Beko SP11 Instructions For Installation And Operation Manual

EN - English

Instructions for installation and operation

Pressure transducer METPOINT® PRM

SP1

1

10-054

2 METPOINT® SP11

Dear customer,

Thank you for deciding in favour of the METPOINT

®

PRM SP11 pressure transducer. Please read these

installation and operating instructions carefully before mounting and starting up the pressure transducer and

follow our directions.

Perfect functioning of the pressure transducer can only be guaranteed when the provisions and notes stipulated here are strictly adhered to.

Inhalt

METPOINT® SP11 3

Contents

1

Pictograms and symbols ........................................................................................................................ 4

2 Signal words in accordance with ISO 3864 and ANSI Z 535 ................................................................. 4

3 General information ................................................................................................................................ 5

4 Safety instructions .................................................................................................................................. 6

5 Proper use .............................................................................................................................................. 7

6 Exclusion from the field of application .................................................................................................... 7

7 Type plate ............................................................................................................................................... 8

8 Technical data ........................................................................................................................................ 9

9 Dimension drawings ............................................................................................................................. 12

10 Function ................................................................................................................................................ 14

11 Installation ............................................................................................................................................ 15

11.1 Installation instructions ......................................................................................................................... 15

11.2 Preparing the thread at the measurement point .................................................................................. 16

11.3 Installation example for connections in accordance with EN 837-1 with a cylindrical thread .............. 16

12 Electrical installation ............................................................................................................................. 17

12.1 Pin assignment PRM SP11, 2-wire ...................................................................................................... 18

13 Maintenance and calibration ................................................................................................................ 20

13.1 Cleaning/decontamination .................................................................................................................... 21

14 Scope of delivery .................................................................................................................................. 22

15 Accessories .......................................................................................................................................... 23

16 Dismantling and diposal ....................................................................................................................... 24

17 Trouble shooting and fault removal ...................................................................................................... 25

18 Declaration of conformity ..................................................................................................................... 26

19 Index ..................................................................................................................................................... 27

Pictograms and symbols

4 METPOINT® SP11

1 Pictograms and symbols

Observe the installation and operating instructions

General advice

Observe the installation and operating instructions

(on the type plate)

General danger symbol (danger, warning, caution)

Use protective gloves

2 Signal words in accordance with ISO 3864 and ANSI Z 535

Pos: 25 /Be ko T echni sc he D ok ume ntati on /Sic her hei t/Sig nal wor te I SO + AN SI @ 0\ mod_1213340310421_6.docx @ 8739 @ @ 1

Danger!

Imminent hazard

Consequences of non-observance: serious injury or death

Warning!

Potential hazard

Consequences of non-observance: possible serious injury or death

Caution!

Imminent hazard

Consequences of non-observance: possibly injury or property damage

Notice!

Potential hazard

Consequences of non-observance: possibly injury or property damage

Important!

Additional advice, info, hints

Consequences of non-observance: disadvantages during operation and maintenance, no dan-

ger

General information

METPOINT® SP11 5

3 General information

Warning!

Risk of injury when used incorrectly!

Prior to the mounting, start-up, and operation of the pressure transducer, it must be ensured that the device was correctly chosen with regard to the measuring range, design and

specific measurement conditions. In the event of non-observance, severe personal injury

and/or damage to materials may occur.

Warning!

Risk of injury in the event of insufficient qualifications!

Improper use can lead to significant personal injury and material damage.

All of the activities described in these operating inst

ructions must only be carried out by

qualified personnel with the qualifications described hereinafter.

Qualified personnel

Due to the specific training and knowledge concerning the measuring and control technology, and due to

their experience and knowledge of the country-specific provisions, standards in force and directives, qualified

personnel are capable of carrying out the described work and of independently identifying the possible risks.

Special employment conditions require further corresponding knowledge, e.g. regarding aggressive media.

Please check, prior to reading the operating instructions, whether or not these instructions correspond to the device. Read these installation and operating instructions carefully prior to any

intervention regarding the METPOINT

®

PRM. The operating instructions must be accessible at

all times at the place of application of the device.

If you have any queries regarding these instructions, please contact BEKO TECHNOLOGIES

GMBH.

Installation works must exclusively be carried out by authorised and qualified personnel. Prior to

undertaking any measures, the qualified personnel shall read up on the device by carefully

studying the operating instructions. The operator of the products is responsible for the adherence to these provisions. The respective directives in force apply to the qualification and expertise of the qualified personnel.

For safe operation, the device must only be installed and operated in accordance with the indications in the operating instructions. In addition, the national and operational statutory provisions and safety regulations, as well as the accident prevention regulations re

quired for the

respective case of application, need to be observed during employment. This applies accordingly when accessories are used.

Safety instructions

6 METPOINT® SP11

4 Safety instructions

Danger!

Compressed air!

Risk of serious injury or death through contact with quickly or suddenly escaping compressed air

or through bursting plant components.

Measures

• Do not exceed the max. operating pressure (see type plate)!

• Only use pressure-resistant installation material!

• Make sure that no persons or objects can be hit by emerging compressed

air!

Danger!

Inadmissible operating parameters!

Under-running or exceeding the limit values involves risks for persons and the material, and malfunction and service failures may occur.

Measures

• Make sure that the pressure transducer is operated only within the permissible limit values that are indi-

cated on the type plate and in the technical data.

• Exact compliance with the performance data of the pressure transducer in connection with the case of

application.

• Carry out service and calibration measures at regular intervals.

Further safety advice

• During installation and operation, the national regulations and safety instructions in force also need to

be observed.

• The pressure transducer must not be employed in hazardous areas.

Additional instructions

• Do not overheat the device!

• The pressure transducer must not be disassembled!

Measures

• Only use the device with the media that are listed in the data sheet and in the technical data.

Note:

The resistance at the double permissible max. operating pressure is confirmed.

For further information, please refer to the enclosed technical data sheet.

Caution!

Damage possible!

Using the pressure transducer with corrosive media involves the risk of premature

technical failure.

Proper use

METPOINT® SP11 7

5 Proper use

The METPOINT

®

PRM pressure transducer detects the relative pressure (gauge pressure) in gaseous and

liquid media and transforms this measured value into a linear output signal 4 … 20 mA or 0 … 10 V.

Pressure transducers transform the physical pressure into a pressure-proportional electrical signal. De-

pending on the version, there are different measuring principles which form the basis of the pressure monitoring.

The METPOINT

®

PRM pressure transducer is exclusively designed and constructed for the proper applica-

tion purpose that is described herein and must be used correspondingly.

A check in order to ascertain whether or not the device is suitable for the chosen employment must be car-

ried out by the user. It must be ensured that the medium is compatible with the components which come into

contact with it. The technical data listed in the data sheet are binding.

Improper handling or operation outside the technical specifications is impermissible. Claims of any kind on

the basis of improper use are excluded.

6 Exclusion from the field of application

• The device is not suitable for use in hazardous areas.

• The device is not suitable for application with corrosive gases.

• Corrosive fluids must not be conducted through the pressure transducer.

• Improper handling or operation outside the technical specifications.

Type plate

8 METPOINT® SP11

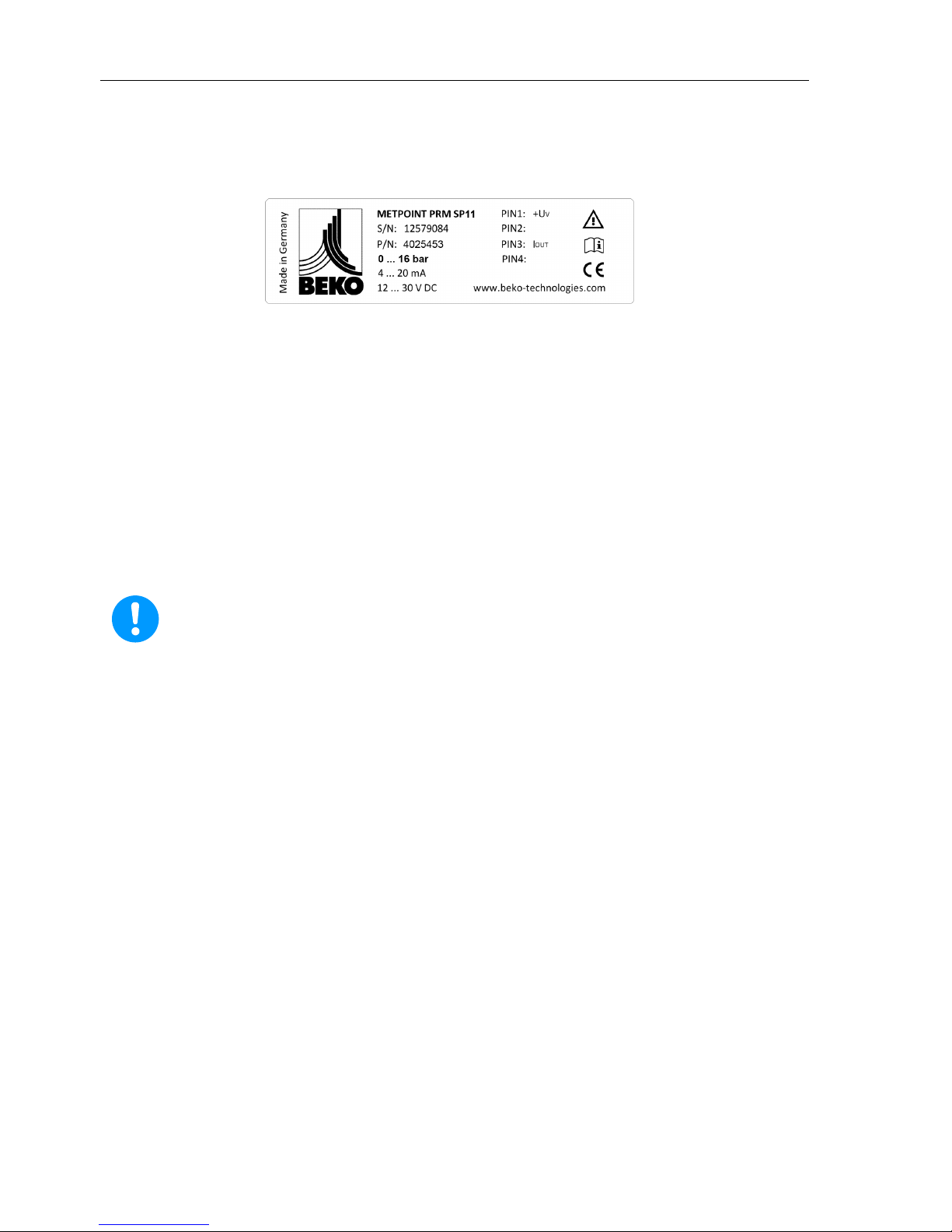

7 Type plate

The type plate is on the housing. It includes all the important data regarding the METPOINT® PRM pressure

transducer which must be communicated to the manufacturer or supplier upon request.

METPOINT® PRM

Product designation

S/N: Serial number

P/N: Item number

0 … 16 bar

Measuring range

4 … 20 mA Output signal

12 … 30 V DC Supply voltage

PIN 1: Power supply (U

v

+)

PIN 2:

PIN 3: Current output (I

out

)

PIN 4:

Note:

Never remove, damage, or obliterate the type plate!

Technical data

METPOINT® SP11 9

8 Technical data

General indications

Model designation

PRM SP11

Measuring principle Stainless-steel thin film technology

Measured parameter Overpressure (gauge pressure)

Output signal, type PRM SP21

4 ... 20 mA, analogue, 2-wire

Measuring range

0 … 16 bar

Overload pressure limit 32 bar

Burst pressure 125 bar

Process medium 1 Gases/fluids

Temperature-compensated range 0 … 60 °C

Reference conditions EN 61298-1

Process connection (connection pin acc. to EM 837-1) G¼ B

Weight 105 g

Service life 10 million load alterations

Protection class acc. to EN 60529 2 IP 67

Nonlinearity after limit point setting 3 ≤ ± 0.15% MBE 5

Max. error of measurement 4 ≤ ± 0.5% MBE 5

1

Process medium

Compressed air, nitrogen, water, oil, and other fluids of group 2 according to Article 9, Clause2.2 of the

PED 97/23/EC. Group 2 comprises fluids which are not toxic, flammable, potentially explosive, and firepromoting. The process medium must be compatible with the materials 1.4404 and 1.4548.

2

The indicated protection classes according to EN 60529 only apply when connected, with a mating

connector with a corresponding protection class.

3

Nonlinearity after the limit point setting, according to EN 61298-2

As regards the limit point setting, the reference line passes through the initial and end point

of the measured characteristic curve.

4

Max. error of measurement according to EN 61298-2

including nonlinearity, hysteresis, non-repeatability, and error of measurement of the measuring range final

value. Calibrated at a vertical installation position with a downward process connection.

5

MBE = Measuring range final value.

Loading...

Loading...