SUPPLY

TRACTOR PROTECTION

CONTROL VALVE

TRACTOR

PROTECTION

VALVE

Key No. Qty. Description

1 1 BP-1

2 1 TR-3™ Inversion Valve

3 1 BP-1

™

(Rear) Valve

™

(Front) Valve

REPLACES FRONT

AXLE LIMITING

VALVE

TEE FITTING

EXISTING

LINE

Ë

TEE FITTING

Ê

Ì

EXISTING REAR

AXLE SERVICE

EXISTING FRONT

AXLE SERVICE

DELIVERY LINE

BRAKE VALVE

TEE FITTING

DELIVERY LINE

REAR AXLE

SERVICE

RESERVOIR

FIGURE 6 TYPICAL INSTALLATION SCHEMATIC OF BRAKE PROPORTIONING SYSTEM

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

4. Install the BP-1™ rear valve into the service line from the

brake valve. Connect the delivery line from the brake

valve to the supply port of the BP-1™ valve and the delivery

port of the BP-1™ valve to the control port on the relay

valve.

5. Connect the TR-3™ inversion valve as follows. Tee the

control port to the delivery of the trailer supply valve,

the supply port to the supply line of the brake valve, and

connect the delivery port to the control port of the BP-1

INSTALLATION (REFER TO FIGURE 6)

1. The vehicle being fitted with a BP-1™ rear brake

proportioning valve must be equipped with a rear axle

service relay valve. It cannot be installed on a vehicle

utilizing a quick release valve system without a relay

valve.

2. For vehicles equipped with a front axle service ratio or

limiting valve (such as the Bendix® LQ-4™ valve) it must

be removed and replaced by the BP-1™ front valve

provided in kit #209924.

Caution: The front and rear BP-1™ valves are not

valve.

Note: If vehicle does not have a front axle ratio or limiting

valve, proceed to “Operational Checks”. If vehicle

has a front axle ratio or limiting valve, continue with

Step 6.

6. Remove the existing front axle ratio or limiting valve and

replace it with the BP-1™ front valve. Connect the front

axle brake valve delivery line to the supply port of the

BP-1™ valve, the delivery port of the BP-1™ valve to the

front axle actuators, and the control port of the BP-1

valve to the delivery of the TR-3™ inversion valve.

interchangeable. They are identified with a metal

tag stamped ‘BP-1 Front’ or ‘BP-1 Rear’ attached

to one of the cap screws on the cover.

3. Mount the BP-1™ rear valve and the TR-3™ inversion valve

in a protected area that is convenient to the service line

between the brake valve and the relay valve.

OPERATIONAL CHECKS

After components have been installed and all connections

made, perform the following checks.

1. With the trailer supply valve pulled out (bobtail running

position) install two air gauges in the service system;

one at an actuator on the front axle and one at an actuator

on a rear axle.

REAR

AXLE

SERVICE

RELAY

VALVE

™

™

4

Page 5

2. Build system pressure to governor cut-out setting.

3. Make a service brake application with the foot valve and

have another person or persons observe the gauges.

When the front axle gauge reaches a 40 psi application

the rear axle gauge should read approximately 10-20

psi depending on rear axle relay valve differential. The

differential between the front axle and rear axles will

decrease as the application pressure is increased.

4. For vehicles without a front axle service ratio or limiting

valve with the trailer connected, push the trailer supply

valve in (applied position) and repeat check made in

Step 3. Gauges should read approximately equal

throughout range of service applications. For vehicles

with a BP-1™ front valve push the trailer supply valve in

(applied position) and repeat check made in Step 3. When

the front axle gauge reads 20 psi, the rear axle gauge

should read approximately 40 psi. As system pressure

increases, the differential between the front and rear axles

diminishes.

5. Test drive the vehicle in a safe area at slow speed and

with the trailer supply valve in the bobtail position make

several brake applications to become familiar with the

brake characteristics prior to placing the unit back into

service.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the BP-1

valve should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

be BP-1™ valve not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

REMOVAL OF THE BP-1™ REAR VALVE

FROM VEHICLE

1. Secure the vehicle on a level surface by means other

than the brakes.

2. Drain the air system completely making sure all reservoirs

are at atmospheric pressure.

3. Remove and identify the air lines from the BP-1™ rear

valve. This valve is usually located along the frame rail

between the brake valve and the rear axle.

4. Remove the two bolts attaching the BP-1™ rear valve to

the vehicle and move the valve to a bench.

5. Clean the exterior of the valve taking care to prevent

contaminates from entering the open ports of the valve.

DISASSEMBLY OF THE BP-1™ REAR VALVE

(REFER TO FIGURE 4)

1. Remove the four Sems screws from the cover. Retain

the screws and the metal tag with ‘BP-1 Rear’ stamped

on it. Separate the cover from the body. Remove and

discard o-ring(7).

2. Remove the spring (8) from the I.D. of the inner piston,

remove the upper piston from the body and push the

inner piston out of the center of the upper piston.

3. Remove the lower piston from the body of the BP-1

rear valve and tip the piston over to remove the spring(6)

and the inlet/exhaust valve(5).

4. Remove the o-rings (1), (2), (3), (4) from the pistons.

CLEAN AND INSPECT

1. Wipe the interior of the cover, body, and the pistons

with a clean dry cloth to remove any contaminates.

2. Visually inspect all components for cracks, scoring, or

damage of any kind. If any of these conditions exist,

the valve should be replaced.

ASSEMBLY

1. Coat the bore surfaces of the cover, body, and upper

piston with a light coating of silicone lubricant.

2. Lubricate the six o-rings with the same material used in

Step 1.

3. Install the o-rings onto the pistons and the cover as shown

in Figure 4.

4. Install the inlet/exhaust valve into the bore of the lower

piston. Place the spring(6) on top of the inlet/exhaust

valve.

5. Install the inner piston into the bore of the upper piston

™

and then place the lower piston into the bottom of the

upper piston.

6. Place the piston assemblies into the body of the valve

and install the spring (8) into the I.D. of the inner piston

as shown in Figure 4.

7. Place the cover with o-ring(7). in place onto the body

with the supply port directly above the control port.

8. Install the four Sems screws and torque to 50-80 inch

pounds.

Note: Be sure that the identification tag stamped ‘BP-1

Rear’ has been reinstalled on one of the screws.

9. Reinstall the BP-1™ rear valve on the vehicle and

reconnect the airlines as identified in ‘Removal’

instructions.

10. Refer to section titled ‘Operational Checks’.

™

5

Page 6

REMOVAL OF BP-1™ FRONT VALVE FROM

VEHICLE

1. Secure the vehicle on a level surface by means other

than the brakes.

2. Drain the air system completely making sure all reservoirs

are at atmospheric pressure.

3. Remove and identify the air lines from the BP-1™ front

valve. The BP-1™ front valve is usually located along the

frame rail between the brake valve and front axle.

4. Remove the two bolts attaching the BP-1™ front valve to

the vehicle and move the valve to a bench.

5. Clean the exterior of the valve taking care to prevent

contaminates from entering the open ports of the valve.

DISASSEMBLY OF BP-1™ FRONT VALVE

(REFER TO FIGURE 5)

1. Remove the four Sems screws from the cover.

Caution: Hold cover down against spring load and

release gently when screws are removed. Retain the

screws and the metal tag with ‘BP-1 Front’ stamped on

it. Separate the cover from the body. Remove and

discard o-ring(7).

2. Remove the upper piston from the cover and the piston

spring(4) and lower piston from the body.

3. With a pair of needle nose pliers grasp the end of the

valve spring(6) inside the lower piston and remove by

pulling and turning the spring in a clockwise manner.

4. Remove the inlet/exhaust valve(5) from the lower piston.

5. Remove the o-rings(1), (2), (3) from the pistons.

CLEAN & INSPECT

1. Wipe the interior of the body, cover and the pistons

with a clean dry cloth to remove any contaminates.

2. Visually inspect all components for cracks, scoring, or

damage of any kind. If any of these conditions exist,

the valve should be replaced.

ASSEMBLY (REFER TO FIGURE 5)

1. Coat bore surfaces of both the cover and the body with

a light film of silicone lubricant.

2. Lubricate the four o-rings in kit with the same material

as Step 1.

3. Install o-rings(1) and (2) on the lower piston, o-ring(3) on

the upper piston and o-ring(7) on the cover. Refer to Figure

4.

4. Install the large end of the upper piston into the bore of

the cover of the valve.

5. Place the inlet/exhaust valve(5) into the I.D. of the lower

piston and retain with valve spring(6). Use needle nose

pliers to install spring(6) by grasping spring on the bar

that intersects the end of the spring and twisting in a

clockwise motion while pressing down.

Caution: Be sure inlet/exhaust valve is seated flat against

the bottom of the piston and the spring is fully

seated below the step on the I.D. of the piston

wall. Refer to Figure 5.

6. Install the lower piston assembly into the body of the

valve. (Large end to enter the bore first.)

7. Install the piston spring into the body of the valve. (Large

diameter of the spring to enter first.)

8. Place the cover and upper piston onto the body so that

the supply port is directly above the control port. Place

the valve on a firm surface and compress the spring by

pushing down on the cover. Hold in this position and

install two of the four 1/4" Sems screws.

9. Place the metal tag stamped ‘BP-1 Front’ onto one of

the remaining 1/4" Sems screws. Install all Sems screws

and torque to 50-80 inch pounds.

10. Reinstall the BP-1

reconnect the air lines as identified in ‘Removal’

instructions.

11. Refer to section titled ‘Operational Checks’.

™

front valve on the vehicle and

BW1554 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 3/2004 Printed in U.S.A.

6

Loading...

Loading...