Page 1

®

SD-08-2415

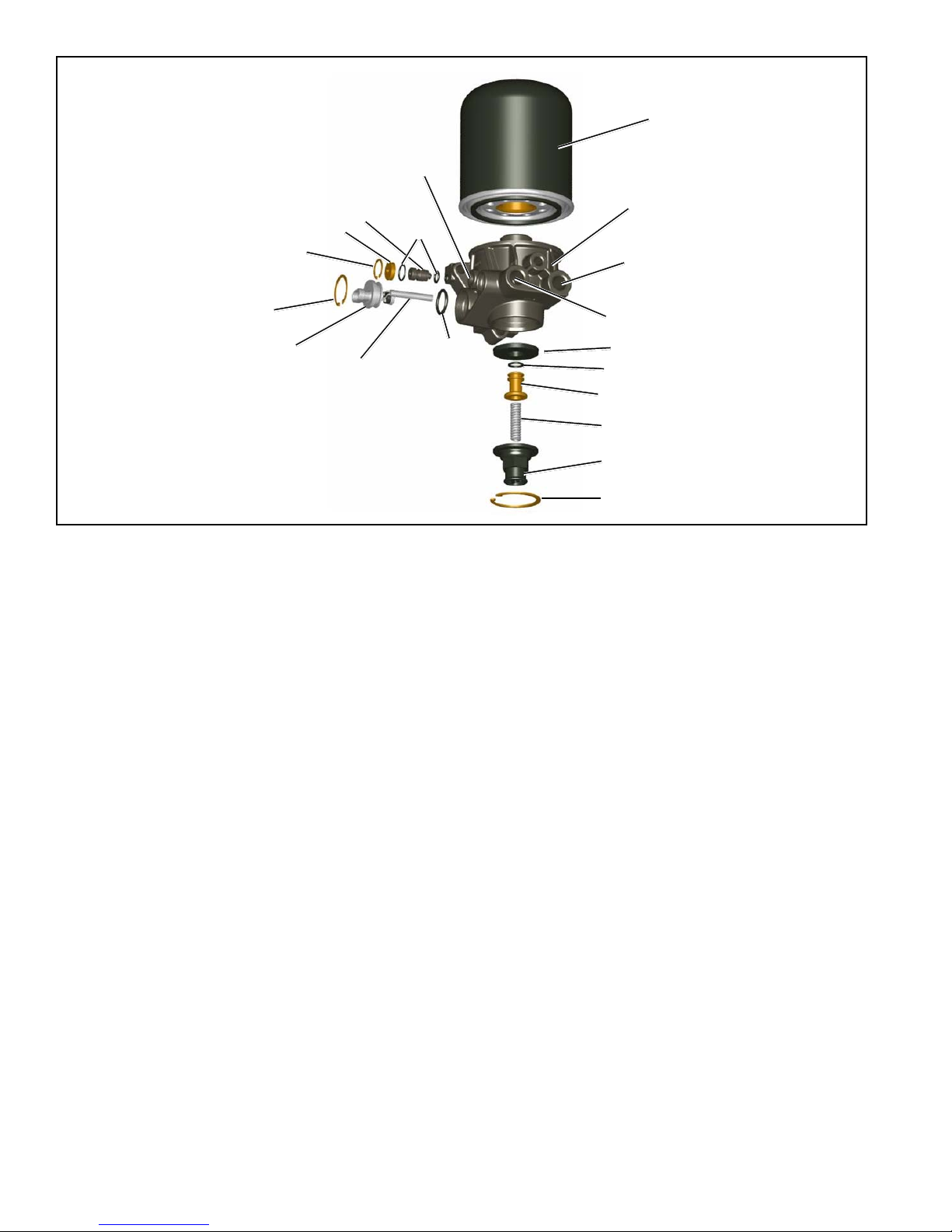

Bendix® AD-SP™ System Purge Air Dryer & SC-PR

Single Check Protection Valve

“SPIN OFF”

DESICCANT

CARTRIDGE

MOUNTING

HOLES (3)

CONTROL

PORT

HEATER &

THERMOSTAT

CONNECTOR

TURBO

CUTOFF VALVE

EXHAUST PORT

MOUNTING

HOLES (3)

SUPPLY

PORT

™

DELIVERY PORT

EXHAUST PORT

FIGURE 1 - AD-SP™ SYSTEM PURGE AIR DRYER

DESCRIPTION

The function of the AD-SP™ System Purge Air Dryer is to

collect and remove air system contaminants in solid, liquid

and vapor form before they enter the brake system. It provides

clean, dry air to the components of the brake system which

increases the life of the system and reduces maintenance

costs. Daily manual draining of the reservoirs is eliminated.

The system purge designation is used because the

AD-SP™ air dryer uses a small portion of system air pressure

from the supply and front axle service reservoirs to perform

the purge or regenerative function. An SC-PR™ single check

protection valve or a valve that performs the same function

is always used in conjunction with the AD-SP™ air dryer to

protect the service system.

The AD-SP™ air dryer consists of two major component

groups, a spin off desiccant cartridge assembly and a die

cast aluminum body assembly. The desiccant cartridge is

self contained and serviced as a complete assembly . The

AD-SP™ air dryer aluminum body contains the following

serviceable components or assemblies; the turbocharger

cut-off valve, heater and thermostat assembly , delivery check

valve assembly and combined purge and relief valve

assembly. In addition, the non-serviceable purge control

valve is located in the body. All service and replacement

can be accomplished from the exterior of the dryer without

removal from the vehicle. The spin-on desiccant cartridge

is removed and installed using a “strap wrench.”

The AD-SP™ air dryer has three female pipe thread air

connections identified as follows:

Air Connection Port ID Function/Connection

CON 4...................... Control Port (purge valve control

& turbo cut-off).

SUP 11 .................... Supply Port (air in).

DEL 2 ...................... Delivery Port (air out).

1

Page 2

COMPRESSOR

GOVERNOR

AD-SP

AIR

DRYER

™

REAR AXLE

™

SC-PR

SUPPLY

VALVE

FRONT AXLE

DELIVERY PORT

(TO FRONT SERVICE

RESERVOIR)

EMBOSSED PORT

IDENTIFICATION “2 DEL”

FIGURE 2 - AD-SP™ AIR DRYER SYSTEM DRAWING WITH EXTERIOR AND TOP VIEW OF SC-PR™ VALVE.

OPERATION

SUPPLY PORT

(FROM SUPPLY

RESERVOIR)

EMBOSSED PORT

IDENTIFICATION

“1 SUP”

After exiting the end cover , the air flows into the desiccant

cartridge where an oil separator, located between the outer

GENERAL

The AD-SP™ air dryer alternates between two operational

modes or “cycles” during operation: the Charge Cycle and

the Purge Cycle. The following description of operation is

separated into these “cycles” of operation.

and inner shells of the cartridge, removes water in liquid

form as well as liquid oil and solid contaminants.

After exiting the oil separator , air enters the space between

the desiccant drying bed and the outer cartridge shell and

flows down through the column of desiccant. Flowing through

the desiccant column, air becomes progressively dryer as

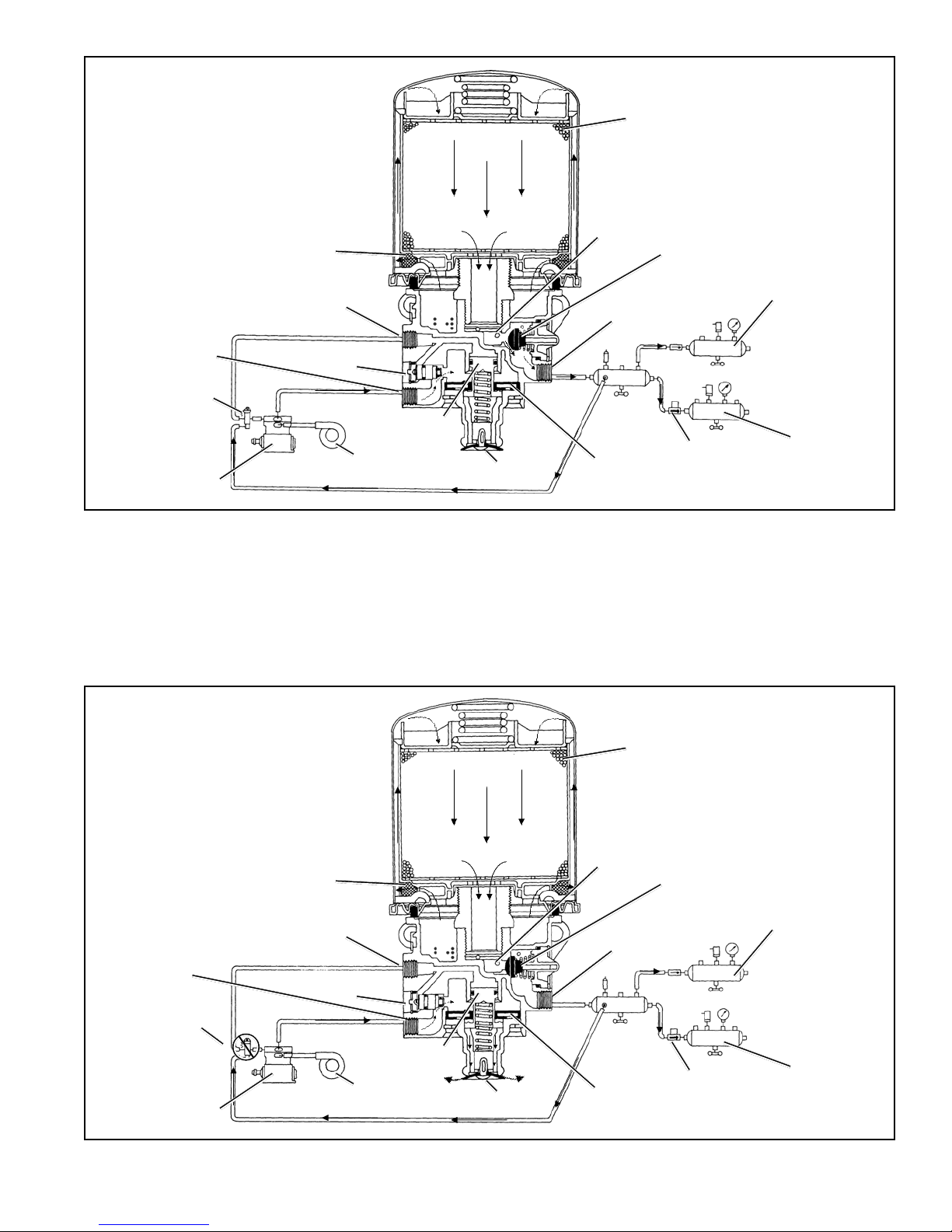

CHARGE CYCLE (refer to Figure 3)

When the compressor is loaded (compressing air)

compressed air, along with oil, oil vapor, water and water

vapor flows through the compressor discharge line to the

supply port of the air dryer body.

Air entering the supply port immediately encounters the

“turbo cut-off” valve. With no air pressure in the control port,

the turbo cut-off piston moves the valve away from its seat

in the body allowing the supply air to enter the body . As air

travels through the end cover assembly , its direction of flow

changes several times, reducing the temperature, causing

contaminants to condense and drop to the bottom or sump

of the air dryer body.

water vapor adheres to the desiccant material in a process

known as “ADSORPTION.” Using the adsorption process,

the desiccant cartridge typically removes 95% of the water

vapor from the pressurized air.

Dry air exits the bottom of the desiccant cartridge through

its center opening and returns to the air dryer body

assembly. As air flows through the supply cavity it is also

conducted, via internal passages, to the non-serviceable

purge control mechanism contained in the body . The purge

control mechanism (not shown) is able to monitor supply

air pressure. The air then flows through the delivery check

valve assembly and out the delivery port to the first (supply)

reservoir of the air system. As air moves p ast the delivery

check valve, on its way to the delivery port, it is also

conducted to the purge control mechanism. The purge

control mechanism is able to monitor air brake system

pressure as well as supply air pressure.

2

Page 3

SUPPLY

PORT

GOVERNOR

COMPRESSOR

FIGURE 3 - AD-SP

OIL

SEPARATOR

CONTROL

PORT

TURBO

CUTOFF

ENGINE

TURBO

™

AIR DRYER CHARGE CYCLE

PURGE

PISTON

EXHAUST

PORT

DESICCANT

PURGE

ORIFICE

DELIVERY

PORT

PURGE /

RELIEF

VALVE

DELIVERY

CHECK

SC-PR

VALVE

REAR

RESERVOIR

™

FRONT

RESERVOIR

The air dryer will remain in the charge cycle until the air

brake system pressure builds to the governor cutout setting.

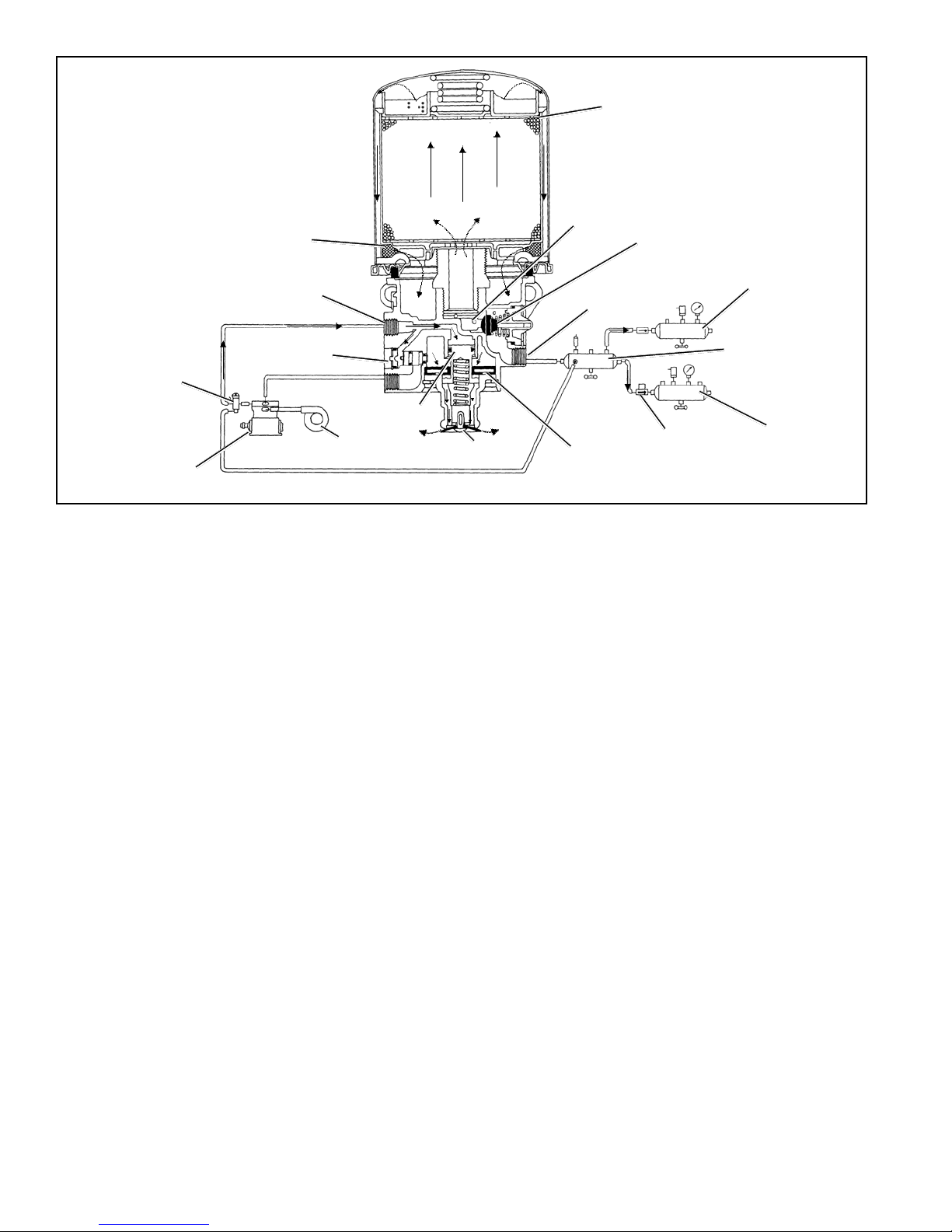

To protect against over pressurization of the AD-SP™ air

dryer, the purge valve incorporates an integral relief valve

feature. In the event that the compressor unloader

OIL

SEPARATOR

CONTROL

PORT

SUPPLY

PORT

MALFUNCTIONING

GOVERNOR

COMPRESSOR

TURBO

CUTOFF

PURGE

PISTON

ENGINE

TURBO

mechanism or governor malfunctions, at approximately 200

psi supply air pressure the AD-SP™ air dryer purge valve

will open (without control pressure), and vent excess air

pressure to atmosphere (refer to Figure 4).

DESICCANT

PURGE

EXHAUST

PORT

ORIFICE

DELIVERY

PURGE /

RELIEF

VALVE

PORT

DELIVERY

CHECK

SC-PR

VALVE

REAR

RESERVOIR

™

FRONT

RESERVOIR

FIGURE 4 - AD-SP™ AIR DRYER RELIEF VALVE OPERATION

3

Page 4

OIL

SEPARATOR

CONTROL

PORT

DESICCANT

PURGE

ORIFICE

DELIVERY

PORT

DELIVERY

CHECK

REAR

RESERVOIR

TURBO

CUTOFF

GOVERNOR

PURGE

PISTON

ENGINE

TURBO

COMPRESSOR

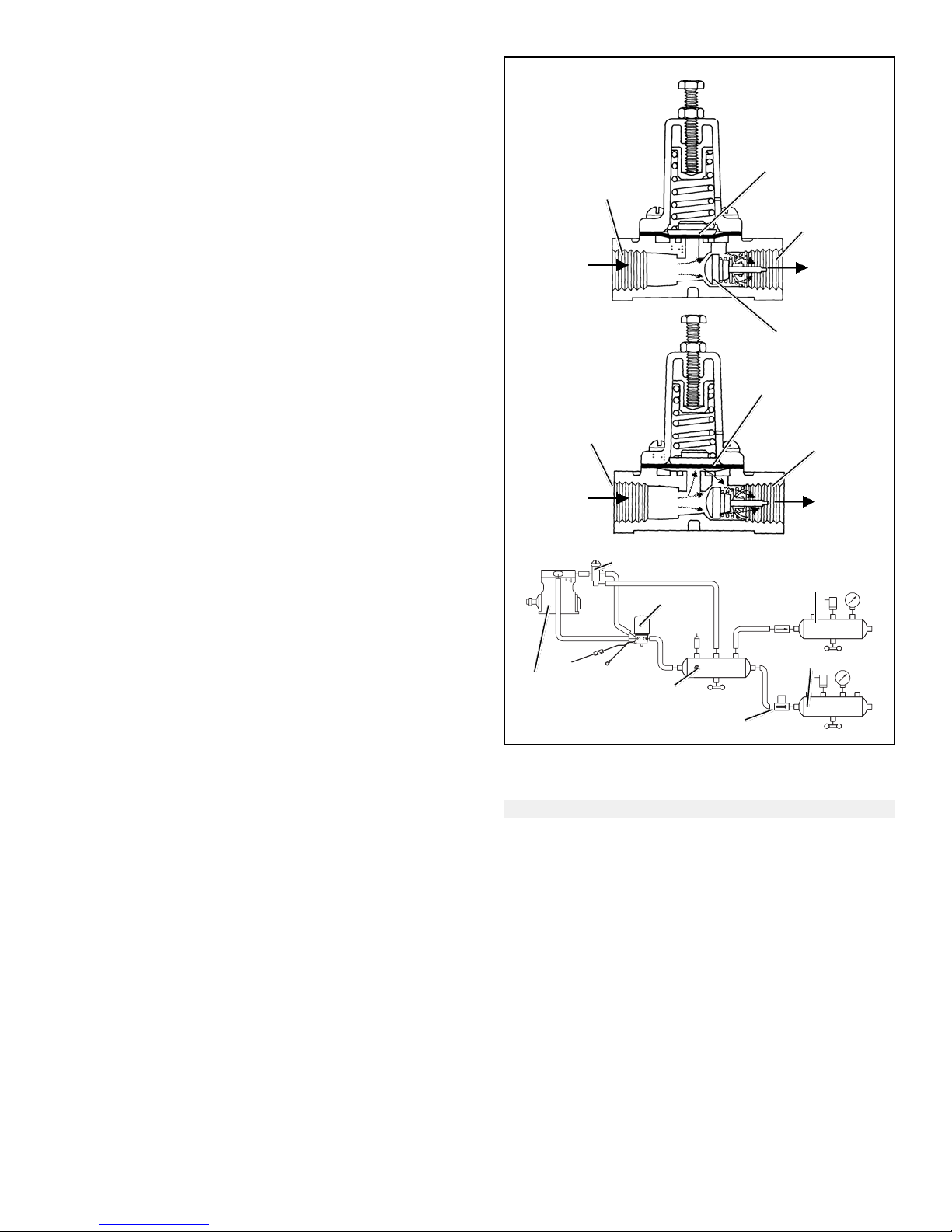

FIGURE 5 - AD-SP™ AIR DRYER PURGE CYCLE

PURGE CYCLE (refer to Figure 5)

When air brake system pressure reaches the cutout setting

of the governor, typically 120 p si, the compressor unloads

(air compression is stopped) and the purge cycle of the air

dryer begins. When the governor unloads the compressor,

it pressurizes the compressor unloader mechanism and

the line connecting the governor unloader port to the control

port of the AD-SP™ air dryer body. Air entering the control

port is simultaneously directed to the turbo cut-off valve

and the purge valve control piston.

The initial purge cycle consists of two simultaneous

occurrences; the closing of the turbo cut-off valve and the

opening of the purge valve. Each is discussed below under

a separate subheading.

TURBO CUT-OFF VALVE (refer to Figure 5)

The primary function of the turbo cut-off valve is to prevent

loss of engine turbocharger air pressure through the

AD-SP™ air dryer in systems where the compressor intake

is connected to the engine turbocharger. The turbo cut-of f

valve also eliminates the “puffing” of air out the open air

dryer exhaust when a naturally aspirated, single cylinder

compressor is equipped with an inlet check valve.

Governor unloader pressure causes the turbo cut-off valve

piston to move and close. With the turbo cut-off valve piston

seated (closed position), air in the discharge line and

AD-SP™ air dryer inlet port is prevented from entering the

air dryer.

SUPPLY

RESERVOIR

FRONT

RESERVOIR

EXHAUST

PORT

PURGE /

RELIEF

VALVE

SC-PR

VALVE

™

PURGE PISTON

The AD-SP™ air dryer purge piston also moves in response

to governor unloader pressure, causing the purge valve to

open to atmosphere. Contaminants in the body sump are

instantly expelled when the purge valve opens. Air which

was flowing through the desiccant cartridge immediately

changes direction and begins to flow back toward the open

purge valve. Oil and solid contaminants collected by the oil

separator are removed by air flowing from the desiccant

drying bed to the open purge valve.

DESICCANT RE-ACTIVATION (DRYING THE

DESICCANT)

The initial decompression of the air dryer assembly lasts

only a few seconds and is evidenced by an audible burst of

air at the AD-SP™ air dryer exhaust. The initial

decompression of the air dryer assembly is “sensed” by

the purge control mechanism and is used by the purge

mechanism as a signal that desiccant re-activation should

begin. The purge control mechanism “remembers” the

highest pressure attained in the air system, the cutout

pressure of the governor.

The actual re-activation of the desiccant drying bed begins

as the purge mechanism allows dry air to flow from the

delivery port (air brake system) back into the AD-SP™ air

dryer body and through the desiccant cartridge. The delivery

check valve assembly prevents air pressure in the brake

system from returning to the air dryer and flowing out the

open purge valve. The delivery check valve forces system

4

Page 5

air to flow through the purge mechanism. Dry air for the

brake system enters the purge control mechanism through

an air channel located in the delivery port, before the delivery

single check valve. It flows through the mechanism and

exits a purge orifice; its pressure is lowered and its volume

increased. The flow of dry air through the drying bed

reactivates the desiccant material by removing the water

vapor adhering to it.

Dry, brake system air will continue to flow through the

desiccant bed until the purge mechanism senses that the

brake system pressure has dropped between 8 - 14 psi

below what it “remembered” as being high (governor cut

out). For example: If governor cutout pressure was 120 psi

the purge mechanism will use air from the supply and front

axle reservoirs until it detects that pressure has dropped to

between 1 12 - 106 psi. System pressure will be reduced in

the supply and secondary (front axle) reservoirs only . The

primary or rear axle service reservoir will retain governor

cutout pressure (in the example, 120 psi). The purge cycle

and re-activation of the desiccant drying bed along with the

resulting pressure reduction takes place in approximately

15 - 20 seconds.

CHARGING

BELOW 100 PSI

SUPPLY

PORT

CHARGING

ABOVE 100 PSI

SUPPLY

PORT

DIAPHRAGM

DELIVERY

PORT

SINGLE

CHECK

VALVE

DIAPHRAGM

DELIVERY

PORT

Once the purge cycle is complete, the purge control

mechanism closes and no further reduction of system

pressure should occur. The air dryer is ready for the next

charge cycle to begin.

The purge valve will remain open and the turbo cut-off valve

closed after the purge cycle is complete and neither will

change position until air brake system pressure is reduced

to governor cut-in pressure and the Charge Cycle begins.

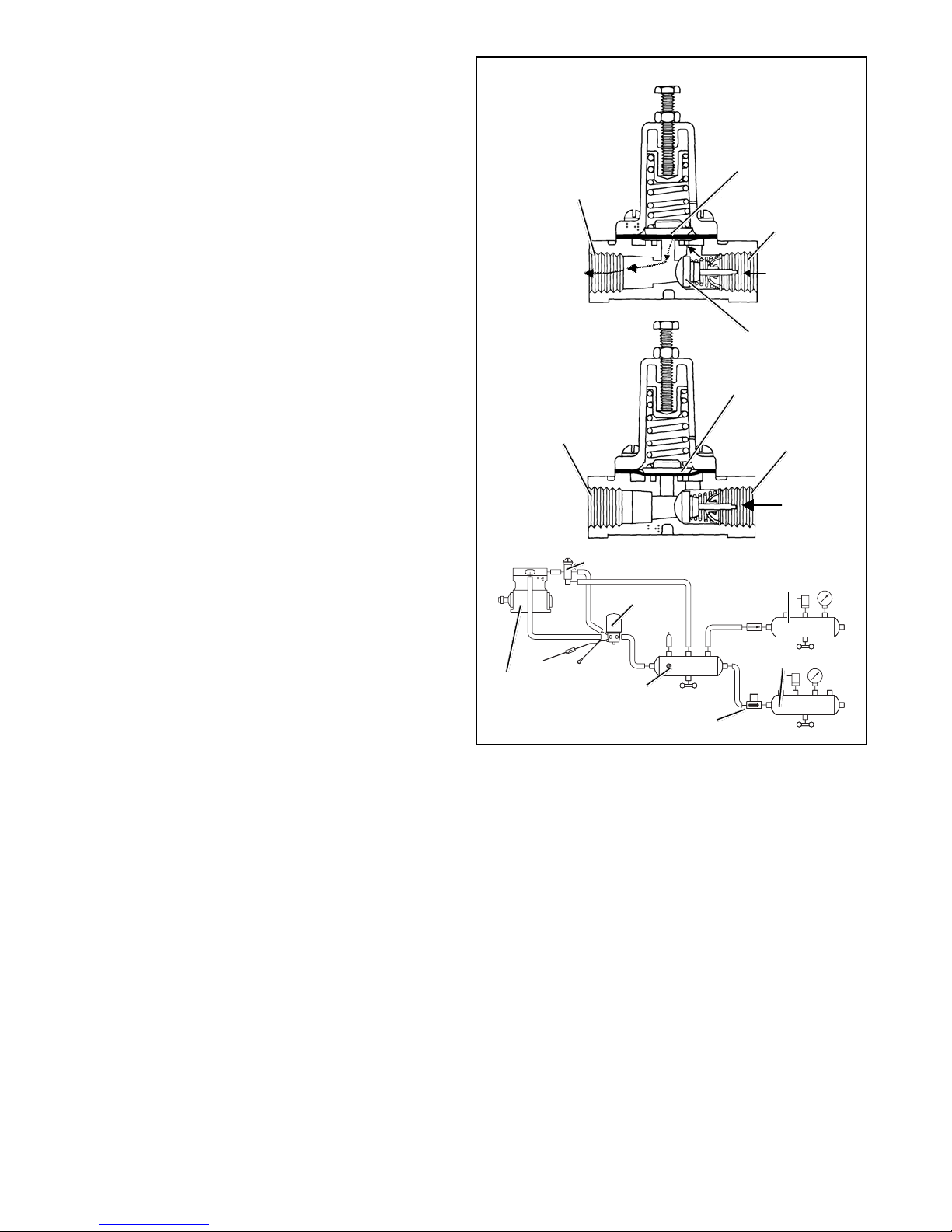

SC-PR™ VALVE DESCRIPTION

The SC-PR™ single check protection valve, combines a

single check valve and a pressure protection valve in a single

assembly . Its primary use is in conjunction with the Bendix

AD-SP™ air dryer and is installed in the front axle

(secondary) service reservoir in place of a standard single

check valve.

The SC-PR™ valve allows the AD-SP™ air dryer to draw air

pressure from the front axle service reservoir during the purge

cycle. It also protects the air pressure in the front axle

service reservoir, in the event of a compressor, supply, or

rear axle reservoir failure, or malfunction of the AD-SP™ air

dryer purge control mechanism.

The SC-PR™ valve is intended for direct mounting to the

service reservoir. Both SC-PR™ valve air connections are

1/2 inch pipe thread and each is identified with cast,

embossed letters for ease of identification and installation.

The letter identifications and connections to the air system

are shown below for reference.

GOVERNOR

™

AD-SP

AIR

DRYER

COMPRESSOR

FIGURE 6 - SC-PR™ VALVE CHARGE POSITION*

®

SUPPLY

RESERVOIR

SC-PR™ VALVE

REAR AXLE

RESERVOIR

FRONT AXLE RES.

Air Connection Identification System Connection

Supply .................... 1 SUP ....................... Connected to Supply (wet)

Reservoir

Delivery................. 2 DEL ......................... Nipple Mounted to Front

Axle Service Reservoir

SC-PR™ VALVE OPERATION

CHARGING

During initial air system build up, air flows from the supply

reservoir to the supply port of the SC-PR™ valve. Air entering

the SC-PR™ valve supply port is present beneath the

pressure protection diaphragm and simultaneously flows

through the single check valve portion into the front axle

service reservoir. With supply air pressure less than 100

psi, the pressure protection diaphragm, which functions as

a valve, remains seated on its inlet due to spring force above.

*Cutaway views are functionally correct, but do not represent current form of SC-PR™ valve.

5

Page 6

When supply pressure reaches 100 psi, the diaphragm moves

away from its seat and air entering the supply port flows through

the pressure protection valve portion, as well as the single

check valve portion, and into the front axle service reservoir.

NORMAL PURGE

The pressure protection valve remains open as long as

supply pressure remains above 95 psi.

PURGING

When the AD-SP™ air dryer begins its purge cycle, air from

the supply and front axle service reservoirs flows back to

the air dryer to re-activate the desiccant. Air flowing from

the front axle service reservoir to the supply reservoir must

pass through the SC-PR

because the single check valve portion is closed to flow in

that direction.

Since an AD-SP™ air dryer purge cycle begins at governor

cutout (120 psi minimum) and only reduces reservoir air

pressure 8 - 14 psi, the SC-PR™ pressure protection valve

will normally remain open. If a malfunction occurs that

causes the supply reservoir to lose pressure, air from the

front axle service reservoir will flow back to the supply

reservoir until the pressure beneath the SC-PR™ pressure

protection valve diaphragm falls to approximately 95 psi.

With 95 psi or less beneath the diaphragm, spring force

moves the diaphragm into contact with the inlet seat and

air flow to the supply reservoir ceases. The supply reservoir

will continue to lose pressure, however 95 psi will be retained

in the front axle service reservoir for braking.

™

pressure protection valve portion

SUPPLY

PORT

PROTECTION

FUNCTION

SUPPLY

PORT

GOVERNOR

AD-SP

DRYER

AIR

DIAPHRAGM

DELIVERY

PORT

SINGLE

CHECK

VALVE

DIAPHRAGM

DELIVERY

PORT

REAR AXLE

™

RESERVOIR

Any malfunction occurring between the compressor and

SC-PR™ valve that causes pressure to drop below 95 psi

will result in the SC-PR™ pressure protection valve closing

and protecting the front axle service reservoir.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

Because no two vehicles operate under identical conditions,

maintenance and maintenance intervals will vary.

Experience is a valuable guide in determining the best

maintenance interval for any one particular operation.

Every 900 operating hours, or 25,000 miles or three (3)

months:

1. Check for moisture in the air brake system by opening

reservoirs, drain cocks, or drain valves and checking for

presence of water. If moisture is present, the desiccant

cartridge may require replacement; however, the following

conditions can also cause water accumulation and

should be considered before replacing the desiccant:

FRONT AXLE RES.

COMPRESSOR

FIGURE 7 - SC-PR™ SINGLE CHECK PROTECTION VALVE

PURGE POSITION*

SUPPLY

RESERVOIR

SC-PR™ VALVE

A. An outside air source has been used to charge the

system. This air does not pass through the drying

bed.

B. Air usage is exceptionally high and not normal for a

highway vehicle.

This may be due to accessory air demands or some

unusual air requirement that does not allow the compressor to load and unload (compressing and

non-compressing cycle) in a normal fashion. Check

for high air system leakage. If the vehicle vocation

has changed it may be necessary to upgrade the

compressor size. Refer to Appendix A, Table A and

the column entitled Vehicle V ocation.

C. The air dryer has been installed in a system that

has been previously used without an air dryer. The

system will be saturated with moisture and several

weeks of operation may be required to dry it out.

6

*Cutaway views are functionally correct, but do not represent current form of SC-PR™ valve.

Page 7

D. A single check valve, or a device with a check valve

feature, may have been installed to the inlet port of

the supply tank or in the delivery line between the

air dryer and the supply tank. This will prevent regeneration of the air dryer desiccant cartridge and

lead to moisture accumulation in the air reservoirs.

E. Location of the air dryer is too close to the air com-

pressor. Refer to Locating AD-SP™ Air Dryer On

Vehicle section and Appendix A, Table A, column 2

for discharge line length.

F. In areas where more than a 30 degree range of tem-

perature occurs in one day , small amounts of water

can temporarily accumulate in the air brake system

due to condensation. Under these conditions, the

presence of small amounts of moisture is normal

and should not be considered as an indication that

the dryer is not preforming properly .

Note: A small amount of oil in the system is normal and

should not be considered as a reason to replace the

desiccant cartridge; oil-stained desiccant can function

adequately.

2. Visually check for physical damage to the AD-SP™ air

dryer such as dented desiccant cartridge, chaffed or

broken air and electrical lines and broken or missing

parts. Check the SC-PR™ valve also.

3. Check mounting bolts for tightness. Re-torque to 50 ft.

pounds.

4. Perform the Operation & Leakage Tests listed in this

publication.

Every 3600 operating hours, or 100,000 miles or twelve

(12) months:

1. T est the AD-SP™ air dryer turbo cut-off and purge valves

for leakage. Disconnect the supply , control and delivery

lines from the AD-SP™ air dryer. Perform the test s below

in the order they are presented.

A. Apply 120 psi shop air pressure to the control port

and a soap solution to the supply port. If leakage

exceeds a 1” bubble in 5 seconds, repair the turbo

cut-off piston and valve before proceeding to step 2.

B. With 120 psi shop air pressure applied to the con-

trol port, apply a soap solution to the purge exhaust

port. If leakage exceeds a 1” bubble in 5 seconds,

repair the purge piston and valve before proceeding

to step 2.

C. With 120 psi shop air pressure applied to the con-

trol and supply port, apply a soap solution to the

purge exhaust port. If leakage exceeds a 1” bubble

in 5 seconds, repair the turbo cut-off piston and valve

before proceeding to step 2.

D. With a plug installed in the delivery port, 0 psi in the

control port, and 120 psi applied to the supply port,

apply a soap solution to the purge exhaust port. If

leakage exceeds a 1” bubble in 5 seconds, repair

the purge piston and valve before proceeding to

step 2.

2. Perform the Operation & Leakage Tests shown in this

publication.

Every 10,800 hours; or 350,000 miles or 36 months:

1. Replace the air dryer desiccant cartridge.

Note: The desiccant change interval may vary from vehicle

to vehicle. Although typical desiccant cartridge life is three

years, many will perform adequately for a longer period of

time. In order to take maximum advantage of desiccant life

and assure that replacement occurs only when necessary ,

it is important that Operation & Leakage T ests be performed.

2. Perform the Operation & Leakage Tests shown in this

publication.

WARNING!

This air dryer is intended to remove moisture and other

contaminants normally found in the air brake system.

Do not inject alcohol, anti-freeze, or other de-icing

substances into or upstream of the air dryer. Alcohol

is removed by the dryer, but reduces the effectiveness

of the device to dry air. Use of other substances can

damage the air dryer and may void the warranty.

OPERATION & LEAKAGE TESTS (ALSO SEE

VIDEO BW2327)

1. Check for excessive leakage around the purge valve.

With the compressor in loaded mode (compressing air),

apply a soap solution to the purge valve exhaust port

and observe that leakage does not exceed a 1” bubble

in 5 second. If the leakage exceeds the maximum

specified, service the purge valve assembly .

2. Check for leakage around the desiccant cartridge. With

the compressor in loaded mode (compressing air), apply

a soap solution around the desiccant cartridge seal and

observe that no leakage occurs. If leakage is noted,

tighten the cartridge using a strap wrench and re-test for

leakage.

3. While observing the dash gauge(s), build up system

pressure at approximately 1,800 engine/compressor rpm

to governor cut-out. Note the pressure on the dash

gauge(s) at the moment governor cutout occurs and that

the AD-SP™ air dryer purges with an audible escape of

air. Observe the dash gauge(s) pressure for two minutes

after the purge cycle begins. The front axle service

(secondary) reservoir pressure should not drop more than

8-14 psi below the governor cutout pressure noted and

the rear axle (primary) reservoir pressure should not drop

more than 2 psi. Perform this test 3 times to positively

confirm the values.

7

Page 8

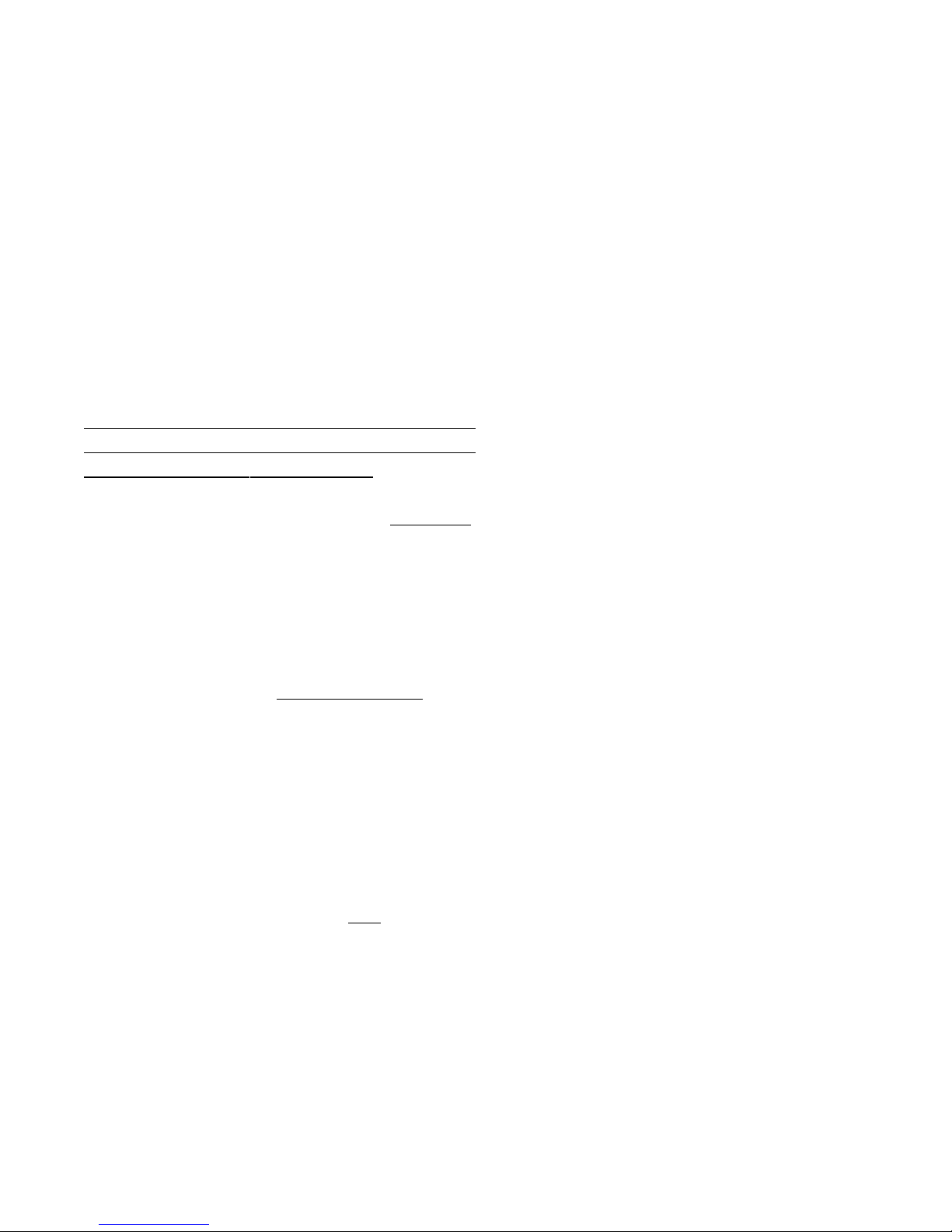

RETAINING RING

CONTROL PORT

PISTON

CAP

O-RINGS

DESICCANT

CARTRIDGE

™

AIR

AD-SP

DRYER BODY

DELIVERY PORT

RETAINING RING

CONNECTOR

HEATER & THERMOSTAT

ASSEMBLY

FIGURE 8 - AD-SP™ SYSTEM PURGE AIR DRYER EXPLODED VIEW

A. If the pressure drop in the front axle reservoir ex-

O-RING

5. Check the operation of the heater and thermostat

ceeds 8-14 psi, check the air brake system for

excessive leakage and repair and re-test. If the excessive pressure drop persists, replace the AD-SP

™

air dryer.

B. If the pressure drop in the rear axle reservoir

exceeds 2 psi, check the air brake system for

excessive leakage and repair.

Build up system pressure to governor cut-out, wait 30

seconds for completion of the purge cycle, then "Fan"

the service brakes to reduce system air pressure to

governor cut-in. Note that the system once again builds

to full pressure and is followed by an AD-SP™ air dryer

purge.

4. Check the operation of the SC-PR™ single check

protection valve. Build system pressure to governor

cutout, wait 30 seconds for completion of the purge cycle,

then drain all air pressure from the supply reservoir while

observing the front axle reservoir dash gauge. Reservoir

pressure should decrease to approximately 95 psi and

stop. If front axle reservoir pressure continues to drop

replace the SC-PR™ valve. Do not attempt to adjust

the SC-PR™ valve. This valve is factory preset and mixadjustment can result in insufficient air pressure in the

front axle reservoir in the event of a line or component

failure. The rear axle reservoir pressure should remain

constant.

Note: If this test is performed in warm weather (above 30

deg. F) it may be necessary to remove the heater and

thermostat assembly and cool it in a freezer.

Using an ohmmeter, check the resistance between the

electrical pins in the connector. The resist ance should be

1.5 to 1.7 ohms for the 12 volt heater assembly and 6.0 to

6.9 ohms for the 24 volt heater assembly . If the resistance

is higher than the maximum stated, replace the heater and

thermostat assembly .

Warm the heater and thermostat assembly to over 90

degrees Fahrenheit and again check the resistance. The

resistance should exceed 1000 ohms. If the resistance

values obtained are within the stated limits, the thermostat

and heater assembly is operating properly . If the resistance

8

values obtained are outside the stated limits, replace the

heater and thermostat assembly .

SUPPLY PORT

PURGE VALVE

O-RING

PURGE PISTON

SPRING

EXHAUST COVER

RETAINING RING

assembly in the body during cold weather operation (if

possible) as follows:

A. Electric Power to the Heater and Thermostat

With the ignition or engine kill switch in the ON

position, check for voltage to the heater and

thermostat assembly using a voltmeter or test light.

Unplug the electrical connector at the air dryer and

place the test leads on each of the pins of the male

connector. If there is no voltage, look for a blown

fuse. broken wires, or corrosion in the vehicle wiring

harness. Check to see if a good ground path exists.

B. Thermostat and Heater Operation

Turn off the ignition switch and cool the body

assembly to below 40 degrees Fahrenheit.

Page 9

REPAIRING THE AD-SP™ AIR DRYER GENERAL

If, after completing the routine operation and leakage tests,

it has been determined that one or more components of the

air dryer requires replacement or maintenance, refer to the

following list to find the appropriate kit(s). When repairing

or replacing components of the air dryer use only genuine

Bendix parts.

MAINTENANCE KITS A V AILABLE:

109495 ... 12 VOLT REPLACEMENT HEA TER AND THERMOSTAT

ASSEMBL Y KIT

109496 ... 24 VOLT REPLACEMENT HEA TER AND THERMOSTAT

ASSEMBL Y KIT

109993 ... TURBO CUT-OFF MAINTENANCE KIT

5008414 . DESICCANT CARTRIDGE REPLACEMENT

109995 ... PURGE & RELIEF VAL VE MAINTENANCE KIT

™

65677... The SC-PR

single check protection valve is

non-serviceable. Replace as an assembly .

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

®

8. Use only genuine Bendix

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a

drive axle are lifted off the ground and moving.

AD-SP™ AIR DRYER REMOVAL

1. Park the vehicle on a level surface and prevent movement

by means other than the brakes.

2. Drain ALL reservoirs to 0 p.s.i. (0 kPa). - Caution:

Compressor discharge line may still contain

residual pressure.

3. Identify, mark and disconnect the supply, delivery and

control port air lines. Disconnect the wiring harness

connector from the heater and thermostat assembly

connector on the body assembly .

4. If so equipped, disconnect, remove and save the exhaust

line from the exhaust port of the air dryer.

5. Remove the three mounting bolts that secure the air

dryer to the vehicle and remove the air dryer.

Note: It is important to retain the three mounting bolts

since their length is specific to mounting the air dryer

without damage. If these bolts must be replaced, the

same length must be used.

6. Remove the AD-SP™ air dryer from its mounting brackets

on the vehicle.

DISASSEMBLY FOR PART REPLACEMENT

AND KIT INSTALLATION

1. The following disassembly and assembly procedures are

™

presented for reference purposes and assumes that the

appropriate AD-SP™ air dryer kits are on hand. The

instructions provided with these parts and kits should

be followed instead of the instructions presented here.

2. The replacement parts and maintenance kits that are

available do not require full disassembly and in most

cases do not require the removal of the AD-SP™ air dryer

from the vehicle.

3. If removal of the air dryer is necessary adhere to the

following caution:

9

Page 10

Caution: While performing service on the AD-SP™ air dryer, it

is not recommended that a clamping device (vise,

C-clamp, etc.) be used to hold any die cast aluminum

component as damage may result. T o hold the body , install a

pipe nipple in the supply port and clamp the nipple into a vise.

DISASSEMBLY - TURBO CUT-OFF VALVE

1. Loosen the supply port line and allow any residual air in

the discharge line to drain.

2. Remove the retaining ring from the body assembly , then

remove the turbo cut-off cap from the body . Remove the

turbo cut-off cap o-ring.

3. Remove the turbo cut-off piston from the body .

4. Remove the large and small diameter o-rings from the

piston.

DISASSEMBLY - PURGE/RELIEF VALVE

1. If so equipped, disconnect, remove and save the exhaust

line from the exhaust port of the air dryer.

2. Remove the retaining ring from the body assembly , then

remove the non-metallic exhaust cover and spring from

the body. Note: The spring exerts a 30 pound force

against the exhaust cover.

3. Carefully remove the purge piston from the body and

remove the o-ring from the purge piston.

4. The purge valve has two different sides. Note which side

is visible before removing the valve. Remove the valve

from the body .

DISASSEMBLY - HEATER AND THERMOSTAT

1. Disconnect the vehicle wiring harness connector that

mates with the heater and thermostat connector on the

body . Pry the lock tabs out, on the vehicle wiring harness

connector, before removal from the air dryer connector .

Make sure connector seal is present on the vehicle wiring

harness connector.

2. Remove the retaining ring that secures the heater and

thermostat in the body .

3. Carefully pull the heater and thermostat assembly straight

out of the body .

4. Remove the o-ring from the heater connector.

DISASSEMBLY - DESICCANT CARTRIDGE

1. Place a strap wrench or equivalent tool on the desiccant

cartridge next to the lip low on the cartridge and rotate

counter clockwise to remove the desiccant cartridge.

CLEANING, INSPECTION AND ASSEMBLY

PREPARATION

1. Clean the exterior of the body.

2. Using a clean rag, wipe the body bores clean.

3. Inspect for physical damage to the body casting, broken

and or missing parts.

4. Inspect the interior and exterior of the body for severe

corrosion, pitting and cracks. Superficial corrosion and

or pitting on the exterior portion is acceptable.

5. Inspect the bores, valve seating and o-ring contact areas

for deep scuffing or gouges or nicks that would not permit

an air tight seal.

6. Inspect the pipe threads in the body. Make certain they

are clean and free of thread sealant.

7. Inspect the purge valve piston seat for nicks and

excessive wear.

8. Inspect all air line fittings for corrosion. Clean all old

thread sealant from the pipe threads.

9. All o-rings removed should be discarded and replaced

with new o-rings provided in appropriate kit(s).

10. Lubricate the body bores and o-ring grooves, in the body

and components, with a silicone grease only such as

those packaged with Bendix maintenance kits.

1 1. Lubricate all o-rings with a silicone grease only, such as

those packaged with Bendix maintenance kits.

Any component exhibiting a condition described in step 3

to 8 should be replaced.

ASSEMBLY - TURBO CUT-OFF VALVE

1. Lubricate all o-rings with a silicone grease only , such as

those packaged with Bendix maintenance kits.

2. Install the large and small diameter o-rings on the piston.

3. Install the turbo cut-off piston assembly in the body.

4. Install the o-ring on the turbo cut-off cap then install the

cap in the body .

5. Install the retaining ring in the body , making certain that

it is fully seated in its groove.

6. Before placing vehicle back into service, perform the

Operation & Leakage Tests stated elsewhere in this

manual.

ASSEMBLY - PURGE/RELIEF VALVE

1. Lubricate the piston o-ring with a silicone grease only,

such as those packaged with Bendix maintenance kits.

Also lubricate completely around the outside edge of

the purge valve.

2. Install the purge valve in the body making certain that it

is firmly and squarely seated in the body with the correct

side visible. Note: The three "bumps" on the purge valve

should not be visible. If the 3 "bumps" are visible after

the purge valve is installed, the valve must be removed

and re-installed.

10

Page 11

3. Install the o-ring on the purge piston, then install the

piston in the body taking care not to cut the piston

o-ring.

4. Install the non-metallic exhaust cover and spring in the

body .

5. Install the retaining ring in the ring in the body, making

certain that it is fully seated in its groove.

6. If so equipped, reconnect the exhaust line from the

exhaust port of the air

7. Before placing vehicle back into service, perform the

Operation & Leakage Tests stated elsewhere in this

manual.

ASSEMBLY - HEATER AND THERMOSTAT

1. Lubricate the connector o-ring with a silicone grease

only , such as those packaged with Bendix maintenance

kits.

2. Install the o-ring on the connector , then slide the heater

and thermostat assembly into the body making certain

not to cut the o-ring. Note that the "tab" on the assembly

fits into the corresponding slot in the body .

3. Install the retaining ring in the ring in the body, making

certain that it is fully seated in its groove.

4. Apply a dielectric grease on the heater and thermostat

connector contacts (both the heater and thermostat and

vehicle wiring harness connector halves).

5. After making certain the accordion seal is in place on

the vehicle wire harness connector, connect the wire

harness to the heater and thermostat assembly on the

dryer until its lock tab snaps ("clicks") into place.

6. Before placing vehicle back into service, perform the

Operation & Leakage Tests stated elsewhere in this

manual.

ASSEMBLY- DESICCANT CARTRIDGE

1. Lubricate the desiccant cartridge sealing ring with a

silicone grease only, such as those packaged with

Bendix maintenance kits and replacement parts.

2. Screw the desiccant cartridge on to the body, by hand,

until the seal makes contact with the body and rotate

clockwise approximately one full turn. If necessary,

place a strap wrench or equivalent tool on the desiccant

cartridge next to the lip low on the cartridge.

3. Before placing vehicle back into service, perform the

Operation & Leakage Tests stated elsewhere in this

manual.

INSTALLATION

1. Install the assembled AD-SP™ air dryer back onto the

vehicle using the same three mounting bolts retained

during removal. Tighten, then torque the three cap screws

to 50 lb. ft.

2. Reconnect the three air lines to the proper ports on the

body (identified during disassembly). If the fittings were

removed from the body, use a thread sealant making

certain none enters the body during re-installation

3. Apply a dielectric grease on the heater and thermostat

connector contacts (both the heater and thermostat and

vehicle wiring harness connector halves).

4. After making certain the accordion seal is in place on

the vehicle wire harness connector, connect the wire

harness to the heater and thermostat assembly on the

dryer by plugging it into the air dryer connector until its

lock tab snaps ("clicks") into place.

5. If so equipped, reconnect the exhaust line to the exhaust

port of the air dryer.

6. Before placing vehicle back into service, perform the

Operation & Leakage Tests stated elsewhere in this

manual.

RETROFITTING THE AD-SP™ AIR DRYER

GENERAL

The following retrofit instructions are presented for reference

purposes only since Bendix aftermarket retrofit and

replacement air dryers are packaged with the most up-todate installation instructions. The instructions packaged

with the AD-SP™ air dryer should be followed instead of

those presented here.

The preceding portion of this manual deals with "in-service"

repair and or replacement of the AD-SP™ air dryer. The portion

of the manual that follows is concerned with installing an

AD-SP™ air dryer on a vehicle not previously equipped with

one.

VEHICLE APPLICATION REQUIREMENTS

The basic application requirements presented here apply

to a standard air dryer installation. The majority of vehicles

in use today will meet these basic requirements however,

some may not.

The following are examples of vehicles where the AD-SP

air dryer should not be used: bulk trailer unloading

operations, city transit coaches, trash compactors and other

high air consumption or continuous flow systems. When

vehicles of this type are encountered other Bendix air dryer

models must be used. Consult your local authorized Bendix

parts outlet or sales representative for additional information.

1. Charge Cycle Time - The AD-SP™ air dryer is designed

to provide clean, dry air for the brake system. When a

vehicle's air system is used to operate non-brake air

accessories it is necessary to determine that during

normal, daily operation the compressor should recover

from governor "cut-in" to governor "cut-out" (usually 100

psi to 120 psi) in 90 seconds or less at engine rpm's

commensurate with the vehicle vocation. Important

Note: The AD-SP™ air dryer must be used in conjunction

™

11

Page 12

with governors which have a 120 to 130 psi nominal cutout pressure. If a governor is used that is not within this

limitation contact your Bendix parts outlet or sales

representative for additional information. If the recovery

time consistently exceeds this limit, it may be

necessary to "by-pass" the air accessory responsible

for the high air usage. Consult your local authorized

Bendix parts outlet or sales representative for additional

information.

2. Purge Cycle Time - During normal vehicle operation, the

air compressor must remain unloaded for a minimum of

30 seconds. This minimum purge time is required to

ensure complete regeneration of the desiccant material.

If the purge time is occasionally shorter than the times

specified, no permanent ill effect should be expected,

however, if the purge time is consistently less than the

minimum, an accessory by-pass system must be

installed.

3. European Air Brake Systems - The AD-SP™ air dryer

must not be installed in brake systems that

incorporate compressors without integral unloading

mechanisms and/or utilize a compressor discharge

line unloader valve. When vehicles of this type are

encountered other Bendix air dryer models must be used.

Consult your local authorized Bendix parts outlet or sales

representative for additional information.

4. Air Compressor Size - The AD-SP™ air dryer was

designed primarily for use with compressors rated up to

30 CFM. It is recommended that when using the

AD-SP™ air dryer with a compressor which has a rated

displacement exceeding 30 CFM that an authorized

Bendix parts outlet or Bendix marketing representative

be contacted for assistance.

5. Holset "E or QE" Type Air Compressors - The AD-SP

air dryer can be installed with the Holset T ype "E or QE"

compressor. When the AD-SP™ air dryer is used in this

installation, the Holset ECON valve should be removed

and the special orifice check valve in the "make-up" line

should be removed and replaced with a conventional

single check valve. This is most easily done using a

special 45 deg. supply port fitting, 112864, and single

check valve 109710.

6. Use the following guidelines to determine the vehicle

application suitable for the AD-SP™ air dryer:

Total Vehicle Res. Air Dryer Model

Volume (Cu. In.)

Less than 9,000 ...........................AD-SP™ Air Dryer

Less than 9,000 w/several ........... AD-9™ Extended Purge

air accessories or high air Volume Air Dryer

usage (e.g. transit coaches

& refuse haulers)

Greater than 9,000.......................AD-9™ Extended Purge

Volume Air Dryer or

Contact Bendix Commercial

Vehicle Systems LLC

12

VEHICLE PREPARATION

1. Park the vehicle on a level surface and prevent movement

by means other than the brakes.

2. Locate the front axle service (secondary) reservoir in

preparation for installing the SC-PR™ single check

protection valve included with AD-SP™ air dryer retro-fit

kits.

A. With full system pressure in all reservoirs, drain any

single reservoir and observe the reaction of the dash

gauges. If the supply reservoir was drained, no

reaction will be noted on the dash gauges. Drain air

from another reservoir. When the front axle service

reservoir gauge displays a pressure loss mark the

reservoir that was drained. Confirm that the front axle

service (secondary) reservoir has been found by

building system pressure to governor cut-out and

draining the marked reservoir. After the reservoir is

completely drained make a service brake application

and have an assistant observe the front axle service

brakes. The front axle brakes should be inoperative.

B. Some vehicles may be equipped with multi-

compartment reservoirs. This type of reservoir is easily identified by the presence of more than one drain

cock in the reservoir shell. The most common is a

two compartment reservoir with a "built-in" single

check valve between the two compartments. In most

instances when this type of reservoir is in use, one

of the two compartments (usually the smallest) will

be the supply reservoir and the second compartment will be either the front or rear service reservoir.

Drain air from either of the two compartments and

observe the dash gauges. If the supply reservoir compartment was drained, no reaction will be noted on

the dash gauges. If one dash gauge displays pressure loss note whether it is the front axle (secondary)

™

or rear axle (primary) reservoir. Mark the front axle

service (secondary) reservoir or compartment. Confirm that the correct reservoir has been found in the

same manner described in 2A.

3. Locate the supply reservoir ("wet tank") and note if a

single check valve is installed in the discharge line

connected to the reservoir. If a single check valve is found

it should be removed before proceeding with the

installation.

4. Locate and mark the single check valve that is used to

protect and isolate the front axle service reservoir.

5. Drain all reservoirs to 0 p.s.i. (0 kPa).

LOCA TING AD-SP™ AIR DRYER ON VEHICLE

1. The AD-SP™ air dryer must be mounted vertically (purge

exhaust port toward road surface) outside the engine

compartment in an area of air flow while the vehicle is in

motion. The AD-SP™ air dryer must not be exposed to

direct wheel splash (located behind axle mud flap is

acceptable).

2. Locate the AD-SP™ air dryer as close to the first (supply)

reservoir as possible.

Page 13

3. Do not locate the AD-SP™ air dryer near heat producing

components such as the vehicle exhaust and make

certain adequate clearance from moving components

(e.g. drive shaft, suspension, pitman arm, etc.) is

provided.

4. Locate the AD-SP

™

air dryer on vehicle so that a minimum

of 1” clearance above the cartridge is available to allow

cartridge servicing. Additionally, provide access to the

bracket bolts so the unit may be removed when

necessary.

5. When choosing the mounting location for the AD-SP

air dryer, note the discharge line length requirements

stated under the heading Connecting the Air Lines,

elsewhere in this manual.

Important Note: Under normal operating conditions, the

™

maximum inlet air temperature for the AD-SP

air dryer

is 150 degrees Fahrenheit.

MOUNTING THE AD-SP™ AIR DRYER

1. Install the AD-SP™ air dryer by referring to Figure 2 and

drilling the triangular mounting hole pattern in a mounting

plate and then mounting the plate on the vehicle or by

drilling the mounting hole pattern in the area of the vehicle

chosen for mounting. Note: Check the vehicle manual

before drilling a frame member.

2. Important: The length of the three mounting bolts used

to attach the AD-SP™ air dryer to the mounting plate is

very important. Refer to Figure 3. The threaded end of

the 1/2" - 13 UNC bolt must be between 1/8" below to

1/4" above the surface of the AD-SP™ air dryer mounting

bracket surface when fully installed and tightened to

50 pound feet. Damage to the dryer body will result if

the bolt warning is ignored.

WIDTH (THICKNESS)

OF AD-SP™ AIR DRYER

MOUNTING

BRACKET

™

VEHICLE FRAME

MEMBER

MOUNTING

BOLT

MOUNTING BOLT

1/4” ABOVE

SURFACE OF

MOUNTING

BRACKET

FIGURE 10 - AD-SP™ SYSTEM PURGE AIR DRYER

MOUNTING BRACKET BOL T LENGTHS

Measure the thickness of all materials that the three

mounting bolts must pass through. Small adjustments can

be made using flat washers under the bolt heads. Do not

use more than 3 flat washers.

3. Mount the AD-SP™ air dryer on the vehicle using three

1/2" bolts (grade 5 min.) of the proper length and washers.

T orque to 50 lb. f t.

MOUNTING

BOLT

1/8” BELOW

SURFACE

OF MTG.

BRACKET

4.134 INCHES

CENTER TO CENTER

FIGURE 9 - AD-SP™ SYSTEM PURGE AIR DRYER

MOUNTING BRACKET DIMENSIONS

1/2” - 13 UNC

THREAD

(3 PLACES)

2.835 INCHES

CENTER TO

CENTER

INSTALLING THE SC-PR™ VA LV E

1. Refer to steps 2A and 2B under Vehicle Preparation. If

the front axle (secondary) reservoir is:

A. A single reservoir and not part of a multiple

compartment, proceed to step 2.

B. One compartment in a multiple compartment,

proceed to step 3.

2. Locate the single check valve that protects and isolates

the front axle reservoir and remove it. Remove the air

line fitting from the single check valve and install the

same fitting in the SC-PR™ valve. Install the SC-PR

valve and fitting in the reservoir port that was formerly

occupied by the single check valve. Reconnect the air

line to the SC-PR™ valve. Refer to Figure 12.

13

™

Page 14

3. Locate an unused port in both the supply compartment

and front axle compartment of the multiple compartment

™

reservoir. Install the SC-PR

valve in the front axle

reservoir (or compartment). Connect the supply port of

the SC-PR

™

valve to either an unused port in the supply

compartment of the reservoir OR T ee into the line between

the AD-SP™ air dryer and the supply compartment of

the reservoir. Note: Use 3/8" air brake tubing. Refer to

Figure 13.

CONNECTING THE AIR LINES

Important General Instructions

The instructions that follow apply to all installations of the

AD-SP

dryer is replacing an existing air dryer or is being installed

on a vehicle that never had one installed.

If the vehicle is currently equipped with an air dryer some

additional considerations apply .

™

air dryer regardless of whether the AD-SP™ air

A. If the AD-SP™ air dryer is replacing an integral purge air

dryer, such as the Bendix

equipped with any compressor except the CumminsHolset type E & QE, all that is necessary is that the air

dryer be removed and the existing air lines be correctly

connected to the AD-SP™ air dryer.

GOVERNOR

COMPRESSOR

FIGURE 11 - AIR SYSTEM WITHOUT AD-SP™ SYSTEM PURGE AIR DRYER

COMPRESSOR

SUPPLY

FRONT AXLE SERVICE RESERVOIR

SINGLE CHECK VALVE

GOVERNOR

™

AD-SP

AIR

DRYER

®

AD-9™ air dryer, on a vehicle

REAR AXLE SERVICE

FRONT AXLE SERVICE

REAR AXLE RESERVOIR

SUPPLY RESERVOIR

FIGURE 12 - AIR SYSTEM WITH AD-SP™ SYSTEM PURGE AIR DRYER

COMPRESSOR

SUPPLY COMPARTMENT

FIGURE 13 - SC-PR™ SINGLE CHECK PROTECTION VALVE INSTALLED IN MULTI-COMPARTMENT RESERVOIR

14

SC-PR™ VALVE

GOVERNOR

INTERNAL SINGLE CHECK VALVE

FRONT AXLE RESERVOIR

REAR AXLE RESERVOIR

™

SC-PR

VALVE

FRONT AXLE COMPARTMENT

Page 15

B. If the AD-SP™ air dryer is replacing an integral purge air

®

dryer such as the Bendix

AD-4™ or AD-9™ air dryer, on

a vehicle equipped with a Cummins-Holset type E or

QE compressor, in addition to removing the existing air

dryer and correctly connecting the existing air lines to

the AD-SP™ air dryer, it will be necessary to remove and

discard the Holset ECON and special orifice check valve.

See Figure 8.

PURGE CONTROL LINE

1. Install a purge control air line having a minimum inside

diameter of 3/16 inches between the AD-SP

control port and an unused unloader port on the governor.

The control line must be plumbed direct to the governor

and not in series with automatic drain valves, lubrication

systems, etc.

2. The control line should slope downward to the AD-SP

air dryer without forming potential water traps.

™

air dryer

DISCHARGE LINE

General:

Refer to Appendix A, Table A for recommended discharge

line lengths and sizes for various vehicle applications and

vocations.

PURGE EXHAUST LINE

1. If it is necessary to direct AD-SP™ air dryer discharge

contaminates away from vehicle components a 1” (25.4

mm) I.D. hose can be clamped on the AD-SP™ air dryer

exhaust

WIRING THE HEATER/THERMOSTAT

1. Determine the vehicle's electrical system voltage and

make certain that the AD-SP™ air dryer that is to be

installed contains the same voltage heater . Confirm the

proper voltage by noting the color of the heater and

thermostat connector .

Heater & Thermostat Connector

Voltage Color

12 Volts ............................. White, (No other markings)

24 Volts ............................. Gray, or White w/Red Dot

The AD-SP™ air dryer is available with either a 12 or 24 volt

heater and each uses 90 watts of power .

2. A separate wire harness and splice kit is with all

AD-SP™ air dryer replacements and retro-fit kits. Refer

to the instructions contained in that kit for the proper

wiring procedure.

TESTING THE AD-SP™ AIR DRYER

GENERAL OPERATIONAL STATEMENT

The AD-SP™ system purge air dryer, operates differently

than integral purge air dryers such as the AD-9™ air dryer.

The "System Purge", designation is used because this air

dryer uses a small portion of the supply and front axle

(secondary) reservoir air pressure to purge or dry the

desiccant material. During the Purge cycle, an

approximately 8 - 14 psi drop in air pressure will be noted

on the front axle (secondary) service reservoir dash gauge.

The drop in pressure is the result of using a small amount

of air from the reservoir to purge the AD-SP™ air dryer

desiccant.

™

The SC-PR

valve protects the air pressure in the front axle

(secondary) service reservoir, in the event of a compressor ,

supply or rear axle reservoir failure or malfunction of the

AD-SP

™

air dryer purge control valving.

TESTING

Before placing the vehicle in service, perform the following

tests:

™

1. Close all reservoir drain cocks.

2. Build up system pressure to governor cut-out while

observing that both the front axle (secondary) and rear

axle service reservoir dash gauges rise equally in

pressure from 0 psi to governor cut-out. Note: When

building up brake system pressure to governor cutout

during testing, the engine/compressor should be run at

approximately 1,800 rpm to simulate normal operation

of the vehicle.

If either gauge fails to display this condition, stop testing

and check the installation of the SC-PR™ valve. Note

that the AD-SP™ air dryer purges with an audible escape

of air when governor cut-out pressure is reached.

3. Note that the front axle (secondary) service reservoir

pressure drops approximately 8 - 14 psi and that the

rear axle service reservoir loses no air pressure.

4. "Fan" the service brakes to reduce system air pressure

to governor cut-in. Note that the system once again builds

to full pressure and is followed by a purge at the

AD-SP™ air dryer exhaust.

5. T est the operation of the SC-PR™ valve. Build system air

pressure to governor cut-out and turn the ignition off.

Drain the supply reservoir and note that pressure in the

front axle (secondary) service reservoir does not drop

below 90 psi.

6. It is recommended that the following items be tested for

leakage to assure that the AD-SP™ air dryer will not

cycle excessively:

(A) T otal air system leakage (See Bendix publication

BW-5057 "Air Brake Handbook").

(B) Compressor unloader mechanism.

(C) Governor.

(D) Drain cock and safety valve in first (supply)

reservoir.

(E) All air connections leading to and from the first

(supply) reservoir.

15

Page 16

AD-SP™ AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS

1. Dryer is constantly

“cycling” or purging.

Dryer purges frequently

(every 4 minutes or less

while vehicle is idling).

CAUSE

A. Excessive system

leakage.

IMPORT ANT : Note whether

air pressure loss is shown

on dash gauge(s). Pressure

loss shown on gauges is

caused by service brake

system or component

leakage. Pressure loss NOT

SHOWN on gauges is

caused by supply system or

component leakage.

REMEDY

A. If leakage IS SHOWN on gauges test for

excessive service brake system leakage.

Allowable leakage:

Single vehicle - 1 psi/minute either service

reservoir.

Tractor trailer - 3 psi/minute either service

reservoir. Rep air and retest as required.

B. If leakage is NOT SHOWN on gauges test for

excessive supply system leakage.

Remove drain cock or valve in supply reservoir (wet

tank) and install air gauge. Build system pressure,

allow air dryer to purge and observe air gauge in

supply reservoir. Pressure drop should not exceed 1

psi per minute. Perform tests 1 to 5 in the order

presented.

16

Page 17

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

REMEDY

1. Test fittings, hoses, lines and connections. Apply

soap solution to detect excessive leakage.

Tighten or replace as needed then repeat the air

dryer charge-purge cycle and observe the gauge

installed in the supply reservoir . If leakage is

within limits remove gauge from reservoir and

replace drain cock or valve. If excessive leakage

is detected, continue testing.

2. T est accessories connected to supply reservoir .

Drain all air pressure from system, disconnect all

air lines leading to accessories (fan clutch,

wipers, air seats, etc.) and plug the reservoir at

disconnection point. Build air system pressure

until air dryer purges and observe supply

reservoir gauge. If leakage is no longer

excessive, repair or replace leaking accessory . If

excessive leakage is detected, continue testing.

3. T est governor leakage. Build system pressure to

governor cut-out, turn off engine and apply soap

solution to governor exhaust port and around

cap. Leakage should not exceed a 1" bubble in 5

seconds. Reduce system pressure to 80 psi or

less, and re-apply soap solution. Leakage should

not exceed a 1" bubble in 5 seconds. If

excessive leakage is detected in either test,

repair or replace governor .

4. Test compressor unloader leakage. Drain all air

pressure from system and remove the governor

from the compressor. T emporarily plug the

governor unloader port or air line that mated with,

or connected to, the compressor. Build air

system pressure until air dryer purges then

IMMEDIA TEL Y SHUT OFF THE ENGINE.

Observe the air gauge in the supply reservoir. If

leakage is within limits, replace the compressor

unloaders. Re-connect the governor to the

compressor (after removing plug installed in

governor) and retest while observing supply

reservoir gauge. If excessive leakage is detected,

continue testing.

5. T est air dryer purge valve and outlet (delivery)

check valve. Drain all air pressure from system,

remove the control line connection at the air

dryer and plug the end of the air line leading to

the governor (not the air dryer control port). Build

system pressure to governor cut-out and observe

air gauge. If little or no pressure drop is observed

replace the air dryer check valve. If pressure drop

continues, apply soap solution to air dryer purge

exhaust and purge control port (where the control

line was removed). Leakage should not exceed a

1" bubble in 5 seconds. If leakage is excessive

repair or replace purge valve assembly .

17

Page 18

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

B. Leaking (internal or

external) SC-PR

check protection valve.

C. Incorrect governor setting

or malfunctioning

governor.

D. Rapid cycling of the

governor due to air

starvation at the RES

port of the governor.

E. Leaking purge control

mechanism or delivery

check valve in AD-SP

air dryer.

F. High air usage - Vehicle

application.

™

single

REMEDY

B. Locate the SC-PR™ valve on the front axle

service (secondary) reservoir and replace.

C. Minimum setting required for AD-SP

™

air dryer

installation 100 cut in and 120 cut out. Test

operation of governor. Repair or replace as

necessary.

D. With gauge installed at RES port of governor ,

pressure should not drop below "Cut In"

pressure at the onset of the compressor

"Unloaded" cycle. If pressure drops, check for

"kinks" or restrictions in line connected to RES

port. Line connected to RES port on governor

must be same diameter, or preferably larger

than, lines connected to UNL port(s) on

governor.

E. Eliminate all leakage possibilities in 1A -

Replace AD-SP™ air dryer.

™

F . Refer to the "Vehicle Application

Requirements" section of this manual and

verify application.

2. Water and/or Oil in

Supply or Service

Reservoir.

A. Improper discharge line

length or improper line

material. Maximum air

dryer inlet temperature is

exceeded.

B. Air system charged from

outside air source

(outside air not passing

through air dryer).

C. Air dryer not purging

(see Symptom #5).

D. Purge (air exhaust) time

insufficient due to

excessive system

leakage (see causes for

Symptom #1).

E. Excessive air usage,

duty cycle too high - Air

dryer not compatible

with vehicle air system

requirement (Improper air

dryer/vehicle

application).

A. Refer to section entitled Connecting the Air Lines

as well as Appendix A, Table A columns 1 & 2

then and check line size and length.

B. If system must have outside air fill provision,

outside air should pass through air dryer . This

practice should be minimized.

C. See Symptom #5.

D. Check causes and remedies for Symptom #1.

E. See Appendix A, T able A, column 1, for

recommended compressor sizes. If the

compressor is “too small” for the vehicle vocation

(for example, where a vehicle’s vocation has

changed or service conditions exceed the

original vehicle or engine OE spec’s) then

upgrade the compressor. Note: The costs

incurred (e.g. installing a larger capacity

compressor, etc.) are not covered under original

compressor warranty .

18

Page 19

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

NOTE: Duty Cycle is the

ratio of time the compressor

spends building air to total

engine running time. Air

compressors are designed

to build air (run “loaded”) up

to 25% of the time. Higher

duty cycles cause

conditions that affect air

brake charging system

performance which may

require additional

maintenance. Factors that

add to the duty cycle are: air

suspension, additional air

accessories, use of an

undersized compressor,

frequent stops, excessive

leakage from fittings,

connections, lines,

chambers or valves, etc.

F . Air compressor

discharge and/or air

dryer inlet temperature

too high.

REMEDY

Charge Cycle Time - The AD-SP™ air dryer is

designed to provide clean, dry air for the brake

system. When a vehicle’s air system is used to

operate non-brake air accessories it is

necessary to determine that; during normal,

daily operation the compressor should recover

from governor “cut-in” to governor “cut-out”

(usually 100 psi to 120 psi) in 90 seconds or

less at engine RPM’s commensurate with the

vehicle vocation. If the recovery time consistently

exceeds this limit, it may be necessary to

“bypass” the air accessory responsible for the

high air usage. An example of where a by-p ass

system would be required is when the

compressor is used to pressurize a tank trailer

for purposes of off-loading product. Consult your

local authorized Bendix parts outlet or sales

representative for additional information.

Purge Cycle Time - During normal vehicle

operation, the air compressor must remain

unloaded for a minimum of 30 seconds. This

minimum purge time is required to ensure

complete regeneration of the desiccant material.

If the purge time is consistently less than the

minimum, an accessory by-pass system must

be installed. Consult your local authorized

Bendix parts outlet or sales representative for

additional information.

Air Compressor Size - Although the AD-SP™ air

dryer can be used in conjunction with larger

compressors, it was designed primarily for units

rated for up to 30 CFM. It is recommended that

when using the AD-SP™ air dryer with a

compressor which has a rated displacement

exceeding 30 CFM that an authorized Bendix

parts outlet or Bendix marketing representative

be contacted for assistance.

F. Restricted discharge line. See Appendix A, Table

A, column 1 & 2 for recommended sizes. If

discharge line is restricted or more than 1/16"

carbon build up is found, replace the discharge

line. Replace as necessary .

Discharge Line Freeze-Up: The discharge line must

maintain a constant slope down from the

compressor to the air dryer inlet fitting to avoid low

points where ice may form and block the flow . If,

instead, ice blockages occur at the air dryer inlet,

insulation may be added here, or if the inlet fitting is

a typical 90 degree fitting, it may be changed to a

straight or 45 degree fitting. For more information on

how to help prevent discharge line freeze-ups, see

Bendix Bulletins TCH-08-21 and TCH-08-22. Shorter

discharge line lengths or insulation may be required

in cold climates.

19

Page 20

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

G . Compressor malfunction.

H. Air by-passes desiccant

cartridge assembly .

I. Desiccant requires

replacement.

REMEDY

Insufficient coolant flow through compressor . Inspect

coolant line. Replace as necessary (I.D. is 1/2"

min.). Inspect the coolant lines for kinks and

restrictions and fittings for restrictions. Replace as

necessary . V erify coolant lines go from engine block

to compressor and back to the water pump. Repair

as necessary.

Restricted air inlet (not enough air to compressor).

Check compressor air inlet line for restrictions,

brittleness, soft or sagging hose conditions etc.

Repair as necessary . Inlet line size is 3/4 ID.

Maximum restriction requirement for compressors is

25 inches of water. Check the engine air filter and

service if necessary (if possible, check the air filter

usage indicator).

Poorly filtered inlet air (poor air quality to

compressor). Check for leaking, damaged or

malfunctioning compressor air inlet components

(e.g. induction line, fittings, gaskets, filter bodies,

etc.). Repair inlet components as needed. Note: Dirt

ingestion will damage compressor and is not

covered under warranty .

If you found excessive oil present in the service

reservoir and you did not find any issues above, the

compressor may be passing oil.

Replace compressor. If still under warranty , follow

normal warranty process.

G . If you found excessive oil present in the service

reservoir and you did not find any issues above,

the compressor may be passing oil. Test the

compressor using the BASIC cup method as

described in the Bendix compressor service

manual and referred to in Appendix A, T able A,

column 5.

Replace compressor. If still under warranty , follow

normal warranty process.

H. When replacing the desiccant cartridge, make

sure desiccant cartridge assembly is properly

installed and sealing rings are in place on

mounting surface of desiccant cartridge.

I. Replace desiccant cartridge assembly . Refer to

Appendix A, Table A columns 3 & 4 for

recommended intervals.

20

Page 21

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

3. Oil present at air dryer

purge exhaust or

cartridge during

maintenance.

4. Air is escaping from air

dryer exhaust during

Charge Cycle but able

to build system air

pressure. (Compressor

pumping.)

A. Air brake charging

system is functioning

normally.

A. Air dryer purge valve

leaking.

B. Compressor unloader

mechanism malfunction.

C. Governor malfunction.

D. Air flow to the supply

reservoir restricted.

E. Excessive pressure

pulsations from

compressor. (Typical

single cylinder type.)

REMEDY

A. Air dryers remove water and oil from the air

brake charging system. A small amount of oil is

normal. Check that regular maintenance is

being performed and that the amount of oil in the

air tanks (reservoirs) is within the acceptable

range shown on the BASIC cup (see also

column 5 of Appendix A, T able A). Replace the

air dryer cartridge as needed and return the

vehicle to service.

A. Repair or replace air dryer purge valve.

B. One or both dash air gauges should show higher

than normal air pressure. T est compressor

unloader mechanism for proper operation. Repair

or replace unloaders as necessary.

C. One or both dash air gauges may show higher

than normal air pressure. T est governor for proper

operation. Repair or replace as necessary .

D. Kinked, plugged, damaged hose tubing or fittings:

Check to determine if air is reaching first

reservoir. Inspect for kinked tubing or hose.

Check for un-drilled or restricted hose or tubing

fittings. Repair or replace as necessary .

Desiccant cartridge plugged: Check compressor

for excessive oil passing and/or correct

compressor installation. Repair or replace as

necessary . Replace desiccant cartridge.

E. Increase volume in discharge line by added length

or size of line, or add a ping tank.

5. Air escaping from air

dryer exhaust port

during entire purge

cycle. (Compressor not

running.)

A. Leaking turbo cutoff valve

B. Leaking purge piston

C. Leaking or

D. Leaking delivery check

in AD-SP™ air dryer.

o-ring in AD-SP™ air

dryer.

malfunctioning purge

control mechanism.

valve.

A. Note dash gauges to verify Purge Cycle has

ended. Perform Air Dryer “Operation & Leakage

T ests” specified in this manual. Repair or replace

as necessary.

B. Perform Air Dryer “Operation & Leakage Tests”

specified in this manual. Repair or replace as

necessary.

C. Replace AD-SP™ air dryer.

D. Perform Air Dryer “Operation & Leakage T est s”

specified in this manual. Repair or replace as

necessary.

21

Page 22

AD-SP™ AIR DRYER TROUBLESHOOTING CHART (Continued)

SYMPTOMS

6. Unable to build air

system pressure. Air

not escaping from

AD-SP™ air dryer

exhaust (not exhibiting

Symptom #4 plus this

symptom.)

7. Unable to build air

system pressure.

8. Air dryer does not purge

or exhaust air. Note:

this symptom often

precedes Symptom #9

if desiccant cartridge is

not replaced.

CAUSE

A. Frozen discharge line.

B. Compressor unloader

mechanism

malfunction.

C. Governor malfunction.

D. Air flow to service brake

system restricted or

plugged. Air pressure on

one dash gauge normal

with no, or low pressure

on other gauge.

A. AD-SP™ air dryer purge

control line incorrectly

connected to governor.

B. Air trapped in purge

control line (between

governor and AD-SP™ air

dryer.)

C. Governor malfunction.

D. Compressor unloader

mechanism

malfunction.

E. AD-SP™ air dryer purge

valve piston frozen

open.

F. AD-SP™ air dryer purge

valve piston stuck.

A. Air not reaching AD-SP

™

air dryer purge control

port.

B. AD-SP™ air dryer purge

valve or piston frozen

closed.

C. Extremely high air usage

requirements on vehicle.

REMEDY

A. Inspect discharge line installation for water traps

that could freeze. Refer to “Connecting The Air

Lines” section in manual. Repair or replace as

necessary.

B. Test compressor unloader mechanism for

proper operation. Repair or replace as

necessary.

C. T est governor for proper operation. Repair or

replace as necessary .

D. Kinked, plugged, damaged hose tubing or fittings

in line between supply reservoir and low

pressure service reservoir