MP-4000 TH Programmer's Manual

Rev.1.4

August 2007

(First edition: November 2006)

Copyright© by Bematech S.A, Curitiba-PR, Brazil. All rights reserved.

No part of this publication may be copied, reproduced, adapted or translated without the prior

written permission of Bematech S.A., except when allowed by patent rights.

Information in this publication is purely informative, subjected to change without notice and no

liability is assumed with respect to its use. However, as product improvements become

available, Bematech S.A. will make every effort to provide updated information for the

products described in this publication. The latest version of this manual can be obtained

through Bematech website:

www.bematech.com

Notwithstanding the other exceptions contained in this Manual, the consequences and

responsibility are assumed by the Purchaser of this product or third parties as a result of: (a)

intentional use for any improper, unintended or unauthorized applications of this product,

including any particular purpose; (b) unauthorized modifications, repairs, or alterations to this

product; (c) use of the product without complying with Bematech S.A. operating and

maintenance instructions; (d) use of the product as component in systems or other

applications in which the failure of this could create a situation where personal injury or

material damages may occur. In the events described above, Bematech S.A. and its officers,

administrators, employees, subsidiaries, affiliates and dealers shall not be held responsible or

respond by any claim, costs, damages, losses, expenses and any other direct or indirect injury,

as well as claims which alleges that Bematech S.A. was negligent regarding the design or

manufacture of the product.

Bematech S.A. shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as original Bematech

products or approved products by Bematech S.A.

Any product names or its logotypes mentioned in this publication may be trademarks of its

respective owners and shall be here recognized.

Product warranties are only the ones expressly mentioned in the Quick Start. Bematech S.A.

disclaims any and all implied warranties for the product, including but not limited to implied

warranties of merchantability or fitness for a particular purpose. In addition, Bematech S.A.

shall not be responsible or liable for any special, incidental or consequential damages or lost

profits or savings arising from the use of the product by the Purchaser, the User or third

parties.

Summary

INTRODUCTION .................................................................................................................5

DEVELOPERS ADVICE......................................................................................................5

1 COMMANDS ....................................................................................................................6

1.1 Direct command.........................................................................................................................6

1.2 Control sequence........................................................................................................................6

2 USING THE COMMAND SUMMARY............................................................................... 7

2.1 ESC/Bema Command Table......................................................................................................7

2.2 ESC/POS Command Table......................................................................................................11

3. ESC/BEMA COMMANDS .............................................................................................14

3.1 Operation Commands ..............................................................................................................14

3.2 Vertical positioning..................................................................................................................22

3.3 Horizontal positioning..............................................................................................................25

3.4 Character Types .......................................................................................................................27

3.5 Print width, character width and height...................................................................................31

3.6 Bit images and graphics...........................................................................................................35

3.6.1 24-bit graphics .............................................................................................................35

3.6.2 8-bit graphics ...............................................................................................................35

3.7 Communication........................................................................................................................42

3.7.1 Serial interface status byte ............................................................................................42

3.7.2 Serial / USB / EPP interface advanced status bytes......................................................43

3.7.3 Standard parallel interface status byte ..........................................................................44

3.8 Data Control.............................................................................................................................46

3.9 Barcodes...................................................................................................................................47

4. ESC/POS COMMANDS ................................................................................................57

4.1 Operation Commands ..............................................................................................................57

4.2 Vertical positioning..................................................................................................................63

4.3 Horizontal positioning..............................................................................................................66

4.4 Character types.........................................................................................................................68

4.5. Communication.......................................................................................................................70

4.6. Data Control............................................................................................................................76

4.7. Barcodes..................................................................................................................................76

4.8. Bit images and graphics..........................................................................................................76

APPENDIX I – TABLES....................................................................................................77

Table 1 - Characters Per Line ........................................................................................................77

Table 2 - Paper Width....................................................................................................................77

APPENDIX II – CHARACTER TABLES............................................................................78

ASCII.............................................................................................................................................78

Code Page 437 ...............................................................................................................................78

Code Page 850 ...............................................................................................................................79

Code Page 858 ...............................................................................................................................80

Code Page 860 ...............................................................................................................................81

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Code Page 866 ...............................................................................................................................82

APPENDIX III - TRANSMISSION STATUS IDENTIFICATION.........................................83

22-aug-2007

Firmware Release: 1.5

4

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Introduction

The objective of this manual is to give to programmers all necessary information to properly

program and integrate the MP-4000 TH printer into a system. The MP-4000 TH printer is able

to interpret ESC/Bema commands and ESC/POS

For further information refer to the documentation below available in our website:

® 1

commands.

www.bematech.com

User’s Manual – Contains information referring to operation, features and specifications of

the MP-4000 TH printer.

Service Manual – Contains information necessary to identify and resolve MP-4000 TH printer

problems.

Developers advice

Beside this manual, the drivers and API (and all their documentation) listed below are available

from our website (http://www.bematech.com

• Windows 2000/XP/Vista-32 – API dynamic-link library driver (mp2032.dll); recent

spooler drivers (BemaSetupXXxX.exe); parallel port driver and USB port driver;

software for testing purposes.

• Windows 9x/ME/NT4 - API dynamic-link library driver (mp2032.dll); old and

unsupported spooler drivers (BemaSetupXXxX.exe);

• Linux (x86) - CUPS

implementantion of mp2320 library as a shared object (mp2032.so);

1 ESC/POS® is registered trademark of Seiko Epson Corporation.

TM

spooler drivers compatible with Redhat 8.0; partial

22-aug-2007

Firmware Release: 1.5

):

5

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

1 Commands

The MP-4000 TH printer has a series of programming commands that may be used in the

remote mode. Two types of commands can be sent:

1.1 Direct command

In this mode, a simple ASCII code is enough to command the printer. For example:

ASCII CODE : LF

DECIMAL : 10

HEXADECIMAL : 0A

This command causes the printer to perform a line feed.

1.2 Control sequence

In this mode, more than one code may be sent to command or program the printer.

This “control sequence” always starts with the ASCII code “ESC”, “FS” or “GS”. For example:

ASCII CODE : ESC W 1

DECIMAL : 27 87 01

HEXADECIMAL : 1B 57 01

This command switches the printing mode to “expanded”.

Following is a summary of all commands accepted by the MP-4000 TH printer.

22-aug-2007

Firmware Release: 1.5

6

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

2 Using the command summary

The following section lists and describes all resident commands including command

parameters. The command syntax is as follows:

•ESC P is a command without parameters;

•ESC Q n is a command with one parameter only;

•ESC K n1 n2 is a command with two parameters;

•ESC D n1...nk is a command with a variable number of parameters.

A character ‘h’ following an alphanumeric string represents an hexadecimal number. A

number with no ‘h’ following it is in decimal mode. An italic item is a parameter to the escape

function.

Note: MP-4000 TH printer is capable of interpreting ESC/Bema commands and

ESC/POS commands.

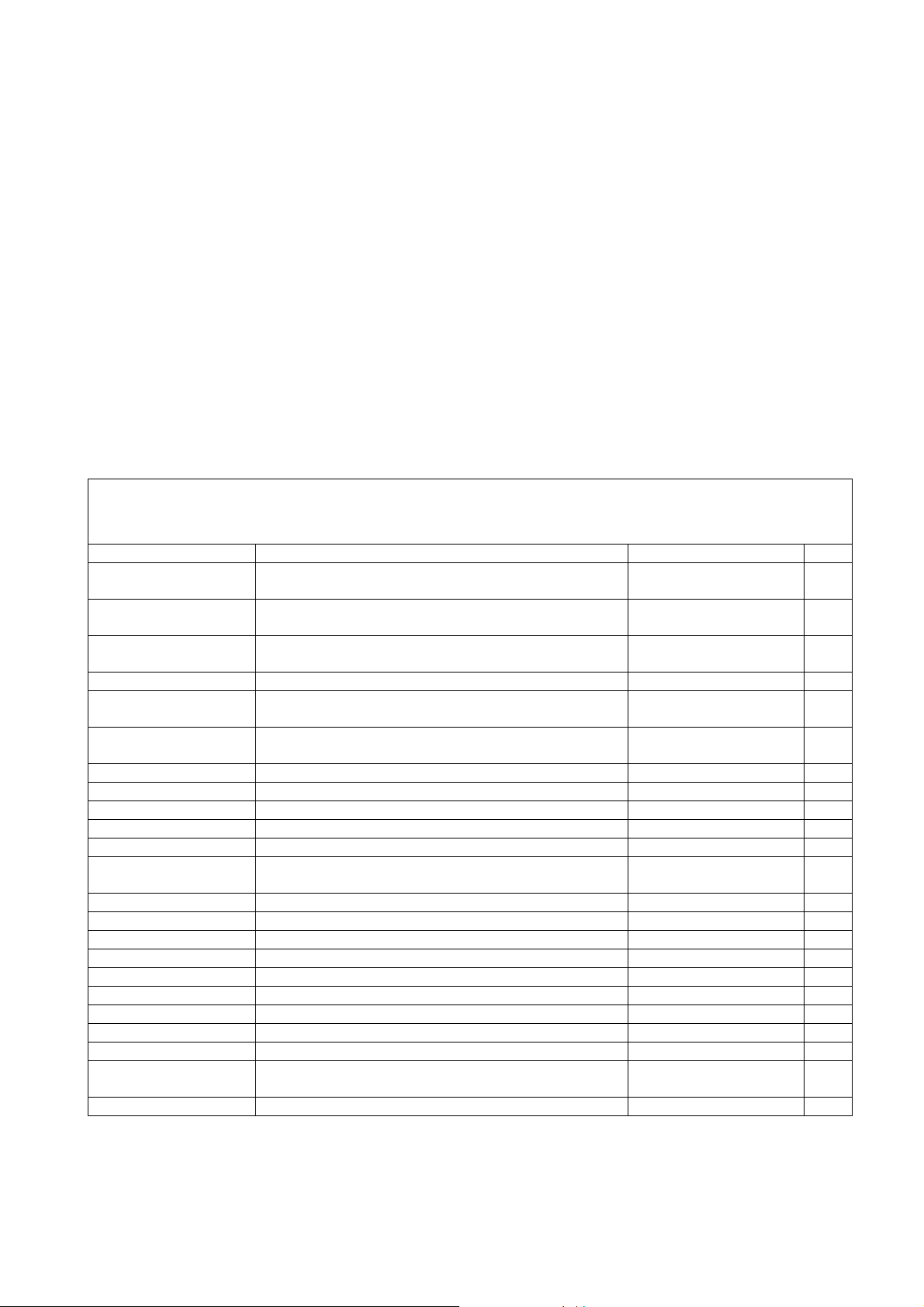

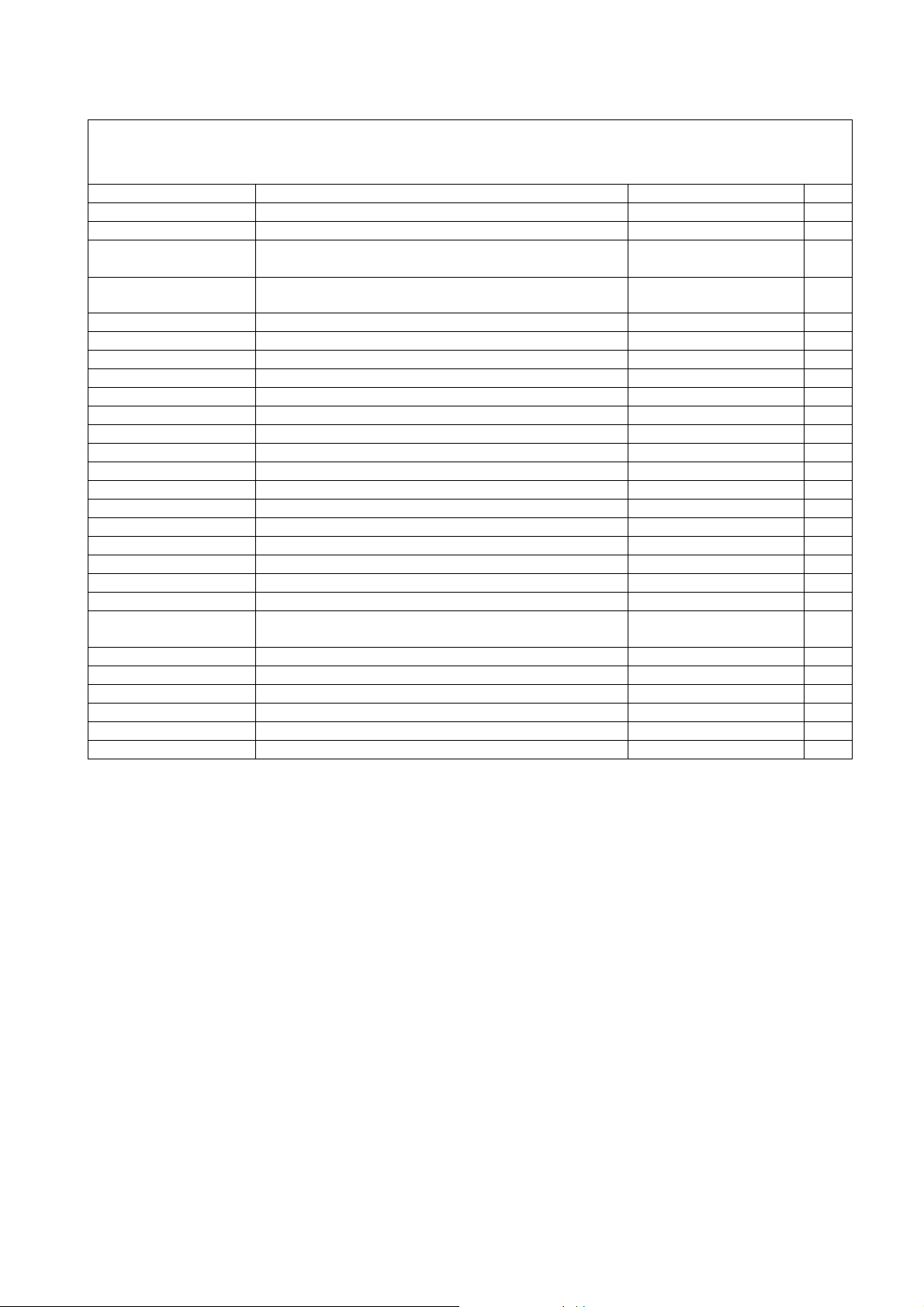

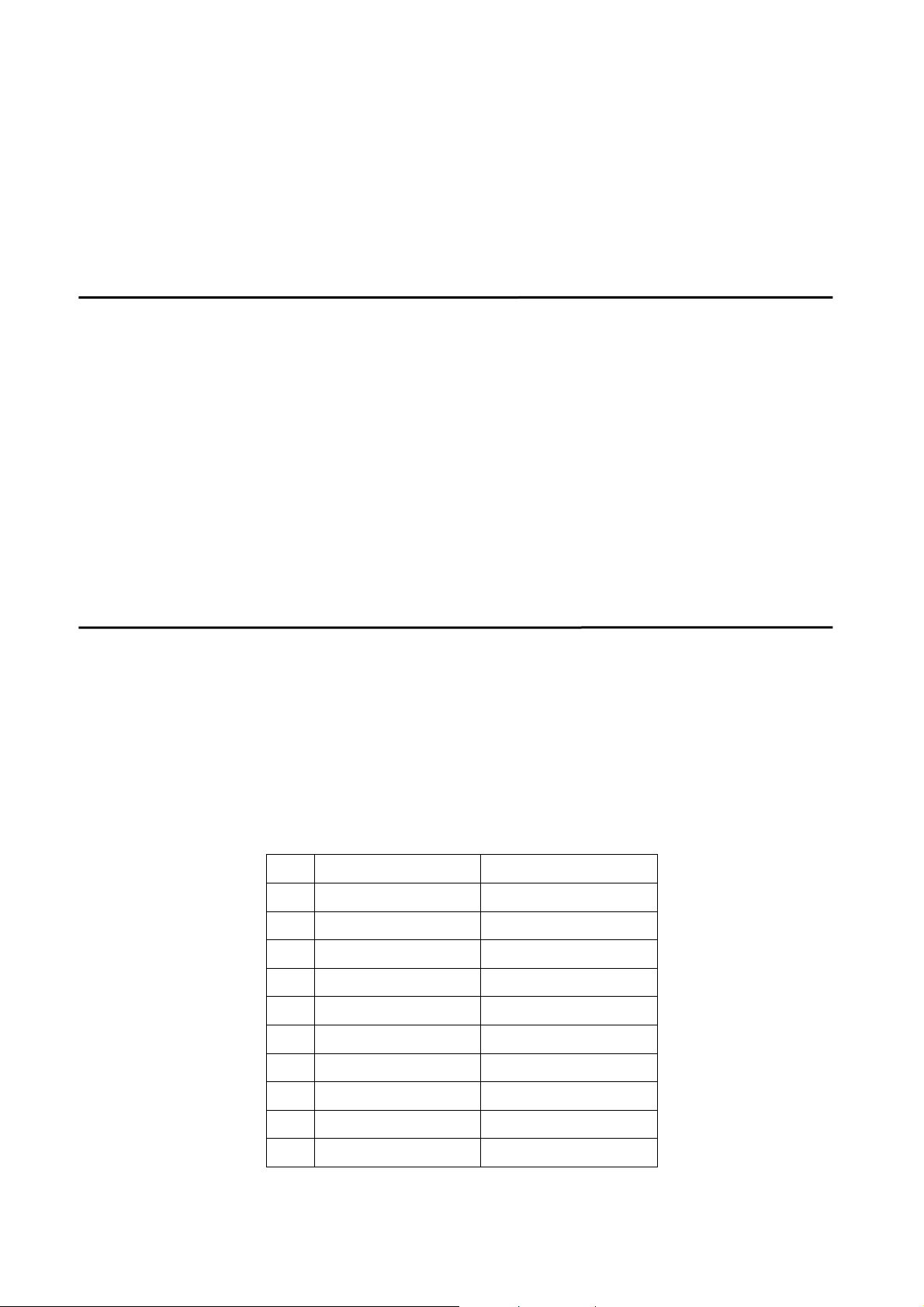

2.1 ESC/Bema Command Table

Operation

Code Function Format hexadecimal Page

GS F9h 5 00h Select ESC/Bema operation mode. Writes on flash.

Use with caution.

GS F9h 20h 30h Select ESC/Bema temporary operation mode.

Doesn’t alters flash.

GS F9h 1Fh 31h Return to previous set of commands configured

before temporary setting.

ESC @ Initializes the MP-4000 TH printer 1B 40 14

ESC b n n = 1 => PE signal reflects drawer sensor

n = 0 => PE signal reflects paper sensor

ESC v n Activate drawer for n milliseconds (-50ms < n <

200ms)

ESC w Performs a full paper cut 1B 77 15

ESC m Performs a partial paper cut 1B 6D 15

ESC y n Enable / disable panel keys 1B 79 n 15

ESC x Enable Dump Mode 1B 78 16

ESC z n Enable (n = 1) / disable (n = 0) automatic line feed 1B 7A n 16

ESC ( A pL pH fn n1

n2 vol

GS F9h – n Set printer priority (high quality or high speed) 1D F9 2D n 17

GS F9h ! n Set paper width 1D F9 21 n 17

GS F9h , n Enable/Disable paper near end sensor 1D F9 2C n 18

GS F9h + n Set and save printing intensity 1D F9 2B n 18

GS FAh n Set printer language 1D FA n 18

GS F9h “ 0 Get printer log 1D F9 22 30 19

GS F9h ‘ n Get printer information 1D F9 27 n 19

GS F9h ( 0 Load default user configuration 1D F9 28 30 20

GS F9h ) 0 Print user configuration 1D F9 29 30 20

GS F7h BS NUL !

i

...i4 s1..s

1

GS F9h * n Set USB address 1D F9 2A n 20

4

Activate/deactivate buzzer 1B 28 41 pL pH fn n1

Set IP address and subnet mask 1D F7 08 00 21 i

1D F9 35 00 13

1D F9 20 30 13

1D F9 1F 31 14

1B 62 n 14

1B 76 n 14

16

n2 vol

...i4

1

s

..s

1

4

20

22-aug-2007

Firmware Release: 1.5

7

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Vertical positioning

Code Function Format hexadecimal Page

ESC C n Set page size in lines 1B 43 n 21

ESC c n1 n2 Set page size in millimeters 1B 63 n1 n2 21

ESC J n Performs a fine line feed 1B 4A n 21

FF Feeds one page 0C 21

LF Feeds one line 0A 22

ESC 2 Line feed of 1/6 inch 1B 32 22

ESC 3 n Line feed of n/144 inch 1B 33 n 23

ESC f 1 n Vertical skipping 1B 66 31 n 23

ESC A n Feeding paper (n * 0,375mm) 1B 41 n 23

Horizontal positioning

Code Function Format hexadecimal Page

ESC f 0 n Horizontal skipping 1B 66 30 n 24

ESC Q n Set right margin 1B 51 n 24

ESC l n Set left margin 1B 6C n 24

ESC a n Centralize (n = 1) or left align (n = 0) characters 1B 61 n 25

Character types

Code Function Format hexadecimal Page

ESC - n Enable / disable underlined print mode 1B 2D n 26

ESC 4 Enable italic print mode 1B 34 26

ESC 5 Disable italic print mode 1B 35 26

ESC E Enable emphasized print mode 1B 45 27

ESC F Disable emphasized print mode 1B 46 27

ESC t n Select code page 1B 74 n 27

ESC S n Enable superscript and / or subscript 1B 53 n 28

ESC T Disable superscript and subscript modes 1B 54 28

ESC N n Select Intensity Mode 1B 4E n 28

ESC ! n Select print mode 1B 21 n 29

ESC } n Enable / Disable inverted mode 1B 7D n 29

Print width, character width and height

Code Function Format hexadecimal Page

DC2 Disable condensed mode 12 30

DC4 Disable on-line expanded print 14 30

ESC d n Enable / Disable double height print mode 1B 64 n 30

ESC H Set default column per line 1B 48 31

ESC P Set default column per line 1B 50 31

ESC SI Set condensed mode 1B 0F 31

ESC SO Set on-line expanded mode 1B 0E 32

ESC V Set on-line double height mode 1B 56 32

ESC W n Enable / Disable expanded mode 1B 57 n 32

SI Enable condensed mode 0F 33

SO Enable on-line expanded mode 0E 33

22-aug-2007

Firmware Release: 1.5

8

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

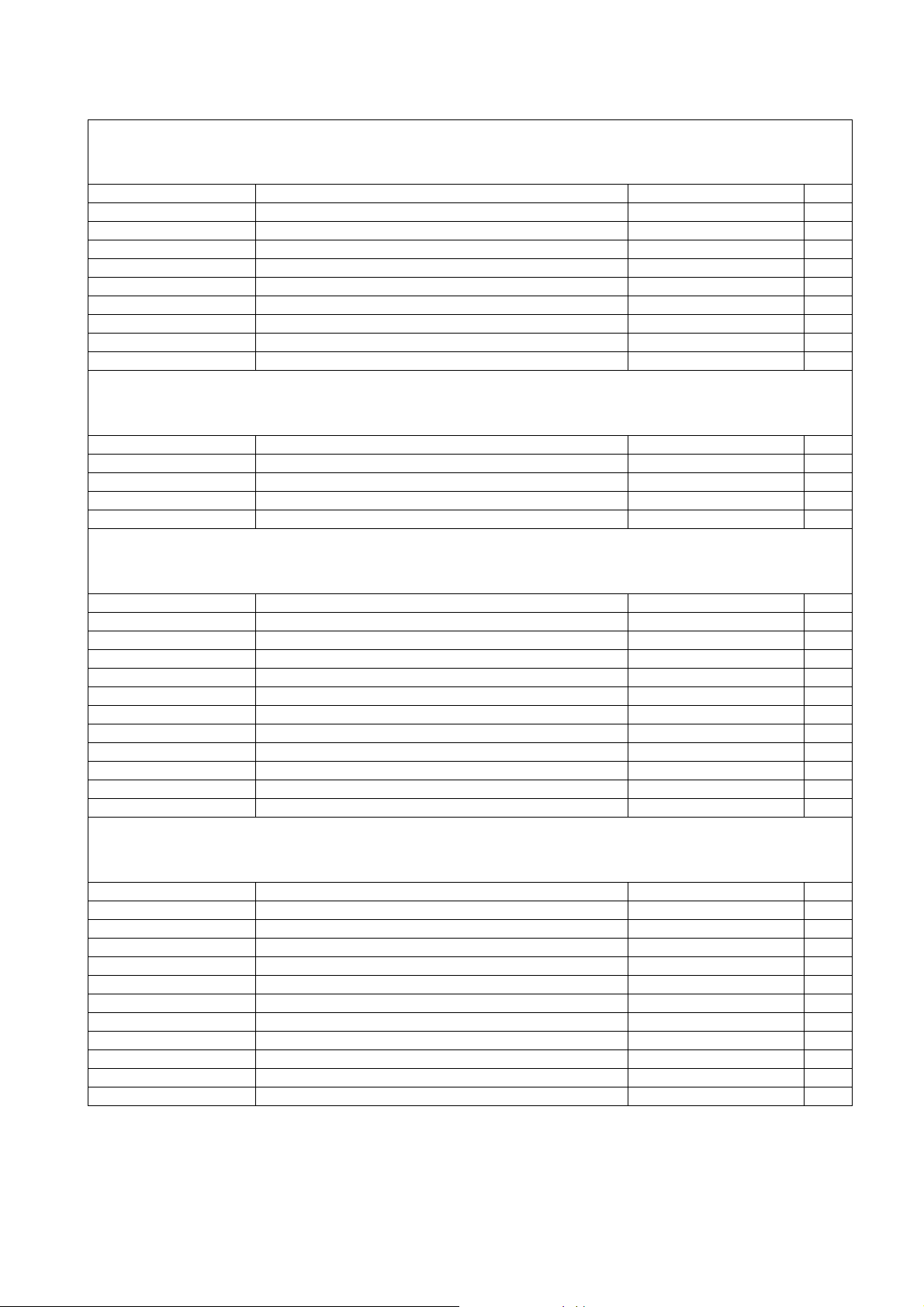

Bit images and graphics

Code Function Format hexadecimal Page

ESC $ n1 n2 Fill in blank bit columns 1B 24 n1 n2 35

ESC * ! n1 n2 b1...bn 24-bit graphics 1B 2A 21 n1 n2 b1 ...

35

bn

ESC K n1 n2 b1...bn 8-bit graphics 1B 4B n1 n2 b1 ... bn 36

FS p n m Print NV bit image 1C 70 n m 36

FS q n [xL xH yL yH

d

...dk]1...[xL xH yL yH

1

d

...dk]

1

n

Define NV bit image 1C 71 n [x

d

...dk]1...[xL xH yL yH

1

d

...dk]

1

n

L xH yL yH

37

GS / m Print downloaded bit image 1D 2F m 38

GS * x y d1...d

GS v 0 m xL xH yL yH

...dk

d

1

Define downloaded bit image 1D 2A x y d1...d

(x × y × 8)

Print Raster Bitmap 1D 76 30 m x

d

1

...d

38

(x × y × 8)

39

L xH yL yH

k

Communication

Code Function Format hexadecimal Page

ENQ Serial communication status enquiry 05 41

GS ° 1

Serial / USB communication advanced status 1D F8 31 41

ETX End buffer 03 44

STX Clear buffer 02 44

Data Control

Code Function Format hexadecimal Page

CAN Cancel last line 18 45

DEL Cancel last character 7F 45

22-aug-2007

Firmware Release: 1.5

9

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Barcodes

Code Function Format hexadecimal Page

GS h n Sets the height n of the barcode generated 1D 68 n 46

GS w n Determines the width of the barcode 1D 77 n 46

GS H n Choose the position of the human readable

1D 48 n 46

information (HRI) of the barcode

GS f n Sets the font used to print the human readable

1D 66 n 47

information (HRI)

GS k 0 d1…d11 NUL Prints an UPC-A barcode 1D 6B 00 d1…d

GS k 65 11 d1...d11 Prints an UPC-A barcode 1D 6B 41 0B d1…d

GS k 1 d1…d6 NUL Prints an UPC-E barcode 1D 6B 01 d1…d

GS k 66 6 d1…d6 Prints an UPC-E barcode 1D 6B 42 06 d1…d

GS k 2 d1…d12 NUL Prints an EAN-13 barcode 1D 6B 02 d1…d

GS k 67 12 d1…d12 Prints an EAN-13 barcode 1D 6B 43 0C d1…d

GS k 3 d1…d7 NUL Prints an EAN-8 barcode 1D 6B 03 d1…d

GS k 68 7 d1…d7 Prints an EAN-8 barcode 1D 6B 44 07 d1…d

GS k 4 d1…dn NUL Prints a CODE 39 barcode 1D 6B 04 d1…d

GS k 69 n d1…dn Prints a CODE 39 barcode 1D 6B 45 n d1…d

GS k 5 d1…dn NUL Prints an ITF barcode 1D 6B 05 d1…d

GS k 70 n d1...dn Prints an ITF barcode 1D 6B 46 n d1…d

GS k 6 d1…dn NUL Prints a CODABAR barcode 1D 6B 06 d1…d

GS k 71 n d1…dn Prints a CODABAR barcode 1D 6B 47 n d1…d

GS k 72 d1…dn Prints a CODE 93 barcode 1D 6B 48 n d1…d

GS k 73 n d1…dn Prints a CODE 128 barcode 1D 6B 49 n d1…d

GS k 128 n1 n2 n3 n4

n

5 n6

d1…d

n

Prints a PDF-417 barcode 1D 6B 80 n

n

d1…d

6

n

GS k 21 d1…d9 NUL Prints an ISBN barcode 1D 6B 15 d1…d

GS k 22 d1…dn NUL Prints a MSI barcode 1D 6B 16 d1…d

GS k 130 n d1…dn Prints a MSI barcode 1D 6B 82 n d1…d

GS k 23 d1…dn NUL Prints a PLESSEY barcode 1D 6B 17 d1…d

GS k 131 n d1…dn Prints a PLESSEY barcode 1D 6B 83 n d1…d

GS k 132 n1 n2 Programs barcode’s left margin 1D 6B 84 n1 n

00 47

11

47

11

00 48

6

48

6

00 48

12

49

12

00 49

7

49

7

00 50

n

50

n

00 50

n

51

n

00 51

n

51

n

52

n

52

n

1 n2 n3 n4 n5

00 53

9

00 54

n

54

n

00 54

n

55

n

55

2

53

22-aug-2007

Firmware Release: 1.5

10

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

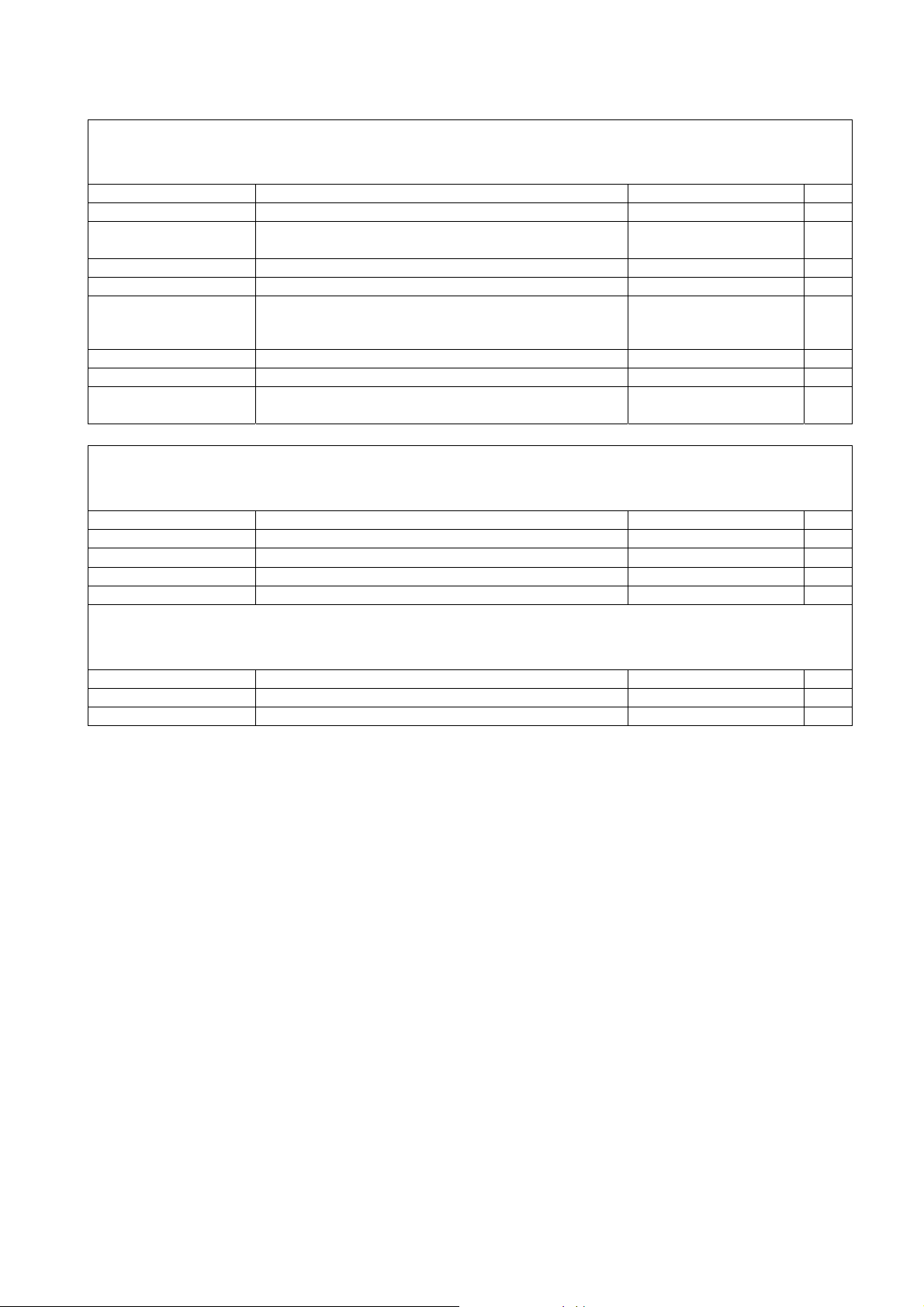

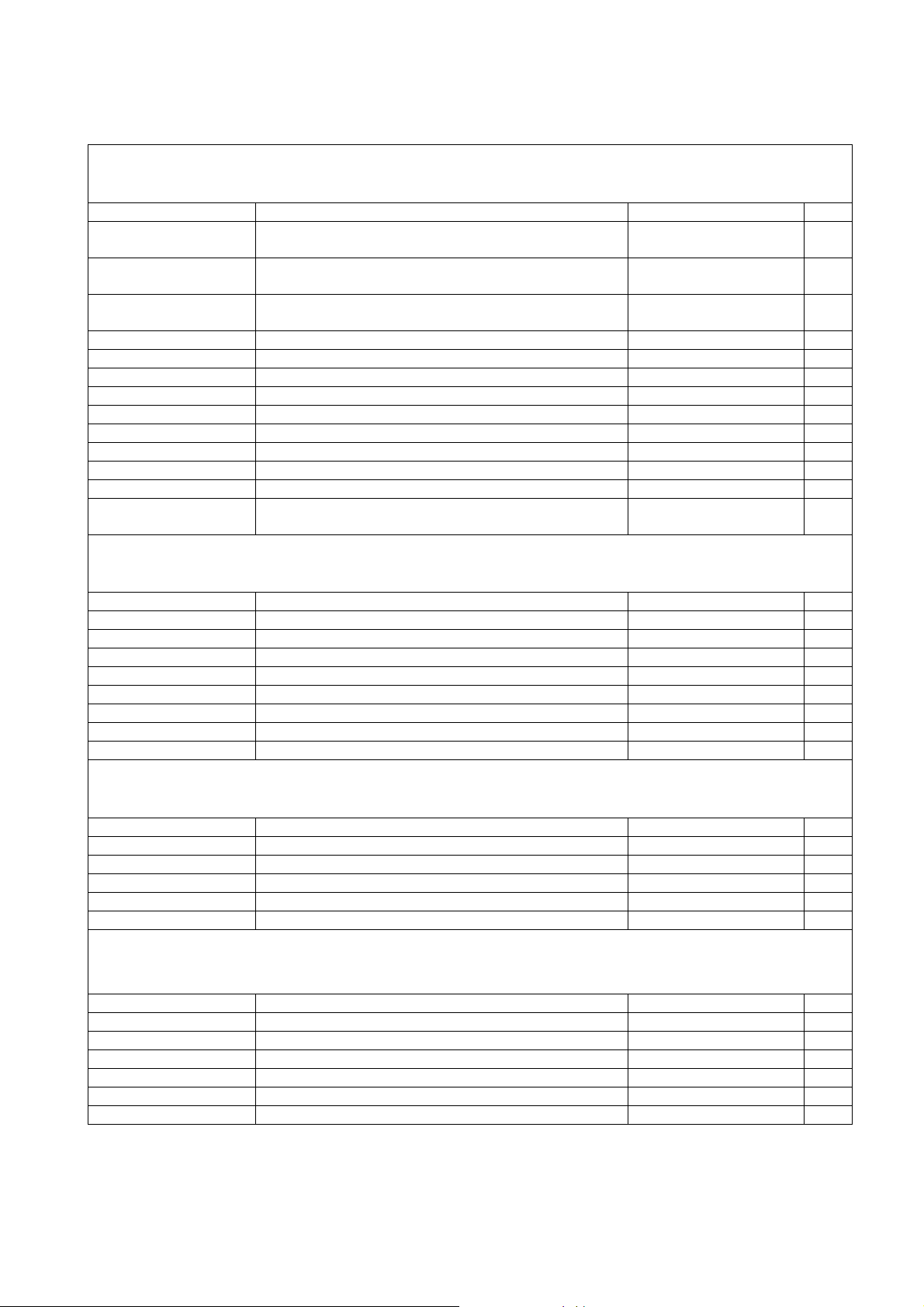

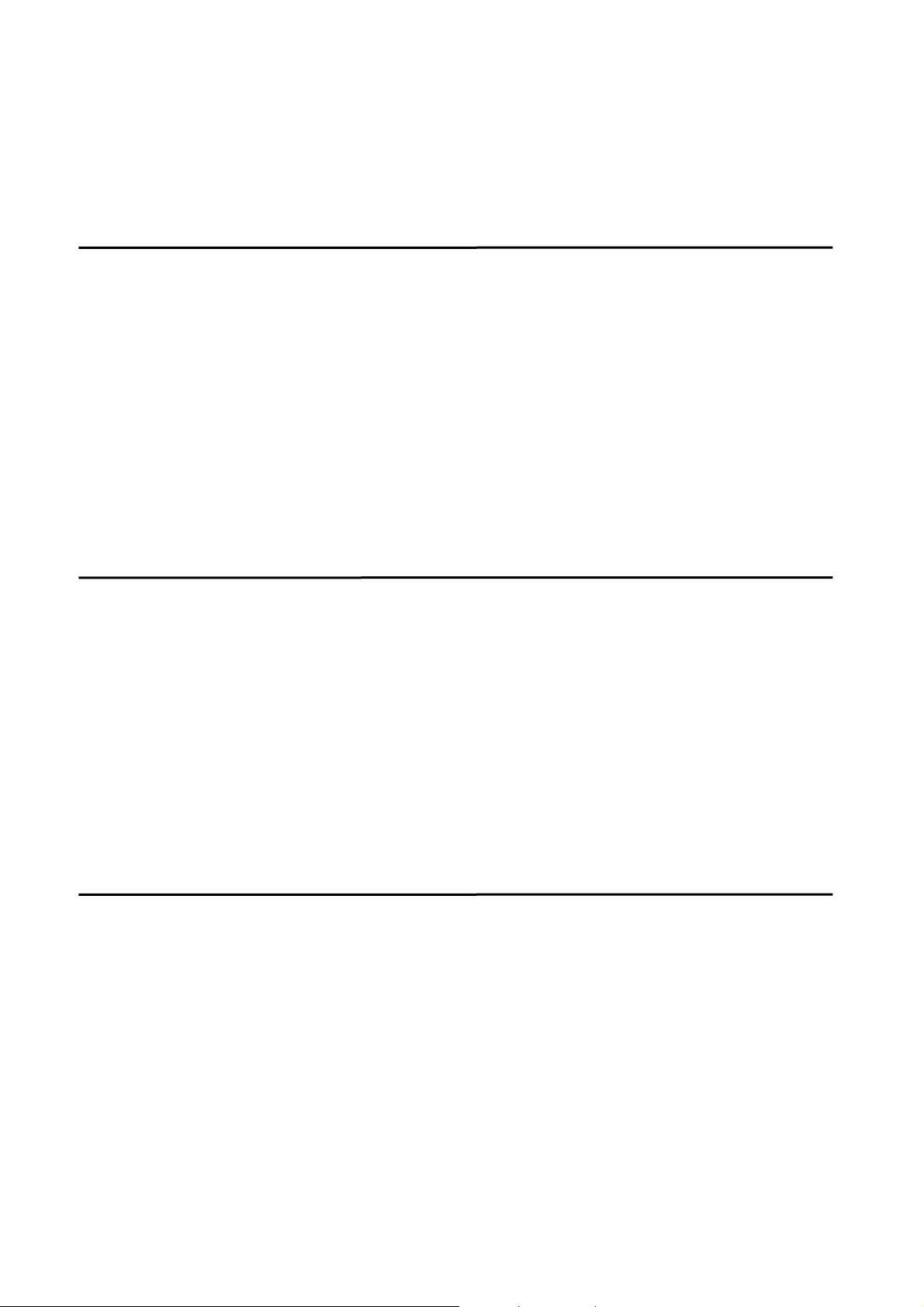

2.2 ESC/POS Command Table

Operation

Code Function Format hexadecimal Page

GS F9h 5 01h Select ESC/POS operation mode. Writes on flash.

Use with caution.

GS F9h 20h 31h Select ESC/POS temporary operation mode.

Doesn’t alters flash.

GS F9h 1Fh 31h Return to previous set of commands configured

before temporary setting.

ESC = n Select peripheral device 1B 3D n 57

ESC @ Initialize printer 1B 40 57

ESC c 3 n Select paper sensor(s) to output paper-end signals 1B 63 33 n 58

ESC c 4 n Select paper sensor(s) to stop printing 1B 63 34 n 58

ESC c 5 n Enable/disable panel buttons 1B 63 35 n 59

ESC p m t1 t2 General pulse 1B 70 m t1 t2 59

GS ( A pL pH n m Execute test print 1D 28 41 pL pH n m 60

DLE DC4 n m t Generate pulse at real-time 10 14 n m t 60

GS V m (n) Select cut mode and cut paper 1D 56 m (n) 61

ESC ( A pL pH fn n c

t1 t2

Activate buzzer 1B 28 41 pL pH fn n c

Vertical positioning

Code Function Format hexadecimal Page

LF Print and line feed 0A 62

FF Print and return to standard mode 0C 62

CR Print and carriage return 0D 62

ESC $ nL nH Set absolute print position 1B 24 nL n

ESC 2 Select default line spacing 1B 32 63

ESC 3 n Set line spacing 1B 33 n 63

ESC \ nL nH Set relative print position 1B 5C nL n

ESC d n Print and feed n lines 1B 64 n 64

Horizontal positioning

Code Function Format hexadecimal Page

HT Horizontal tab 09 65

ESC SP n Set right-side character spacing 1B 20 n 65

ESC D n1…nK NUL Set horizontal tab positions 1B 44 n1…nk 00 65

ESC a n Select justification 1B 61 n 66

GS L nL nH Set left margin 1D 4C nL nH 66

Character types

Code Function Format hexadecimal Page

ESC – n Turn underline mode on/off 1B 2D n 67

ESC E n Turn emphasized mode on/off 1B 45 n 67

ESC M n Select character font 1B 4D n 67

GS B Activate/deactivate black/white reverse printing 1D 42 n 68

ESC R n Select an international character set 1B 52 n 68

ESC t n Select character code table 1B 74 n 68

1D F9 35 01 56

1D F9 20 31 56

1D F9 1F 31 57

61

t1 t2

63

H

63

H

22-aug-2007

Firmware Release: 1.5

11

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Communication

Code Function Format hexadecimal Page

DLE EOT n Real-time status transmission 10 04 n 69

DLE ENQ n Real-time request to printer 10 05 n 70

GS I n Transmit printer ID 1D 49 n 71

GS a n Enable/disable Automatic Status Back (ASB) 1D 61 n 72

GS r n Transmit status 1D 72 n 73

Data Control

Code Function Format hexadecimal Page

CAN Cancel print data 18 75

Barcodes

Code Function Format hexadecimal Page

GS h n Set bar code height 1D 68 n 46

GS w n Set bar code width 1D 77 n 46

GS H n Select printing position of HRI characters 1D 48 n 46

GS f n Select font for HRI characters 1D 66 n 47

GS k 0 d1…d11 NUL Prints an UPC-A barcode 1D 6B 00 d1…d1

GS k 65 11 d1...d11 Prints an UPC-A barcode 1D 6B 41 0B d1…d1

GS k 1 d1…d6 NUL Prints an UPC-E barcode 1D 6B 01 d1…d

GS k 66 6 d1…d6 Prints an UPC-E barcode 1D 6B 42 06 d1…d

GS k 2 d1…d12 NUL Prints an EAN-13 barcode 1D 6B 02 d1…d1

GS k 67 12 d1…d12 Prints an EAN-13 barcode 1D 6B 43 0C d1…d1

GS k 3 d1…d7 NUL Prints an EAN-8 barcode 1D 6B 03 d1…d

GS k 68 7 d1…d7 Prints an EAN-8 barcode 1D 6B 44 07 d1…d

GS k 4 d1…dn NUL Prints a CODE 39 barcode 1D 6B 04 d1…d

GS k 69 n d1…dn Prints a CODE 39 barcode 1D 6B 45 n d1…d

GS k 5 d1…dn NUL Prints an ITF barcode 1D 6B 05 d1…d

GS k 70 n d1...dn Prints an ITF barcode 1D 6B 46 n d1…d

GS k 6 d1…dn NUL Prints a CODABAR barcode 1D 6B 06 d1…dn 00 51

GS k 71 n d1…dn Prints a CODABAR barcode 1D 6B 47 n d1…d

GS k 72 d1…dn Prints a CODE 93 barcode 1D 6B 48 n d1…d

GS k 73 n d1…dn Prints a CODE 128 barcode 1D 6B 49 n d1…d

GS k 128 n1 n2 n3 n4

n

5 n6

d1…d

n

Prints a PDF-417 barcode 1D 6B 80 n1 n2 n

d1…d

n

6

n

GS k 21 d1…d9 NUL Prints an ISBN barcode 1D 6B 15 d1…d9 00 53

GS k 22 d1…dn NUL Prints a MSI barcode 1D 6B 16 d1…d

GS k 130 n d1…dn Prints a MSI barcode 1D 6B 82 n d1…d

GS k 23 d1…dn NUL Prints a PLESSEY barcode 1D 6B 17 d1…dn 00 54

GS k 131 n d1…dn Prints a PLESSEY barcode 1D 6B 83 n d1…d

GS k 132 n1 n2 Programs barcode’s left margin 1D 6B 84 n1 n2 55

00 47

1

47

1

00 48

6

48

6

00 48

2

49

2

00 49

7

49

7

00 50

n

50

n

00 50

n

51

n

51

n

52

n

52

n

53

3 n4 n5

00 54

n

54

n

55

n

22-aug-2007

Firmware Release: 1.5

12

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

Bit images and graphics

Code Function Format hexadecimal Page

ESC * ! n1 n2 b1...bn 24-bit graphics 1B 2A 21 n1 n2 b1 ...

35

bn

FS p n m Print NV bit image 1C 70 n m 36

FS q n [xL xH yL yH

...dk]1...[xL xH yL yH

d

1

d

...dk]

1

n

Define NV bit image 1C 71 n [x

...dk]1...[xL xH yL yH

d

1

d

...dk]

1

n

L xH yL yH

37

GS / m Print downloaded bit image 1D 2F m 38

GS * x y d1...d

GS v 0 m xL xH yL yH

d

...dk

1

Define downloaded bit image 1D 2A x y d1...d

(x × y × 8)

Print Raster Bitmap 1D 76 30 m x

d

1

...d

38

(x × y × 8)

L xH yL yH

k

39

22-aug-2007

Firmware Release: 1.5

13

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3. ESC/Bema Commands

3.1 Operation Commands

The following section details each of the commands presented in the Command Table,

ESC/Bema section.

GS F9h 5 00h

[Function] Select ESC/Bema operation mode.

[Format] ASCII GS F9h 5 00h

Hexadecimal 1D F9 35 00

Decimal 29 249 53 0

[Description] Tells printer to interpret ESC/Bema commands from now.

[Notes] ● This command saves data on printer flash memory and therefore is

slow, which may affect printer performance and funcionality if mixed with

other faster commands. Please, use with caution.

● When ESC/Bema mode is enabled and a DB25 serial interface is

connected, the printer will automatically change its flow control to

RTS/CTS.

GS F9h 20h 30h

[Function] Select ESC/Bema temporary operation mode.

[Format] ASCII GS F9h 20h 30h

Hexadecimal 1D F9 20 30

Decimal 29 249 32 48

[Description] Tells printer to interpret ESC/Bema commands from now.

[Notes] ● This command doesn’t writes anything on flash memory, so it can be

used anyway.

● When ESC/Bema mode is enabled and a DB25 serial interface is

connected, the printer will automatically change its flow control to

RTS/CTS.

22-aug-2007

Firmware Release: 1.5

14

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS F9h 1Fh 31h

[Function] Return to previous set of commands configured before temporary setting.

[Format] ASCII GS F9h 1Fh 31h

Hexadecimal 1D F9 1F 31

Decimal 29 249 31 49

[Description] Tells printer to interpret the command set that was configured before an

temporary set has been done.

ESC @

[Function] Initializes the MP-4000 TH printer.

[Format] ASCII ESC @

Hexadecimal 1B 40

Decimal 27 64

[Description] All settings, including character font, line spacing, left margin, right

margin, intensity and inverted mode are canceled.

ESC b n

[Function] Select sensor to signalize.

[Format] ASCII ESC b n

Hexadecimal 1B 62 n

Decimal 27 98

[Range] n = 0, 1, 48, 49

[Default] n = 0

[Description] When n = 1 (or n = 49), PE signal reflects drawer sensor. When n = 0 (or

n = 48), PE signal reflects paper sensor.

[Notes] PE is a signal from the parallel interface.

ESC v n

[Function] Activate drawer.

[Format] ASCII ESC v n

Hexadecimal 1B 76 n

Decimal 27 118 n

[Description] Activate drawer pin for n milliseconds (-50ms < n < 200ms).

22-aug-2007

Firmware Release: 1.5

15

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC w

[Function] Performs a full paper cut.

[Format] ASCII ESC w

Hexadecimal 1B 77

Decimal 27 119

[Description] This command operates the auto cutter, performing a full cut in the

paper.

[Notes] When presenter is activated there is a minimum receipt size (roughly 3.3

inches) to avoid paper jam inside the presenter. If the receipt size is less

than the minimum, the full cut command will automatically add line feeds

to perform the cut.

ESC m

[Function] Performs a partial paper cut.

[Format] ASCII ESC m

Hexadecimal 1B 6D

Decimal 27 109

[Description] This command operates the auto cutter, performing a partial cut in the

paper.

[Notes] This command is available only if presenter is not activated.

ESC y n

[Function] Enable / disable panel keys.

[Format] ASCII ESC y n

Hexadecimal 1B 79 n

Decimal 27 121 n

[Range] n = 0,1

[Default] n = 1

[Description] Enables or disables the panel key.

9 When n is 0 (00h or 30h), the panel key is disabled.

9 When n is 1 (01h or 31h), the panel key is enabled.

9

[Notes] When the panel key is disabled, no button on the panel is usable.

22-aug-2007

Firmware Release: 1.5

16

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC x

[Function] Enable Dump Mode.

[Format] ASCII ESC x

Hexadecimal 1B 78

Decimal 27 120

[Description] Enables dump mode. In this mode advanced users and programmers

can identify communication problems between the host and the printer

or check if a certain programmed data is correctly being sent to the

printer, thus being a debugging tool.

[Note] The dump mode is disabled just resetting the printer.

ESC z n

[Function] Enable / disable automatic line feed.

[Format] ASCII ESC z n

Hexadecimal 1B 7A n

Decimal 27 122 n

[Description] Enables automatic line feed.

9 When n is 1 (01h or 31h), the automatic line feed is enabled.

9 When n is 0 (00h or 30h), the automatic line feed is disabled.

[Notes] If automatic line feed is enabled, the printer will perform a LF if a CR is

received.

ESC ( A pL pH fn n1 n2 vol

[Function] Activate/deactivate buzzer.

[Format] ASCII ESC ( A pL pH fn n1 n2 vol

Hexadecimal 1B 28 41 pL pH fn n1 n2 vol

Decimal 27 40 65 p

[Description] Activate or deactivate printer buzzer.

(p

fn = 1, 31h – activate buzzer

22-aug-2007

Firmware Release: 1.5

+ pH × 256) = 4, i.e., pL must be 4 and p

L

fn n1 n2 vol

L pH

must be 0.

H

17

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

fn = 0, 30h – deactivate buzzer

n = (n1 + n

vol = 0, 30h – low volume

vol = 1, 31h – high volume

× 256) – time in milliseconds

2

GS F9h - n

[Function] Set printer priority.

[Format] ASCII GS F9h - n

Hexadecimal 1D F9 2D n

Decimal 29 249 45 n

[Description] Set printer priority to high quality or high speed.

n = 1, 31h – high quality

n = 0, 30h – high speed

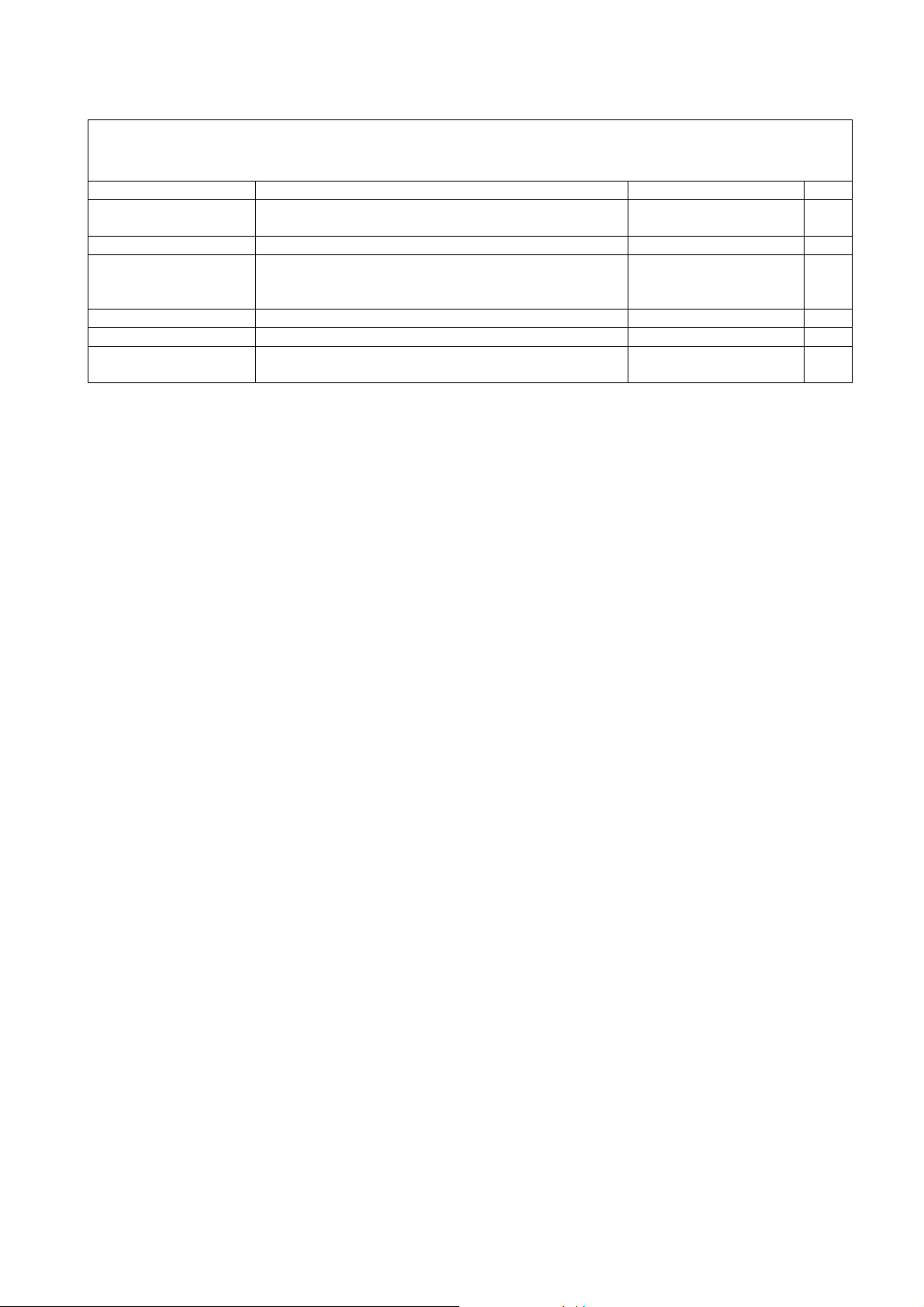

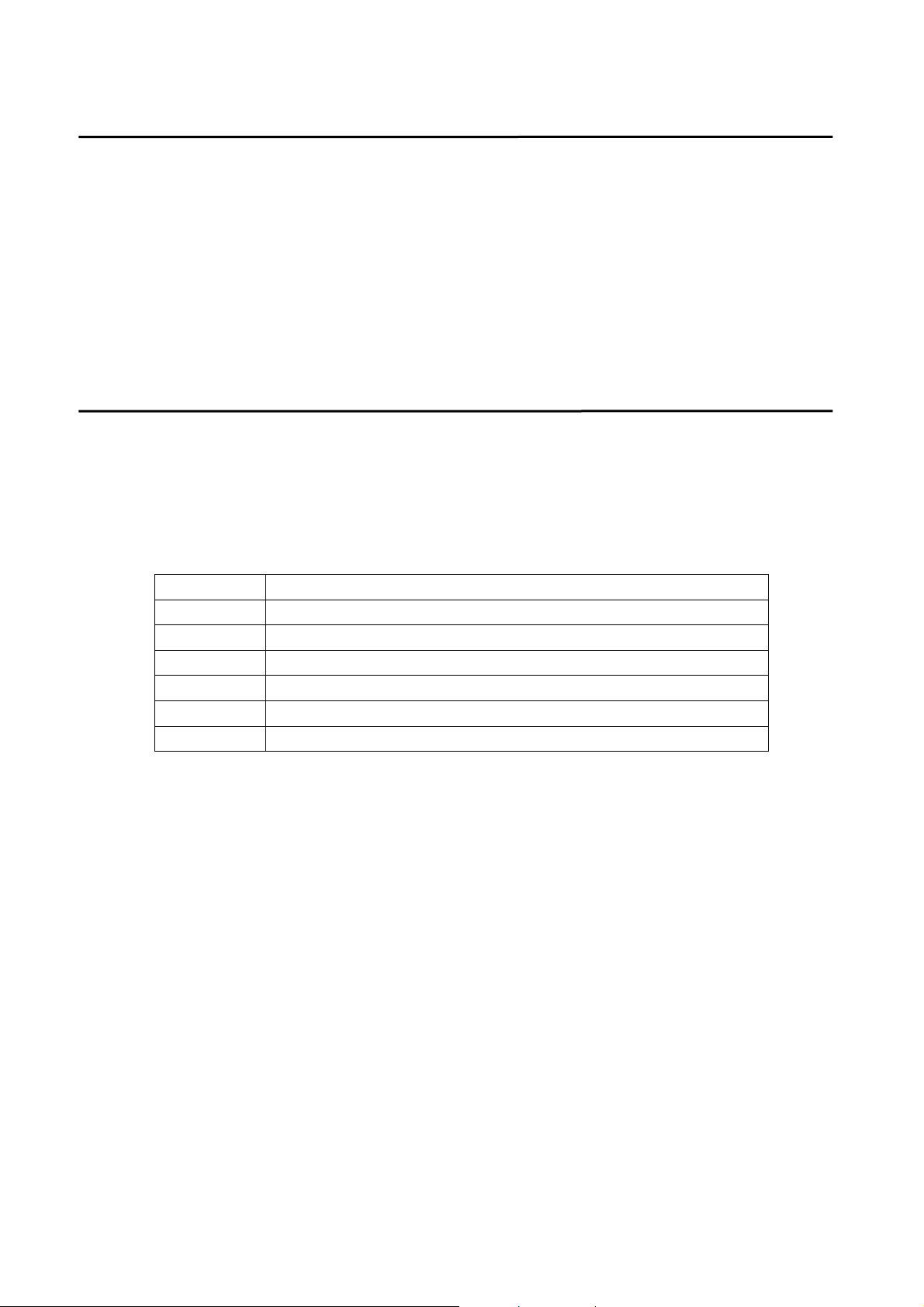

GS F9h ! n

[Function] Set paper width.

[Format] ASCII GS F9h ! n

Hexadecimal 1D F9 21 n

Decimal 29 249 33 n

[Description] Set printer paper width as shown on following table:

paper width (mm) printing width (mm)

n

00h 58 48

01h 76 72

02h 80 72

03h 80 76

04h 82.5 72

05h 82.5 76

22-aug-2007

Firmware Release: 1.5

06h 82.5 80

07h 76 64

08h 80 64

09h 82.5 64

18

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

[Description] This command has no effect when ESC/POS mode is enabled.

ESC/POS mode fixes paper/printing width to 80 mm / 76 mm.

GS F9h , n

[Function] Enable/disable paper near end sensor.

[Format] ASCII GS F9h , n

Hexadecimal 1D F9 2C n

Decimal 29 249 44 n

[Description] Enable or disable paper near end sensor (PNES).

n = 1, 31h – enable PNES

n = 0, 30h – disable PNES

GS F9h + n

[Function] Set and save printing intensity.

[Format] ASCII GS F9h + n

Hexadecimal 1D F9 2B n

Decimal 29 249 43 n

[Description] Set and save printing intensity on flash memory.

n may vary from 0 (00h, 30h) to 4 (04h, 34h), meaning weakest to

strongest printing respectively.

GS FAh n

[Function] Set printer language.

[Format] ASCII GS FAh n

Hexadecimal 1D FA n

Decimal 29 250 n

[Description] Set printer language.

n = 0, 30h – english

n = 1, 31h – portuguese

n = 2, 32h - spanish

22-aug-2007

Firmware Release: 1.5

19

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS F9h “ 0

[Function] Get printer log.

[Format] ASCII GS F9h “ 0

Hexadecimal 1D F9 22 30

Decimal 29 249 34 48

[Description] Tells the printer to send its log.

[Note] This command doesn’t work with parallel port in SPP mode.

GS F9h ‘ n

[Function] Get printer information.

[Format] ASCII GS F9h ‘ n

Hexadecimal 1D F9 27 n

Decimal 29 249 39 n

[Description] Get printer information as shown on following table:

n Information

0, 30h Product code

1, 31h Serial number

2, 32h Manufacturing date

3, 33h Firmware version

4, 34h Reserved

5, 35h Manufacturing timestamp (dd/mm/yyyy hh:mm:ss format)

22-aug-2007

Firmware Release: 1.5

20

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS F9h ( 0

[Function] Load default user configuration.

[Format] ASCII GS F9h ( 0

Hexadecimal 1D F9 28 30

Decimal 29 249 40 48

[Description] Reload all configurations from flash memory.

GS F9h ) 0

[Function] Print user configuration.

[Format] ASCII GS F9h ( 0

Hexadecimal 1D F9 29 30

Decimal 29 249 41 48

[Description] Print user configuration.

GS F7h BS NUL ! i1...i4 s1..s4

[Function] Set IP address and subnet mask.

[Format] ASCII GS F7h BS NUL ! i1...i4 s1..s4

Hexadecimal 1D F7 08 00 21 i1...i4 s1..s4

Decimal 29 247 08 00 33 i1...i4 s1..s4

[Description] Set IP address and subnet mask on hexadecimal format without

points.

[Example] IP 10.1.1.250 and SUBNET 255.0.0.0 must be sent as 0Ah 01h 01h

FAh FFh 00h 00h 00h

GS F9h * n

[Function] Set USB address.

[Format] ASCII GS F9h * n

Hexadecimal 1D F9 2A n

Decimal 29 249 42 n

[Description] Set USB address to allow the use of more than one printer on same

computer.

22-aug-2007

Firmware Release: 1.5

21

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.2 Vertical positioning

ESC C n

[Function] Set page size in lines.

[Format] ASCII ESC C n

Hexadecimal 1B 43 n

Decimal 27 67 n

[Range] 0 < n < 256

[Default] n = 12

[Description] Sets the page size where n is the number of lines (single height).

ESC c n1 n2

[Function] Set page size in millimeters.

[Format] ASCII ESC c n1 n2

Hexadecimal 1B 63 n1 n2

Decimal 27 99 n1 n2

[Range] 0 < n1 < 256; 0 < n2 < 256

[Description] Sets the page size in millimeters where size is 0,125mm*n1 *n2.

ESC J n

[Function] Performs a fine line feed.

[Format] ASCII ESC J n

Hexadecimal 1B 4A n

Decimal 27 74 n

[Range] 0 < n < 256

[Description] Performs the feeding of n*0,125mm of paper.

[Notes] This command is very useful in the graphic mode.

22-aug-2007

Firmware Release: 1.5

22

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

FF

[Function] Feeds one page.

[Format] ASCII FF

Hexadecimal 0C

Decimal 12

[Description] Performs a form feed to the top of the form.

[Notes] The form feed command can be disabled. Set the page size to zero.

LF

[Function] Feeds one line.

[Format] ASCII LF

Hexadecimal 0A

Decimal 10

[Description] Prints the contents of the buffer (if exists) and performs one line feed

using the default line spacing.

[Notes] The next character print position is on the left margin of the next line.

ESC 2

[Function] Line feed of 1/6”.

[Format] ASCII ESC 2

Hexadecimal 1B 32

Decimal 27 50

[Description] Sets the line feed of 1/6 inch. The line feed rate per line is specified by

1/6 inch.

[Notes] This is the default value when printer performed a reset or ESC @ was

received.

22-aug-2007

Firmware Release: 1.5

23

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC 3 n

[Function] Line feed of n/144 inch.

[Format] ASCII ESC 3 n

Hexadecimal 1B 33 n

Decimal 27 51 n

[Range] 16 ≤ n ≤ 255

[Description] The line feed rate per line is specified by n/144 inch.

[Notes] This command takes effect immediately.

ESC f 1 n

[Function] Vertical skipping

[Format] ASCII ESC f 1 n

Hexadecimal 1B 66 31 n

Decimal 27 102 49 n

[Range] 0 ≤ n ≤ 255

[Description] Performs a vertical skipping of n characters.

[Notes] The command 1Bh 66h 01h n has the same effect.

ESC A n

[Function] Feeding paper n * 0,375mm.

[Format] ASCII ESC A n

Hexadecimal 1B 41 n

Decimal 27 65 n

[Range] 0 < n < 256

[Description] Performs the feeding of n * 0,375mm.

[Notes] If n < 17, the line feed will be equal to zero. For n > 100, the line feed

will be equal to 32mm. For other values, the line feed is equal to

n*0,375mm.

22-aug-2007

Firmware Release: 1.5

24

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.3 Horizontal positioning

ESC f 0 n

[Function] Horizontal skipping

[Format] ASCII ESC f 0 n

Hexadecimal 1B 66 30 n

Decimal 27 102 48 n

[Range] 0 ≤ n ≤ 255

[Description] Performs a horizontal skipping of n characters.

[Notes] The command 1B 66 00 n has the same effect.

ESC Q n

[Function] Set right margin.

[Format] ASCII ESC Q n

Hexadecimal 1B 51 n

Decimal 27 81 n

[Range] 0 < n < 256

[Description] Sets right margin in characters from the default left margin.

[Notes] If the right margin is set to the left of the current horizontal position, the

new margin becomes valid in the next line.

ESC I n

[Function] Set left margin.

[Format] ASCII ESC I n

Hexadecimal 1B 6C n

Decimal 27 108 n

[Range] 0 < n < 256

[Description] Sets left margin in characters from the default left margin.

[Notes] If the left margin is set to the right of the current horizontal position, the

new margin becomes valid in the next line.

22-aug-2007

Firmware Release: 1.5

25

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC a n

[Function] Aligning the characters

[Format] ASCII ESC a n

Hexadecimal 1B 61 n

Decimal 27 97 n

[Range] n = 0, 1

[Default] n = 0

[Description] This command sets the horizontal justification.

9 When n is 0 (00h or 30h), align is left justified.

9 When n is 1 (01h or 31h), align is center justified.

[Notes] The power on default is left justified.

22-aug-2007

Firmware Release: 1.5

26

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.4 Character Types

ESC - n

[Function] Enable / disable underlined print mode

[Format] ASCII ESC - n

Hexadecimal 1B 2D n

Decimal 27 45 n

[Range] n = 0,1

[Default] n = 0

[Description] Enables or disables the underlined print mode.

9 When n is 1 (01h or 31h), underlined mode is enabled.

9 When n is 0 (00h or 30h), underlined mode is disabled.

[Notes] All subsequent text and spaces are underlined.

ESC 4

[Function] Enable italic print mode

[Format] ASCII ESC 4

Hexadecimal 1B 34

Decimal 27 52

[Description] Enables italic print mode.

[Notes] Italic is available in all print modes.

ESC 5

[Function] Disable italic print mode

[Format] ASCII ESC 5

Hexadecimal 1B 35

Decimal 27 53

[Description] Disables italic print mode.

22-aug-2007

Firmware Release: 1.5

27

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC E

[Function] Enable emphasized print mode

[Format] ASCII ESC E

Hexadecimal 1B 45

Decimal 27 69

[Description] Enables emphasized print mode.

[Notes] Emphasized print is bolder than normal print. Emphasized print is

available in all print modes.

ESC F

[Function] Disable emphasized print mode

[Format] ASCII ESC F

Hexadecimal 1B 46

Decimal 27 70

[Description] Disables emphasized print mode.

ESC t n

[Function] Selects code page

[Format] ASCII ESC t n

Hexadecimal 1B 74 n

Decimal 27 116 n

[Range] n = 2, 3, 4, 5

[Default] n = 2

[Description] Selects character code page.

9 When n is 2 (02h or 32h), CODEPAGE 850 is selected.

9 When n is 3 (03h or 33h), CODEPAGE 437 is selected.

9 When n is 4 (04h or 34h), CODEPAGE 860 is selected.

9 When n is 5 (05h or 35h), CODEPAGE 858 is selected.

[Notes] CODEPAGE 850 is the default character code page.

22-aug-2007

Firmware Release: 1.5

28

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC S n

[Function] Enable superscript and / or subscript

[Format] ASCII ESC S n

Hexadecimal 1B 53 n

Decimal 27 83 n

[Range] n = 0, 1

[Description] Enables superscript character and or subscript.

9 When n is 0 (00h or 30h), the superscript is enabled. The

following characters are printed on the upper side of the print

line.

9 When n is 1 (01h or 31h), the subscript is enabled. The

following characters are printed on the bottom side of the print

line.

ESC T

[Function] Disable superscript and subscript modes

[Format] ASCII ESC T

Hexadecimal 1B 54

Decimal 27 84

[Description] Disables both superscript and subscript print modes.

ESC N n

[Function] Select Intensity Mode

[Format] ASCII ESC N n

Hexadecimal 1B 4E n

Decimal 27 78 n

[Range] n = 0, 1, 2, 3, 4

[Default] n = 2

[Description] Selects intensity mode.

9 When n is 0 (30h), the intensity selected is VERY WEAK.

9 When n is 1 (31h), the intensity selected is WEAK.

22-aug-2007

Firmware Release: 1.5

29

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

9 When n is 2 (32h), the intensity selected is NORMAL.

9 When n is 3 (33h), the intensity selected is STRONG.

9 When n is 4 (34h), the intensity selected is VERY STRONG.

ESC ! n

[Function] Select print mode

[Format] ASCII ESC ! n

Hexadecimal 1B 21 n

Decimal 27 33 n

[Description] Selects the print mode depending on byte n as shown in the table

below:

Bit Function

0 Undefined

1 Undefined

2 Undefined

3 Emphasized Canceled Specified

4 Double height Canceled Specified

5 Double width Canceled Specified

6 Undefined

7 Underlined Canceled Specified

ESC } n

[Function] Enable / Disable Inverted mode

[Format] ASCII ESC } n

Hexadecimal 1B 7D n

Decimal 27 125 n

Value

0 1

[Range] n = 0, 1

[Default] n = 0

[Description] Enables or disables inverted mode.

9 When n is 1 (01h or 31h), the inverted mode is enabled.

9 When n is 0 (00h or 30h), the inverted mode is disabled.

22-aug-2007

Firmware Release: 1.5

30

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.5 Print width, character width and height

DC2

[Function] Disable condensed mode

[Format] ASCII DC2

Hexadecimal 12

Decimal 18

[Description] Disables the condensed mod set by the ESC SI or SI command.

DC4

[Function] Disable on-line expanded print

[Format] ASCII DC4

Hexadecimal 14

Decimal 20

[Description] Disables the on-line expanded print set by ESC SO or SO command.

ESC d n

[Function] Enable / Disable double height print mode

[Format] ASCII ESC d n

Hexadecimal 1b 64 n

Decimal 27 100 n

[Range] n = 0, 1

[Default] n = 0

[Description] Enables or disables double height print mode.

9 When n is 1 (01h or 31h), the double height is enabled.

9 When n is 0 (00h or 30h), the double height is disabled.

22-aug-2007

Firmware Release: 1.5

31

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC H

[Function] Set default column per line

[Format] ASCII ESC H

Hexadecimal 1B 48

Decimal 27 72

[Description] Set the default cpl. All characters type can be set in this mode. See

table 1 to know the number of cpl, according to your printer model.

ESC P

[Function] Set default column per line

[Format] ASCII ESC P

Hexadecimal 1B 50

Decimal 27 80

[Description] This command set the default cpl. All characters type can be set in this

mode. See table 1 to know the number of cpl, according to your printer

model. It is a copy of ESC H.

ESC SI

[Function] Set condensed mode

[Format] ASCII ESC SI

Hexadecimal 1B 0F

Decimal 27 15

[Description] This command set the ESC SI cpl. All characters type can be set in

this mode. See table 1 to know the number of cpl, according to your

printer model.

22-aug-2007

Firmware Release: 1.5

32

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC SO

[Function] Set on-line expanded mode

[Format] ASCII ESC SO

Hexadecimal 1B 0E

Decimal 27 14

[Description] If this command is received in the beginning of the line, expanded is

valid for all line. If already exist some characters in the line, next

characters in this line (if any) will be in expanded mode. Next lines will

be in normal mode.

ESC V

[Function] Set on-line double height mode

[Format] ASCII ESC V

Hexadecimal 1B 56

Decimal 27 86

[Description] If this command is received in the beginning of the line, double height

is valid for all line. If already exist some characters in the line, next

characters in this line (if any) will be in double height mode. Next lines

will be in normal mode.

ESC W n

[Function] Enable / Disable expanded mode

[Format] ASCII ESC W n

Hexadecimal 1B 57n

Decimal 27 87 n

[Description] Set expanded mode (double width).

9 When n is 1 (01h or 31h), the expanded mode is enabled.

9 When n is 0 (00h or 30h), the expanded mode is disabled.

[Notes] This command can be sent at any time, even in the middle of the line.

22-aug-2007

Firmware Release: 1.5

33

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

SI

[Function] Set condensed mode

[Format] ASCII SI

Hexadecimal 0F

Decimal 15

[Description] This command set the ESC SI cpl. All characters type can be set in

this mode. See table 1 to know the number of cpl, according to your

printer model. It is a copy of ESC SI command.

SO

[Function] Set on-line expanded mode

[Format] ASCII SO

Hexadecimal 0E

Decimal 14

[Description] If this command is received in the beginning of the line, expanded is

valid for all line. If already exist some characters in the line, next

characters in this line (if any) will be in expanded mode. Next lines will

be in normal mode. It is a copy of ESC SO command.

22-aug-2007

Firmware Release: 1.5

34

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

t

t

)

t

3.6 Bit images and graphics

3.6.1 24-bit graphics

s

1

s

1

byte

2nd byte

rd

byte

3

{

{

{

The command sequence to print this graphic pattern would be (numbers in

decimal):

ESC * ! 8 0 1 1 1 2 2 2 4 4 4 8 8 8 16 16 16 32 32 32 64 64 64 128 128 128

bit-column

8th bit-column

MSB (bit 7)

LSB (bit 0

For this 24-bit graphic pattern

we have eight bit-columns, each with

a height of 3 bytes (24 bits). The

printer must, after the command is

stated, receive the 1

st

, 2nd and 3rd

bytes of the first bit-column, than the

1st , 2nd and 3rd bytes of the second

bit-column and so on, until the last bit-

Where you have 8 + 0 * 256 = 8 bit-columns to be filled, each with 3 bytes that will

give us a total of 24 bytes to be sent (excluding the command sequence).

3.6.2 8-bit graphics

1 byte

{

s

1

bit-column

8th bit-column

MSB (bit 7)

LSB (bit 0)

we have eight bit-columns, each with

a height of 1 byte (8 bits). The printer

must, after the command is stated,

receive the byte for the first bitcolumn, than the byte for the second

bit-column and so on, until the last bitcolumn is filled. The resolution is

lower but needs less bytes to be sent

For this 8-bit graphic pattern

The command sequence to print this graphic pattern would be (numbers in

decimal):

ESC K 8 0 1 2 4 8 16 32 64 128

Where you have 8 + 0 * 256 = 8 bit-columns to be filled, each with 1 byte that will

give us a total of 8 bytes to be sent (excluding the command sequence).

22-aug-2007

35

Firmware Release: 1.5

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC $ n1 n2

[Function] Fill in blank bit columns

[Format] ASCII ESC $ n1 n2

Hexadecimal 1B 24 n1 n2

Decimal 27 36 n1 n2

[Description] This command fills in blank bit columns, from the actual column until

column number (n1+n2*256), where n1+n2*256<= N. See ‘N’ value in

the table 2.

ESC * ! n1 n2 b1...bn

[Function] 24-bit graphics

[Format] ASCII ESC * ! n1 n2 b1...bn

Hexadecimal 1B 2A 21 n1 n2 b1 ... bn

Decimal 27 42 33 n1 n2 b1 … bn

[Description] This command programs bit image for 24 bits, in double density where

n1+n2*256 is the number of bit-columns that will be sent (see Bit

images and graphics) and b1...bn are the bytes that compose the bit

image. For each column one may need 3 bytes to complete. So, if you

need to send an image with an 8-column width you may send 24 bytes

to fill those columns. A full line has ‘N’ bit columns so a full line will

need N*3 bytes. If the image you want to print has less than ‘N’

graphic columns, a LF must be sent to complete line printing. Text and

graphic can be mixed in the same line. If the printer is used with

pograms that convert text to graphics, the printer is slower than if the

printer is sent ASCII text. See N value in the Table 2.

22-aug-2007

Firmware Release: 1.5

36

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ESC K n1 n2 b1...bn

[Function] 8-bit graphics

[Format] ASCII ESC K n1 n2 b1...bn

Hexadecimal 1B 4B n1 n2 b1 ... bn

Decimal 27 75 n1 n2 b1 … bn

[Description] Selects the “8 pin” bit image (compatible with matrix printers) where

you use n1+n2*256 columns, with 1 byte per column thus using a

lower resolution and up to ‘N’ columns. If the image you want to print

has less than ‘N’ graphic columns, a LF must be sent to complete line

printing. Text and graphic can be mixed in the same line. See ‘N’ value

in the Table 2.

FS p n m

[Function] Print NV bit image.

[Format] ASCII FS p n m

Hexadecimal 1C 70 n m

Decimal 28 112 n m

[Description] Prints a NV bit image n using the mode specified by m.

m

0, 48 Normal 180 dpi 180 dpi

1, 49 Double-width 180 dpi 90 dpi

2, 50 Double-height 90 dpi 180 dpi

3, 51 Quadruple 90 dpi 90 dpi

• n is the number of the NV bit image (defined using the FS q

command).

• m specifies the bit image mode.

• NV bit image means a bit image which is defined in a non-volatile

Mode Vertical Dot Density Horizontal Dot Density

[dpi: dots per 25.4 mm {1"}]

memory by FS q and printed by FS p.

• This command is not effective when the specified NV bit image has

not been defined.

22-aug-2007

Firmware Release: 1.5

37

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

FS q n [xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]

n

[Function] Define NV bit image.

[Format] ASCII FS q n [xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]n

Hexadecimal 1C 70 n [xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]

Decimal 28 112 n [xL xH yL yH d1...dk]1...[xL xH yL yH d1...dk]

[Range] 1 ≤ n ≤ 255

0 ≤ xL ≤ 255

0 ≤ xH ≤ 3 (when 1 ≤ (xL + xH × 256) ≤ 1023)

0 ≤ yL ≤ 255

0 ≤ yL ≤ 1 (when 1 ≤ (yL + yH × 256) ≤ 288)

0 ≤ d ≤ 255

k = (xL + xH × 256) × (yL + yH × 256) × 8

Total defined data area = 2M bits (256K bytes).

[Description] Define n NV bit images that are stored on non-volatile memory.

• n specifies the number of defined NV bit images.

• xL, xH specifies (xL + x

× 256) × 8 dots in the horizontal direction for the NV

H

bit image you are defining.

• yL, yH specifies (yL + y

× 256) × 8 dots in the vertical direction for the NV bit

H

n

n

image you are defining.

• This command cancels all NV bit images that have already been defined by

this command.

The printer can not redefine only one of several data definitions previously

defined. In this case, all data needs to be sent again.

22-aug-2007

Firmware Release: 1.5

38

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS / m

[Function] Print downloaded bit image.

[Format] ASCII GS / m

Hexadecimal 1D 2F m

Decimal 29 47 m

[Description] Prints a downloaded bit image using the mode specified by m.

m

0, 48 Normal 180 dpi 180 dpi

1, 49 Double-width 180 dpi 90 dpi

2, 50 Double-height 90 dpi 180 dpi

3, 51 Quadruple 90 dpi 90 dpi

Mode Vertical Dot Density Horizontal Dot Density

[dpi: dots per 25.4 mm {1"}]

• m specifies the bit image mode.

• This command is ignored if a downloaded bit image has not been

defined.

GS * x y d1...d

(x × y × 8)

[Function] Define downloaded bit image.

[Format] ASCII GS * x y d1...d

(x × y × 8)

Hexadecimal 1D 2A x y d1...d

Decimal 29 42 x y d1...d

(x × y × 8)

[Range] 1 ≤ x ≤ 255

1 ≤ y ≤ 64

(x × y × 8)

x × y ≤ 2048

0 ≤ d ≤ 255

Total defined data area = 16K bytes.

[Description] Defines a downloaded bit image using the number of dots specified.

• x specifies the number of dots in the horizontal direction.

• y specifies the number of dots in the vertical direction.

• The number of dots in the horizontal direction is x × 8, in the vertical

direction it is y × 8.

• The downloaded bit image definition is cleared when:

ESC @ is executed.

FS q is executed.

Printer is reset or the power is turned off.

22-aug-2007

Firmware Release: 1.5

39

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

• The following figure shows the relationship between the downloaded bit

image and the printed data:

GS v 0 m xL xH yL yH d1...d

[Function] Print raster bitmap.

[Format] ASCII GS v 0 m xL xH yL yH d1...dk

Hexadecimal 1D 76 30 m xL xH yL yH d1...dk

Decimal 29 118 48 m x

[Range]

0 ≤ m ≤ 3, 48 ≤ m ≤ 51

0 ≤ x

0 ≤ x

0 ≤ y

0 ≤ y

≤ 255

L

≤ 255

H

≤ 255

L

≤ 8

H

0 ≤ d ≤255

k

L xH yL yH d1

...d

k

k = (xL + xH × 256) × (yL + yH × 256) (k ≠ 0)

[Description] Print raster bitmap using the mode defined by m:

m

0, 48 Normal 180 dpi 180 dpi

1, 49 Double-width 180 dpi 90 dpi

2, 50 Double-height 90 dpi 180 dpi

3, 51 Quadruple 90 dpi 90 dpi

Mode Vertical Dot Density Horizontal Dot Density

[dpi: dots per 25.4 mm {1"}]

22-aug-2007

Firmware Release: 1.5

40

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

• xL, xH, select the number of data bytes (xL+xH×256) in the horizontal

direction for the bit image.

• yL, yH, select the number of data bytes (yL+yH×256) in the vertical

direction for the bit image.

• Data outside the printing area is read in and discarded on a dot-by-dot

basis.

• The position at which subsequent characters are to be printed for raster bit

image is specified by HT (Horizontal Tab), ESC $ (Set absolute print

position), ESC \ ( Set relative print position), and GS L (Set left margin ). If

the position at which subsequent characters are to be printed is not a

multiple of 8, print speed may decline.

• The ESC a (Select justification) setting is also effective on raster bit images.

• d indicates the bit-image data. Set time a bit to 1 prints a dot and setting it

to 0 does not print a dot.

[Example] When printing 640 dots, xL+x

figure:

×256 must be 80, as illustrated on following

H

22-aug-2007

Firmware Release: 1.5

41

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.7 Communication

ENQ

[Function] Serial communication status enquiry

[Format] ASCII ENQ

Hexadecimal 05

Decimal 05

[Description] After this command is issued, the printer returns a status by the serial

RS-232 communication port, defined below.

3.7.1 Serial interface status byte

The serial interface status byte is composed of 8 bits – 7 through 0 – the most

significant bit is Bit 7 and the least significant bit is Bit 0.

Status bit number Logic “0” Logic “1”

0 Printer Off Line Printer On Line

1 Replicates Drawer status

2* Drawer pin low Drawer pin high

3 Print head raised Print head down

4 Paper Full Paper Near End

5 Command not executed Command executed

6 – 7 Not used (will always be logic “0”)

* Refer to your drawer’s manual to know what this levels mean.

GS ° 1

[Function] Serial / USB communication advanced status

[Format] ASCII GS ° 1

Hexadecimal 1D F8 31

Decimal 29 248 49

[Description] After this command is issued, the printer returns a status by the serial

RS-232 communication port, defined below.

22-aug-2007

42

Firmware Release: 1.5

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

r

3.7.2 Serial / USB / EPP interface advanced status bytes

The serial/USB/EPP interface status bytes is composed of 8 bits – 7 through 0 – the

most significant bit is Bit 7 and the least significant bit is Bit 0.

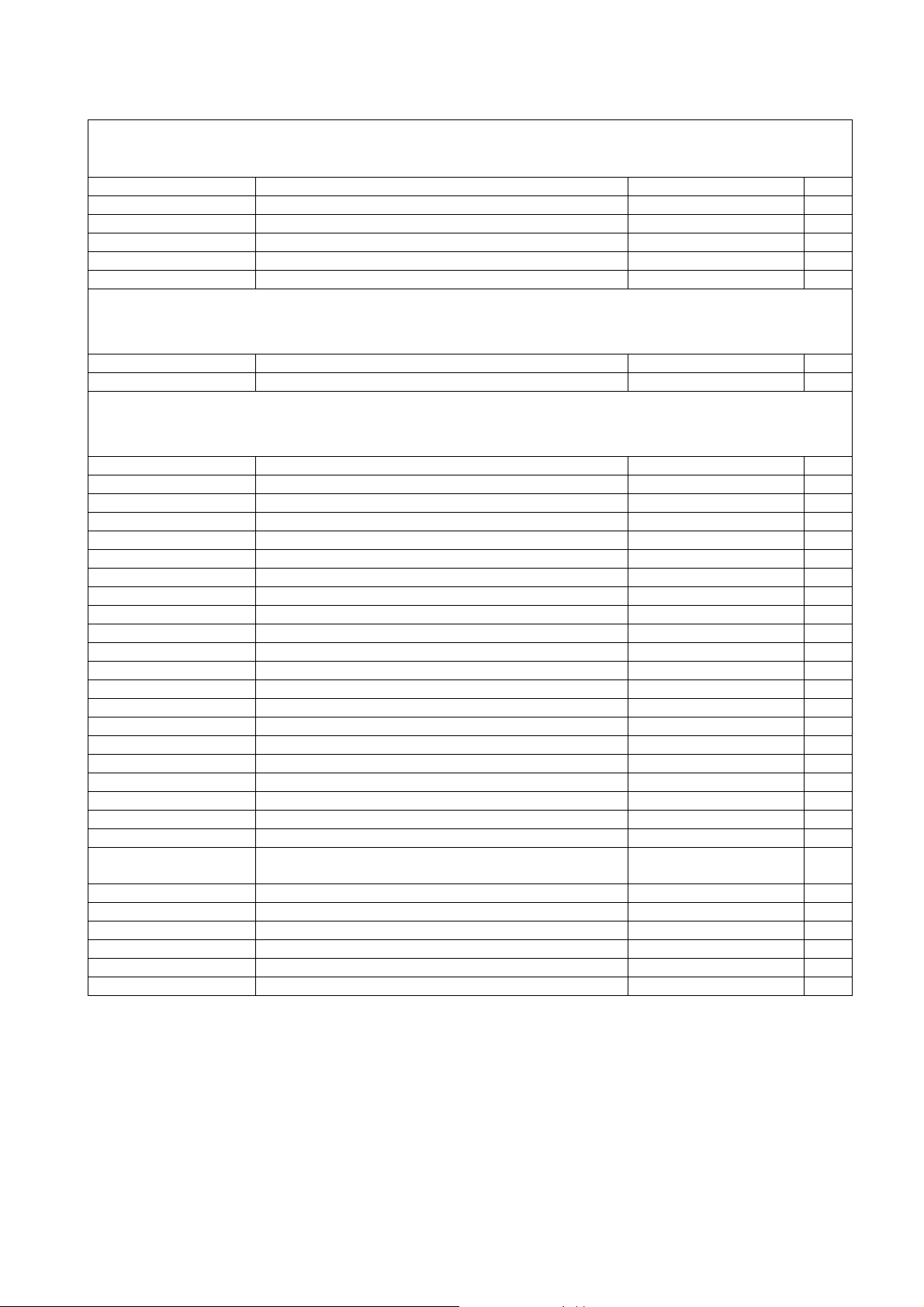

1) Printer Status

7 6 5 4 3 2 1 0

1 Buffer

status

Bit 2: Overrun Error – indicates when data sent to printer will be losted.

0 - data received will be printed

1 - data received will be lost

Bit 3: On / Off line – indicates when printer is operational (on-line) or not.

0 - on-line

1 - off-line

Bit 4: Wait – indicates when printer is busy or not.

0 – printer is busy and printing

1 – printer has printed all buffer and is waiting for commands

Bit 6 & 5: Buffer status – details the status of the printer buffer.

00 - buffer empty

01 - buffer less 1/3 full

10 - buffer more 1/3 full

11 - buffer more 3/4 full

Wait On / Off

line

Overrun

Error

0 0

2) Off-line Status

7 6 5 4 3 2 1 0

Cover

status

Bit 1: Paper near end sensor – informs the status of the paper near end sensor.

0 – there’s paper for printing

1 - there’s few paper for printing

Bit 2: Paper sensor – informs the status of the paper sensor.

0 – there’s paper on sensor

1 – there’s no paper on sensor

Bit 4: Drawer status – indicates status for drawer sensor.

0 – drawer sensor is indicating low level (logical 0)

1 – drawer sensor is indicating high level (logical 1)

Bit 5: No paper – indicates if there is available paper for printing.

0 – there’s paper available

1 – no paper is available

Bit 6: Error Reported – informs if an error was reported on Error Status.

0 – no error reported

1 – there’s error reported

Bit 7: Cover status – tells about the printer paper cover.

0 – cover is open

1 – cover is closed

Error

Reported

No paper

Drawer

status

0

Paper

sensor

Paper

near end

sensor

1

3) Error Status

7 6 5 4 3 2 1 0

1

Bit 2: Cutter presence – indicates the presence of a cutter on printer.

Recoverable

error

Non

ecoverable

error

1

Cutter

error

Cutter

presence

0 0

22-aug-2007

43

Firmware Release: 1.5

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

0 - cutter present

1 - cutter absent

Bit 3: Cutter error

0 – no cutter error

1 - cutter error

Bit 5: 0 - without non-recoverable error

1 - an non-recoverable error occurred

Bit 6: 0 - without recoverable error

1 - an recoverable error occurred

4) Continuous Paper Sensor Status

1 0 0 1 0

Bit 2: Head temperature – informs about the printer head temperature

0 - normal temperature

1 - temperature above the normal

Head

temperature

5) Firmware Version

0 1

0 Major firmware version digit Minor firmware version digit

It is not necessary to send any command to the printer to receive the status using

the parallel interface. The parallel interface provides status using hardware pins as shown

below.

3.7.3 Standard parallel interface status byte

The table below shows the printer statuses obtained through the standard parallel

interface, with the printer configured for ESC/Bema commands:

Parallel Interface Status Byte

/BUSY /ACK PE SEL /ERROR U U U HEX

1 1 0 1 1 x x x

0 1 1 0 0 x x x

1 1 1 1 1 x x x

0 1 1 1 0 x x x

D8h Online

60h Paper end

F8h Paper near end

70h Head up

Description

The table below shows the printer statuses obtained through the standard parallel

interface, with the printer configured for ESC/POSTM commands:

Parallel Interface Status Byte

/BUSY /ACK PE SEL /ERROR U U U HEX

1 1 0 1 1 x x x

0 1 1 1 0 x x x

1 1 1 1 0 x x x

0 1 0 1 1 x x x

D8h Online

70h Paper end

F0h Paper near end

58h Head up

Description

22-aug-2007

Firmware Release: 1.5

44

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

ETX

[Function] End buffer

[Format] ASCII ETX

Hexadecimal 03

Decimal 03

[Description] The printer will be BUSY while the printing is performed, changing

status only when the buffer is empty. On serial interfaces DTR (RTS)

will be low while the printing is performed.

STX

[Function] Clear buffer

[Format] ASCII STX

Hexadecimal 02

Decimal 02

[Description] This commands clears the print buffer and any un-printed information

in the printer receive before it. This command does not restore default

conditions.

22-aug-2007

Firmware Release: 1.5

45

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.8 Data Control

CAN

[Function] Cancel last line

[Format] ASCII CAN

Hexadecimal 18

Decimal 24

[Description] This commands clears the last line sent to the printer. All other data is

stored.

DEL

[Function] Cancel last character

[Format] ASCII DEL

Hexadecimal 7F

Decimal 127

[Description] This commands clears the last character sent to the printer. All other

data is stored.

22-aug-2007

Firmware Release: 1.5

46

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

3.9 Barcodes

GS h n

[Function] Sets the height n of the barcode generated

[Format] ASCII GS h n

Hexadecimal 1D 68 n

Decimal 29 104 n

[Description] Each height unit corresponds to a dot of 0.125 mm, so the final height

is n x 0.125 mm where 1 ≤ n ≤ 255. The default is n=162.

GS w n

[Function] Determines the width of the barcode

[Format] ASCII GS w n

Hexadecimal 1D 77 n

Decimal 29 119 n

[Description] This command changes the barcode width where n=2 correspond to

normal width, n=3 is double width and n=4 is quadruple width. The

default is n=3.

GS H n

[Function] Choose the position of the human readable information (HRI) of the

barcode

[Format] ASCII GS H n

Hexadecimal 1D 48 n

Decimal 29 72 n

[Description] n=0: No HRI

n=1: On top of the barcode (default)

n=2: On the bottom of the barcode

n=3: Both on top and on the bottom of the barcode

22-aug-2007

Firmware Release: 1.5

47

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS f n

[Function] Sets the font used to print the human readable information (HRI)

[Format] ASCII GS f n

Hexadecimal 1D 66 n

Decimal 29 102 n

[Description] For a normal font (‘N’ characters per line), n=0 or n=48. For a

condensed font (‘N’ characters per line), n=1 or n=49. The default is

normal font. See N value in the Table 2.

GS k 0 d1…d11 NUL

[Function] Prints an UPC-A barcode

[Format] ASCII GS k 0 d1…d

Hexadecimal 1D 6B 00 d1…d

Decimal 29 107 0 d1…d

NUL

11

11

11

00

0

[Description] d1…d11 is a sequence of 11 bytes containing the barcode information

with 48 ≤ d ≤ 57. A check sum digit will be added automatically.

GS k 65 11 d1…d11

[Function] Prints an UPC-A barcode

[Format] ASCII GS k 65 11 d1…d

Hexadecimal 1D 6B 41 0B d1…d

Decimal 29 107 65 11 d1…d

[Description] It is a copy of GS k 0 d1…d

NUL command.

11

11

11

11

22-aug-2007

Firmware Release: 1.5

48

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 1 d1…d6 NUL

[Function] Prints an UPC-E barcode

[Format] ASCII GS k 1 d1…d

Hexadecimal 1D 6B 01 d1…d

Decimal 29 107 1 d1…d

NUL

6

00

6

0

6

[Description] d1...d6 is a sequence of 6 bytes containing the barcode information

with 48 ≤ d ≤ 57. A check sum digit will be added automatically.

GS k 66 6 d1…d6

[Function] Prints an UPC-E barcode

[Format] ASCII GS k 66 6 d

Hexadecimal 1D 6B 42 06 d1…d

Decimal 29 107 66 6 d1…d

[Description] It is a copy of GS k 1 d1…d

NUL command.

6

1…d6

6

6

GS k 2 d1…d12 NUL

[Function] Prints an EAN-13 barcode

[Format] ASCII GS k 2 d

1…d12

Hexadecimal 1D 6B 02 d

Decimal 29 107 2 d1…d

[Description] d1...d12 is a sequence of 12 bytes containing the barcode information

with 48 ≤ d ≤ 57. The printer generates automatically the 13

NUL

1…d12

12

00

0

th

digit.

22-aug-2007

Firmware Release: 1.5

49

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 67 12 d1…d12

[Function] Prints an EAN-13 barcode

[Format] ASCII GS k 67 12 d1…d

Hexadecimal 1D 6B 43 0C d1…d

Decimal 29 107 67 12 d1…d

[Description] It is a cop of command GS k 2 d1…d

12

12

12

NUL.

12

GS k 3 d1…d7 NUL

[Function] Prints an EAN-8 barcode

[Format] ASCII GS k 3 d1…d

Hexadecimal 1D 6B 03 d1…d

Decimal 29 107 3 d1…d

[Description] d1…d7 is a sequence of 7 bytes containing the barcode information

with 48 ≤ d ≤ 57. The printer generates automatically the 8

NUL

7

00

7

0

7

th

digit.

GS k 68 7 d1…d7

[Function] Prints an EAN-8 barcode

[Format] ASCII GS k 68 7 d

Hexadecimal 1D 6B 44 07 d

Decimal 29 107 68 7 d1…d

[Description] It is a copy of GS k 3 d1…d

NUL command.

7

1…d7

1…d7

7

22-aug-2007

Firmware Release: 1.5

50

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 4 d1…dn NUL

[Function] Prints a CODE 39 barcode

[Format] ASCII GS k 4 d1…d

Hexadecimal 1D 6B 04 d1…d

Decimal 29 107 4 d1…d

NUL

n

00

n

0

n

[Description] d1…dn is the sequence of n bytes containing the barcode information.

The bytes that can be used in d are 32, 36, 37, 42, 43, 45 to 57 and 65

to 90 (upper case letters) or 97 to 122 (lower case letters). Lower case

and upper case letters can’t be combined in the same barcode. A

check sum digit will be added automatically. Number of digits in the

barcode limited by the print field as well as the configured barcode

width.

GS k 69 n d1…dn

[Function] Prints a CODE 39 barcode

[Format] ASCII GS k 69 n d1…d

Hexadecimal 1D 6B 45 n d1…d

Decimal 29 107 69 n d1…d

[Description] It is a copy of the command GS k 4 d1…d

n

n

n

NUL.

n

GS k 5 d

…dn NUL

1

[Function] Prints an ITF barcode

[Format] ASCII GS k 5 d1…d

Hexadecimal 1D 6B 05 d1…d

Decimal 29 107 5 d1…d

[Description] d1…dn is the sequence of n bytes containing the barcode information

with 48 ≤ d ≤ 57. Number of digits in the barcode limited by the print

field as well as the configured barcode width.

NUL

n

00

n

0

n

22-aug-2007

Firmware Release: 1.5

51

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 70 n d1…dn

[Function] Prints an ITF barcode

[Format] ASCII GS k 70 n d1…d

Hexadecimal 1D 6B 46 n d1…d

Decimal 29 107 70 n d1…d

[Description] It is a copy of the command GS k 5 d1…d

n

n

n

NUL

n

GS k 6 d

…dn NUL

1

[Function] Prints a CODABAR barcode

[Format] ASCII GS k 6 d1…d

Hexadecimal 1D 6B 06 d1…d

Decimal 29 107 6 d1…d

[Description] d1…dn is the sequence of n bytes containing the barcode information.

The bytes that can be used in d are 36, 43, 45 to 57 and 65 to 68

(upper case letters) or 97 to 100 (lower case letters). Lower case and

NUL

n

00

n

0

n

upper case letters can’t be combined in the same barcode. A check

sum digit will be added automatically. Number of digits in the barcode

limited by the print field as well as the configured barcode width. If the

first character is a letter, the last character must also be a letter.

Excluding these two characters (the first and the last one), any other

character can be a letter.

GS k 71 n d1…dn

[Function] Prints a CODABAR barcode

[Format] ASCII GS k 71 n d1…d

Hexadecimal 1D 6B 47 n d1…d

Decimal 29 107 71 n d1…d

[Description] It is a copy of the command GS k 6 d1…d

n

n

n

NUL

n

22-aug-2007

Firmware Release: 1.5

52

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 72 d1…dn

[Function] Prints a CODE 93 barcode

[Format] ASCII GS k 72 d1…d

Hexadecimal 1D 6B 48 n d1…d

Decimal 29 107 72 n d1…d

n

n

n

[Description] n indicates the number of bytes that will be sent and d1…d

sequence of n bytes containing the barcode information. This code

can use all bytes from 0 to 127. A check sum digit will be added

automatically. Number of digits in the barcode limited by the print field

as well as the configured barcode width.

GS k 73 n d1…dn

[Function] Prints a CODE 128 barcode

[Format] ASCII GS k 73 n d1…d

Hexadecimal 1D 6B 49 n d1…d

n

n

is the

n

Decimal 29 107 73 n d1…d

n

[Description] n indicates the number of bytes that will be sent and d1…d

sequence of n bytes containing the barcode information. This code

can use all bytes from 0 to 127. The subset is automatically chosen by

the printer based on the data received. A check sum digit will be

added automatically. Number of digits in the barcode limited by the

print field as well as the configured barcode width.

is the

n

22-aug-2007

Firmware Release: 1.5

53

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 128 n1 n2 n3 n4 n5 n6 d1…dn

[Function] Prints a PDF-417 barcode

[Format] ASCII GS k 128 n1 n2 n3 n4 n5 n6 d1…d

Hexadecimal 1D 6B 80 n1 n2 n3 n4 n5 n6 d1…d

Decimal 29 107 128 n1 n2 n3 n4 n5 n6 d1…d

[Description] n

is the ECC level (from 0 to 8) (Error correction level).

1

n2 is the pitch height (from 1 to 8) where height=n2 x 0.125mm.

is the pitch width (from 1 to 4) where width=n3 x 0.125mm.

n

3

n

is the number of codewords per row – if n

4

is 0, the maximum

4

number of columns allowed for the pitch width informed will be used. If

the barcode can’t fit the print width the printer automatically adjusts it

for the maximum permitted width within the line field.

n5 and n

indicate the number of bytes that will be coded, where

6

total=n5 + n6 x 256, and total must be less than 900.

d1…d

is the actual sequence of bytes that will be coded.

n

n

n

n

GS k 21 d1…d9 NUL

[Function] Prints an ISBN barcode

[Format] ASCII GS k 21 d1…d

Hexadecimal 1D 6B 15 d1…d

[Description] d

Decimal 29 107 21 d

is the sequence of 9 bytes containing the barcode information.

1…d9

The bytes that can be used in d are 45, 48 to 57 and 88. If hyphens

were included in the information as in the example below, they will not

be computed as a byte received. After the ninth valid digit, an hyphen

can be added followed by an “X” (58h) or any other digit (30h to 39h).

In this case there are two options:

1. Send the 00h and the barcode will be printed

2. Send space (20h) and more 5 digits (30h to 39h)

Example: 1-56592-292-X 90000

1…d9

NUL

9

00

9

0

22-aug-2007

Firmware Release: 1.5

1-56592-292-1 90000

1-56592-292-X

1-56592-292-1

54

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 22 d1…dn NUL

[Function] Prints a MSI barcode

[Format] ASCII GS k 22 d1…d

Hexadecimal 1D 6B 16 d1…d

Decimal 29 107 22 d1…d

NUL

n

00

n

0

n

[Description] d1…dn is the sequence of n bytes containing the barcode information.

The bytes that can be used in d are 48 to 57. The limitation of size for

this barcode is given by the print field as well as the configured bar

width. A check sum digit will be added automatically.

GS k 130 n d1…dn

[Function] Prints a MSI barcode

[Format] ASCII GS k 130 n d1…d

Hexadecimal 1D 6B 82 n d1…d

Decimal 29 107 130 n d1…d

[Description] It is a copy of the command GS k 22 d1…d

n

n

n

NUL

n

GS k 23 d1…dn NUL

[Function] Prints a PLESSEY barcode

[Format] ASCII GS k 23 d

Hexadecimal 1D 6B 17 d

Decimal 29 107 23 d1…d

[Description] d1…dn is the sequence of n bytes containing the barcode information.

The bytes that can be used in d are 48 to 57 plus 65 to 70 (upper case

letters) or 97 to 102 (lower case letters). Lower case and upper case

letters can’t be combined in the same barcode. The limitation of size

for this barcode is given by the print field as well as the configured bar

width. A check sum digit will be added automatically.

1…dn

1…dn

NUL

00

0

n

22-aug-2007

Firmware Release: 1.5

55

MP-4000 TH POS Printer Rev.1.4 Programmer’s Manual

GS k 131 n d1…dn

[Function] Prints a PLESSEY barcode

[Format] ASCII GS k 131 n d1…d

Hexadecimal 1D 6B 83 n d1…d

Decimal 29 107 131 n d1…d

[Description] It is a copy of the command GS k 23 d1…d

n

n

n

NUL

n

GS k 132 n1 n2

[Function] Programs barcode’s left margin

[Format] ASCII GS k 132 n1 n

Hexadecimal 1D 6B 84 n1 n

Decimal 29 107 132 n1 n

[Description] Programs the position of the barcode’s left margin position given by n

+ n

x 256.

2