Beijing GH Operating manual

BEIJING CTB SERVO CO., LTD.

Address: Wanggezhuang Industry Base, Shilipu Town, Miyun County,

Beijing

Tel.: 010 -82755611

Fax: 010 -82755610

24-hour national free service Tel.: 400 -888-9055

Data No.: ZL-14-808-IBCN

The data may subject to change without notice as improvement of

the product.

CTB TECHNOLOGY

Distributor

BEIJING CTB SERVO CO.,LTD.

Data No.: Z L-14-808-I B C N

GH DRIVER

Operating manual

AC servo driver

Model: BKSC-□ □ □ □ GHX

Class 400V, 1.5 ~ 315KW (2.5 ~ 460KVA)

Please send the manual to final user, and keep it properly.

CTB TECHNOLOGY

GH DRIVER CTB

Preface

Thank you for purchasing GH series servo driver produced by Beijing CTB Servo Co., Ltd. The GH

series AC servo driver is a high-quality, multi-functional and low-noise AC servo driver that was

researched, developed and manufactured by Beijing CTB Servo Co., Ltd. The driver is servo driver for

AC induction motor (IM) and AC permanent magnet synchronous motor (PM). It can control the position,

speed, acceleration and output torque of various AC servo motor appropriately.

In command to achieve control functions of various machine tools, GH series AC servo driver is

equipped with dual 32-bit CPU and abundant control function module. It can be conveniently connected

with various domestic and foreign CNC systems through standard control interfaces to allow full play for

function of CNC system. The characteristics of torque, acceleration and deceleration, precision and

efficiency of machine tool which is equipped with GH series AC servo driver are remarkable, and

accurate stop, C-axis, rigid tapping, electronic shift, multi-axis synchronization and other functions can

be realized easily.

As the first choice of driving product of various machine tool power shaft, GH series AC servo driver can

be widely used for drive of product such as CNC milling machine, vertical machining center, horizontal

machining center, CNC boring machine, CNC lathe, vertical lathe, heavy horizontal lathe and gantry

machine tool.

For proper application, please read the manual carefully before using the GH series AC servo driver.

Abnormal operation, fault or reduction of service life, and even personal injury accident may be caused

by inappropriate use. Therefore, the manual shall be read repeatedly before use, and operate in strict

accordance with the instructions. The manual is attachment with the equipment. Please keep it properly

after using for future repair and maintenance of the driver.

01

CTB GH DRIVER

Use the symbol where danger, even personal injury or death when wrong about the

described content.

Use the symbol where danger, even mild or moderate personal injury and

equipment damage when wrong about the described content.

Prohibited matters (matters that cannot do).

Certain matters do not belong to "danger", and "caution", but they are required to

be abided by user. They are marked in the relevant sections.

Safety -related symbol description

The following symbols are used for safety-related content in the manual. Sentences marked by the

safety symbols describe important content, and must be abided. If the requirements in the safety-related

content are not abided, application of the product may lead to abnormal product operation, damage to

the product, even danger and personal injury.

GH DRIVER CTB

Caution

● For risk of injury, please do not install damaged or part missing driver.

Caution

● For risk of fire, please install the equipment on nonflammable metal plate without combustible

materials around.

● Please be sure to tighten the mounting screws of the driver. Falling and damage of the driver or

personal injury may be caused by mounting screws loosing.

●Please do not install the equipment in environment with flammable gas where an explosion is

caused easily.

Danger

● For risk of electric shock and fire, please make sure that the input power supply is in the OFF state

before wiring.

●For risk of electric shock, the operation on main circuit terminal of the controller shall be conducted

after the power is cut off for five minutes, and the power charge indicator CHARGE in the controller

completely extinguished.

●For risk of electric shock and fire, the wiring shall be carried by professional electrical engineering

personnel.

●For risk of electric shock and fire, the ground terminal must be grounded reliably. (earth resistance

shall be lower than 4Ω)

● It's prohibited to directly connect terminals of P / PB and N, or connect the zero line or the earth

wire to the N terminal. Otherwise, the rectifier bridge will be shorted and the main loop will be burned.

●It's prohibited to connect the high-voltage line to control terminal of the driver. Otherwise, the control

board will be burned.

●For risk of injury, please set emergency stop and locking circuit at the outside of the controller (user

is responsible for the wiring) .

● There is a risk of electric shock and short circuit.

Caution

●For risk of injury and fire, please ensure that the voltage of the main circuit AC input power and the

Safety precautions

◆ Unpacking inspection

◆ Installation

◆ Wiring

◆ Wiring

03

CTB GH DRIVER

rated voltage of the driver are consistent.

● Please do not conduct withstand voltage and insulation test to the controller arbitrarily. Otherwise,

the semiconductor and other components in the controller may be damaged.

●For risk of fire, please connect braking resistor and braking unit according to the wiring diagram.

● Please do not connect the AC input power cord to the output U, V, W terminals. Otherwise,

damage to inside of the controller may be caused.

●For risk of fire and malfunction of the controller, please tighten the terminals of main loop and

control circuit with appropriate torque.

●Please do not connect the phase shifting electrolytic capacitor and LC / RC noise filter to the output

circuit. Otherwise, damage to inside of the controller may be caused.

●Please do not connect the electromagnetic switch and electromagnetic contactor to the output

circuit to connect or disconnect the load. During loaded operation of the controller, the surge current

will cause protection circuit action of the controller.

Danger

●For risk of electric shock and short circuit, please do not touch the terminals of the main circuit

directly after power-on.

●Please confirm the input and output signals to guarantee safe operation. Malfunction of the system

will cause casualties and damage to the work piece and nearby equipment..

●For risk of injury, alarm reset only can be done after ensuring that the operating signal is cut off.

Alarm reset with operating signal will lead to suddenly re-start.

●For risk of driver burning, the inside of long term stored driver shall be checked for water and

condensation.

●For risk of electric shock and burning the equipment, it's prohibited to touch the terminals of the

driver with hand during operating.

Caution

●For risk of scalding, the running servo driver and motor may have a high temperature rise, please do

not touch.

●For risk of scalding and electric shock as the braking resistor has a high temperature rise for

discharging, please do not touch.

●For risk of damage to the equipment and accident, please do not change the settings of the drive

arbitrarily.

Danger

◆ Trial run

◆ Maintenance and inspection

GH DRIVER CTB

●For risk of electric shock, please do not directly touch terminals of the controller. Some of them

have high voltage and very dangerous.

●For risk of electric shock, please do install the housing before power-on; and must disconnect the

power firstly before removing the housing.

●For risk of electric shock and fire, please confirm that the power source is in the OFF state or not

before wiring.

● Inspection and maintenance only can be carried out after cut off the main circuit input power and

confirm that the power charge indicator CHARGE completely extinguished. There is a risk of

electric shock as residual power in electrolytic capacitor.

●Please make designated professional electrical engineering personnel to conduct inspection and

maintenance. Before work, please take off metal object (watch, rings etc.), and use tools with

insulation protection during operation. Otherwise, it may cause electric shock.

●For risk of explosion and fire, used battery, circuit printing plate must not be throw into fire.

Otherwise, it may cause explosion.

Caution

●CMOS IC integrated circuit is installed on main control panel. Full attention shall be paid during

operating. The electrostatic induction due to direct touching of finger on the main control panel may

cause damage to the main control panel.

●For risk of electric shock, please do not conduct wiring and removing terminal when the equipment

is energized.

●For risk of damage to the equipment, the appropriate parameter settings must be carried out

before running after control panel replacing.

05

CTB GH DRIVER

Table of contents

Preface………………………………………………………...……………………………………1

Safety -related symbol description………………………..…………………………………..2

Safety precautions……………………………………………..…………………..……………..3

Chapter 1 - Installation…………………………………………..………………………….…1-1

Introduction to GH DRIVER…………………………………..…………………………………1-2

Unpacking inspection…………………………………………..………..………………………1-3

Standard specifications and performance parameters………………………….……………1-4

Driver nameplate description……………………………………………………………………1-5

External dimensions and installation dimensions……………………………………….……1-5

Confirmation and requirements of the installation space……………………………………1-8

Notes on motor and load…………………………………………………………………..……1-8

Notes on the driver………………………………………………………………………………1-9

Notes on scrapping………………………………………………………………………..……1-10

Chapter 2 – wiring……………………………………………………………………...……….2-1

Selection and connection of peripheral devices……………….……………………...………2-2

Wiring of the main circuit terminals……………………………………………………………2-3

Wiring of control circuit ……………..…………………………………………………………2-11

Connection of the encoder interface…………………………………………………………2-20

Connection of the serial communication port ………………………………………………2-21

Chapter 3 - Manipulator application…………………………………………..…………….3-1

Digital tube display 0.4 ~ 18.5kw driver:

Configuration and key functions of the manipulator…………………………………………3-2

Operative mode of the driver……………………………………………………………………3-3

Operative mode of the manipulator……………………………………………………………3-4

Use method of the manipulator………………………………..………………………………3-4

Modify the parameters with the manipulator…………………………………………………3-5

Monitor operating state with the manipulator………………….………………………………3-5

Digital tube display 22 ~ 315kw driver:

Configuration and key functions of the manipulator…………………………………………3-6

Operative mode of the driver………………………………….……….………………………3-8

Operative mode of the manipulator…………………………………….………………………3-8

GH DRIVER CTB

Use method of the manipulator………………………………...……….………………………3-9

Modify the parameters with the manipulator…………………….…….………………………3-9

Monitor operating state with the manipulator……………………….………………………3-10

Liquid crystal display 0.4 ~ 18.5kw driver:

Configuration and key functions of the manipulator…………………………………………3-11

Operative mode of the driver……………………………………….….………………………3-12

Operative mode of the manipulator………………………………….………………………3-12

Use method of the manipulator……………………………….……….………………………3-13

Modify the parameters with the manipulator……………….……….………………………3-13

Monitor operating state with the manipulator…………………….…………………………3-14

Liquid crystal display 22 ~ 315kw driver:

Configuration and key functions of the manipulator…………………………………………3-15

Operative mode of the driver………………………………………….………………………3-17

Operative mode of the manipulator………………………………..….………………………3-17

Use method of the manipulator…………………………………….….………………………3-18

Modify the parameters with the manipulator……………………….………………………3-18

Monitor operating state with the manipulator………………………...………………………3-19

Chapter 4 - Test run…………………………………………………………………..………..4-1

Basic procedure of test run………………………………………..……………………………4-2

Confirmation of connection of the main circuit………………………………………………4-2

Control circuit wiring confirmation……………………………………………………………4-3

Initial power-on of the driver……………………………………….……………………………4-3

Motor and driver parameters confirmation……………………………………………………4-3

No-load test run……………………………………………………..……………………………4-4

Loaded test run……………………………………………………..……………………………4-4

Chapter 5 - Parameter list……………………………………………………………………5-1

Hierarchical structure diagram of display function of the manipulator .............................5-2

Monitor parameter Un........................................................................................................5-3

Application parameter An...................................................................................................5-9

Chapter 6 – Setting parameters by function………...………………..……………………6-1

Analog speed control……………………………………………..……………………………..6-2

Pulse speed control……………………………………………...………………………………6-4

07

CTB GH DRIVER

Analog rigid tapping…………………………………………….………………………………6-6

Pulse rigid tapping/pulse position …………………………….……………………….…….. 6-7

Orientation……………………………………………………………………….. ………………6-8

Swing……………………………………………………………….……….. …………………6-10

Operation panel operation ……………………………………………….. …………………6-12

modbus communication settlement …………………………………….. …………………6-12

Chapter 7 – PLC functions introduction…………………………………………………..7-1

Introduction to system software resourse ……………………………………………..……..7-2

PLC CAN communication …………………………….………………………………………..7-3

PLC modbus communication ………………….…………………………………………..…..7-5

Pmotion program software description …………….………………………………………..7-6

Speed control …………………………………….……………………………………..……..7-8

Positioning control …………………………….……………………………………………..7-11

Pulse position synchronization control…………….………………………………………..7-13

Position limit and restoration……………………….………………………………………..7-14

Chapter 8 – Troubleshooting………………………………………………………………..8-1

List of fault alarm and remedies ………………………………………………………………..8-2

Common fault analysis……………………………….………………………………………..8-4

Alarm reset method……………………………………….....………………………...………..8-7

Chapter 9 - Routine maintenance...................................................................................9-1

Prompt...............................................................................................................................9-2

Routine maintenance .......................................................................................................9-2

Regular maintenance.......................................................................................................9-3

Wearing parts of the driver .............................................................................................9-3

Driver storage..................................................................................................................9-4

Driver warranty.................................................................................................................9-4

GH DRIVER CTB

Installation

The chapter describes matters to be confirmed and installation requirements for the user

after getting the GH DRIVER.

Introduction to GH DRIVER…………………………………….…..………………………….1-2

Unpacking inspection………………………………..…………………………………….……1-3

Standard specifications and performance parameters…..………………………………..…1-4

Driver nameplate description……………………….………..……………………………..…..1-5

External dimensions and installation dimensions.………..........................................……..1-5

Confirmation and requirements of the installation space.….………………………………...1-8

Notes on motor and load…………………………….……………………………………….….1-8

Notes on the driver…………………………….……………..……………...…………………..1-9

Notes on scrapping………………………….……………………………..…………………..1-10

CTB GH DRIVER

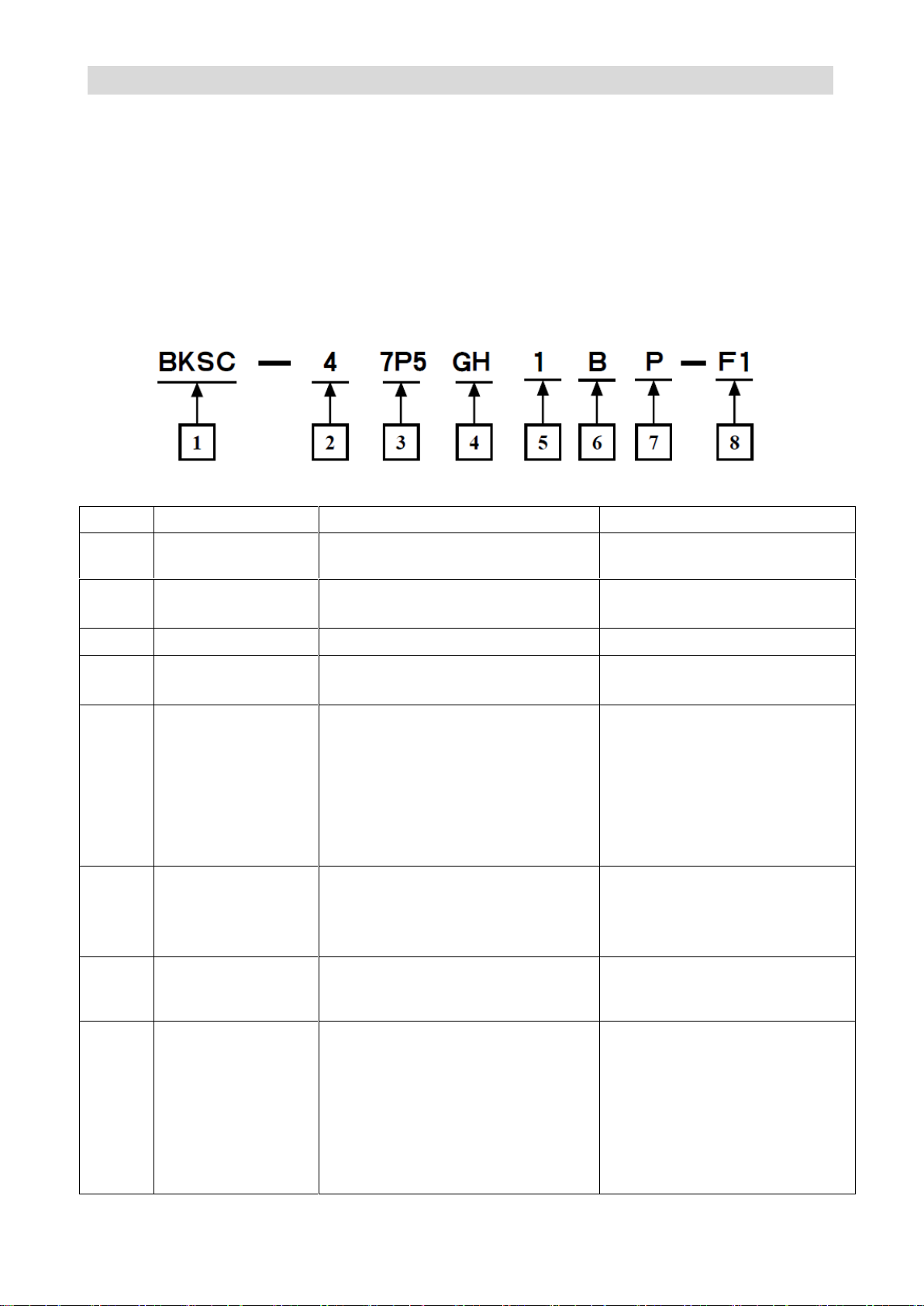

Code

Item

Description

Illustrated model meaning

1

Manufacturer code

BKSC: code for driver product of the

manufacturer

Manufactured by BEIJING CTB

SERVO CO., LTD.

2

Voltage level

2: level 200V

4: level 400V

level 400V

3

Power code

See power code list for detail

7.5kW

4

Product series

GS: GS series driver

GH: GH series driver

GH series driver

5

Encoder model

None: incremental 10 driver

0:without encoder

1: incremental encoder

2: rotary transformer

3: Sin-Cos encoder

4: absolute value encoder

5: magnetic encoder

incremental encoder

6

Product model

None: standard type

(CP1000A1/C1)

B: general type(CP1000B1/D1)

T:special type (CP1000AT1/CT1)

general type(CP1000B1)

7

Production

upgrading

identification

None: conventional design

P: new energy-saving design

new energy-saving design for

main board of the driver

8

Non-standard

identification

None: standard product

F1: Non-standard requirements to

main board

F2: Non-standard requirements to

driver

F3: Non-standard requirements to

housing

Other: special customer

Non-standard requirements to

main board of driver

Introduction to GH DRIVER

GH DRIVER is a type of driver that specifically designed for machine tool. Precise control of position,

speed, acceleration and output torque of AC induction servo motor and AC inverter motor is allowed

through the driver. It can be used for control of motor of machining center, CNC milling machine, CNC

drilling machine, CNC lathe, CNC grinder, and feed motor of large gantry equipment and vertical lathe.

To achieve the best operation effect, please complete wiring with CNC system by the " CTB servo

application manual ", and carry out installation and commissioning in accordance to the manual.

Model description (taking 7.5kW as example)

Table 1-1 Detailed description of motor model designation

GH DRIVER CTB

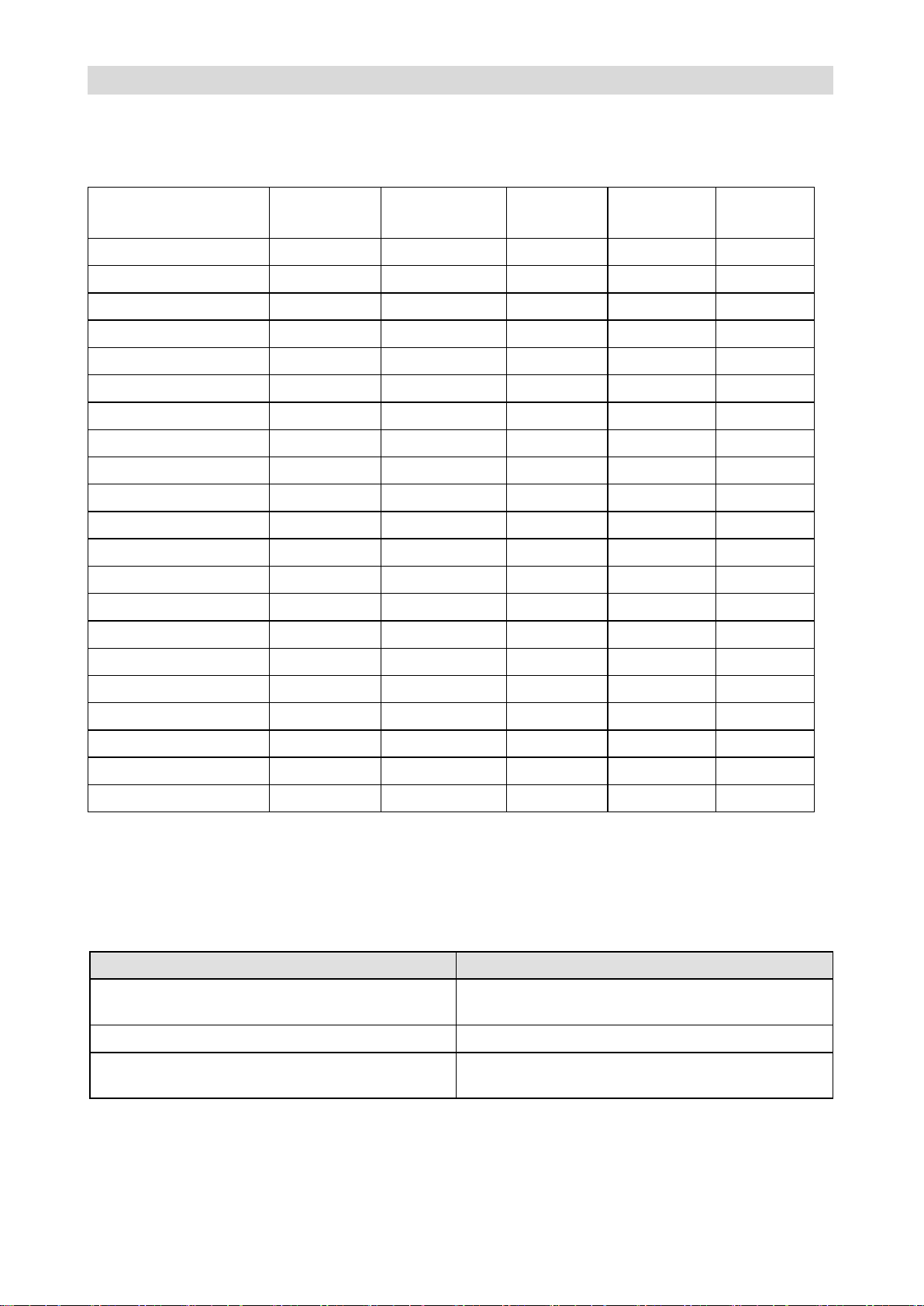

Driver model

Rated

capacity(KVA)

Rated input

current (A)

Rated output

current (A)

Adapt motor

power (kW)

Built-in

brake unit

BKSC-41P5GHX

2.5 4 3

1.5

Yes

BKSC-42P2GHX

3 6 5

2.2

Yes

BKSC-43P7GHX

5.5 9 8

3.7

Yes

BKSC-45P5GHX

8.5

14.2

13

5.5

Yes

BKSC-47P5GHX

11

18

17

7.5

Yes

BKSC-4011GHX

17

26

25

11

Yes

BKSC-4015GHX

21

35

32

15

Yes

BKSC-4018GHX

24

38.5

37

18.5

Yes

BKSC-4022GHX

30

46.5

45

22

Yes

BKSC-4030GHX

40

62

60

30

Yes

BKSC-4037GHX

50

76

75

37

Yes

BKSC-4045GHX

60

92

90

45

Yes

BKSC-4055GHX

72

113

110

55

Yes

BKSC-4075GHX

100

157

152

75

Yes

BKSC-4090GHX

116

190

185

90

Yes

BKSC-4110GHX

138

236

230

110

Yes

BKSC-4132GHX

167

288

280

132

Yes

BKSC-4160GHX

200

345

336

160

Yes

BKSC-4200GHX

250

420

370

200

No

BKSC-4250GHX

300

530

460

250

No

BKSC-4315GHX

360

680

570

315

No

Confirm item

Confirm method

Confirm that the materials listed on the packing

list are complete.

Check the materials in the packing against the

packing list stuck to the external packing.

Are they in line with the ordered merchandise?

Please confirm the label at the side of the driver.

Is there any damage?

Check the overall appearance for damage during

transportation.

● GH DRIVER series applies for 21 types with a motor capacity of 1.5kW to 315kW. Please

see table 1-2 for detail

Table 1-2 GH DRIVER model (rated voltage: 400v)

Unpacking inspection

Please confirm the following items when you get the product. Please contact directly with the dealer or

manufacturer that purchased from for any adverse situation. Please see Table 1-3 for detail.

Table 1-3 Confirm items

GH DRIVER CTB

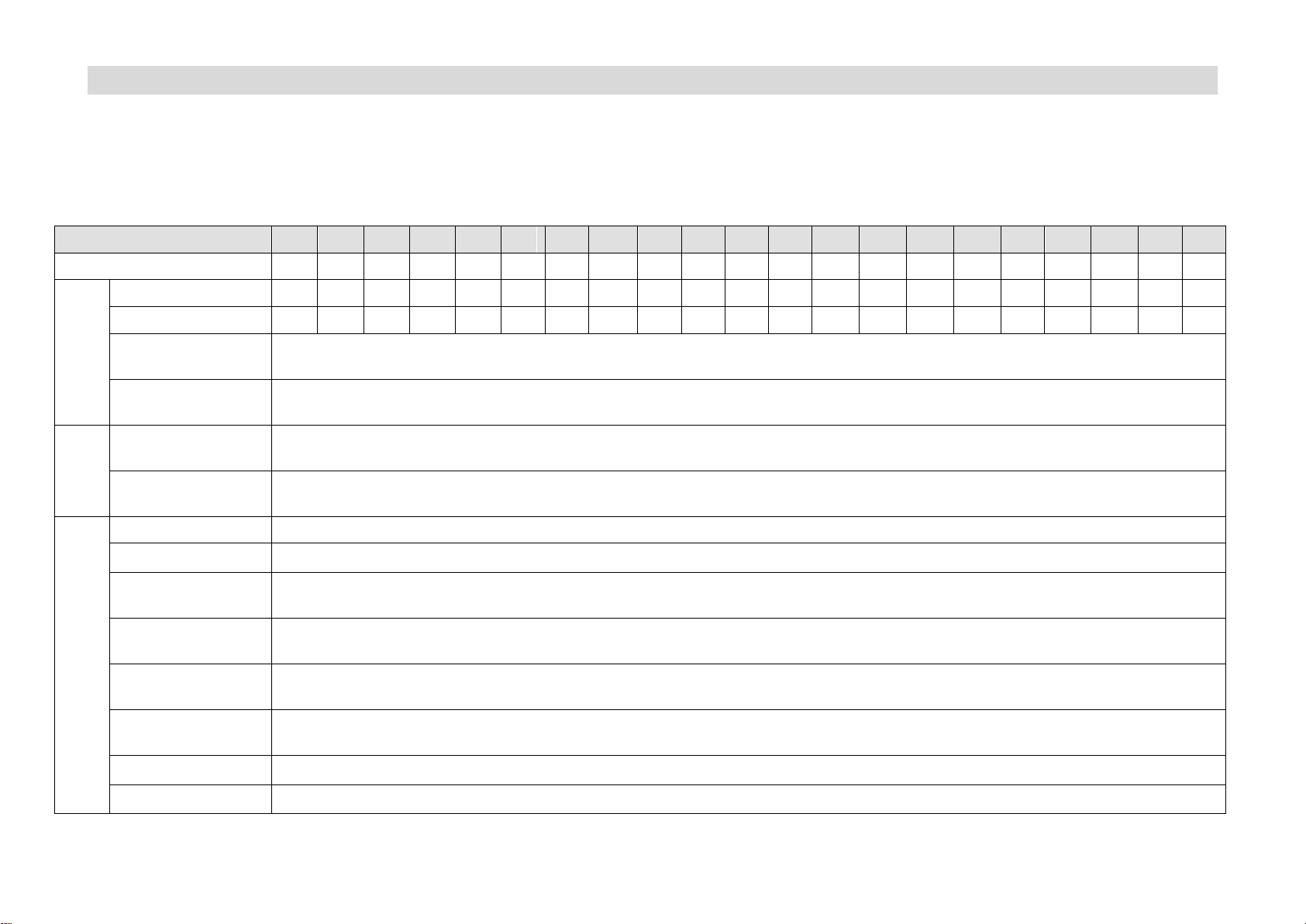

Model BKSC-××××GHX

41P5

42P2

43P4

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4200

4250

4315

Adapt motor power kW

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

160

200

250

315

Output

Capacity KVA

2.5 3 5.5

8.5

11

17

21

24

30

40

50

60

72

100

116

138

167

200

250

300

360

Current A

3 5 8

13

17

25

32

37

45

60

75

90

110

152

185

230

280

336

370

460

570

Maximum output

voltage V

3-phase 380/400/415/440V corresponding input voltage

Maximum output

speed rpm

4-pole motor 15000rpm: 500Hz

Power

Rated voltage and

frequency

3-phase 380/400/415/440V: 50/60Hz±5%

Allowed voltage

pulsation

+10%, -15%

Control characteristics

Control mode

Sine wave PWM modulation, entirely closed-loop vector control

Torque feather

200% rated torque output below the fundamental frequency. Accuracy: ±5%

Range of speed

regulation

1: 15000

Speed control

accuracy

±0.1%

Frequency set

resolution

Digital quantity: : 0.01Hz; Analog: Unipolar, maximum output frequency is /4092; bipolar, maximum output frequency is / 2046

Position control

accuracy

±1PULSE

Acceleration

0.05~3000Hz/s

Brake mode

dynamic braking. 125% rated torque: built-in braking unit (external braking resistor)

Standard specifications and performance parameters

Please see Table 1-4 for standard specifications and performance parameters of 3-phase Class 400V driver

Table 1-4 Standard specifications and performance parameters of GH DRIVER

CTB GH DRIVER

Overload capacity

200% rated current 30s

Input and output interface

Digital quantity input

7-channel isolation photo-coupler input; input mode: PNP, NPN optional

Digital quantity

output

2-channel isolation photo-coupler output; 24V, 10mA

Analog input

2-channel; -10V~+10V 1 channel, 0~10V 1-channel

Analog output

2-channel; -10V~+10V

Relay output

1 channel: a group of N.O/N.C contact: AC250V/DC30V, 1A

Fault output relay

1 channel: a group of N.O/N.C contact: AC250V/DC30V, 1A

Encoder input

interface

two: maximum receive frequency is 300KHz: cable driven receive mode: RS422 standard

PULSE input

interface

One: direction PULSE or orthotropic PULSE

Encoder output

interface

One: maximum output frequency is 300KHz: cable driven output mode: RS422 standard

Bus interface

None

function

Speed control

Range: 0~15000rpm; turning: positive and negative; speed order: Analog, PULSE frequency

Accurate stop

Accuracy: ±1PULSE; position adjustment: set by user's parameter

Rigid tapping

May be connected to several domestic and foreign systems. Tapping error: ±2%

Other function

C-axis control, thread cutting, electronic gear, reaming, swing control

Protection

function

motor over-current

Greater than 200% rated current output

Motor overload

Specified time of exceeding overload alarm value. Alarm output: set by parameters

Overvoltage

The voltage of main circuit bus is higher than 800V. Alarm output

Low voltage

The voltage of main circuit bus is lower than 400V. Alarm output

Service

environment

Service site

Free of dust, corrosive gas and inflammable gas

Temperature

-10~45℃

Humidity

Lower than 95%RH (no condensation)

Vibration

vibration frequency≤20Hz: 9.8m/s2;20Hz≤vibration frequency≤50Hz: 2m/s

2

;

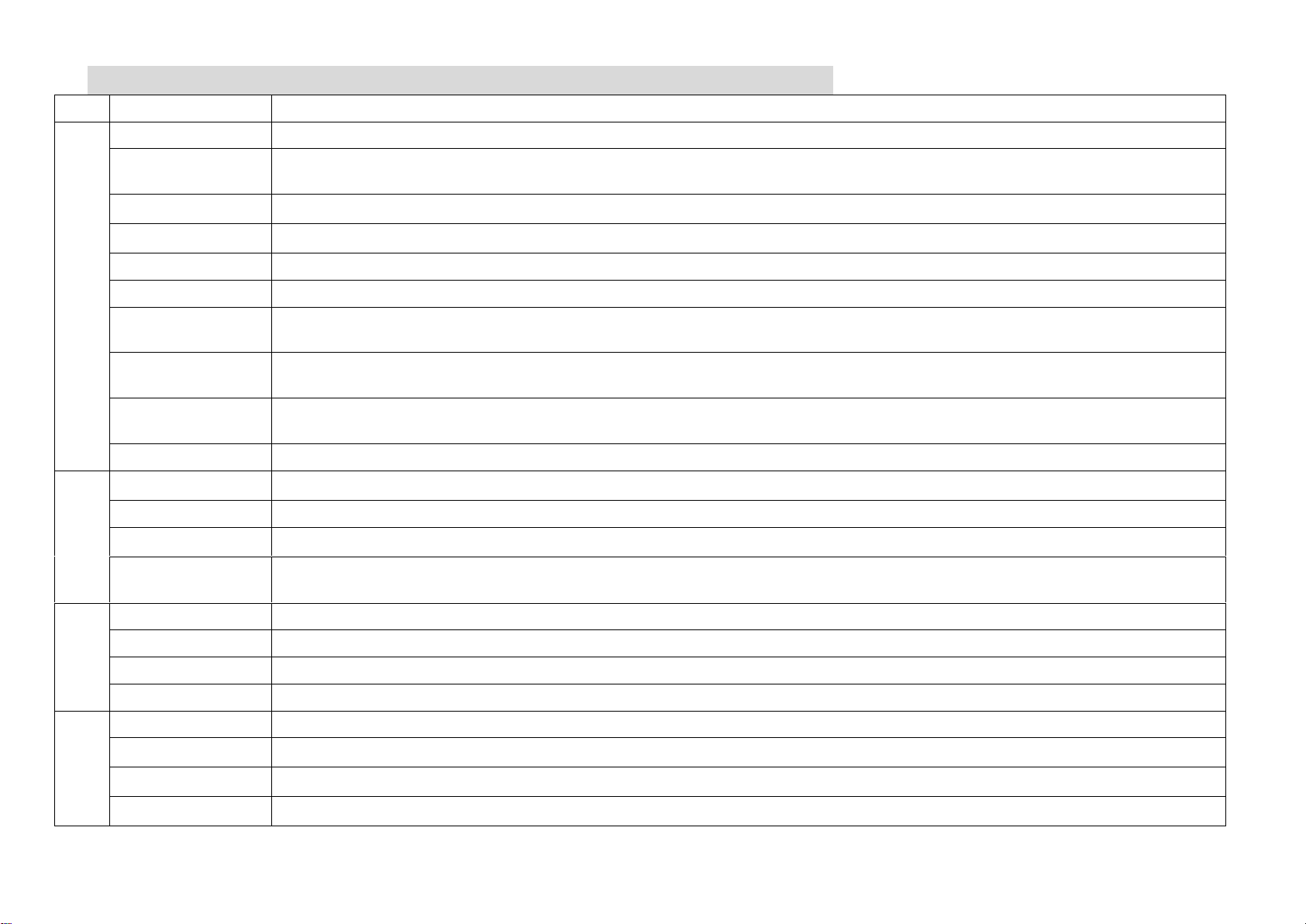

GS DRIVER CTB

Dimension

Model

A B W H D

Connecting

terminal screw

Installati

on screw

Weight (kg)

BKSC-41P5GHX

45.

5

276

91

290

200

Wire nail width

3mm

M6

3

BKSC-42P2GHX

BKSC-43P7GHX

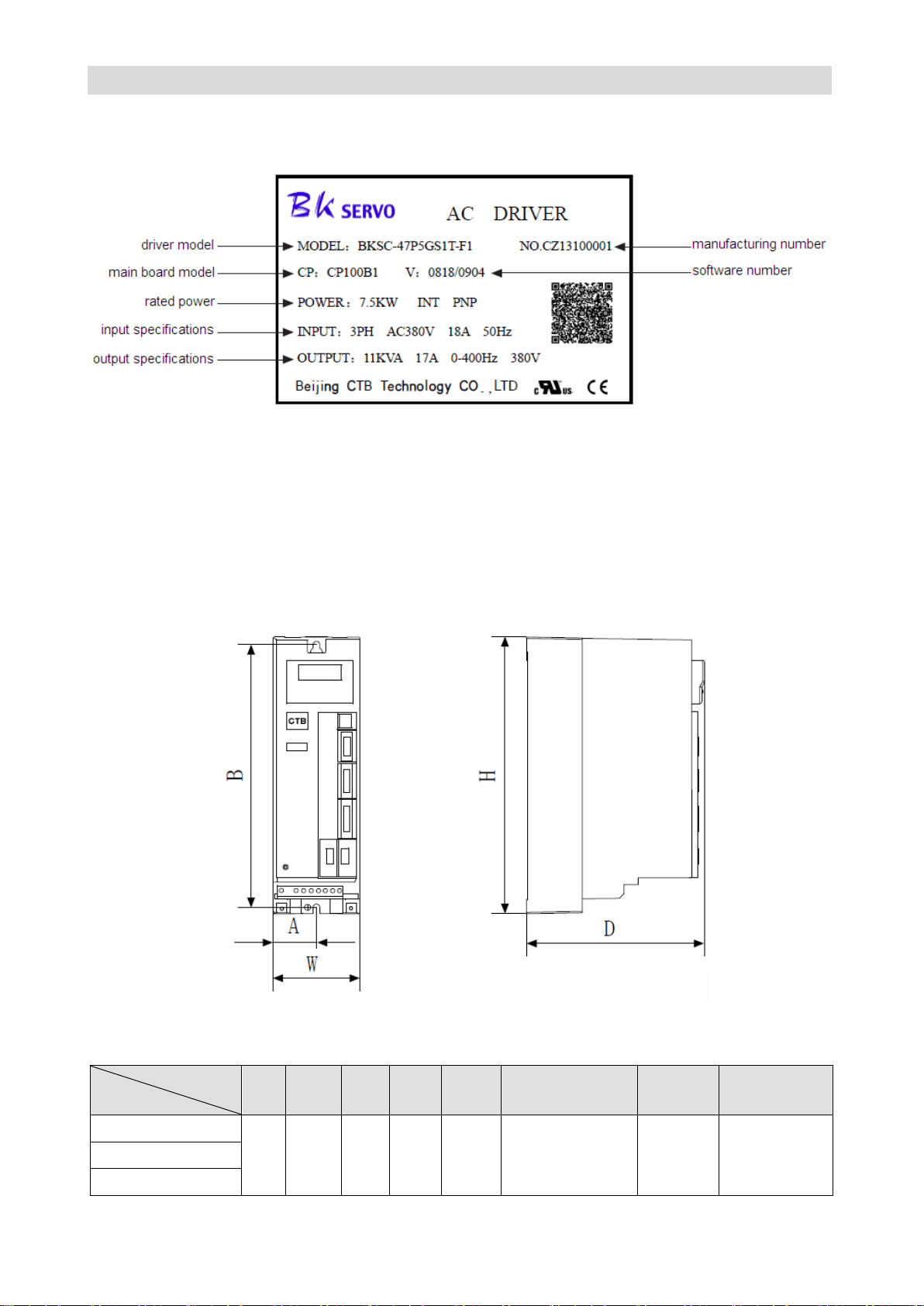

Driver nameplate description

Nameplate which indicates model and rated values of the driver is affixed to the lower right of housing of

the driver. The content of the nameplate is shown in Figure 1-1.

Figure 1-1 AC Servo driver nameplate

Note: the two-dimension code includes manufacturing number of the driver; customer name of the driver

(take BEIJING CTB SERVO CO., LTD. as an example); contract number; driver model; main board

model; software number; non-standard (take standard as an example) and other description.

External dimensions and installation dimensions

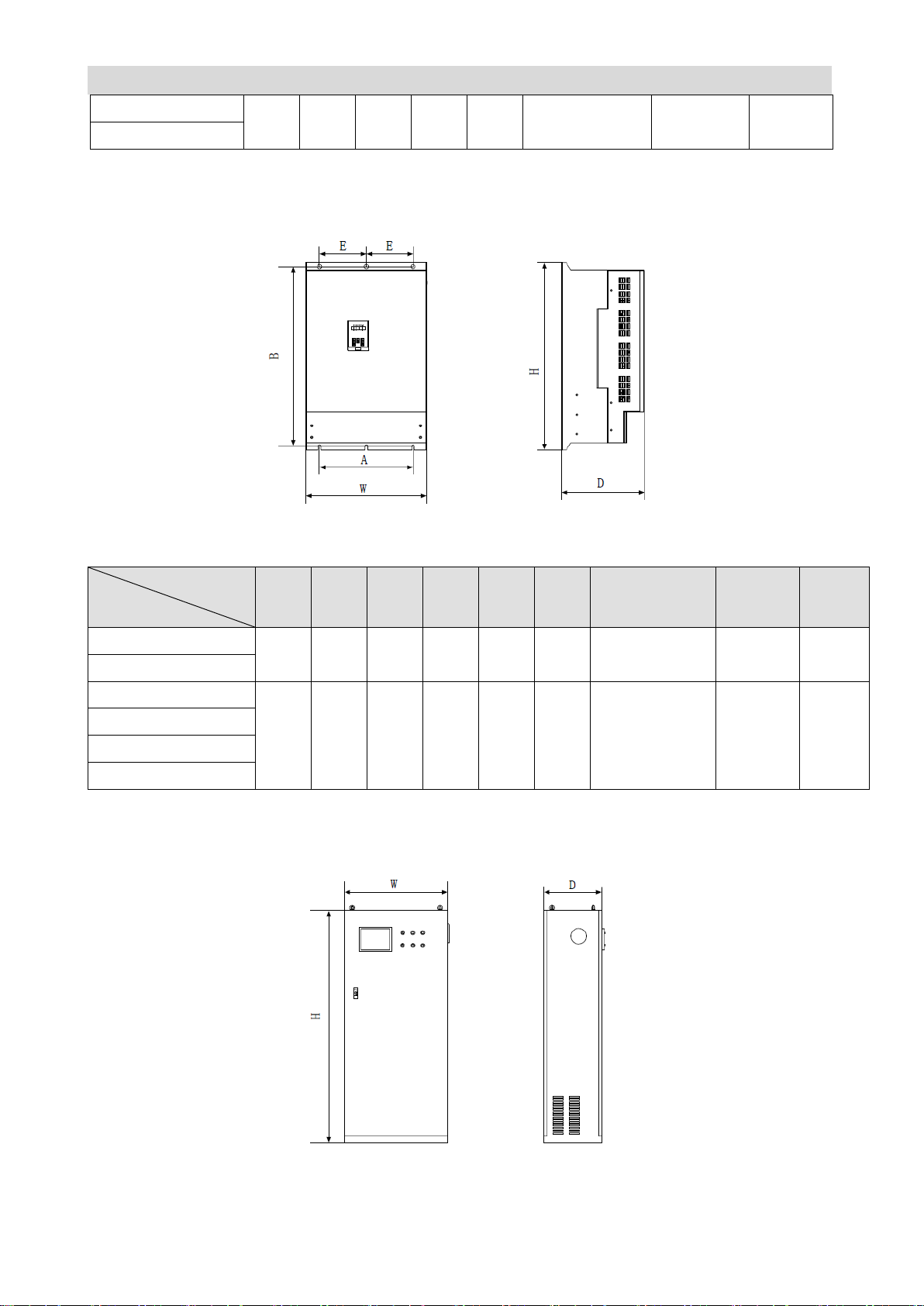

1. 1.5-3.7kw driver

Please see diagram 1-2 for external dimensions and installation dimensions

Figure 1-2

Table 1-5 Dimensions (mm) and weight (kg) of GH DRIVER (1.5-3.7kw) driver

CTB GH DRIVER

Dimension

Model

A B W H D

Connecting

terminal screw

Installation

screw

Weight

(kg)

BKSC-45P5GHX

80

276

132

290

200

Wire nail width

3mm

M6

5

BKSC-47P5GHX

BKSC-4011GHX

Dimension

Model

A B W H D

Connecting

terminal screw

Installation

screw

Weight

(kg)

BKSC-4015GHX

140

376

194

390

228

M6

M6

14

BKSC-4018GHX

BKSC-4022GHX

236

376

282

390

228

M6

M8

20

BKSC-4030GHX

2. 5.5~11kw driver

Please see diagram 1-3 for external dimensions and installation dimensions

Figure 1-3

Table 1-6 Dimensions (mm) and weight (kg) of GH DRIVER (5.5-11kw) driver

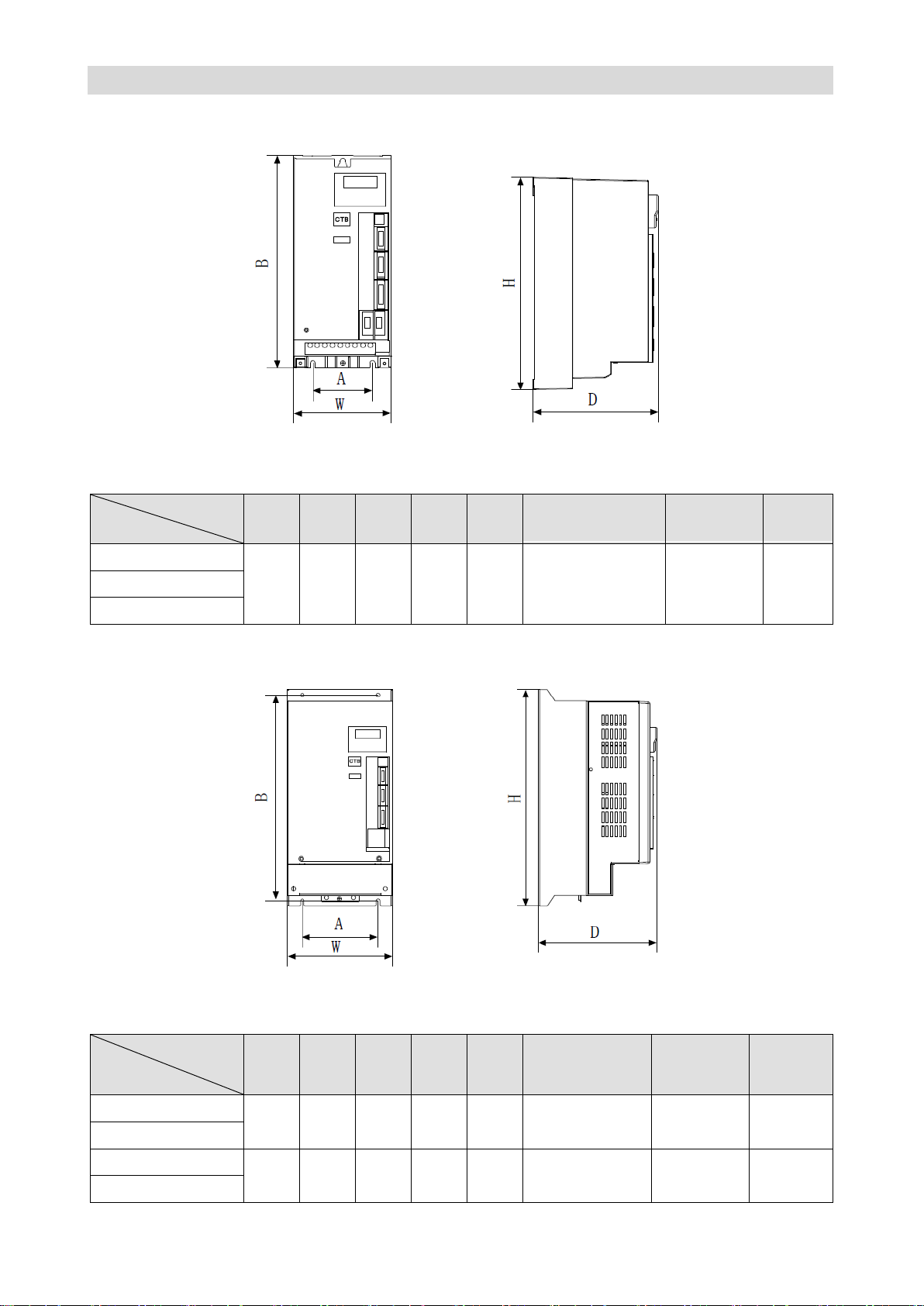

3. 15~45kw driver

Please see diagram 1-4 for external dimensions and installation dimensions.

Figure 1-4

Table 1-7 Dimensions (mm) and weight (kg) of GH DRIVER (15-45kw) driver

GS DRIVER CTB

BKSC-4037GHX

300

376

380

390

269

M8

M8

26

BKSC-4045GHX

Dimension

Model

A B W H D

E

Connecting

terminal screw

Installati

on screw

Weight

(kg)

BKSC-4055GHX

392

376

472

390

269

196

M10

M8

33

BKSC-4075GHX

BKSC-4090GHX

360

690

464

720

320

180

M10

M16

90

BKSC-4110GHX

BKSC-4132GHX

BKSC-4160GHX

4. 55~160kw driver

Please see diagram 1-5 for external dimensions and installation dimensions

Figure 1-5

Table 1-8 Dimensions (mm) and weight (kg) of GH DRIVER (55-160kw) driver

5.200 ~ 315kw driver

Please see diagram 1-6 for external dimensions and installation dimensions

Figure 1-6

Table 1-9 Dimensions (mm) and weight (kg) of GH DRIVER (200-315kw) driver

CTB GH DRIVER

Dimension

Model

A B W H D

Connecting

terminal screw

Installation

screw

Weight

(kg)

BKSC-4200GHX

- - 800

1800

450 - -

230

BKSC-4250GHX

BKSC-4315GHX

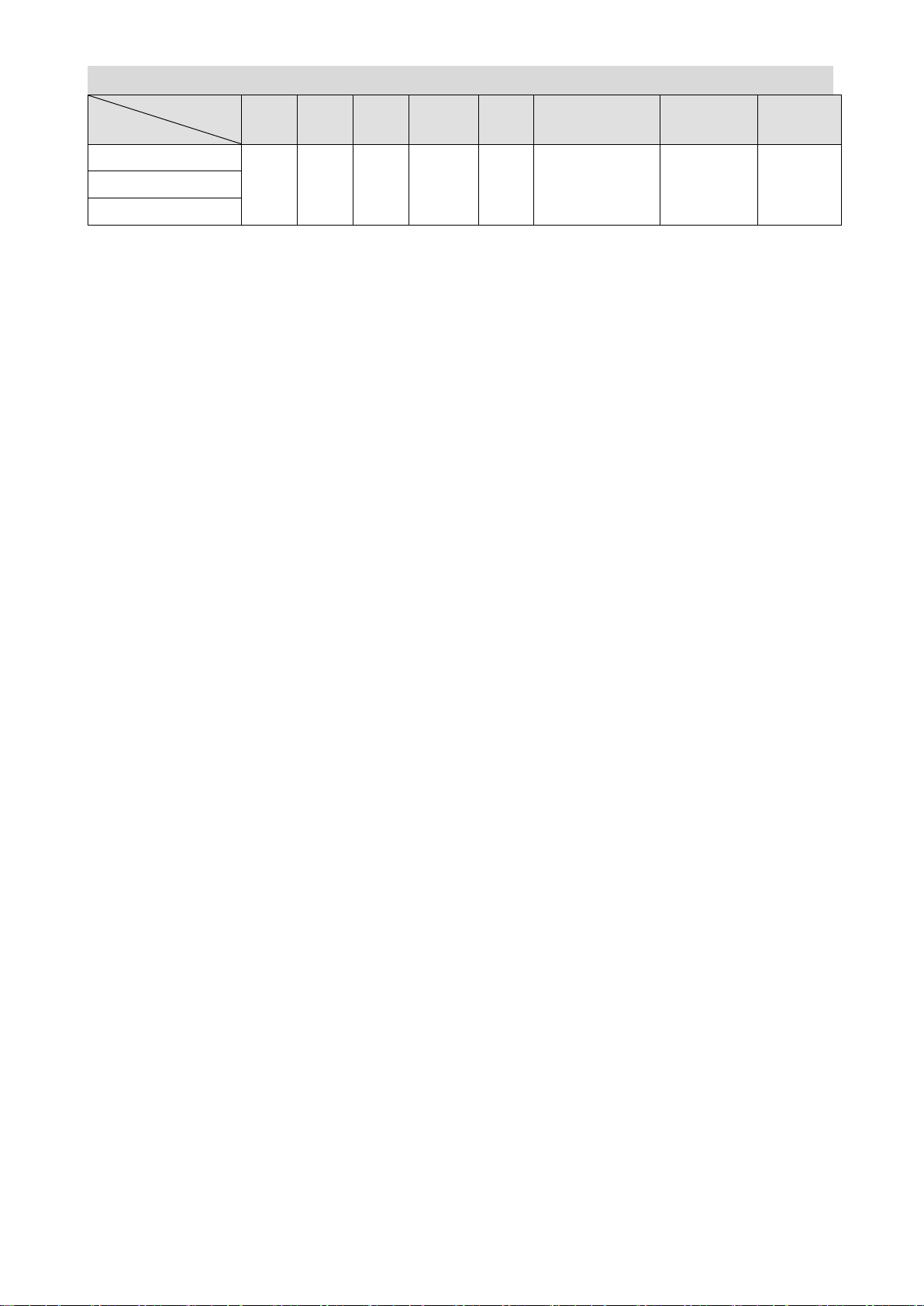

Confirmation and requirements of the installation space

Installation environment

The following items shall be noted when selecting the installation environment:

1. Ambient temperature: operate in -10℃ ~ 45℃; if the ambient temperature is higher than 45℃, the

equipment shall be used with 30% derating for each 5℃ temperature rise.

★ Note: If the ambient temperature is higher than 45℃, the ventilation shall be strengthened, and use by

the specified derating.

2. The humidity of the installation site shall lower than 95%, and free of condensing;

3. Do not install the equipment in place with dust or metal powder;

4. The equipment shall be installed at place without corrosive, explosive gas;

5. The equipment shall be installed at place that meets the requirements of vibration. The vibration

frequency ≤ 20Hz: 9.8m/s2; 20Hz ≤ vibration frequency ≤ 50Hz: 2m/s

6. The equipment shall be installed at place away from direct sunlight.

2

;

Installation direction and space

●Installation spacing and distance requirements of single driver are shown in Figure 1-7.

● Generally, abreast installation mode is adopted when multiple drivers are installed in the control

cabinet, and air inlet, outlet and dedicated cooling fan shall be equipped; if up and down installation

mode is adopted, stream guidance clapboard shall be added between drivers to guarantee good cooling

effect as shown in Figure 1-8.

GS DRIVER CTB

Figure 1-7 Single controller installation

Figure 1-8 Multiple controllers installation

Notes on motor and load

Compared with frequency conversion operation

GH DRIVER is full closed-loop vector servo driver. It adjusts output voltage and current automatically

according to the load change. It's more energy-efficient than inverter with higher speed control accuracy

and wider speed regulation range. As the controlled motor and driver are closed loop, the control of

position, speed and torque can be achieved conveniently.

Constant torque operation

When motor works in constant torque area, the output torque of the motor is required by the mechanical

operation instead of the rated torque of the motor. However, the maximum continuous output torque of

the motor must not exceed the rated torque.

High-speed operation in constant power area

For high-speed operation in constant power area, the increased vibration and noise shall be considered,

and the service speed range of motor bearing and mechanical devices must be confirmed, and

consulted in advance. It's strictly prohibited to make the machine operate above the rated speed.

Lubrication of the mechanical device

For reduction box and gear head motor and other mechanical device that requires lubrication, damage

may be caused due to deterioration of lubricating effect in long-term low-speed operation. It must be

consulted in advance.

Negative torque load

Negative torque load occurs frequently for load such as lifting. The driver will generate over-current and

overvoltage alarm and trip. Equipping of brake components or mechanical safety devices shall be

considered.

CTB GH DRIVER

Reciprocating load

Please pay attention to unstable phenomenon in output current when the driver is driving piston

reciprocating load. The phenomenon is more prominent in long-term low-frequency operation. The

capacity of driver shall be increased.

Mechanical resonance point of the load device

The driver may encounter the mechanical resonance point of the load device in certain output frequency

range. It can be avoided by setting jump frequency.

Notes on the driver

Applications not in rated voltage

The servo driver shall not be used in voltage that not in the working voltage range. Please conduct

voltage transformation with appropriate step-up or step-down unit as required.

Note on the drive 3 phase input into 2-phase input

The device shall not be changed into 2-phase input, otherwise, default phase protection will occur.

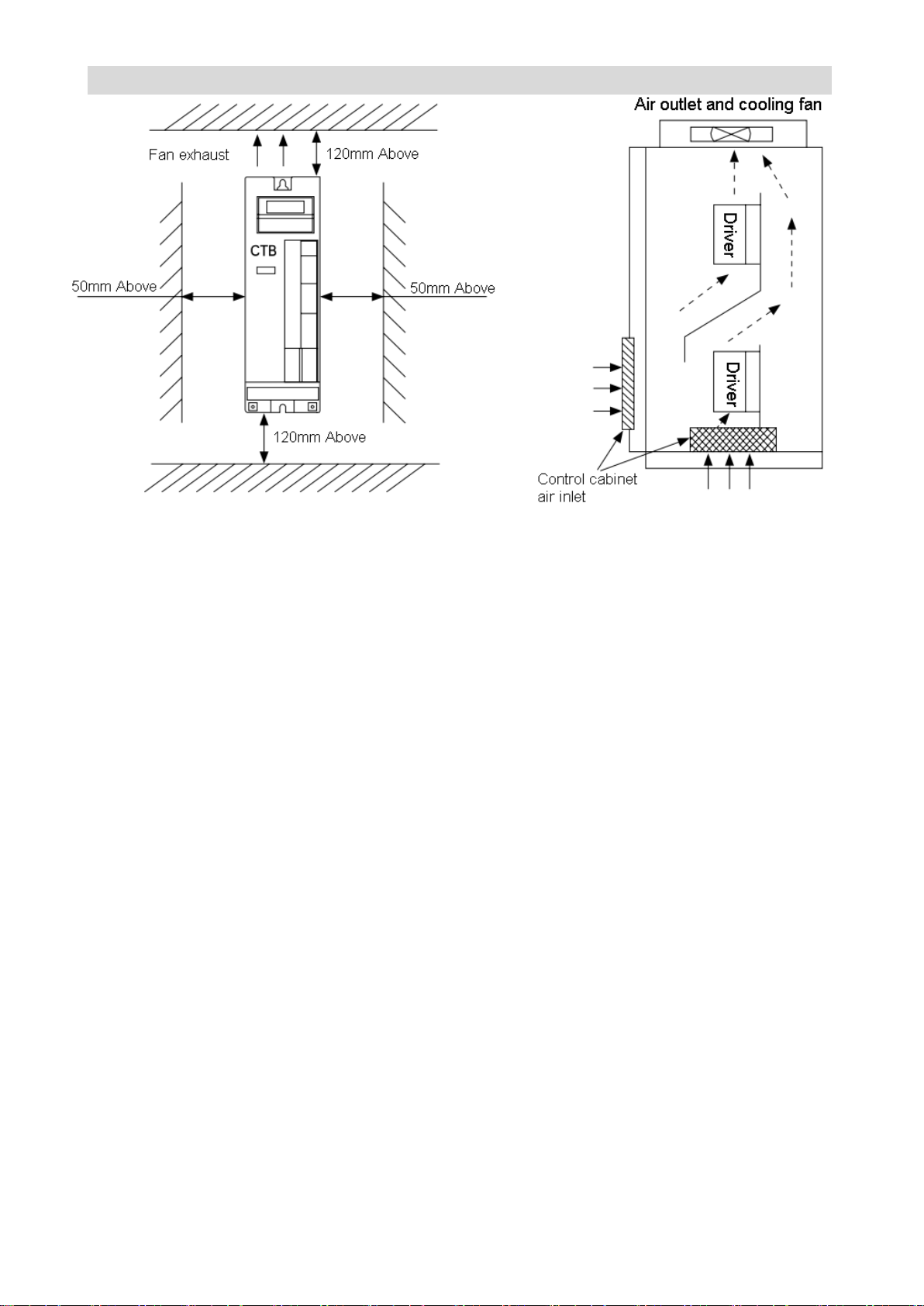

Capacitor or pressure-sensitive device to improve power factor

As shown in Figure 1-9, the output of the driver is PULSE wave, drive failure tripping or damage to the

device will be caused due to capacitor or pressure-sensitive device for lightning to improve power factor

installed at the output side. They must be removed.

Figure 1-9 Capacitor is prohibited at the output end of controller

Lightning attack protection

lightning over-current device is equipped in the driver for self-protection to induction stroke

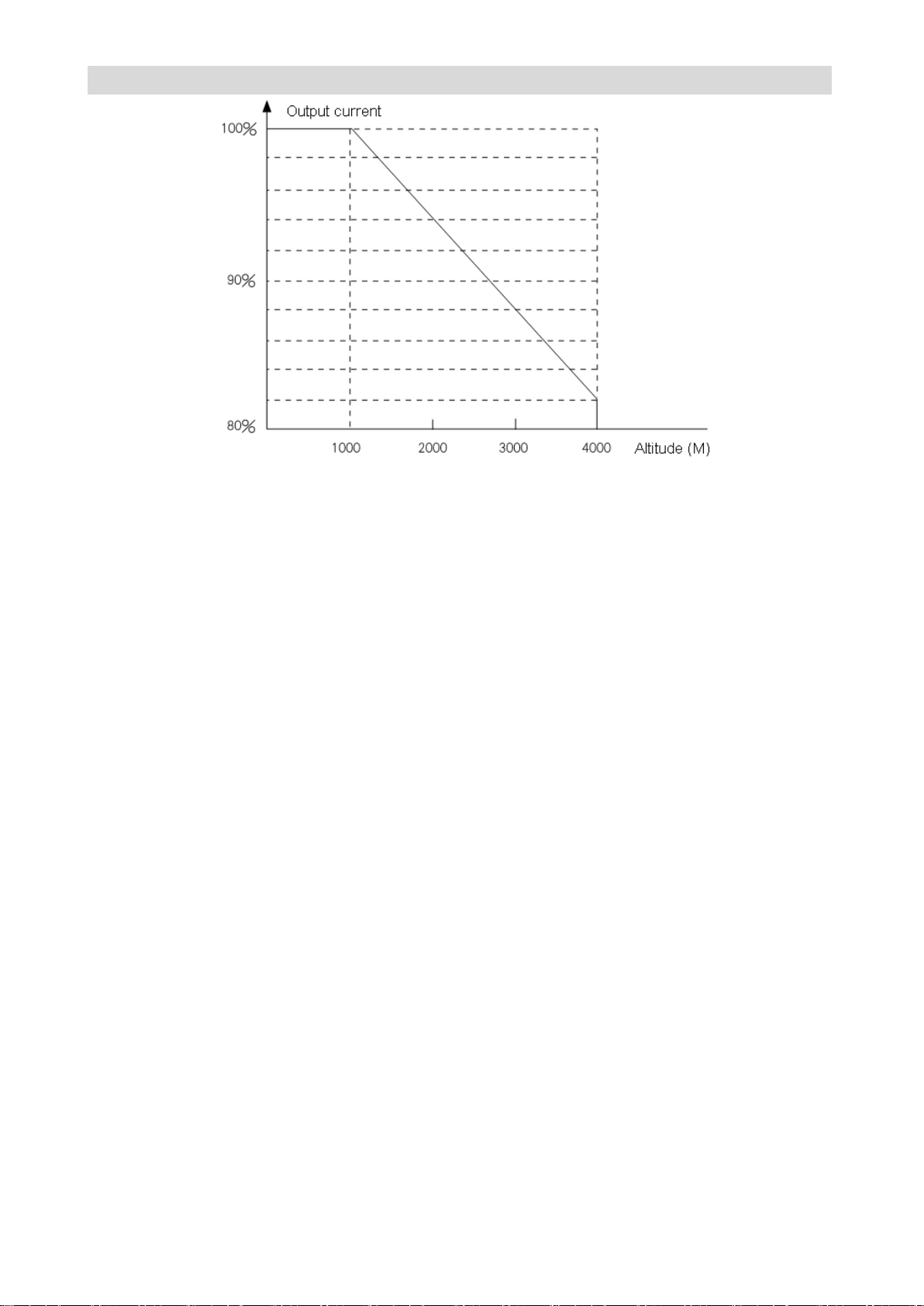

Altitude and derating operation

For areas with altitude over 1000 m, derating operation is necessary due to deterioration of cooling effect

of the drive caused by thin air. The relationship curve of rated current of driver and altitude is shown in

Figure 1-10.

GS DRIVER CTB

Figure 1-10 Derating curve of rated current of driver and altitude

Notes on scrapping:

Explosion of electrolytic capacitor: the electrolytic capacitors on main circuit and printed panel may

explode when incinerated.

Plastic incineration waste gas: toxic gases will be generated in incineration of front panel and other

plastic parts.

Processing method: please process the waste as industrial waste.

★ Description: The contents of the manual are subject to change due to product upgrade or optimize.

The new version shall prevail.

CTB GH DRIVER

Wiring

The chapter describes the wiring specifications of power supply terminals and control circuit

terminals, and install wiring specifications of control board jumpers and expansion interface

board.

Selection and connection of peripheral devices…………………………………..…………..2-2

Wiring of the main circuit terminals…..……………………………………………..…………2-3

Wiring of control circuit ……………………….………………………………………………..2-11

Connection of the encoder interface………….……………………..………………………..2-20

Connection of the serial communication port …….……………………………………..…..2-21

GS DRIVER CTB

Item

Usage

Selection note

Remarks

Air circuit breaker

Turn on or off driver power

Select by 150% of rated

current of the driver

Refer to Table 2 - 3

Electromagnetic

contactor

For automatic power on of

driver

Select by 150% of rated

current of the driver

Refer to Table 2 - 3

Input side reactor

Improve power factor of

power grid

Select by 100% of rated

current of the driver

Input noise filter

Suppress interference of

driver to power supply

Select by 150% of rated

current of the driver

Braking resistor

Consume regenerated

energy of the driver

Select by standard provided

by the factory

Refer to Table 2 - 2

Filtering magnet

ring

Suppress wireless

interference of the driver to

outside

Select by standard provided

by the factory

Refer to GH model

selection sample

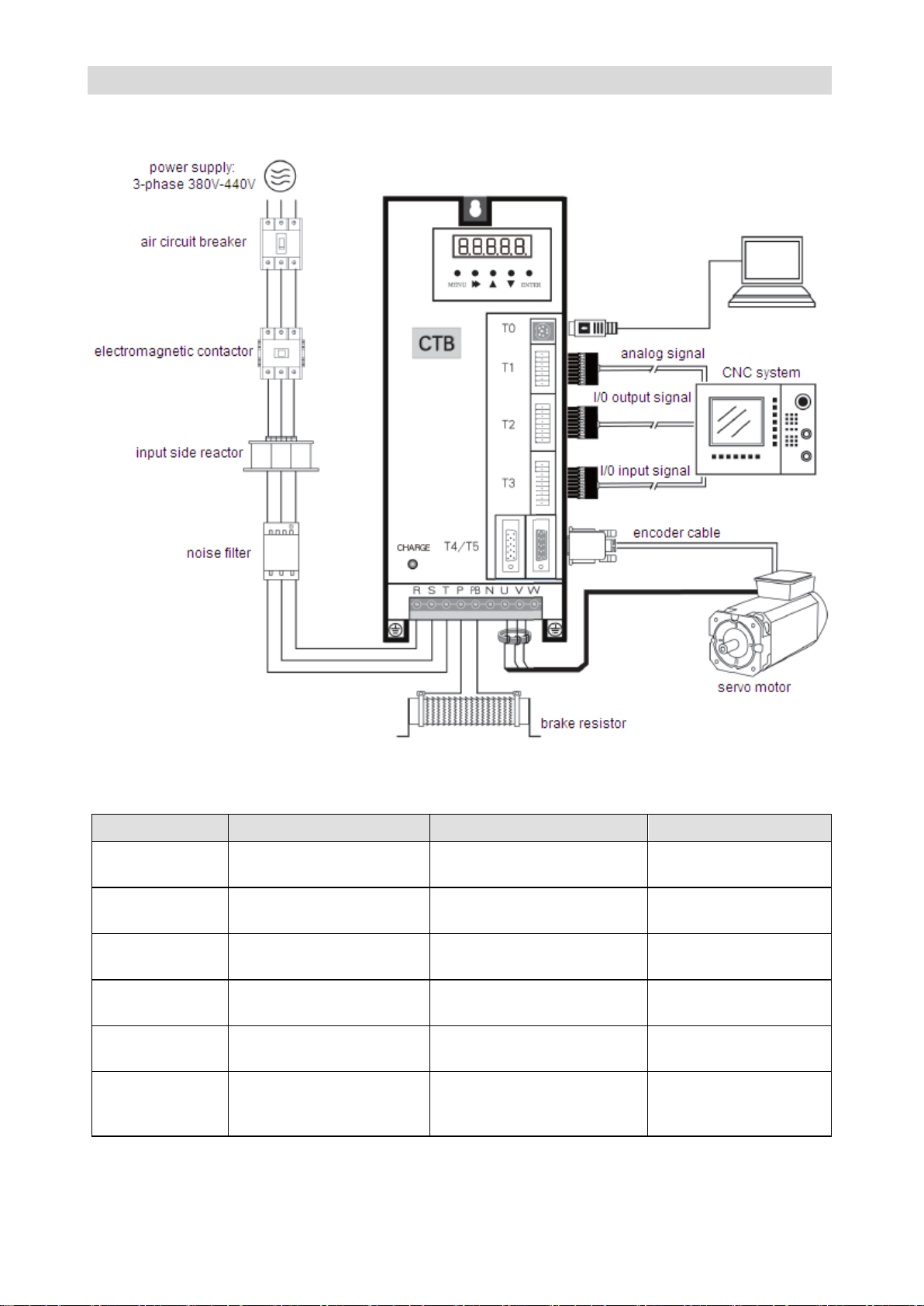

Selection and connection of peripheral devices

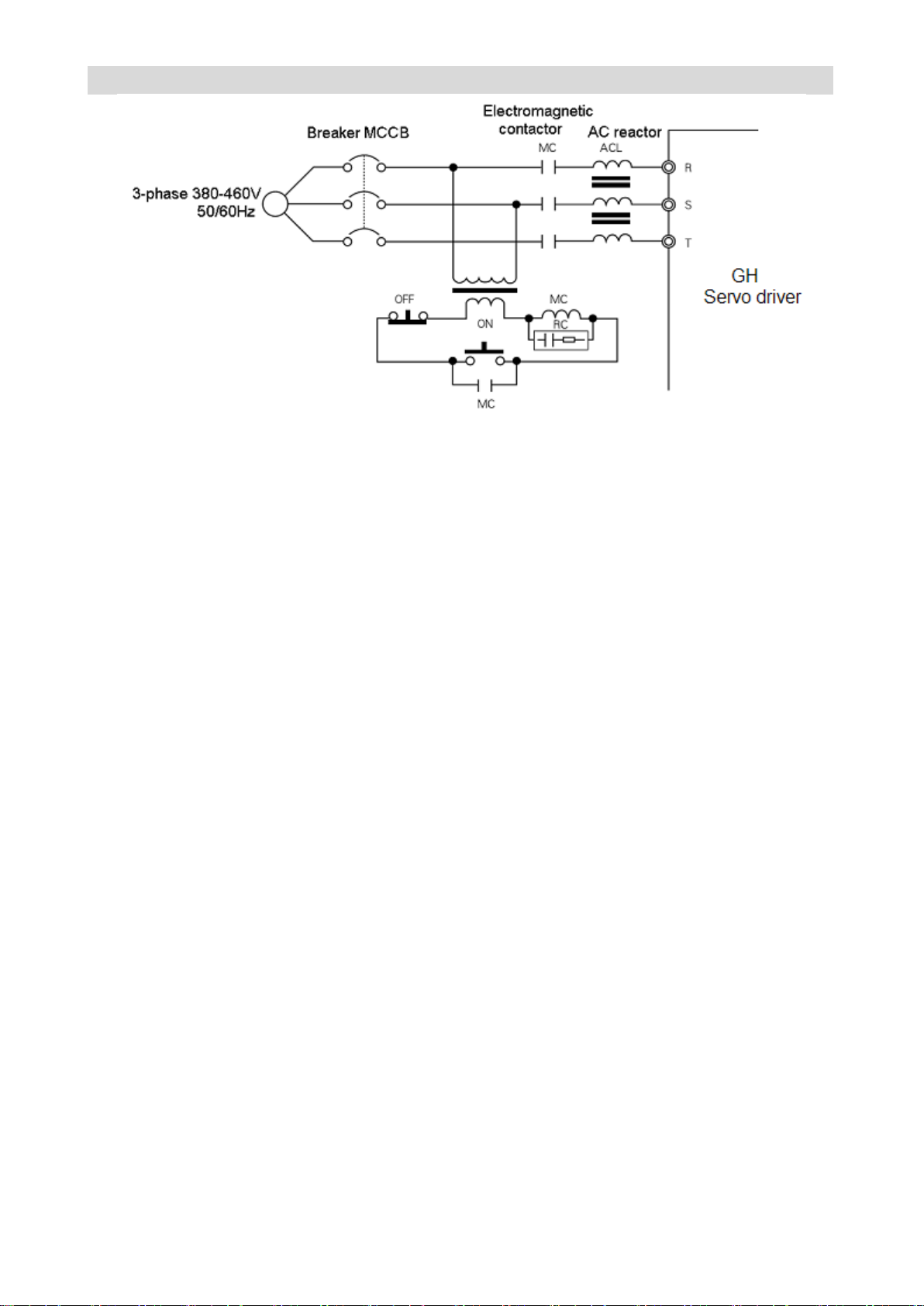

Driver and peripheral devices connection diagram taking 7.5kw drives as an example in Figure 2-1.

Figure 2-1 driver and peripheral devices connection diagram

Parts selection description

CTB GH DRIVER

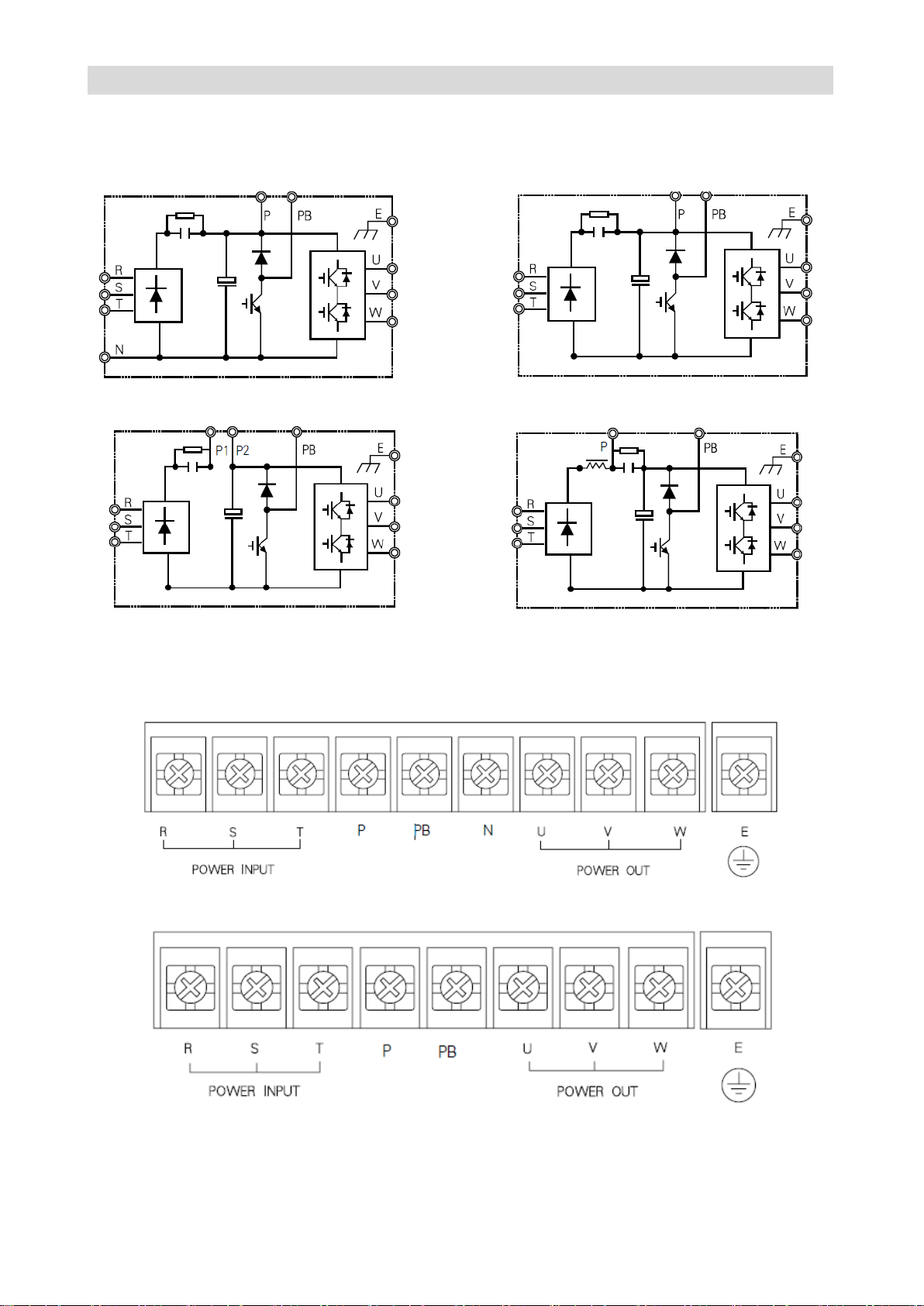

Wiring of the main circuit terminals

The structure of the main circuit

See Figure 2-2A, 2-2B, 2-2C and 2-2D for internal structure diagram of the main circuit.

Figure 2-2A 1.5~11kw main circuit composition Figure 2-2B 15~30kw main circuit composition

Figure 2-2C 37~75kw main circuit composition Figure 2-2D 90~160kw main circuit composition

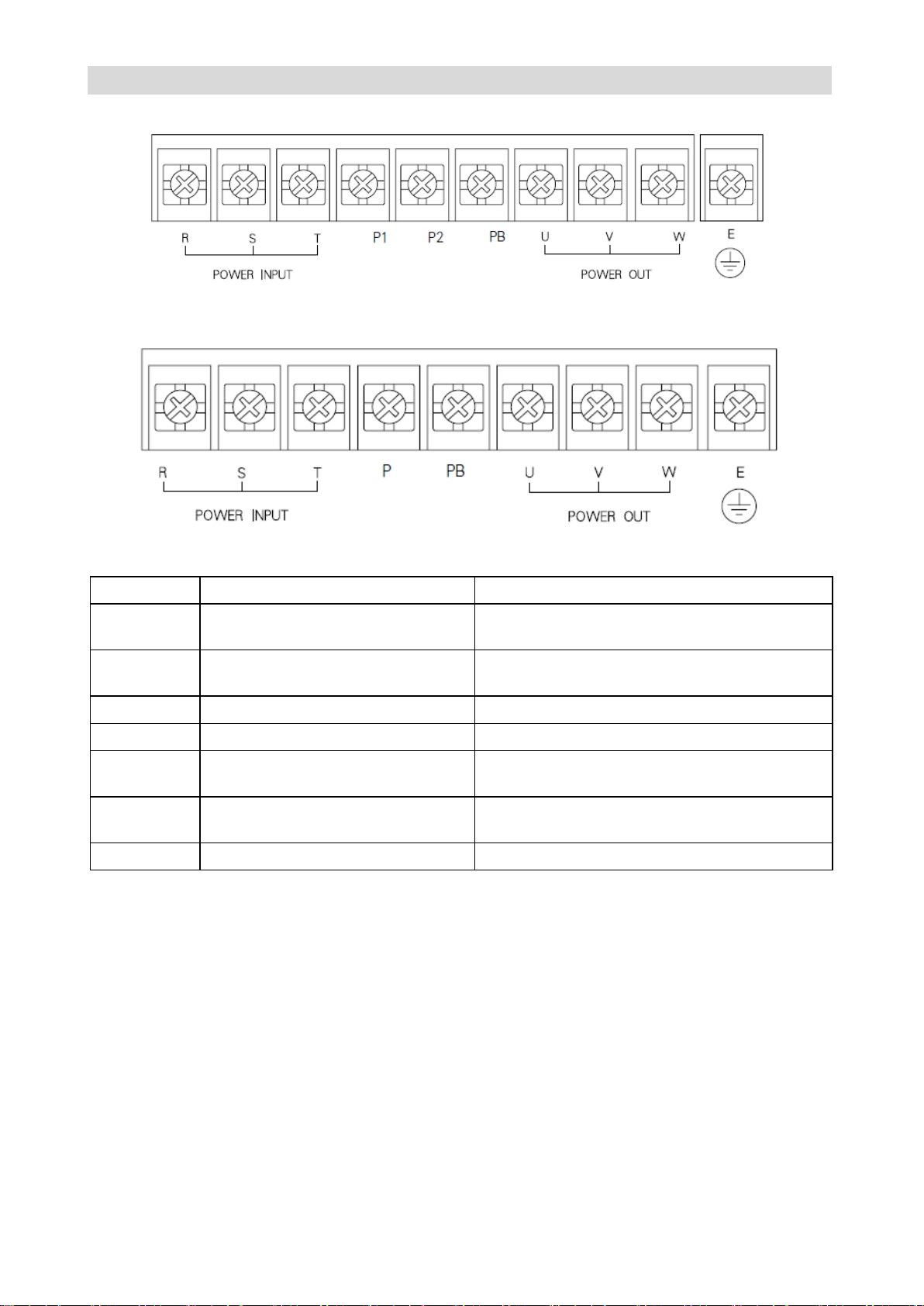

Main circuit terminals composition

1.5~11kw main circuit terminals composition

1.5~30kw main circuit terminals composition

GS DRIVER CTB

Item

Function

Notes

R S T

3-phase AC supply input terminal.

380~440V, 50/60Hz

Need to install breaker for protection

P P1

DC bus positive pole

P and N are for input of external braking unit or

DC power input

P2

DC reactor wiring terminal

P1 and P2 are for external DC reactor

PB

Braking resistor wiring terminal

P, P2 and PB are for external braking resistor

N

DC bus negative pole

N and P are for external braking unit or DC

power input

U V W

Driver output terminal

Consistent with the phase sequence of the motor

during wiring

E

Earth terminal

C type grounding, the grounding resistance≤ 4Ω

37~75kw main circuit terminals composition

90~160kw main circuit terminals composition

Main circuit terminals and functional description

Wiring of input side of the main circuit

Please pay attention to the following items for wiring of input side of the main circuit. See2-3

CTB GH DRIVER

Figure 2-3 Standard wiring diagram for incoming line

Incoming line circuit breaker (MCCB)

The main circuit power input terminals (R, S, T) must be connected to 3-phase AC power through line

protection circuit breaker (MCCB).

● The selection of MCCB must be in accordance with requirements in Table 2-3.

● The time characteristics of MCCB must take overload characteristics (rated output current 200%/min)

and time characteristics of the servo driver into account.

● Each AC servo driver shall be equipped with independent breaker; when multiple drivers share a

circuit breaker, to cut off the power supply and prevent the failure expansion during driver failure, it's

recommended to control the incoming line electromagnetic contactor with the fault output relay of the

driver to ensure safety.

Installation of the residual current circuit breaker

The output of the servo driver is a high frequency PULSE wave so that there is high-frequency leakage

current generated. Residual current circuit breaker can be used at the incoming line side of the driver to

remove high-frequency leakage current, and only inspect channel current that dangerous to human body.

Please select special residual current circuit breaker for servo (inverter) for wiring.

● When select special residual current circuit breaker, please select model for control of one driver with

an induction current over 30ma.

●When select normal residual current circuit breaker, please select model for control of one driver with

an induction current over 200ma, and a time over 0.1s.

●Installing isolation transformer between normal residual current circuit breaker and AC servo driver can

effectively avoid malfunction of the breaker.

Incoming line electromagnetic contactor

Incoming line electromagnetic contactor may be used to cut off the power in sequential control. It cannot

be used as start of AC servo driver. When cut off power of AC servo driver compulsorily with incoming

line electromagnetic contactor, AC servo driver is in power-off alarm state, motor only can slide freely

and stop.

● Frequent turning on/off incoming line magnetic contactor may cause heating, even burning of charging

GS DRIVER CTB

Driver model

41P5

42P2

43P7

45P5

47P5

4011

4015

4030

4037

4045

4055

4075

4090

4110

4132

4160

AC

reactor

Current

(A)

5 7 10

15

20

30

40

50

60

80

90

120

150

200

230

250

290

330

Model

ACL

0005

0007

0010

0015

0020

0030

0040

0080

0090

0120

0150

0200

0230

0250

0290

0490

DC

reactor

Current

(A)

Without connection to DC reactor

90

110

150

180

Built-in driver

Model

DCL

090

0110

0150

0180

resistor of the driver (driver interior).

● The time interval of turning on/off incoming line magnetic contactor shall be longer than 10 minutes.

AC reactor

Installing AC reactor at the incoming line side of the servo driver can effectively suppress the surge of

power, avoid burning of rectification part of the driver, and also can improve the power factor of the

power supply side. Please see Figure 2-3 for connection of AC reactor, see Table 2-1 for selection of AC

reactor.

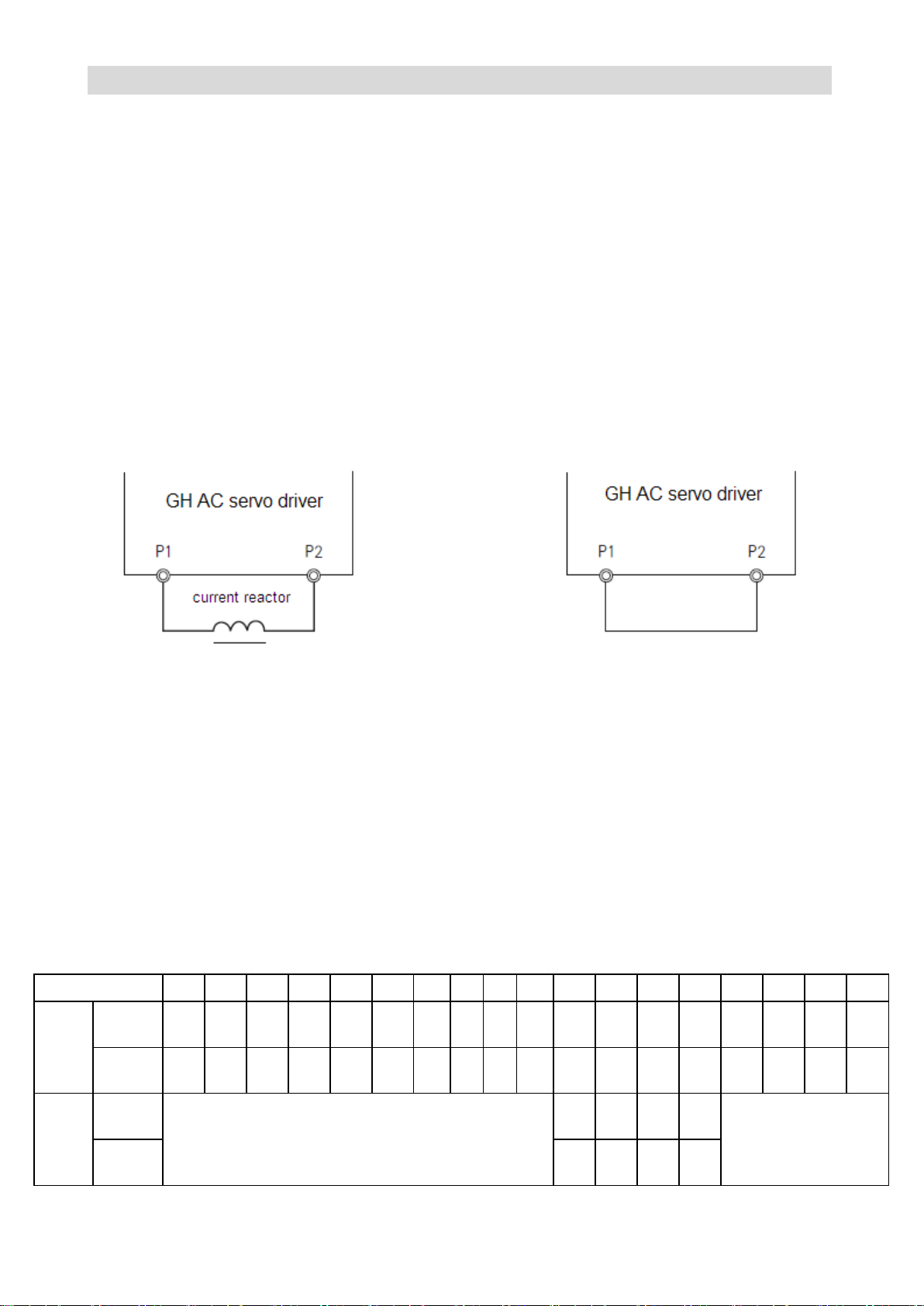

DC reactor

External DC reactor can be connected to GH AC servo driver of 37 to 75KW. It can effectively suppress

the surge of power, avoid burning of rectification part of the driver, and also can improve the power factor

of the power supply side. Please see Figure 2-4 for connection of DC reactor.

If external DC reactor is not connected, P1, P2 or D C + terminals shall be shorted as shown in Figure

2-5.

Figure 2-4 DC reactor connection diagram Figure 2-5 Connection diagram without DC reactor

Precautions for wiring of DC reactor

1. Please do not connect DC reactor to any main circuit terminal except P1, P2, otherwise, it may cause

internal short circuit of the driver, and burn the driver.

2. Please see Table 2-3 for specifications of DC driver connecting cable, the standard of the main circuit

cable.

3. Please see Table 2-1 for selection standard of DC reactor.

4. With external DC reactor, the P2 terminal shall be multiplex terminal, and one end of braking resistor

also shall be connected to the terminal.

Table 2-1 Selection of AC reactor, DC reactor and input filter

CTB GH DRIVER

Input

filter

Current

(A)

6 6 6

10

16

25

30

50

50

65

80

100

120

150

200

250

250

320

Model

EMI

06

06

06

010

016

025

030

050

050

065

080

0100

0120

0150

0200

0250

0250

0320

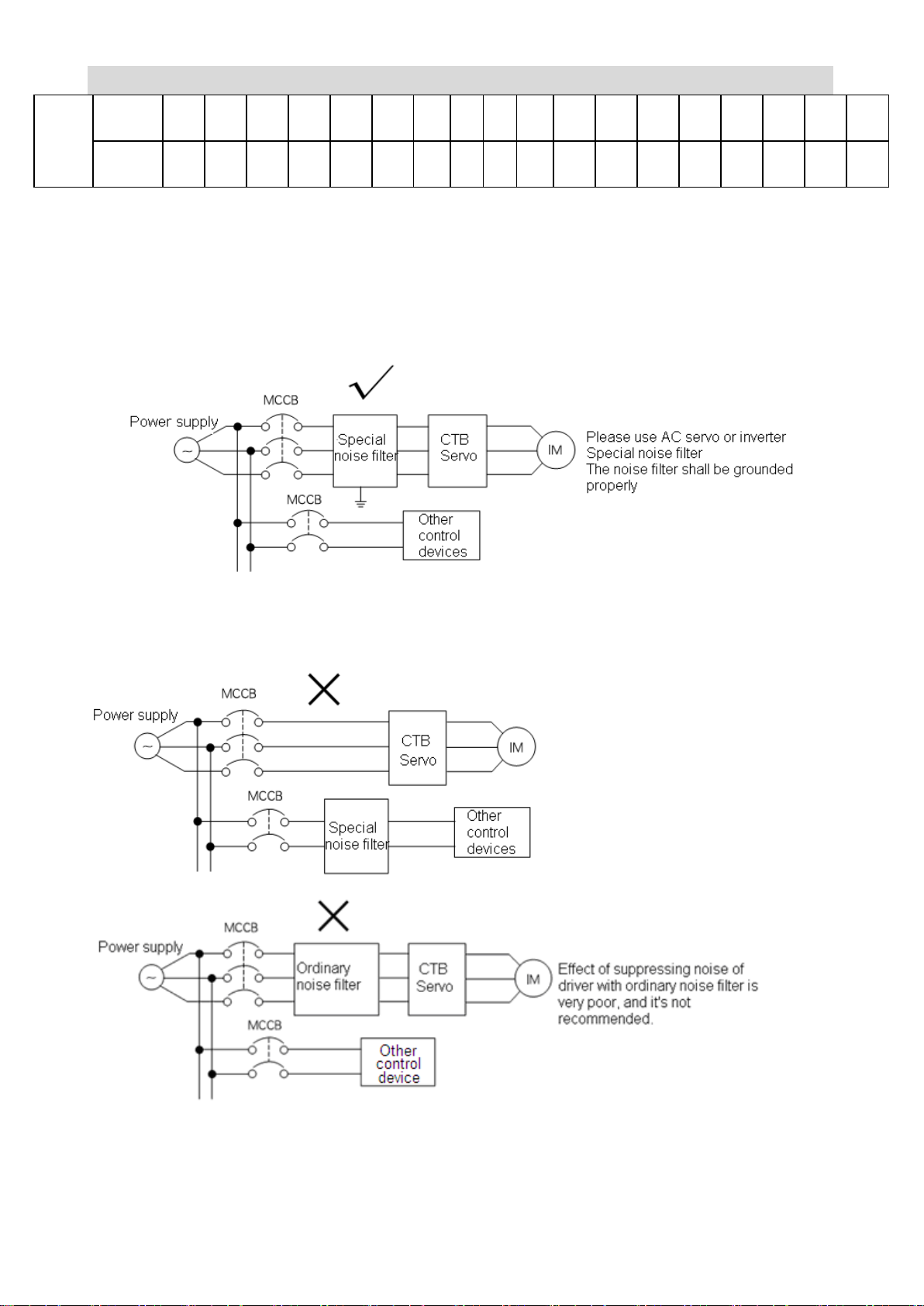

Power side noise filter

In command to reduce high-frequency interference noise from power line coupling to the driver, and

suppress the noise feedback to power from the driver, noise filter with appropriate model and

specifications at the power input side of the driver.

Set and connect the incoming line filter correctly as shown in Figure 2-6.

Figure 2-6 Correct installation of noise filter at the input side of the power supply

Please see Figure 2-7 for examples of incorrect settings and connection

Figure 2-7 Incorrect settings and connection of noise filter at the input side of the power supply

Loading...

Loading...