Bendix AR-2 User Manual

®

Bendix® AR-2™ AntiLock Relay Valve

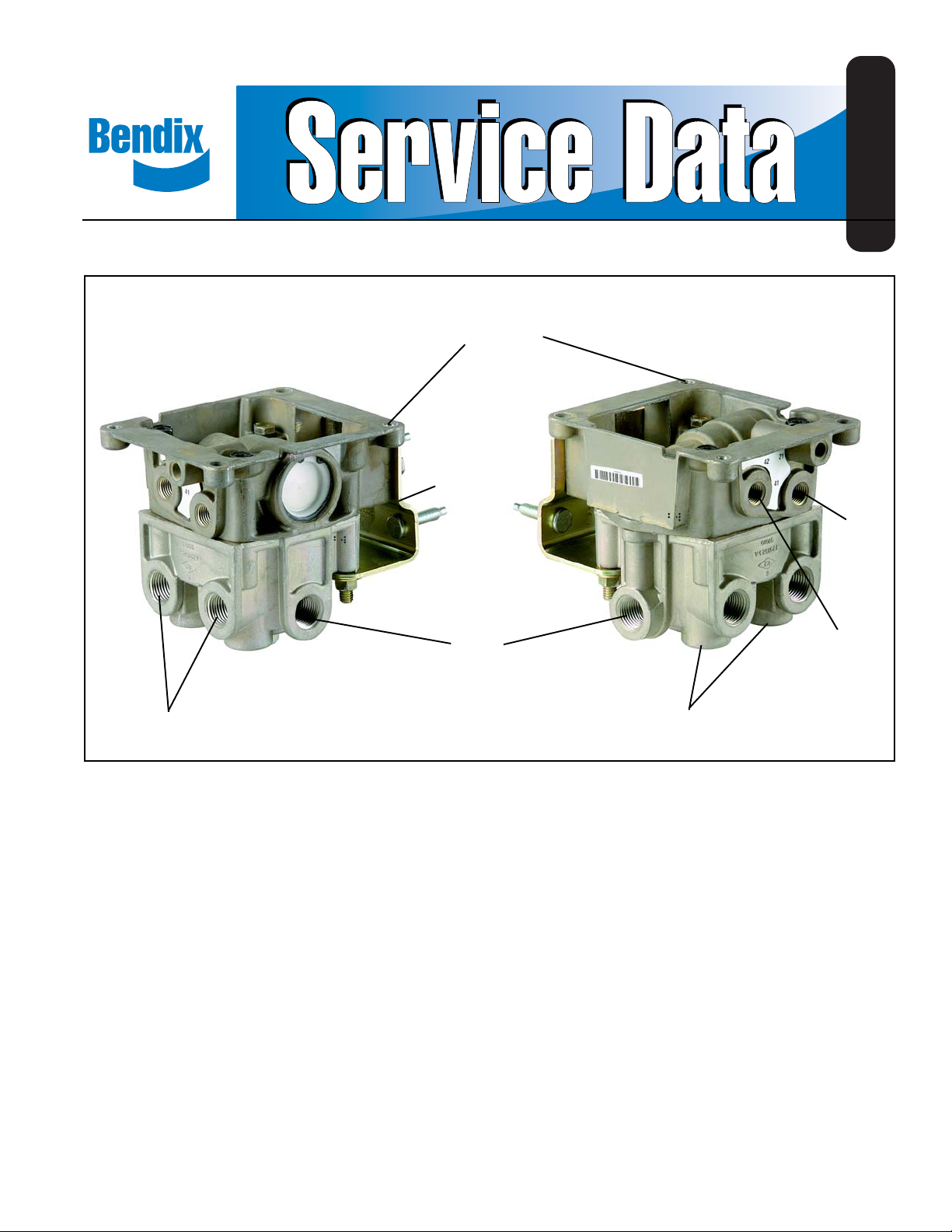

ANTILOCK CONTROLLER

MOUNTING HOLES(4)

MOUNTING

BRACKET

SD-13-4796

SERVICE

SUPPLY

DELIVERY

FIGURE 1 - AR-2™ ANTILOCK RELAY VAL VE ASSEMBLY

DESCRIPTION

The AR-2™ antilock relay is a specialized air brake valve

developed for use on antilock equipped tractors only. It is

essentially a BP-R1™ “bobtail” brake proportioning relay valve

(Bendix Service Data Sheet SD-03-1067) with a modified

cover that permits direct attachment of a Bendix® antilock

controller such as the EC-15™. When combined with an

antilock controller the resulting assembly is referred to as a

antilock controller relay assembly. For example when the

AR-2™ valve is combined with the EC-15™ electronic

controller, the resulting assembly is referred to as a CR-16

controller relay assembly .

While it is intended for use on antilock equipped tractors,

the AR-2™ valve functions solely as an air brake relay and

contains no electronics of its own.

DELIVERY

The AR-2™ valve replaces the standard relay valve used to

control the rear axle service brakes and performs the standard

relay function during tractor-trailer operation. During tractor

bobtail operation, the AR-2™ valve reduces brake application

pressure to the lighter rear axle(s) brakes to improve vehicle

controllability and minimize rear axle(s) wheel skid before

antilock is required. The AR-2™ valve provides added vehicle

braking control and reduces the number of times antilock is

actually needed.

Like the standard relay valve it replaces, the AR-2™ valve

™

and its attached antilock controller is normally mounted near

the service brakes it serves. A mounting bracket, furnished

with the valve, permits either frame or cross member

mounting. All air connections on the AR-2™ valve are identified

with cast, embossed letters for ease of identification and

installation. The letter identification and air line connections

are shown below for reference.

CONTROL

1

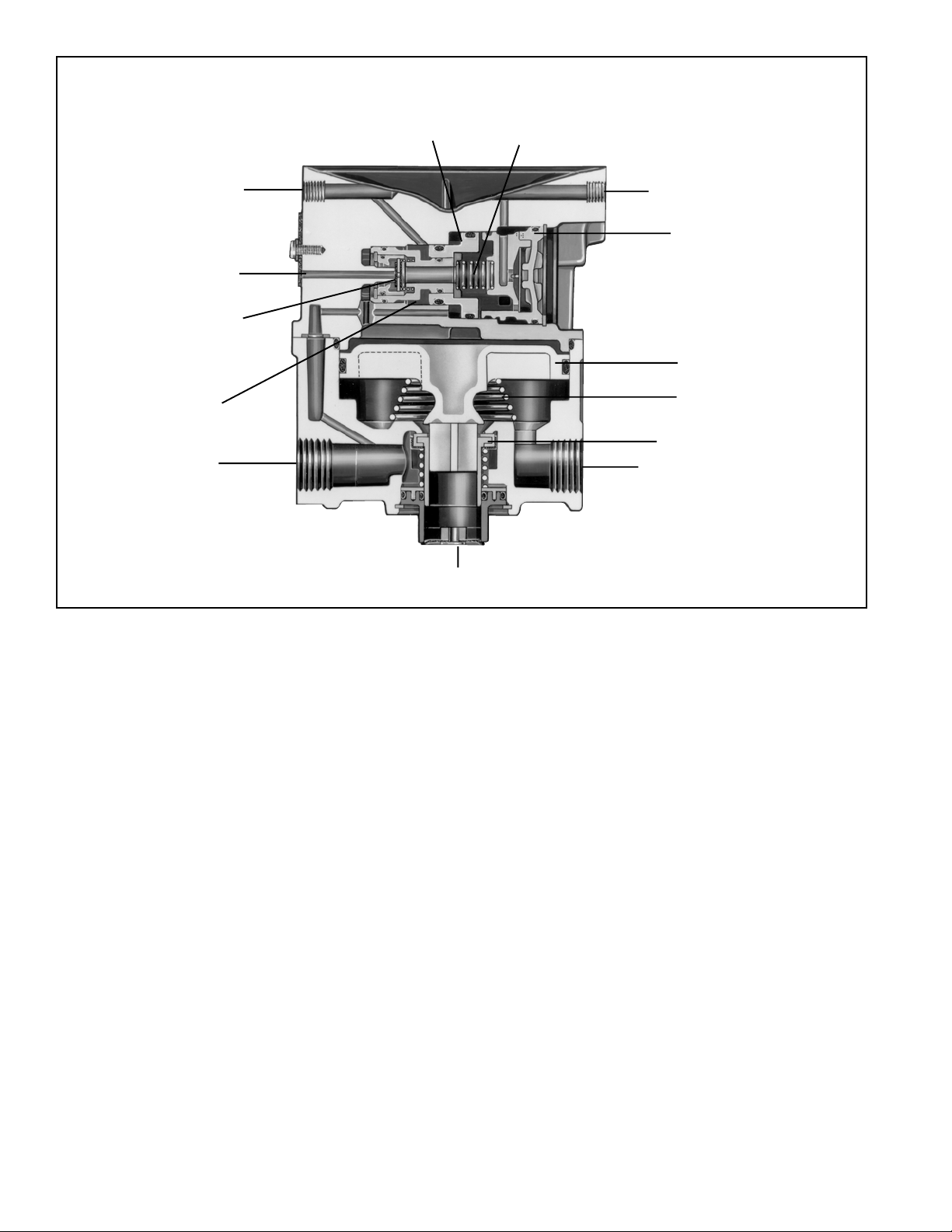

BLEND BACK

PISTON

SPRING

CONTROL PORT

EXHAUST

INLET/EXHAUST VALVE

PROPORTIONING

PISTON

SUPPLY PORT

EXHAUST

FIGURE 2 - SECTIONAL VIEW AR-2™ ANTILOCK RELAY VAL VE

SERVICE PORT

SERVICE PISTON

RELAY PISTON

SPRING (NOT IN ALL

MODELS)

INLET/EXHAUST VALVE

DELIVERY PORT

AR-2™ VALVE

AIR CONNECTION EMBOSSED IDENT .

Supply (to reservoir) SUP

Delivery (to brake chamber) DEL

Service (to brake valve rear service delivery) SE R

Control (to delivery of trailer supply valve) CO N

The AR-2™ valve is part of the R-12™ family of relay valves

which includes the R-12™, R-14™, BP-R1™, and AR-1™ valves.

The internal components of the relay portion of all of these

valves are interchangeable with the R-12™ valve and therefore

the same basic components are used to service all of them.

The AR-2™ valve incorporates various crack pressures to

accommodate specific applications, the standard is 4 psi.

OPERATION

GENERAL

Because the AR-2™ valve is actually a relay valve, the

following description of operation refers to its function in the

vehicle’s air brake system and does not address the separate

antilock components and their operation. For a description

of antilock operation refer to the appropriate Service Data

Sheet covering the electronic controller used with the AR-2

valve (ie; SD-13-4785 covering the EC-15™ electronic

controller). Other useful information regarding antilock

system components used in conjunction with the AR-2

valve is contained in publications SD-13-4793 covering the

M-21™ antilock modulator and SD-13-4754 covering the

WS-20™ wheel speed sensor.

INITIAL CHARGING

During the initial build up of tractor system air pressure,

reservoir air flows into the supply port and through internal

body and cover passages to the blend back piston. When

sufficient air pressure is applied to the blend back piston, it

moves against the resistance of its spring until it comes to

rest against the service piston.

Activating the trailer supply valve (dash control with red

octagonal button), simultaneously charges the trailer and

the AR-2™ valve control port. Air entering the AR-2™ valve

control causes the proportioning piston to move toward its

stop in the cover. The integral inlet and exhaust valve is

carried along with the piston until it seats and seals the

exhaust passage. Continued movement of the proportioning

piston opens the inlet seat. With the tractor and trailer air

system fully charged the vehicle may be operated.

™

™

2

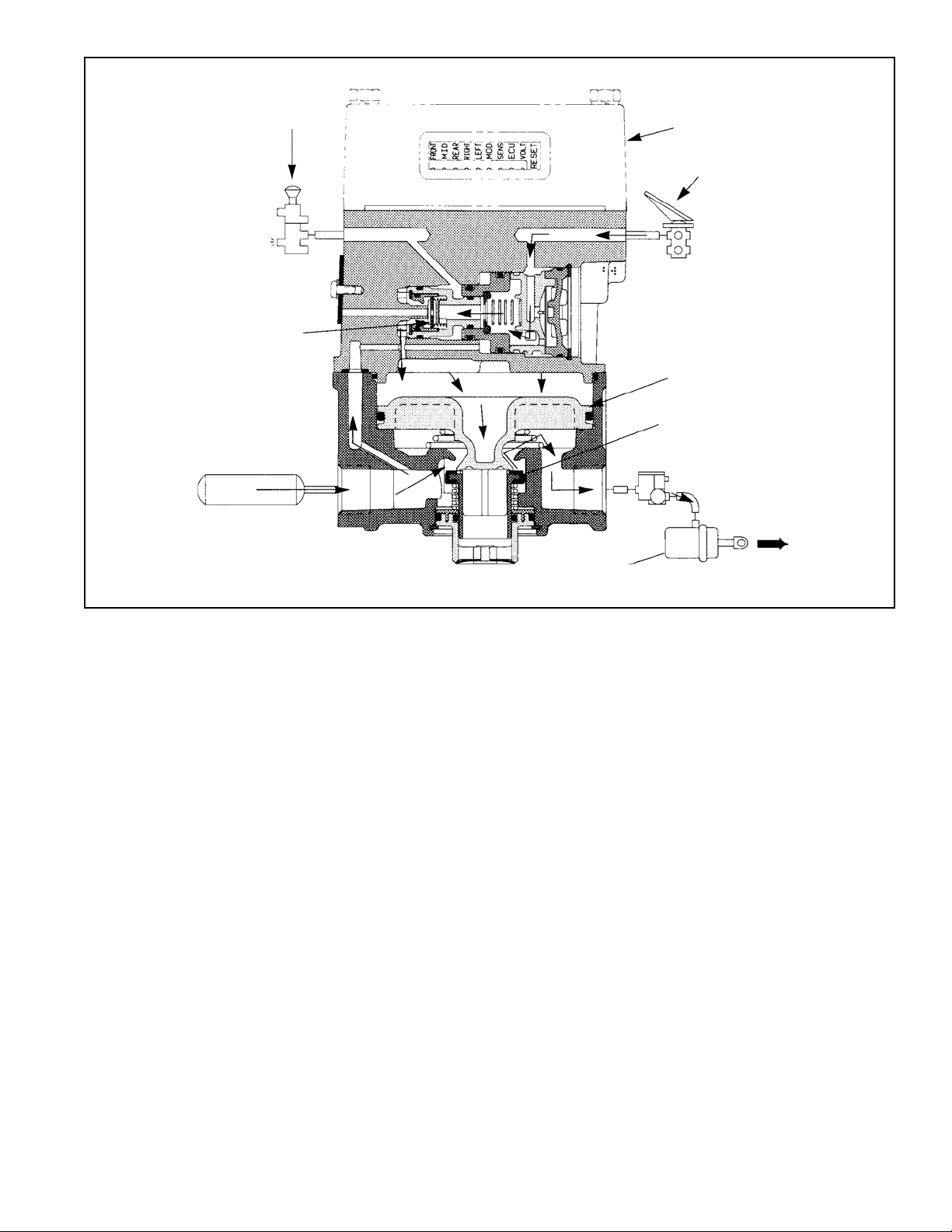

TRAILER

SUPPLY

VALVE

INLET-OPEN

EXHAUST-CLOSED

REAR AXLE

SERVICE

CHAMBER

ANTILOCK

CONTROLLER

SERVICE

BRAKE

VALVE

RELAY PISTON

INLET-OPEN

EXHAUST-CLOSED

™

M-21

MODULATOR

FIGURE 3 - TRACTOR SERVICE BRAKES APPL YING - TRACTOR TRAILER COMBINATION

SERVICE BRAKES APPLYING - TRACTOR/TRAILER

COMBINA TION

Brake application air enters the AR-2™ valve service port

and is conducted through the service piston then through

the center of both the blend back and proportioning pistons

to the inlet and exhaust valve. Flowing around the inlet valve,

application air moves through a passage in the cover to the

top of the service relay piston. In response to air pressure,

the relay piston moves into contact with the exhaust portion

of its inlet and exhaust valve. With the exhaust passage

sealed, continued movement of the piston unseats the inlet

portion of the inlet and exhaust valve, allowing supply air

from the reservoir to flow out the AR-2™ valve delivery ports

to the brake chambers.

SERVICE BRAKES RELEASING - TRACTOR/TRAILER

COMBINA TION

When the brake application is released, air from above the

relay piston, flows back through the proportioning, blend

back and service pistons to the foot brake valve and is

exhausted. As air pressure is reduced above the relay

piston, pressure beneath it lifts the piston away from the

exhaust valve and opens the exhaust passage. Air from the

service brake chambers returns to the AR-2™ valve and flows

out the open exhaust.

SERVICE APPLICATION - BOBT AIL TRACTOR

When the trailer supply valve (dash control with red octagonal

button) is activated to disconnect the trailer, air in the AR-2

valve control port and trailer supply line is exhausted to

SERVICE BRAKES HOLDING - TRACTOR/TRAILER

COMBINA TION

The air pressure being delivered to the brake chambers is

also present beneath the relay piston.

When the air pressure above and below relay piston is

equal, the piston moves slightly allowing the inlet valve to

return to its seat. The exhaust valve remains closed. With

both the inlet and exhaust valves closed, air pressure in the

brake chambers is held stable and neither increases nor

atmosphere. During bobtail tractor operation, service

application air enters the AR-2™ valve service port and as it

passes through the blend back piston air exerts a force on

the full effective diameter of the piston. The blend back piston

remains stationary at application pressures below

approximately 80 psi because of opposing reservoir air

acting on the large diameter. Application air flowing through

the blend back piston also exerts a force on the small

diameter of the proportioning piston while simultaneously

decreases.

™

3

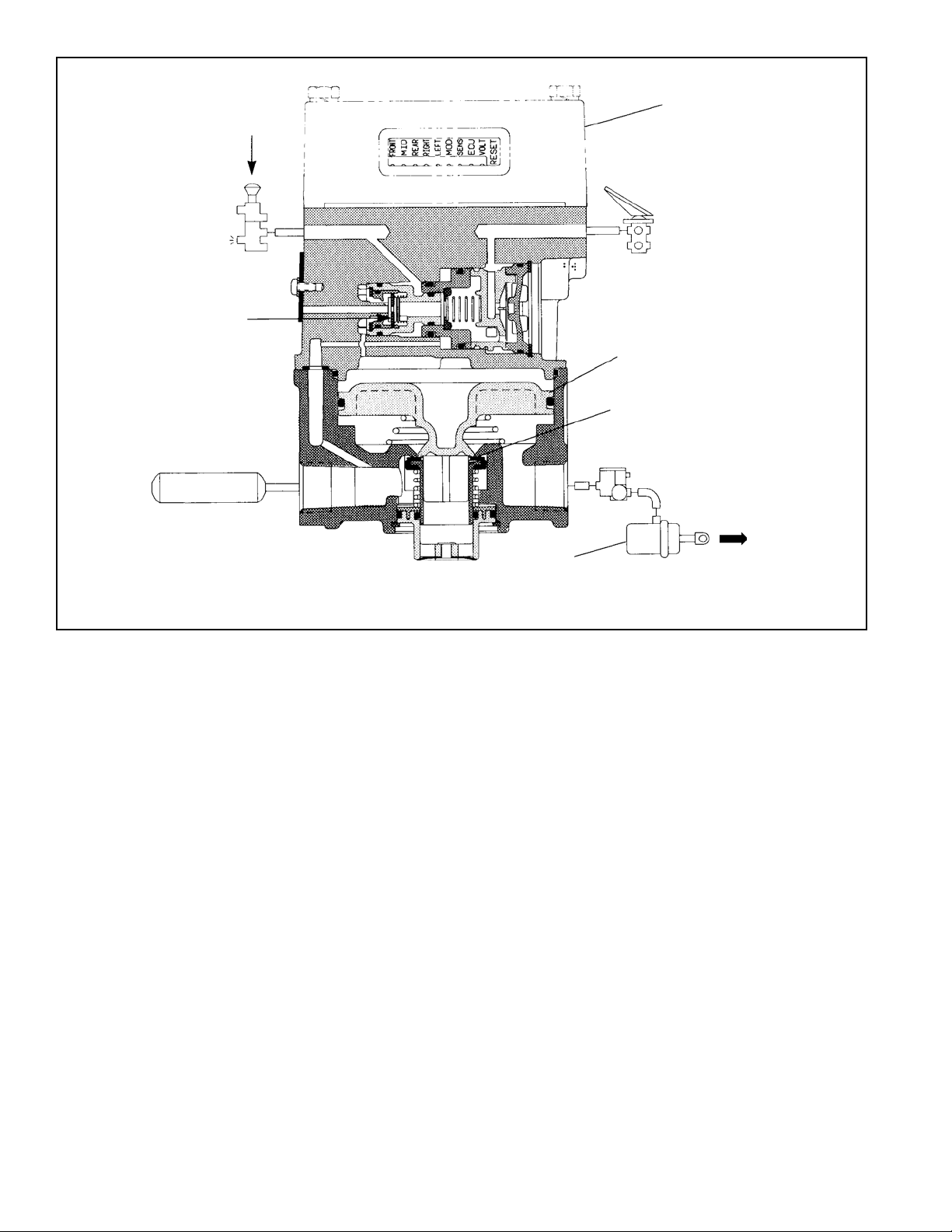

ANTILOCK

CONTROLLER

TRAILER

SUPPLY

VALVE

INLET-OPEN

EXHAUST-CLOSED

REAR AXLE

SERVICE

CHAMBER

FIGURE 4 - TRACTOR SERVICE BRAKES HOLDING - TRACTOR TRAILER COMBINATION

SERVICE

BRAKE

VALVE

RELAY PISTON

INLET-CLOSED

EXHAUST-CLOSED

™

MODULATOR

M-21

flowing through the center of it on its way to the inlet and

exhaust valve.

Once past the inlet and exhaust valve, service air pressure

exerts a force on the larger diameter end of the proportioning

piston, which opposes the air pressure and spring force

exerted on the other end. The proportioning piston inlet

valve remains open until a preset, initial application pressure

has reached the relay piston assuring that the foundation

brake shoes are brought into contact with the drum. As

service pressure begins to exceed the preset initial

application, the proportioning piston will have moved

sufficiently to close its inlet valve without opening the

exhaust.

The inlet remains closed, preventing additional air delivery

to the relay piston and a subsequent increase in brake

chamber pressure, until service application pressure

exceeds approximately 30 psi. Service applications above

this pressure will result in a proportioned increase of the

preset initial brake application to the tractor’s rear brakes.

Proportioning occurs due to the difference in effective area

on each end of the proportioning piston. Tractor rear axle

brake proportioning will occur for all service applications

between approximately 30 and 80 psi.

4

Service applications of more than 80 psi cause the blend

back piston to begin to move. Service air pressure acting

on the full diameter of the blend back piston over comes

the resistance of reservoir pressure acting on the large

diameter of the other side. Above 80 psi the ratio between

control and delivered air pressure is reduced and “blends

back” from a proportioned delivery to a full 1 to 1 delivery .

Complete “blend back” to a 1 for 1 delivery is achieved

when a full brake application is made.

SERVICE BRAKES RELEASING - BOBT AIL TRACT OR

When the brake application is released, all air pressure from

between the closed proportioning piston inlet valve and the

AR-2™ valve service port returns to the brake valve and is

exhausted. Air from above the relay piston, flows back to

the proportioning piston causing it to move. As it moves, the

proportioning piston unseats the exhaust valve allowing air

from above the relay piston to escape to atmosphere.

Reducing the air pressure above the relay piston, causes

pressure beneath it to lift the piston away from the exhaust

valve. Air from the service brake chambers returns to the

AR-2™ valve and flows out the open exhaust.

Loading...

Loading...