Page 1

®

Bendix® A-18™ Trailer ABS (Gen 4™ and Gen 5™ ABS)

GEN 4™ AND GEN 5™ ABS INTRODUCTION

This manual describes the Bendix® A-18™ trailer ABS

system and contains two primary sections:

• Installation

• Service

The Installation section provides the information required

for the proper installation of a FMVSS-121 compliant trailer

air brake systems that incorporate the Bendix Trailer ABS

system and complementary trailer components.

The Service section of the manual includes the information

necessary to properly maintain, troubleshoot and repair the

™

A-18

trailer ABS system.

Following the installation, service, and troubleshooting

procedures contained in this manual will produce a high

performance, long life, low maintenance antilock braking

system.

For assistance in your area call Bendix at 1-800-247-2725

or RoadRanger

®

at 1-800-826-4357.

Benefits of T railer ABS

ABS-controlled trailer braking ensures optimum vehicle

stability while minimizing the stopping distance. During

vehicle operation, the trailer ABS Electronic Control Unit

(ECU) continuously monitors all wheel speed sensors. Data

input from the wheel speed sensors allows the ECU to:

• Detect impending wheel lock.

• Maintain optimum wheel slip.

• Maximize overall braking effectiveness.

• Minimize tendencies for trailer swing out during hard

braking conditions.

Document Revision Level

This document is subject to revision.

For updates please visit www.bendix.com.

Power Requirements for ABS . . . . . . . . . . . . . . . . . . . 3

General Air Brake Requirements . . . . . . . . . . . . . . . . . 4

Brake Priority Options . . . . . . . . . . . . . . . . . . . . . . . . . 5

ABS Performance Characteristics . . . . . . . . . . . . . . . . 6

ABS Controlled Braking . . . . . . . . . . . . . . . . . . . . . . . . 6

ABS Component Function . . . . . . . . . . . . . . . . . . . . . . 6

Trailer ABS Configurations . . . . . . . . . . . . . . . . . . . . . 7

Sensor Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Trailer ABS Component Overview . . . . . . . . . . . . . . . . 9

Electronic Control Unit (ECU) . . . . . . . . . . . . . . . . . . 11

Relay Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Relay Valve Operation Modes . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Install the ECU/Relay V alve and

Stand Alone Relay Valve . . . . . . . . . . . . . . . . . . . . . 16

Install the Inline Power Connector . . . . . . . . . . . . . . . 17

Install the Main ABS Harness . . . . . . . . . . . . . . . . . . 17

Install the Trailer Mounted Warning Light . . . . . . . . . 18

End-Of-Line Diagnostics . . . . . . . . . . . . . . . . . . . . . . 23

Use of Hand Held Tool for Configuration . . . . . . . . . . 23

Troubleshooting and Fault Codes . . . . . . . . . . . . . . . 25

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ServiceRanger PC Software . . . . . . . . . . . . . . . . . . . 27

ABS Valve Troubleshooting . . . . . . . . . . . . . . . . . . . . 28

Speed Sensor Troubleshooting . . . . . . . . . . . . . . . . . 29

Accessing Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fault Code Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

®

Bendix

is a registered trademark of Bendix Commercial

Vehicle Systems LLC.

®

Eaton

, RoadRanger®, and ServiceRanger® are registered

trademarks of Eaton Corporation.

SD-13-4757

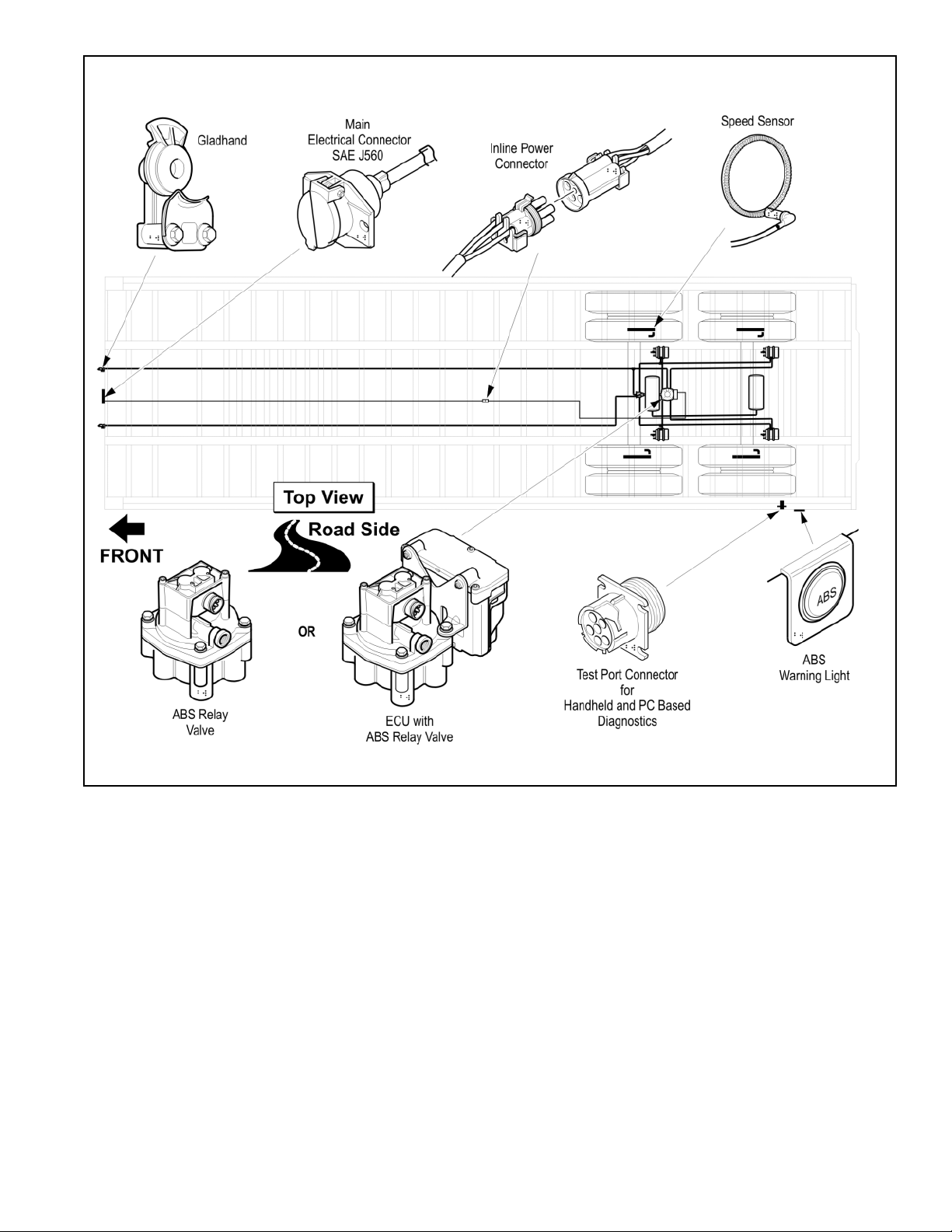

FIGURE 1 - ABS Controller Assemblies

Table of Contents

1

Page 2

Tractor and trailer ABS systems operate independently of

ABS

each other. Therefore, systems will work together properly

even if they are not supplied by the same manufacturer.

For information on disassembly , installation, and service of

related axle and brake components, refer to their individual

Bendix

®

Service Manuals.

For assistance in your area call Bendix at 1-800-247-2725

or RoadRanger

®

at 1-800-826-4357.

These ABS controllers and systems were originally

marketed under the Eaton

®

Brand name. For more

information, contact Bendix or refer to your local authorized

®

Bendix dealer, or RoadRanger

.

Power Requirements for ABS

Since March 1998 the trailer wiring systems provide two

sources of power for the antilock system.

The two power sources are:

1. Full-time power (when ignition is on) must be provided

by the tractor. This full-time power source may be

shared with other trailer circuits. The SAE J560 Blue

(AUX) circuit is commonly used as the full-time power

source. In other cases, a separate ISO3731 connector

is provided.

2. Brake light power is provided as a secondary source of

power in cases where an older tractor that does not

provide full-time power is used to operate an ABS

equipped trailer.

The industry requires that the tractor provide at least 10

amps at 12 volts at the trailer end of the SAE J560 or ISO

cable on all ABS power circuits. These specifications meet

TMC RP-137 and are consistent with SAE-2247.

There are no formal requirements. However , suppliers of

Trailer ABS have agreed to provide for proper antilock brake

operation down to a minimum of 8.5 volts (at which time

the warning lamp will activate). A new TMC RP

(Recommended Practice) is being developed which

recommends that trailer manufacturers provide a 1.0 volt

safety margin over the 8.5 volt minimum.

System current requirements will not exceed 0.5 amps per

control unit and three amps per valve.

™

A-18

trailer ABS system modulators have a nominal

resistance of 5.5 ohms and require approximately two amps

to operate. The control unit is designed to power warning

lamps with a typical current of 300mA for trailer mounted

warning lamps and 100mA for cab mounted warning lamps.

Administration (NHTSA). These requirements were

effective as of March 1, 1998.

Location

The lamp mounting location shall be near the left side rear

of the trailer, no closer than 150 mm (5.9 inches) and not

more than 600 mm (23.6 inches) from the rear red side

marker indicator lamp. (Refer to Figure 22.) On a converter

dolly , the lamp mounting location shall be on a permanent

structure of the dolly at least 375 mm (14 inches) above

the road surface.

Color and Labeling

The malfunction indicator lamp must be yellow in color and

identified with the letters “ABS” to distinguish the lamp from

other yellow side markers. The letters may be on the lens,

on the lens housing, or on the trailer itself, near the lamp.

Intensity and Photometric Requirements

The external ABS malfunction indicator lamp must conform

to SAE-J592 JUN92. Trailers shall use a combination

clearance/side marker lamps marked with a “PC” or “P2”.

These lamps offer a widely diffused beam pattern

throughout a full 180-degree left and right range.

Trailer Mounted ABS Warning Light

Rules for the location, color, labeling, intensity and

photometrics for external ABS warning lamps have been

established by the National Highway Transportation Safety

2

Page 3

General Air Brake Requirements

Basic design requirements for trailer air brake systems are

set forth in FMVSS-121. FMVSS-121 covers requirements

for new construction. Once put into operation, the trailer’s

brake systems must be maintained in accord with the

following FHWA/OMC standards.

• FMCSR 393 - Covers required equipment

• FMCSR 396 - Covers inspection and repair

Air Timing Requirements

FMVSS-121 specifies the maximum times that are

permitted for application and release of brake chamber

pressure. Refer to Figure 2. ABS equipped trailers must

meet the same air timing requirements as prior , non-ABS

equipped trailers.

Reservoirs

Trailers must be equipped with air reservoirs that provide

a volume of air eight times that of the service brake

chambers.

For example: a type 30 air chamber has an effective surface

area of 30 sq. in. For short stroke type 30 air chambers,

the volume is typically 89 CID. For a typical two axle trailer,

the minimum required volume is therefore 2848 CID.

Reservoir size requirements for non-ABS and ABS

equipped systems are the same.

Air Consumption

During ABS activation there is a loss of reservoir pressure.

There are no specific requirements limiting air consumption

in the U.S. (In Europe Regulation R13 states specific

limitations). ABS manufacturers take air consumption into

account when developing and evaluating ABS control

algorithms. There has been no need to change reservoir

size requirements as a result of the ABS mandate.

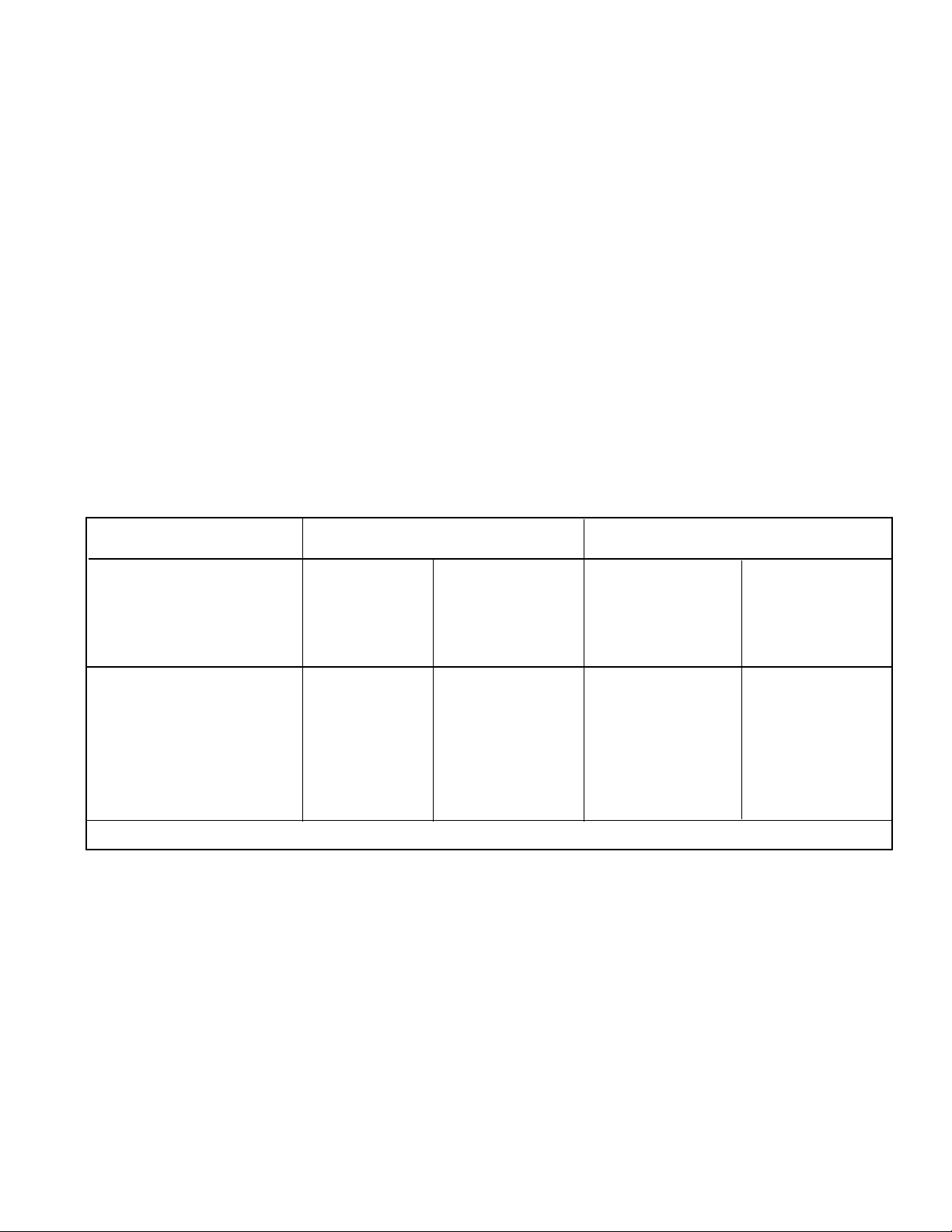

VehicleClassification Application Time (seconds) Release Time (seconds)

From pedal

movement

for chambers

to reach 60 PSI

Pedal movement

to reach 60 PSI

at 50 cu. Res

at gladhand

From pedal

movement to

reach 5 PSI

(w/95 PSI initial

chamber pressure)

From movement

of the pedal until

50 cu. in. reservoir

reaches 5 PSI

(With 95 PSI initial

chamber pressure)

Tractors,Trailersand Buses .45 .35

.55

Towing Trailer .50 .50 1.001.00

Converter Dolly .55 .55 1.101.10

Single Trailer .60 — 1.20 —

Note:A50cubic inch reservoiris used tosimulate the towed trailer volume at the gladhands of towing units.

FIGURE 2 - Air Timing Requirements Chart

.75

3

Page 4

Brake Priority Options

In prior years, there were requirements for a protected

reservoir, separate from the main reservoir. The purpose

of the protected reservoir was to hold off the spring brakes

in the event of a failure of the service brake system.

In 1994, FMVSS-121 was revised to allow other approaches

to reservoir management. The protected reservoir

approach, although not required, is still acceptable.

Conventional trailers are designed for either:

• Spring Brake Priority or

• Service Brake Priority .

Spring Brake Priority–The advantage of spring brake

priority is that the parking brakes (spring brake) can be

released quickly to permit moving the trailer at start up.

However, spring brake priority systems have failure modes

under which the parking brakes can be released and the

vehicle operated without functional service brakes.

Service Brake Priority–The advantage of the service brake

priority system is that it assures that the service brakes

have adequate air pressure available to them before release

of the spring brakes is allowed. However, service brake

priority systems require more time to bring a vehicle up to

operational level.

The Bendix

both Spring Brake Priority and Service Brake Priority

systems and does not require special installation

procedures. A number of spring brake control valves are

suitable for meeting current requirements. Bendix offers

spring brake valves suitable for a range of applications.

®

A-18™ trailer ABS system is compatible with

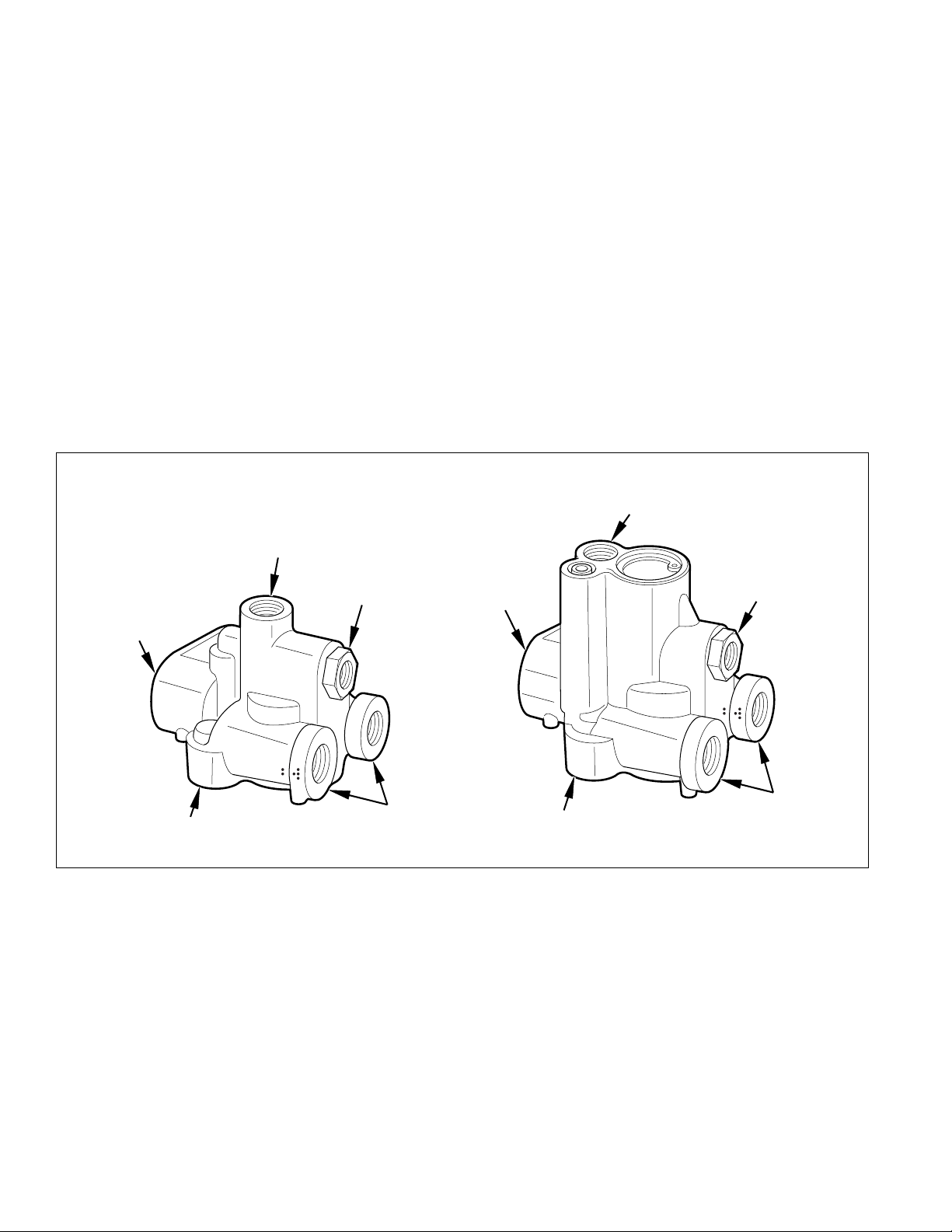

TEV

1/4"

Supply Port

3/4"

Reservoir

Port

3/8"

Delivery Ports

FIGURE 3 - Spring Brake Control Valves

1/4"

Control

Port

Delivery

3/8"

Ports

3/4"

Reservoir

Port

3/8"

Delivery Ports

STEV

1/4" Supply Port

1/4"

Control

Port

3/8"

Delivery

Ports

4

Page 5

ABS PERFORMANCE CHARACTERISTICS

Routine Braking

During routine braking operations, there is no indication of

excessive wheel slip. The electronic control unit interprets

this condition as normal and ABS remains inactive.

ABS Controlled Braking

The control unit continuously monitors all available wheel

speed sensors. Data from the sensors is used to calculate

values of wheel speed and wheel slip and to make a best

estimate of the true vehicle speed. This data allows the

control unit to detect impending wheel lock and to hold the

wheel slip at an optimum value to maximize braking

effectiveness. The best possible vehicle stability is assured

while stopping distance is minimized.

Control is accomplished by operation of relay based

modulator valves. The control unit makes a new

assessment of conditions and updates the control signal

to the modulator valves at a rate of approximately 100 times

per second.

Under normal (non-ABS) conditions, trailer ABS relay valves

operate exactly like conventional mechanical relay valves.

(Refer to Figures 11 through 14.) During ABS operation,

the control unit operates the valves to override the supply

of air to the chambers. During an ABS release, supply air

is held off while the chambers are vented to the atmosphere.

In hold mode, supply air is blocked and chamber air is held

constant. When required, air is applied to the chamber at

a controlled rate by modulating the hold side of the valve.

The antilock system does not apply additional braking

power. Rather, it controls air pressure to release and hold

brake torque, thereby increasing a vehicle’s capacity for

quick, straight stops. With ABS installed, vehicle operation

is safer, resulting in improved protection of driver, cargo

and equipment.

System Designs

When operating on high traction surfaces with a loaded

vehicle, there is little difference between types of ABS

control. Performance differences appear when vehicles

are lightly loaded and operating on variable and poor traction

surfaces. Examples of poor traction surfaces are ice and

combinations of ice, snow and asphalt. Operating a vehicle

in a curve highlights differences in stability between various

systems.

ABS system designs provide compromises between stability

and stopping distance while addressing cost, complexity

and reliability issues.

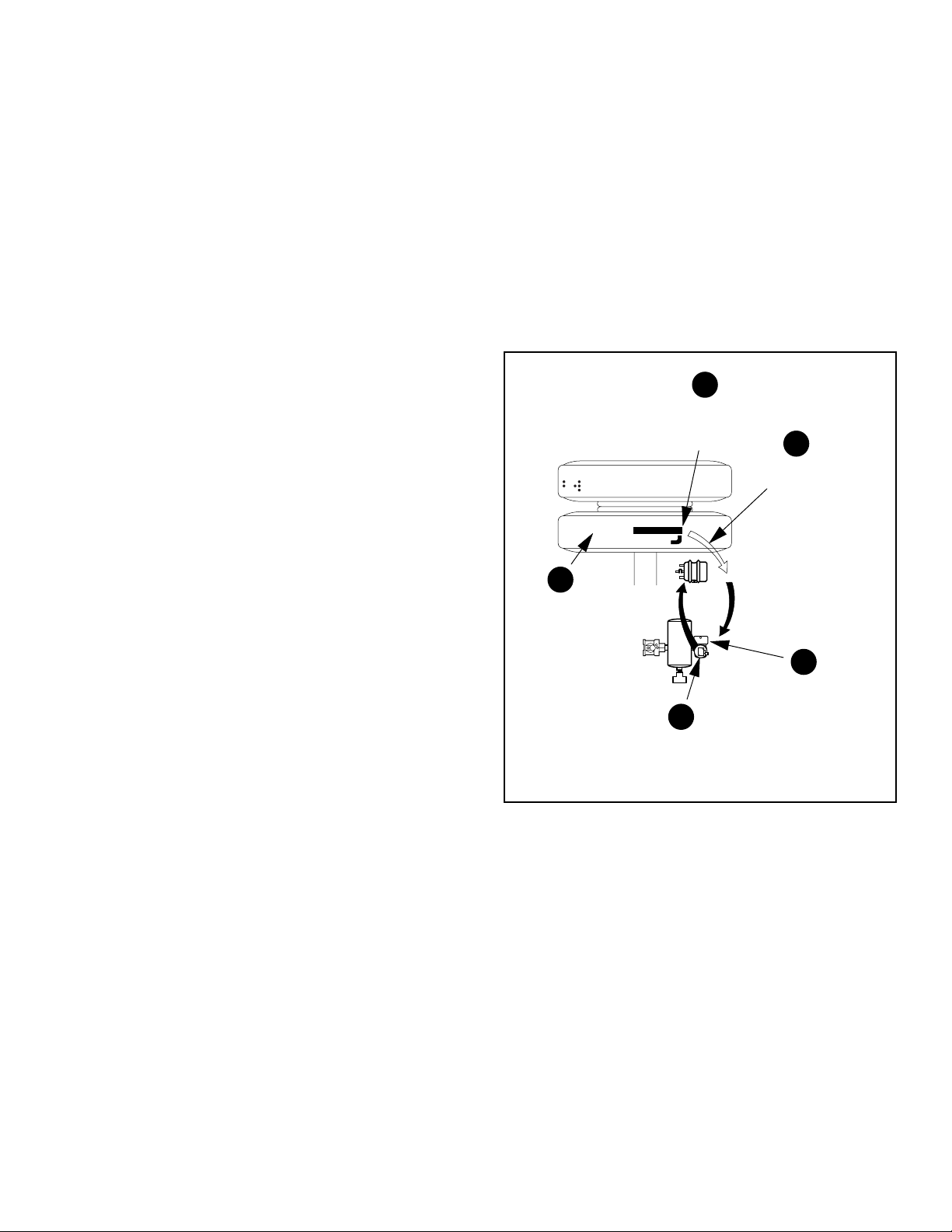

1

Speed sensors

monitor wheel

rotation

2

Speed signal

to ECU

5

Braking force

remains at

optimum level

Res.

4

Hold and release solenoids

control air pressure in the

brake chambers

3

ECU interprets

speed signals

and activates valves

ABS Component Function

Figure 4 shows an overview of the operation of the Bendix

A-18™ trailer ABS system.

Speed sensors (1) monitor wheel rotation and provide

information (2) on wheel rotation to the central electronic

control unit.

The Electronic Control Unit (3) receives the sensor signal,

interprets the pulse information, and constantly calculates

the relationship of speed, acceleration, and deceleration.

A control signal (4) is sent to the ABS relay valve (5), which

then controls the pressure to the air chambers.

FIGURE 4 - Overview of Trailer ABS Operation

®

5

Page 6

Independent Regulation

The most obvious control concept is independent wheel

control. In this case a single sensor controls a valve that

operates the brakes at one wheel site. Individual control

makes the best trade off between stability and stopping

distance. However, these systems have greater complexity

and higher cost with potentially lower reliability than less

complex systems. In many cases it is necessary to control

a single valve with inputs from two sensors.

Select Low

Select low systems monitor several wheels and controls

them with a single valve. Control is based on the wheel

that is at the lowest speed. Select low systems are very

stable but sacrifice stopping distance on split coefficient

surfaces. Modified select low systems incorporate a delay

before releasing to reduce the bias slightly away from the

low speed wheel.

Select High

Select high systems also monitor several wheels and control

them with a single valve. Control is based on the wheel

which is at the highest speed. Modified select high systems

activate a release before the low speed wheel becomes

severely locked. Select high systems generally have good

stopping distances at the expense of stability. These

systems may also have an increased risk of tire flat spotting.

Select Smart

Select Smart systems operate as select low systems when

there is little difference in traction between wheel control

sites. They operate as select high systems when there is a

significant difference in traction between sites. These

systems offer many of the advantages of individual control

systems while using a simpler design and fewer

components.

Bendix® A-18™ Trailer ABS Control Strategy

Select Smart is used for the most common applications.

Select low is used on the standard system 4S/2M Axle

Control configuration and is available as an option on the

basic system.

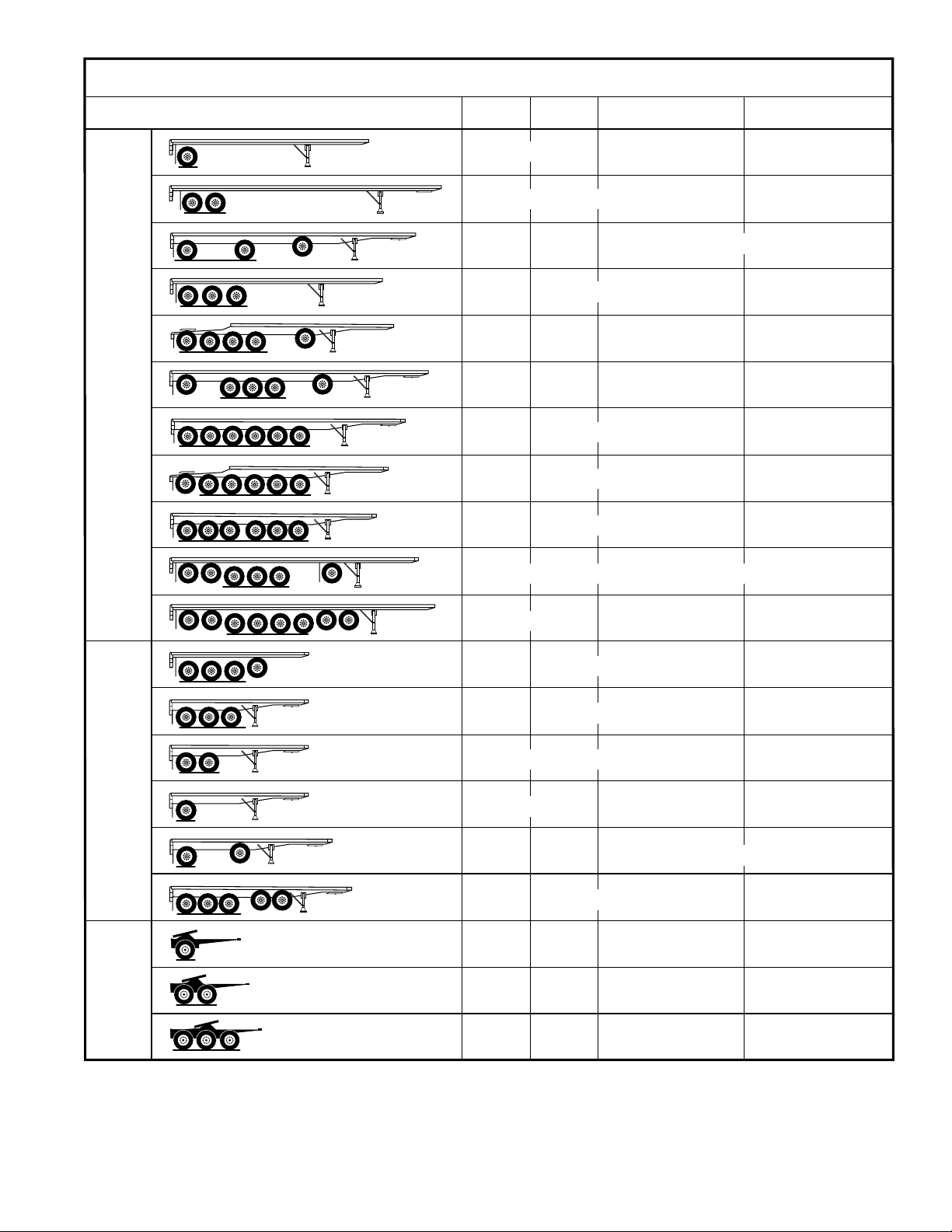

TRAILER ABS CONFIGURATIONS

Application Recommendations

Refer to the chart on page 8 to determine a recommended

ABS installation for your application.

Basic System (2S/1M)

The basic system includes two speed sensors and one

modulator valve for direct control of one axle and indirect

control of an additional axle. Other features of the basic

system include one ECU connector and a single-pin

diagnostic lead.

Standard System (2S/1M, 2S/2M and 4S/2M)

Bendix’s standard systems offer either two or four speed

sensors and up to two modulator valves. Standard systems

can directly control one or two axles and allow full

diagnostics via J1587. The standard system may be

configured in one of four ways to function as follows:

• 2S/1M—This configuration uses two sensors and one

modulator valve to directly control one axle and indirectly

control an additional axle.

• 2S/2M—This configuration uses two speed sensors and

two modulator valves for direct control of one axle and

indirect control of up to three additional axles.

• 4S/2M—This configuration uses four speed sensors

and two modulator valves for direct control of two axles

and indirect control of up to two additional axles.

• 4S/2M Axle Control—Special configuration for full

trailers and widely spaced axles. This configuration

uses the select low strategy .

Sensor Placement

When more than one wheel is controlled by a single valve,

sensors should be mounted at the axle which tends to lock

first. For spring suspensions this is usually the forward

axle. For air suspensions this is usually the rear most axle.

Lift Axles

• Gen-4™ ABS: Sensor inputs “C” and “D” of the control

unit may be used for lift axle wheel speed sensing.

• Gen-5

™

ABS: Direct lif t axle control is not available. Use

indirect control.

Reading Configuration Codes

On Basic systems, the jumper method must be used to

access the configuration. On Standard systems, access

to configuration information can be achieved by any of the

three methods:

• ServiceRanger diagnostic software on a PC

• Hand-held tester

• Jumper method.

For more information on accessing configuration codes,

refer to Accessing Codes on p age 30.

6

Page 7

SystemApplication Chart

Semi

Trailer

or

1st

Trailer

TrailerType

2S/1M 2S/2M

or

(1) (1)

or or

(1) (1) (1)

4S/2M Side Control

or

(1)

or

(2)

or

(2)

(2)

or

(1)

(1)(1)

(1)

(2)

(2)

(2)

4S/2MAxle Control

or

(1)

1st

2nd

or

3rd

Trailer

Trailer

Dolly

orand

(1)(2)

and

(1)(2)

(1) (1)

or

(1) (1)

or

or or

(1) (1) (1)

or

(1) (1)

(2)

(1)

(2)

or

(2)

(1)

(1)

or

or

(2)

(1)

FIGURE 5 - System Application Chart

(1)

7

Page 8

Trailer ABS Component Overview

Bendix® A-18™ trailer ABS system includes the following

components:

• Electronic Control Unit (ECU): The ECU monitors

wheel speeds and controls the trailer ABS valves. It

also diagnoses ABS malfunctions and stores failurespecific fault codes. The ECU is usually attached to a

relay valve with a mounting bracket. The ECU may

also be directly frame mounted. One ECU can monitor

either two or four speed sensors and control either one

or two relay valves. If necessary more than one ECU

may be used on a single trailer.

• Relay Valve: This component regulates brake chamber

air pressure. It houses the hold and release solenoids.

Each relay valve can control either two or four brake

chambers on an ABS equipped trailer. A relay valve

can have the ECU mounted to it (valve A in the

installation diagrams) or be a stand alone relay valve

(valve B in the installation diagrams) that is controlled

remotely by the ECU mounted on valve A.

• Trailer Mounted ABS Warning Lamp: This indicator

lamp, located on the “Road Side” near the rear of the

trailer, warns the driver of ABS malfunctions (steady

“ON”). It is also capable of blinking diagnostic fault

codes.

• Cab Mounted ABS Warning Lamp: This indicator

lamp, located on the driver instrument panel, also warns

the driver of ABS malfunctions. It is not capable of

blinking diagnostic fault codes.

• Wheel End Speed Sensor and Tone Wheel: Single

point variable reluctance (magnetic) sensor that

generates an alternating current signal in response to

the movement of teeth on a tone wheel. The signal is

interpreted by the ECU to monitor wheel speed.

• Diagnostic Port Connector: The diagnostic port

connector is an industry standard connector which is

used to provide a connection to the J1587 diagnostic

link. This connector also provides power and ground

for diagnostic test equipment.

• Gladhand: The gladhands used on the ABS system

are the same as those used on non-ABS trailers.

• Seven Way Main Electrical Connector: The seven

way receptacle is the same as those used on non-ABS

systems. This receptacle provides full-time power,

backup power via the brake light switch and ground for

the ABS electrical system.

• Optional ISO 3731 connector: This is a 7-pin

connector similar to the J560 connector. The most

noticeable difference is that the ground terminal has a

gender opposite that of the other terminals. The primary

use for ISO 3731 is for the lighting connections on

European trailers. However, this connector is used to

provide interface to trailer ABS in some U.S.

applications. (In Europe another connector designated

as ISO 7638 is used to provide interface to the trailer

braking system.)

8

Page 9

FIGURE 6 - ABS Trailer Components

9

Page 10

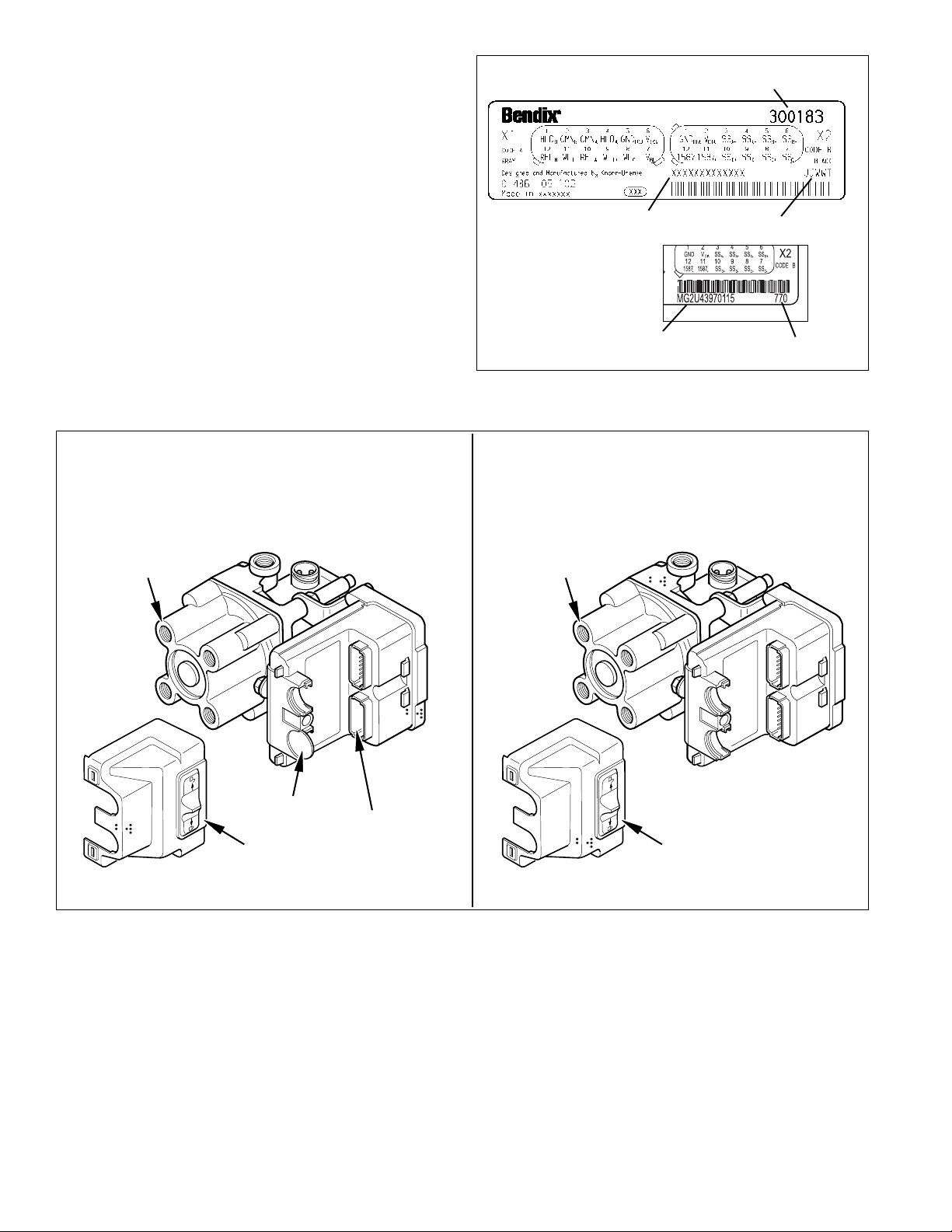

Electronic Control Unit (ECU)

The Bendix® A-18™ ECU is the trailer ABS control center.

Identification

Identification information for the ECU is located on the

connector pinout label (refer to Figure 7). The label is

located under the ECU cover. Refer to the label for the:

• Part Number

• Serial Number

• Date Code.

Depending on configuration, the A-18

ECUs may be equipped with either one connector (basic

system) or two connectors (standard system). Refer to

Figure 8.

BASIC STANDARD

™

trailer ABS system

Bendix Part Number

Basic System

Serial Number

Standard System

Serial Number

FIGURE 7 - Electronic Control Unit Identification Tags

Date Code

Date Code

Relay Valve

Plug

ECU Cover

FIGURE 8 - Trailer ABS ECU Configurations

Relay Valve

Blank

Connector

ECU Cover

10

Page 11

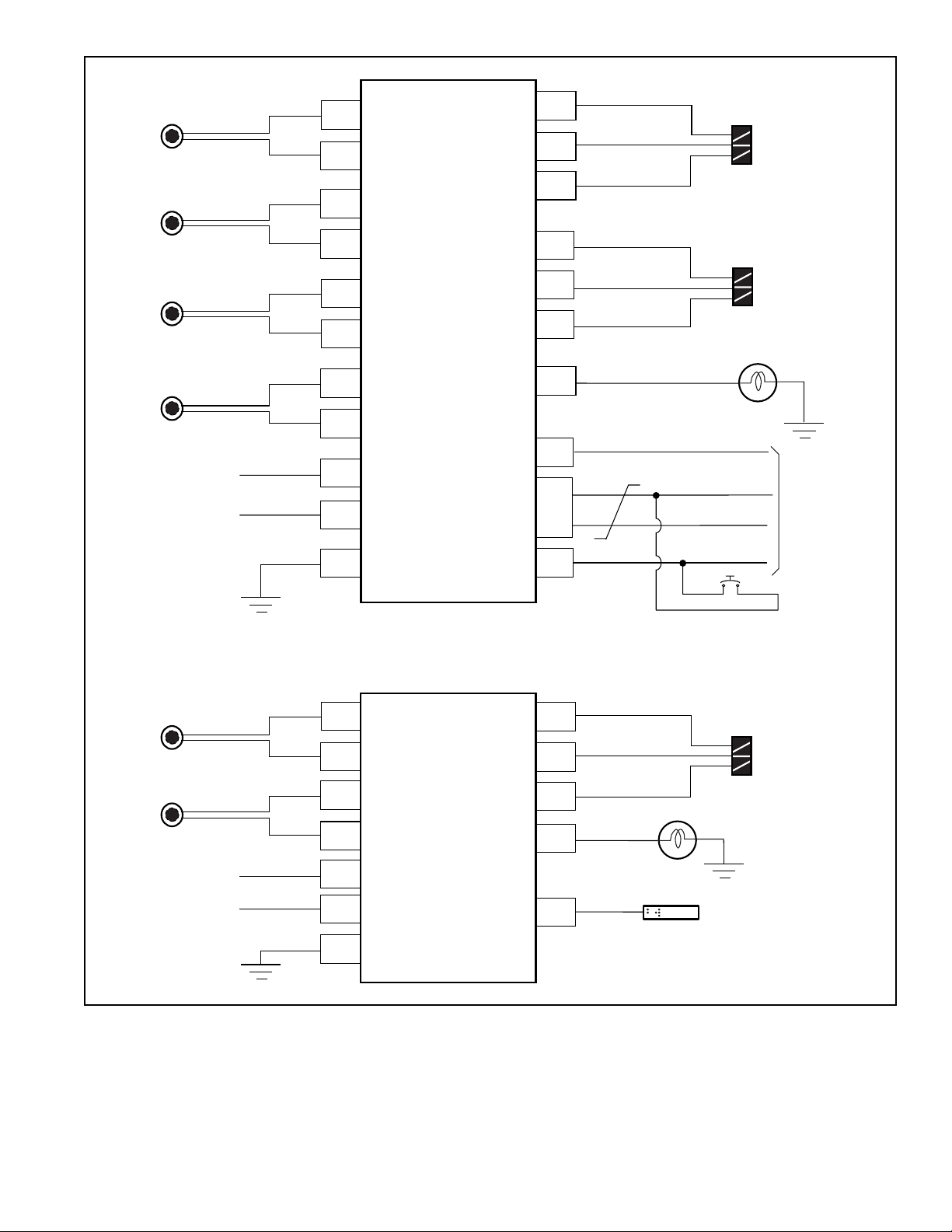

Inputs

Outputs

SensorA

Sensor B

Sensor C

Sensor D

Brake Light Power

Full Time Power

+

X2-4

-

X2-3

+

X2-6

-

X2-5

+

X2-8

-

X2-7

Standard

Trailer

ECU

(2 Connectors)

+

X2-10

-

X2-9

X1-7

X1-6

X1-5

X1-10

X1-3

X1-4

X1-12

X1-2

X1-1

X1-9

X2-2

X2-11

X2-12

X2-1

Common

Hold

Release

Common

Hold

ValveA

ValveB

J1587+

J1587 Gnd

TrailerMounted

WarningLight

J1587

Diagnostic Link

Diagnostic

Switch

Inputs

SensorA

Sensor B

Brake Light Power

Full Time Power

FIGURE 9 - Standard and Basic ECU Block Diagrams

+

X1-1

-

X1-2

+

X1-12

-

X1-11

X1-7

X1-6

X1-5

Trailer

(1 Connector)

Basic

ECU

Outputs

X1-10

X1-3

X1-4

X1-8

X1-9

Release

ValveA

Common

Hold

TrailerMounted

WarningLight

Diagnostic Plug

11

Page 12

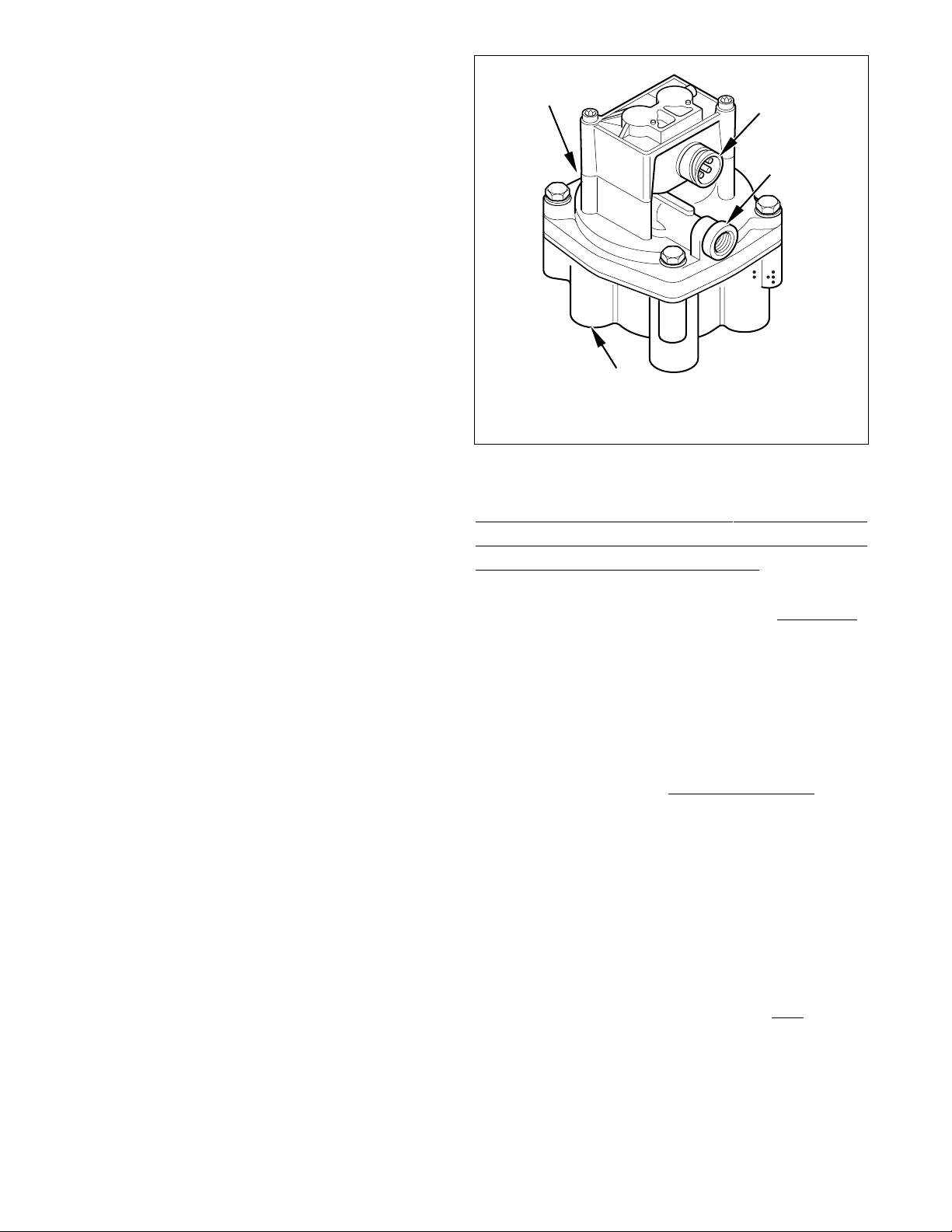

Relay Valve

The trailer ABS relay valve controls air pressure to individual

brake assemblies, and functions as a standard relay valve

when there are no ABS control signals. Depending on the

particular ABS configuration, a system may utilize one or

two relay valves. See Figure 10.

Each relay valve contains two solenoids for air control. The

hold solenoid maintains air pressure; the release solenoid

removes pressure from the brake. The Electronic Control

Unit signals the relay valve(s) for air hold and release by

activating the appropriate solenoid.

Each relay valve has a three-pin terminal for connection to

the Electronic Control Unit.

Delivery Ports

Both 2-port and 4-port versions of the relay valve are

available. These are all tapped for 3/8 NPT fittings.

Crack Pressure

St andard valves are available with 4.0 PSI ±0.5 PSI crack

pressure. Other crack pressures can be provided. For

example, 6.0 PSI valves may be used with wedge brakes.

Bracket, Valve, ECU combinations

Various combinations of mounting brackets, ECUs and

valves are available preassembled to facilitate system

installation on a variety of vehicles. Refer to the Bendix

A-18™ trailer ABS Illustrated Parts List for further

information.

Port Orientation

If necessary , the control and supply ports of the valve can

be reoriented with respect to each other. Remove the four

assembly bolts. Rotate top with respect to bottom as

required. Use care to maintain cleanliness of valve interior .

Retorque bolts to 10.0 lb-ft (13.6 N•m). Do not exceed

12.0 lb-ft (16.3 N•m).

Pipe Fitting Torques

Refer to the following torque specifications when installing

pipe nipples. Torques are for NPT threads with thread

sealant applied. Do not use thread tape. Contamination

by thread tape can cause component failure.

Tighten pipe nipples as follows:

• With Thread Sealant - Finger tight plus 1 1/2 turns

• Without Thread Sealant - Finger tight plus 2 turns

Clamping

A fixture may be necessary to hold the relay valve when

reorienting ports or when attaching fittings. If a vise is used,

there is a potential danger of distorting the barrel and piston

within the valve rendering the valve inoperative. It is

recommended that a fixture be used that avoids the

potential for stressing the valve.

3/4" Supply Port

Out

(3/8" Delivery Port to

Brake Chamber)

Figure 10 - Relay Valve

Three-Pin

ECU Connector

3/8" Control Port

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

®

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work on

the vehicle. If the vehicle is equipped with an

AD-IS™ air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

12

Page 13

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

part s should be replaced rather than rep aired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

Hold

Solenoid

Release

Solenoid

Relay Valve Operation Modes

1. Apply–Treadle pressure is applied to the top of the

piston. The sleeve is depressed until the outlet pressure

matches the pressure at the top of the piston.

2. Normal Release–Pressure at the top of the piston is

vented through the treadle valve. The sleeve rises to

block the inlet while allowing the chamber air to exhaust

through the center of the sleeve.

3. ABS Hold–Hold solenoid blocks treadle pressure. The

piston stabilizes, holding the chamber pressure at the

same level as that which is above the piston.

4. ABS Release–The release solenoid vents air at the top

of the piston while blocking treadle pressure. The sleeve

rises to block the inlet while allowing the chamber air to

exhaust through the center of the sleeve.

Control

Sleeve

Outlet

FIGURE 11 - Normal Apply and ABS Apply

Control

Piston

Supply

Control

Supply

Outlet Exhaust

FIGURE 12 - Normal Release

Control

Outlet Exhaust

FIGURE 13 - ABS Hold

Supply

Supply

Outlet Exhaust

FIGURE 14 - ABS Release

13

Page 14

Installation

Installation of the Bendix® A-18™ trailer ABS system is similar

from one configuration to another. All systems use the same

speed sensors and valves. The differences are in

placement and quantity and the type of ECU, either standard

or basic. Refer to the following general component

instructions and to the wiring and plumbing diagrams for

specific system configuration.

Suggested Order Of Installation

Following is a suggested order of installation of the A-18

trailer ABS.

1. Install Wheel Speed Sensors (often part of a dressed

axle).

2. Install Relay V alve(s)/ECU assembly .

3. Install the Power Cable, but do not apply power until

the installation is complete.

4. Route and connect the main ABS Harness.

5. Install the Diagnostic Port Connector .

6. Install the trailer-mounted ABS Warning Lamp.

7. Perform the End-of-Line Checkout.

Install the Wheel Speed Sensors and Sensor

Friction Sleeves

Refer to the appropriate diagram for your system and locate

the wheel speed sensors. Refer to Figures 23-26.

1. Install the sensor friction sleeve with the flange stops

towards the inboard side of the vehicle.

2. Apply high-temperature silicon-based grease to the

body of the speed sensor.

3. Push the speed sensor completely into sensor friction

™

sleeve by hand until it stops against the tone ring. The

speed sensor is properly installed and adjusted when it

is touching the tone ring. Allowable TIR for the tone

ring is 0.008 inches.

NOTE: The speed sensor must be able to slide freely in

and out of the sensor friction sleeve bore. Operating the

vehicle with seized components will damage the speed

sensor and the tone ring.

4. Route the cable to the frame. Use tie wraps as required

to restrain cable. Use care not to stress sensor cables.

5. Connect sensor cable to harness and install fasteners

to hold the sensor cable in position.

Push

Sensor

FIGURE 15 - Speed Sensor Installation

Sensor

Friction Sleeve

FIGURE 16 - Wheel Speed Sensor Components

ABS

Sensor

Bushing

14

Page 15

Install the ECU/Relay Valve and Stand Alone

Relay Valve

In all installations, the ECU/Relay V alve assembly appears

as Relay V alve “A” in the diagrams. The S tand Alone Relay

Valve is identical to the ECU/Relay Valve except it does

not have the ECU and ECU mounting bracket. The relay

valves may be installed on the reservoirs or a frame

member.

The Stand Alone Relay Valve is the second relay valve in

systems with two relay valves and is labeled Relay Valve

“B” in the diagrams.

Pipe Fitting Torques

Refer to the following torque specifications when installing

pipe nipples. Torques are for NPT threads with thread

sealant applied. Do not use thread tape. Contamination

by thread tape can cause component failure.

Tighten pipe nipples as follows:

• With Thread Sealant - Finger tight plus 1 1/2 turns

• Without Thread Sealant - Finger tight plus 2 turns

Leak and Performance Test

1. Park vehicle on level surface and block wheels.

2. Make and hold brake application. No audible air leaks

are permitted.

3. Release parking brake and fully charge the air system

(governor cut out point).

4. Turn engine OFF . Apply the service brake several times,

then hold and check for prompt brake air chamber

application and release at all wheels.

5. Apply brake, then hold. Coat outside of relay valve with

a soap solution. No leakage is permitted.

NOTE: If a sluggish response is noted at all wheels, inspect

for kinked or obstructed air line leading to or from valve.

6. Increase system air pressure to governor cut-off. With

brakes released, coat exhaust port of relay valve with a

soap solution. Leakage of a 1” bubble in 5 seconds is

permissible.

7. Depress foot valve and keep depressed. Coat exhaust

port with a soap solution. Leakage of a 1” bubble in 3

seconds is permissible.

3/4" Heavy Wall

Steel Pipe Nipple

Reservoir Tank

Relay Valve

FIGURE 17- Tank Mounted ECU/Relay Valve

Frame

Member

ECU

Relay Valve

ECU

FIGURE 18 - Frame Mounted Relay Valve

15

Page 16

Install the Inline Power Connector

The inline power connector is on the end of the main ABS

harness and connects the ABS system to the trailer

electrical system.

To

To

ECU/

Modulator

Valve

FIGURE 19 - Inline Power Connector

J560

Nose

Box

Trailer

Side

Power

Cable

ECU Side

Bayonett Connector

at Relay Valve

(Up to 2)

5 Pin

Weatherpack

Install the Main ABS Harness

1. Remove power from the trailer.

2. Unlock the ECU cover and remove.

3. Install the ECU connectors as follows:

Standard: Plug the grey harness connector into the

ECU connector labeled “X1”. The connector is keyed

and can only fit in one direction. Plug the black harness

connector into the ECU connector labeled “X2”. This

connector is also keyed.

Basic: Plug the green harness connector into the ECU

connector labeled “X1”. This connector is also keyed

and is the only connector on the ECU.

4. Install the ECU cover by first engaging the alignment

tabs and then hinging the cover closed, ensuring that

the convoluted tubing is captured in the strain relief slots.

Slide the cover lock to the locked position. An optional

tie wrap may be used to lock the cover in place.

5. Route harness to designated locations. Make sure that

the harness is properly routed and secured to prevent

damage to the harness.

BASICSTANDARD

One Bayonett Connector

at Relay Valve

J560

Diagnostic

5 Pin

Weatherpack

6" Pigtail

Deutsch

Male

Bayonet

Warning

Light

Chassis

Ground

FIGURE 20 - Standard and Basic ABS Harnesses

ABS ABS

Hd-10

Diagnostic

Speed

Sensor

(2 or 4)

Warning

Light

6" Pigtail

Male

Bayonet

Two

Speed

Sensors

Road SideRoad Side

Chassis

Ground

16

Page 17

To Frame

Diagnostic

Port

Diagnostic

Port Bracket

FIGURE 21 - Diagnostic Port Installation (Standard)

Install the Diagnostic Port (Standard System)

On standard systems, the diagnostic port is installed on

the road side of the trailer, on the frame forward of the

trailer axle(s). To install the diagnostics port, bolt or weld

the diagnostic port bracket to the trailer frame.

Install the Trailer Mounted Warning Light

The warning light is mounted on the road side of the trailer,

forward of the marker light according to the following

drawing.

ABS

5.9"

(160mm)

ABS

Warning

Lamp

23.6"

(600mm)

Rear

of

Trailer

Rear

Side Marker

FIGURE 22 - Warning Light Location

17

Page 18

2S-1M Electrical Configuration(Top View)

Front

J560 Connector

Power Cable

ECU Side

Trailer

Side

Parts List

Description Quantity

ECU/Relay Valve 1

Sensor/Diagnostics Cable 1

Valve/PowerCable 1

Sensors —0.4mCable 2

Sensor FrictionSleeve 2

WarningLampConnector

Warning

Light Side

Harness Side

Diagnostic Port

(Shown with

Extension)

Top View

Road Side

Wheel Sensor Speed Sensor

ECU

Side

Wheel

Side

Sensor B

SensorA

ABS WarningLampECU

Modulator

Valve

ABS

2S-1MAir System Configuration (Top View)

Key

3/8" O.D.NylonTubing

3/8" O.D.NylonTubing (Alt. 1/2" O. D.)

3/8" I.D.Hose

Gladhand

Service (Control)Line

Front

Supply Line

Gladhand

Top View

Road Side

FIGURE 23 - Typical 2S-1M ABS Electrical and Air System

TEV orSTEV

Spring Brake

Control

ABS

ECU

3/4" HeavyWall

Steel PipeNipple

Res. Res.

ABS

Relay

Valve

Service

Brake

Chamber

Emergency

Brake

Chamber

18

Page 19

2S-2M Electrical Configuration (Top View)

J560 Connector

Power Cable

Diagnostic Port

Wheel Sensor

Speed Sensor

Front

WarningLampConnector

Warning

Light Side

ECU Side

Trailer

Side

Parts List

Description Quantity

ECU/Relay Valve 1

StandAloneRelay Valve 1

Sensor/Diagnostic Cable 1

Valve/PowerCable 1

Sensors —0.4mCable 2

Sensor FrictionSleeve 2

Harness Side

Top View

Road Side

Relay

ValveA

ECU

Side

Wheel

Side

Stand

Alone

Relay

ValveB

Sensor B

SensorA

ABS WarningLampECU

ABS

2S-2MAirSystem Configuration (TopView)

Key

3/8" O.D.NylonTubing

3/8" O.D.NylonTubing (Alt. 1/2" O.D.)

3/8" I.D.Hose

Gladhand

Service (Control)Line

Front

Gladhand

Supply Line

Spring BrakeControl

Top View

Road Side

FIGURE 24 - Typical 2S-2M ABS Electrical and Air System

TEV orSTEV

Service BrakeChamber

ABS

ECU

Relay

Valve

Res. Res.

B

Relay Valve A

Emergency BrakeChamber

19

Page 20

4S-2M Side ControlElectrical Configuration (Top View)

J560 Connector

Power Cable

Diagnostic Port

Wheel Sensor

Speed Sensor

Front

WarningLampConnector

Warning

Light Side

ECU Side

Trailer

Side

Parts List

Description Quantity

ECU/Relay Valve 1

StandAloneRelay Valve 1

Sensor/Diagnostic Cable 1

Valve/PowerCable 1

Sensors — 0.4mCable 4

Sensor Friction Sleeve 4

Harness Side

Top View

Road Side

Relay

ValveA

SensorA

Sensor B

ECU

Side

Wheel

Side

Stand

Alone

Relay

ValveB

Sensor D

Sensor C

ABS WarningLampECU

ABS

4S-2M Side ControlAirSystem Configuration (TopView)

Key

3/8" O. D.NylonTubing

3/8" O. D.NylonTubing (Alt. 1/2" O. D.)

3/8" I. D.Hose

Gladhand

Service (Control) Line

Front

Gladhand

Supply Line

TEV or STEV

Spring Brake Control

Top View

Road Side

FIGURE 25 - Typical 4S-2M Side Control ABS Electrical and Air System (Top View)

Service Brake Chamber

ABS

ECU

Relay

Valve

Res. Res.

B

Relay ValveA

Emergency Brake Chamber

20

Page 21

4S-2MAxle Control ElectricalConfiguration (TopView)

J560 Connector

Power Cable

Diagnostic Port

Wheel Sensor

Speed Sensor

Front

WarningLampConnector

Warning

Light Side

ECU Side

Trailer

Side

Parts List

Description Quantity

ECU/Relay Valve 1

StandAloneRelayValve 1

Sensor/Diagnostic Cable 1

Valve/PowerCable 1

Sensors — 0.4mCable 4

Sensor Friction Sleeve 4

LiftAxle

(Gen-4 Only)

Top View

Harness Side

Road Side

Sensor C

Stand

Alone

Relay

ValveB

ECU

Side

Wheel

Side

Sensor D

Sensor B

SensorA

ABS WarningLampECU

Relay

ValveA

ABS

4S-2MAxle Control Air System Configuration (TopView)

LiftAxle

(Gen-4 Only)

Gladhand

Service (Control) Line

Front

Gladhand

Top View

Supply Line

Service Brake Chamber

Road Side

ABS Relay B

(No ECU)

Key

3/8" O. D.NylonTubing

3/8" O. D.NylonTubing (Alt. 1/2" O. D.)

3/8" I. D.Hose

ABS

Res. Res. Res.

Emergency Brake Chamber

Relay

A

TEV or STEV

Spring Brake Control

FIGURE 26 - Typical 4S-2M Axle Control ABS Electrical and Air System (Tank Mount Shown) (Top View)

21

Page 22

End-Of-Line Diagnostics

Automatic System Configuration:

The Bendix® A-18™ trailer ABS system automatically

configures itself to any valid ABS system installed on the

trailer. The automatic configuration process occurs each

time the system receives power at the permanent power

input. In most cases this ECU input is connected to the

SAE J560 connector AUX connection. During the automatic

configuration process, the ECU will only configure upwards.

That is, it will add but not subtract components from its

configuration.

The configuration can be checked by using the hand held

diagnostic tool or by activating the blink code as described

in the “End-of-Line Checkout Procedure” listed below.

Compare the two part blink code with the chart. Part 1 of

the blink code is the current system configuration.

Use of Hand Held Tool for Configuration

The system always configures upwards depending on the

components which are found connected to it. If a lower

configuration is desired, a hand held tester must be used

to reconfigure the system.

End-of-Line Checkout Procedure (Basic):

Note: It is not possible to miswire the components on a

2S/1M (Basic) system. Therefore, the checkout procedure

does not require the use of a hand-held tester.

1. Apply power to ECU (do not use a battery charger as a

power source).

2. Verify that the ABS warning light turns OFF and remains

OFF after the bulb test.

Note: If there was a past speed sensor fault in the

system, the warning light will not turn OFF until the trailer

has been operated at a speed sufficiently high to be read

at the ECU, typically 3 to 5 mph.

End-of-Line Checkout Procedure (Standard):

Note: For 2S/1M systems, it is not possible to miswire

the components. Therefore it is only necessary to perform

step 6 of the end-of-line checkout.

1. Apply power to ECU (do not use a battery charger as a

power source).

2. Remove the weather cap from the trailer

diagnostic port.

3. Connect either a hand-held tester with a Bendix

Diagnostic Card or a PC Based Diagnostic system with

ServiceRanger’s End-of-Line Software Package to the

trailer diagnostic port.

4. Follow the appropriate menu selections to verify:

a. That the sensors and valves are connected in their

proper locations.

b. That the proper system configuration has been

obtained.

c. That there are no faults. If necessary, clear historic

faults.

5. After completion of the End-of-Line checkout procedure,

disconnect the tool or PC from the trailer diagnostic

port.

6. Verify that the ABS warning light turns off and remains

off after the bulb test. If there was a past speed sensor

fault in the system, the warning light will not turn off

until the trailer has been operated at a speed sufficiently

high to be read at the ECU, typically 3 to 5 mph.

22

Page 23

ABS Component

ECU Deutsch DT (Deutsch) Socket (Deutsch) W12S-P012 (Deutsch) 114017(Deutsch)

Harness Connector

Shell

DT06 12SA-BK01 (Grey) 0462-201-16141

DT06 12SB-BK01 (Black)

DT06 12SC-B016 (Green)

Harness Terminal Wire Seal Lock Plug

N/A

Relay Valve Bayonett Socket(Amp) Seal (Amp)

26570 14414-627-626

N/A N/A

Wheel End Sensor

MPSI ScanTool Diagnostic Port(Deutsch) Pin (Deutsch) 114017(Deutsch)

WarningLight

2-Pin Kostal

w/overmold

Length Eaton PartNo.

2 meters 300090

3 meters 300091

5 meters 300092

8 meters 300093

HD10-6-12P 0460-204-12141

N/A N/A

N/A N/A

N/A N/A

ABS

Power Cable (Packard) Socket (Packard) Seal (Packard) 12010300 (Packard)

ECU Side 12124580 12015323

12034342 12010293

N/A

Power Cable (Packard) Pin (Packard) Seal (Packard) 12010300 (Packard)

TrailerHarnessSide 12124582 12015323

12065158 12010293

N/A

FIGURE 27 - ABS Parts Identification Chart

N/A N/A N/A

N/A

N/A

N/A

23

Page 24

Troubleshooting and Fault Codes

An important feature of the Bendix® A-18™ trailer ABS

system is the diagnostics that are reported via the Electronic

Control Unit. This section describes how to use error codes

to identify ABS system operating problems.

There are three ways to retrieve and display trailer ABS

fault codes:

• ServiceRanger PC software: Displays configuration

information and fault codes on the PC monitor. Refer

to the ServiceRanger PC software information later in

this section.

Cycle ignition key

OFF to ON

ObserveABS

warning light operation

• Automatic retrieval via a hand-held tester: Displays

fault codes on the hand-held tester’s display. Refer to

the hand-held tester information later in this section to

retrieve and display fault codes. The low-cost diagnostic

cable provided with the 2S/1M system does not

accommodate the hand held tester.

• Manual blink code diagnostics: Flashes the codes

on the ABS indicator lamp. Refer to the blink codes in

this section.

Before the ABS system can be properly diagnosed and

repaired, the foundation brake system must be eliminated

as a possible cause of the problem. Follow the

troubleshooting chart in Figure 28 to isolate and identify

the brake problem.

Light turns OFFafter

2 second lampcheck

ABS system notreporting

faults–perform traditional

foundation brake

troubleshooting and repair

Activate blink codes

with jumper method

Check ECU configuration

Warninglight

blinking when activated

with jumper method?

NO

Check power circuit

for ECU

Light stays ON

Select Eaton ABS diagnostictool

Use Service Ranger

diagnostic software

(standard ECU only)

Does tester

communicate with

ECU?

YES

Check ECU configuration

Does configuration

information agree

YES

with available

hardware?

YES

Read fault codesand descriptions

Takecorrective action

Clear active andinactive faultcodes

Light never ON

Check for powerto ABSECU.

Check warning lightand wiring

Use MPSI

ProLink tool

(standard ECU only)

NO

NO

Check J1587 datalink wiring

Reconfigure ECU

Reconfigure ECU

FIGURE 28 - Brake System Troubleshooting Chart

24

Recheck fault codesafter clearing.

If warning lightremains litor

17-12 fault codeis set,

drive vehicle toclear andturn off

warning light.

Page 25

Test Equipment

Eaton recommends the use of the following products to

troubleshoot the ABS system:

• A multimeter or digit al volt-ohmmeter (DVOM).

• Eaton ServiceRanger PC software or an MPSI ProLink

hand-held tester.

This section covers the use of test tools and equipment to

find and correct system problems.

Hand-Held Tester

The hand-held tester employs menu-driven tests for reading

ABS fault codes. See the documentation provided with

the tool for more information.

An MPSI hand-held tester with Bendix proprietary cartridge

can be used to read and clear error codes and obtain a

EatonABS

Press Enter

short description of failures. The tester can initiate valve

test sequences and can also read system parameters

(example: wheel speeds).

Note: The hand-held tester activates output tests for all

output devices. Since these tests can affect operation of

®

the vehicle’s braking system, the test units incorporate

special safety protection. At least one axle must show zero

speed or the test will be halted.

A standard heavy duty truck cartridge may also be used,

but cannot initiate test sequences.

Figure 29 shows hand-held tester menu option.

Multimeter

Schematics, error codes, and a multimeter can be used to

check sensor and solenoid resistances and to find wiring

harness defects.

1. SystemINFO

Part No.

Date

Serial No.

Software No.

System Configuration

2. FaultCodes

Read FaultCodes

Clear FaultsCodes

3. MonitorData

Wheel Speeds

Cut OutSpeeds

System Volts

TravelDistance

FIGURE 29 - Hand-Held Tester Operation Procedures

1. System INFO

2. Fault Codes

3. Monitor Data

4. Component Test

5. System Set-up

6. English/Metric

7. Exit

4. ComponentTest

ValveRoutines

WL, Trailer

WL, Cab(optional)

5. SystemSetup

System Config

6. English/Metric

7. Exit

25

Page 26

ServiceRanger PC Software

ServiceRanger PC software can be used to read and clear

error codes and obtain a short description of failures. The

software can initiate test sequences for controller outputs

and can also read system data such as voltage at the ECU,

wheel speeds and cutout speeds.

Deutsch HD-10

Connector

Serial Communication

Laptop PC

Interface

PCINTERFACE

CAUTION: ServiceRanger PC software can activate output

tests for all output devices. Since these tests can affect

operation of the vehicle braking system, the ECU

incorporates special safety protection. One axle must show

zero speed or the test will be halted.

To Diagnostic

Connector

ServiceRanger

Software CD

1. MonitorData

Wheel Speeds

Cut-Out Speeds

Input Voltages

Switch States

FIGURE 30 - ServiceRanger Menus & Hardware Setup

2. RetrieveFault Codes

Retrieve FaultCodes

Clear FaultCodes

ServiceRanger MainMenu Options

1. MonitorData

2. RetrieveFault Codes

3.Advanced Product Functions

4. ProductDownloads

3. Adv.Prod. Functions

TestValves

TestLights

4. ProductDownloads

Read ECUConfiguration

Configure ECU

26

Page 27

Troubleshooting Procedures

ABS Valve Troubleshooting

Follow the steps listed below to locate and correct ABS

modulator valve problems.

1. Access active fault code(s) using the blink code

procedure, the hand-held tester or ServiceRanger

software.

2. Lookup the code description, the possible causes and

the repair procedures provided in this section.

3. Perform the recommended repair procedures.

4. After the repairs are completed, clear all codes and

check for any additional codes.

6

12111210394857

X2 Black

Coding B

STANDARD

Harness Connector Pin Circuit Description

X1 Grey(CodingA) 1 ValveB,Hold

X1 Grey(CodingA) 2 ValveB,Com.

X1 Grey(CodingA) 3 ValveA, Com.

X1 Grey(CodingA) 4 ValveA, Hold

X1 Grey(CodingA) 10 ValveA,Rel.

X1 Grey(CodingA) 12 Valve B, Rel.

FIGURE 31 - ABS Valve Pin Identification

6

X1 Grey

CodingA

No

Connection

Common

6

12111210394857

X1 Green

Coding C

12111210394857

BASIC

Harness Connector Pin Circuit Description

X1 Green(CodingC) 3 Valve A, Com.

X1 Green(CodingC) 4 Valve A, Hold

X1 Green(CodingC) 10 ValveA, Rel.

Release

Measure

1

32

Hold

From:

Pin 2 Pin 1 3-8 Ohms

Pin 2 Pin 3

Measure

To:

Pin 1 Pin 3

Resistance

Range:

3-8 Ohms

6-16 Ohms

Looking Into Valve

Valve Resist ance Test

Measure resistance at the ABS valve location to check the solenoid.

Measure resistance at the appropriate ECU harness connector pins to check the cable and valve.

Note: Refer to the chart for pin identification.

FIGURE 32 - Valve Pin Identification and Resistance Chart

27

Page 28

Speed Sensor Troubleshooting

Follow the steps listed below to locate and correct sensorrelated ABS diagnostic trouble codes.

1. Access active diagnostic trouble code(s) using the blink

code procedure, the hand-held tester or ServiceRanger

software.

2. Look up the code description, the possible causes and

the repair procedures provided in this section.

3. Perform the recommended repair procedures.

4. After the repairs are completed, clear all codes and

check for any additional codes.

Note: Drive the vehicle. The indicator lamp will remain

on until proper sensor output is detected, even though the

diagnostic trouble code has been cleared.

Speed Sensor Resisitance Test

The correct resistance for the

speed sensor circuit is between

1500 ohms and 2500 Ohms.

Measure resistance at the wheel

location to check the speed sensor.

Measure resistance at the

appropriate ECU harness

connector pins to check the cable

and speed sensor.

Note: Refer to the chart for pin

identification.

FIGURE 33 - Typical Wheel Speed Sensor Circuit

6

12111210394857

X2 Black

Coding B

STANDARD

Harness Connector Pin Circuit Description

X2 Black (Coding B) 3 Sensor A-

X2 Black (Coding B) 4 Sensor A+

X2 Black (Coding B) 5 Sensor B-

X2 Black (Coding B) 6 Sensor B+

X2 Black (Coding B) 7 Sensor C-

X2 Black (Coding B) 8 Sensor C+

X2 Black (Coding B) 9 Sensor D-

X2 Black (Coding B) 10 Sensor D+

FIGURE 34 - Sensor Pin Identification

6

X1 Grey

Coding A

6

12111210394857

X1 Green

Coding C

12111210394857

BASIC

Harness Connector Pin Circuit Description

X1 Green (Coding C) 1 Sensor A+

X1 Green (Coding C) 2 Sensor A-

X1 Green (Coding C) 11 Sensor B-

X1 Green (Coding C) 12 Sensor B+

28

Page 29

Accessing Codes

The ABS W arning Lamp output s a two-part blink code. To

interpret the blink code, record the number of flashes in

each part and compare with the Gen-4

™

or Gen-5™ ABS

charts.

On Gen-4

™

ABS systems, the first p art of the flash sequence

indicates the configuration, while the second part of the flash

sequence indicates any fault codes that exist.

Example: A blink code of three flashes, a pause, then three

more flashes (3-3) indicates a 4S-2M side control

configuration with a fault on Sensor B.

B

F

A

E

D

Short Terminals Aand E andRelease

toAccess the Configuration Code

C

On Gen-5

™

ABS systems, both the configuration codes and

the fault codes are reported separately as two-part blink

codes. There are different procedures for retrieving

configuration and fault codes. Refer to the retrieving codes

section of this manual.

Example: A blink code of one flash, a pause, then one

more flash (1-1) indicates a 2S-1M system configuration

when retrieving configuration codes. However, 1-1 indicates

No Trouble Found when retrieving fault codes.

Retrieving Configuration Codes Live Feed

™

(Gen-5

ABS PLC Capable ECUs)

1. Turn ignition key ON.

2. Use appropriate jumper method. Apply the jumper for

2 seconds and remove.

3. Immediately apply the jumper again for 2 seconds and

remove.

4. Record the 2-digit blink code as it is flashed on the

external trailer warning light.

Retrieving Configuration Codes (Gen-4™ ABS)

1. Turn ignition key ON.

2. Use appropriate jumper method. Apply the jumper for

2 seconds and remove.

3. Two-digit blink codes are retrieved and displayed.

CONFIGURATION CODES

Gen-5

Blink Code

1st 2nd

1

1

2

1

3

1

4

1

Configuration

2S-1M

2S-2M

4S-2M Side Control

4S-2MAxleControl

Gen-4

Blink Code Configuration

1 2S-1M

2 2S-2M

3 4S-2M Side to Side

4 4S-2MAxletoAxle

FIGURE 35 - Accessing Trailer ABS Configuration Codes

29

Page 30

Fault Code Charts

Fault codes can be retrieved as two-digit blink codes. Refer

to Figures 37 and 38 for a description of these codes.

Blink codes are retrieved by jumping pins A and E on

St andard Systems and jumping the diagnostic bullet to the

frame on basic systems. The jumping method can also be

used to clear codes. To perform the activities listed below,

follow the steps exactly as given. If you make a mistake

during one of the steps, stop and start over at the beginning

of the procedure.

Note: When using the jumping method for a designated

amount of time to retrieve blink codes, use a method such

as counting—one thousand one, one thousand two. This

will allow more accurate fault code retrieval and reduce the

possibility of misreading blink code information.

Before attempting any repairs, first retrieve the fault codes

and write them down. Next, clear the fault codes. Then

once again retrieve the fault codes. Only active codes will

now be displayed.

Retrieving Fault Codes Live Feed

™

(Gen-5

1. Turn ignition key ON.

2. Use appropriate jumper method. Apply the jumper for

3. Record the 2-digit blink codes as they are flashed on

ABS PLC Capable ECUs)

2 seconds and remove.

the external trailer warning lamp.

Retrieving Fault Codes (Gen-4™ ABS)

1. Turn ignition key ON.

2. Use appropriate jumper method. Apply the jumper for

2 seconds and remove.

3. Two-digit blink codes are retrieved and displayed.

Clearing Fault Codes

1. With the power OFF, use the appropriate jumping

method.

2. Turn the power ON while continuing to apply the jumper.

• Wait at least 3 seconds and remove the jumper.

• Blink fault codes are cleared.

• Repeat the “Retrieving Fault Codes” procedure to

verify that fault codes are cleared.

• Active fault codes will be re-established until

corrected action has been taken.

BASIC SYSTEM STANDARD SYSTEM

ABS

ECU

ABS

Wiring Harness

Jumper

With ignitionON,jumpthe diagnostic

plug tochassisgroundfor 2 seconds

to activatetheblinkcodes on theABS

warning light.

Trailer

Frame

FIGURE 36 - Jumper Method of Accessing Blink Codes

Jump PinsAand E

and Release

To Access

Blink Codes

30

Page 31

Check sensor resistance (1500-2500 ohms).

FIGURE 37 - Gen 4™ ABS Diagnostic Trouble Code Chart

31

Page 32

Blink Code

1st 2nd

1

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

5

5

8

8

8

8

8

8

8

8

9

9

9

9

9

9

9

9

10

10

10

10

11

15

all

16

16

17

10

17

12

Description Location

1

No trouble found.

1

Sensor air gap too large.

2

Sensor air gap too large or sensor shorted.

3

Noisy signal, check tone ring.

4

Excessive wheel lock.

5

Intermittent sensor signal.

6

Sensor shorted or open.

1

Sensor air gap too large.

2

Sensor air gap too large or sensor shorted.

3

Noisy signal, check tone ring.

4

Excessive wheel lock.

5

Intermittent sensor signal.

6

Sensor shorted or open.

1

Sensor air gap too large.

2

Sensor air gap too large or sensor shorted.

3

Noisy signal, check tone ring.

4

Excessive wheel lock.

5

Intermittent sensor signal.

6

Sensor shorted or open.

1

Sensor air gap too large.

2

Sensor air gap too large or sensor shorted.

3

Noisy signal, check tone ring.

4

Excessive wheel lock.

5

Intermittent sensor signal.

6

Sensor shorted or open.

1

Short circuit from the release solenoid to voltage.

2

Short circuit from the release solenoid to ground.

3

Open circuit at the release solenoid.

4

Open circuit on the common line to the valve.

5

Short circuit from the hold solenoid to voltage.

6

Short circuit from the hold solenoid to ground.

7

Open circuit at the hold solenoid.

8

System configuration is incorrect.

1

Short circuit from the release solenoid to voltage.

2

Short circuit from the release solenoid to ground.

3

Open circuit at the release solenoid.

4

Open circuit on the common line to the valve.

5

Short circuit from the hold solenoid to voltage.

6

Short circuit from the hold solenoid to ground.

7

Open circuit at the hold solenoid.

8

System configuration is incorrect.

9

Common side of valve(s) - stray voltage detected.

Common side of valve(s) shorted high.

Common side of valve(s) shorted to ground.

ECU internal error.

1

Over voltage on ECU power line.

2

Low voltage on ECU power line.

Warninglightshorted high or J1587+ shorted to ground.

Sensor signal check required. Pull trailer or turn wheels one after the other.

SensorA

Sensor B

Sensor C

Sensor D

ValveA

ValveB

Valve(s)

ECU

ECU Power Line

WarningLightor J1587+

Sensors

FIGURE 38 - Gen-5™ ABS Fault Code Chart

32

Page 33

Cover Lock

ECU Cover

STANDARD SYSTEM

Top–Looking into Harness Connector

4

5

6

SS

SS

SS

B+

7

SS

C-

A+

B-

9

8

SS

SS

C+

D-

11

1587

1

2

V

GND

DIA

DIA

12

1587

+

-

V

ECU

BL

GND

DIAGV

HLD

A

ECU

WL

T+

123456

B

CMNCMN

HLD

A

A

B

1110987

12

T-

WLREL

REL

B

3

SS

A-

10

SS

D+

ECU

Connector

Pin#

1

2

3

4

5

6

7

8

9

10

11

12

Cable

Guides

Ref. Description

GND

DIA

Diagnostic Port Ground

VDIA

SSA-

SSA+

SSB-

SSB+

SSC-

SSC+

SSD-

SSD+

1587+

1587-

Diagnostic Port Power (12V)

Speed SensorA,Negative

Speed SensorA,Positive

Speed Sensor B, Negative

Speed Sensor B, Positive

Speed Sensor C, Negative

Speed Sensor C, Positive

Speed Sensor D, Negative

Speed Sensor D, Positive

Diagnostic Link, Positive

Diagnostic Link, Negative

Alignment

Tabs

X2-CODING B

(BLACK)

Pin#

HLD

1

2

CMNB

3

CMNA

4

HLDA

5

GNDECU

VECU

6

7

8

9

WLT+

10

REL

11

RELB

12

BASIC SYSTEM

Ref. Description

B

ValveB,HoldSolenoid

ValveB,Common

ValveA, Common

ValveA, Hold Solenoid

ECU Ground

ECU Continuous Power (with Ignition ON)

VBL

NCC

Brake Light Power (Secondary Power Source)

No Connection

WarningLightPower,Trailer Mounted

ValveA, Release Solenoid

A

NC

No Connection

ValveB,ReleaseSolenoid

X1-CODINGA

(GREY)

Cover Lock

ECU

Connector

SS

1

2

CMNA

3

4

HLDA

GNDECU

5

VECU

6

A+

SSA-

Cable

Guides

Speed SensorA,Positive

Speed SensorA,Negative

ValveA, Common

ValveA, Hold Solenoid

ECU Ground

ECU Continuous Power (with Ignition ON)

FIGURE 39 - ECU Pin Identification Chart

ECU Cover

Alignment

Tabs

Pin#Pin#

7

8

9

10

11

12

Top–Looking into Harness Connector

X1-CODING C

(GREEN)

Ref. DescriptionRef. Description

VBL

WLT+

DIAGC

REL

SSB-

SSB+

Brake Light Power (Secondary Power Source)

WarningLightPower,Trailer Mounted

Diagnostic Plug

A

ValveA, Release Solenoid

Speed Sensor B, Negative

Speed Sensor B, Positive

3

4

5

6

CMN

HLD

GND

V

ECU

7

V

BL

A

ECU

8

WL

T+

DIAG

A

10

9

REL

A

1

2

SS

SS

A-

A+

12

11

SS

SS

B-

B+

33

Page 34

White (Ground)

Top–Looking into Harness

Red

(Brake Light Power)

Blue (Switched 12V

Constant Power From

Tractor)

Wheel Side

ECU Side

5

GND

4

HLD

A

ECU

8

9

DIAG

WL

T+

6

V

ECU

7

V

BL

CMN

REL

2

3

A

10

A

1

SS

SS

A-

A+

11

12

SS

SS

B-

B+

X1-CODING C (GREEN)

ECU

+

Warning

Light Side

Power

ECU Side

Front

Cable

Harness Side

Trailer

Side

A

D

B

E

C

A–Brake Light

B–Perm. Power

C–Not Used

D–WarningLamp

E–Ground

Diagnostic Port

(Shown with

Extension)

Top View

Road Side

No Connection

Common

Release

1

23

Hold

Looking Into Valve

FIGURE 40 - 2S-1M Electrical Connections

34

Page 35

White (Ground)

Top–Looking into Harness

Red

(Brake Light Power)

Blue (Switched 12V

Constant Power From

Tractor)

Wheel Side

ECU Side

4

5

6

SS

SS

SS

B+

7

SS

C-

A+

B-

9

8

SS

SS

C+

D-

2

1587

1

V

GND

DIA

DIA

11

12

1587

+

-

V

ECU

BL

DIAGV

GND

HLD

A

ECU

WL

T+

123456

CMNCMN

HLD

B

A

A

B

121110987

WLREL

REL

T-

B

3

SS

A-

10

SS

D+

X1-CODINGA(GREY)X2-CODING B (BLACK)

ECU

+

Warning

Light Side

Power

Cable

ECU Side

Front

Harness Side

Trailer

Side

A

D

B

E

C

A–Brake Light

B–Perm. Power

C–Not Used

D–WarningLamp

E–Ground

F

A

E

D

Top View

A–SAE J1587+

B–SAE J1587–

B

C–+12 Volts

D–Not Used

C

E–Ground

F–Not Used

Road Side

No

Connection

Common

Looking Into Valve

Release

1

23

Hold

FIGURE 41 - 2S-2M Electrical Connections

35

Page 36

White (Ground)

Top–Looking into Harness

Red

(Brake Light Power)

Blue (Switched 12V

Constant Power From

Tractor)

Wheel Side

ECU Side

4

5

6

SS

SS

SS

B-

B+

7

SS

C-

9

8

SS

SS

C+

2

1587

1

HLD

GND

V

GND

DIA

DIA

11

12

1587

+

-

V

ECU

BL

A

ECU

WL

DIAGV

T+

3

SS

A+

A-

10

SS

D+

D-

123456

CMNCMN

HLD

B

A

A

B

121110987

WLREL

REL

T-

B

X1-CODINGA(GREY)X2-CODING B (BLACK)

ECU

+

Warning

Light Side

Power

Cable

ECU Side

Front

Harness Side

Trailer

Side

A

D

B

E

C

A–Brake Light

B–Perm. Power

C–Not Used

D–WarningLamp

E–Ground

Top View

Road Side

B

F

A

C

E

D

A–SAE J1587+

B–SAE J1587–

C–+12 Volts

D–Not Used

E–Ground

F–Not Used

No

Connection

Common

Release

1

32

Hold

Looking Into Valve

FIGURE 42 - 4S-2M Side Control and Axle Control Electrical Connections

36

Page 37

FIGURE 43 - Electrical Schematic

37

Page 38

Glossary

ABS — Antilock Brake System. A control system that maintains

wheel slip at a level that minimizes stopping distance while

maintaining lateral stability to the extent possible.

Air Gap — Distance between the sensor pole piece and tone

ring.

Anti-Compounding — A method to prevent the application of

the service brakes and spring brakes at the same time to prevent

excessive stress on brake components.

Apply Timing — The time from the first movement of the service

brake control for the brake chamber to reach 60 PSI beginning

with an initial service reservoir pressure of 100 PSI.

Channel — A controlled wheel site.

CAN — Controller Area Network.

Clear Codes — Method for erasing historical faults from the ECU,

using either the diagnostic switch input or a hand-held diagnostic

tool. (Only repaired faults may be cleared).

Coefficient of Friction: — The horizontal force required to move

a body (on a relatively smooth level surface) divided by the weight

of the body.

Configuration — Process of identifying a “normal” set of sensors

and modulators for the Electronic Control Unit, so that it can

identify future missing sensors and modulators.

Crack Pressure — The ascending input pressure or input force

to an air valve required to initiate output pressure of flow.

Diagnostic Connector — Deutsch HD-10 Series connector used

for interface to hand-held testers or PC based diagnostic

equipment based on the J1587 protocol. The tester can initiate

test sequences, and can also read system parameters.

Directly Controlled Wheel — A wheel that is sensed to be

slipping, and is adjusted to correct for that slip.

ECU — Electronic Control Unit.

FMVSS-121 — Federal Motor Vehicle Safety Standard that

regulates air brake systems.

Friction Sleeve — A beryllium copper sleeve which has fingers

cut into it. It is pressed between an ABS sensor and mounting

hole to hold the sensor in place.

Full-Treadle Brake Application — A brake application in which

the treadle valve pressure in any of the valve’s output circuits

reaches 100 psi within 0.2 seconds after the application is

initiated.

Independently Controlled Wheel — Directly controlled wheel