Belimed WD290 Service manual

Technical Manual

WD 290

Item Number: 10537-0118-EN

Version: 001-08/09

Index of contents

Index of contents

1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

1.1 Before you read on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 1.2 Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 1.3 Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 1.4 Symbols and notices used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 |

For your safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.2 Care responsibilities for dealing with the device . . . . . . . . . . . . . . . . 8 2.3 Instruction of personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.4 Safety instructions on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.5 Fields of application for the device . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.6 Process validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 |

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

3.1 Device dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 3.2 Device dimensions with condenser (optional). . . . . . . . . . . . . . . . . 11 3.3 Optional additional components . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.3.1 Additional panelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.3.2 Switchable heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.3.3 Condenser with heat retrieval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.3.4 Dosing pump set with empty level indicators and flow meter . . . . . 12 3.3.5 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.3.6 Independent process data management system (IPD). . . . . . . . . . 13 3.4 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 3.5 Surrounding conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.5.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.5.2 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.5.3 Setup location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.6 Connection requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3.6.1 General requirements for mains power supply . . . . . . . . . . . . . . . . 16 3.6.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 3.6.3 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 3.6.4 Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3.6.5 Exhaust air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3.6.6 Connection requirements for installation. . . . . . . . . . . . . . . . . . . . . 19 3.6.7 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 3.6.8 Electric function diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.6.9 Function diagram with steam heating and steam drying. . . . . . . . . 22

4 |

Consumption data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

4.1 Water consumption for tiered tracks . . . . . . . . . . . . . . . . . . . . . . . . 23 4.2 Water consumption for anaesthesia rack . . . . . . . . . . . . . . . . . . . . 23

5 |

Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

5.1 Device loading side (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 5.2 Device unloading side (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 5.3 Operating unit on loading side (LS) . . . . . . . . . . . . . . . . . . . . . . . . 26 5.3.1 Description of operating unit on loading side . . . . . . . . . . . . . . . . . 26

2/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Index of contents

5.4 Operating unit on unloading side (US) . . . . . . . . . . . . . . . . . . . . . . 28 5.4.1 Description of operating unit on unloading side . . . . . . . . . . . . . . . 28 5.5 Process status display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 5.5.1 Process status display description . . . . . . . . . . . . . . . . . . . . . . . . . 29 5.6 Procedure for changing settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 5.7 Alphanumeric entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 5.7.1 Procedure for alphanumeric entry. . . . . . . . . . . . . . . . . . . . . . . . . . 31 5.7.2 Operating buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 |

Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

6.1 Logging on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 6.2 Automatic start / Autom. switch-off / Self-disinfection . . . . . . . . . . . 35 6.2.1 Automatic switch-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 6.2.2 Automatic start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 6.2.3 Self-Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Why self-disinfection? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Activating and setting the self-disinfection function . . . . . . . . . . . . 37 Starting self-disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 6.3 Machine information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Messages, Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 6.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 6.5.1 Printing the setup settings and program recipe . . . . . . . . . . . . . . . 42 6.5.2 Batch print-out in the event of error or program interruption . . . . . . 42 6.5.3 Batch print-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 6.6 Cleaning the screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 6.7 User management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 6.8 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 |

System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

7.1 General Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 7.1.1 User log-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 7.1.2 Rack identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 7.1.3 Batch content identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 7.1.4 Communication address RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 7.2 Machine parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 7.2.1 Periodic Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 7.2.2 Hours of operation of the air filter . . . . . . . . . . . . . . . . . . . . . . . . . . 53 7.2.3 Door locking function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 7.2.4 Program recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 7.2.5 Pumping off upon program termination. . . . . . . . . . . . . . . . . . . . . . 55 7.2.6 Step repeat (foam control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 7.2.7 PW tank pre-heating temperature / pre-heating time . . . . . . . . . . . 56 7.2.8 PW tank disinfection temperature / disinfection time . . . . . . . . . . . 56 7.2.9 Operating level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 7.2.10 Empty level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 7.2.11 Drainage time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 7.2.12 Drying lag time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 7.2.13 Heating interlock tank / washing chamber . . . . . . . . . . . . . . . . . . . 57 7.2.14 Steam dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 7.2.15 Delay interval for water heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Technical Manual WD290 |

001 |

3/143 |

© Belimed |

10537 |

|

Index of contents

7.2.16 Potential-free outputs K28, K57 and K58 . . . . . . . . . . . . . . . . . . . . 57 7.2.17 Rack position delay interval for loading and unloading . . . . . . . . . . 58 7.2.18 Waste water cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 7.2.19 Batch counter adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 7.2.20 Support modem number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 7.2.21 Adjustment of threshold values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 7.3 Program parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 7.3.1 Parameter entry overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 7.3.2 Utility M1 Cold Water Step (CW) . . . . . . . . . . . . . . . . . . . . . . . . . . 60 7.3.3 Utility M2 Warm Water Step (WW) . . . . . . . . . . . . . . . . . . . . . . . . . 62 7.3.4 Utility M3 Mixed Water Step (CW+WW) . . . . . . . . . . . . . . . . . . . . . 62 7.3.5 Utility M4 Purified Water Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 7.3.6 Utility M5 Drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 7.3.7 Condenser M6 functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 7.3.8 Pre-heated Purified Water M9 (Final Rinse) . . . . . . . . . . . . . . . . . . 63 7.3.9 Utility MA (1 step with 4 or more phases) . . . . . . . . . . . . . . . . . . . . 63 7.3.10 Function F0 - inactive step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 7.3.11 Function F1 - Pre-Rinsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 7.3.12 Functions F2-F5, F8, FD, FE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 7.3.13 Function F9 Clean Rinsing (optional IPD). . . . . . . . . . . . . . . . . . . . 64 7.3.14 Functions F6+F7 - thermal or chemical disinfection . . . . . . . . . . . . 64 7.3.15 Function FA - Thermal Disinfection A0=3000 . . . . . . . . . . . . . . . . . 64 7.3.16 Function FB - Thermal Disinfection A0=600 . . . . . . . . . . . . . . . . . . 65 7.3.17 Function FC - thermal disinfection A0=60. . . . . . . . . . . . . . . . . . . . 65 7.3.18 Functions FD, FE and FF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 7.4 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.4.1Adjustment of temperature sensors using reference sensor . . . . . 69

7.4.2 Adjustment of temperature sensors in calibrating bath . . . . . . . . . . 70 7.4.3 Mix-Dosing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 7.4.4 Calibrating the dosing pumps (time) . . . . . . . . . . . . . . . . . . . . . . . . 71 7.4.5 Calibrating the flow meters (impulses) . . . . . . . . . . . . . . . . . . . . . . 72 7.4.6 Setting LS door contact pressure (potentiometer value). . . . . . . . . 73 7.4.7 Setting US door contact pressure (potentiometer value) . . . . . . . . 73 7.5 Manual function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8 |

Configuration of connections . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 74 |

8.1 |

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 74 |

8.2 |

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 75 |

8.3 |

Inputs X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.1 |

SA Peak load block (building) . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.2 |

SB Floor pan leakage . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.3 |

SC PW tank code . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.4 |

SD PW tank float switch . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.5 |

SE Open LS door . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.3.6 |

SF Close door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.4 |

Temperature sensors . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 76 |

8.5 |

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . 77 |

8.5.1 |

Batch Documentation System ICS 8535 / 8565 . . . |

. . . . . . . . . . |

. . 77 |

8.5.2 |

Telegram allocation for batch documentation system. . . . . . . . . |

. . 77 |

|

8.5.3 |

Overview of interfaces for printer, barcode reader and modem . |

. . 79 |

|

9 |

Downloading the control software . . . . . . . . . . . |

. . . . . . . . . . |

. . 80 |

|

|

|

|

4/143 |

001 |

Technical Manual WD290 |

|

|

10537 |

|

© Belimed |

Index of contents

9.1 Locating and downloading the software . . . . . . . . . . . . . . . . . . . . . 80

10 Errors with process termination and their elimination . . . . . . . 81

10.1 Procedure in the event of errors with process termination . . . . . . . 81 10.2 Low voltage colour code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 10.3 Error display, cause and remedy . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11 Process data of factory programs. . . . . . . . . . . . . . . . . . . . . . . . 97

11.1 Process time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 11.2 Water and electric power consumption . . . . . . . . . . . . . . . . . . . . . . 97 11.3 Validated process parameters P1-P12 . . . . . . . . . . . . . . . . . . . . . . 97 11.4 Allocation of the utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 11.4.1 With condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 11.4.2 Purified water pre-heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 11.4.3 Deactivating program steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 11.5 Overview of ex-factory programs . . . . . . . . . . . . . . . . . . . . . . . . . . 99 11.6 P1 Alkaline washing of anaesthetics material . . . . . . . . . . . . . . . . 100 11.7 P2 Mildly alkaline washing of anaesthetics material . . . . . . . . . . . 101 11.8 P3 Alkaline washing of OT shoes . . . . . . . . . . . . . . . . . . . . . . . . . 102 11.9 P4 Alkaline washing of instruments . . . . . . . . . . . . . . . . . . . . . . . 103 11.10 P5 Alkaline intensive washing of instruments . . . . . . . . . . . . . . . . 104 11.11 P6 Highly alkaline washing of instruments . . . . . . . . . . . . . . . . . . 105 11.12 P7 Neutral washing of containers . . . . . . . . . . . . . . . . . . . . . . . . . 106 11.13 P8 Neutral washing of MIS instruments . . . . . . . . . . . . . . . . . . . . 107 11.14 P9 Alkaline washing of MIS instruments . . . . . . . . . . . . . . . . . . . . 108 11.15 P10 Alkaline washing of baby bottles . . . . . . . . . . . . . . . . . . . . . . 109 11.16 P11 Alkaline intensive washing of laboratory glassware . . . . . . . 110 11.17 P12 Supplementary drying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

112 |

12.1 Maintenance in general. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 12.2 Replacing the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 12.3 Error code and batch number statistics . . . . . . . . . . . . . . . . . . . . 113 12.4 Overview of maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . 114 12.5 Spare parts for maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 12.6 Maintenance of the lower wash arm . . . . . . . . . . . . . . . . . . . . . . . 117 12.7 Maintenance of the upper wash arm. . . . . . . . . . . . . . . . . . . . . . . 118 12.8 Cleaning fine screens and coarse screen . . . . . . . . . . . . . . . . . . . 119 12.9 Cleaning the water intake pre-filter . . . . . . . . . . . . . . . . . . . . . . . . 120 12.10 Tube clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 12.11 Heating elements / dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 12.12 Steam heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 12.13 Dosing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 12.13.1Peristaltic tubes for peristaltic pumps . . . . . . . . . . . . . . . . . . . . . . 122 12.14 Drying system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 12.14.1Air tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 12.14.2Pre-filter and fine filter (HEPA) . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 12.14.3Non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Technical Manual WD290 |

001 |

5/143 |

© Belimed |

10537 |

|

Index of contents

12.14.4Differential pressure (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 12.15 Door system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 12.15.1Safety switch actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 12.15.2Replacing the door seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 12.15.3Retightening the door belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 12.15.4Vertical door movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 12.15.5Readjusting door clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 12.15.6Calibrating the door setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 12.16 Electro drawer with PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 12.17 Maintenance of the electro drawer . . . . . . . . . . . . . . . . . . . . . . . . 130 12.18 Dismantling the door system (LS) . . . . . . . . . . . . . . . . . . . . . . . . . 132 12.19 Dismantling the door system (US) . . . . . . . . . . . . . . . . . . . . . . . . 135 12.20 Dismantling the linear drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 12.21 Maintenance of washing chamber lighting . . . . . . . . . . . . . . . . . . 138 12.22 Adjusting the temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . 139 12.23 Automatic loading and unloading (optional) . . . . . . . . . . . . . . . . . 139

13 |

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

13.1 |

Disposing of packaging material . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

13.2 |

Disposal of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

13.3 |

Disposing of dosage media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

14 |

Conformity and certifications . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

15 |

Organisation Belimed AG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

15.1 |

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

15.2 |

Subsidiaries, Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

16 |

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

6/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Introduction

1Introduction

1.1 Before you read on

Your product meets high standards and is easy to operate. Nevertheless, please take time to read these instructions carefully. You will become familiarised with your product and be able to use it to its best.

1.2Target group

These instructions are a component of the product and are intended for the following personnel:

Installation instructions |

Installer; Operating company; Technical support |

|

|

Operating instructions |

Operator; Operating company; Technical support |

|

|

Technical manual |

Operating company; Technical support |

|

|

They must be accessible for this group of persons!

1.3Changes

The text, graphics and data correspond to the technical status of the product at the time of going to print. Changes due to further development may occur.

Language original for this document is German (DE)

1.4Symbols and notices used

The following symbols and occupational safety alerts used throughout the documentation are important to avoid harm to health and life.

Danger

Indicates a hazard with high risk which, if not avoided, causes death or serious injury.

Warning

Indicates a hazard with medium risk which, if not avoided, can cause death or serious injury.

Caution

Indicates a hazard with low risk which, if not avoided, can cause minor or moderate injury.

Note

Operating tips and useful information on the best possible utilization.

Technical Manual WD290 |

001 |

7/143 |

© Belimed |

10537 |

|

For your safety

2For your safety

We affirm with the EC Declaration of Conformity and the CE mark that this product complies with the basic health and safety requirements in accordance with Directive 93/42/EEC Annex II (see Chap. 14 "Conformity and certifications").

Hazards may still arise from the product if it is used incorrectly by inadequately trained personnel or not as intended.

2.1Intended use

This product is exclusively approved for the uses stated in the instructions. Namely for central sterilisation, substerilisation in surgery, in hospitals and in laboratories. All other applications are considered as non-intended use.

2.2Care responsibilities for dealing with the device

•Only use original racks, spare parts and accessories

•Load racks as intended (see Chap. 5 "Device description")

•Daily maintenance work on the device must be performed regularly and according to instructions (see Chap. 12 "Maintenance")

•Validation of the program parameters must be performed regularly (see Chap. 2.6 "Process validation")

•Installation, deinstallation, maintenance or modification must only be performed by persons authorised by Belimed

2.3Instruction of personnel

This product must only be used, maintained and repaired by authorised, trained and briefed personnel. This assumes that these instructions are read and understood.

Responsibilities and competencies in operation, servicing and maintenance must be clearly defined and observed.

2.4Safety instructions on the device

Warning"Dangerous voltage"

Warning"Hot surface"

Warning"Caustic substances"

Follow safety instructions of the dosage media manufacturer!

8/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

For your safety

2.5Fields of application for the device

Cleaning and reconditioning of:

•Surgical instruments

•Minimally invasive instruments

•Instruments for anaesthesia and intensive care

•Baby bottles and teats

•Containers

•OT Shoes

•Laboratory instruments used in research and production

•Rigid endoscopes

•Eye instruments

•Neurosurgery

Warning

No single-use products may be reconditioned! Always adhere to the instructions of the medical device manufacturer!

2.6Process validation

The aim of process validation is to achieve a high level of safety in the reconditioning of medical devices in order to afford the operators and patients the greatest possible protection.

Process validation consists of:

a)Type testing / factory testing

b)Process validation consisting of:

•IQ (Installation Qualification)

•OQ (Operational Qualification)

•PQ (Performance Qualification)

c)Routine testing / Annual requalification

Note

Further information on process validation may be obtained from Belimed

Customer Service.

Caution

Validation must only be carried out by authorised persons!

Devices must only be operated with processes validated in accordance with regulations! Only use components (items to be washed, racks, programs and dosage media) which have been validated together.

The safety of operators and patients may be compromised if the devices used are not validated in accordance with the regulations.

Technical Manual WD290 |

001 |

9/143 |

© Belimed |

10537 |

|

Device specifications

3Device specifications

3.1 Device dimensions

max.670mm

Dimensions |

|

Measurements |

|

|

|

Height |

|

1,840 mm |

|

|

|

Width |

|

900 mm |

|

|

|

Depth |

|

940 mm |

|

|

|

Height of base |

|

100 mm |

|

|

|

Loading height |

|

870 mm |

|

|

|

Clearance height of washing chamber |

|

690 mm |

|

|

|

Clearance width of washing chamber |

|

630 mm |

|

|

|

Clearance depth of washing chamber |

|

800 mm |

|

|

|

Dimension height of rack |

|

670 mm |

|

|

|

Dimension width of rack |

|

610 mm |

|

|

|

Dimension depth of rack |

|

750 mm |

|

|

|

Unloaded weight |

|

310 kg |

|

|

|

Total weight |

|

380 kg |

|

|

|

Volume of washing chamber min./max. |

|

310 / 350 L |

|

|

|

|

|

900mm |

|

940mm |

|

|

800mm |

|

610mm |

|

1840mm |

690mm |

|

|

750mm |

|

|

870mm |

|

100mm |

Fig 493

10/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.2Device dimensions with condenser (optional)

Dimensions |

Measurements |

|

|

Height |

2,210 mm |

|

|

Width |

900 mm |

|

|

Depth |

940 mm |

|

|

Height of base |

100 mm |

|

|

Loading height |

870 mm |

|

|

Clearance height of washing chamber |

690 mm |

|

|

Clearance width of washing chamber |

630 mm |

|

|

Clearance depth of washing chamber |

800 mm |

|

|

Dimension height of rack |

670 mm |

|

|

Dimension width of rack |

610 mm |

|

|

Dimension depth of rack |

750 mm |

|

|

Unloaded weight |

365 kg |

|

|

Total weight |

490 kg |

|

|

Volume of washing chamber min./max. |

310 / 350 L |

|

|

940mm

900mm

900mm

610mm

max.670mm

800mm

690mm

690mm

750mm

870mm |

630mm |

|

2210 mm

100mm

Fig 494

Technical Manual WD290 |

001 |

11/143 |

© Belimed |

10537 |

|

Device specifications

3.3Optional additional components

3.3.1Additional panelling

•Side panelling, two-door

•Side panelling, single door

•Rear panel, single door

•Base panelling

•Intermediate panelling

•Panelling for condenser and purified water pre-heating system

3.3.2Switchable heating system

•Bivalent water heating system with steam or electricity, automatically switchable

3.3.3Condenser with heat retrieval

•Condenser with purified water pre-heating and heat retrieval

•Exhaust air condenser

•Purified water pre-heating system

3.3.4Dosing pump set with empty level indicators and flow meter

•Empty level monitoring system for dosage media, small/large (see Chap. 7.4 "Adjustment")

•Flow monitoring system for dosage media (see Chap. 7.4 "Adjustment")

•Dosing pumps with empty level indicators (max. 5 units) (see Chap. 7.4 "Adjustment")

12/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.3.5Miscellaneous

•Diverse racks (instructions supplied separately with the rack)

•Steam heating system (tank heater) (Chap. 3.6.9 "Function diagram with steam heating and steam drying")

•Steam dryer (see Chap. 7.2.14 "Steam dryer") and (Chap. 3.6.9 "Function diagram with steam heating and steam drying")

•Floor pan with leakage sensor (see Chap. 8.3.2 "SB Floor pan leakage")

•Drainage pump

•Built-in printer on loading or unloading side

•Tabletop printer

•Servicing and program recipe management with diagnostic software CADI for PC via RS 232

•Pressure gradient monitoring system for sterile dryer-filter

•Modem connection for remote support

•Automatic loading and unloading system

•User, batch content and rack identification via barcode reader

•Batch documentation system with PC ICS 8535 or 8565

•IQ, OQ, PQ Documentation

•Barcode reader for PC (see Chap. 7.2.4 "Program recognition")

•Potential-free contacts (see Chap. 7.2.16 "Potential-free outputs K28, K57 and K58")

3.3.6Independent process data management system (IPD)

Independent process data management system (IPD) for conductivity measurement, analogue pressure, two additional temperature sensors and redundant flow monitoring system. Process verification between controller and independent batch documentation system.

Technical Manual WD290 |

001 |

13/143 |

© Belimed |

10537 |

|

Device specifications

3.4 Technical data

Performance characteristics / components |

Data/performance/specifi- |

|

cations |

|

|

Circulation pump nominal delivery rate (delivery height) |

585 L/min (10 m) |

|

|

Circulation pump effective delivery rate (delivery height) |

Depending on load and water |

|

temperature |

|

|

Power rating of circulation pump |

2.2 kW |

|

|

Material of pump rotor |

Chrome steel 1.4301 |

|

|

380-415 V Electrical tank heating capacity |

22.5 kW |

|

|

200-220V Electrical tank heating capacity |

18 kW |

|

|

Steam tank heating capacity (450 kPa) |

30 kW |

|

|

Length of wash arm in the device |

600 mm |

|

|

Drainage valve |

Chrome steel 1.4301 |

|

|

Dosing pumps |

24 V AC / 10L / min |

|

|

Number of dosing pumps in basic model |

3 - 5 |

|

|

Flow meters for impulse measurement |

Max. 4 (optional) |

|

|

Dryer electrical heating capacity |

10.5 kW |

|

|

Dryer heating capacity for steam and pure steam |

16 kW at 300 kPa |

|

|

Dryer, nominal (2 brush-free DC turbines) |

2.4 kW |

|

|

Dryer fan max. nominal ventilation capacity |

650 m3/h |

Dryer fan max. nominal pressure increase |

13.4 kPa |

|

|

Air filter: Filter class H13 EN 1822, retention rate for particle |

99.95% |

sizes from 0.1-0.2 |

|

|

|

Heat radiation when standing free |

500 (+/- 200) W |

|

|

Max. noise emission |

65 dB (A) |

|

|

Opening and closing of washing chamber doors |

Automatic |

|

|

Door safety shut-off |

Safety switch actuator |

|

|

Washing chamber seal |

Silicone |

|

|

Washing chamber and doors of chrome steel (CNS) |

1.4404, AISI 316 L |

|

|

Frame and panelling of chrome steel (CNS) |

Chrome steel 1.4301 |

|

|

Thickness of washing chamber wall |

1.5 mm |

|

|

Drainage pump (optional) |

100 L/min |

|

|

14/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.5 Surrounding conditions

3.5.1 Storage

Criterion |

Requirement |

|

|

Surrounding or room temperature |

0°C - +50°C |

|

|

Relative humidity, non-condensing |

10 - 90% |

|

|

Max. storage period |

1 Year |

|

|

Surrounding atmosphere |

Non-corrosive |

|

|

|

|

Caution

Avoid direct sunlight or one-sided air currents (near window).

3.5.2 |

Transportation |

|

|

|

|

|

|

|

|

Criterion |

Requirement |

|

|

|

|

|

|

Room temperature |

-25°C - +55°C |

|

|

|

|

|

|

Short-term room temperature (24 h) |

-25°C - +70°C |

|

|

|

|

|

|

Relative humidity, non-condensing |

10 - 90% |

|

|

|

|

|

|

Max. duration of transport |

1 Month |

|

|

|

|

3.5.3 |

Setup location |

|

|

|

|

|

|

|

|

Criterion |

Requirement |

|

|

|

|

|

|

Max. altitude of setup location |

1600 m above sea level |

|

|

|

|

|

|

Max. relative humidity |

80% |

|

|

|

|

|

|

Surrounding or room temperature |

+5°C - +40°C |

|

|

|

|

|

|

Degree of contamination |

2 (P2) |

|

|

|

|

|

|

Space required for each device |

5 m2 |

|

|

Min. load bearing capacity of floor |

500 kg/m2 |

|

|

Floor characteristics |

Fire proof |

|

|

|

|

|

|

Minimum distance between devices |

50 mm |

|

|

|

|

|

|

Evenness of floor - difference in levels |

< 10 mm |

|

|

|

|

|

|

|

|

Caution

Avoid direct sunlight or one-sided air currents (near window).

Technical Manual WD290 |

001 |

15/143 |

© Belimed |

10537 |

|

Device specifications

3.6Connection requirements

3.6.1General requirements for mains power supply

General mains power supply requirements for error-free operation of the devices

Voltage |

Frequency |

|

|

|

|

3N 380-415 V ~ |

50 Hz |

|

|

|

|

3N 380-415 V ~ |

60 Hz |

|

|

|

|

208 V 3 ~ |

60 Hz |

|

|

|

|

200-220 V 3 ~ |

60 Hz |

|

|

|

|

200-220 V 3 ~ |

50 Hz |

|

|

|

|

|

|

|

Caution

Largest permissible mains voltage fluctuation +/- 10%.

Largest permissible frequency tolerance +/- 1Hz

3.6.2Electrical connections

Voltage |

3N 380-415 V ~ |

3N 380-415 V ~ |

208 V 3 ~ |

200-220 V 3 ~ |

200-220 V 3 ~ |

|

|

50 Hz |

60 Hz |

60 Hz |

60 Hz |

50 Hz |

|

Electrically heated |

|

|

|

|

|

|

Washing chamber; dryer; |

|

|

|

|

|

|

PW tank "interlocked" |

|

|

|

|

|

|

Power rating of connection |

25 kW |

25 kW |

20 kW |

21 kW |

21 kW |

|

Fuse |

40 A |

40 A |

50 A |

60 A |

60 A |

|

|

|

|

|

|

|

|

Steam heated |

|

|

|

|

|

|

Washing chamber |

|

|

|

|

|

|

Electrically heated |

|

|

|

|

|

|

Dryer; PW tank "interlocked" |

|

|

|

|

|

|

Power rating of connection |

13 kW |

13 kW |

13 kW |

13 kW |

13 kW |

|

Fuse |

25 A |

25 A |

40 A |

40 A |

40 A |

|

|

|

|

|

|

|

|

Steam heated |

|

|

|

|

|

|

Washing chamber; dryer |

|

|

|

|

|

|

Power rating of connection |

3.5 kW |

3.5 kW |

3.5 kW |

3.5 kW |

3.5 kW |

|

Fuse |

16 A |

16 A |

15 A |

16 A |

16 A |

|

|

|

|

|

|

|

|

Steam heated |

|

|

|

|

|

|

Washing chamber; dryer |

|

|

|

|

|

|

Electrically heated |

|

|

|

|

|

|

PW tank "non-interlocked" |

|

|

|

|

|

|

Power rating of connection |

13 kW |

13 kW |

13 kW |

13 kW |

13 kW |

|

Fuse |

25 A |

25 A |

40 A |

40 A |

40 A |

|

|

|

|

|

|

|

16/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.6.3Water connections

Cold water (CW) |

Min. temperature |

°C |

5 |

|

|

Max. temperature |

°C |

20 |

|

|

Water hardness |

mmol/L |

0.7 - 2.0 |

|

|

|

°dH |

3.9 - 11.2 |

|

|

|

°fH |

7 |

- 20 |

|

Salt content |

mg/L |

< 500 |

|

|

Chloride content |

mg/L |

< 100 |

|

|

pH |

|

5 |

- 8 |

|

Water pressure (absolute) |

kPa |

200 - 600 |

|

|

Min. volume flow |

L/min |

8 |

|

|

Connection thread on building side |

inch |

3/4" |

|

|

|

|

|

|

Warm water (WW) |

Max. temperature |

°C |

60 |

|

|

Water hardness |

mmol/L |

0.7 - 2.0 |

|

|

|

°dH |

3.9 - 11.2 |

|

|

|

°fH |

7 |

- 20 |

|

Salt content |

mg/L |

< 500 |

|

|

Chloride content |

mg/L |

< 100 |

|

|

pH |

|

5 |

- 8 |

|

Water pressure (absolute) |

kPa |

200 - 600 |

|

|

Min. volume flow |

L/min |

8 |

|

|

Connection thread on building side |

inch |

3/4" |

|

|

|

|

|

|

Purified water (PW) |

Max. recommended conductivity |

S/cm |

5 |

- 15 |

|

pH |

|

5 |

- 8 |

|

Water hardness |

mmol/L |

0.02 |

|

|

Salt content |

mg/L |

< 10 |

|

|

Phosphate |

mg/L |

< 0.5 |

|

|

Silicate |

mg/L |

< 1 |

|

|

Chloride content |

mg/L |

< 2 |

|

|

Water pressure (absolute) |

kPa |

200 - 600 |

|

|

Min. volume flow |

L/min |

8 |

|

|

Connection thread on building side |

inch |

3/4" |

|

|

|

|

|

|

Waste water |

Max. temperature |

°C |

95 |

|

|

pH |

|

5 |

- 12 |

|

Connection |

DN |

55 |

|

|

Max. short term discharge |

L/min |

150 |

|

|

|

|

|

|

Technical Manual WD290 |

001 |

17/143 |

© Belimed |

10537 |

|

Device specifications

3.6.4Steam

Heating steam |

Steam pressure (a) |

kPa |

350 - 450 |

|

Max. boiling temperature (a) |

°C |

160 |

|

Design capacity at 600 kPa (160°C) |

kg/h |

50 |

|

Connection thread (flat sealing) |

inch |

1/2" External |

|

|

|

thread |

|

|

|

|

Water heating |

Mass flow of saturated steam |

kg/min |

0.8 |

|

Consumption / batch at 300 kPa (a) |

kg |

12 - 16 |

|

|

|

|

Dryer |

Mass flow of saturated steam |

kg/min |

0.45 |

|

Consumption / batch for 10 min |

kg |

4.5 |

|

drying at 300 kPa |

|

|

|

|

|

|

(a) = absolute

3.6.5 Exhaust air

Exhaust air connection |

Connecting piece machine side |

mm |

D 114.5 |

||

|

|

|

|

|

|

I. Exhaust facility con- |

Max. length of exhaust air pipe on building side |

m |

5 |

|

|

nected directly to out- |

Exhaust air volume flow |

m3/h |

250 - 350 |

||

door surroundings(not |

Temperature average / short term max. |

°C |

70 |

/ 90 |

|

recommended) |

|||||

|

|

|

|

||

Do not merge the exhaust |

Rel. humidity - average / short term max. |

% |

80 |

/ 100 |

|

|

|

|

|

||

facilities of several clean- |

Exhaust air pipe - maximum permissible pres- |

Pa |

350 |

||

ing and disinfecting units |

sure drop |

|

|

|

|

|

|

|

|

||

II. Connection without |

Volume flow of building exhaust facility |

m3/h |

250 - 350 |

||

condenser to building |

Temperature average / short term max. |

°C |

70 |

/ 90 |

|

exhaust facility with fan |

|||||

Rel. humidity - average / short term max. |

% |

80 |

/ 100 |

||

|

|||||

|

|

|

|

||

III. Connection with con- |

Volume flow of building exhaust facility |

m3/h |

250 - 350 |

||

denser to building exhaust |

Temperature average / short term max. |

°C |

70 |

/ 90 |

|

facility with fan |

|||||

Rel. humidity - average / short term max. |

% |

< 70 / 100 |

|||

|

|||||

|

Condenser power rating |

kW |

2.7 |

|

|

|

Quantity of condensed water |

mL |

approx. 100mL |

||

|

(applies only to thermal disinfection A0 3000 |

|

|

|

|

|

93°C; 12 minutes drying at 120°C) |

|

|

|

|

|

|

|

|

|

|

18/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.6.6Connection requirements for installation

|

Building side |

Machine side |

|||||

|

|

|

|

|

|

||

Water |

• |

Shut-off valve, 3/4" |

• |

Armoured tube, 2 m |

|||

Cold, Warm |

|

|

|

|

• |

Fine filter, 3/4" / mesh width 250 |

|

Purified |

|

|

|

|

• |

Free flow passage |

|

|

|

|

|

|

|

||

Drain |

• |

Floor drain with syphon |

• |

T-Piece for condensed water drainage |

|||

|

• |

Drainage nozzle |

|

inner |

= 20 mm |

||

|

|

|

|

||||

|

|

outer |

= 55 mm |

|

outer |

= 26 mm |

|

|

|

|

|

|

|||

|

• |

Odour trap |

• |

Drainage tube, EPDM |

|||

|

|

|

|

||||

|

|

|

|

|

|

inner |

= 55 mm |

|

|

|

|

|

|

||

Drainage pump |

• |

Drainage pipe with syphon |

• |

Max. delivery height 1 m (100 L/min) |

|||

|

|

|

|

|

|

(optional) |

|

|

|

|

|

|

• |

Drainage tube, EPDM |

|

|

|

|

|

|

|

inner |

= 19 mm |

|

|

|

|

|

|

||

Exhaust air |

• |

Exhaust air pipe, water resistant |

• |

Exhaust air pipe |

|||

|

|

inner |

= 115 mm |

|

outer |

= 114.5 mm |

|

|

• |

Motor-driven exhaust flap |

• |

Condensed water drain |

|||

|

• |

Draught interrupter, exhaust |

• |

Exhaust flap with false-air opening |

|||

|

|

air channel |

|

|

|

||

|

|

|

|

|

|||

Electrical |

Mains power supply requirements - see |

• |

Harmonised cable, 5 x 6 mm2 |

||||

mains connec- |

Chap. 3.6.2 "Electrical connections" |

|

Cable length 1 m |

||||

tion |

Installation category (CAT II) |

• |

Harmonised cable, 5 x 2.5 mm2 |

||||

|

|||||||

|

Device can be separated from mains via |

|

Cable length 1 m |

||||

|

main switch or mains plug within easy |

• |

Terminal clamp |

||||

|

reach. |

|

|||||

|

|

|

|

|

|||

|

|

|

|

|

|

||

Steam connec- |

• |

Two shut-off valves, 1/2" |

• |

One 2/2 solenoid valve, 1/2" 24VAC |

|||

tion |

• |

Dirt separator, 1/2" |

• |

Connection G1/2", 60°inner cone |

|||

|

|||||||

|

• Isolated armoured tube, 2 x 3.5 m |

• |

Outlet G1/2", 60°inner cone |

||||

|

• |

Pressure gauge recommended |

• |

Two condensed water separators, |

|||

|

|

|

|

|

|

1/2" |

|

|

|

|

|

|

• Two non-return valves |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning

Maximum operating pressure for steam connection 700 kPa (a)! A building excess-pressure protective device at the steam connection site with 700 kPa

(a) response pressure must be provided. Use certified armatures only!

Note

Pressurised air connection must not be provided.

Steam supply and discharge pipes are flushed via bypass.

Keep electrical supply and steam supply separate.

Note

A line disconnector is to be installed on-site near the device and must be well within reach! The operational current is at least 60 A.

Technical Manual WD290 |

001 |

19/143 |

© Belimed |

10537 |

|

Device specifications

3.6.7Connection diagrams

11 |

10 |

1 |

2 |

3 |

4 |

5 |

6 |

7

8

Fig 495

1 Cold water supply (blue)

2Warm water supply (red)

3 Purified water supply (green)

4 Steam connections (optional)

5 Main connecting cable

6 Floor-type connection

7 Drainage valve

8Water drainage

9 Drainage pump (optional)

10Exhaust air casing

11Exhaust air pipe

9 |

20/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device specifications

3.6.8Electric function diagram

|

|

|

DI |

WW CW |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Y27 |

|

|

|

SD |

|

3 |

26 |

|

|

|

|

NTC4 |

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

4 |

|

|

|

|

|

|

|

R26 |

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y14 |

|

|

|

|

|

|

|

|

|

|

|

5 |

27 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S109 |

|

|

26 |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

S211 |

|

|

|

|

|

|

|

Y13 |

Y12 |

Y11 |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

P |

P1 |

7 |

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

24 |

|

|

|

|

|

|

S31 |

|

|

|

|

|

|

|

S101 |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

S102 |

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S103 |

NTC2 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

S106 |

|

|

|

|

|

|

|

|

|

|

|

31 |

|

|

|

|

|

|

|

S107 |

T |

|

|

|

|

|

|

|

|

S105 |

|

|

|

|

|

|

|

|

|

|

|

|

11 |

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 |

13 |

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

S212 |

|

|

|

4 |

|

|

|

|

|

|

|

|

|

T |

T |

|

|

|

|

|

|

13 |

|

|

5 |

1 |

M15 |

|

|

|

|

|

|

|

NTC |

NTC |

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

14 |

||

|

|

|

|

|

|

R18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P18 |

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Y31 |

|

|

|

|

|

16 |

18 |

|

|

|

|

M17.1 |

M17.2 |

|

|

|

|

|

|

|

|

|

|

|

||

19 |

|

|

|

|

|

|

|

|

17 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 |

Fig 237

M31

1)Water connections

2)PW tank

3)Float switch

4)PW tank temperature sensor

5)PW tank valve

6)Pressure switch for clogged screen

7)Pressure switch

8)Level sensor

9)Free flow passage

10)Safety level pressure switch

11)WaterAir valve

12)Filter differential pressure switch

13)Temperature limiter

14)Dryer heating

15)Pressure sensor ventilator

16)Ventilators with fine filters

17)Electro drawer

18)Drainage valve, drainage pump

19)Drain

20)Circulation pump

21)Codensate separator

22)Tank heater, heat exchanger

23)Rack coding

24)Rack

25)Exhaust air condensed water/Overflow

purified water

26)Water valves

27)Exhaust flap

28)Condenser

29)Non-return flap

30)Exhaust air

31)Air temperature sensor

32)Fine filter

Technical Manual WD290 |

001 |

21/143 |

© Belimed |

10537 |

|

Device specifications

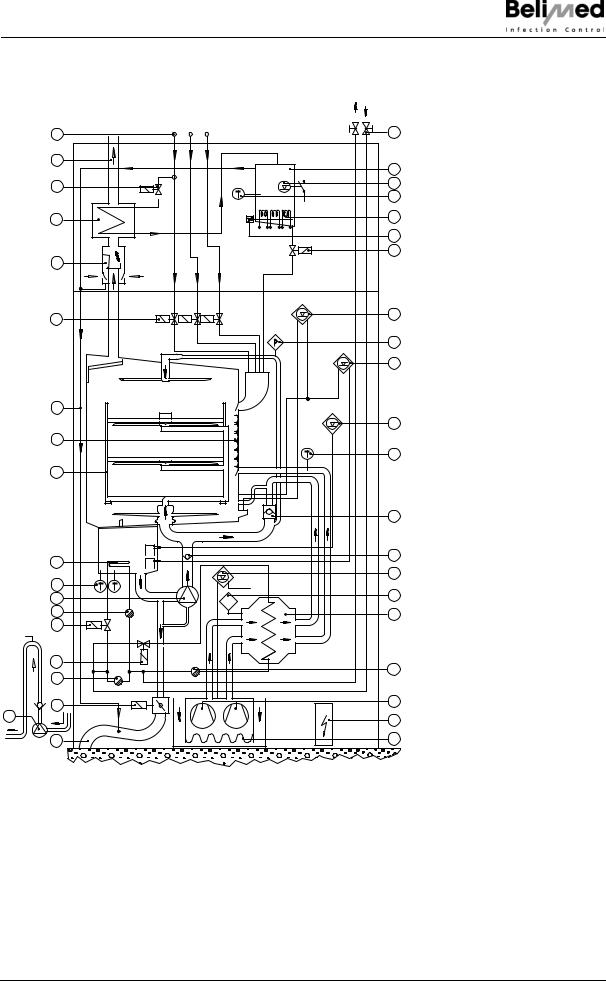

3.6.9Function diagram with steam heating and steam drying

|

|

|

DI |

WW CW |

|

|

|

1 |

|

|

34 |

|

|

|

|

|

|

|

|

|

33 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SD |

2 |

|

|

|

Y27 |

|

|

|

|

|

|

|

30 |

|

|

|

NTC4 |

|

|

3 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

4 |

|

|

|

|

|

|

|

R26 |

|

|

|

32 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y14 |

35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

31 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S109 |

|

|

30 |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y13 |

Y12 |

Y11 |

S211 |

|

|

|

|

|

|

|

|

|

P |

|

8 |

|

|

|

|

|

|

|

|

|

P1 |

|

|

|

|

|

|

|

|

|

9 |

|

29 |

|

|

|

|

|

|

|

S31 |

|

|

|

|

|

|

S101 |

|

|

10 |

|

|

|

|

|

|

S102 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

|

|

|

|

S103 |

|

|

|

|

|

|

|

|

S106 |

|

NTC2 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

S107 |

|

T |

11 |

|

|

|

|

|

|

S105 |

|

|

|

|

27 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

26 |

|

|

|

|

|

|

|

36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

M15 |

|

|

|

|

|

13 |

|

4 |

|

|

|

S212 |

|

|

|

|

|

T |

T |

|

|

|

|

|

||

|

25 |

NTC5 |

NTC1 |

|

|

P18 |

|

|

14 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

24 |

|

|

|

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

16 |

|

|

|

|

|

|

|

|

|

|

|

Y31 |

|

|

|

|

|

17 |

|

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

M17.1 |

M17.2 |

|

|

18 |

|

|

|

|

|

|

|

|||

M31 |

20 |

|

|

|

|

|

|

|

19 |

|

|

|

|

|

|

|

|

||

Fig 238

1)Steam connection

2)PW tank

3)Float switch

4)PW tank temperature sensor

5)Purified water heating

6)Tank valve

7)Pressure switch for clogged screen

8)Pressure switch

9)Level sensor

10)Safety level pressure switch

11)Air temperature sensor

12)WaterAir valve

13)Filter differential pressure switch

14)Pressure sensor ventilator

15)Dryer heat exchanger

16)Codensate separator

17)Ventilators

18)Electro drawer

19)Fine filter

20)Drain

21)Drainage pump

22)Drain valve

23)Dryer steam valve

24)Tank heating steam valve

25)Circulation pump

26)Tank heat exchanger

27)Rack

28)Rack coding

29)Exhaust air condensed water/Overflow

purified water

30)Water valves

31)Exhaust flap

32)Condenser

33)Exhaust air

34)Water connections

35)Temperatur limiter

36)Non-return flap

22/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Consumption data

4Consumption data

The data in the table below were measured with the single-tier rack.

Description |

|

Water consumption (litres)* |

|

Consumption of chemicals (mL) |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CW |

WW |

PW |

Total |

Type |

Concen- |

Con- |

||||||

|

|

|

|

|

|

|

|

|

|

|

tration |

sumption |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

|

|

|

Min |

Max |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Pre-rinse |

31 |

40 |

|

|

|

|

31 |

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Washing** |

16 |

18 |

15 |

18 |

|

|

31 |

40 |

Chemicals |

5.0 |

mL/L |

155 |

200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. |

Neutralisa- |

|

|

31 |

40 |

|

|

31 |

40 |

Neutraliser |

1.5 |

mL/L |

46 |

60 |

tion |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

Rinsing / |

|

|

|

|

31 |

40 |

31 |

40 |

|

|

|

|

|

disinfecting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total |

47 |

58 |

46 |

58 |

31 |

40 |

124 |

160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*depending on load

**Relation CW / WW depends on temperature and programming

4.1Water consumption for tiered tracks

1-Tier rack approx. 31 litres

2-Tier rack approx. 33 litres

3-Tier rack approx. 34 litres

4-Tier rack approx. 35 litres

5-Tier rack approx. 36 litres

4.2Water consumption for anaesthesia rack

Anaesthesia rack approx. 40 litres

Technical Manual WD290 |

001 |

23/143 |

© Belimed |

10537 |

|

Device description

5Device description

5.1 Device loading side (LS)

1

2

3 9

3 9

4

5

8

6

7

Fig 496

1 Process status display

2Operating unit

3 Safety switch actuator

4 Washing chamber door

5 Emergency Stop

6Lower front panel

7 Location of power rating plate

8 Transfer cart

9Rack

24/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device description

5.2Device unloading side (US)

5 |

4 |

1 |

2 |

3 |

Fig 497

1 Process status display

2 Washing chamber door

3 Lower front panel

4 Emergency Stop

5Operating unit

Technical Manual WD290 |

001 |

25/143 |

© Belimed |

10537 |

|

Device description

5.3Operating unit on loading side (LS)

1 |

2 |

3 |

4 |

5 |

1)Menu button

2)Display

–Displays the

status bar, communication bar, activity bar, selection options

3)Selection buttons

4)Confirmation button <OK>

5)On/Off button

6)Activity buttons

6 |

Fig 499 |

5.3.1Description of operating unit on loading side

Status bar

The status bar draws attention to certain settings and events by means of icons and data. The status bar is device-dependent and in each case has the same content on all screens.

Status bar icons

Symbol |

Description |

Symbol |

Description |

|

|

|

|

|

Message inactive |

|

Warning active |

|

|

|

|

|

Error active |

|

Doors locked |

|

|

|

|

|

Doors open |

|

Doors closed |

|

|

|

|

|

Door on loading side open |

|

Door on unloading side open |

|

|

|

|

|

Automatic system active |

|

Automatic system inactive |

|

|

|

|

|

Automatic system error |

|

|

|

|

|

|

26/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device description

Communication bar

The communication bar comprises an icon for the scroll wheel and a two-line text display. The scroll wheel icon indicates, whether the operating unit is displaying the "Home screen" or the "Information screen" .

Communication bar icons

Symbol |

Description |

Symbol |

Description |

|

|

|

|

|

Scroll wheel Home |

|

Scroll wheel Info |

|

|

|

|

Activity bar

The respective function options of the activity buttons are shown in the activity bar. For screens with several pages, the respective page number and total number of pages is additionally displayed in the activity bar.

Activity bar icons

Symbol |

Description |

Symbol |

Description |

|

|

|

|

|

Cursor forward |

|

Cursor back |

|

|

|

|

|

Delete |

|

Delete all |

|

|

|

|

|

Cursor up |

|

Cursor down |

|

|

|

|

|

Capital letters |

|

Lower case letters |

|

|

|

|

|

Numbers |

|

New |

|

|

|

|

|

Page forward |

|

Page back |

|

|

|

|

|

Open door |

|

Close door |

|

|

|

|

|

Value minus (smaller) |

|

Value plus (larger) |

|

|

|

|

|

Back |

|

|

|

|

|

|

|

No user logged on |

|

New user |

|

|

|

|

|

Program pause |

|

Program start |

|

|

|

|

|

Deactivate door contact |

|

Activate door contact pres- |

|

pressure |

|

sure |

|

|

|

|

Technical Manual WD290 |

001 |

27/143 |

© Belimed |

10537 |

|

Device description

5.4Operating unit on unloading side (US)

|

|

|

1) |

LED Displays |

|

|

|

|

|

|

|

– a) LED Red flashes - Warning active; |

|

||

|

|

|

|

|

LED Red lights permanently - error ac- |

||

a |

b |

c |

1 |

|

tive |

|

|

|

|

|

|

– b) LED Green lights |

permanently |

- |

|

|

|

|

2 |

|

Program cycle active |

|

|

|

|

|

|

– |

c)LED Green lights permanently - |

||

|

|

|

3 |

|

Doors locked |

|

|

|

|

|

|

|

|

|

|

|

|

|

2) |

Display |

|

|

|

|

|

|

|

– |

Displays the |

|

|

|

|

|

|

|

Status bar, activity bar |

|

|

|

|

|

3) |

Activity button |

|

|

|

|

|

|

Fig 500 |

|

|

|

|

5.4.1Description of operating unit on unloading side

Status bar

The status bar draws attention to certain settings and events by means of icons and data.

Status bar icons

Symbol |

Description |

Symbol |

Description |

|

|

|

|

|

Automatic system active |

|

Automatic system inactive |

|

|

|

|

|

Doors locked |

|

|

|

|

|

|

|

Doors open |

|

Doors closed |

|

|

|

|

|

Door on loading side open |

|

Door on unloading side open |

|

|

|

|

28/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Device description

Activity bar

The respective function option of the activity button is shown in the activity bar. The options available depend on the respective machine status of the device.

Activity bar icons

Symbol |

Description |

When displayed |

|

|

|

|

Open door |

Program completed correctly, door |

|

ready to open |

|

|

|

|

|

|

|

|

Close door |

Door ready to close |

|

|

|

|

Brightness and background |

User setting, display settings for |

|

illumination setting |

unloading side |

|

|

|

|

Contrast setting |

User setting, display settings for |

|

unloading side |

|

|

|

|

|

|

|

|

Confirmation of display set- |

User setting, display settings for |

|

tings |

unloading side |

|

|

|

5.5Process status display

*

*

•Display starting position

–All LEDs = Dark (no display)

•Program in Progress-Display

–see description

•Error display

–All LEDs = Red, flashing

•Process interruption display

–All LEDs = Red, flashing

* = 1. LED

Fig 576

5.5.1Process status display description

Process status display

The process status display is located above the washing chamber door on the loading side and the unloading side. The process status display shows the current operating status of the device.

Technical Manual WD290 |

001 |

29/143 |

© Belimed |

10537 |

|

Device description

Display while program is in progress:

•If the remaining run time is more than 55 min, a running light which rotates clockwise is displayed.

•If the remaining run time is between 50 and 55 min, the first LED lights up. Every 5 min, a further LED lights up.

•At the end of the program, all 12 LEDs flash.

•The LEDs are turned off when the door is opened or in the event of an error.

5.6Procedure for changing settings

Example - Setting the date:

O

Settings

Operating language

German

Date

09.02.2009

Weekday

Monday

Time

07:15

|

|

|

|

|

|

O |

|

|

|

Select date display

The current cursor position is lighted up

Select value to be modified using the activity button

Increase value using activity button  , or decrease with

, or decrease with

After setting all values, confirm settings with <OK> -Button

30/143 |

001 |

Technical Manual WD290 |

|

10537 |

© Belimed |

Loading...

Loading...