Page 1

Donut System

GLAZING

Worldwide Leader in the Design and Manufacture of Donut Production Equipment

CENTURY AUTOMATIC

GL AZER

Belshaw’s Century Glazer minimizes your

labor requirements by automating donut

glazing. Donuts are automatically conveyed

through a continuously flowing cur tain of

glaze, allowing uniform glaze application

to each donut while reducing labor and

sanitation concerns.

The Century Glazer is ideal for exhibitionstyle production. Donuts traveling under

the gla ze waterfall are an integral part of the

donut production “show”.

Features

■

Large glaze tank.

■

Easy to clean glaze pump.

■

Adjustable glaze flow.

■

Adjustable glaze applicator height.

■

Adjustable leg height.

■

Heavy-duty stainless steel wire belting.

■

Removable conveyor unit for easy

cleaning.

■

Simple, water-resistant plug-in connection

to other Century equipment.

■

Variable speed drive.

■

Moisture-proof, wash-down motor.

■

Glaze heater option.

FOODSERVICE EQUIPMENT

Century glazer GL30

(compatible with C300, C600,

and C10G systems)

16

(matches C100/ C200 /C40 0/Mark VI)

GL18

GL36

(matches C800)

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144- 4590 USA

W http://www.belshaw.com

800-578-2547 (USA/Canada)

206-322-5474 (International)

Glaze Tank and trough

(GL36 shown)

©20 05 Belshaw Bros, Inc. Rev 3/0 5

FAX

206-322-5425

Page 2

DONUT SYSTEM

MODEL CENTURY SYSTEM

CONVEYOR

BELT WIDTH

DIMENSIONS

APPROX SHIPPING

WEIGHT

ELECTRICAL

LENGTH WIDTH HEIGHT

V A

GL18 Mark VI

� C100 � C200 � C400 18" (46cm) 52" (132cm) 34" (86cm) 47in (119cm) 650lbs (295kg) 208/240V 50/60hz 1ph 6.0 A

GL30 C300

� C600 � C10G 30" (76cm) 52" (132cm) 46" (117cm) 47in (119cm) 790lbs (359kg) 208/240V 50/60hz 1ph 6.0 A

GL36 C800 36" (91cm) 52" (132cm) 52" (132cm) 47in (119cm) 930lbs (423kg) 208/240V 50/60hz 1ph 6.0 A

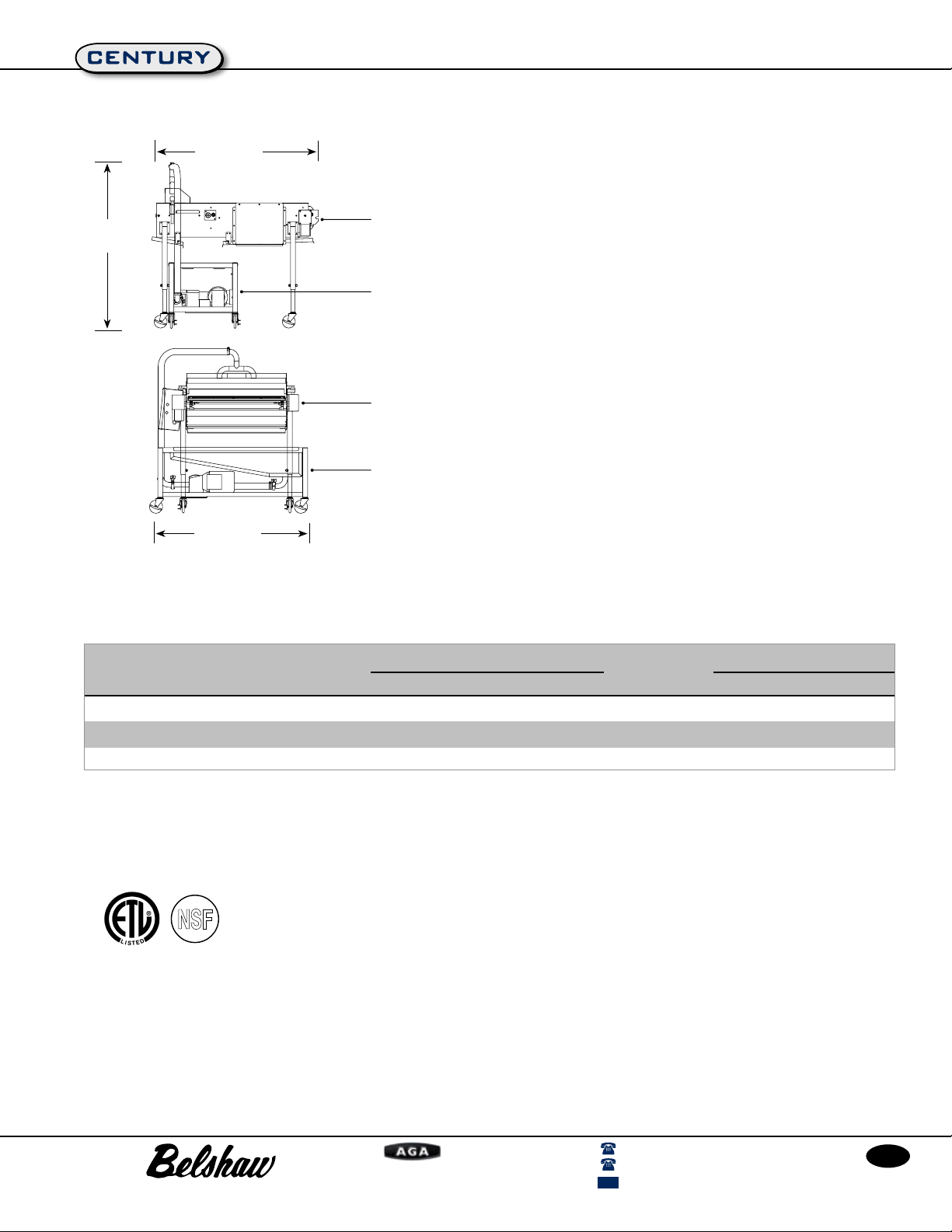

CENTURY GLAZER VIEWS

OVERALL

LENGT H

OVERALL

HEIGHT

GLAZING

DONUT

CONVEYOR

GLA ZE UNIT

DONUT

CONVEYOR

GLA ZE UNIT

OVERALL

WIDTH

Dimensions And Power

NSF

®

Manufac ture d by

FOODSERVICE EQUIPMENT

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

17

Page 3

Donut System

FINISH-LINE

CONVEYORS

Worldwide Leader in the Design and Manufacture of Donut Production Equipment

CENTURY FINISH-LINE

CONVEYORS

Belshaw’s Century Conveyor line is

designed to work in conjunction with

other Centur y equipment. All of Belshaw’s

Conveyors use high-quality stainless steel

belting and are constructed for heav y-duty

service and long life. These conveyors

combine practical uses such as direction

change and a cooling period with today’s

allure of exhibition-style production.

Curved Conveyors

■

45°, 90° and 180° conveyors.

■

Lef t-hand and right-hand configura-

tions.

■

Keep donuts organized in lines.

■

Top-quality, stainless steel wire belting.

■

Filler rods for small products such as

donut balls/holes (optional).

■

Adjustable safety clutch that uncouples

motor in event of obstruction.

■

Removable drip pans.

■

Variable speed drive.

■

Moisture-proof, wash-down motor.

Century 180º

curve conveyor

u

FOODSERVICE EQUIPMENT

t

Century 90º

curve conveyor

Cooling Conveyors

■

Straight configuration.

■

CC models include fans for extra

cooling

■

SC models do not include fans

■

6, 9 or 12 foot lengths

■

Speed alterations with replaceable

speed-change gears.

■

Variable speed drive.

■

Moisture-proof, wash-down motor.

6 foot long model

u

CC30 -6

12 foot long model

SC30 -12

u

18

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144- 4590 USA

W http://www.belshaw.com

800-578-2547 (USA/Canada)

206-322-5474 (International)

©20 05 Belshaw Bros, Inc. Rev 3/0 5

FAX

206-322-5425

Page 4

FILLER

RODS

APPROX

SHIPPING

WEIGHT

ELECTRICAL

MODEL CENTURY SYSTEM LENGTH WIDTH HEIGHT

V A

90DC-2000 Curve conveyor Mark VI

�C100�C200�C400 No 58 in (147 cm) 50 in (127 cm) 37 in (94 cm) 350lbs (159kg) 240V 50/60Hz 1ph 2.5 A

90DC-2001 Curve conveyor Mark VI�C100�C200�C400 Yes 58 in (147 cm) 50 in (127 cm) 37 in (94 cm) 350lbs (159kg) 240V 50/60Hz 1ph 2.5 A

90DC-2002 Curve conveyor C300 � C600 � C10G No 70 in (178 cm) 62 in (157 cm) 37 in (94 cm) 475lbs (216kg) 240V 50/60Hz 1ph 2.5 A

90DC-2003 Curve conveyor C300 � C600 � C10G Yes 70 in (178 cm) 62 in (157 cm) 37 in (94 cm) 350lbs (159kg) 240V 50/60Hz 1ph 2.5 A

180DC-2000 Curve conveyor Mark VI�C100�C200�C400 No 101 in (257 cm) 59 in (150 cm) 37 in (94 cm) 650lbs (295kg) 240V 50/60Hz 1ph 2.5 A

180DC-2001 Curve conveyor Mark VI

�C100�C200�C400 Yes 101 in (257 cm) 59 in (150 cm) 37 in (94 cm) 500lbs (228kg) 240V 50/60Hz 1ph 2.5 A

180DC-2002 Curve conveyor C300 � C600 � C10G No 122 in (310 cm) 70 in (178 cm) 37 in (94 cm) 800lbs (364kg) 240V 50/60Hz 1ph 2.5 A

180DC-2003 Curve conveyor C300 � C600 � C10G Yes 122 in (310 cm) 70 in (178 cm) 37 in (94 cm) 500lbs (228kg) 240V 50/60Hz 1ph 2.5 A

SC18-6 � CC18-6 Cooling conveyor Mark VI�C100�C200�C400 n/a 75 in (190 cm) 42 in (107 cm) 39 in (99 cm) 300lbs (136 kg) 240V 50/60Hz 1ph 4 A

SC18-9 � CC18-9 Cooling conveyor Mark VI�C100�C200�C400 n/a 111 in (282 cm) 42 in (107 cm) 39 in (99 cm) 450lbs (205 kg) 240V 50/60Hz 1ph 4 A

SC18-12 � CC18-12 Cooling conveyor Mark VI�C100�C200�C400 n/a 147 in (374 cm) 42 in (107 cm) 39 in (99 cm) 600lbs (272 kg) 240V 50/60Hz 1ph 4 A

SC30-6 � CC30-6 Cooling conveyor C300 � C600 � C10G n/a 75 in (190 cm) 54 in (137 cm) 39 in (99 cm) 375lbs (170 kg) 240V 50/60Hz 1ph 4 A

SC30-9 � CC30-9 Cooling conveyor C300 � C600 � C10G n/a 111 in (282 cm) 54 in (137 cm) 39 in (99 cm) 562lbs (256 kg) 240V 50/60Hz 1ph 4 A

SC30-12

� CC30-12 Cooling conveyor C300 � C600 � C10G n/a 147 in (374 cm) 54 in (137 cm) 39 in (99 cm) 750lbs (341 kg) 240V 50/60Hz 1ph 4 A

SC36-6 � CC36-6 Cooling conveyor C800 n/a 75 in (190 cm) 60 in (152 cm) 39 in (99 cm) 450lbs (205 kg) 240V 50/60Hz 1ph 4 A

SC36-9

� CC36-9 Cooling conveyor C800 n/a 111 in (282 cm) 60 in (152 cm) 39 in (99 cm) 675lbs (306 kg) 240V 50/60Hz 1ph 4 A

SC36-12

� CC36-12 Cooling conveyor C800 n/a 147 in (374 cm) 60 in (152 cm) 39 in (99 cm) 900lbs (409 kg) 240V 50/60Hz 1ph 4 A

DONUT SYSTEM

FINISH-LINE CONVEYORS

90° / 180° CURVE CONVEYORS

(90DC models)

OVERALL

LENGT H

(180DC models)

OVERALL

LENGT H

90°/ 180° Curve

90° Curve

180° Curve

COOLING CONVEYOR (SC30-12 shown)

OVERA LL

HEIGH T

DRIVE M OTOR

+ GEAR BOX

OVERA LL

WIDTH

CONVE YOR

BELT

COOLING CONVEYOR (CC30-6 shown)

OVERA LL

LENGT H

OVERA LL

HEIGH T

3 COOLI NG FANS

EACH SI DE

OVERALL

HEIGHT

NSF

®

OVERALL

WIDTH

Maximum open space between curve conveyor rods

C100/MK VI/20 0/400 C300/600

No filler rods (standard) 7/8” (22mm) 1” (25mm)

With filler rods (optional) 3/8” (10mm) 5/16” (8mm)

Dimensions And Power

Manufac ture d by

FOODSERVICE EQUIPMENT

DRIVE M OTOR

+ GEAR BOX

OVERA LL

WIDTH

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

NSF

®

19

Page 5

Donut System

AUXILIARY CONVEYORS

Worldwide Leader in the Design and Manufacture of Donut Production Equipment

CENTURY SCREEN LOADER

Belshaw’s Century Screen Loader (SL) is

designed to automatically load donuts on

standard size wire screens. Donuts can then

be easily transported to display, packaging

or directly onto a Belshaw HI Batch Icer. The

Screen Loader reduces labor by speeding

up the screening process, improves yield by

reducing the handling of warm donuts and

provides further donut cooling time prior to

packaging.

Features

■

Three belt widths – 16in (41cm), 24in (61cm),

32in (81cm).

■

DC drive motor outfeed with dial control.

■

Moisture-proof, wash-down motor.

CENTURY TRANSFER CONVEYOR

Belshaw’s Century Transfer Conveyor (TC)

gently transfers yeast donuts from the proofer to

fryer. The ‘rubber-band’ belting of the TC helps

reduce starch and flour from entering the fryer,

thereby extending shor tening life.

The TC can be easily moved to allow for

space for quick changeover to cake-donut

production using a Multimatic Cake-Donut

Depositor, eliminating the need to move a large

Thermomatic Proofer.

FOODSERVICE EQUIPMENT

Century Screen Loader

(SL30 shown)

Features

■

Adjustable safety clutch to uncouple motor in

event of obstruction.

■

Standard wash-down motor.

■

Rubber “O-ring” belting.

CENTURY SWEEP CONVEYOR

■

Provides 180° direction change.

■

Lower square footage requirements.

■

Lef t-hand and right-hand configurations.

■

Adjustable safety clutch that uncouples

motor in event of obstruction.

■

Removable drip pans.

■

Removable conveyor for easy cleaning.

■

Moisture-proof, wash-down motor.

■

NSF, ETL Listed.

20

Belshaw Bros., Inc., 1750 22nd Avenue South, Seattle WA 98144- 4590 USA

W http://www.belshaw.com

Century Transfer

Conveyor ( TC600)

Sweep conveyor operation

800-578-2547 (USA/Canada)

Century sweep conveyor

(DC200)

©20 05 Belshaw Bros, Inc. Rev 3/0 5

206-322-5474 (International)

FAX

206-322-5425

Page 6

DONUT SYSTEM

CENTURY SYSTEM

CONVEYOR

BELT WIDTH

OVERALL DIMENSIONS

APPROX SHIPPING

WEIGHT

ELECTRICAL

MODEL TYPE LENGTH WIDTH HEIGHT

V A

TC600 Transfer conveyor C300

� C600 � C10G 24in (61cm) 38in (97cm) 30in (76cm) 37in (94cm) 290lbs (132 kg) 208/240V 50/60hz 1ph 1.5 A

DC200 Sweep conveyor Mark VI

�C100�C200�C400 10" (25cm) 50 in (127 cm) 15 in (38 cm) 37 in (94 cm) 290lbs (132 kg) 240V 50/60Hz 1ph 1.5 A

DC600 Sweep conveyor C300

� C600 � C10G 10" (25cm) 88 in (224 cm) 15 in (38 cm) 37 in (94 cm) 400lbs (182 kg) 240V 50/60Hz 1ph 1.5 A

DC800 Sweep conveyor C800 10" (25cm) 96 in (244 cm) 15 in (38 cm) 37 in (94 cm) 475lbs (216 kg) 240V 50/60Hz 1ph 1.5 A

SL18 Screen loader Mark VI

�C100�C200�C400 18in (46cm) 129in (328cm) 39in (99cm) 38in (97cm) 850lbs (386 kg) 208/240V 50/60hz 1ph 3.5 A

SL30 Screen loader C300

� C600 � C10G 30in (76cm) 129in (328cm) 51in (129cm) 38in (97cm) 1050lbs (477 kg) 208/240V 50/60hz 1ph 3.5 A

SL36 Screen loader C800 36in (91cm) 129in (328cm) 57in (145cm) 38in (97cm) 1210lbs (550 kg) 208/240V 50/60hz 1ph 3.5 A

AUXILIARY CONVEYORS

TRANSFER CONVEYOR (TC models)

OVERA LL

HEIGH T

OVERA LL

WIDTH

OVERA LL

LENGT H

SCREEN LOADER (SL models)

DONUTS

DONUTS ON SCR EENS

SWEEP CONVEYOR (DC models)

WIDTH

OVERALL

LENGT H

NSF

®

OVERALL

HEIGH T

SCREENS

WIRE BELT

OVERALL

WIDTH

OVERALL

LENGT H

Auxiliary Conveyors – Dimensions And Power

Manufac ture d by

FOODSERVICE EQUIPMENT

800-578-2547 (USA/Canada)

206-322-5474 (International)

FAX

206-322-5425

21

Loading...

Loading...