Page 1

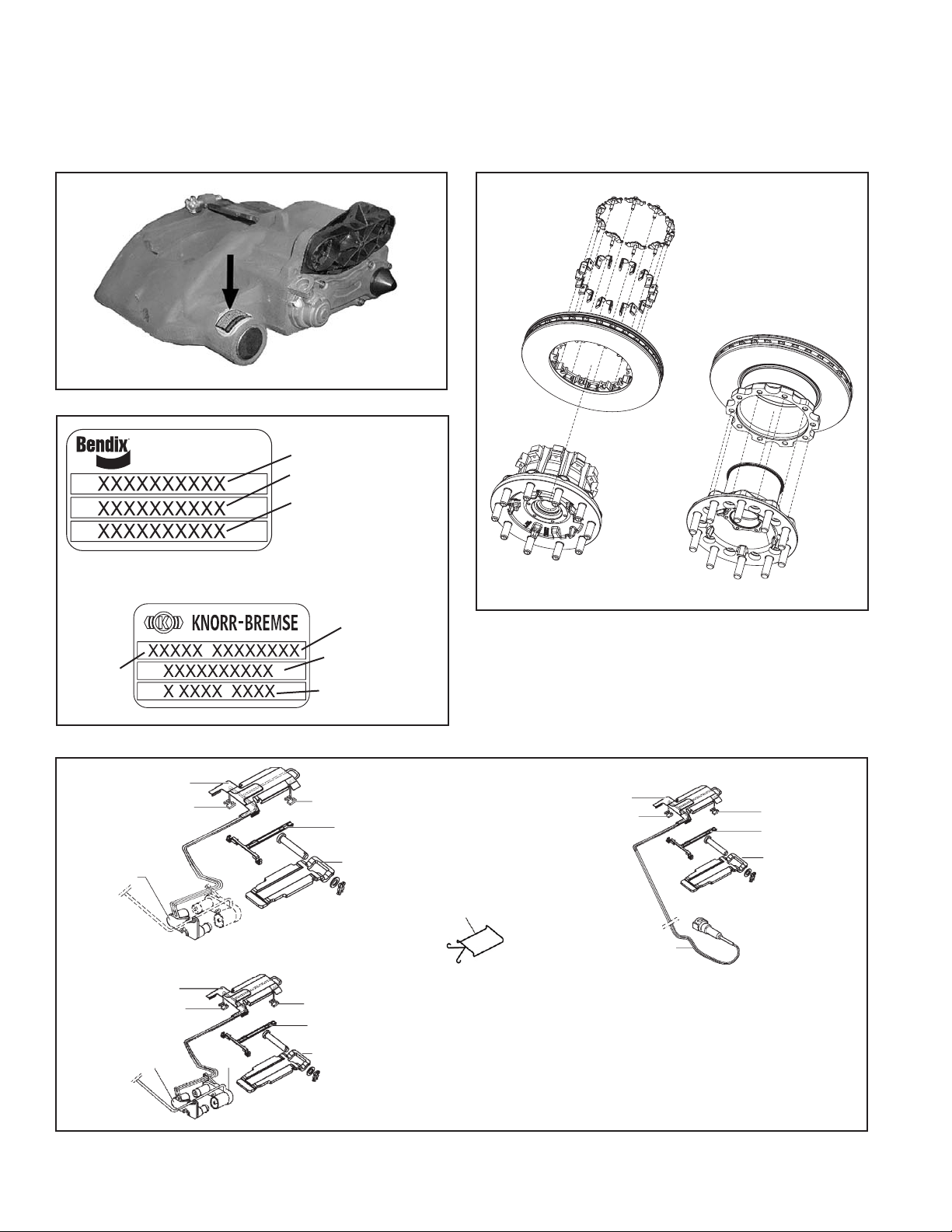

Bendix® ADB 22X™, ADB 225™, SN6™, SN7™, SK7™ Air Disc Brakes

DESCRIPTION

Bendix® Air Disc Brakes use a floating caliper design to

provide foundation braking on all axles of heavy commercial

vehicles, buses and trailers. Bendix Air Disc Brakes

provide safety and performance, as well as ease of service.

Available in models with or without a combination spring

brake unit, these brakes may also include optional wear

sensors and/or wear diagnostic equipment.

OPERATION

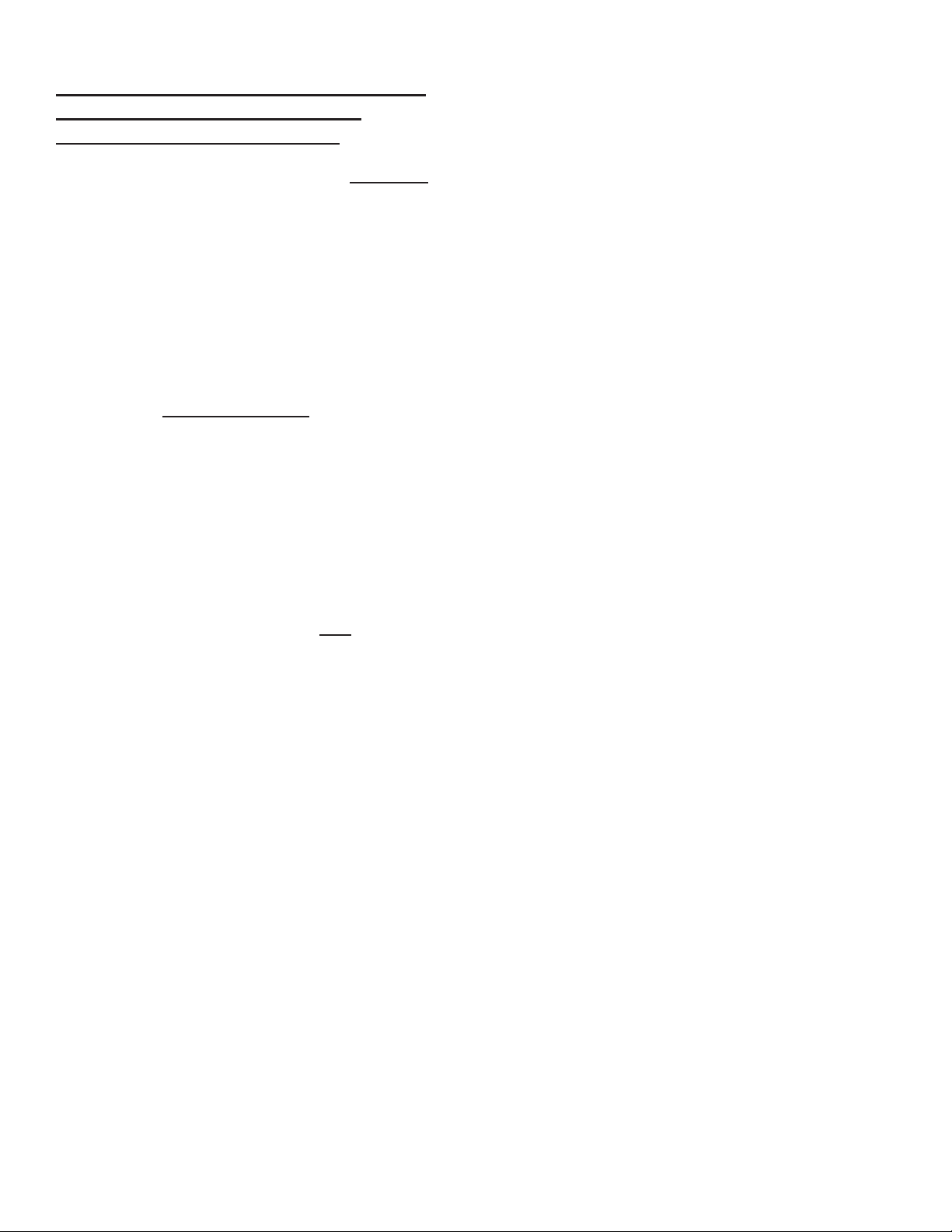

Bendix Air Disc Brakes convert air pressure into braking

force. (See Figure 2.) When the vehicle brakes are

applied, air enters the service brake chamber through

the supply port, applying pressure within the diaphragm.

The pressure expands the diaphragm, applying force to,

and moving the pressure plate and pushrod forward. The

pushrod acts against a cup in the internal lever which

pivots on an eccentric bearing moving the bridge. Moving

against a return spring, the bridge transfers the motion to

two threaded tubes and tappets, which move the inner

brake pad. The inner brake pad (from its normal position of

having a running clearance between it and the rotor) moves

into contact with the brake rotor. Further movement of the

bridge forces the caliper, sliding on two stationary guide

pins, away from the rotor, which pulls the outer brake pad

into the rotor. The clamping action of the brake pads on

the rotor applies braking force to the wheel.

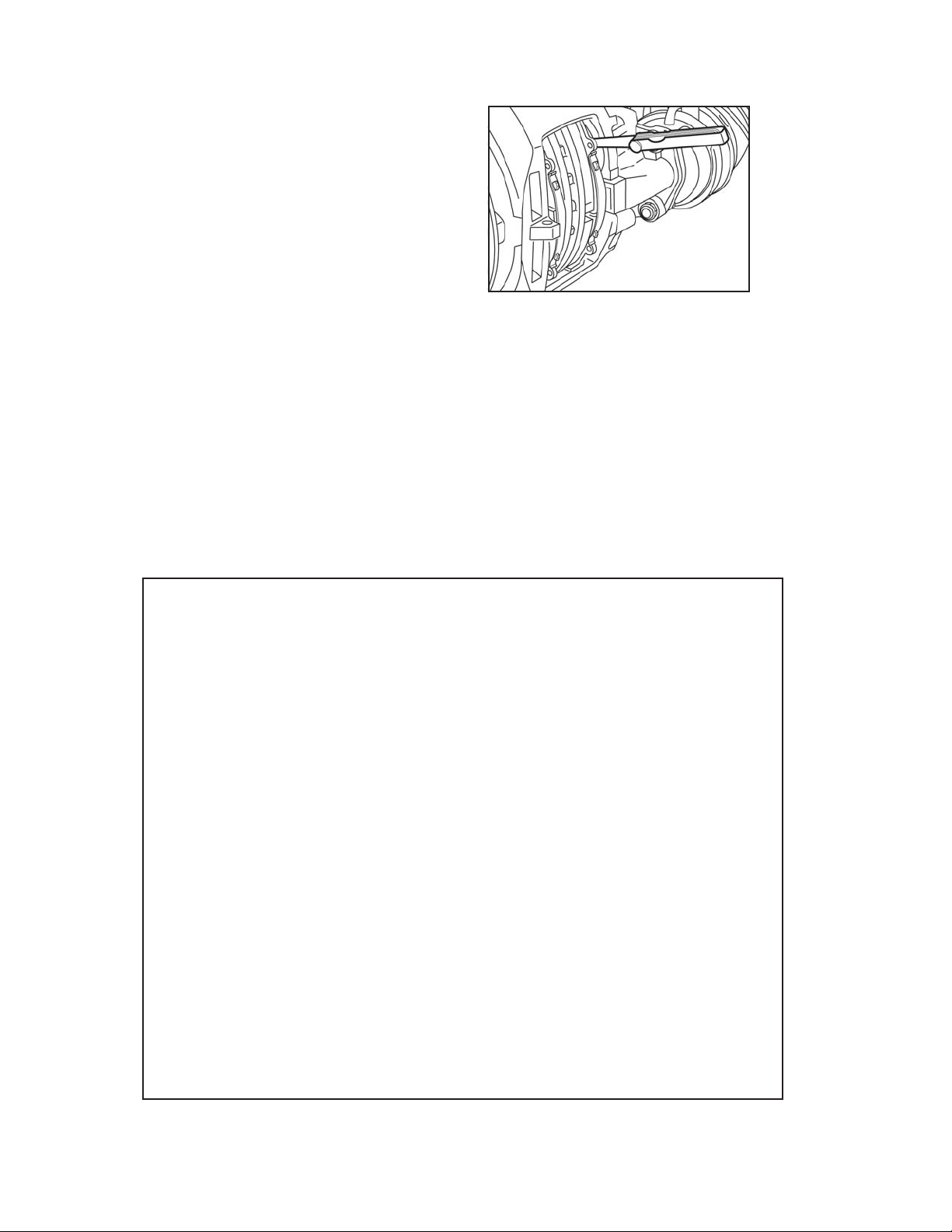

FIGURE 1 - BENDIX® ADB 22X™ AIR DISC BRAKE

Service Brake

Chamber

Lever

Return Spring

Pressure

Plate

Pushrod

SD-23-7541

Supply Port

Brake Release and Adjustment

When the vehicle brakes are released, the air pressure

in the service brake chamber is exhausted and the return

springs in the chamber and the bridge return the air disc

brake to a neutral, non-braked position. To maintain the

running clearance gap between the rotor and the brake

pads over time, the non-braked position is mechanically

adjusted by a mechanism in the caliper. The adjustment

mechanism operates automatically whenever the brakes

are activated, to compensate for rotor and brake pad wear

and to keep the running clearance constant. During pad

or rotor maintenance, the technician manually sets the

system’s initial non-braked position. The total running

clearance (sum of clearances on both sides of the rotor)

should be between 0.024 to 0.043 in. (0.6 and 1.1 mm).

Diaphragm

Eccentric Bearing

Bridge

Pad

Rotor

Inner Brake Pad

Outer Brake

FIGURE 2 - CROSS-SECTION VIEW SHOWING BRAKE

OPERATION

1

Page 2

SAFE MAINTENANCE PRACTICES

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times:

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear

safety glasses. Where specifically directed, the

parking brakes may have to be released, and/or

spring brakes caged, and this will require that the

vehicle be prevented from moving by other means

for the duration of these tests/procedures.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When working

in the engine compartment, the engine should be

shut off and the ignition key should be removed.

Where circumstances require that the engine be in

operation, EXTREME CAUTION should be used to

prevent personal injury resulting from contact with

moving, rotating, leaking, heated or electrically

charged components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

dryer system or a dryer reservoir module, be sure

to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power from

the vehicle.

6. Nev e r ex c e e d manufacturer’s re c o m m e nded

pressures.

7. Ne v er connect or disconnec t a hose or l i ne

containing pressure; it may whip. Never remove a

component or plug unless you are certain all system

pressure has been depleted.

8. Use only genuine Bendix

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make certain

all components and systems are restored to their

proper operating condition.

®

replacement parts,

®

air

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

WARNING: Not all wheels and valve stems are

compatible with Bendix Air Disc Brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid the risk of valve stem shear and

other compatibility issues.

BRAKE DUST WARNING:

AVOID CREATING DUST WHEN WORKING

WITH BRAKE PADS DUE TO POSSIBLE

CANCER AND LUNG DISEASE HAZARD.

While Bendix Spicer Foundation Brake LLC does

not offer asbestos-containing brake linings or disc

pads, the long-term effects of certain non-asbestos

fibers have not been determined. Current OSHA

Regulations cover exposure levels to some, but not all,

components of non-asbestos linings and pads. The

following precautions should be used when handling

these materials:

• Avoid creating dust. Compressed air or dry

brushing must never be used to clean brake

assemblies or the work area.

• Brake workers must take steps to minimize

their exposure to airborne brake lining particles.

Procedures to reduce exposure include: working

in a well-ventilated area, segregating areas where

brake work is performed, using local filtered

ventilation systems or enclosed cells with filtered

vacuums for all brake work. Respirators approved

by the Mine Safety and Health Administration

(MSHA) or National Institute for Occupational

Safety and Health (NIOSH) should be worn at all

times during brake servicing.

• Workers must wash before eating or drinking,

should not use tobacco products in any form,

shower after working, and not wear work clothes

home. Work clothes should be vacuumed using

a high efficiency particulate filter (HEPA) vacuum

and laundered separately without shaking.

• OSHA Regulations regarding testing, disposal

of waste and methods of reducing exposure

for asbestos are set forth in 29 Code of Federal

Regulations §1910.001. These Regulations provide

valuable information which can be utilized to

reduce exposure to airborne particles.

• Material Safety Data Sheets on Bendix

brake pads, as required by OSHA, are available

from Bendix Spicer Foundation Brake LLC.

®

air disc

2

Page 3

SERVICE DATA INDEX

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safe Maintenance Practices. . . . . . . . . . . . . . . . . . . . 2

Air Disc Brake Sectional and Exploded Views

Air Disc Brake Identification . . . . . . . . . . . . . . . . . . . . 6

Rotor Identification

Electronic Wear Indicator Exploded Views. . . . . . . . . 6

Preventive Maintenance Schedule. . . . . . . . . . . . . . . 7

Running Clearance Inspection . . . . . . . . . . . . . . . . . . 7

Mechanical Wear Indicators . . . . . . . . . . . . . . . . . . .8-9

Electronic Wear Indicators, including

Hand Held Diagnostic Equipment . . . . . . . . . . . . . 10

Troubleshooting Flowchart

Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Caliper Running Clearance . . . . . . . . . . . . . . . . . . . 14

Adjuster Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . 15

Guide Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Preventive Maintenance

Troubleshooting

. . . . . . . . . . . . . . . . . . . . 11

Inspections

. . . . .4-5

Maintenance Procedures

Pad Replacement. . . . . . . . . . . . . . . . . . . . . . . . .18-19

Electronic Wear Indicator Replacement

Tappet and Boot Assemblies

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier/Caliper Assembly Replacement

Brake Actuator and Spring

Brake Replacement . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .20-21

22-24

. . . . . . . . . . 25

26-27

3

Page 4

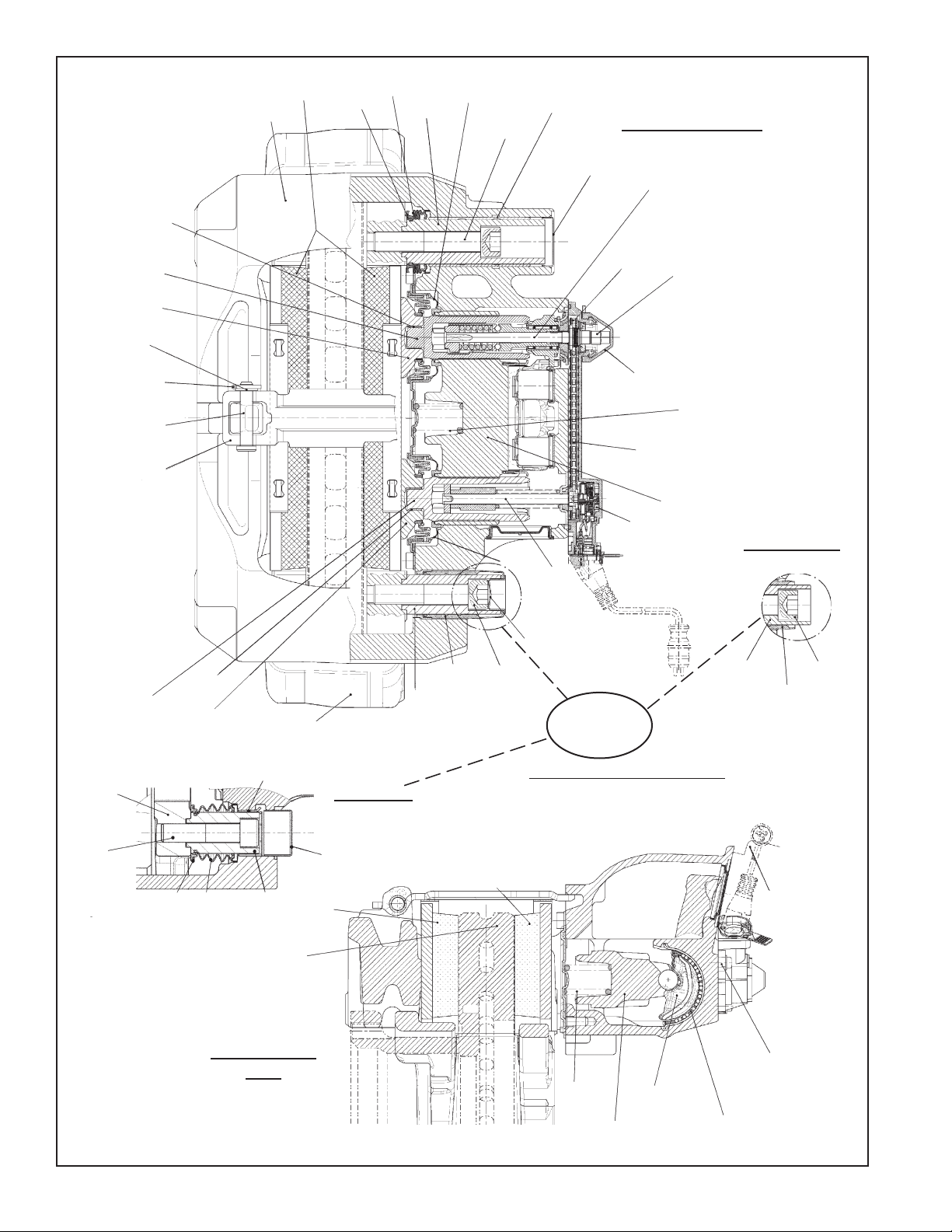

1

Caliper

12

Pad

Assembly

58

Ring

9

Inner

Boot

5

Guide

Pin

22

Inner Seal

Caliper Bolt

Brass Bushing

40

7

Top Sectional View

161

Tappet

Bushing

16

Threaded Tube

13

Tappet and Boot

Assembly

45 Washer

26

Spring Clip

44

Pad Retainer Pin

Pad Retainer

10

Cover

Adjuster Cap

11

22

Inner

Seal

24

Turning

Device

Wear Sensor

Adjuster Unit

32

Chain

Wheel

37

30

Chain

33

23

61

Shear Adapter

27 Spring

17

Bridge

Caliper Bolt B

(Uses Solid Rubber Bushing)

161

58

Ring

Tappet

Bushing

Tappet

and Boot

Assembly

Inner

Boot

13

6c Guide Sleeve

9

Guide Pin

16

Threaded Tube

2

Carrier

39c

Caliper Bolt

Side Sectional

View

FIGURE 4 - SECTIONAL VIEW

68a Cap

39b

Caliper Bolt

2

Carrier

4a

Guide

Pin

6a

Rubber

Bushing

39a

Caliper Bolt

One of Three

Alternate

Caliper Bolt

Styles Used

4b

Guide Pin

6b

Rubber

Bushing

Main Diagram shows Caliper Bolt A

Caliper Bolt C

(Has External Metal

Cover)

68c

Cover

4c

12

Pad

Assembly

46

Rotor

Pad Assembly 12

(Uses Flexible Rubber Wear

Indicator Sleeve)

27

Spring

Bridge

19

Lever

17

18/1 Spring Brake or

18/2

Brake Chamber

43

Bolt

20

Eccentric

Bearing

4

Page 5

One of Three Different

Caliper Bolt Styles are

Used (Designated by

A, B, or C)

39c

Caliper Bolt

68c

Cover

68a Cap

18/1 Spring Brake

Uses White Assembly

Grease

6b

Rubber

Bushing

6c Guide

Sleeve

39b

Caliper

Bolt

39a

Caliper Bolt

18/2

Brake

Chamber

6a

Rubber Bushing

Adjuster Cap

5

Guide

Pin

37

Guide

Shear

Adapter

10

Cover

4c

Pin

61

Bushing

Inner

Boot

7

Brass

58

Ring

9

Pre-Applied

Thread Adhesive

11

Pad Retainer

4a, 4b

Guide Pin

40

Caliper Bolt

44

Pad Retainer Pin

45

Washer

Inner

Boot

Spring Clip

Caliper

9

Ring

1

58

26

12/2

12/1

12

Pad Assembly

13

Tappet and Boot

Assembly

161

Tappet

Bushing

22

Inner Seal

Uses

White

Assembly

Grease

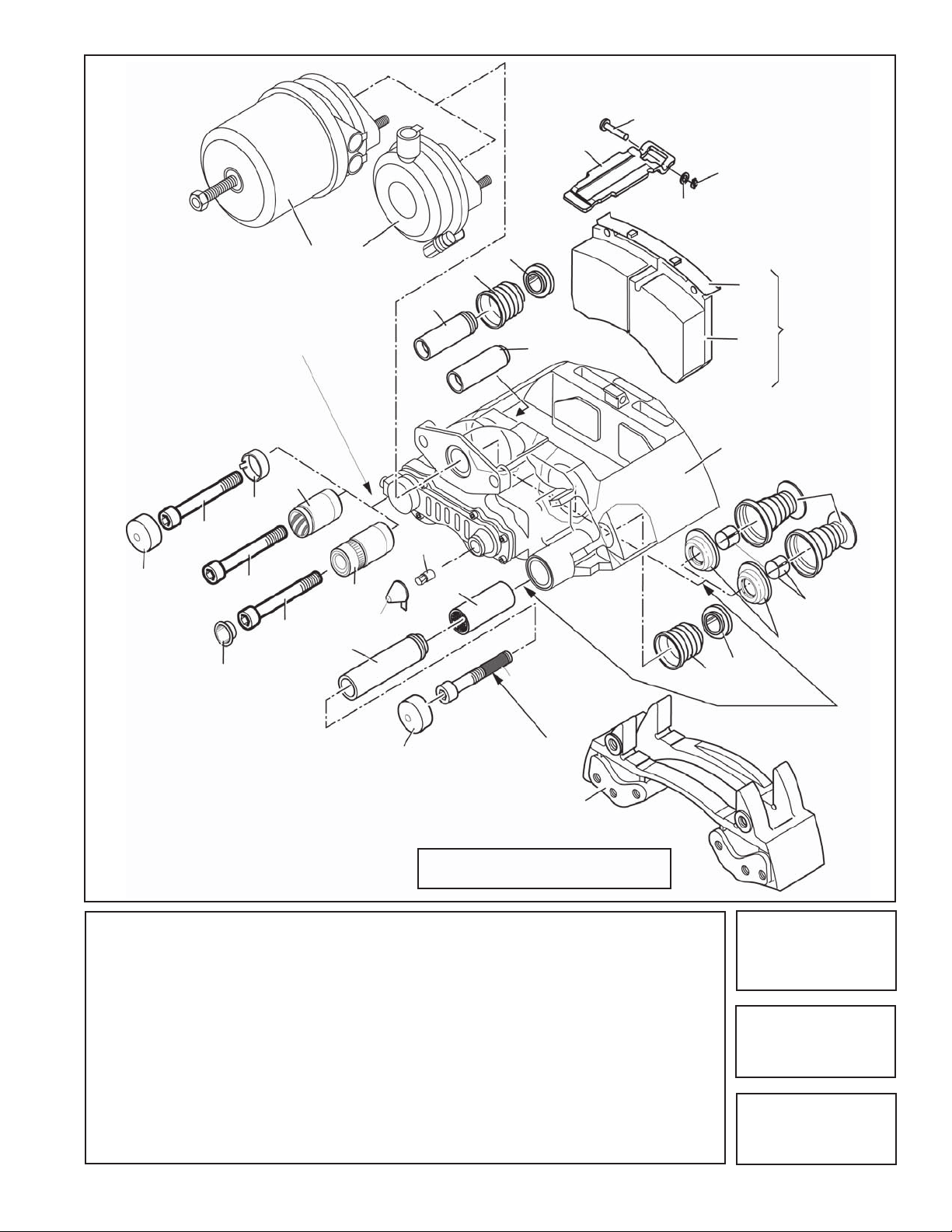

FIGURE 5 - EXPLODED VIEW FOR REFERENCE ONLY - MANY OF THE

PARTS SHOWN ARE ONLY FACTORY

SERVICEABLE AT THIS TIME.

Chain . . . . . . . . . . . . . . . . . . . . 30

KEY

Adjuster Cap. . . . . . . . . . . . . . . 37

Adjuster Unit. . . . . . . . . . . . . . . 23

Bolt . . . . . . . . . . . . . . . . . . . . . . 43

Brake Chamber . . . . . . . . . . 18/2

Brass Bushing . . . . . . . . . . . . . . 7

Bridge . . . . . . . . . . . . . . . . . . . . 17

Caliper . . . . . . . . . . . . . . . . . . . . 1

Caliper Bolt. . . . 39a, 39b, 39c, 40

Carrier. . . . . . . . . . . . . . . . . . . . . 2

Chain Wheel. . . . . . . . . . . . . . . 32

Cover . . . . . . . . . . . . . . . . . . . . 10

Eccentric Bearing . . . . . . . . . . . 20

Guide Pins . . . . . . . . 4a, 4b, 4c, 5

Guide Sleeve . . . . . . . . . . . . . . 6c

Inner Boot. . . . . . . . . . . . . . . . . . 9

Inner Seal . . . . . . . . . . . . . . . . . 22

Lever . . . . . . . . . . . . . . . . . . . . 19

Pad . . . . . . . . . . . . . . . . . . . . 12/1

Pad Holder Spring . . . . . . . . 12/2

Pad Assembly

Pad Retainer . . . . . . . . . . . . . . 11

2

Carrier

See Figure 9, on Page 6 for exploded

views of electronic wear indicators

Pad Retainer Pin . . . . . . . . . . . 44

Ring . . . . . . . . . . . . . . . . . . . . . 58

Rubber Bushings . . . . . 6a, 6b, 6c

Shear Adapter . . . . . . . . . . . . .

Spring . . . . . . . . . . . . . . . . . . . . 27

Spring Brake. . . . . . . . . . . . . 18/1

Spring Clip . . . . . . . . . . . . . . . . 26

Tappet and Boot Assembly

Tappet Bushing

Threaded Tube. . . . . . . . . . . . . 16

Turning Device . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . 12

Washer . . . . . . . . . . . . . . . . . . . 45

Wear Sensor

61

. . . . 13

. . . . . . . . . . . . 161

. . . . . . . . . . . . . . . 33

Caliper Bolt A

Caliper Bolt. . . . . . . . 39a

Cap. . . . . . . . . . . . . . 68a

Guide Pin . . . . . . . . . .4a

Rubber Bushing . . . . .6a

Caliper Bolt B

Caliper Bolt. . . . . . . . 39b

Guide Pin . . . . . . . . . .4b

Rubber Bushing . . . . .6b

Caliper Bolt C

Caliper Bolt. . . . . . . . 39c

Guide Pin . . . . . . . . . . 4c

Cover . . . . . . . . . . . . 68c

5

Page 6

AIR DISC BRAKE IDENTIFICATION

To determine which version of the Bendix air disc brake is

installed, locate the identification label near the guide pin

housing. See below for examples of the different styles of

label you may find.

FIGURE 6 - PART NUMBER LABEL LOCATION

Bendix Part No.

Serial No.

Brake Designation followed

by the Caliper/Carrier part

number

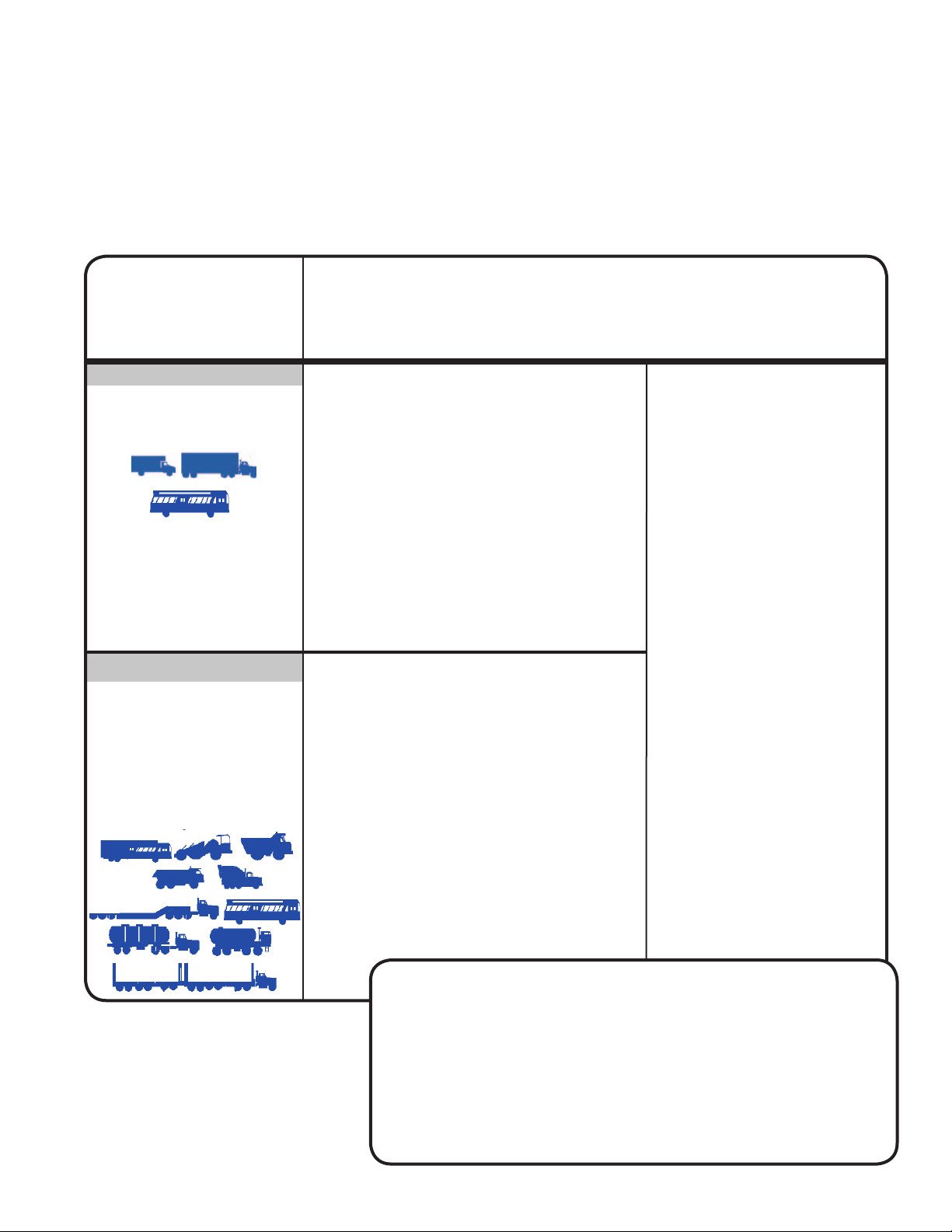

ROTOR IDENTIFICATION

Certain maintenance inspection procedures depend on

the type of rotor installed (See Page 13). See below for

examples of the different styles of rotor in use.

Spline Rotor

Conventional Rotor

Some air disc brakes carry the

Knorr-Bremse label shown below.

Type of

Caliper

Manufacturer's No.

Date of Manufacture

FIGURE 7 - PART NUMBER LABEL FIELDS

104

Type 1

Type 2

Cable Protection

Plate

Sensor

101

Sensor

104

Cable Protection

Plate

101

Sensor

101

Sensor

101

103

101

Sensor

101

Sensor

105

Cable Guide

11 Pad Retainer

Part No.

Axle or Vehicle

105 Cable

Guide

11 Pad

Retainer

FIGURE 8 - ROTOR IDENTIFICATION

104

Cable Protection

Plate

101

Sensor

Type 3

105a

Cable

Guide

Alternative to

103

Cable to Electrical

Supply

Item 105

Pad Retainer . . . . . . . . . . . . . . 11

Sensor . . . . . . . . . . . . . . . . . . 101

Cable to Electrical Supply . . . 103

Cable Protection Plate . . . . . . 104

Cable Guide . . . . . . . . . . . . . . 105

Cable Guide . . . . . . . . . . . . . 105a

101

Sensor

105

Cable Guide

11 Pad

Retainer

FIGURE 9 - ELECTRONIC WEAR INDICATOR COMPONENTS

6

Page 7

PREVENTIVE MAINTENANCE

Regular inspection and maintenance of air disc brake

components is an important part of vehicle maintenance.

The maintenance practices outlined here are recommended

in addition to all standard industry practices (including e.g.

daily pre-trip inspections, etc.) Also, see the vehicle's

manual for recommendations.

Pad & Rotor Wear,

Vehicle Used for:

(Inspection with the wheel mounted)

Running Clearance

Use the table below for a guide to maintenance interval

planning, however, depending on the vehicle use, more

frequent checks of the components may be necessary.

Keep track of the results of your maintenance inspections to assist you determine the ideal maintenance

interval for the vehicle.

Basic Inspection Program

At Least Once Annually and at

Every Pad Replacement

(Inspection with wheel removed)

Over the Road

e.g. Line haul, RV,

Open Highway Coach.

Higher Duty Use

e.g. Pick-Up & Delivery,

Off-Highway, Construction,

Loggers, Concrete Mixer,

Dump Truck,

City Transit Bus, Refuse,

Urban Region Coach,

School Bus.

• For vehicles with electronic wear indicators,

use the dash indicator(s) and/or the hand-held

diagnostic tool to regularly monitor the pad

wear.

• In all cases, visually inspect the wear indicator

(see Pages 8-9) every four months (or keep

track of the results of maintenance inspections

to schedule checks 4 to 5 times during the

pad lifetime). At the same time, conduct the

Running Clearance Inspection (see below).

• A visual check of the mechanical wear indicator

every time the tire pressures are checked is

recommended. Be alert for any rotor cracks,

etc. visible (See Page 13 for criteria.)

• For vehicles with electronic wear indicators,

use the dash indicator(s) and/or the hand-held

diagnostic tool to regularly monitor the pad

wear.

• In all cases, visually inspect the wear indicator

(see Pages 8-9) every three months (or keep

track of the results of maintenance inspections

to schedule checks 4 to 5 times during the

pad lifetime). At the same time, conduct the

Running Clearance Inspection (see below).

• A visual check of the mechanical wear indicator

every time the tire pressures are checked is

recommended. Be alert for any rotor cracks,

etc. visible (See Page 13 for criteria.)

Inspect:

• The rotor for cracks, etc. (see

Page 13 for criteria)

• The running clearance

and adjuster function (see

Page 15)

• The caliper travel (see Pages

16-17)

• The tappet and boot

assemblies (see Page 14)

• All covers, caps, hoses, and

brake exterior for damage etc.

Air Disc Brake Running Clearance Inspection.

Follow all industry safety guidelines, including those listed on Page 2. On

level ground, with the wheels chocked and the parking brake temporarily

released, check for movement of the brake caliper. This small movement,

less than 0.80" (2 mm) - approximately the thickness of a nickel - in the

inboard/outboard direction indicates that the brake is moving properly

on its guide pins. If the caliper has no movement or appears to move

greater than the distances above, a full wheel-removed inspection will be

necessary. See Page 16.

7

Page 8

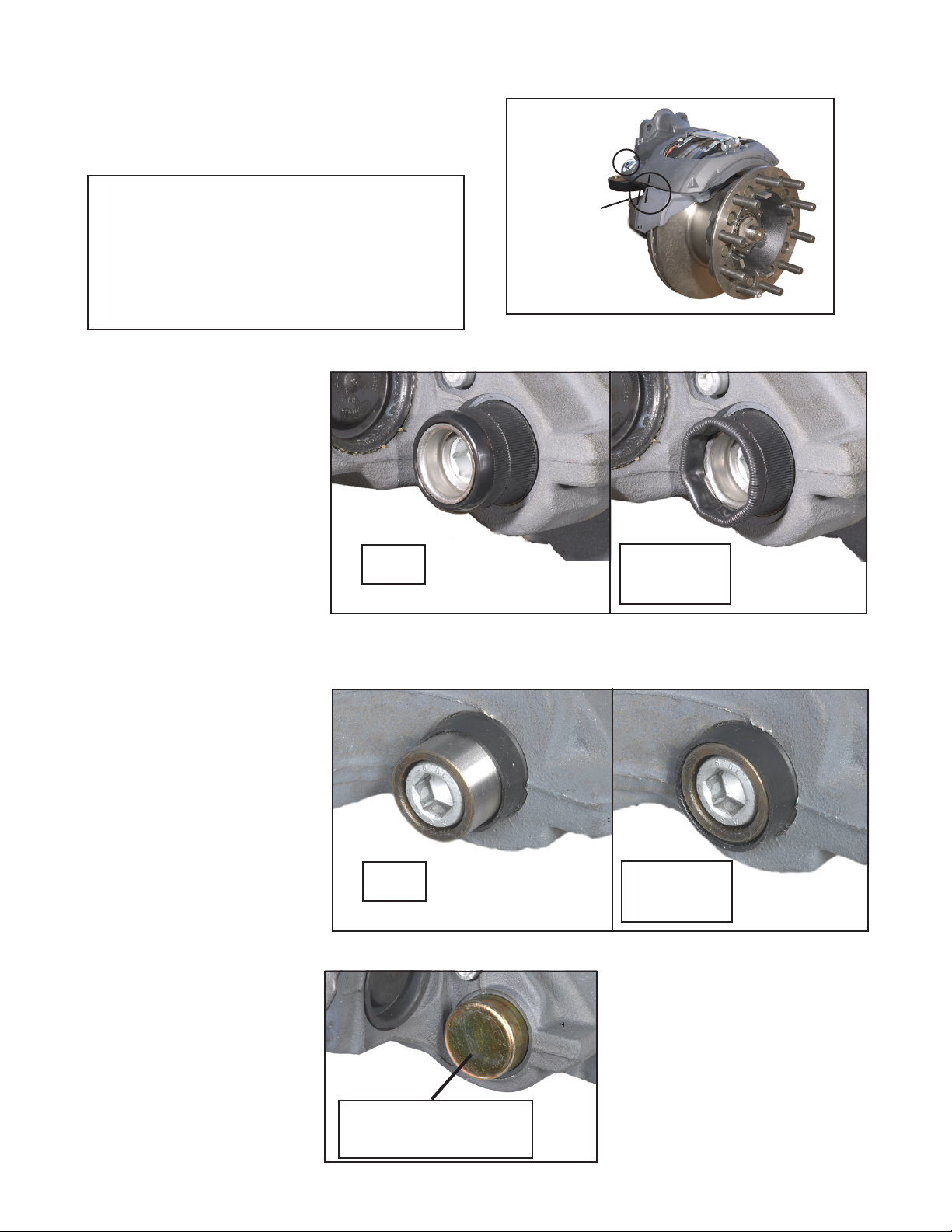

MECHANICAL BRAKE PAD AND ROTOR WEAR INDICATORS

A preliminary visual check of the condition of the brake pad/rotor

wear can be made without removing the wheels. See below

for the inspection to make for each of the three guide pin styles

in use for Bendix air disc brakes.

Style A and B

- Inspect position

of wear indicator

pin

Note: These inspections provide an indication of

when to schedule a full wheel-removed inspection of

the brake pads and rotor. The thicknesses of both the

pad and rotor will affect the wear indicator position at

which maintenance is actually needed.

These inspections do not constitute

“out-of-service” criteria.

Style A: Rolling Boot Style Wear Indicator

Inspect the position of the guide pin

flexible rubber bushing. See Figure

10. When the guide pin has moved

in so that the ribbed section of the

flexible rubber bushing reaches the

point where it folds back in, it is time

to schedule a full wheel-removed

inspection of the pads and rotor. Note:

This is only an indication that the pads

and rotor are ready for inspection,

and does not necessarily mean that

maintenance is required.

FIGURE 10 - ROLLING BOOT-STYLE WEAR INDICATOR INSPECTION

New

Style C and D -

Where the indicator

pin is covered (see

Figure 12), inspect

notches in carrier

and caliper or

backing plate - see

Page 9

Time to Schedule

Inspection of

Pads and Rotor

Style B: Solid Rubber Bushing Style Wear Indicator

Inspect the position of the guide pin

compared to the solid rubber bushing.

See Figure 11. When the guide pin

is aligned with the bushing, it is time

to schedule a full wheel-removed

inspection of the pads and rotor. Note:

This is only an indication that the pads

and rotor are ready for inspection,

and does not necessarily mean that

maintenance is required.

FIGURE 11 - SOLID RUBBER BUSHING-STYLE WEAR INDICATOR INSPECTION

New

Where the Guide Pin is enclosed

by a cover - see next page for

inspection criteria.

Time to Schedule

Inspect ion of

Pads and Rotor

FIGURE 12 - PIN COVER

8

Page 9

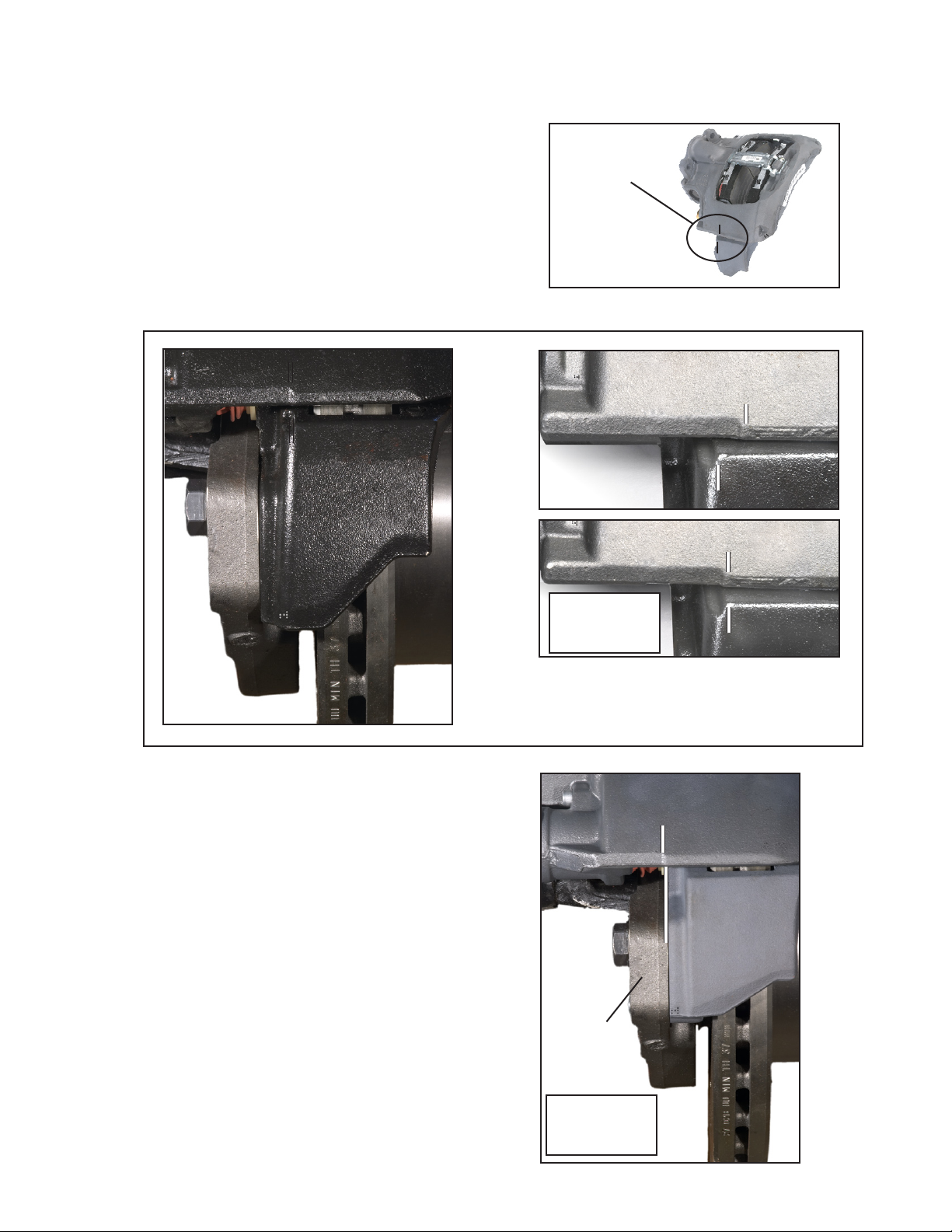

MECHANICAL BRAKE PAD AND ROTOR WEAR INDICATORS (continued)

Style C: Where Both the Carrier and Caliper

Have an Indicator Notch

Compare the relative position of two notches cast into the

Carrier and Caliper. See Figure 13. When the two notches

align, it is time to schedule a full wheel-removed inspection

of the pads and rotor. Note: This is only an indication that

the pads and rotor are ready for inspection, and does not

necessarily mean that maintenance is required.

Location of

Inspection

Grooves

Notch in Caliper

Notch in

Carrier

Style D: Where Only the Caliper has an

Indicator Notch

When the notch in the Carrier aligns with the front edge of

the torque plate, it is time to schedule a full wheel-removed

inspection of the pads and rotor. Note: This is only an

indication that the pads and rotor are ready for inspection,

and does not necessarily mean that maintenance is

required.

Notches

Line Up

Time to Schedule

Inspection of

Pads and Rotor

FIGURE 13 - STYLE C - NOTCHED

CARRIER AND CALIPER

Notch in

Caliper

Backing

Plate

Lines Up

FIGURE 14 - CARRIER WEAR

INDICATOR NOTCH AND BACKING

PLATE ALIGNMENT

Torque

Plate

Time to Schedule

Inspection of

Pads and Rotor

9

Page 10

11

Pad Retainer

101

Wear Sensor

Cable

Brake Pad Assembly

Example of

a Wear Sensor

(101) Installed into

Slot in Brake Pad

12

46 Rotor

To Vehicle Electronic

Monitoring System

or for use with

Diagnostic Tool

FIGURE 15 - EXAMPLE OF NORMALLY OPEN OR CLOSED

WEAR SENSOR

ELECTRONIC BRAKE PAD WEAR

INDICATORS

The electronic monitoring system uses sensors installed

in a pre-formed slot in the brake pad to allow the status of

the pad wear to be monitored. When the pad wears away

through use, the point is reached when the indicator itself

comes into contact with the rotor.

For in-pad Normally-Closed Indicators, when the point

is reached when the indicator itself is worn through, the

circuit flowing through it is broken and the vehicle operator

is alerted.

For in-pad Normally-Open Indicators, when the point

is reached when the indicator itself is worn through, the

circuit is completed by the rotor touching the contacts and

the vehicle operator is again alerted.

On some vehicles, the electronic system is fully integrated

into the vehicle monitoring system and uses a buzzer

or indicator lamp to alert the driver. Alternate vehicle

arrangements permit a hand-held diagnostic tool to be

used to test individual wheel connectors, or where installed,

attach to a DIN socket in the dash, and allow up to six

brakes to be checked from that location. The system

provides feedback on the pad wear and can also conduct

a test of the Wear Indicator Potentiometer.

Even when using wear indicators, always follow the

standard preventive maintenance schedule outlined on

page 7.

Refer to the vehicle manual and/or the diagnostic tool

manual for specific device operating instructions.

FIGURE 16 - EXAMPLE OF POTENTIOMETER WEAR

SENSOR

13-Pin Plug

(DIN 72570)

to vehicle

Plug for Individual

Wheel Inspection

FIGURE 17 - HAND HELD DIAGNOSTIC TOOL

10

Page 11

GENERAL TROUBLESHOOTING PROCEDURE FLOWCHART

FIGURE 18 - TROUBLESHOOTING BENDIX AIR DISC BRAKES

11

Page 12

INSPECTIONS

Follow all standard safety procedures including, but not

limited to, those on page 2 of this service manual.

BRAKE PADS AND ROTORS

Bendix Air Disc Brakes are precision-engineered braking

mechanisms. The “friction couple” braking characteristics

have been carefully optimized and the rotor design and

materials have been matched with special formulation

brake pads for optimal performance.

CAUTION: When replacing brake pads, Bendix

strongly recommends using only replacement pads

and replacement rotors approved by the OEM. Use

of non-approved rotors or non-approved replacement

disc pads can cause excess wear to brake components,

and can increase the risks of rotor cracking, etc. Note

that two thicknesses of backing plate are generally

available, so to maintain the vehicle within spec's

only use brake pads with the type of backing plate

and lining material originally supplied by the vehicle

manufacturer. See the manual supplied with the

vehicle for further information.

INSPECT BRAKE PADS

Regular inspection of the brake pads (even for vehicles

that use a wear indicator) is an important part of vehicle

maintenance.

See Figure 16. If the thickness of the friction material (M2)

is less than 0.079 in. (2 mm) the pads must be replaced.

Bendix® ADB 22X™, ADB 225™, SN6™, SN7™ (and some

SK7™) air disc brakes use 0.35 in. (9 mm) backing plates,

so P2 (the combined pad and backing plate thickness)

must be a minimum of 0.43 in. (11 mm).

®

Note that for some Bendix

(7 mm) backing plate is used, so P2 (the combined pad

and backing plate thickness) must be a minimum of 0.35 in.

(9 mm).

If the pad thickness is within the acceptable range, inspect

the pad surface. Minor damage at the edges is permitted

(see Figure 20), but replace the pads if major damage on

the surface of the pad is found (see Figure 21).

When replacing brake pads, Bendix strongly recommends

that all the brake pads on an axle be replaced at one time.

See pages 18-19 for the pad replacement procedure. Also

see the vehicle manual recommendations.

SK7™ air disc brakes, a 0.28 in.

B (Backing P2 (Pad min.

plate thickness) thickness)

Bendix® ADB 22X™,

ADB 225™, SN6™,

and some SK7™

Air Disc Brake Pads

SK7™ Air Disc Brake

Pads with 0.28 in.

(7 mm) backing plate

FIGURE 19 - PAD AND ROTOR DIMENSIONS

0.35 in. 0.43 in.

(9 mm.) (11 mm.)

0.28 in. 0.35 in.

(7 mm.) (9 mm.)

Small Amount of

Brake Material

Chipped from

Edge

FIGURE 20 - MINOR

PAD DAMAGE IS

ACCEPTABLE

FIGURE 21 - MAJOR

PAD DAMAGE IS

NOT ACCEPTABLE

Section

Damaged or

Missing

12

Page 13

INSPECT ROTORS

Identify if the rotor is a conventional or a splined assembly

(see Page 6).

Examine the rotor and measure the thickness at thinnest

point. Avoid measuring near the edge of the rotor as minor

burrs may be present.

Replace Bendix rotors when the minimum thickness of

1.46 in. (37 mm) is reached or as instructed by vehicle

manufacturer. When replacing Rotors, please refer to the

instructions of the Vehicle Manufacturer. It is recommended

to install Bendix Brake Rotors, available from your local

Bendix Spicer Foundation Brake parts outlet, and it is

also recommended that the pads should be replaced at

the same time.

Non-Bendix rotors. If a non-Bendix rotor is used,

refer to the vehicle manual and rotor manufacturer’s

recommendations. CAUTION: The use of non-approved

brake rotors may reduce levels of safety and invalidate

warranty.

Rotor Surface Inspection

Inspect the rotor at each change of pads for grooves and

cracks. The action to take depends on the type of rotor,

and also the size, depth and direction of the imperfections,

see Figure 22.

Rotor Turning (Grinding)

Bendix rotors are normally service-free.

Turning of Bendix spline rotors is not permitted.

Conventional rotors may be turned when changing pads,

but is not normally necessary. In the case of severe

grooving of the entire friction surface, however, turning

could be useful, and may increase the load-bearing

surface of the pads. To meet Bendix recommendations,

the minimum rotor thickness after turning must be greater

than 1.53 in. (39 mm).

CAUTION: Always maintain air disc brake pads and rotors

within specifications. Excessive pad or rotor wear will

degrade optimum performance. When replacing Rotors, be

sure to adhere to the vehicle manufacturer’s recommended

bolt tightening torques.

A

No action is needed for

small cracks spread

over the surface (e.g.

Area A)

Rotor

Friction

Surface

Width

“a”

D

Cracks reaching

either edge of the

rotor

are not

acceptable

for either

type of

rotor

a

Area D

Area A

C

C i r c u m f e r e n t i a l

Grooves, as in Area

C, are acceptable

if less than 0.06 in.

(1.5 mm) deep.

Area B

Area C

B

• For standard Bendix rotors, cracks

running in a radial direction, that is,

from the inside to the outside, (see

Area B), less than 0.06 in. (1.5 mm)

deep or wide are acceptable. Cracks

are only acceptable if they are less

than 75% of the width of the rotor

contact area (i.e. 75% of dimension

“a”).

• For spline Bendix rotors, radial

cracks are only acceptable if they

are less than 0.04 in. (1.0 mm) deep

or wide, and if they are less than

75% of the width of the rotor contact

area (i.e. 75% of dimension “a”).

In ad d it io n , f o l lo w t he

recommenda tions of the

vehicle manufacturer. An

axle should only have either

spline or standard rotors.

FIGURE 22 - EXAMPLES OF ACCEPTABLE AND NON-ACCEPTABLE ROTOR CRACKS AND GROOVES

13

Page 14

2. CALIPER RUNNING CLEARANCE

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

CALIPER MOVEMENT TEST

Remove the wheel. With the spring brakes caged, push

the caliper assembly inboard on its guide pins. Using a

suitable tool, press the inboard pad (12) away from the

tappets and check the gap between the tappet and the

inboard pad backplate - it should be between 0.024 in.

(0.6 mm) & 0.043 in. (1.1 mm). If the movement is within

the range there is no need to inspect further.

CAUTION: If the clearance is too wide, there is a danger

of brake failure. If the clearance is too small, there is a

danger of overheating. That may lead to consequential

damage.

FIGURE 23 -

MEASURING

THE RUNNING

CLEARANCE

If there is no movement at all, go to pages 16-17 for

the “Guide Pin Inspection Procedure.”

If inst ead, there is movemen t, but the running

clearance is too small or too large, the adjuster may

not be functioning correctly and should be checked.

See “Inspect Adjuster Mechanism” on Page 15.

CONTACTING BENDIX

www.foundationbrakes.com

Bendix on-line information is available 24/7. In the on-line contacts directory, you can find:

technical support contacts; service engineers; Bendix account managers; international

contacts and more. www.foundationbrakes.com is your complete Bendix resource.

Bendix Technical Assistance Team

For direct personal technical support, call the Bendix technical assistance team at:

1-800-AIR-BRAKE (1-800-247-2725),

Monday through Friday, 8:00 A.M. to 6:00 P.M. EST, and follow the instructions in the

recorded message.

Alternatively, you may e-mail the Bendix technical assistance team at:

techteam@bendix.com.

To better serve you, please record the following information before you call the

Bendix Tech Team, or include this information in your e-mail:

• Bendix product model number, part number and configuration.

• Vehicle make and model.

• Vehicle configuration. (Number of axles, tire size, etc.)

• System performance symptoms: When do they occur?

• What troubleshooting/measurements have been performed?

• What Bendix service data literature do you have or need?

14

Page 15

3. INSPECT ADJUSTER MECHANISM

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

Aside from the normal maintenance schedule, this

Adjuster Check is also carried out when the Caliper

Movement Test (see Page 14) finds that the running

clearance is too small or too large.

The adjuster should then be checked as follows:

With the spring brake released (or caged), remove the

adjuster cap (37) using the tab, taking care not to move

the shear adapter (61). Note: One of two styles of adjuster

cover (stamped metal or plastic) may be used.

Although exploded view (Figure 25) shows the adjuster (23)

and shear adapter (61) separated, only turn the adjuster

with the shear adapter installed on the adjuster. Using a

box-end wrench or socket, turn the Shear Adapter (61)

counter-clockwise and listen for the sound of 2 or 3 clicks

as the mechanism increases the running clearance. Note:

Do not use an open-ended wrench as this may damage

the adapter.

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent an excess

of torque being applied to the adjuster. The shear

adapter will fail (by breaking loose) if too much torque

is applied.

If the shear adapter fails, you may attempt a second time

with a new (unused) shear adapter. A second failure of the

shear adapter confirms that the adjustment mechanism is

seized and the caliper must be replaced.

With a box-end wrench (or socket) positioned so that it

can turn freely without coming into contact with parts of

the vehicle (See Figure 27) on the shear adapter, make

five to ten moderate applications of the brakes [at about

30 psi (2 Bar)]. For a normally functioning Bendix air disc

brake, the box-end wrench or socket should turn clockwise

in small increments. NOTE: As the number of applications

increases, the turning movement will decrease (as the

brake reaches its normal calibration point).

If the box-end wrench or socket does not: (a) turn at all,

or (b) turns only with the first application, or (c) turns

forward and backward with every application, the automatic

adjuster has failed and the caliper/carrier assembly must

be replaced.

61

37

12

Inboard

Brake

12

Pad

Outboard

Brake Pad

FIGURE 24 - COVER REMOVAL

37

Cap

23 Adjuster

61 Adapter

37

Cap

Tab

FIGURE 25 - EXPLODED

VIEW OF ADJUSTER

AND ADAPTER

FIGURE 27 - ADJUSTMENT MECHANISM TEST

FIGURE 26 - TAB

POSITION

Tab

Bendix recommends installing a new adjuster cap (lightly

greased using white lithium-based grease) when returning

the air brake to service. Ensure that the tab is in the position

shown in Figure 26.

15

Page 16

GUIDE PINS

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

Note: If the steps below lead the technician to a step where

the wheel needs to be removed, inspect first to see that

there is no contact between the caliper and axle, vehicle,

chassis sections or carrier, etc. that may be impeding the

caliper movement. When removing wheels, refer to the

vehicle manufacturer’s recommendations.

This guide pin inspection should be carried out if the

result of the Caliper Movement Test (see Page 13) is

that the technician cannot move the caliper.

GUIDE PIN BEARING INSPECTION

Use the following procedure to check caliper movement

along the guide pins:

Remove the Pads (see Page 18).

One of the three different styles of guide pin (A, B, or C)

may be present (See Figure 28). The bearings for styles

A and B use a rubber bushing, and style C uses a guide

sleeve. Clean dirt, road grime, etc. from the guide pin or

cover.

Using hand pressure only (no tools), the Caliper (1)

should slide freely along the whole length of the Guide

Pin arrangement. With the pads removed, this movement

should be at least 0.8 inch (20mm). If the movement is less

than this amount, replace the caliper/carrier assembly.

To measure the clearance from the rubber bushing (6a,

6b) or guide sleeve (6c) to the guide pin:

See Figures 29 and 30. Remove the wheel. Remove the

pad retainer (11), but leave the pads (12) in position. Attach

a magnetic dial-gauge holder to the carrier (2) on the short

bearing side of the caliper (1).

Use the measuring point on the caliper (1) - see the arrow

in Figure 28. Press the caliper in the direction of carrier

(2) and set the dial-gauge to zero.

Place a suitable tool (e.g. screwdriver) between Carrier

(2) and Caliper (1) forcing them in opposite directions, and

read the maximum value on the dial-gauge.

For styles A and B guide pins, if the value is greater than

0.079 in. (2.0 mm), or for style C guide pins, if the value

is greater than 0.039 in. (1.0 mm), the caliper/carrier

assembly must be replaced.

13

Tappet and Boot

1

Caliper

FIGURE 28 - GUIDE PINS

Assembly

Caliper

Movement

39c

Caliper Bolt

12 Pad Assembly

5

Guide Pin

6a

39a

4a

4b

6b

6c Guide Sleeve

4c Guide Pin

2

Caliper

Brass Bushing

39b

Cover

1

Carrier

7

10

Cover

BEARING SIDE

23

Adjuster Unit

61

Shear Adapter

37

Adjuster

Cap

SHORT

BEARING SIDE

68a

Cap

(6a): Rubber Bushing

(39a): Caliper Bolt

(4a): Guide Pin

(6b): Rubber Bushing

(39b): Caliper Bolt

(4b): Guide Pin

68c

LONG

16

FIGURE 29 - MAGNETIC DIAL-GAUGE

Page 17

GUIDE PIN SEAL INSPECTION

Caliper Guide Pin Seals

The long bearing side guide pin (5) is sealed with the cover

(10) and with the inner boot (9). See Figure 28. Note: It

may be necessary to remove the pads to inspect the inner

boots (9) if pad wear is minimal. The guide pin (4a, 4b,

or 4c, depending on the style) is also sealed with an inner

boot (9) and a cover (style C), or a flexible rubber wear

indicator in the case of style A guide pins.

Inspect the above components, and if damage is found,

replace the caliper/carrier assembly. No kits are available

at this time for Guide Pin Seals.

TAPPET AND BOOT ASSEMBLY

INSPECTION

In order to inspect the tappet and boot assembly, it may

be necessary to remove the pads (12) (see Page 18) and

advance the shear adapter (61) clockwise (see Page 15)

until the boots are clearly visible.

13

Extend Less

Than 1.18 in.

(30 mm)

FIGURE 30 - TAPPET EXTENSION LIMIT

CAUTION: NEVER EXTEND THE TAPPET MORE THAN

1.18 in. (30 mm). Over-extending the tappet will result

in the tappet losing engagement with the threads of the

synchronizing mechanism. Since the mechanism can

only be set at the manufacturing plant, the CALIPER/

CARRIER ASSEMBLY MUST BE REPLACED if this

happens.

Inspect the tappet and boot assemblies (13) for evidence

of damage, corrosion, etc. The penetration of dirt and

moisture into the brake can lead to corrosion and impair

the function of the air disc brake. Replace as necessary

(see Pages 22-24).

After re-installing a wheel according to the vehicle

manufacturer’s recommendations, please ensure that there

is sufficient clearance between the tire inflation valve stem,

the caliper and the wheel rim, to avoid damage.

WARNING : Not all whee ls and valve stems are

compatible with Bendix Air Disc Brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid risk of valve stem shear and

other compatibility issues.

17

Page 18

MAINTENANCE PROCEDURES

PAD REPLACEMENT

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

When installing pads, where appropriate use heavy

duty gloves and always keep fingers away from

potential pinch hazard areas.

As noted earlier, Bendix Air Disc Brakes are precisionengineered braking mechanisms. The “friction couple”

braking characteristics have been carefully optimized and

the rotor design and materials have been matched with

special formulation brake pads for optimal performance.

PAD REMOVAL

Bendix strongly recommends that when replacing brake

pads, pads are replaced as an axle set.

Release or cage spring brakes and remove the wheel (refer

to the vehicle manufacturer’s recommendations).

Note: Before removing the brake pads it is strongly

recommended that the adjuster mechanism be checked

for correct operation (see Page 15).

Remove the clip (26) and washer (45), depress the pad

retainer (11) and remove the pad retainer pin (44). Discard

these four items - replacements are included in the service

kits. As necessary remove any in-pad wear sensor

components and discard.

Pull off the adjuster cap (37) using the tab, taking care to

keep the shear adapter (61) in position on the adjuster

(23).

Using a box-end wrench or socket, fully wind back the

tappet and boot assemblies (13) by rotating the shear

adapter (61) in an counter-clockwise direction (see Page

15). Note: Do not use an open-ended wrench as this may

damage the adapter.

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent an excess

of torque being applied to the adjuster. The shear

adapter will fail (by breaking loose) if too much torque

is applied.

If the shear adapter fails, you may attempt a second time

with a new (unused) shear adapter. A second failure of

the shear adapter confirms that the adjustment mechanism

is seized and the caliper/carrier assembly must be

replaced.

To remove the outboard brake pad (12), slide the caliper

44

Pin

11 Pad Retainer

45 Washer

26 Clip

FIGURE 31 - BRAKE PAD REMOVAL

Inboard

Outboard

Brake Pad

12

FIGURE 32 - BRAKE PAD REMOVAL

(1) fully to the outboard position first. Similarly, to remove

the inboard pad, first move the caliper fully to the inboard

position, and then remove the pad. See Figure 32.

Inspect the rotor.

See Page 13 for full information.

Assembly

23

61

37

Inboard Pad

12

PAD INSTALLATION

CAUTION: When replacing brake pads take care

to always use the correct replacement pads. For

example, note that two thicknesses of backing plate

are generally available - to maintain vehicle within

spec's only use brake pads with the type of backing

plate and lining material originally supplied by the

vehicle manufacturer. See the manual supplied with

the vehicle for further information.

As noted above, Bendix strongly recommends that

when replacing brake pads, pads are replaced as an

axle set. Use only pads which are permitted by the

vehicle manufacturer, axle manufacturer and/or disc

brake manufacturer. Failure to comply with this may

invalidate the vehicle manufacturer’s warranty.

18

Page 19

Check that the tappet and boot assemblies have been fully

retracted, as outlined above. Clean the brake as needed

- see the vehicle manufacturer’s recommendations.

To install the outboard brake pad (12), slide the caliper

(1) fully to the outboard position before inserting the pad

(with the brake lining material facing the rotor). Similarly,

to install the inboard pad, move the caliper fully to the

inboard position, and then install the brake pad (with the

lining material facing the rotor). See Figure 30.

Install new in-pad wear indicator kit, if appropriate (see

Pages 20-21).

Using a box-end wrench or socket, turn the shear adapter

(61) clockwise until the pads come into contact with the

rotor. Then turn back the shear adapter counter-clockwise

two clicks to set the initial running clearance.

Note: Use only pads with the same backing plate thickness

as originally specified for the vehicle’s brakes.

Note: The Bendix air disc brakes covered by this service

manual use more than one pad retainer design. Be sure

to install the correct part number for the vehicle.

After installing the pad retainer (11) supplied with the kit,

into the groove of the caliper (1), it must be depressed to

enable the insertion of the pad retainer pin (44).

Install the supplied washer (45) and spring clip (26) to

the pad retainer pin (44). It is recommended that the pad

retainer pin (44) be installed pointing downwards (see

Figure 35).

Apply and release the brake and then check that the hub

turns easily by hand.

Lightly grease and install a new adjuster cap (37) using

white lithium-based grease. Note: The tab of the adjuster

cap should be positioned as shown by the arrow in

Figure 34 for ease of access.

Re-install the wheel according to the vehicle manufacturer’s

recommendations. Note: Not all wheels (and or valve

stems) are compatible with Bendix Air Disc Brakes.

Use only wheels and valve stems approved by the

vehicle manufacturer.

CAUTION: Bendix recommends that after every air

brake service, if available, the technician checks the

brake performa nce and the syste m behavior on a

dynamometer.

Outboard

Backplate

of Pad

FIGURE 33 - PAD

INSTALLATION

37 Cap

Tab

44

Pin

Inboard

23

61

12

Inboard

Pad

12

Brake Pad

Assembly

FIGURE 34 - TAB POSITION

11 Pad Retainer

45 Washer

37

26 Clip

FIGURE 35 - BRAKE PAD INSTALLATION

19

Page 20

ELECTRONIC WEAR INDICATOR

REPLACEMENT

(Normally-Closed or Normally-Open Type) See page 10.

New wear indicators are normally installed whenever brake

pads are replaced. Please see Brake Pad Installation on

Page 18 for cautions and procedures. The wear indicator

is installed after the new brake pads are installed into the

brake, but before the retainer hardware.

Remove and retain the pad holder springs.

See page 6 for typical contents of wear indicator kits.

Installation: The longer branch of the wear indicator cable

(see arrow) must be installed in the outboard pad. Insert

the Wear Indicator Cables (101) into the pre-cut slot in the

pads. The wear indicators snap into place.

1

101

Outboard Pad

Long

Cable

12/1

FIGURE 36 - WEAR INDICATOR CABLE

12/1

2

12/1

2. Insert wear indicator sensors into

the pads.

4

44

11

3

12/2

12/2

101

3. Install the pad holder springs (12/2)

onto the pads (12/1) with the wear

indicator cable (101) as shown.

5

105

20

45

26

101

4. Install the pad retainer (11), pad

retainer pin (44), washer (45) and

spring clip (26) with the wear indicator

cable (101) as shown.

5. Install the cable guide (105) onto

the pad retainer (11). The cable guide

(105) snaps into place when pressing

lightly onto the pad retainer (11).

Page 21

6

101

short cable end

7

101

105a

6. Press the wear indicator cable

(101) into the locating tabs of the

cable guide (105) (see arrows A). The

short cable end of the wear indicator

cable (101) must not be secured by

locating tabs of the cable guide (105).

According to vehicle type, install

the cable that leads to the electrical

supply of the vehicle, in one of the two

locating tabs (see arrows B).

8

7. Install the indicator cable (101) in

the middle of the pad retainer (11).

Insert the cable guide (105a) at one

side of the pad retainer (11) (see

arrow B). Slightly press in on the

other side of the pad retainer (11) (see

arrows A). The cable guide (105a)

snaps into place.

According to vehicle type, install the

cable that leads to the electric supply

of the vehicle, in one of the wire loop

(see arrows C). The short end of the

wear indicator cable (101) must not

be secured by a wire loop of the cable

guide (105a) (see arrows C).

8. Carefully install the cable protection

plate (104) with attention to the correct

position of the cable protection plate’s

catch (see arrows).

The cable protection plate (104) will

snap into place.

21

Page 22

TAPPET AND BOOT ASSEMBLIES

REPLACEMENT

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

When installing pads, where appropriate use heavy

duty gloves and always keep fingers away from

potential pinch hazard areas. Cage spring brakes

before beginning procedure.

Note: In some cases, the technician may find it easier to

remove the caliper from the vehicle before making the

replacement (see Page 25 for instructions on caliper/carrier

removal).

REMOVAL OF TAPPET AND BOOT

ASSEMBLIES (13)

Follow the procedure for removing brake pads (12) on

Page 18.

CAUTION: Never turn the adjuster (23) without the

shear adapter (61) installed. The shear adapter is a

safety feature and is designed to prevent an excess

of torque being applied to the adjuster. The shear

adapter will fail (by breaking loose) if too much torque

is applied.

CAUTION: NEVER EXTEND THE TAPPET MORE THAN

1.18 in. (30 mm). Over-extending the tappet will result

in the tappet losing engagement with the threads of the

synchronizing mechanism. Since the mechanism can

only be set at the manufacturing plant THE CALIPER/

CARRIER ASSEMBLY MUST BE REPLACED if this

happens.

Removal of the tappet and boot assembly (13) requires

the use of the wedge fork (A). See Figure 39. Extend the

tappets less than 1.18 in. (30 mm) by turning the shear

adapter (61) clockwise until there is sufficient access

to the boots to remove the tappet boot from the caliper

bore. A screwdriver (B) should be used to move the boot

location ring - see Figure 40 and allow the wedge fork (A)

to be inserted. CAUTION: Take care not to damage the

inner sealing face (see arrow “X” in Figure 40). Gouges

or grooves that would prevent a good seal necessitate

caliper replacement.

The tappet and boot assemblies (13) can then be removed

from the threaded tubes (16) by using the wedge fork

(A).

Remove the old tappet bushing(s) (161). Inspect the inner

sealing face (see arrow “X”) for damage. If damage is

found to the inner seal the caliper/carrier assembly must

be replaced.

Inboard

Outboard

23

61

Inboard Pad

12

12

FIGURE 37 - BRAKE PAD REMOVAL

B

13

13

Extend

Less Than

1.18 in.

(30 mm)

FIGURE 38 - TAPPET EXTENSION

Press-in Tool

arrangement for

Tappet and Boot

Assembly (13)

when Caliper

is fitted on the

vehicle.

Ring T24 for SK7

Brakes. Installation device for Tappet and

Boot Assembly (13) when Caliper is removed

™

and 225™ and 22X™ Air Disc

from axle.

Press-in Tool

arrangement for

Tappet and Boot

Assembly (13)

when Caliper is

removed from the

vehicle.

Press-in Tool (Z004190) for Tappet and

Boot Assembly (13) . . . . . . . . . . . . . . . T1, T2 T3, T4

Wedged Fork (II32202) for removal of

Tappet and Boot Assembly (13) . . . . . . . . . . T15

Ring (K004082) for Tappet and

Boot Assembly (13) . . . . . . . . . . . . . . . . . . . T24

FIGURE 39 - TAPPET REMOVAL TOOL

37

22

Page 23

13

A

2.76 in.

(70 mm)

22

X

FIGURE 40 - WEDGE TOOL USE

A

13

161

16

46

12

16

FIGURE 42 - USE OF A SPACER (OFF VEHICLE USE)

13

161

FIGURE 43 - ON VEHICLE BOOT INSTALLATION

B

E

1

FIGURE 41 - USE OF A NEW BRAKE PAD AS A SPACER

INSPECT THE THREADED TUBES (16)

For the inspection of the threads, the tubes must be

extended, but by less than 1.18 in. (30mm), by turning the

shear adapter (61) clockwise. If working with the caliper

on the vehicle, the technician may place a new brake pad

(12) into the outboard gap to help avoid the loss of thread

engagement of the threaded tubes. If the work is being

carried out at a workbench, the technician may insert a 2.76

in. (70 mm) spacer (E) into the caliper (1) to help avoid the

loss of thread engagement. See CAUTION on Page 22.

Check the threads for rust, corrosion, or damage etc.

If there is evidence of damage to the threads, rust or

corrosion, the caliper/carrier assembly must be replaced

(see Page 25).

If the threads are in good condition, fully wind back the

threaded tubes (16) by turning the shear adapter (61)

counter-clockwise.

INSTALLING THE TAPPET AND BOOT

ASSEMBLIES (13)

Grease threads with white grease (Part No. II14525 or

II32868).

L

16

X

FIGURE 44 - INNER SEAL INSTALLATION

Screw back the threaded tubes (16), by turning the shear

adapter (61) counter-clockwise (see Cautions earlier in

these instructions).

The sealing seat in the caliper for tappet and boot

assemblies (13) must be clean and free of grease. See

Figure 44.

Fit a new tappet bushing (161) onto the center post of each

threaded tube (16).

L

22

23

Page 24

B

13

FIGURE 45 - ON VEHICLE TAPPET INSTALLATION

Technicians working with the caliper installed on

vehicle:

• Install the boots using the press-in tool (B) with the short

press-in extension (T3) for positioning and pressing

into place - see Figure 43.

• Position a tappet assembly (13) onto each tappet

bushing. Using press-in tool (B) in a reversed

orientation with the press-in extension (T3) towards

the threaded tube, install each tappet onto its tappet

bushing - see Figure 45.

Technicians working with the caliper not installed on

vehicle:

• Install the boots using the press-in tool (B) with the

long press-in extension (T3 + T4) for positioning and

pressing into place - see Figure 43.

• Position a tappet (13) onto each tappet bushing. Using

press-in tool (B) in a reversed orientation with the pressin extension (T3 + T4) towards the threaded tube, install

each tappet onto its tappet bushing - see Figure 45.

After assembly, check that the tappet (13) is free to turn

in both directions.

Note: When installing the tappet for Bendix

®

ADB 22X™,

ADB 225™, and SK7™ disc brakes, use the supplemental

ring (T24), inserted into the tool (T2) - see Figure 48 - to

assist the installation, since the caliper’s back plate is too

thin using only Tool (B) to achieve the correct position.

B

13

FIGURE 46 - OFF VEHICLE BOOT INSTALLATION

13

B

FIGURE 47 - OFF VEHICLE TAPPET INSTALLATION

24

13

B

T24

FIGURE 48 - OFF VEHICLE - USE OF EXTRA TOOL FOR

SOME STYLES

Page 25

CALIPER/CARRIER ASSEMBLY

REPLACEMENT

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

With the caliper/carrier assembly securely supported,

remove and discard the six bolts attaching the carrier to

the axle.

CAUTION: Do not attempt to use the pad retainer (11)

to attach any lifting device to the brake. The pad retainer

is not suitable for this purpose, and damage to the brake

and/or unsafe conditions may result.

Clean and inspect the axle contact area. See axle or

vehicle manual for instructions if damage is found.

CALIPER/CARRIER ASSEMBLY

INSTALLATION

The correct choice of caliper/carrier must be ensured by

using the air disc brake part number on the identification

label when ordering replacement parts. See Page 6.

Replacement caliper/carrier assemblies may be delivered

with a plastic cap, adhesive tape, or a breakthrough

diaphragm in the area of the actuator attachment. Remove

the cap or tape only after installing the replacement

caliper on the vehicle. If the replacement caliper has the

breakthrough diaphragm, it should be left in place.

FIGURE 49 - CALIPER/CARRIER ASSEMBLY

REPLACEMENT

If the replacement caliper/carrier assembly is equipped with

a potentiometer for wear indication, then the connection

must be made using the appropriate mating plug – refer

to the vehicle manufacturer’s recommendations.

CAUTION: See the cautions in this document with regard

to possible pinch hazard, and the restriction against using

the pad retainer (11) as a place to secure lifting devices.

With the replacement carrier/caliper assembly held in

position, install with new bolts. Note: Replacement bolts

are not supplied by Bendix - use only those of a grade and

type specified by the vehicle manufacturer. Consult the

vehicle manual for required torques.

25

Page 26

BRAKE ACTUATOR AND SPRING BRAKE

REPLACEMENT

CAUTION: Replace actuator and spring brakes only

with the same as originally installed on the vehicle.

Replacement with alternate equipment (without written

authorization from Bendix and the vehicle manufacturer)

could compromise brake performance.

CAUTION: Follow all standard safety procedures

including, but not limited to, those on page 2 of this

service manual. See the vehicle manufacturer's

recommendations. When working on foundation

brakes, be sure that the vehicle is on level ground,

that the vehicle is parked by other means than the

foundation brakes, and that the wheels are chocked.

B

A

18/2

Brake

Chamber

B

or

18/1

Spring

Brake

Brake Chamber Removal

With all air pressure drained from the air brake system,

disconnect the air hose from the brake chamber (18/2).

Remove and discard brake chamber mounting nuts (see

Figure 50, arrows B).

Brake Chamber Installation

Note: New brake chambers (18/2) have drain plugs

installed (see Figure 50, arrows A). After installation,

remove whichever plug is at the lowest position. Be sure

that all other drain holes remain plugged. The drain hole

must be aligned downwards (or within ±30°) when installed

on the vehicle.

Before installing the new brake chamber, the actuator

flange (see Figure 51, arrow C) must be cleaned, and

inspected. Consult the vehicle manual. The spherical

cup in the lever (19) must be greased with white grease

(Part No. II14525 or II32868).

CAUTION: Do not use grease containing molybdenum

disulfate.

See Figure 52. The seal, as well as the pushrod area must

be clean and dry.

CAUTION: Do not use brake chambers with seals with a

thickness less than 0.12 in. (3 mm). Use only actuators

which are recommended by the vehicle manufacturer.

Install the brake chamber using new self-locking nuts (EN

ISO 10513). Tighten alternately both the nuts step by step

up to a final torque of 133 ± 7 ft. lbs (180 ± 10 Nm).

Re-connect the air hose and be sure that the hose is not

twisted or in contact with moving vehicle components. The

air hose routing must allow for full caliper travel. Test for

leakage and check the brake operation and effectiveness

before returning vehicle to service.

FIGURE 50 - ACTUATOR INSTALLATION

19

FIGURE 51 - ACTUATOR FLANGE

Seal

Pushrod area

FIGURE 52 - CAP INSTALLATION

C

0.12 in.

(3 mm)

26

Page 27

Spring Brake Removal

CAUTION: Follow all standard safety procedures - see note

above. Be familiar with the spring brake manufacturer’s

recommended safety practices.

With all air pressure drained from the air brake system,

disconnect the air hose from the brake chamber (18/1).

Back out the release bolt (Figure 53, arrow D) using a

maximum torque of 26 ft. lbs. (35 Nm) to release spring

force on the pushrod. Refer to the spring brake and vehicle

manufacturer’s recommendations - in some cases it may

be permissible to cage the spring brake while the spring

brake is engaged. While supporting the spring brake in

position, remove and discard brake chamber mounting nuts

(see Figure 53, arrows B). Remove the spring brake.

A

B

A

D

18/1

B

Spring Brake Chamber Installation

Note: New spring brake chambers (18/1) have drain plugs

installed (see Figure 53, arrows A). After installation,

remove whichever plug is at the lowest position. Be sure

that all other drain holes remain plugged. The drain hole

must be aligned downwards (or within ±30°) when installed

on the vehicle.

Before installing the new brake chamber, the actuator

flange (see Figure 51, arrow C) must be cleaned, and

inspected. Consult the vehicle manual. The spherical

cup in the lever (19) must be greased with white grease

(Part No. II14525 or II32868).

CAUTION: Do not use grease containing molybdenum

disulfate.

See Figure 54. The seal, as well as the pushrod area must

be clean and dry.

CAUTION: Do not use brake chambers with seals with a

thickness less than 0.12 in. (3 mm). Use only actuators

which are recommended by the vehicle manufacturer.

Install the brake chamber using new self-locking nuts (EN

ISO 10513). Tighten alternately both the nuts step by step

up to a final torque of 133 ± 7 ft. lbs (180 ± 10 Nm).

Re-connect the air hose and be sure that the hose is not

twisted or in contact with moving vehicle components. The

air hose routing must allow for full caliper travel. Test for

leakage and check the brake operation and effectiveness

before returning vehicle to service.

FIGURE 53 - SPRING BRAKE INSTALLATION

0.12 in.

(3 mm)

Pushrod

area

Seal

FIGURE 54 - CAP INSTALLATION

27

Page 28

28

BW7308 ©2005 Bendix Spicer Foundation Brake LLC • All rights reserved. • 12/05 • Printed in U.S.A.

Loading...

Loading...