Page 1

®

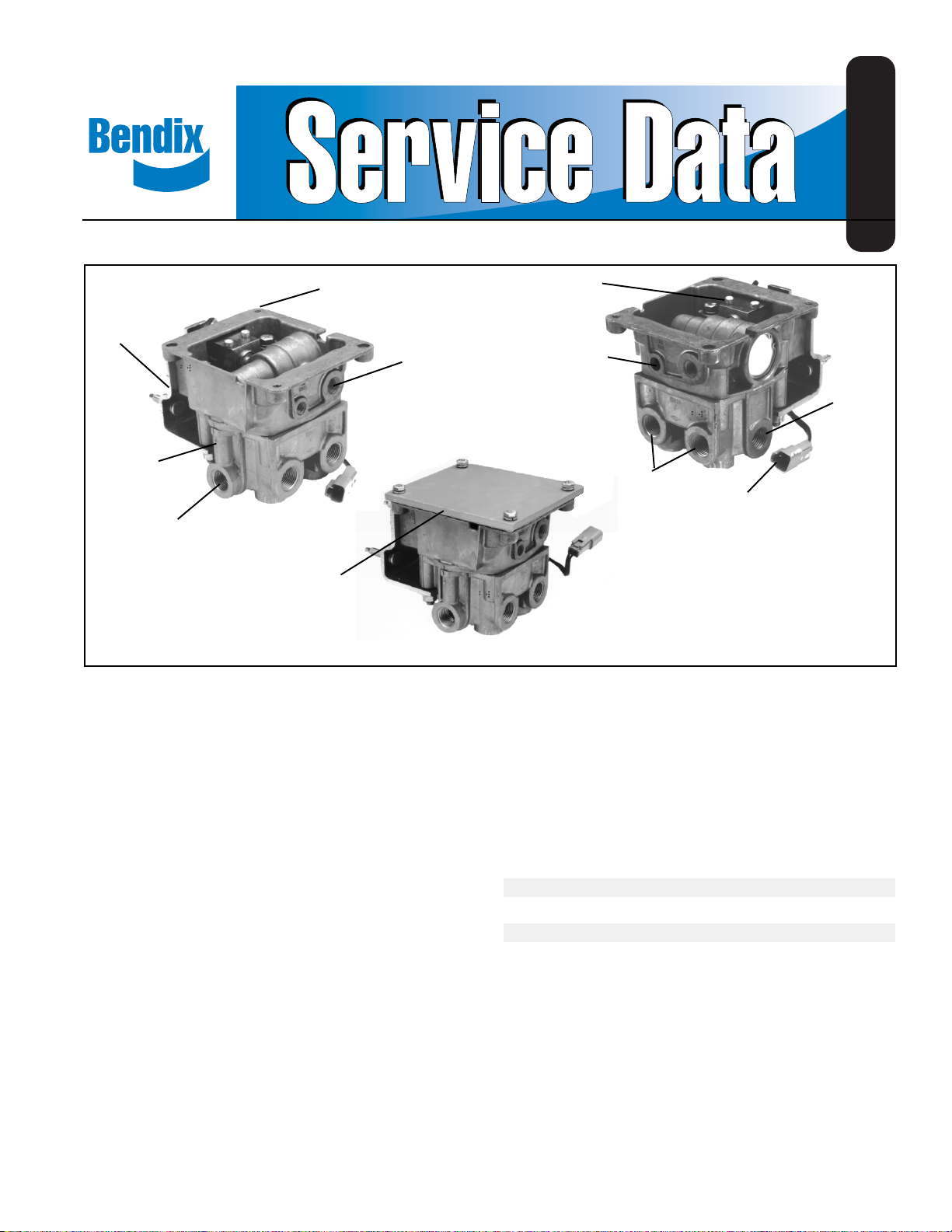

Bendix® ATR-1™ AntiLock Traction Relay Valve

SD-13-4811

CONTROLLER

MOUNTING HOLES (4)

MOUNTING

BRACKET

SERVICE

PORT

BODY

SUPPLY

PORT

COVER PLATE FOR

REMOTE MOUNT

REMOTE MOUNT ATR-1™ RELAY VALVE

FIGURE 1 - ATR-1™ ANTILOCK TRACTION RELAY VALVE

DESCRIPTION

The ATR-1™ antilock traction relay is a specialized air brake

valve developed for use on Bendix antilock/traction equipped

vehicles.

It is essentially three separate valves working in combination

in a single housing. An R-14™ style service relay is the base

valve and is fitted with a modified cover containing a double

check valve and a traction control solenoid. The ATR-1™ valve

contains both air and electric components to provide the

service braking and traction control (differential braking)

functions. A Bendix antilock traction controller can be

mounted to the ATR-1™ valve or a cover plate can be installed

and the antilock controller mounted elsewhere on the vehicle.

When an ATR-1™ valve is combined with an antilock traction

controller the resulting assembly is referred to as an antilock

traction assembly.

The ATR-1™ valve replaces the standard relay valve used to

control the rear axle service brakes and performs the standard

relay function. Like the standard relay valve it replaces, the

ATR-1™ valve (sometimes with attached antilock controller)

TRACTION CONTROL

SOLENOID

UNDRILLED

“CON” PORT

DELIVERY

PORT (4)

2 PIN SOLENOID

CONNECTOR

is normally mounted near the service brakes it serves. A

mounting bracket, furnished with the valve, permits either

frame or cross member mounting. All air connections on

the ATR-1™ valve are identified for ease of installation. The

letter identification and air line connections are shown below

for reference.

EMBOSSED

ATR-1™ VALVE AIR CONNECTION IDENT.

Supply (to reservoir) SUP

Delivery (to brake Chamber) DEL

Service (to brake valve rear delivery) SER

Control (not drilled or threaded on ATR-1™ valve) CON

The ATR-1™ valve is part of the R-12™ family of relay valves

which includes the R-12™, R-14™, BP-R1™, AR-1™.

The internal components of the relay portion of all of these

valves are interchangeable with the R-12™ valve and therefore

the same basic components are used to service all of them.

The ATR-1™ valve is available with various crack pressures

to accommodate specific applications, however the standard

is 4 psi.

SUPPLY

PORT

1

Page 2

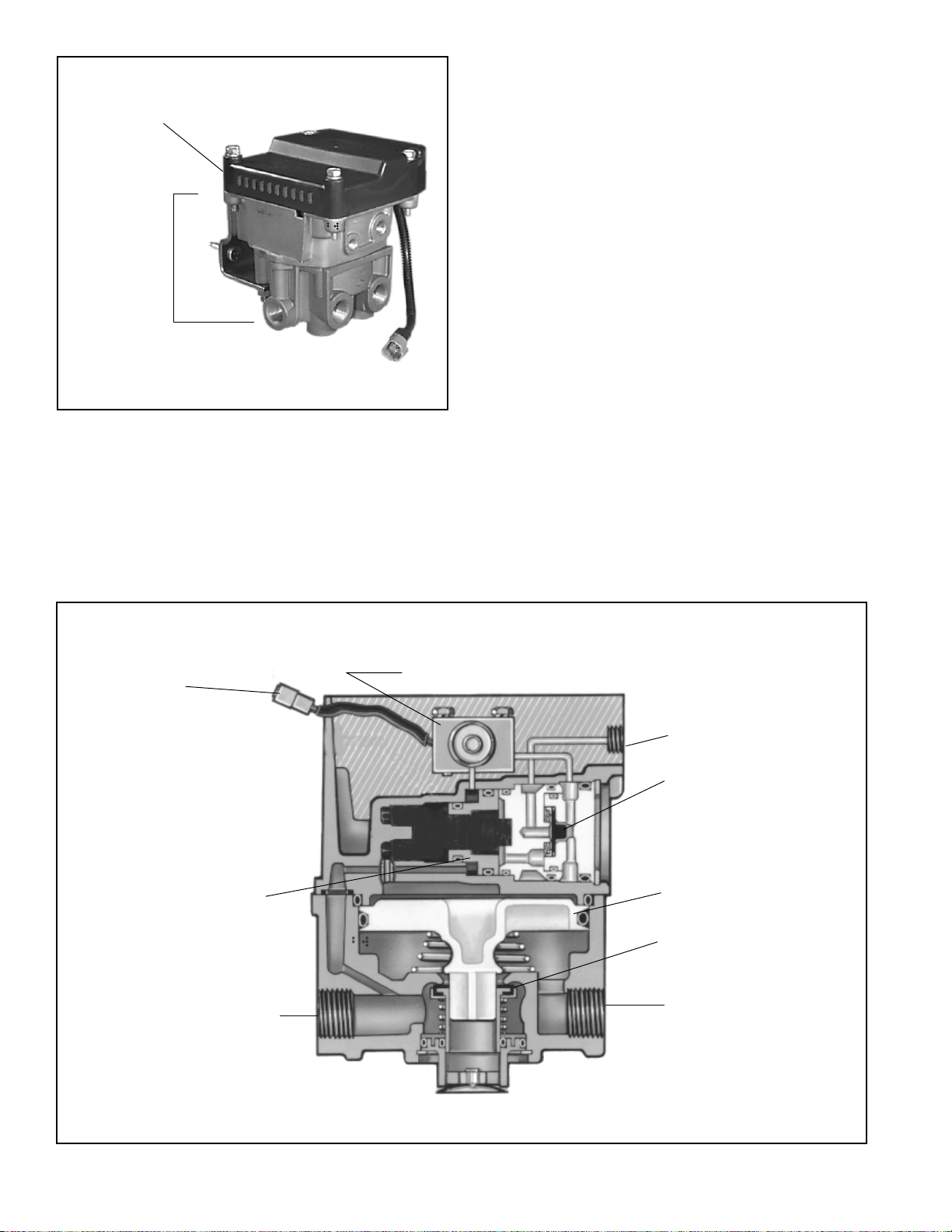

CONTROLLER

ATR-1™ ANTILOCK

TRACTION RELAY

VALVE

FIGURE 2 - ANTILOCK TRACTION ASSEMBLY

OPERATION

GENERAL

Because the ATR-1™ is essentially a relay valve, the following

description of operation refers to its function in the vehicles

air brake system and does not address all of the separate

antilock components and their operation. For a description

of antilock operation, refer to the appropriate Service Data

Sheet covering the electronic controller used with the

ATR-1™ valve.

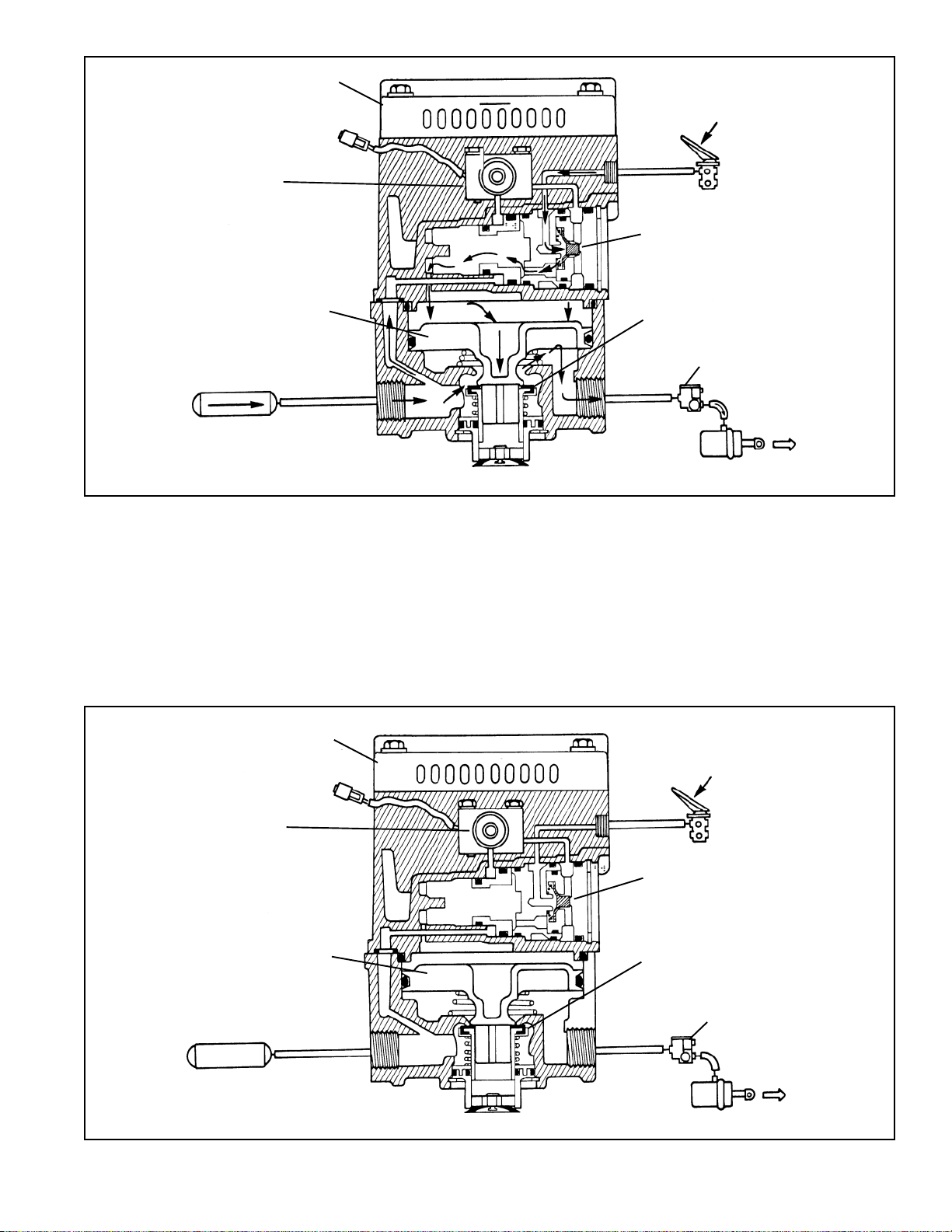

SERVICE BRAKES APPLYING (FIGURE 4)

Reservoir air pressure is present at the supply port and flows

through internal body and cover passages to the supply of

the normally closed (NC) traction control solenoid.

Brake application air enters the ATR-1™ valve’s service port

and is conducted to the single check valve. The check valve

diaphragm flexes in response to application pressure and

seals the passage to the open exhaust of the traction

solenoid. Air flows through the service piston then through

the center of the blend back and through a passage in the

cover to the top of the service relay piston. In response to air

pressure, the relay piston moves into contact with the

exhaust portion of its inlet and exhaust valve. With the

exhaust passage sealed, continued movement of the piston

unseats the inlet portion of the inlet and exhaust valve,

allowing supply air from the reservoir to flow out the ATR-1

valve’s delivery ports to the brake chambers.

™

SOLENOID

CONNECTOR

BLEND BACK

PISTON

SUPPLY

TRACTION CONTROL

SOLENOID

SERVICE

DOUBLE

CHECK VALVE

RELAY PISTON

INLET-EXHAUST

VALVE

DELIVERY

FIGURE 3 - ATR-1™ ANTILOCK TRACTION ASSEMBLY

2

EXHAUST

Page 3

CONTROLLER

TRACTION

SOLENOID

BRAKE

VALVE

CHECK VALVE

RELAY PISTON

REAR AXLE

RESERVOIR

FIGURE 4 - SERVICE BRAKE APPLICATION

SERVICE BRAKES HOLDING (FIGURE 5)

The air pressure being delivered to the brake chambers is

also present beneath the relay piston.

When the air pressure above and below relay piston is equal,

the piston moves slightly allowing the inlet valve to return to

CONTROLLER

INLET EXHAUST

MODULATOR

SPRING BRAKE

its seat. The exhaust valve remains closed. With both the

inlet and exhaust valves closed, air pressure in the brake

chambers is held stable and neither increases nor decreases.

TRACTION

SOLENOID

RELAY PISTON

REAR AXLE

RESERVOIR

FIGURE 5 - SERVICE BRAKES HOLDING

BRAKE

VALVE

CHECK VALVE

INLET EXHAUST

MODULATOR

SPRING BRAKE

3

Page 4

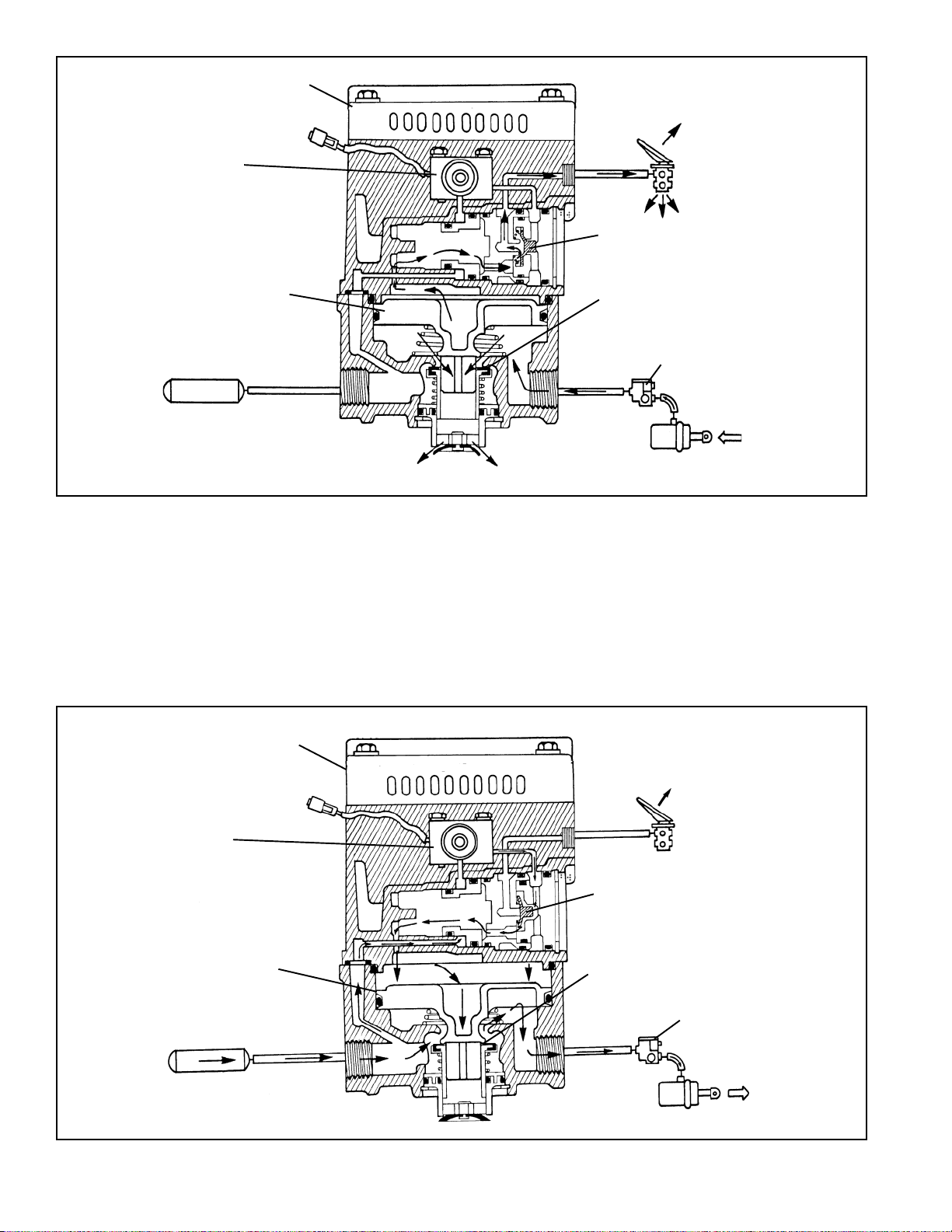

CONTROLLER

TRACTION

SOLENOID

RELAY PISTON

REAR AXLE

RESERVOIR

FIGURE 6 - SERVICE BRAKES RELEASING

SERVICE BRAKES RELEASING (FIGURE 6)

When the brake application is released, air from above the

relay piston flows back through the blend back and service

pistons to the foot brake valve and is exhausted. As air

pressure is reduced above the relay piston, pressure beneath

it lifts the piston away from the exhaust valve and opens the

exhaust passage. Air from the service brake chambers

returns to the ATR-1™ valve and flows out the open exhaust.

BRAKE

VALVE

CHECK VALVE

INLET EXHAUST

MODULATOR

EXHAUST

SPRING BRAKE

TRACTION CONTROL SERVICE APPLICATION

(FIGURE 7)

GENERAL

While under the control of an antilock traction controller, the

ATR-1™ valve’s solenoid is able to initiate a brake application

that allows the traction system to control wheel spin upon

acceleration under 25 mph. When wheel spin is detected

CONTROLLER

TRACTION

SOLENOID

RELAY PISTON

REAR AXLE

RESERVOIR

FIGURE 7 - TRACTION CONTROL BRAKE APPLICATION

4

BRAKE

VALVE

CHECK VALVE

INLET EXHAUST

MODULATOR

SPRING BRAKE

Page 5

BRAKE

REAR AXLE

MODULATOR

MODULATOR

BRAKE

REAR AXLE

EXCITER

ANTILOCK

™

MODULATOR

AT-30

TRACTION ASSY.

(ECM)

ENGINE CONTROL MODULE

MODULATOR

VALVE

BRAKE

SPEED SENSOR

EXCITER

SPEED SENSOR

MODULATOR

TRAILER ABS

(IF SO EQUIPPED)

TRACTION DASH LAMP

TRACTION SWITCH

ANTILOCK DASH LAMP

RETARDER SWITCH

FIGURE 8 - PARTIAL ANTILOCK TRACTION SYSTEM SCHEMATIC

BRAKE

CHAMBER

5

Page 6

and the vehicle is stopped, or moving at any speed up to 25

mph, the antilock traction controller instantly energizes the

™

solenoid in the ATR-1

valve which then applies air to each

of the rear axle modulators as shown in figure 8. The

modulators are equipped with solenoid valves also and

because they are also controlled by the controller, the

solenoid valves in the appropriate modulator are opened and

closed to gently pump the brake on the spinning wheel only.

This brake application, to the spinning wheel, forces the

differential to drive the stationary or slowly spinning wheel.

OPERATION

Reservoir air pressure is constantly present at the traction

solenoid. When the electronic controller detects wheel spin

it energizes the solenoid and in response the solenoid opens

momentarily. While the solenoid is open, air is delivered

through internal passages to the double check valve. The

check valve diaphragm flexes in response and seals the

passage to the open exhaust of the brake valve. Once past

the double check valve, air from the solenoid flows through

the rest of the valve in the same manner as a normal service

brake application and air is delivered out the delivery ports

of the ATR-1

™

valve.

When the electronic controller de-energizes the solenoid,

air between the solenoid and the double check valve returns

to the solenoid and is exhausted. Air between the relay piston

and double check valve is exhausted at the brake valve while

delivery pressure is exhausted at the main ATR-1™ valve’s

exhaust port.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before

performing any intrusive maintenance procedures. An

extended warranty may be voided if intrusive

maintenance is performed during this period.

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable guide

in determining the best maintenance interval for a vehicle.

GENERAL

Perform the tests and inspections presented at the

prescribed intervals. If the ATR-1™ valve fails to function as

described, or leakage is excessive, it should be repaired or

replaced with a new or genuine Bendix remanufactured unit,

available at any authorized parts outlet.

EVERY 3 MONTHS, 25,000 MILES OR 900 OPERATING

HOURS

1. Remove any accumulated contaminates and visually

inspect the exterior for excessive corrosion and physical

damage.

2. Inspect all air lines connected to the ATR-1™ valve for

signs of wear or physical damage. Replace as necessary.

3. Test air line fittings for excessive leakage and tighten or

replace as necessary.

4. Perform the Leakage Test described in this manual.

EVERY YEAR, 100,000 MILES, OR 3,600 OPERATING

HOURS

1. Perform the Operation and Leakage Tests described in

this manual.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

™

6

Page 7

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any

vehicle maintenance where one or more wheels

on a drive axle are lifted off the ground and

moving.

OPERATION & LEAKAGE TESTS

GENERAL

A change in vehicle braking characteristics or a low pressure

warning may indicate a malfunction in one or the other brake

circuit, and although the vehicle air brake system may

continue to function, the vehicle should not be operated until

the necessary repairs have been made and both braking

circuits, including the pneumatic and mechanical devices

are operating normally. Always check the vehicle brake

system for proper operation after performing brake work and

before returning the vehicle to service.

OPERATION TEST

1. Apply and release the brakes several times and check

for prompt application and release at each wheel. If a

prompt reaction is noted at some, but not all wheels,

test the antilock modulator between the ATR-1™ valve

and the brake chamber for proper operation. If a sluggish

response is noted at all wheels, inspect for a kinked or

obstructed air line leading to or from the ATR-1™ valve. If

a complete release of the brakes is noted at some, but

not all wheels, test the antilock modulator between the

ATR-1™ valve and the brake chamber for proper operation.

If an incomplete release is noted at all wheels, inspect

for a kinked or obstructed air line leading to or from the

ATR-1™ valve.

Note: The ATR-1™ valve’s differential pressure can be

checked by applying 10 psi to the service port and noting

the pressure registered at the delivery port. Subtract

delivery port pressure from the 10 psi service pressure

to obtain the differential. Compare the measured

differential with the pressure specified for the ATR-1

valve’s part number (see the l.D. washer also for the

differential). NOTE: For ATR-1™ valves not incorporating

a relay piston return spring(14) the measured differential

should be approximately 4 psi. When a spring is in use,

the differential will be higher.

2. Disconnect the ATR-1™ valve’s two pin solenoid connector

from the controller wire harness. Apply the probes of a

volt-ohm meter to the connector leading to the solenoid

and note the resistance of the solenoid is between 10

and 12 ohms. If resistance other than this is noted,

™

replace the ATR-1

valve.

3. Apply and remove vehicle power (12 vdc) to the two pin

connector half leading to the ATR-1

™

valve’s (solenoid)

while observing the brake chambers. Note that a brake

application is made and held while power is applied to

the ATR-1™ valve’s solenoid and that it is released when

power is removed.

LEAKAGE TESTS

1. Build the air system pressure to governor cutout. Apply

a soap solution to the exhaust port. The leakage noted

should not exceed a 1” bubble in less than 3 seconds.

2. Make and hold a full brake application and apply a soap

solution to the exhaust port and around the cover where

it joins the body. The leakage noted should not exceed

a 1” bubble in less than 3 seconds at the exhaust port.

If the ATR-1™ valve fails to function as described, or

leakage is excessive, it should be replaced with a new

or genuine Bendix remanufactured unit or repaired using

a genuine Bendix maintenance kit piece number 109368,

available at any authorized parts outlet.

VEHICLE PREPARATION

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

REMOVAL

1. Identify and mark or label all electrical wiring harnesses

and air lines and their respective connections on the

assembly to facilitate ease of installation.

2. Disconnect the air lines and wire harnesses.

3. Remove the controller and valve assembly from the

vehicle.

™

INSTALLATION

1. Install the assembled unit on the vehicle.

2. Reconnect all air lines and wire harnesses to the unit

using the identification made during REMOVAL step 1.

3. After installing the unit, perform the OPERATION &

LEAKAGE TESTS for the air valve before placing the

vehicle in service.

7

Page 8

35

2

34

33

32

1

PRIOR INTERNAL

COMPONENT

CONFIGURATION

12

16

31

30

29

28

27

26

25

24

Assembly

of items

3

18

21

19

20

17

4

29-35

15

35

34

14

Key Description

22

1 ECU Control

2 Bolts (4)

3 Cover

4 Base

5 Retaining Ring

6 Exhaust Cover

7 O-Ring

8 O-Ring

9 Valve Spring

10 Valve Retainer

11 Valve Assembly

12 Cap Screws (2)

13 Nuts and Washers (2)

14 Lock Washers (2)

15 Bracket

16 Cap Screws (2)

17 O-Ring

18 O-Ring

Key Description

19 Relay Piston

20 Piston Spring (if used)

21 O-Ring

22 Retaining Ring

23 Check Valve*

24 O-Ring

25 Inlet Seat*

26 Check Valve Seat

27 O-Ring

28 Check Valve

29 Spring Seat

30 Spring

31 Inlet Seat

32 O-Ring

33 O-Ring

34 O-Ring

35 Alternate Plug*

36 Bolts (2)

23

22

11

10

9

8

7

13

6

5

FIGURE 9 - ANTILOCK TRACTION ASSEMBLY EXPLODED VIEW

8

* Note: For new style ATR-1™ valves either both

items 23 - 25, or item 35 will be present.

Page 9

DISASSEMBLY

PREPARATION FOR DISASSEMBLY

1. Remove all air fittings and plugs from the valve.

2. Mark the relationship of the valve cover(3) to the body(4)

and, if the valve is equipped with a mounting bracket(15),

mark the relationship of the bracket to the cover and

body(4).

3. Mark the relationship of the electronic controller(1) to

the cover(3).

DISASSEMBLY

The following disassembly and assembly procedure is

presented for reference purposes only. Instructions packaged

with repair and maintenance kits should always be followed

instead of the instructions presented here.

Then, depending on the internal configuration:

12a. Remove check valve seat(23), with o-rings(27 & 28).

Remove o-rings(27 & 28) from the check valve seat.

Then Remove the check valve(24), guide(25), and

spring(26).

OR,

12b. Remove plug(35), with o-ring(34).

13. Remove the inlet seat(29) with o-rings(30 & 31), then

remove o-rings(30 & 31) from the inlet seat(29).

14. Remove the blend back piston(32) from the valve cover(3).

Remove both o-rings(33 & 34) and the piston stop

ring(35). Note: The piston stop ring may have to be

removed from the cover(3) rather than the piston(32).

15. Do not disassemble the ATR-1™ valve any further than

described here.

CAUTION: The valve may be lightly clamped in a bench

vise during disassembly, however, over clamping will

result in damage to the valve and result in leakage

and/or malfunction. If a vise is to be used, position the

valve so that the jaws bear on the supply ports on

opposing sides of the valve body.

1. Remove and retain the four cap screws(2) that secure

the electronic controller(1) to the cover(3), then separate

and retain the controller(1), from the cover(3). Note: In

some instances a controller, Item 1, will not be present

and only a cover plate will be noted. Remove the cover

plate in the same manner described for the controller.

2. While holding the exhaust cover(6), remove the retaining

ring(5) that secures it to the body(4).

3. Remove the exhaust cover(6) along with both o-rings(7

& 8).

4. Remove the valve spring(9), valve retainer(10), and the

valve assembly(11) from the body(4).

5. Remove and retain the two long cap screws(12) and

nuts(13) that secure the cover(3) to the body(4).

6. Remove and retain the two cap screws and lock

washers(14) that secure the bracket(15) to the cover(4),

then remove and retain the bracket.

7. Remove and retain the two short cap screws(16) that

secure the cover(3) to the body(4).

8. Separate the cover(3) from the body(4), then remove the

sealing ring(17) and o-ring(18).

9. Remove the relay piston(19) and relay piston spring(20)

from the body(4). NOTE: The relay piston spring, item

14 is not used in all valves.

10. Remove the o-ring(21) from the relay piston(19).

11. Remove the retaining ring(22).

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Wash all retained, nonmetallic components in a soap

and water solution making certain to rinse and dry

thoroughly.

3. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superficial corrosion and/or pitting on the exterior portion

of the body(4) and cover(3) is acceptable. Replace the

entire valve if the interior of the body or cover exhibit

signs of corrosion or pitting.

4. Inspect each nonmetallic component for cracks, wear

or distortion. Replace the entire valve if these conditions

are found.

5. Inspect the bores of both the body(4) and cover(3) for

deep scuffing or gouges. Replace the entire valve if ether

are found.

6. Make certain the air channel running between the top

surface of the body(1) and its supply port is clear and

free of obstruction.

7. Make certain all air channels and exhaust passages in

the valve cover(3) are clear and free of obstruction.

8. Inspect the pipe threads in the body(4) and valve cover(3).

Make certain they are clean and free of thread sealant.

9. Inspect the relay piston spring(20) for signs of corrosion,

pitting and cracks. Replace as necessary.

10. Inspect all air line fittings for corrosion and replace as

necessary. Make certain to remove all old thread sealant

before reuse.

9

Page 10

1234

1234

1234

1234

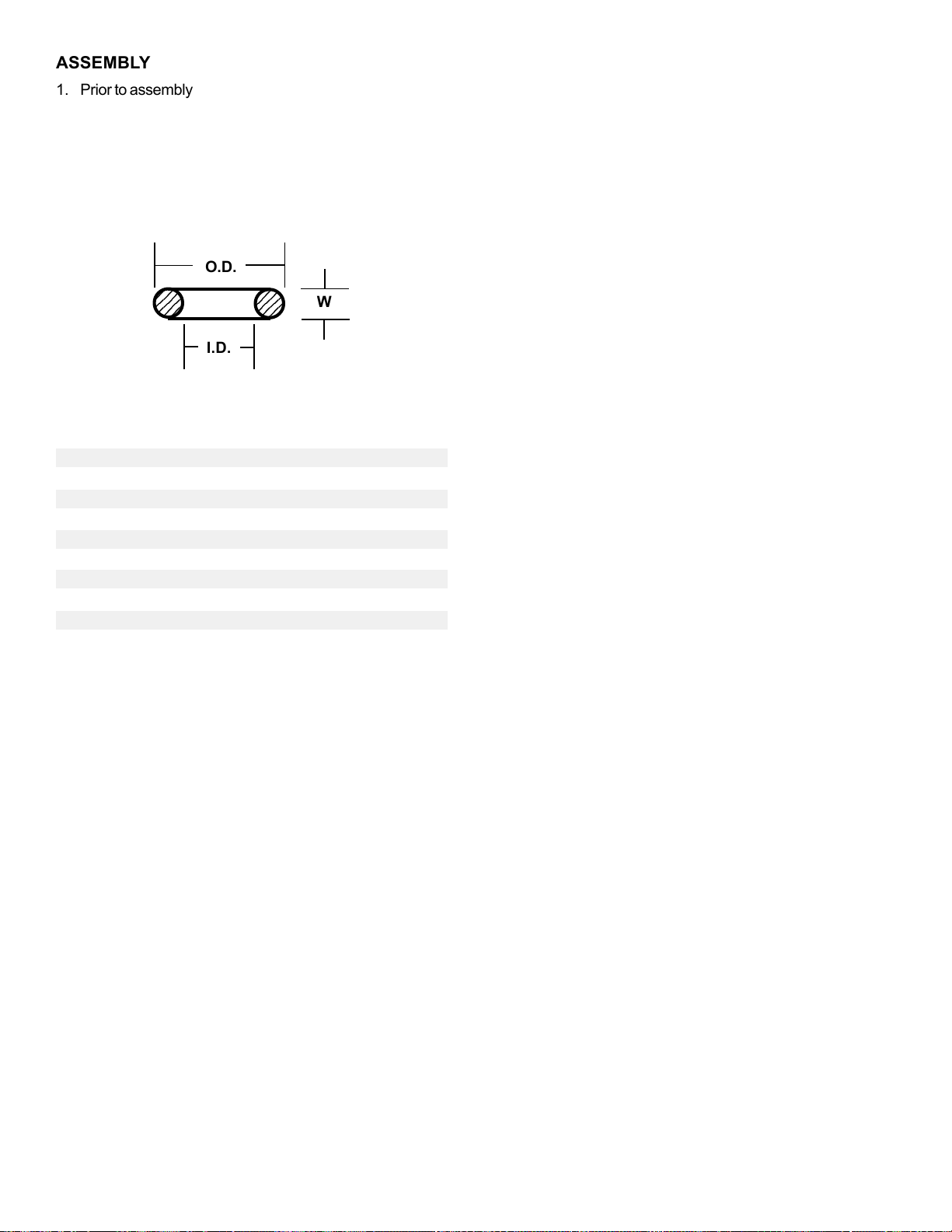

ASSEMBLY

1. Prior to assembly, lubricate all o-rings, seals, and pistons,

as well as body and cover bores, using silicone lubricant.

2. Install the piston stop ring(35), then both the large and

small diameter o-rings(33 & 34) on the blend back

piston(32), then insert the small diameter of the

proportioning piston(32) into the bore in the cover(3). Do

not cut or pinch the o-rings.

O.D.

W

I.D.

O-Ring Identification

Key Description Qty. I.D. O.D. W

7 O-Ring 1 0.862 1.068 0.103

8 O-Ring 1 1.424 1.63 0.103

18 O-Ring 1 3.487 3.693 0.103

21 O-Ring 1 3.234 3.512 0.139

27 O-Ring 1 1.362 1.568 0.103

28 O-Ring 1 1.114 1.254 0.07

30 O-Ring 1 1.356 1.496 0.07

31 O-Ring 1 1.176 1.316 0.07

33 O-Ring 1 1.112 1.318 0.103

34 O-Ring 1 0.737 0.943 0.103

(O-rings available in maintenance kit #109368.)

3. Install the small and large diameter o-rings (30 & 31) on

the inlet seat(29) then insert the inlet seat into the bore

in the cover(2).

Depending on the configuration/kit being installed:

4a. Install the small and large diameter o-rings (27 & 28) on

the check valve seat(23). Then install the spring(26) on

the inlet seat(29) so that the small diameter fits over

and around the air passage through the center of the

inlet seat. Install the check valve(24) and valve guide(25)

in the check valve seat(23). Note; The check valve must

be installed so that the top hat portion fits into the valve

seat(23). Install the valve guide(25) so that its flange

contains (surrounds) the coils of the large end of the

spring(26), when the valve seat (23) is installed in the

cover(3). Use a small amount of grease to hold these

parts in the valve seat (23). Install the assembled valve

seat(23) with the check valve and valve guide(24 & 25)

into the cover(3) bore and while holding it in place install

the retaining ring(22). Make certain the retaining ring is

fully seated in its groove.

OR,

4b. Install the o-ring(34) onto the plug(35). Install into the

cover(3) bore and while holding it in place install the

retaining ring(22). Make certain the retaining ring is fully

seated in its groove.

5. Install the valve retainer(10) on the inlet and exhaust

valve(11) so that the flange of the retainer(10) surrounds

the rubber portion of the valve. Install the inlet and exhaust

valve in the body(4).

6. Install the inlet and exhaust valve return spring(9) in the

body(4).

7. Install the large and small diameter o-rings(7 & 8) in the

exhaust cover(6), then install the exhaust cover in the

body(4) taking care not to damage the o-rings. Hold the

exhaust cover in place.

8. While depressing the exhaust cover(6), install the

retaining ring(5) in the body(4). Make certain the

retainer(5) is fully seated in its groove in the body.

9. If the valve was equipped with a relay piston return

spring(20), install the spring in the body, large diameter

first.

10. Using lubricant to hold them in place, install the large

and small sealing rings(18 & 17) on the cover(3).

11. Install the o-ring(21) on the relay piston(19), then install

the piston in the body(4).

12. Note the relationship marks made prior to disassembly,

then install the cover(3) on the body(4). Secure the cover

on the body using the two, short cap screws(16). Again,

noting the relationship marks, secure the bracket(15)

on the cover(3) and body(4) and using the two long cap

screws(12) and two nuts and washers(13). Torque the

four cap screws to 120 to 150 lb. in.

13. Install the two cap screws(14) that secure the bracket(15)

to the cover(3) and torque to 180-220 pound inches.

14. Noting the relationship marks made during disassembly,

secure the controller(1) or cover plate to the cover(3)

using the four cap screws(2). Torque the four cap screws

to 50-80 pound inches.

15. Install all air line fittings and plugs making certain thread

sealing material does not enter the valve.

16. Install the rebuilt valve on the vehicle and perform the

OPERATION AND LEAKAGE TESTS before placing the

vehicle in service.

10

Page 11

NOTES

11

Page 12

12

BW1794 © 2004 Bendix Commercial Vehicle Systems LLC 10/2004 Printed in U.S.A. All rights reserved.

Loading...

Loading...