Page 1

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

BelsonBelson

SERVICE SERVICE

MANUALMANUAL

BSV-29251

Page 2

CONTENTS

SAFETY INSTRUCTION AND PRODUCT SAFETY NOTICE………………………..……1

X-RAY RADIATION PRECAUTION………………………………………………………1

SAFETY PRECAUTION…………………………………………………………………..1

PRODUCT SAFETY NOTICE…………………………………………………………….2

ALIGNMENT PROCEDURE…………………………………………………………….3

TEST EQUIPMENT……………………………………………………………………3

ALIGNMENT INSTRUCTION………………………………………………………………..3

B+ CONFIRM……………………………………………………………………………………3

AGC ALIGNMENT………………………………………………………………………………4

SOUND CHECK…………………………………………………………………………………4

FOCUS POTENTIOMETER ADJUSTMENT…………………………………………………4

H-CENTER ADJUSTMENT……………………………………………………………………4

V-SIZE, VERTICAL S-CORRECTION, V-CENTER, H-SIZE, E/W CORRECTION

ADJUSTMENT……………………………………………………………………………4

SCREEN-GRID VOLTAGE VG2 ADJUSTMENT…………………………………………4

WHITE BALANCE ADJUSTMENT(AUTO DARK BALANCE)……………………………4

LUMINANCE/CHROMA TIME DELAY ADJUSTMENT……………………………………5

HIGH VOLTAGE AND FILAMENT VOLTAGE CHECK……………………………………5

X-RAY PROTECTION CHECK………………………………………………………………5

BEAM CURRENT CHECK……………………………………………………………………5

AV F U N C T I O N C H E C K ………………………………………………………………………5

OUT-FACTORY STATUS SETTING…………………………………………………………5

APPENDIX 1……………………………………………………………………………………6

APPENDIX 2……………………………………………………………………………………8

WIRING DIAGRAM……………………………………………………………………….9

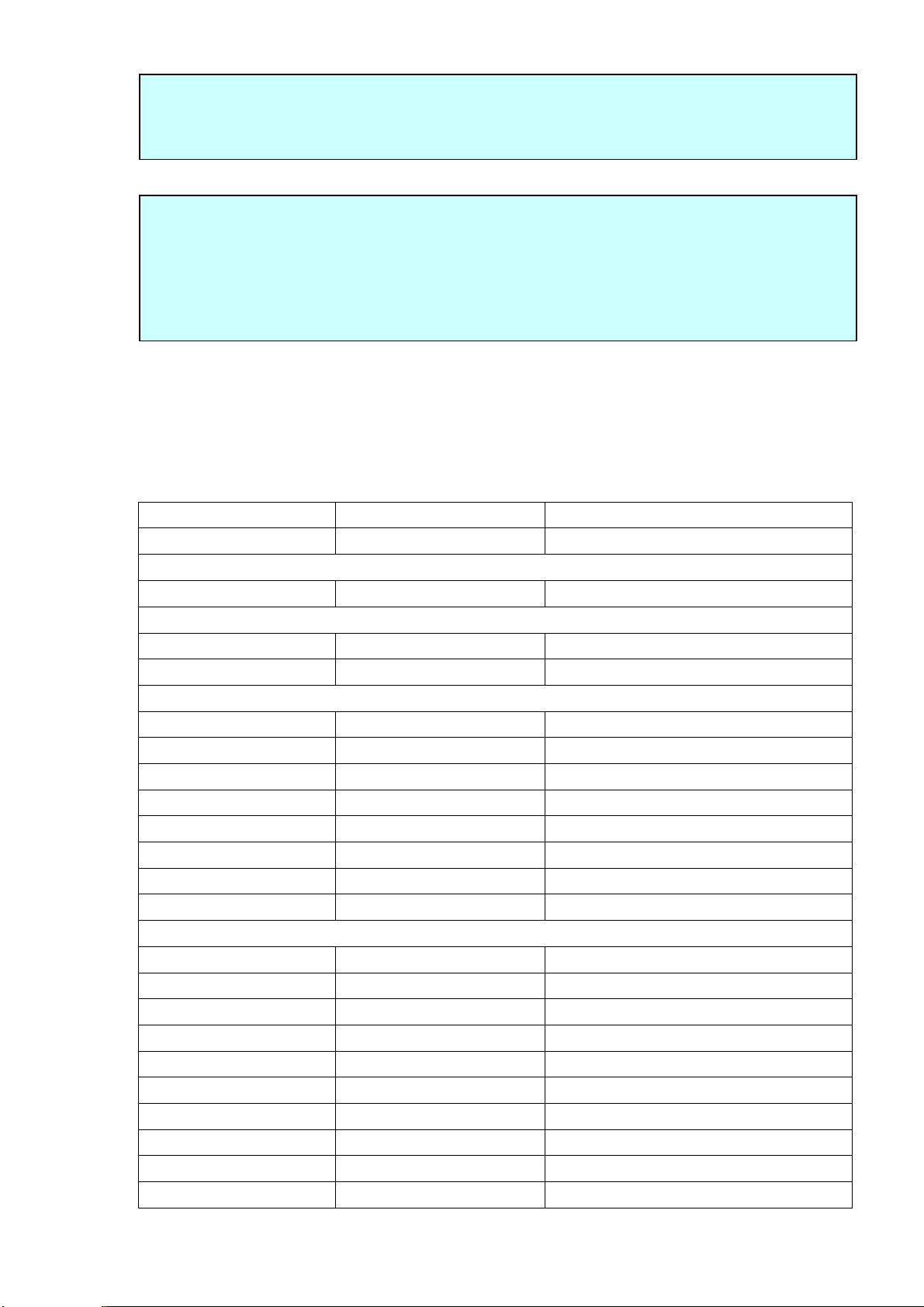

BLOCK DIAGRAM………………………………………………………………………...10

IC BLOCK DIAGRAM……………………………………………………………………..11

SCHEMATIC DIAGRAM………………………………………………………………….15

ELECTRICAL PARTS LIST………………………………………………………………16

1

Page 3

CAUTION: THIS SERVICE MANUAL IS ONLY FOR PROFESSIONAL SERVICE PERSONNEL’S

REFERENCE. BEFORE SERVICING THIS CHASSIS, PLEASE READ THE

FOLLOWING NOTICE ITEMS.

1. SAFETY INSTRUCTION AND PRODUCT SAFETY NOTICE

Before servicing and aligning this equipment, please read the following “X-RAY RADIATION

PRECAUTION” ,“SAFETY PRECAUTION” and “PRODUCT SAFETY NOTICE”.

1.1 X-RAY RADIATION PRECAUTION

Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards,

1

the high voltage must not be above the specified limit. The normal value of the high voltage of this

receiver is: 26.5kV(25”) at 1.3mA beam current; 29kV(29” super flat) at 1.4mA beam current; 30kV(29”

pure flat) at 1.4mA beam current. The high voltage must not, under any circumstances, exceed

31kV(25”)/33kV(29”)/35kV(29” pure flat).

2

Each time a receiver requires servicing, the high voltage should be checked following the HIGH

VOLTAGE CHECK procedure in this manual. It is recommended the reading of the high voltage be

recorded as a part of service record. It is important to use an accurate and reliable high voltage meter.

The primary source of X-RAY RADIATION in this TV receiver is the picture tube. For continuous X-RAY

3

RADIATION protection, the replacement tube must be exactly the same type tube as specified in the parts

list.

Some parts in this receiver have special safety-related characteristics for X-RAY RADIATION protection.

4

For continuous safety, parts replacement should be undertaken only after referring to the PRODUCT

SAFETY NOTICE below.

1.2 SAFETY PRECAUTION

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precaution on this receiver. The

following are the necessary precautions to be observed before servicing this chassis.

1) Since the power supply circuit of this receiver is directly connected to the AC power line, an isolation

transformer should be used during any dynamic service to avoid possible shock hazard.

2) Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube.

The picture tube is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter

proof goggles and keep picture tube away from the unprotected body while handling.

3) When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in

place, such as: non-metallic control knobs, insulating covers, shields, isolation resistor-capacitor network

etc.

4) When replacing parts or circuit boards, disconnect the power cord.

5) When replacing a high wattage resistor (oxiode metal film resistor) on the circuit board, keep the resistor

10mm (1/2in) away from circuit board.

1

Page 4

6) Connection wires must be kept away from components with high voltage or high temperature.

7) If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis parts list.

8) Before returning the set to your customer, always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, screwheads, metal overlays, control shafts etc. to

be sure the set is safe to operate without danger of electrical shock. Plug the AC power cord into a 220V

AC outlet (do not use a line isolation transformer during this check). Use an AC voltmeter having 5000

ohms per volt or more sensitivity in the following manner:

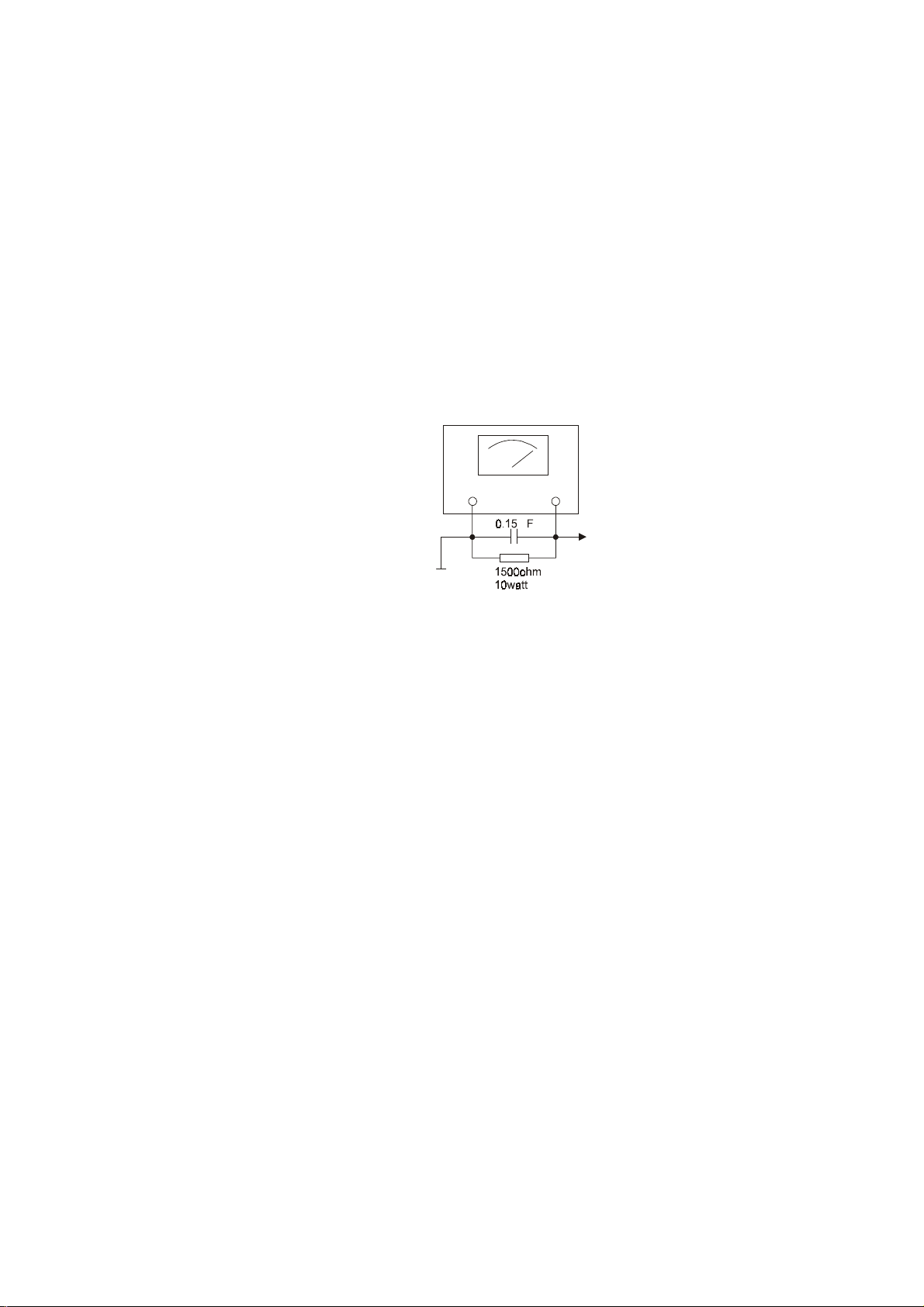

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15µF, AC type capacitor, between a known good

earth ground (water pipe, conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500 ohm resistor and 0.15µF capacitor. Reverse the AC plug at the AC

outlet and repeat AC voltage measurements for each exposed metallic part. Voltage measured must not

exceed 0.3 volts RMS. This corresponds to 0.2 milliamp. AC. Any value exceeding this limit constitutes a

potential shock hazard and must be corrected immediately.

AC VOLTMETER

µ

9) DC voltage breakdown test

Good earth ground

such as a water

pipe, conduit, etc.

C.

R.

Place this probe on

Each exposed

Metallic part.

Before packing, the following touchable parts should be conducted with withstand voltage test for 1s.

Apply the voltage and test, the voltage should be AC 3000V.

Part name : Position:

Antenna terminal Back cabinet

Outcabinet screws Back cabinet

AV terminals Back and side

1.3 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection and the X-RAY RADIATION

protection afforded by them cannot necessarily be obtained by using replacement components rated for

higher wattage, etc. Replacement parts which have these special safety characteristics are identified in

this manual and its supplement electrical components having such features are shaded on the schematic

diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same characteristics as specified in the parts list may

create shock, fire, X-RAY RADIATION or other hazards.

2

Page 5

y

n

h

y

Col

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

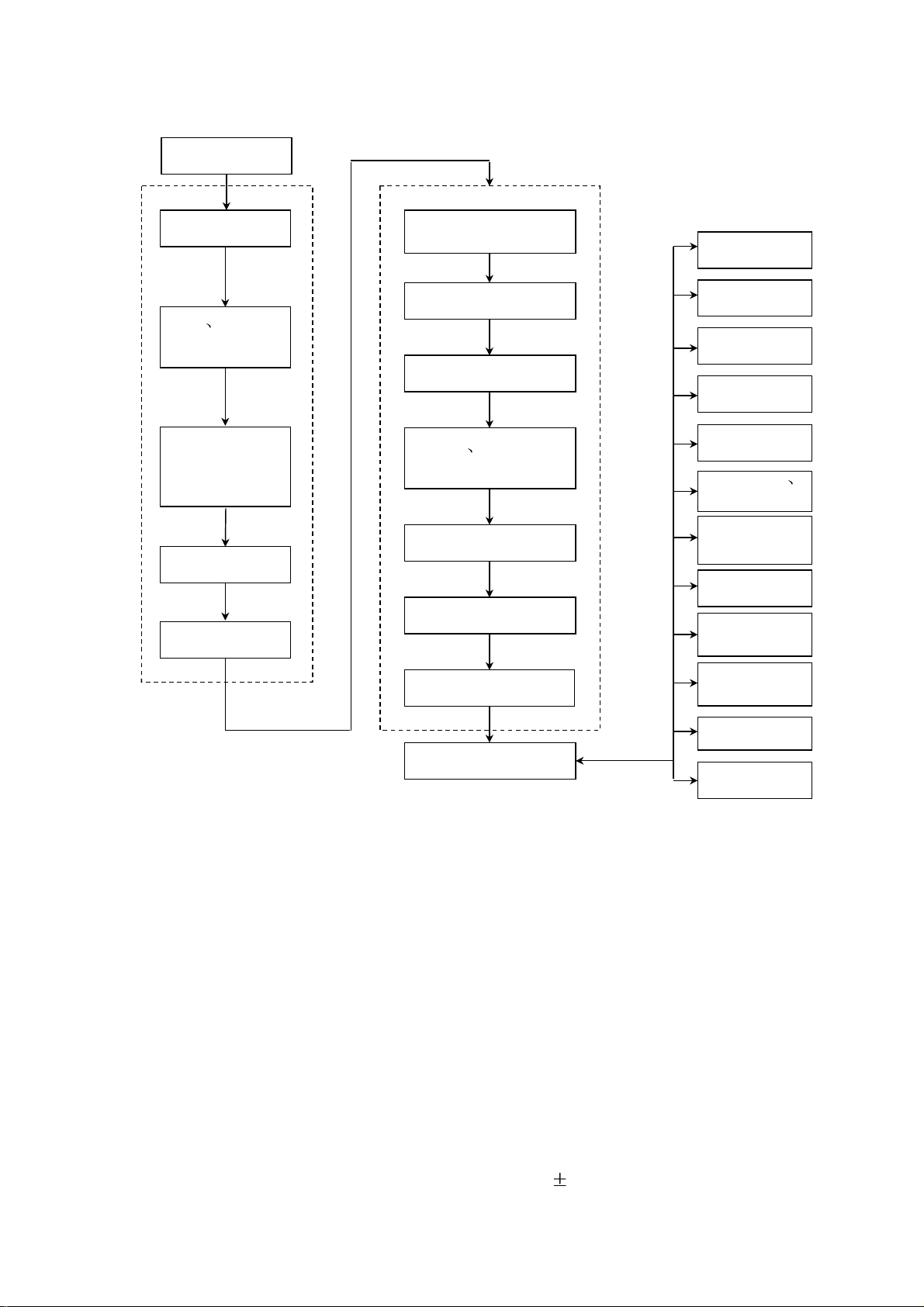

2 Alignment procedure

The alignment procedure flow chart see below figure:

EEPROM copy

Chassis

B+ check

V-size V-linearit

rough adjust

H-size,

E/W pincushio

correction roug

adjust

RF AGC

Sound check

The whole unit

Focus rough adjust and

aging

VG2 adjust

White balance and

sub-brightness adjust

H-center V-center and

V-size realign

H-size and E/W

correction

OSD vertical position

Focus fine-adjust

Check

Fig.2

High voltage

check

Filament voltage

check

X-ray protection

check

Picture and

sound check

White balance

check

or purity

convergence

check

Luminance,

chroma time

dela

AV terminal

check

The TV set

button’s function

check

The remote

controller’s

function check

Installation and

packing check

Safety check

3. TEST EQUIPMENT

3.1 DC regulated power supply PAB18-1.8

3.2 Audio voltameter

3.3 Oscilloscope

3.4 High-voltage meter

3.5 Digital multimeter

3.6 AC break-down testing equipment

4 Alignment instruction

The way to enter into factory alignment menu by using remote control: when there is no OSD on the

screen, in turn press MIX, CANCEL, HOLD and REVEAL button and the period of two-press should be

less than 3 seconds. To exit, press TV button.

4.1 B+ confirm

Use DC voltameter of DC200V to check B+ voltage (C529 two terminals), 29” pure flat CRT should

be 140V or 138V (depending on different CRT), the error is

0.5 V.

4.2 AGC alignment

3

Page 6

4.2 AGC alignment

4.2.1 Receive D-8 signal 60 dB, use DC voltameter to measure C104 positive pole testing point voltage.

4.2.2 Adjust TOP item to make AGC voltage just start dropping from highest point (about 4V).

4.2.3 From antenna input inputs 100 dB signal, the picture should not appear non-synchronization and

distortion. Input 35 dB

40 dB weak signal, the colour should not appear and picture is in

synchronization and sound is normal.

4.3 Sound check

4.3.1 Receive 1kHz 100% modulation sound signal, XV03 connect with a simulated speaker load of 8 ohm,

audio voltmeter or oscilloscope measure the voltage of the load.

4.3.2 Turn the volume to maximum, the sound power consumption should be

the distortion should be

7% (allow maximum volume sine wave have clipping distortion)

7 W 2 (about 7.5 Vrms),

4.4 Focus potentiometer adjustment

4.4.1 The whole unit preheats 30 minutes.

4.4.2 Receive testing signal.

4.4.3 Press PP button to select DYNAMIC mode.

4.4.4 Adjust FBT’s FOCUS potentiometer to make picture clearest.

4.5 H-center adjustment

4.5.1 Receive 50 Hz testing signal.

4.5.2 Enter into 5HSH item, adjust the level to make picture symmetry in horizontal.

4.5.3 Receive 60Hz testing signal. To 6HSH adjust, the method is as same as the above two steps.

4.6 V-size, Vertical S-correction, V-center, H-size, E/W correction adjustment (50 Hz/60 Hz

independently)

4.6.1 Receive testing signal, enter into factory menu VSL item, adjust the value to make picture’s lower half

part just disappear.

4.6.2 Enter into factory menu corresponding item, adjust the value to make V-center and CRT’s geometrical

center be in accordance, vertical S-linearity be proper and vertical reproduction rate be

90%.

4.6.3 Enter into factory menu corresponding items, adjust horizontal geometrical distortion until be in proper.

EWW Adjust H-size

EWP Adjust east/west pincushion correction size

EWT Adjust east/west trapezoid size

UCT Adjust east/west left upper corner and right upper corner distortion

LCR Adjust east/west left lower corner and right lower corner distortion.

BOW Adjust east/west arch.

PAR Adjust parallelogram.

The adjustment results meet scan linearity geometrical distortion and over-scan (reproduction rate)

requirements.

4.7 Screen-grid voltage VG2 adjustment

Enter into factory menu, set VG2B to 29, press digit button “0”, enter into alignment status, turn FBT

accelerated pole potentiometer to end anticlockwise, then clockwise turn the potentiometer until the

indication “OUTSIDE LOW” just jump to “INSIDE HIGH”.

4.8 White balance adjustment (auto dark balance)

4.8.1 Dark balance just need fine tune, under 4.5 nit, colour temperature 12000K+8MPCD (X=0.270,

Y=0.283)

4.8.2 Bright balance also has already automatically adjusted at some white coordinate. Only need to fine tune

around 31 value, under 60 nits, colour temperature 12000K+8MPCD (X=0.270, Y=0.283)

4

Page 7

4.9 Luminance/chroma time delay adjustment (YD_ _)

Respectively input PAL,SECAM,NTSC RF signal or PAL AV signal and adjust YD_ _ to make

luminance tallied with chroma.

For those model with SVM function, on the condition that SVM is set to ON, input split field or

crosshatch signal, respectively adjust YD_ _ until SVM’s edge from black to white is in symmetry with

that from white to black, give attention to the data that make luminance tallied with chroma.

4.10 High voltage and filament voltage check

4.10.1 Connect high voltage meter between CRT high voltage cap and GND, use effective and precise

voltameter to measure filament voltage.

4.10.2 Receive D35 signal, set picture mode to “DYNAMIC”. Measure the high voltage and filament voltage

and the reading should be: for 29” super flat CRT, the high voltage is 29 kV

flat CRT, the high voltage is 30 kV

0.5 kV, filament voltage 6.3 0.3 Vrms.

0.5 kV, for 29” pure

4.11 X-ray protection check

4.11.1 Receive normal picture.

4.11.2 Press S301 switch, horizontal scan should stop vibration and turn off.

4.11.3 Turn off the power switch and wait about 30 seconds, turn on the set again, it should restore to

normal.

4.12 Beam current check

Receive D35 signal, set picture mode to “DYNAMIC”, measure R313 two terminals, for 29” super flat

it should be

1.6 V, for 29” pure flat it should be 1.7V.

4.13 AV function check

According to Instruction manual, connect the AV equipment to the AV terminals which need to be

check, the following is required:

VIDEO IN: 1 Vp-p 75

, AUDIO IN: -8 dBm 3 dBm 47 k .

4.14 Out-factory status setting

Contrast: 45 Comb filter: ON

Brightness: 28 Blue back: ON

Colour: 40 Black stretch: ON

Sharpness: 35 SVM: ON

Treble: 31 AVL: OFF

Bass: 31 Surround: OFF

Balance: 0

The following appendix is factory menu and data.

5

Page 8

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

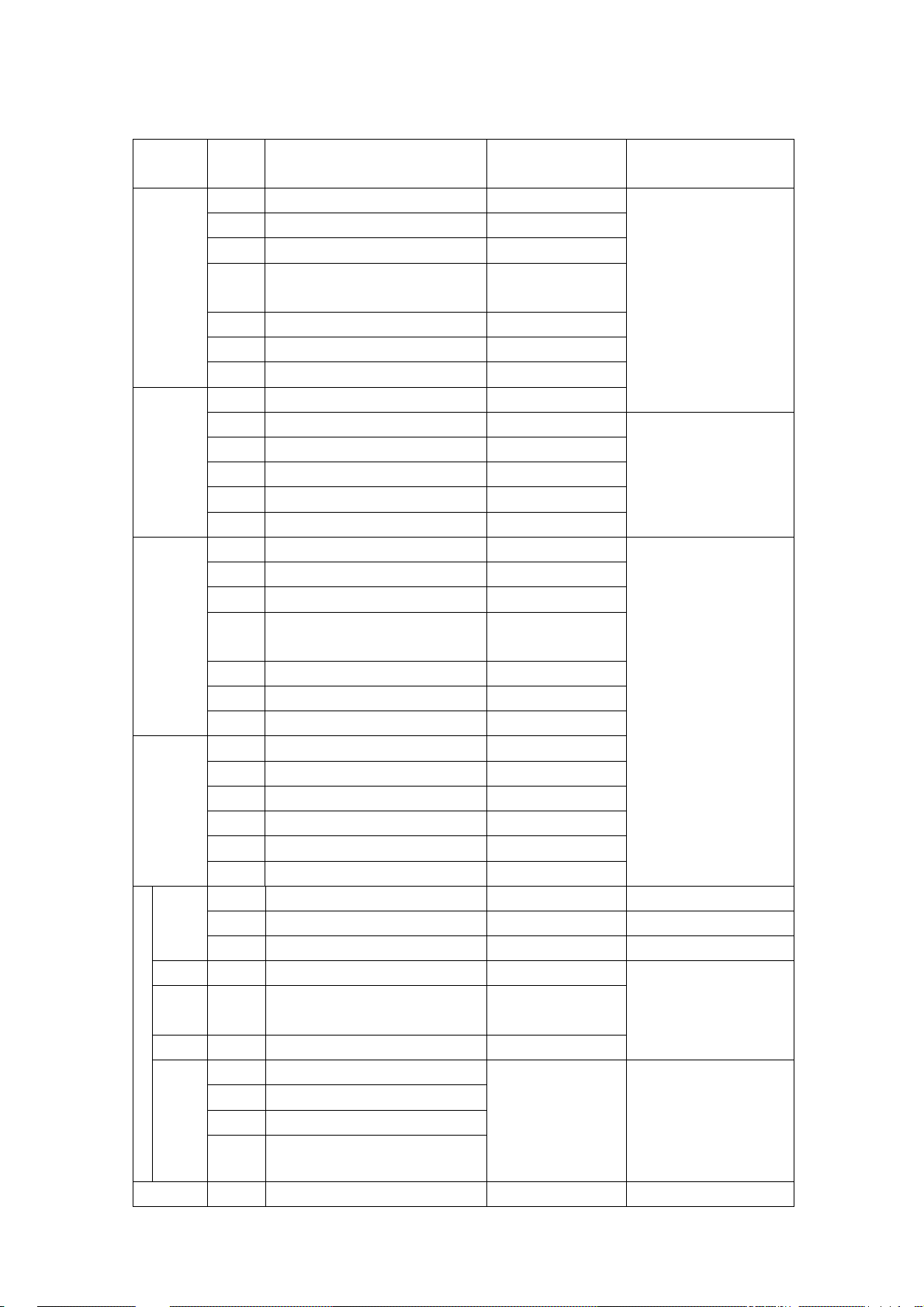

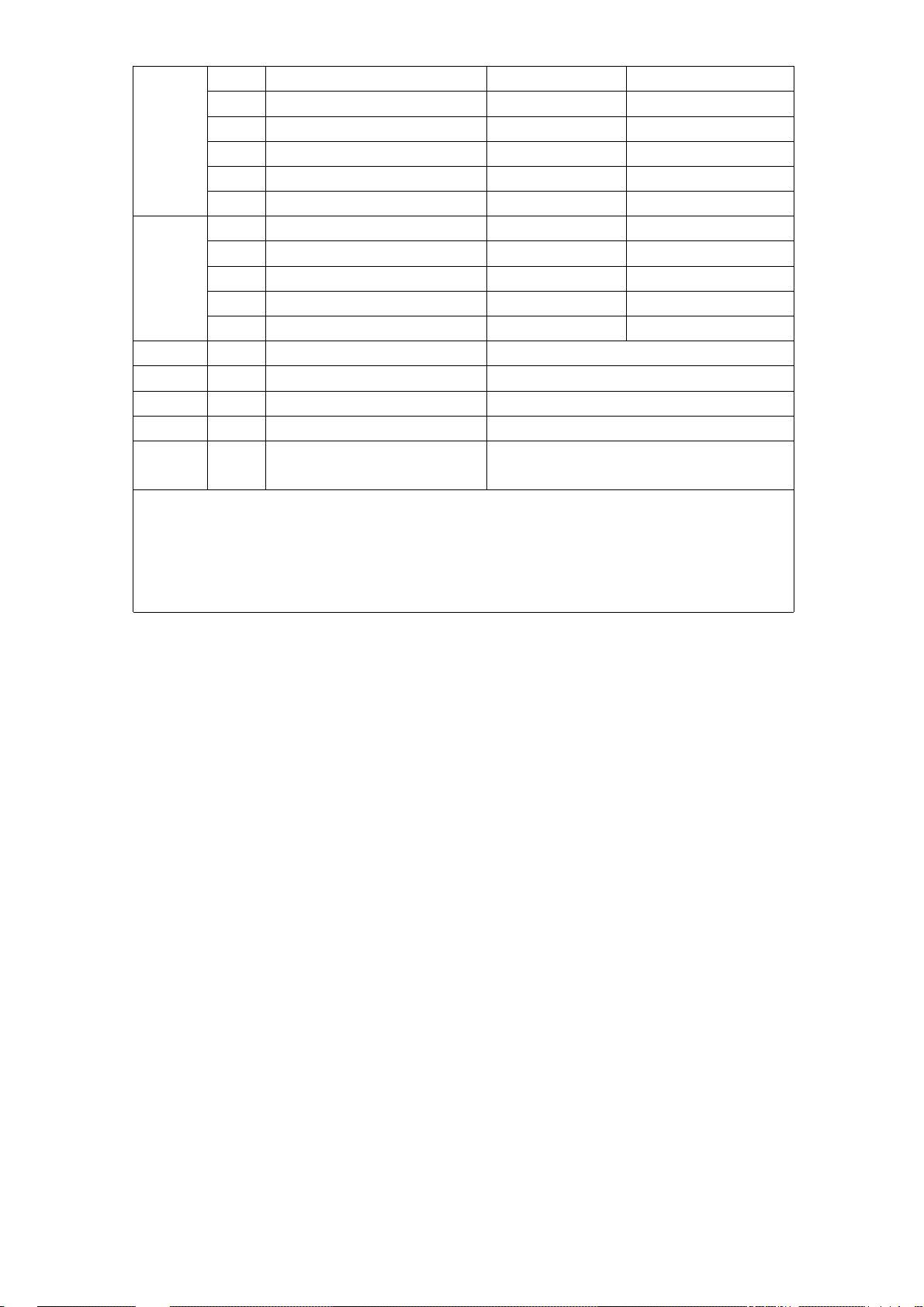

Appendix 1 factory menu and data

Page/

Button

1

2

1

Item Meaning Reference value Remark

5PAR Horizontal parabola 0-63

5BOW Horizontal bow 0-63

5HSH Horizontal shift 0-63

5EWW EW width 0-63

5EWP EW parabola 0-63

5UCR EW upper corner parabola 0-63

5LCR EW lower corner parabola 0-63

5EWT EW trapezium 0-63

5VSL Vertical slope 0-63

5VAM Vertical amplitude 0-63

5SCL S-Correction 0-63

5VSH Vertical Shift 0-63

5VOF Text Position Vertical offset

6PAR Horizontal parabola 0-63

6BOW Horizontal bow 0-63

6HSH Horizontal shift 0-63

6EWW EW width 0-63

For 50Hz

41

6EWP EW parabola 0-63

6UCR EW upper corner parabola 0-63

6LCR EW lower corner parabola 0-63

6EWT EW trapezium 0-63

6VSL Vertical slope 0-63

2

RED WPR White Point R 0-63

GREEN WPG White Point G 0-63

6VAM Vertical amplitude 0-63

6SCL S-Correction 0-63

6VSH Vertical Shift 0-63

6VOF Text Position Vertical offset

VX Vertical Zoom

RED Black level offset R 32

GRN Black level offset G 32

28

25

3

BLUE WPB White Point B 0-63

YDFP Y-Delay for PAL

YDFN Y-Delay for NTSC

YDFS Y-Delay for SECAM

YDAV Y-Delay for AV

4 TOP AGC Take-Over Point 0-63

0-15

For 60Hz

Adjust around 31

Brightness, colour in

accordance. For model

with SVM function,

SVM edge should be

in symmetrical.

6

Page 9

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

VOL Volume

9874 Gain control for TDA9874

IFFS Vision IF

HDOL Cathode drive level

AGC IF AGC speed

AG2B VG2 Brightness 33 Before adjust AG2, fix it

OP1 Option byte 1 218 (11011010)

OP2 Option byte 2 33 (00100001)

5

6 INT Initial E2PROM According to actual need initial EEPROM

7 LOGO Logo According to actual need set the logo.

8 STS Status

9 AGIN Aging(escape by local Menu) Press Menu button on the set to exit.

0 VG2 Adjust VG2

Note1: the letter in bold and italic is fixed setting.

Note2: use blank EEPROM, after turning on the set for the first time, please first initial EEPROM (at INT item

press VOL+ button), and reset other factory menu item.

OP3 Option byte 3 123 (01111011)

OP4 Option byte 4 251 (11111011)

OP5 Option byte 5 63 (00111111)

45

20

2

8

1

‘In High’/’Out Low’

or line disappear

2-38.9M,3-38M

7

Page 10

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

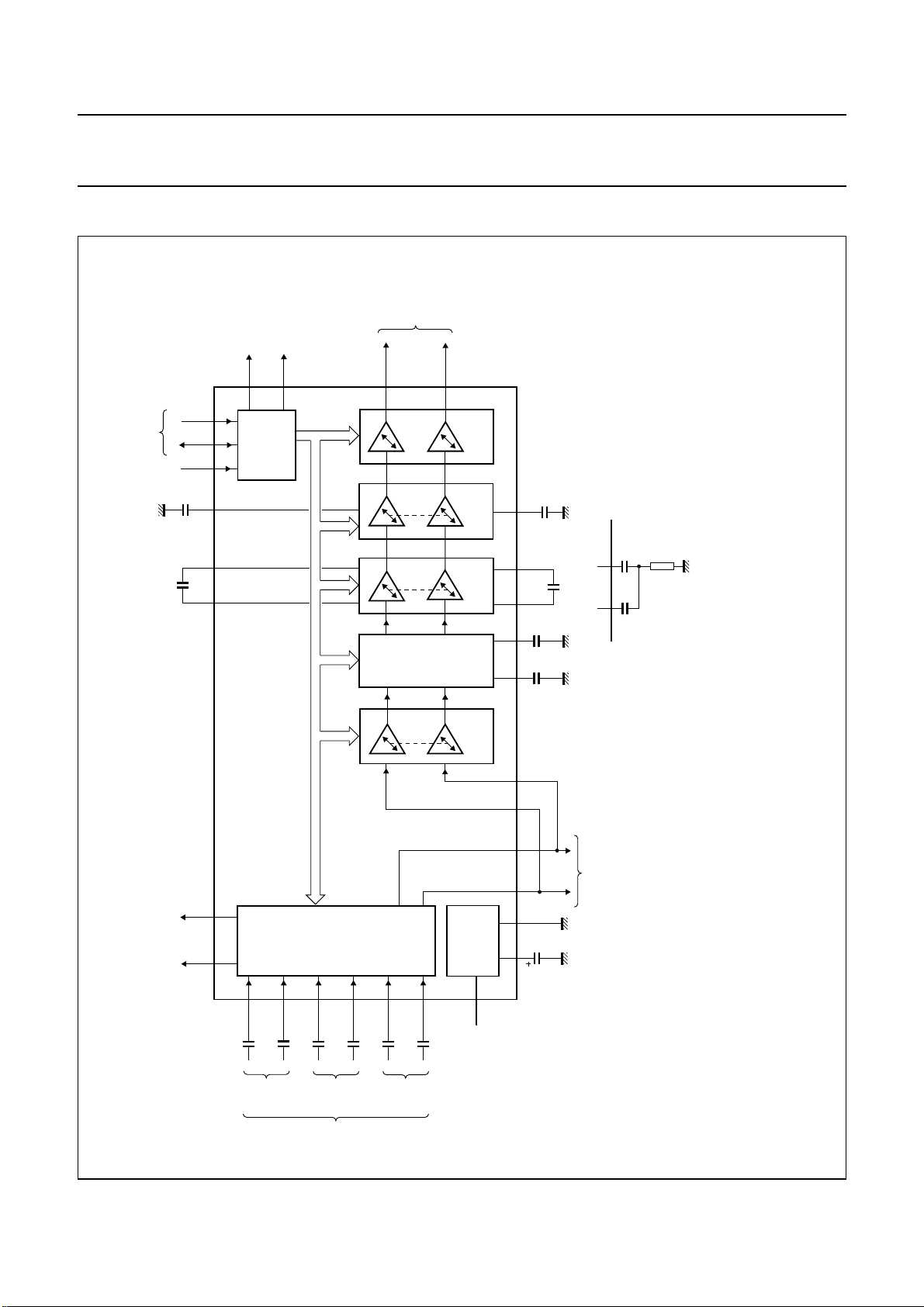

Addendix2 Option byte 1-5 meaning

Bit Option 1 Option 2 Option 3 Option 4 Option 5

7

6

5

4

3

2

1

0

Note1: the letter in bold and capital is fixed setting.

Note2: for model without NICAM, please set AVL=0.

Note3: for sound filter in absorbing type in main board (for example K3959D), please set AUTO SOUND=0.

OSD1 FSL2

1-enable 0-disable 0- disable 1- disable

Reserved

1

DVD Sound BG PSNS Italian

0- RGB

1-enable 1-enable 1-TDA9363 1-enable

1-enable 1-enable 1-enable 1-enable

0-disable

1-enable 1- disable

0-normal mode 1-enable 1-enable

1)OSO Switch Off in vertical Over Scan

2)FSL Forced Slicing Level

3)Function SVM is disable when in RGB,DVD,TEXT or SECAM mode

4)PSNS More PAL color sensitivity for Asian market areas

5)FMWS Active when M system

1-DVD

SVHS Sound DK HCO French

AV2 Secam-SVM LOGO German

Super woofer

Comb filter Auto sound EEPROM Spanish

VG2 mode AVL AFC Store FMWS English

Function

01-SVM

10-BBE

11-SRS

00-none

000-Pan Euro

001-Ukrainian

010-Russian

011-Farsi

100-Arabic

3

Teletext

Sound M DFL

Sound I OSD syn.

1-enable 1-stable

1-enable

Off-RBL AKB Arabic

0-enable 0-on 1-enable

1-8k 250prg

4

1-more

1-Memory Stb

0-Power on Stb

1- large

Switch on

5

Reserved

Reserved

1-enable

1-enable

1-enable

8

Page 11

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Page 12

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

RF

TUNER101

TDQ-3B9H

BAND-UV

AGC

BAND-HL

SW

P2

VT

IF

SW

P2

SAW

SIF

N201

ST24C08

EEPROM

Z205 K2958M

ZZ01

K9260M

IF1

IF2

BAND-HL

BAND-UV

IIC

AGC

VT

NZ01

LA7510

SIF'

IIC

NZ02

TDA9874AH

MONO

FM MONO

Audio

Out

L

R

L R

NA03 TC4052BP

N203 TDA9363N2

Audio

Scart

Out

L R L RL RL R

In 2

Scart

In

NV01 TDA9859

L

R

Audio

In 1

AV0

P2

P1-MUTE

IIC

L

R

RGB 3

Ib

V-drive

Guard

H-drive

FB

+8V

EW

L R

N511

TDA8944J

RGB 3

TDA6107J

TDA8359J

+16V +45V

T302 FBT

N801

N350

H.D

EHT

E/W

V

H

EHT

De-Gauss

VIDEO OUT

SCART OUT

AV-3

AV-2

VIDEO IN 1

AV-1

S-VIDEO

TV

SCART IN

VIDEO IN 2

Y IN

C IN

NA02

TC4052BP

P2

NA01

TC4052BP

ZA01

ZA02

ZA03

ZA04

SIF TRAP

AV0

AV1

V/Y

C

P/N

S.C.

Sys2Sys1

FSC

BN01 TDA9181

+140V

Standby

3.3V

SMPS

5V

N502 TDA16846

8V

V501 SPP11N60S5

CY

G

Y

BUR

V

To AV-3 scart in

(when YUV used)

BL

AV/TV

(From Scart)

15V

+140V

Page 13

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Philips Semiconductors Tentative Device Specification

Integrated multistandard comb filter TDA9181

BLOCK DIAGRAM

out

Y/CVBS

out

C

OUTSEL

DD

V

CC

V

LPF

adaptive

comb

LPF

filter

sc

4 x f

clock

generator

AGND DGND

SYS2SYS1

FSCSEL

delay

2H/4H

LPF

clamp

2

Y/CVBS

INPSEL

clamp

1

Y/CVBS

1999 Jun 14 3

FSC

Fig.1 Block diagram

filter

tuning

(LPFs)

detector

sandcastle

in

C

SC

Page 14

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Philips Semiconductors Preliminary specification

Universal hi-fi audio processor for TV TDA9859

BLOCK DIAGRAM

outputs

channel

loudspeaker

C-bus

2

I

MAD SDA SCL

33 nF

5.6 nF

(1)

C

C

C

TL

BL2

BL1

P1

P2

2

31

C-BUS

2

I

INTERFACE

19 25 17 16

22 21

L

L

LOUT

18

STEREO

SPATIAL

MUTE

PSEUDO

STEREO

R

R

LOUT

15

STEREO

VOLUME

BALANCE

TREBLE

CONTROL

BASS

CONTROL

MONO

FORCED

14

11 12

29 27

MHA778

BR2

C

(1)

BR1

C

5.6 nF

TR

(1)

C

33 nF

PS2

extended bass control

C

PS1

C

11 (22) 12 (21)

0.15 µF

13 kΩ

68 nF

width

R

SCOUT

L

output

SCART

LR

SCOUT

VOLUME

CONTROL

R

23 10

24 9

48

VOLTAGE

LIN

L

LIN

R

MOUT

L

MOUT

LR

GND

100

SMO

C

LINE output or optional

µF

connection

surround sound decoder

should be replaced by the extended bass control network.

BR/L2

Fig.1 Block diagram and application circuit.

and C

BR/L1

(1) For extended bass control, the capacitor between C

TDA9859

26 7

28

L

AIN

L

30

R

AIN

470 nF

AUX

SOURCE

MULTIPLE

AND MODE

1

L

SCIN

470 nF

L

R

SELECTOR

470 nF

SCART

audio

32

R

SCIN

R

inputs

SWITCH)

(CROSSBAR

3

L

MIN

470 nF

470 nF

L

5

R

MIN

MAIN

R

470 nF

REFERENCE

6

P

V

+8 V

1997 Sep 01 3

Page 15

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Philips Semiconductors Product specification

Digital TV sound demodulator/decoder TDA9874A

4 BLOCK DIAGRAM

handbook, full pagewidth

P1

P2

ADDR1

ADDR2

SCL

SDA

XTALI

XTALO

SYSCLK

SDO

WS

SCK

41 (37)

4 (42)

18 (13)

23 (19)

33 (29)

34 (30)

20 (15)

19 (14)

38 (34)

35 (31)

36 (32)

37 (33)

2

C-BUS

I

INTERFACE

IDENTIFICATION

CLOCK

PEAK

DETECTION

I2S-BUS

INTERFACE

SIF2

27 (23)

INPUT SWITCH

FM/AM

DEMODULATION

DEMATRIX

2-CHANNEL

ANALOG/

SATELLITE

DECODER

DIGITAL

SELECTOR

AGC, ADC

DEMODULATION

SIF1

29 (25)

NICAM

NICAM

DECODER

LEVEL

ADJUST

POST FILTER

3 DACs

SUPPLY

SIF

DIGITAL

SUPPLY

SUPPLY

DACs

OPAMPS

REFERENCE

(21) 25

(20) 24

(28) 32

(27) 31

(24) 28

(18) 22

(10) 15

(12) 17

(7) 13

(6) 12

(5) 11

(35) 39

(36) 40

(26) 30

(3) 9

(4) 10

(44) 6

(41) 3

(8)

V

DEC

V

SSA2

V

DDA3

V

SSA3

V

ref1

I

ref

NICAM

PCLK

n.c.

V

SSD2

V

DDD1

V

SSD1

V

DDD3

V

SSD3

CRESET

V

DDA1

V

SSA1

V

SSA4

V

ref2

TDA9874APS

(TDA9874AH)

TP1

TP2

TP3

26 (22)

21 (17)

16 (11)

14 (9)

(16)

TEST

TEST1

TEST2

The pin numbers given in parenthesis refer to the TDA9874AH.

Fig.1 Block diagram.

2000 Aug 04 6

CROSSBAR

MONO

CHANNEL

OUTPUT

BUFFERS

5 (43)

OUTM

ANALOG

SWITCH

2-CHANNEL

OUTL OUTR

OUTPUT

BUFFERS

7 (1) 8 (2)

(39) 1

(40) 2

(38) 42

MHB584

EXTIR

EXTIL

MONOIN

Page 16

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Philips Semiconductors Tentative Device Specification

TV signal processor-Teletext decoder with

embedded µ-Controller

BLOCK DIAGRAM

61

+3.3 V

SDASCL

54 56

12

9

I/O PORTS (4x)

5-8

ADC IN (4x)

VST OUT

34

2

10/11

LED OUT (2x)

1/10 PAGE

MEMORY

1+62-64

C-BUS

2

I

TRANSCEIVER

VST PWM-DAC

I/O PORTS

DISPLAY

TELETEXT/OSD

V

H

TELETEXT

ACQUISITION

CVBS

ROGOB0

515253

BL

B

RG

CONTR/BRIGHTN

OSD/TEXT INSERT

COR

SYNC

TDA935X/6X/8X PS/N1 series

BLKIN

BCLIN

49

50

45

484746

CCC

GB

R

WHITE-P. ADJ.

RGB/YUV INSERT

SATURATION

RGB/YUV MATRIX

YUV/RGB MATRIX

Y

U

V

(20)

(EW GEOMETRY)

G/Y B/U BL

R/V

EWD

36

EHTO

TRAP

SOUND

VPE

RESET

AUDOUT

AUDEXT

SNDIF

TUNERAGC

60 55 59 58 57

44

35

29 28

(20)

31

(32)

27 37 38

(32)

80C51 CPU

ENHANCED

(AVL)

DEEMPHASIS

AUDIO SWITCH

VOLUME CONTROL

AGC/AFC

VISION IF

23

VIDEO AMP.

PLL DEMOD.

ALIGNMENT-FREE

24

IFIN

ROM/RAM

PLL

AGC CIRCUIT

NARROW BAND

DEMODULATOR

VIDEO IDENT.

VIDEO SWITCH

VIDEO FILTERS

42

40

43

CHROMA

CVBS/Y

PEAKING

LUMA DELAY

BASE-BAND

REF

REF

PAL/SECAM/NTSC

13

BLACK STRETCH

DELAY LINE

DECODER

30

41

(32)

18

V-DRIVE +

GEOMETRY

V

LOOP

nd

H-SHIFT

H-DRIVE

2

H

H-OSC. + PLL

H/V SYNC SEP.

19

39

14

+8V

21

222625

33

16

34

HOUT V-DRIVE

Fig. 1 Block diagram TDA935X/6X8X with mono intercarrier sound demodulator

17

15

2000 Jul 25 6

Page 17

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Page 18

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Page 19

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

Page 20

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION

PERCAUTION”, “SAFETY PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON

PAGE 1&2 OF THIS MANUAL.

CAUTION: 1. The shaded areas makes in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with

type identical to those in the original circuit or specified in the parts list. Before replacing

any of these components, read carefully the PRODUCT SAFETY NOTICE on page 2.

2. Do not degrade the safety of the receiver through improper servicing.

ELECTRICAL PARTS LIST

MAIN BOARD

SYMBOL PART NO. DESCRIPTION

G201 329-61203-00 JA117 12M

D501 340-80015-00 RS405G

D510 340-80012-00 FMLG12S

D206 340-50200-003 HZ2B1

D508 340-50410-003 HZ4C1

D320 340-50520-003 HZ5C3

D201 340-50550-003 HZ6A3

D202 340-50550-003 HZ6A3

D350 340-51260-003 HZ12B1

D313 340-51560-003 HZ16-1

D307 340-52990-003 HZ30-2

V501 343-00600-50 SPP11N60S5

V301 343-15690-00 2SC1569

V302 343-25530-00 2SD2553

V303 343-52480-30 2SC5248E

VV01 343-18150-704 2SC1815-GR

V202 343-10150-104 2SA1015Y Pr2.5

V203 343-10150-104 2SA1015Y Pr2.5

V304 343-10150-104 2SA1015Y Pr2.5

VA01 343-10150-104 2SA1015Y Pr2.5

VA08 343-10150-104 2SA1015Y Pr2.5

16

782-H2917-0100

CRYSTAL

RECTIFIER

REGULATED DIODE

TRANSISTOR

MAIN PCB

Page 21

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

V502 343-18150-104 2SC1815-Y

VA02 343-18150-104 2SC1815-Y

VA03 343-18150-104 2SC1815-Y

VB01 343-18150-104 2SC1815-Y

VB02 343-18150-104 2SC1815-Y

VV02 343-18150-104 2SC1815-Y

VV03 343-18150-104 2SC1815-Y

V503 343-18150-104 2SC1815-Y

V201 343-18150-704 2SC1815-GR

V305 343-18150-704 2SC1815-GR

V306 343-18150-704 2SC1815-GR

V101 343-23690-004 PH2369

V106 343-27170-004 2SC2717

Z201 458-05022-00 K3959D

R355 467-2D215-G03 1/4W-1.5K-G

R356 467-2D215-G03 1/4W-1.5K-G

R518 467-2E110-H0 1/2W-100Ω-JL

R310 467-2FA22-H0 1W-2.2Ω-JL

R361 467-2F001-H0 1W-1Ω-JL

R351 467-2F010-H0 1W-10Ω-JL

R318 467-2F133-H0 1W-330Ω-JL

R328 467-2F133-H0 1W-330Ω-JL

R303 467-2F227-H0 1W-2.7KΩ-JL

R329 467-2F247-H0 1W-4.7K-JL

R326 467-2F351-H0 1W-51kΩ-JL

R516 467-2G022-H0 2W-22Ω-JL

R360 467-2G127-H0 2W-270Ω-JL

R304 467-2G318-H0 2W-18kΩ-JL

SAW FILTER

METAL RESISTOR

INDUCTANCE WITH COLOUR CODES

LB02 471-2010K-003 SPT0305-100K-5

L101 471-2010K-003 SPT0305-100K-5

L203 471-2010K-003 SPT0305-100K-5

L204 471-2010K-003 SPT0305-100K-5

L206 471-2010K-003 SPT0305-100K-5

L207 471-2010K-003 SPT0305-100K-5

LA14 471-2010K-003 SPT0305-100K-5

LA15 471-2010K-003 SPT0305-100K-5

LB01 471-2010K-003 SPT0305-100K-5

L504 471-2068K-103 LGA0410-68uH-K

LA02 471-1010K-00 EL0606SKI-100K

17

Page 22

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

L201 471-1010K-00 EL0606SKI-100K

L202 471-1010K-00 EL0606SKI-100K

LA07 471-1010K-00 EL0606SKI-100K

LA01 471-1010K-00 EL0606SKI-100K

LA06 471-1010K-00 EL0606SKI-100K

LA10 471-2A68K-A0 SP0203-6.8uH-K

LA12 471-2A68K-A0 SP0203-6.8uH-K

L102 471-2001K-A0 SP0203-1uH-K

L208 471-2010K-00 SPT0305-100K-5

RV02 467-4FA56-H0 1W-5.6Ω-JL

R317 467-4FB33-H0 1W-0.33Ω-JL

R321 467-4FA27-H0 1W-2.7Ω-JL

R314 467-4FB33-H0 1W-0.33Ω-JL

R315 467-4FB33-H0 1W-0.33Ω-JL

R528 467-4FB33-H0 1W-0.33Ω-JL

R529 467-4FB33-H0 1W-0.33Ω-JL

R530 467-4FB68-H0 1W-0.68Ω-JL

R319 467-4F001-H0 1W-1Ω-JL

R354 467-4F001-H0 1W-1Ω-JL

R510 467-4GA22-H0 2W-2.2Ω-JL

R507 467-4GB27-H0 2W-0.27Ω-JL

R317 467-4FA15-H0 1W-1.5Ω-JL

RV02 467-4FA56-H0 1W-5.6Ω-JL

R317 467-4FB33-H0 1W-0.33Ω-JL

MELTABLE RESISTOR

IC

N510 *352-11170-70 GS1117CT-3.3

N502 352-02540-40 TNY254P

N506 352-04310-00 LM431A

N301 352-05740-00 uPC574

N503 352-06210-60 TLP621-GB

N504 352-06210-60 TLP621-GB

N505 352-06210-60 TLP621-GB

N501 352-16846-00 TDA16846

N202 352-24080-50 M24C08BN6

NA01 352-40520-60 TC4052BP

N507 352-78050-00 KA7805

N508 352-78080-00 AN7808

N350 352-83590-90 TDA8359J/N2

NV02 352-89440-70 TDA8944J

NB01 352-91810-00 *TDA9181P

N201 352-93630-00 *TDA9363PS/N2/5I

18

Page 23

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

NV01 352-98590-00 TDA9859

C503 459-B147M-20 ECK-DNS471MBX !

C504 459-B147M-20 ECK-DNS471MBX !

C548 459-B222M-20 ECK-DNS222MEX !

C505 459-B247R-00 DE0807F472ZAC250V !

C506 459-B247R-00 DE0807F472ZAC250V !

C507 459-B247R-00 DE0807F472ZAC250V !

C508 459-B247R-00 DE0807F472ZAC250V !

L302 477-40020-00 LE1919

L506 477-40028-00 L912

L505 477-40057-00 LG101

L304 477-40107-00 160uH

477-40205-00 * LEY-433-1T

T302 472-27130-00 BSC29-3991N !

CERAMIC CAPACITOR

FIXED INDUCTANCE

FBT

POWER TRANSFORMER

T502 470-00191-00 SRW16ES-X03V112 !

SWITCH TRANSFORMER

T501 470-00269-00 BCK200-1D !

CERAMIC TRAP FILTER

ZA02 475-25551-00 XT5.5MB

ZA01 475-25601-00 XT6.0MB

ZA04 475-25651-00 XT6.5MB

POWER FILTER

L502 477-20047-00 LCL-205

H-LINEARITY INDUCTANCE

L305 477-00057-00 HL1835H-X10

H-DRIVE TRANSFORMER

T301 472-10027-00 HTB-835

CEMENT RESISTOR

R301 467-50251-H8 RJG27-3C-5W-5.1K-J

R514 467-50322-H8 RJG27-3C-5W-22K-J

R502 467-51127-H4 RX27-3H-7W-270Ω-J

VITREOUS-ENAMEL RESISTOR

R504 467-7F447-H0D RI40-1W-470K-JL

WIRE-ROUND RESISTOR

R352 467-6FA15-H0 RX21-1-1.5Ω-J

R353 467-6FA15-H0 RX21-1-1.5Ω-J

CARBON RESISTOR

R505 467-8E539-K0 1/2W-3.9MΩ-KL !

19

Page 24

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

R534 467-8E582-H0A 1/2W-8.2MΩ-J !

RT501 469-10007-00 PTH451C262BG200N270

RT502 469-40004-00 5D2-14LC

DEGAUSSING COIL 477-12801-00 BD-205-3 !

POWER SWITCH 360-30028-00 KDC-A04-S !

POWER CORD 493-75710-07 VDE !

CRT 335-2932H-00 A68QCP891X001 !

TUNER101 590-30533-00 TDQ-3B9H/124XS !

SYMBOL PART NO. DESCRIPTION

782-H2917-3100 NICAM PCB

THERMISTOR

OTHER

NICAM BOARD

CRYSTAL

GZ01 329-62404-00 HC-49/US 24.576MHZ

TRANSISTOR

VZ04 343-18150-60 2SC1815-0

VZ05 343-18150-60 2SC1815-0

VZ01 343-27170-00 2SC2717

IC

NZ01 352-75100-00 LA7510

NZ02 *352-98740-10 TDA9874AH

SAW FILTER

ZZ01 458-05023-00 K9260M

INDUCTANCE WITH COLOUR CODES

LZ02 471-1110H-00 EL0606SKI-101J

LZ03 471-1110H-00 EL0606SKI-101J

LZ01 471-2001K-00 SPT0305-1R0K-5

BUTTON BOARD

SYMBOL PART NO. DESCRIPTION

782-H2930-0500 BUTTON PCB

TRANSISTOR

V902 343-18150-10 2SC1815-Y

V903 343-18150-10 2SC1815-Y

LIGHT-EMITTING DIODE

VD901 340-10055-90 HFT505M

METAL RESISTOR

R915 467-2D218-G0 1/4W-1.8K-G

R916 467-2D236-G0 1/4W-3.6K-G

20

Page 25

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

RC901 352-03810-80 AT138B-T12 (M)

SYMBOL PART NO. DESCRIPTION

782-H2930-2900 SIDE AV PCB

RAA9 467-2E115-H0 1/2W-150Ω-JL

RAA10 467-2E115-H0 1/2W-150Ω-JL

RAA11 467-2E118-H0 1/2W-180Ω-JL

RAA12 467-2E118-H0 1/2W-180Ω-JL

INDUCTANCE WITH COLOUR CODES

LAA1 471-2010K-A0 SP0203-10uH-K

LAA2 471-2010K-A0 SP0203-10uH-K

LAA3 471-2010K-A0 SP0203-10uH-K

IC

SIDE AV BOARD

METAL RESISTOR

CRT BOARD

SYMBOL PART NO. DESCRIPTION

782-R2990-020A CRT PCB

DIODE

VD801 340-00010-00 S5295G

VD802 340-00010-00 S5295G

VD803 340-00010-00 S5295G

IC

N801 352-61070-70 TDA6107JF (M)

CRT SOCKET

X803 364-58220-00 GZS10-301D !

METAL RESISTOR

R809 467-2G110-H0 2W-100Ω-JL

MELTABLE RESISTOR

R810 467-4GA22-H0 2W-2.2Ω-JL

CARBON RESISTOR

R804 467-8E227-H0A 1/2W-2.7KΩ-J !

R805 467-8E227-H0A 1/2W-2.7KΩ-J !

R806 467-8E227-H0A 1/2W-2.7KΩ-J !

METAL RESISTOR

R801 467-2E110-H0 1/2W-100Ω-JL

R802 467-2E110-H0 1/2W-100Ω-JL

R803 467-2E110-H0 1/2W-100Ω-JL

21

Page 26

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

VM BOARD

SYMBOL PART NO. DESCRIPTION

782-29FA0-6400 VM PCB

DIODE

VD611 340-00001-00 1N4148

VD606 340-00001-00 1N4148

VD604 340-00001-00 1N4148

VD603 340-00001-00 1N4148

VD607 340-00001-00 1N4148

VD608 340-00001-00 1N4148

VD610 340-00079-00 FR103

VD609 340-00079-00 FR103

TRANSISTOR

V603 343-07520-10 2SC752GTM-Y

V607 343-07520-10 2SC752GTM-Y

V610 343-10150-11 2SA1015Y

V602 343-10150-11 2SA1015Y

V615 343-12060-00 RN1206

V614 343-12060-00 RN1206

V613 343-12060-00 RN1206

V604 343-18150-11 2SC1815-Y

V605 343-18150-11 2SC1815-Y

V606 343-18150-11 2SC1815-Y

V609 343-18150-11 2SC1815-Y

V619 343-18150-11 2SC1815-Y

V620 343-18150-11 2SC1815-Y

V601 343-18150-11 2SC1815-Y

V611 343-19640-30 2SA1964E

V612 343-52480-30 2SC5248E

METAL RESISTOR

R640 467-2EA27-G0 1/2W-2.7Ω-GL

R639 467-2EA27-G0 1/2W-2.7Ω-GL

R630 467-2E010-H0 1/2W-10Ω-JL

R638 467-2E033-H0 1/2W-33Ω-JL

R642 467-2E033-H0 1/2W-33Ω-JL

R644 467-2E068-H0 1/2W-68Ω-JL

R628 467-2E133-H0 1/2W-330Ω-JL

R619 467-2E147-H0 1/2W-470Ω-JL

R643 467-2F115-H0 1W-150Ω-JL

INDUCTANCE WITH COLOUR CODES

L601 471-2047K-A0 SP0203-47uH-K

22

Page 27

C.E.C BELSON/DPTO.TECNICO/MOD:BSV-29251/Ed.01

SYMBOL PART NO. DESCRIPTION

Z602 475-25361-00 TPS3.58MJ

Z601 475-25441-00 TPS4.43M

DL601 591-10018-00 YBL 48E08

POWER FILTER BOARD

SYMBOL PART NO. DESCRIPTION

782-66830-511A POWER FILTER PCB

462-2B410-M0V 250VAC-0.1uF-M !

467-8E522-H0A 1/2W-2.2M-J !

477-20031-00 LCL-21 !

CERAMIC TRAP FILTER

BRIGHTNESS DELAY LINE

THIN-FILM CAPACITOR

CARBON RESISTOR

POWER FILTER

FUSE

569-14141-80 50T 4AL 250V !

DYNAMIC FOCUS BOARD

PART NO. DESCRIPTION

782-29FA0-711B DYNAMIC FOCUS PCB

CARBON RESISTOR

467-8E227-H1A 1/2W-2.7KΩ-J !

DYNAMIC FOCUS TRANSFORNIER

472-60001-00 BCT222

ADJUSTABLE INDUCTANCE

477-30011-00 TLN2110

23

Loading...

Loading...