Page 1

BELSON

BSA-1061 (2 W remote)

MICRO COMPONENT SYSTEM

Page 2

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

MODEL BSA-1061

CAUTION: Before servicing the chassis, read the " important service safety information"

section on page 2 of this manual.

MICRO HI-FI STEREO RADIO WITH CD PLAYER

SPECIFICATIONS CONTENTS

AM/FM

ANTENNA

FM : AERIAL

TUNING RANGE

AUDIO SECTION

SPEAKER IMPEDANCE : 4 OHM

GENERAL : 2 W x 2

POWER INPUT : AC 230 V, ~ 50Hz

AC POWER CONSUMPTION

DIMENSIONS : (136W)x(240D)x(146H)mm

TUNER SECTION

SYSTEM

AM : FERRITE BAR

PIGTAIL

530 - 1600

AM :

FM : 88 - 108 MHz

kHz

ANT.

IMPORTANT SERVICE SAFETY INFORMATION------2

ADJUSTMENT LOCATION--------------------------3

DISASSEMBLY INSTRUCTION----------------------4

ALIGNMENT PROCEDURES----------------------5-6

VOLTAGE CHARTS--------------------------------7

IC BLOCK DIAGRAMS-------------------------8-12

BLOCK DIAGRAM--------------------------------13

WIRING DIAGRAM------------------------------14

PRINTED CIRCUIT BOARDS-------------------15-16

SCHEMATIC DIAGRAMS-----------------------17-20

EXPLODED VIEW/PARTS LIST (CABINET)------21-23

Page 3

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

IMPORTANT SERVICE SAFETY INFORMATION

1.SAFETY PRECAUTIONS

Before returning a unit to the customer, always make a safety check of the

Entire unit, including, but not limited to the following items:

a. Be sure that no built-in protective devices are defective and/or have been

defeated during servicing.

(1) protective shields are provided to protect both the technician and the

customer. Correctly replace all missing protective shields including any

removed for servicing convenience.

(2) when reinstalling the chassis and/or other assemblies in the cabinet, be

sure to put back in place all protective devices, including , but not limited

to , nonmetallic control knobs, insulating fishpapers .

adjustment and compartment covers/shields and isolating resistor/

capacitor networks. Do not operate this or permit it to be operated

Without all protective devices correctly installed and functioning .

b . Be sure that there are no cabinet openings through which an adult or child

might be able to insert their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively wide cabinet ventilation

slots, and an improperly fitted and/or incorrectly secured cabinet

back cover.

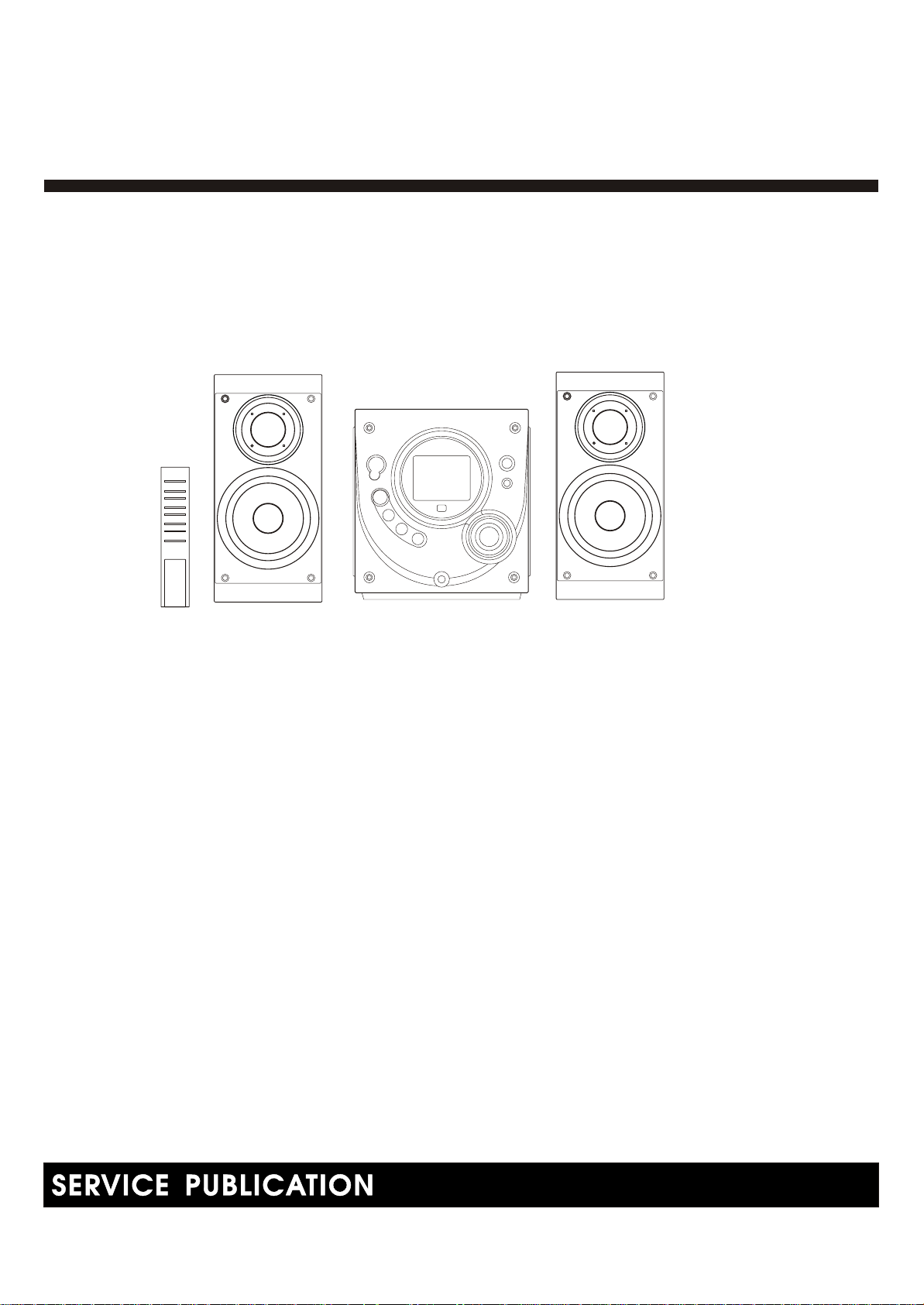

Leakage current hot check - with the unit completely reassembled ,plug the AC

line cord directly into a 120V AC outlet. (Do not use an isolation transformer

During this test.) Use a leakage current tester or a metering system that complies

with American National standards Institute (ANSI) C101.1"Leakage Current for

Appliances "and Underwriters Laboratories(UL) 1410 (50.7). WITH THE UNIT AC

switch first in the ON position And then in the OFF position, measure from a known

earth ground (metal water pipe, conduit, etc.) To all exposed metal parts of the

Unit (antennas, handle bracket, metal cabinet, screw heads , metallic overlays,

control shaft, etc.) Especially any exposed metal parts that offer an

electrical return path to the chassis. Any current measured must not exceed 0.5

milliamp, reverse the unit power cord plug in the outlet and repeat test . ANY

MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HERENING INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED RETURNING THE UNIT TO THE CUSTOMER.

AC LEAKAGE TEST

TEST ALL

EXPOSED METAL

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

D. Insulation resistance test cold check

unplug the power supply cord and connect a jumper wire between the two prongs

of the plug .

Turn on the power switch of the unit.

Measure the resistance with an ohmmeter between jumpered AC PLUG AND EACH

Exposed metallic cabinet part on the unit, such as screw heads, antenna, control

shafts, handle brackets, etc. When the exposed metallic part has a return path to

the chassis , the reading should be between 1 and 5.2 megohms. When there is

no return path to the chassis, the reading must be " infinite". If it is not within the

limits specified, there is the possibility of a shock hazard, and the unit must be

repaired and rechecked before it is returned to the customer.

SURFACES

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

ANTENNA

TERMINAL

EXPOSED

METAL

PAR T

OM

OHMMETER

2. PRODUCT SAFETY NOTICE

some electrical and mechanical parts have special safety related

characteristics which are often not evident from visual inspection.

Nor can the protection they give necessarily be obtained by replacing

them with components rated for higher voltage , wattage, etc. Parts

that have special safety characteristics are identified by a on

!

schematic and parts list. Use of a substitute replacement that dose not

have the same safety characteristics as the recommended replacement

part might create shock, fire, and/or other hazards. Product safety is

under review continuously and new instructions are issued whenever

Appropriate.

3. Servicing precautions

caution: before servicing the unit covered by this service by this service

manual and its supplements. Read and follow the SAFETY PRECAUTIONS on

this page. NOTE: if unforeseen circumstances create a conflict between

the following servicing precautions and any of the safety precautions,

always follow the safety precautions. Remember: safety first.

General servicing precautions.

A. Always unplug the unit's AC power cord from the AC power source

Before:

(1) removing or reinstalling any component, circuit board, module or

any other unit assembly.

(2) disconnecting or reconnecting any unit electrical plug or other

Electrical connection.

(3) connecting a test substitute in parallel with an electrical capacitor

caution: a wrong part substitution or incorrect polarity installation

Of electrolytic capacitors may result in an explosion hazard.

B. Do not defeat any plug/socket b+ voltage interlocks with which

the unit covered by this service manual might be equipped.

C. Do not apply AC power to this unit and/or any its electrical assemblies

unless all solid-state device heat sinks are correctly installed.

D. Always connect a test unit instrument's ground lead to the unit's

chassis ground before connecting the test instrument's positive lead

always remove the test instrument's ground lead last.

4. Laser precautions

warning!

1. When servicing.(In case it is necessary to confirm laser beam

emission ) be sure not to place your eyes any closer than 1 or

30cm from the surface of the objective lens on the Optical

pickup block.

HANDLING THE LASER PICKUP

2. Laser Diodes are Extremely Susceptible to damage from static

electricity even if a static discharge dies not ruin the diode, it can

shorten its life or cause it to work improperly. When replacing

the pickup, use a conductive mat on the floor and desk and wear

a wrist band connected to ground through a 1M ohm resistor to

protect the laser diode from static damage. If the lens should get

dusty, blow off the dust carefully from the object.

3. There are no adjustable parts in the pickup assembly. If it is defective,

replace the whole pickup assembly.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF PROCEDURES

HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

DANGER:

IF INTERLOCK FAILS OR IS DEFEATED, THE LASER LIGHT IS ABLE TO

FUNCTION. THE LASER IS INVISIBLE, AVOID DIRECT EXPOSURE TO BEAM.

2

Page 4

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

3

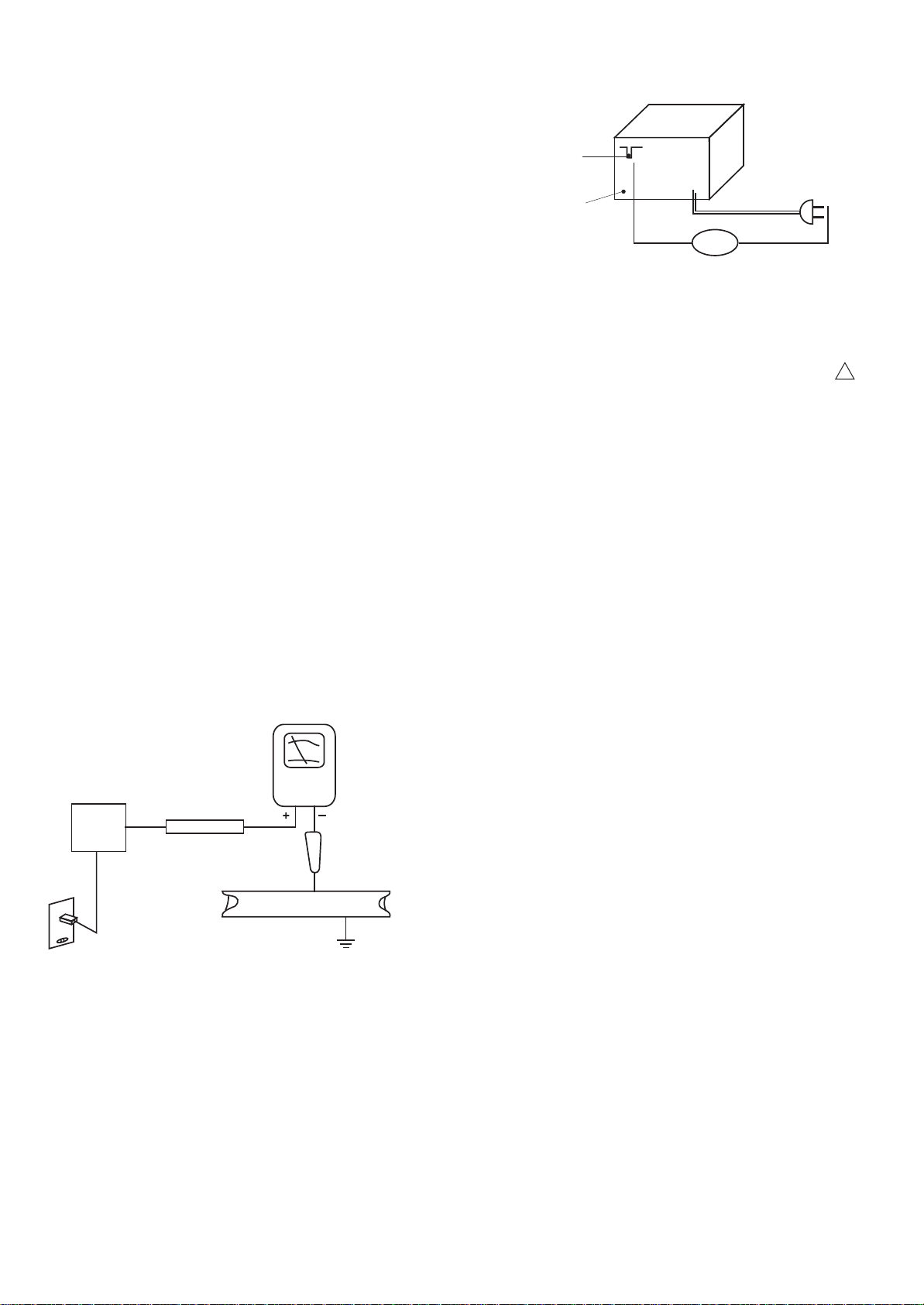

MODEL :BSA-1061

DISASSEMBLY INSTRUCTIONS

3x12KA

3x10PA

3x12KA

Page 5

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

4

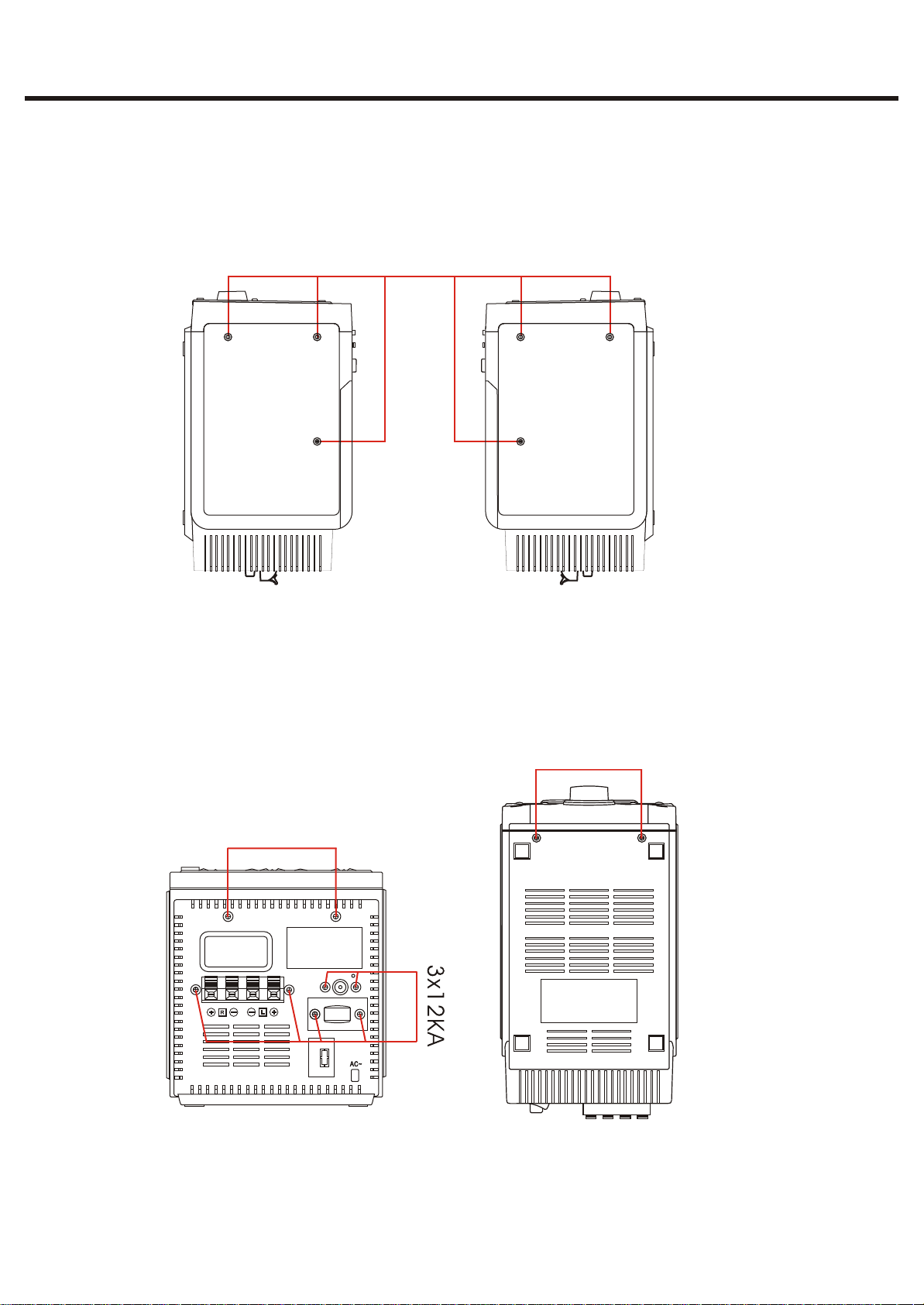

BSA-1061

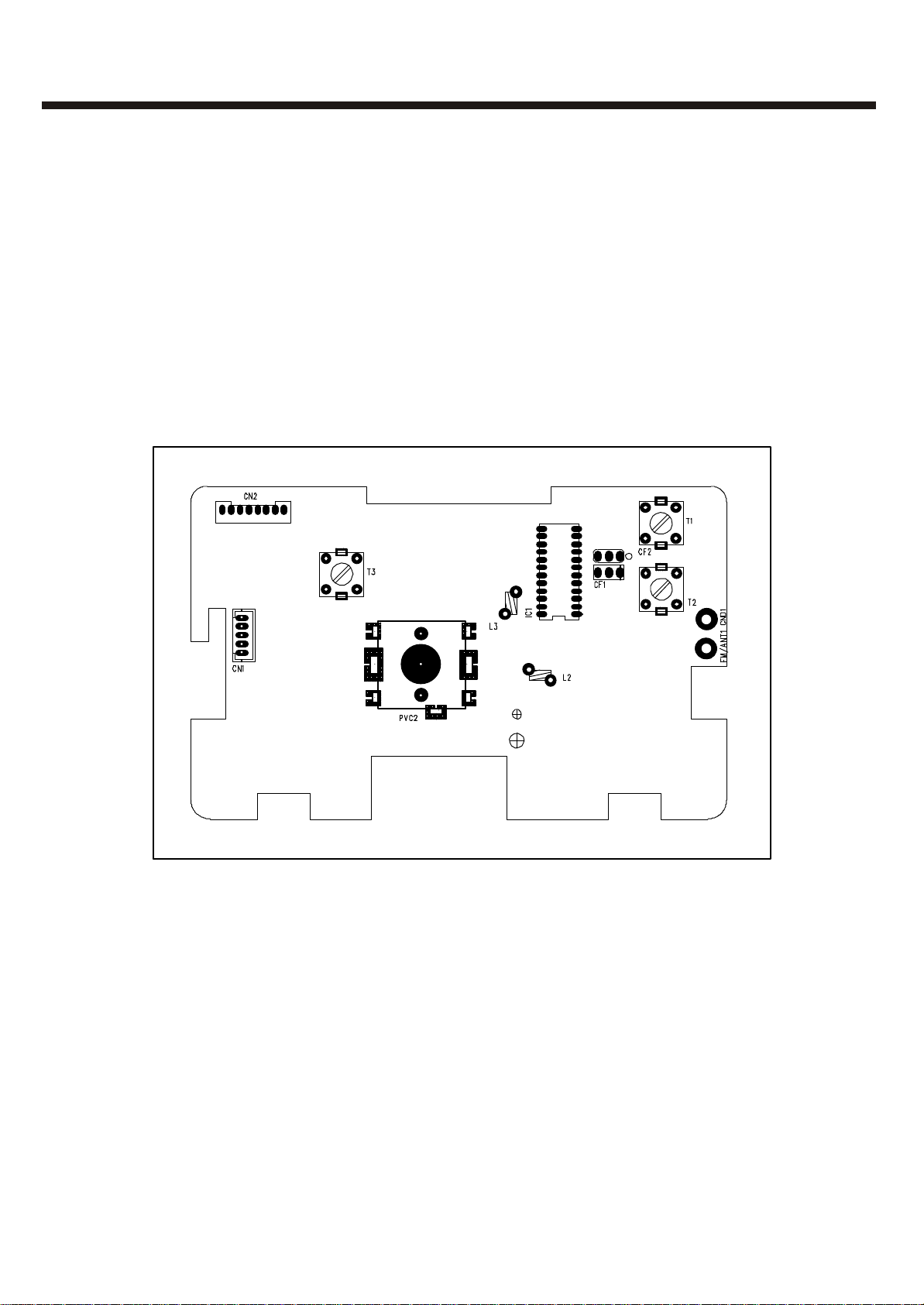

ADJUSTMENT LOCATION

Page 6

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

5

BSA-1061

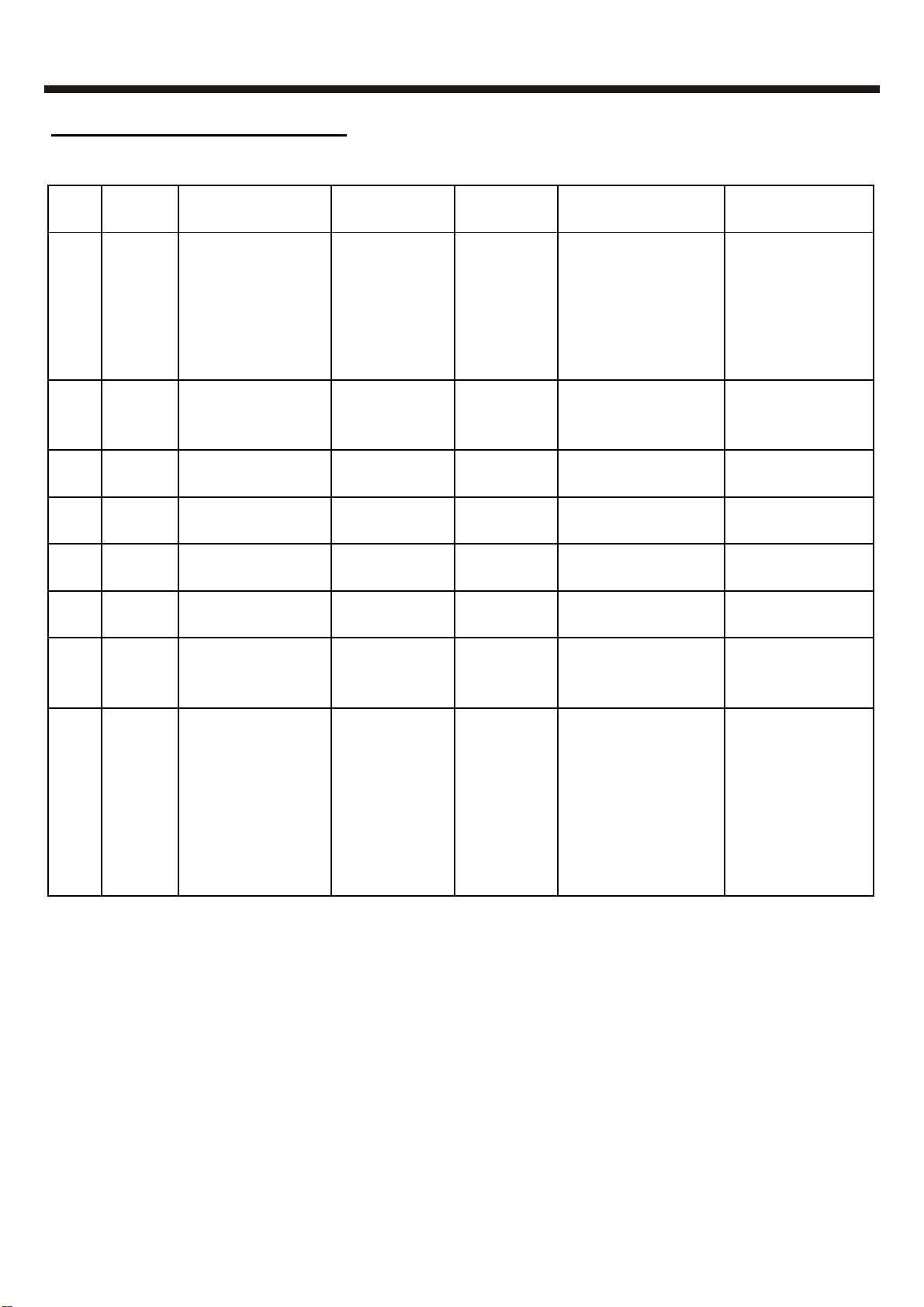

ALIGNMENT PROCEDURE

ALIGNMENT INSTRUCTION

FM & FM STEREO SECTION NE -291/MW/FM/FM.ST IC-TA2111N DATE: 2002-05-10

STEP ALIGN TEST EQUIPMENT SIGNAL IN SIGNAL OUT ALIGNMENT REMARK

FREQ

1 10.7MHz (1) FM IF SWEEP THROUGH A TP4 & TP5 ADJUST T203 FOR PVC AT HIGH END

GENESCOPE 100PF AND GND MAX.OUTPUT &

(2) POWER SUPPLY CAPACITOR LINEARITY AND 'S'

TO TP2& GND CURVE BALANCE

AROUND 10.7MHz

2 87.35MHz FM SIGNAL TP1& GND TP4 & TP5 ADJUST L202 FOR PVC AT LOW END

GENERATOR MOD AND GND 87.35MHz FREQ

22.5KHz/1KHz

3 108.5MHz SAME AS STEP 2 SAME AS SAME AS ADJUST PVC FC2 PVC AT HIGH END

STEP 2 STEP 2 FOR 108.5MHz FREQ

4 REPEAT 2,3 FOR

BEST RESULTS

5 90MHz SAME AS STEP 2 SAME AS SAME AS ADJUST L201 FOR TUN PVC TO

STEP 2 STEP 2 MAX OUTPUT RECEIVE SIGNAL

6 106MHz SAME AS STEP 2 SAME AS SAME AS ADJUST PVC FC1 SAME AS

STEP 2 STEP 2 FOR MAX OUTPUT STEP 5

7 REPEAT5, 6 AND

THEN REPEAT 2,3,5,6

FOR BEST RESULTS

8 98MHz 1.FM SIGNAL SAME AS STEP2 CHECK WHETHER FM STEREO

GENERATOR TP7 & TP8 THE STEREO LED ON POSITION

SEV 75KHZ AND GND MUST BE ON

1KHZ W/STEREO VCO FREQ:76KHz

2. 2-CH.V.T.V.M

3. OSCILLOSCOPE

4. DC POWER

SUPPLY

Page 7

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

6

BSA-1061

ALIGNMENT PROCEDURE

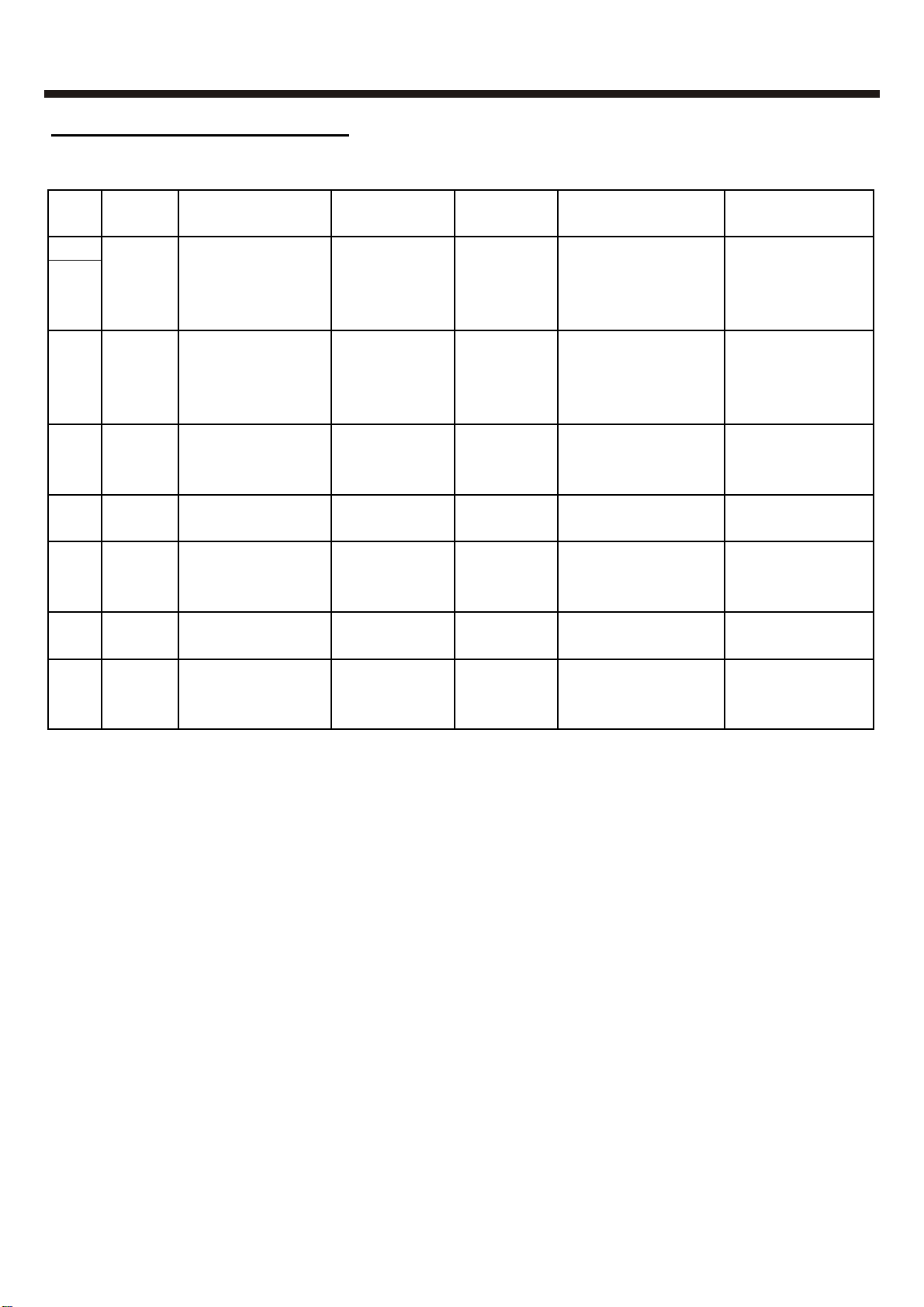

ALIGMENT INSTRUCTIONS

MW SECTION

STEP ALIGN TEST EQUIPMENT SIGNAL IN SIGNAL OUT ALIGNMENT REMARK

FREQ

465KHz (1)AM IF SWEEP MW ANT. COIL TP4 & TP5 ADJUST T202 (1)MW POSITION

1 &455KHz GENSCOPE CLOSE TO AND GND FOR MAX OUTPUT (2)PVC AT HIGH

(2)LOOP ANT LOOP ANT. AROUND 465 KHz & END

(3)POWER SUPPLY 455KHz

520KHz (1)LOOP ANT. RADIATE 60CM TP4 & TP5 ADJUST L205 FOR (1)MW POSITION

2 (2) AM SIGNAL APART FROM AND GND 520KHz (2)PVC AT LOW

GENERATOR TEST UNIT

MOD.1KHz 30%

1620KHz SAME AS STEP 2 SAME AS SAME AS ADJUST PVC C2 (1)MW POSITION

3 STEP 2 STEP 2 1620KHz (2)PVC AT HIGH

END

4 REPEAT 2,3 FOR

BEST

5 600KHz SAME AS STEP2 SAME AS SAME AS ADJUST L2 FOR (1)MW POSITION

STEP 2 STEP 2 MAX OUTPUT (2)TUNE PRC TO

RECEIVE SIGNAL

6 1400KHz SAME AS STEP 2 SAME AS SAME AS ADJUST PVC C1 SAME AS

STEP 2 STEP 2 FOR MAX OUTPUT ABOVE

7 REPEAT 5,6, AND

THAN REPEAT 2,3,5.6

FOR BEST RESULTS

Page 8

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

7

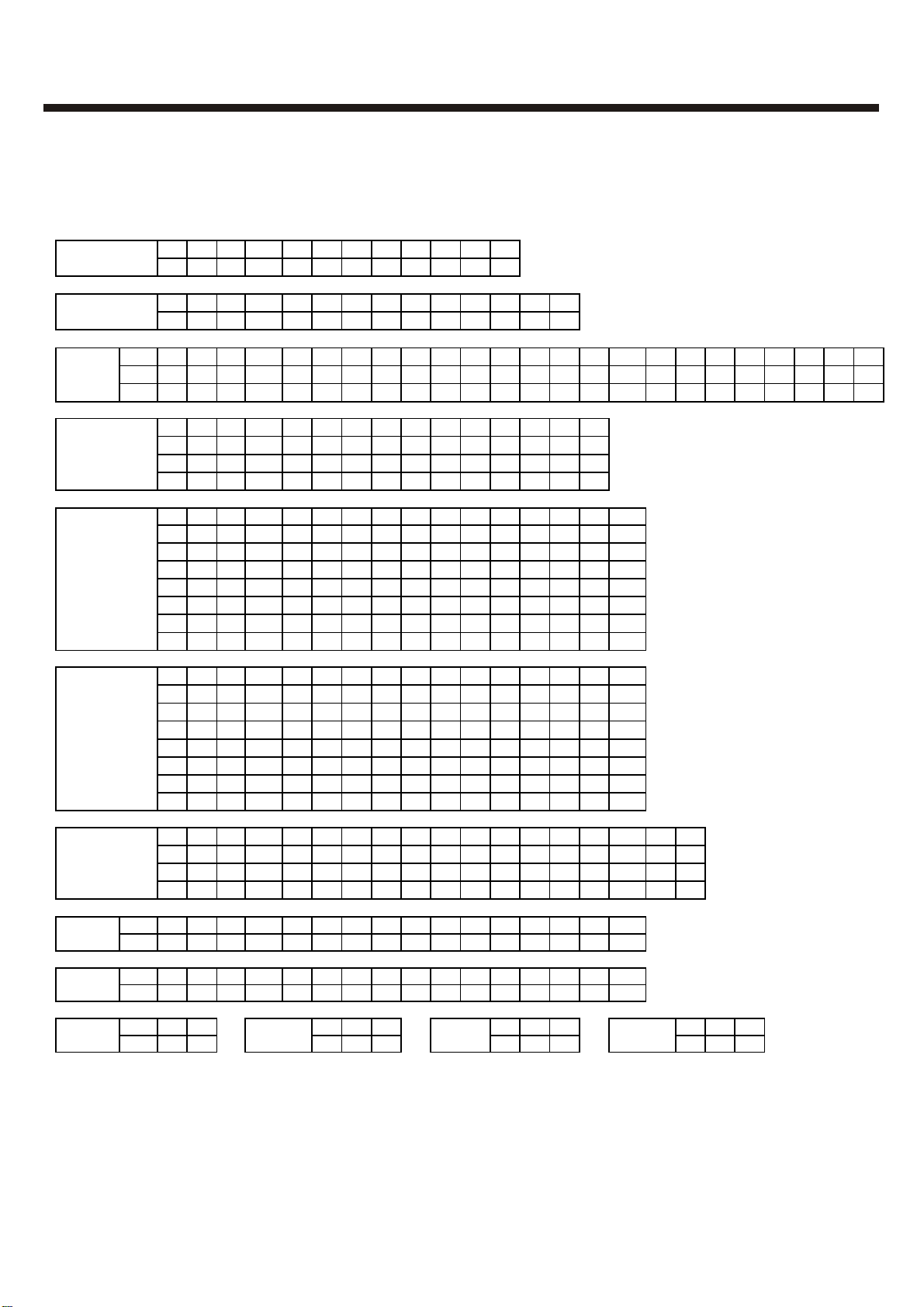

BSA-1061

VOLTAGE CHARTS

IC VOLTAGE TABLE

{NO SIGNAL INPUT (EXCEPT FM STEREO BAND),VOLUME MINMUN}

MODEL : NE-291(2-3W-REM)

IC306 PINS 1 2 3 4 56789101112

TA8227P 16 8 0 0 0.5 000.5 8 15 8 16

IC 304 PINS 1 2 3 4 567891011121314

TC4013BP 6.2 00 0 00006.5 006.5 0 6.5

IC202 PINS 1 2 3 4 56789101112131415161718192021222324

TA2111P FM 0.8 0 0.3 6 0 6.1 5.6 5.9 0 0 4.6 5.4 1.3 1.3 5.4 5.3 0.7 0.9 0.3 6.1 6.1 6.6 6.1 6.1

AM 001.1 6.8 0.5 6.6 6.1 6.8 005.3 6.3 1.3 1.3 6.1 6.8 0.7 1.4 1.4 6.8 6.8 6.8 6.8 6.8

PINS 1 2 3 4 56789101112131415

U201 8 0 2.5 2.5 3.6 3.6 0 0 0 3.5 3.5 2.5 2.5 5 7.3

LA6541D PINS 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

8 4.8 2.5 2.5 3.5 3.5 0 0 0 3.6 3.6 2.5 2.5 2.5 8

123 4 5678910111213141516

2.9 0.9 2.7 2.7 2.6 2.6 2.6 2.7 0 2.7 2.7 2.7 2.7 2.7 2.7 0

U101 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.5 2.5 1.6 0

LA9242M 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

000 0 0002.755002.7002.7

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

0 2.4 0 0 0 2.7 0 5 5 2.7 2.7 0 0 2.7 0 0

123 4 5678910111213141516

U301 0 0 0.2 1.1 5 2 0 2.5 2.4 0 2.6 2.6 0 0 0 5

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

52.60 0 040000052.505 5

LC78601RE 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

2.9 2.8 2.9 0.9 0.9 0 0 2.8 2.8 5 5 0 0.1 0.1 0 0

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

500 0 022402002.555 0

PINS 1 2 3 4 56789101112131415161718

IC2 2.1 2.1 2.1 2.1 2.1 2.8 2.3 2.1 2.6 2.4 2.4 2.4 2.4 2.6 1.8 1.8 0.5 1

SC3610 PINS 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

0 1.5 4.6 4.6 4.6 4.6 4.6 4.3 0 0 0 000 3.3 0 1.6 5.2

IC 302 PINS 1 2 3 4 5678910111213141516

PT2249 0 0 0 0 00000000003.16.2

IC 305 PINS 1 2 3 4 5678910111213141516

PT2253A 0 3.3 3.3 3.3 0 0 6.6 6.6 6.6 6.6 3.3 0 3.3 3.3 3.3 6.6

Q303 E B C Q304 E B C Q306 E B C Q219 E B C

9014 0.7 1.4 0.9 9014 6.2 6.8 14 A928 17 16 17 8050 8 0.1 7.9

Page 9

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

8

BSA-1061

IC BLOCK DIAGRAM

Page 10

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

9

BSA-1061

IC BLOCK DIAGRAM

TA2111N

PT22

V

RXIN

HP1

HP2

HP3

HP4

HP5

SP5

49A

SS

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

CC

OSC

COD

COD E3

SP1

SP2

SP3

SP4

E2

Page 11

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

10

BSA

-1061

TA8227P

IC BLOCK DIAGRAM

LC78601RE

Page 12

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

11

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

BSA-1061

IC BLOCK DIAGRAM

LA6541D

Level shift

1

Level shift

4

Level shift

2

Regulator

Level shift

3

Top view

Page 13

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

12

BSA-1061

IC BLOCK DIAGRAM

LA9242M

Page 14

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

13

BSA-1061

BLOCK DIAGRAM

Page 15

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

14

BSA-1061

WIRING DIAGRAM

Page 16

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

15

T2L/250V

BSA-1061

PRINTED CIRCUIT BOARTD

Page 17

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

16

BSA-1061

PRINTED CIRCUIT BOARTD

Page 18

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

17

BSA-1061

SCHEMATIC DIAGRAM

Page 19

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

18

BSA-1061

SCHEMATIC DIAGRAM

Page 20

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

19

BSA-1061

SCHEMATIC DIAGRAM

Page 21

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

20

BSA-1061

Page 22

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

21

Page 23

42

43

44

45

46

47

48

P1

P2

P3

P4

P5

P6

P7

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

22

BSA-1061

NO.

1 353-029100-2490

2 335-028812-8981 DISPLAY LENS 1

3 400-029100-2490

4 311-029100-6500 FRONT CAB. 1

5 202-000040-01

6 303-000090-0101 MOUNTING POST

7 403-028904-8JX0 POWER/STANDBY BUT.

8 472-029109-1010

9 403-029109-2490 MUTE BUTTON CHROME

10 464-02891B-1C20 SHAFT BUSHING

11 464-028923-1C20 TUNING SHAFT

12 408-028106-2490 PROGRAM BUT CHROME

13 408-029105-2490 REPEAT BUT CHROME

14 408-029103-2490 STOP BUTTON CHROME

15 408-029102-2490 PLAY BUTTON CHROME

16 408-029104-2490 SKIP BUTTON CHROME

17 472-029101-1010 FUNCTION BUT BASE

18 472-029106-1010 SKIP BUTTON BASE

19 134-029930-05 LCD 93435TT-P

20 234-028900-01 DRAFTING FILM

21 461-028902-1100 LCD BRACKET 1

22 315-000015-01200 AC CORD COVER 1

23 303-000060-0100 DUAL VOLTAGE COVER 1

24 185-122110-01 DUAL VOLTAGE 1

25 188-111702-08

26 117-109500-01 COAXIAC FM ANT JACK 1

27 303-000010-0000 AC POWER SW COVER 1

28 156-472313-71 X’FORMER N48133BF AF PT 1 S1 203-301720-06 TAPPING SCREW 4

29 213-000005-16 CUSHION BUBBER 4 S2 204-260000-05 MACHINE SCREW 1

30 219-DA11B3-N1

31 303-000072-0001 DUST COVER 1 S4 203-260200-10 TAPPING SCREW 12

32 462-02890V-1C20 VOL.BUT.HOLDER 1 S5 207-261600-10 TAPPING SCREW 4

33 460-028900-1C20 VC GEAR 1 S6 203-300800-18 TAPPING SCREW 2

34 460-028914-1C20 TUNING GEA 1 S7 203-300800-12 TAPPING SCREW 1

35 403-028902-2500 VOLUME BUTTON SPR 1 S8 203-300900-10 TAPPING SCREW 4

36 466-028900-1C20 CD DOOR HOOK 1 S9 203-300200-10 TAPPING SCREW 7

37 461-02890A -1C20 MOUNTING BRACKET 2 S10 203-300700-12 TAPPING SCREW 8

38 316-028920-6500 TOP CABINET 1 S11 203-200200-12 TAPPING SCREW 2

39 401-028900-2500 SLIKE DBOB SPR 2

40 401-028906-2500 BASS KNOB SPR 1

41 199-000002-12

PART DESCRIPTION QTY

DECORATION RING CHROME

TUNING KNOB CHROME

EAR HEADPHONE PCB PRESS PLATE

MUTE BUTTON

AC POWER SWITCH

CD MECHANISM VERTICAL

OIL DAMPER

mEXPLODED VIEW/PARTS LIST

NO.

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1 S3 203-260200-08 TAPPING SCREW 3

1

PART DESCRIPTION QTY

202-028903-01 CD OPEN BUTTON SPRING

408-028908-2500

188-011511-01

202-028902-01

371-028930-6500

208-028900-60

322-028900-53J0

173-029907-01

173-029903-01 A/F ST RADIO BOARD 1

173-029906-01 REMOTE SENSOR BOARD 1

173-029904-01 CPU+LCD+KEY BOARD 1

173-029905-01 BACK LIGHT BOARD 1

173-028910-0101 CD+2W AUDIO AF

173-028902-0101

DOOR OPEN BUTTON SPR 1

TACT SWITCH 1102-2 2

CD DOOR SPRING 1

CD DOOR REV.3 SPR 1

CD DOOR L ENS “STD” 1

REAR CABINET 1

HEADPHONE JACK BOARD

FUNCTION SWITCH 1

1

1

1

Page 24

C.E.C BELSON/DPTO.TECNICO/MOD:BSA-1061/Ed.01

23

BSA-1061

EXPLODED VIEW/PARTS LIST

Loading...

Loading...