Page 1

G

EtherCAT network adapter

GN-9386

User manual

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 1 of (44)

Page 2

GN-9386 User Manual

G

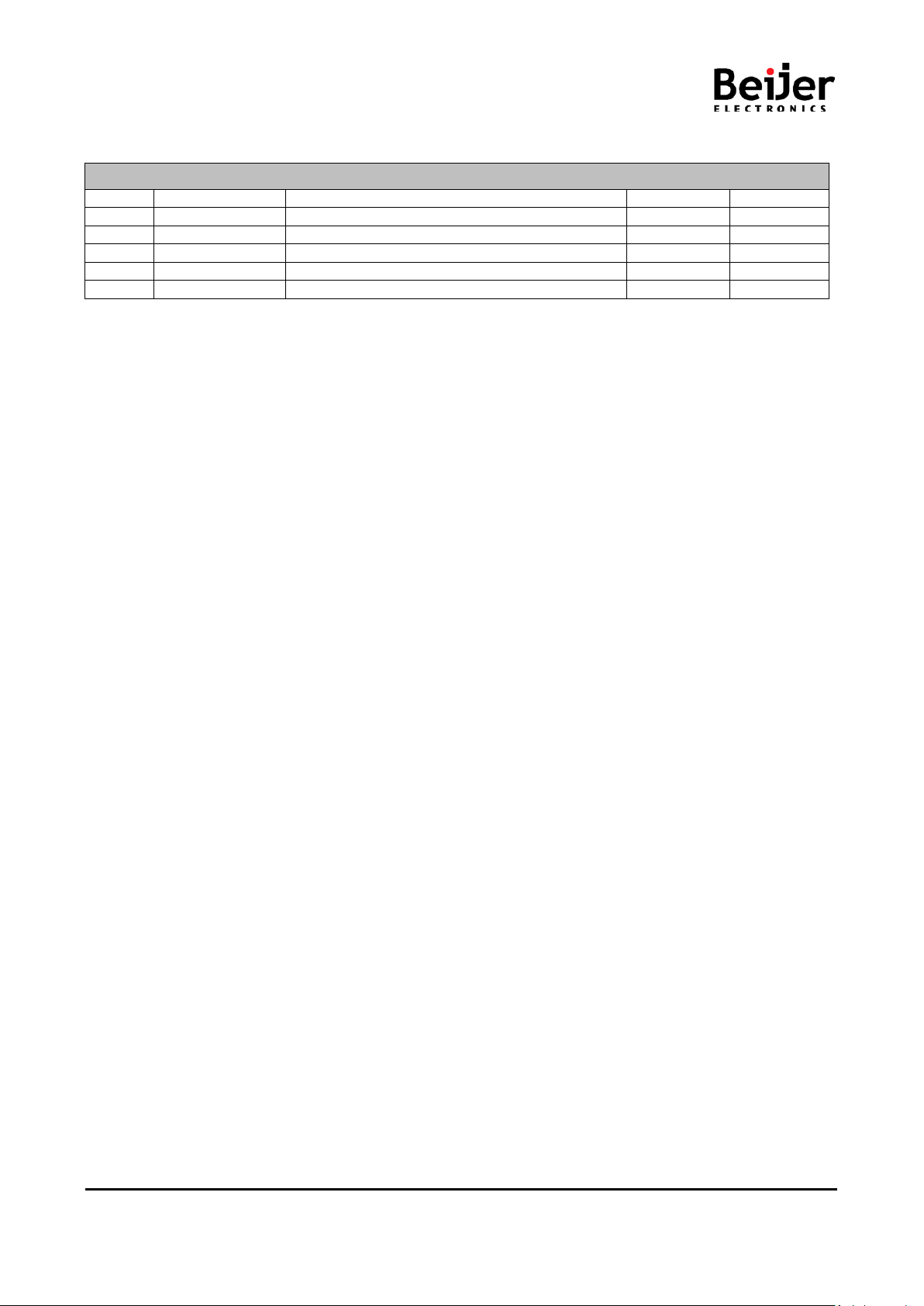

DOCUMENT CHANGE SUMMARY

REV.

PAGES

REMARKS

DATE

Editor

1.00

New Document

2018/7/30

1.01

First release

2019/01/29

NJL

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 2 of (44)

Page 3

GN-9386 User Manual

G

Contents

1. Important Notes ............................................................................................................................................................. 5

1.1. Safety Instruction .............................................................................................................................. 6

1.1.1. Symbols .............................................................................................................................................................. 6

1.1.2. Safety Notes ..................................................................................................................................................... 6

1.1.3. Certification ....................................................................................................................................................... 6

2. Environment Specification ........................................................................................................................................... 7

3. General Description ....................................................................................................................................................... 8

3.1. GN-9386 Specification ..................................................................................................................... 8

3.2. GN-9386 Wiring Diagram................................................................................................................. 9

3.3. GN-9386 LED Indicator .................................................................................................................. 10

3.3.1. LED Indicator .................................................................................................................................................. 10

3.3.2. MOD(Module Status LED) ........................................................................................................................ 10

3.3.3. RUN(Current Running Status LED) ....................................................................................................... 10

3.3.4. ERROR(Error State LED) ....................................................................................................................... 11

3.3.5. IOS LED(Extension Module Status LED) ....................................................................................... 11

3.3.6. Field Power, System Power LED(Field Power, System Power Status LED) ............... 11

3.3.7. Indicator states and flash rates .......................................................................................................... 12

3.4. GN-9386 Electrical Interface......................................................................................................... 13

3.4.1. RJ-45 Socket ................................................................................................................................................ 13

3.4.2. DIP Swit ch ..................................................................................................................................................... 13

3.4.3. RS232 Port for MODBUS/RTU, Touch Panel or I/O Guide .................................................... 14

3.5. EtherCAT ID Type Setup ............................................................................................................... 14

3.5.1. Hot Connection On TwinCAT .............................................................................................................. 14

3.6. I/O Process Image Map .................................................................................................................. 17

3.6.1. Example of Input Process Image (Input Register) Map ......................................................... 18

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 3 of (44)

Page 4

GN-9386 User Manual

G

3.6.2. Example of Output Process Image (Output Register) Map ................................................. 19

4. Dimension ........................................................................................................................................................................ 21

4.1. GN-9386 ............................................................................................................................................. 21

5. EtherCAT Basics ............................................................................................................................................................. 22

5.1. EtherCAT Protocol .......................................................................................................................... 22

5.2. EtherCAT State Machine ............................................................................................................... 22

5.3. EtherCAT Mailbox ........................................................................................................................... 24

5.4. CoE Interface .................................................................................................................................... 26

5.4.1. Parameter management in the EtherCAT system .................................................................... 26

5.4.2. Communication Objects ........................................................................................................................ 27

6. MODBUS Interface ....................................................................................................................................................... 29

6.1. MODBUS Interface Register/Bit Map ......................................................................................... 29

6.2. Supported MODBUS Function Codes ....................................................................................... 30

6.2.1. 8 (0x08) Diagnostics ................................................................................................................................. 32

6.2.2. Error Response ........................................................................................................................................... 33

6.3. MODBUS Special Register Map .................................................................................................. 34

6.3.1. Adapter Identification Special Register (0x1000, 4096) ......................................................... 34

6.3.2. Adapter Information Special Register (0x1100, 4352) ............................................................ 35

6.3.3. Expansion Slot Information Special Resister (0x2000, 8192) ............................................ 36

6.4. Supported MODBUS Function Codes ....................................................................................... 38

7. TROUBLE SHOOTING .................................................................................................................................................. 39

APPENDIX A ....................................................................................................................................................................... 41

A.1. Product List ..................................................................................................................................... 41

A.2. Glossary............................................................................................................................................ 43

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 4 of (44)

Page 5

GN-9386 User Manual

G

Warning!

Caution!

1. Important Notes

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls describes some

important differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will CREVIS be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, CREVIS cannot assume responsibility

or liability for actual use based on the examples and diagrams.

If you don’t follow the directions, it could cause a personal injury, damage to the equipment or

explosion

Do not assemble the products and wire with power applied to the system. Else it may cause an electric

arc, which can result into unexpected and potentially dangerous action by field devices. Arching is

explosion risk in hazardous locations. Be sure that the area is non-hazardous or remove system power

appropriately before assembling or wiring the modules.

Do not touch any terminal blocks or IO modules when system is running. Else it may cause the unit to an

electric shock or malfunction.

Keep away from the strange metallic materials not related to the unit and wiring works should be

controlled by the electric expert engineer. Else it may cause the unit to a fire, electric shock or

malfunction.

If you disobey the instructions, there may be possibility of personal injury, damage to equipment

or explosion. Please follow below Instructions.

Check the rated voltage and terminal array before wiring. Avoid the circumstances over 55℃ of

temperature. Avoid placing it directly in the sunlight.

Avoid the place under circumstances over 85% of humidity.

Do not place Modules near by the inflammable material. Else it may cause a fire.

Do not permit any vibration approaching it directly.

Go through module specification carefully, ensure inputs, output connections are made with the

specifications. Use standard cables for wiring.

Use Product under pollution degree 2 environment.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 5 of (44)

Page 6

GN-9386 User Manual

G

1.1. Safety Instruction

1.1.1. Symbols

Identifies information about practices or circumstances that can cause an explosion

in a hazardous environment, which may lead to personal injury or death property

damage or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal

injury, prop ert y dam age, or ec onomic loss.

Attentions help you to identity a hazard, avoid a hazard, and recognize

the consequences.

1.1.2. Safety Notes

The modules are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the modules, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. G-BUS Pin.

1.1.3. Certification

c-UL-us UL Listed Industrial Control Equipment, certified for U.S. and Canada

See UL File E235505

FCC, Reach, RoHS- II, China RoHS

CE Certificate

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 6 of (44)

Page 7

GN-9386 User Manual

G

Environment Specification

Operating Te mperature

-40℃~70℃

UL Temperature

-20℃~60℃

Storage Temperature

-40℃~85℃

Relative Humidity

5% ~ 90% non-condensing

Mounting

DIN rail

General Specification

Shock Operating

IEC 60068-2-27

Vibration resistance

Sine Vibration (Based on IEC 60068-2-6)

- Test time : 1hrs for each test

EMC resistance burst/ESD

EN 61000-6-2 : 2005

EN 61000-6-4/ALL : 2011

Installation Pos. / Protect. Class

Variable/IP20

Product Certifications

CE, UL

2. Environment Specificati o n

- 5 ~ 25Hz : ±1.6mm

- 25 ~ 300Hz : 4g

- Sweep Rate : 1 Oct/min, 20 Sweeps

Random Vibration (Based on IEC 60068-2-64)

- 10 ~ 40 Hz : 0.0125 g

- 40 ~ 100 Hz : 0.0125 → 0.002 g

- 100 ~ 500 Hz : 0.002 g

- 500 ~ 2000 Hz : 0.002 → 1.3 x 10

2

/Hz

2

/Hz

2

/Hz

-4g2

/Hz

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 7 of (44)

Page 8

GN-9386 User Manual

G

3. General Description

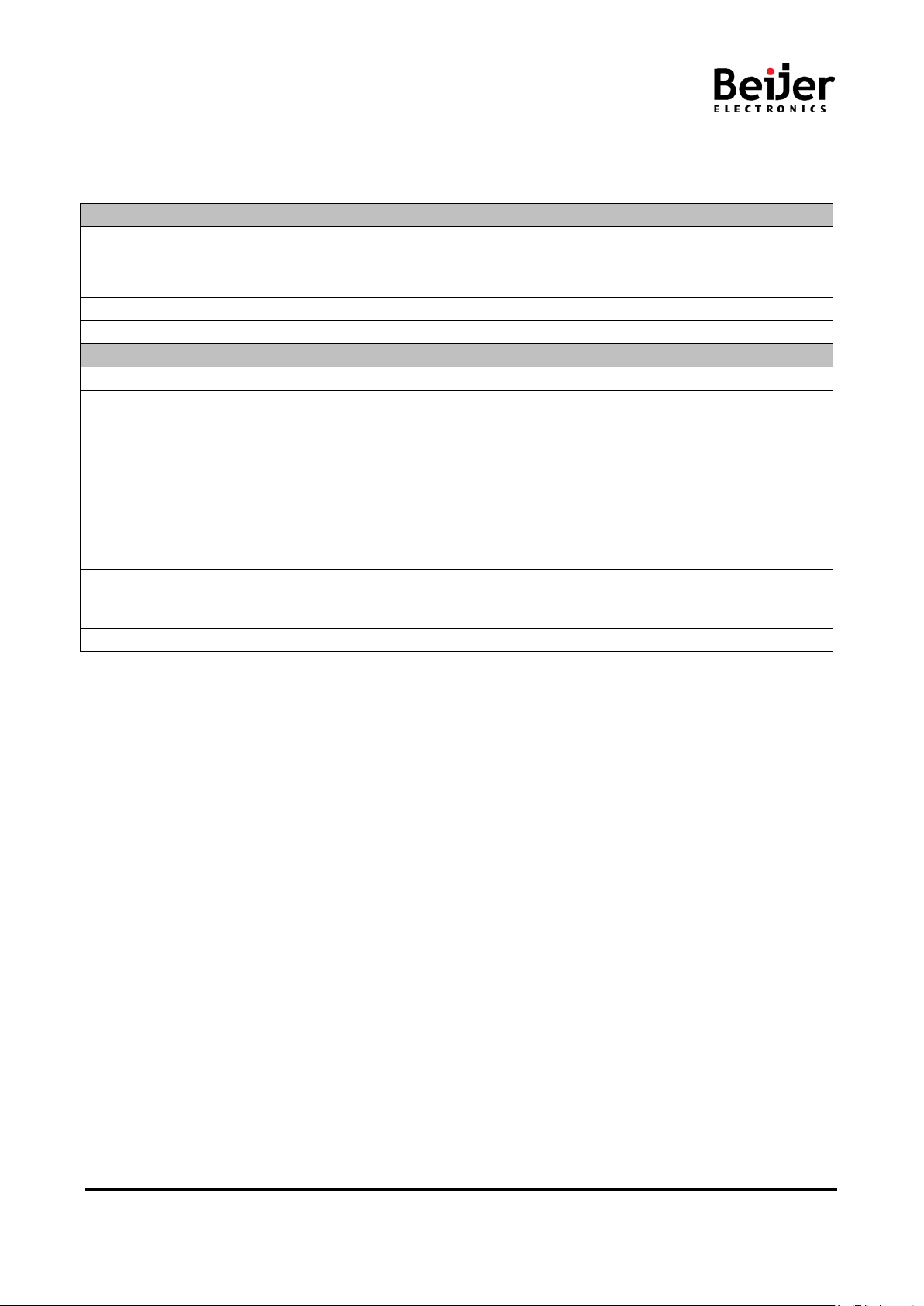

3.1. GN-9386 Specification

Items Specification

Communication Interface Specification

Adapter Type Slave Node (EtherCAT)

Max. Expansion Slot 63 slots

I/O Data Size Max 128 bytes each slot

Max. Network Node 65535

Baud Rate 100Mbps

Bus Connection 2 x RJ-45

Mac Address / IP Address Not needed

Other Serial Port RS232 for MODBUS/RTU, Touch Panel or I/O Guide(Crevis Soft ware)

Node : 1 (Fixed)

Serial Configuration

(RS232)

Baud Rate : 115200 (Fixed)

Data bit : 8 (Fixed)

Parity bit : No parity (Fixed)

Stop bit : 1 (Fixed)

6 Status LEDs

1 Green/Red, Module Status (MOD)

Indicator

Module Location Starter module left side of G-Series system

Field Power Detection About 14Vdc

General Specification

System Power

Power Dissipation 70mA @ 24Vdc

Current for I/O Module 1.5A @ 5Vdc

Isolation

Field Power

1 Green, Network Status (RUN)

1 Red, Error Status (ERROR)

1 Green/Red Expansion I/O Module Statsus (IOS)

1 Green, System Power Status

1 Green, Field Power Status

Supply voltage : 24Vdc nominal

Supply voltage range : 15~32Vdc

Protection : Output current limit (Min. 1.5A)

Reverse polarity protection

System power to internal logic : Non-Isolation

System power I/O driver : Isolation

Supply voltage : 24Vdc typical (Max. 32Vdc)

* Field Power Range is different depending on IO Module series.

Refer to IO Module`s Specification.

Weight 167g

Module Size 54mm x 99mm x 70mm

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 8 of (44)

Page 9

GN-9386 User Manual

G

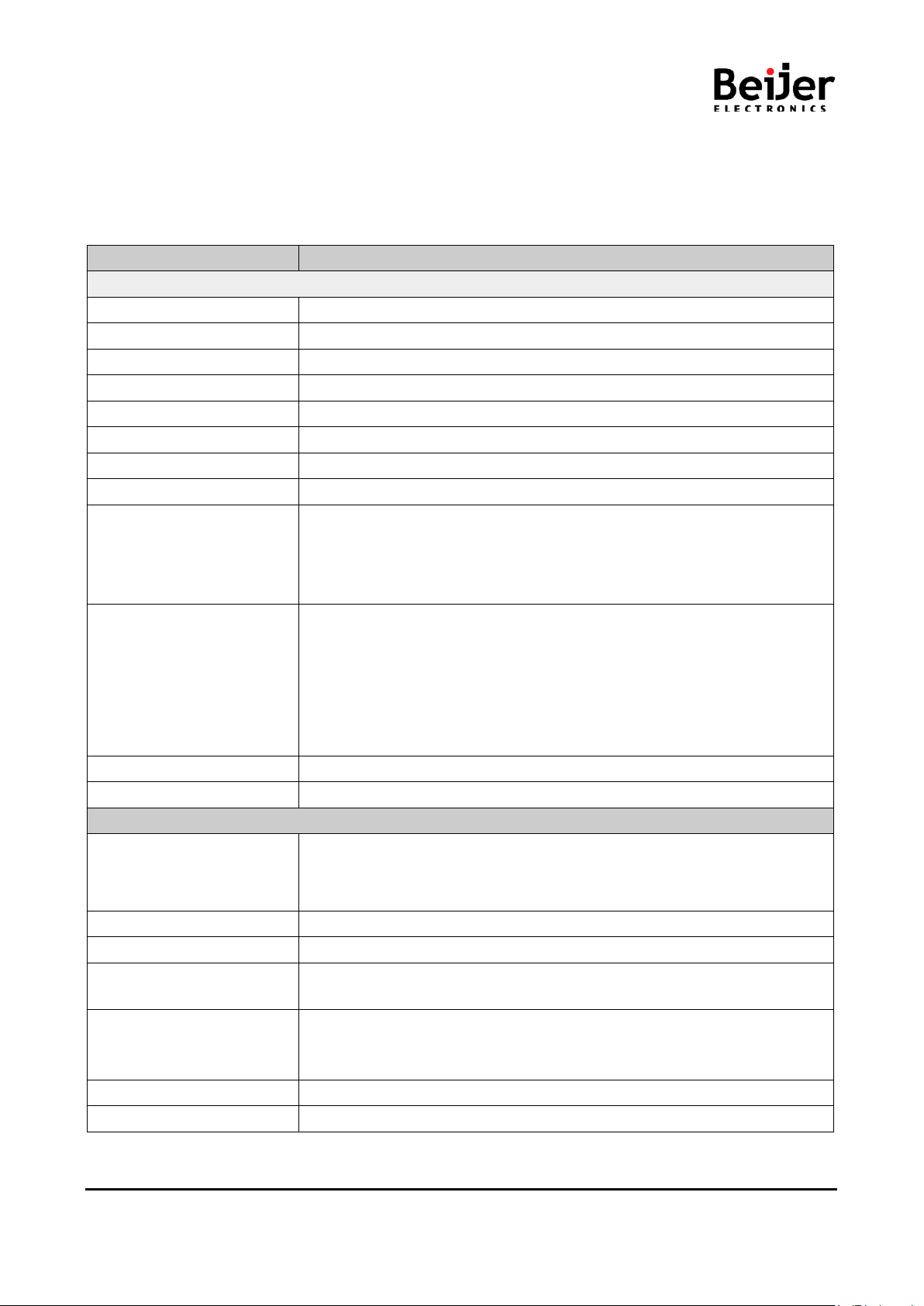

3.2. GN-9386 Wiring Diagram

Pin No. Signal Description Signal Description Pin No.

0 System Power, 24V System Power, Ground 1

2 System Power, 24V System Power, Ground 3

4 F.G F.G 5

6 Field Power, Ground Field Power, Ground 7

8 Field Power, 24V Field Power, 24V 9

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 9 of (44)

Page 10

GN-9386 User Manual

G

Status

LED

Not Powered

OFF

Normal, Operational

Green

Device in Standby

Flashing Green

Minor Fault

Flashing Red

Unrecoverable Fault

Red

Status

LED To ind icate

Init OFF State of the EtherCAT State Machine: INIT = Initialization.

Pre

Blinking

State of the EtherCAT State Machine: PREOP =

Safe

Single Flash

State of the EtherCAT State Machine: SAFEOP = Safe

Initialization or Bootstrap

Flashes

State of the EtherCAT State Machine: BOOT = Bootstrap (Update

of the coupler firmware)

Operational

ON State of

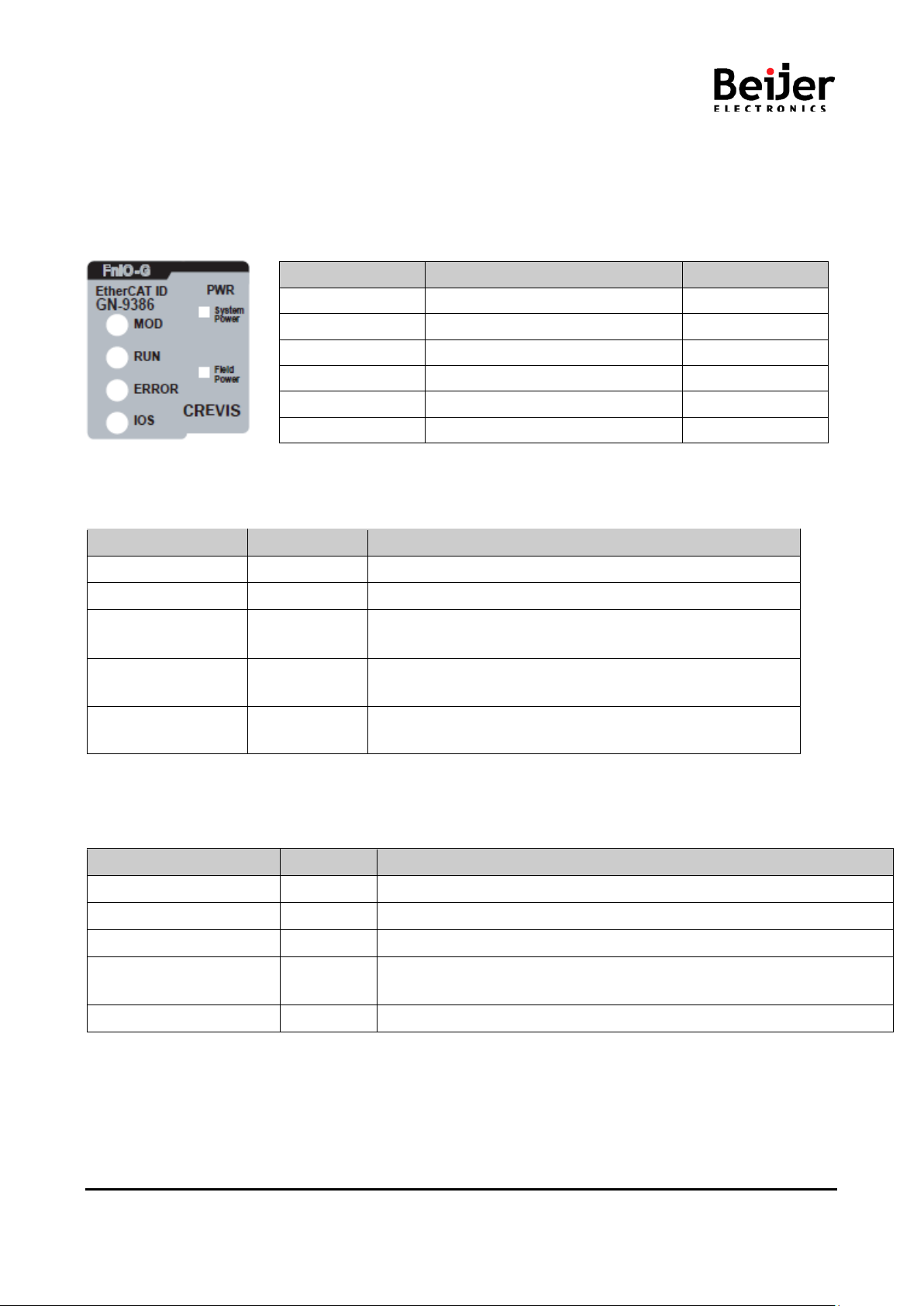

3.3. GN-9386 LED Indicator

3.3.1. LED Indicator

LED No. LED Function / Description LED Color

MOD Module Status Green/Red

RUN Current Running Status Green

ERROR Error Status (EtherCAT) Red

IOS Extension Module Status Green/Red

System Power System Power Enable Green

Field Power Field Power Enable Green

3.3.2. MOD(Module Status LED)

To indicate

power is not supplied to the unit.

The unit is operating in normal condition.

The EEPROM parameter is not initialized yet.

Serial Number is zero value (0x00000000)

The unit has occurred recoverable fault in self-testing.

- EEPROM checksum fault.

The unit has occurred unrecoverable fault in self-testing.

- Firmware fault

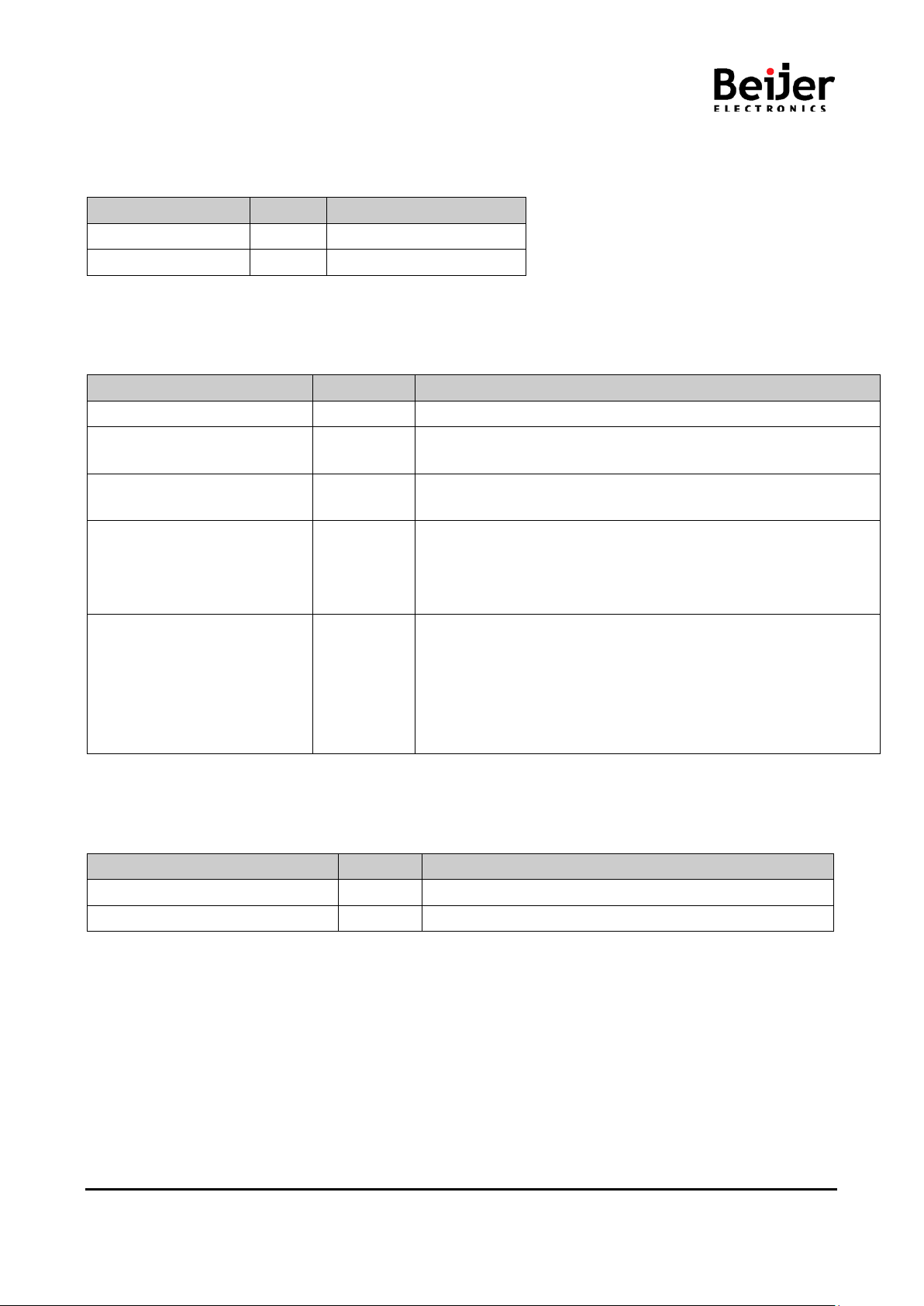

3.3.3. RUN(Current Running Status LED)

-Operation

-Operation

the EtherCAT State Machine: Operational.

Pre-Operation.

-Operation.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 10 of (44)

Page 11

GN-9386 User Manual

G

Status

LED

To indicate

3.3.4. ERROR(Error State LED)

No Error OFF No Error.

Invalid Configuration Blinking Invalid Configuration.

3.3.5. IOS LED(Extension Module Status LED)

Status LED To indicate

Not Powered OFF Device has no expansion module or may not be powered.

Internal Bus On-line,

Do not Exchanging I/O

Internal Bus Connection,

Run Exchanging I/O

Internal Bus Connection Fault

during Exchanging I/O

Expansion Configuration

Failed

Flashing

Green

Green Exchanging I/O data.

Red

Flashing

Red

Internal Bus is normal but does not exchanging I/O data.

(Passed the expansion module configuration)

One or more expansion module occurred in fault state.

- Changed expansion module configuration.

- Internal Bus communication failure.

- Mismatch vendor code be tw een ad apter and expansion module.

Failed to initialize expansion module.

- Detect invalid expansion module ID.

- Overflow Input/Output size.

- No expansion module.

- Too many expansion module.

- Initial protocol failure.

3.3.6. Field Power, System Power LED(Field Power, System Power Status LED)

Status LED To indicate

Not supplied field, system power OFF Not supplied 24Vdc field power, 5Vdc system power.

Supplied field, system power Green Supplied 24Vdc field power, 5Vdc system power.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 11 of (44)

Page 12

GN-9386 User Manual

G

LED ON

Constantly ON

3.3.7. Indicator states and flash rates

LED OFF Constantly OFF.

LED flickering

LED blinking

LED single flash

LED double flash

LED triple flash

Equal ON and OFF times with a frequency of approximately 10 Hz: ON for approximately

50ms and OFF for approximately 50ms.

Equal ON and OFF times with a frequency of approximately 2, 5Hz: ON for approximately

200ms followed by OFF for approximately 200ms.

One short flash (approximately 200ms) followed by a long OFF phase

(approximately 1000ms)

A sequence of two short flashes (approximately 200ms), separated by an OFF phase

(approximately 200ms).

The sequence is finished by a long OFF phase (approximately 1000ms)

A sequence of three short flashes (approximately 200ms), separated by an OFF phase

(approximately 200ms).

The sequence is finished by a long OFF phase (approximately 1000ms)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 12 of (44)

Page 13

GN-9386 User Manual

G

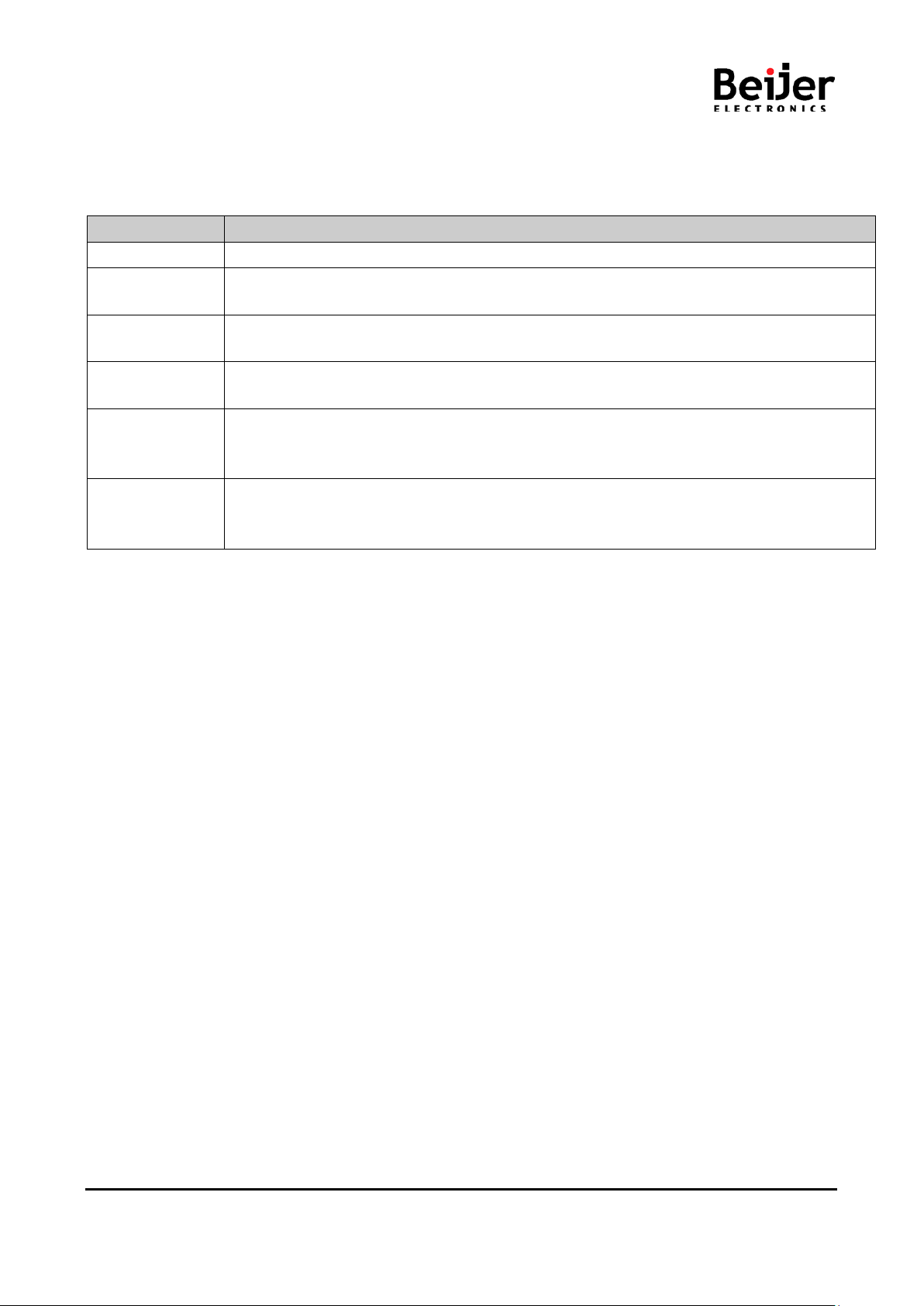

3.4. GN-9386 Electrical Interface

3.4.1. RJ-45 Socket

RJ-45 Signal Name Description

1 TD+ Transmit +

2 TD- Transmit 3 RD+ Receive +

4 -

5 -

6 RD- Receive 7 -

8 -

Case Shield

Shielded RJ-45 Socket

3.4.2. DIP Switch

DIP Pole# Description

1 IdentificationValue DIP bit#0

2 IdentificationValue DIP bit#1

3 IdentificationValue DIP bit#2

4 IdentificationValue DIP bit#3

5 IdentificationValue DIP bit#4

6 IdentificationValue DIP bit#5

7 IdentificationValue DIP bit#6

8 IdentificationValue DIP bit#7

9 Not Used

10 Not Used

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 13 of (44)

Page 14

GN-9386 User Manual

G

3.4.3. RS232 Port for MODBUS/RTU, Touch Panel or I/O Guide

Pin# Signal Name Description

1 Reserved ---2 TXD RS232 TXD

3 RXD RS232 RXD

4 GND RS232 GND

3.5. EtherCAT ID Type Setup

3.5.1. Hot Connection On TwinCAT

Hot connection function c an be used to remove a node from a preconf igured Configuration or change the

location of nodes and flexible.This featur e is avai labl e only Ethercat ID Type in TwinCAT.

The user can use the external Dip Switch settings of the Adapter Identification Value.

For an example of using an external Dip Switch ( Refer to 2.4.2. )

Ex) node 1 (Min)

Ex) node 255 (Max)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 14 of (44)

Page 15

GN-9386 User Manual

G

Hot Connection setting procedure

1. Add the EtherCAT ID Type in TwinCAT.

2. Hot Connect Group settings

Set the identification value same as dip-switch.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 15 of (44)

Page 16

GN-9386 User Manual

G

3. Hot connection group set up is completed, run the Reload I/O device(F4).

4. Now you can use the Hot connection feature.

Node is not overlapped between products. If there are same nodes, It should be changed.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 16 of (44)

Page 17

GN-9386 User Manual

G

3.6. I/O Process Image Map

An expansion module may have 3 types of data as I/O data, configuration parameter and memory register.

The data exchange bet wee n network adapter and ex pansio n modules is done vi a an I/O pr oces s image data

by G-Series protocol. T he following figure shows the data flow of process image between n etwork adapter

and expansion modules.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 17 of (44)

Page 18

GN-9386 User Manual

G

3.6.1. Example of Input Process Image (Input Register) Map

Input image data depends on slot position and expansion sl ot data type. Input process im age data is only

ordered by expansion slot position.

For example slot configuration

Slot Address Module Description

#0 EtherCAT Adapter

#1 8-discrete input

#2 8-discrete input

#3 4-analog input

#4 8-discrete input

#5 8-discrete input

#6 8-discrete input

#7 16-discrete input

#8 8-discrete input

• Input Process Image

TXPDO Entries Byte Bit 7 Bit 6 Bti 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x1A01 0x6010 0 Discrete Input 8 pts (Slot#1)

0x1A02 0x6020 1 Discrete Input 8 pts (Slot#2)

2 Analog Input Ch0 low byte (Slot#3)

3 Analog Input Ch0 high byte (Slot#3)

4 Analog Input Ch1 low byte (Slot#3)

0x1A03 0x6030

0x1A04 0x6040 10 Discrete Input 8 pts (Slot#4)

0x1A05 0x6050 11 Discrete Input 8 pts (Slot#5)

0x1A06 0x6060 12 Discrete Input 8 pts (Slot#6)

0x1A07 0x6070

0x1A08 0x6080 15 Discrete Input 8 pts (Slot#8)

5 Analog Input Ch1 high byte (Slot#3)

6 Analog Input Ch2 low byte (Slot#3)

7 Analog Input Ch2 high byte (Slot#3)

8 Analog Input Ch3 low byte (Slot#3)

9 Analog Input Ch3 high byte (Slot#3)

13 Discrete Input 8 pts (Slot#7)

14 Discrete Input 8 pts (Slot#7)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 18 of (44)

Page 19

GN-9386 User Manual

G

3.6.2. Example of Output Process Image (Output Register) Map

Output image data de pen d s on s lot pos i tio n and ex pans ion s lot d ata t ype. O utp ut pr oc ess image data is only

ordered by expansion slot position.

For example slot configuration

Slot Address Module Description

• Output Pr o cess Image

RXPDO Entries Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x1601 0x7010 0 Discrete Output 8 pts (Slot#1)

0x1602 0x7020 1 Discrete Output 8 pts (Slot#2)

2

3 Analog Output Ch0 high byte (Slot#3)

4 Analog Output Ch1 low byte (Slot#3)

5 Analog Output Ch1 high byte (Slot#3)

0x1603 0x7030

6 Analog Output Ch2 low byte (Slot#3)

7 Analog Output Ch2 high byte (Slot#3)

8 Analog Output Ch3 low byte (Slot#3)

9 Analog Output Ch3 high byte (Slot#3)

0x1604 0x7040 10 Discrete Output low 4 pts (Slot#4)

0x1605 0x7050 12 Discrete Output low 4 pts (Slot#5)

0x1606 0x7060 13 Discrete Output low 8 pts (Slot#6)

0x1607 0x7070 14 Discrete Output low 8 pts (Slot#7)

Analog Output Ch0 low byte (Slot#3)

#0 EtherCAT Adapter

#1 8-discrete output

#2 8-discrete output

#3 4-analog output

#4 4- relay output

#5 4-relay output

#6 8-discrete output

#7 8-discrete output

#8 4-analog output

#9 4-relay output

#10 16-discrete output

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 19 of (44)

Page 20

GN-9386 User Manual

G

15 Analog Output Ch0 low byte (Slot#8)

16 Analog Output Ch0 high byte (Slot#8)

17 Analog Output Ch1 low byte (Slot#8)

0x1608 0x7080

0x1609 0x7090 24 Discrete Output low 8 pts (Slot#9)

0x160A 0x70A0

18 Analog Output Ch1 high byte (Slot#8)

19 Analog Output Ch2 low byte (Slot#8)

20 Analog Output Ch2 high byte (Slot#8)

21 Analog Output Ch3 low byte (Slot#8)

22 Analog Output Ch3 high byte (Slot#8)

25 Discrete Output low 8 pts (Slot#10)

26 Discrete Output high 8 pts (Slot#10)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 20 of (44)

Page 21

GN-9386 User Manual

G

4. Dimension

4.1. GN-9386

(mm)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 21 of (44)

Page 22

GN-9386 User Manual

G

5. EtherCAT Basics

The EtherCAT protocol uses an officially assigned EtherType inside the Ethernet Frame. The use of this

EtherType allows transport of control data directly within the Ethernet frame without redefining the standard

Ethernet frame. The frame may consist of several sub-telegrams, each serving a particular memory area of

the logical process images that can be up to 4 gigabytes in size. Addressing of the Ethernet terminals can be

in any order because the data sequence is independent of the physical order. Broadcast, Multi-cast and

communication between slaves are possible.

5.1. EtherCAT Protocol

The EtherCAT protocol uses an officially assigned EtherType inside the Ethernet Frame. The use of this

EtherType allows transport of control data direc tly within the Ethernet f rame without redef ining the standard

Ethernet frame. T he frame m ay consist of se veral sub-telegram s, each serving a particular m emory area of

the logical process im ages that c an b e up t o 4 g iga b yt es in si ze. A ddres s in g of th e Eth er net t erminals can be

in any order because the data sequence is independent of the physical order. Broadcast, Multicast and

communication between slaves are possible.

5.2. EtherCAT State Machine

The state of the EtherCAT slave is controlled vi a the EtherCAT State Machine (ESM). Depen ding upon the

state, different functions are accessible or executable in the EtherCAT slave. Specific commands must be

sent by the EtherCAT master to the device in each state, particularly during the boot up of the slave.

A distinction is made between the following states:

• Init

• Pre-Operational

• Safe-Operational and

• Operational

• Bootstrap

The regular state of each EtherCAT slave after bootup is the OP state.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 22 of (44)

Page 23

GN-9386 User Manual

G

Init

After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible.

The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication.

Pre-Operational (Pre-Op)

During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized

correctly.

In Pre-Op state mailbox communication is possible, but not process data communication. The EtherCAT

master initializes the sync manager channels for process data (from sync manager channel 2), the FMMU

channels and, if the slave supports configurable mapping, PDO mapping or the sync manager PDO

assignment. In this state the settings for the process data transfer and perhaps terminal-specific parameters

that may differ from the default settings are also transferred.

Safe-Operational (Safe-Op)

During transition between Pre-Op and Safe-Op the EtherCAT slave checks whether the sync manager

channels for process data communication and, if required, the distributed clocks settings are correct. Before it

acknowledges the change of state, the EtherCAT slave copies current input data into the associated DP-RAM

areas of the EtherCAT slave controller (ECSC).

In Safe-Op state mailbox and process data communication is possible, although the slave keeps its outputs in

a safe state, while the input data are updated cyclically.

Operational (Op)

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output

data.

In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox

communication is possible.

Bootstrap

In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state.

In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no

other mailbox communication and no process data communication.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 23 of (44)

Page 24

GN-9386 User Manual

G

5.3. EtherCAT Mailbox

The device profiles describe the application parameters and the functional behavior of the devices including

the device class-specific state machines. For many device classes, fieldbus technology already offers reliable

device profiles, for example for I/O devices, drives or valves. Users are familiar with these profiles and the

associated parameters and tools. No EtherCAT-specific device profiles have therefore been developed for

these device classes. Instead, simple interfaces for existing device profiles are being offered (see Fig. 1).

This greatly assists users and device manufacturers alike during the migration from the existing fieldbus to

EtherCAT. At the same time the EtherCAT specification keeps it simple because all the protocols are optional.

The device manufacturer only has to implement the protocol that the device application needs.

<Fig. 1> Several Device Profiles and Protocols can co-exist side by side

CAN application layer over EtherCAT (CoE)

CANopen® device and application profiles are available for a wide range of device classes and applications,

ranging from I/O components, drives, encoders, proportional valves and hydraulic controllers to application

profiles for plastic or textile machinery, for example. EtherCAT can provide the same communication

mechanisms as the familiar CANopen [1] mechanisms: object dictionary, PDO (process data objects) and

SDO (service data objects) – even the network management is comparable. EtherCAT can thus be

implemented with minimum effort on devices equipped with CANopen. Large parts of the CANopen firmware

can be reused. Objects can optionally be expanded in order to account for the larger bandwidth offered by

EtherCAT.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 24 of (44)

Page 25

GN-9386 User Manual

G

Servo drive profile according to IEC 61800-7-204(SERCOS) (SoE)

SERCOS interfac e™ is acknowledged as a high-performance real-time communication interface, particularly

for motion control applications. The SERCOS profile for servo drives and the communication technology are

covered by the IEC 61800-7-204 standard. The mapping of this profile to EtherCAT (SoE) is specified in part

304 [2]. The service channel, and therefore access to all parameters and functions residing in the drive, is

based on the EtherCAT mailbox.

Here too, the focus is on compatibility with the existing protocol (access to value, attribute, name, units, etc.

of the IDNs) and expandability with regard to data length limitation. The process data, with SERCOS in the

form of AT and MDT data, are transferred using EtherCAT device protocol mechanisms. The mapping is

similar to the SERCOS mapping. The EtherCAT slave state machine can also be mapped easily to the

phases of the SERCOS protocol. EtherCAT provides advanced real-time Ethernet technology for this device

profile, which is particularly widespread in CNC applications. Optionally, the command position, speed or

torque can be transferred. Depending on the implementation, it is even possible to continue using the same

configuration tools for the drives.

Ethernet over EtherCAT (EoE)

The EtherCAT technology is not only fully Ethernet-compatible, but also characterized by particular openness

“by design”: the protocol tolerates other Ethernet-based services and protocols on the same physical network

– usually even with minimum loss of performance. There is no restriction on the type of Ethernet device that

can be connected within the EtherCAT segment via a switchport.

The Ethernet frames are tunneled via the EtherCAT protocol, which is the standard approach for internet

applications(e.g. VPN, PPPoE (DSL), etc.). The EtherCAT network is fully transparent for the Ethernet device,

and the real-time characteristics are not impaired (see Fig. 2).

The master acts like a layer 2 switch that redirects the frames to the respective devices according to the

address

information. All internet technologies can therefore also be used in the EtherCAT environment: integrated web

server, e-mail, FTP transfer, etc.

<Fig. 2> Transparent for all Ethernet Protocols

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 25 of (44)

Page 26

GN-9386 User Manual

G

File Access over EtherCAT (FoE)

any data structure in the device. Standardized firmware upload to devices is therefore possible, irrespective of

whether or not they support TCP/IP.

Literature

[1] EN 50325-4: Industrial communications subsystem based on ISO 11898 (CAN) for controller-device

interfaces. Part 4: CANopen.

[2] IEC 61800-7-301/304, Adjustable speed electrical power drive systems – Par t 7-301: Generic interface

and use

of profiles for power drive systems – Mapping of profile type 1 to network technologies – Part 7-304: Generic

interface and use of profiles for power drive systems – Mapping of profile type 4 to network technologies

5.4. CoE Interface

5.4.1. Parameter management in the EtherCAT system

The CiA organization (CAN in Automation) pursues among other things the goal of creating order and

exchange abilit y between devices of the same type by the standardizati on of device descriptions. For this

purpose so-called profiles are defined, which conclusively describe the changeable and unchangeable

parameters of a device. Such a parameter encompasses at least the following characteristics:

• Index number – for the unambiguous identification of all parameters. The index number is divided into

a main index and a subindex in order to mark and arrange associated parameters.

- Main index

- Subindex, offset by a colon ‘:’

• Official name – in the form of an understandable, self-descriptive text

• Specification of changeability, e.g. whether it can only be read or can also be written

• A v alue – depending upon t he parameter the value can be a text, a number or another parameter

index.

Index Range

The relevant ranges for EtherCAT fieldbus users are:

x1000 : This is where fixed identity information for the device is stored, including name, manufacturer,

serial number etc., plus information about the current and available process data configurations.

x8000 : T his is where the operational and funct ional parameters for all channels ar e stored, such as filter

settings

or output frequency.

Other important ranges are:

x4000 : In some EtherC AT devices the channe l parameters are stored her e (as an alternative to the x8000

range).

x6000 : Input PDOs ("input" from the perspective of the EtherCAT master)

x7000 : Output PDOs ("output" from the perspective of the EtherCAT master)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 26 of (44)

Page 27

GN-9386 User Manual

G

1018

10F1

1601*

1A01*

1C00

1C12

1C13

5.4.2. Communication Objects

Index Sub-index Name Flags Default value

1000 Device type RO 0x00001389

1001 Gbus Status RO Normal Operation : 0x00 **

1002 Master Fault Aaction RW 0x00

1008 Device name RO GN-9386(Crevis)

1009 Hardware version RO GN-9386.v1

100A Software version RO 1.000

Identity RO 0x05

01 Vendor ID (Crevis: 029D) RO 0x0000029D

02 Product code RO 0x4E419386

03 Revision RO 0x0001000

04* Serial number RO 0xFFFFFFFF

05 Release date RO 0x20160823

Error Settings RO 0x02

01 Local Error Reaction RO 0x00000000

02 Sync Error Counter Limit RO 0x00000004

Slot#x, GT--xxxx,RXPDO RO 0xnn

01 SubI ndex 001 RO 0x7010:01, 8

... ... ... ...

nn SubI ndex nnn RO 0x7010:nn, 8

Slot#x, GT-xxxx,TXPDO RO 0xnn

01 SubI ndex 001 RO 0x6010:01, 8

... ... ... ...

nn SubI ndex nnn RO 0x6010:nn, 8

Sync manager type RO 0x04

01 SubIndex 001 RO 0x01

02 SubI ndex 002 RO 0x02

03 SubI ndex 003 RO 0x03

04 SubI ndex 004 RO 0x04

RxPDO assign RO 0x01

01 SubI ndex 001 RO 0x1601

TxPDO assign RO 0x02

01 SubI ndex 001 RO 0x1A01

02 SubI ndex 002 RO 0x1A02

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 27 of (44)

Page 28

GN-9386 User Manual

G

7010*

8000

8nn0*

F000

F010*

F050

GT-xxxx RO 0xnn

01 Byte#0 RW P 0x00

... ... ... ...

nn Byte#nnn RW P 0x00

GN-9386(Parameter) RO

01 Byte#0 RW

02 Byte#1 RW

03 Byte#2 RW

04 Byte#3 RW

GT-xxxx(Parameter) RO

01 Byte#0 RW

... ... ... ...

nn Byte#nnn RW

Module device profile RO

01 Module index distance RO

02 Maximum numver of modules RO

Module List RO

01 Subindex 001 (GN-9386) RO 0x00009386

... ... ... ...

63 Subindex 063 RO 0x0000xxxx

Detected Module Ident List RO

01... SubIndex 001 RO

*This value can be changed depending on the configuration of expansion modules

** G-BUS Status

- Normal Operation : 0x00

- Communication Fault : 0x02

- Configuration Failed : 0x03

- No Expansion Module : 0x04

- Vendor Error : 0x07

- Not expected slot : 0x08

- CRC Error : 0x09

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 28 of (44)

Page 29

GN-9386 User Manual

G

6. MODBUS Interface

6.1. MODBUS Interface Register/Bit Map

• Register Map

Start Address Read/Write Description Func. Code

0x0000 ~ Read Process input image registers (Real Input Register) 3,4,23

0x0800 ~ Read/Write Process output image registers (Real Output Register) 3,16,23

0x1000 * Read A dapter Identification special registers. 3,4,23

0x1020 * Read/Write Adapter Watchdog, other time special register. 3,4,6,16,23

0x1100 * Read/Write Adapter Information special registers. 3,4,6,16,23

0x2000 * Read/Write Expansion Slot Information special registers. 3,4,6,16,23

* The special register map must be accessed by read/write of every each address (one address).

• Register Map

Start Address Read/Write Description Func. Code

0x0000~ Read

0x1000~ Read/Write

Process input image bits

All input registers area are addressable by bit address.

Size of input image bit is size of input image register * 16.

Process output image bits

All output registers area are addressable by bit address.

Size of output image bit is size of output image register * 16.

2

1,5,15

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 29 of (44)

Page 30

GN-9386 User Manual

G

6.2. Supported MODBUS Function Codes

Function

Code

1(0x01)

2(0x02)

Function Description

This function code is used to read from 1 to 2000 contiguous

status of coils in a remote device. The Request PDU specifies the

Read Coils

(Read output bit)

Read Discrete Inputs

(Read input bit)

starting address, i.e. the address of the first coil specified, and the

number of coils. In the PDU Coils are addressed starting at zero.

Therefore coils numbered 1-16 are addressed as 0-15. The coils

in the response message are packed as one coil per bit of the

data field. Status is indicated as 1= ON and 0= OFF.

This function code is used to read from 1 to 2000 contiguous

status of discrete inputs in a remote device. The Request PDU

specifies the starting address, i.e. the address of the first input

specified, and the number of inputs. In the PDU Discrete Inputs

are addressed starting at zero. Therefore Discrete inputs

numbered 1-16 are addressed as 0-15.

The discrete inputs in the response message are packed as one

input per bit of the data field.

Status is indicated as 1= ON; 0= OFF.

3(0x03)

4(0x04)

5(0x05)

6(0x06)

Read Holding Registers

(Read output word)

Read Input Registers

(Read input word)

Write Single Coil

(Write one bit output)

Write Single Register

(Write one word output)

This function code is used to read the contents of a contiguous

block of holding registers in a remote device. The Request PDU

specifies the starting register address and the number of

registers. The register data in the response message are packed

as two bytes per register, with the binary contents right justified

within each byte. For each register, the first byte contains the high

order bits and the second contains the low order bits.

This function code is used to read from 1 to approx. 125

contiguous input registers in a remote device. The Request PDU

specifies the starting register address and the number of

registers. The register data in the response message are packed

as two bytes per register, with the binary contents right justified

within each byte. For each register, the first byte contains the high

order bits and the second contains the low order bits.

This function code is used to write a single output to either ON or

OFF in a remote device. The requested ON/OFF state is specified

by a constant in the request data field. A value of FF 00 hex

requests the output to be ON. A value of 00 00 requests it to be

OFF. All other values are illegal and will not affect the output.

This function code is used to write a single holding register in a

remote device. Therefore register numbered 1 is addressed as 0.

The normal response is an echo of the request, returned after the

register contents have been written.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 30 of (44)

Page 31

GN-9386 User Manual

G

Diagnostics

8(0x08)

15(0x0F)

16(0x10)

(Read diagnostic register)

*Refer to the 4.2.1

Write Multiple Coils

(Write a number of

output bits)

Write Multiple registers

(Write a number of

output words)

MODBUS function code 08 provides a series of tests for checking

the communication system between a client ( Master) device and

a server ( Slave), or for checking various internal error conditions

within a server. The function uses a two–byte sub-function code

field in the query to define the type of test to be performed. The

server echoes both the function code and sub-function code in a

normal response. Some of the diagnostics cause data to be

returned from the remote device in the data field of a normal

response.

This function code is used to force each coil in a sequence of

coils to either ON or OFF in a remote device. The Request PDU

specifies the coil references to be forced. Coils are addressed

starting at zero. A logical '1' in a bit position of the field requests

the corresponding output to be ON. A logical '0' requests it to be

OFF. The normal response returns the function code, starting

address, and quantity of coils forced.

This function code is used to write a block of contiguous registers

(1 to approx. 120 registers) in a remote device.

The requested written values are specified in the request data

field. Data is packed as two bytes per register.

The normal response returns the function code, starting address,

and quantity of registers written.

Read a number of input words /Write a number of output words

This function code performs a combination of one read operation

and one write operation in a single MODBUS trans ac ti on. The

Read/Write Multiple registers

(Read a number of

23(0x17)

- Refer to MODBUS APPLICATION PROTOCOL SPECIFICATION V1.1a

input words

/Write a number of

output words)

write operation is performed before the read. The request

specifies the starting address and number of holding registers to

be read as well as the starting address, number of holding

registers, and the data to be written. The byte count specifies the

number of bytes to follow in the write data field.

The normal response contains the data from the group of

registers that were read. The byte count field specifies the

quantity of bytes to follow in the read data field.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 31 of (44)

Page 32

GN-9386 User Manual

G

Sub-function

Data Field (Request)

Data Field (Response)

Description

Sub-function

Data Field (Request)

Data Field (Response)

Description

Sub-function

Data Field (Request)

Data Field (Response)

Description

Sub-function

Data Field (Request)

Data Field (Response)

Description

Sub-function

Data Field (Request)

Data Field (Response)

Description

6.2.1. 8 (0x08) Diagnostics

Sub-function 0x0000(0) Return Query Data

The data passed in the request data field is to be returned (looped back) in the response.

The entire response message should be identical to the request.

0x0000(0) Any Echo Request Data

Sub-function 0x0001(1) Restart Communications Option

The remote device could be initialized and restarted, and all of its communications event counters are

cleared.

Especially, data field 0x55AA make the remote device to restart with factory default setup of EEPROM.

Sub-function Data Field (Request) Data Field (Response) Description

0x0001(1) 0x0000 or 0xFF00 Echo Request Data Reset

0x0001(1) 0x55AA+0xAA55+Sumcheck Echo Request Data Reset with Factory

Sub-function 0x000B(11) Return Bus Message Count

The response data field returns the quantity of messages that the remote device has detected on the

communications system since its last restart, clear counters operation, or power–up.

0x000B(11) 0x0000 Total Message Count

Sub-function 0x000C(12) Return Bus Communication Error Count

The response data field returns the quantity of CRC errors encountered by the remote device since its last

restart, clear counters operation, or power–up.

0x000C(11) 0x0000 CRC Error Count

Sub-function 0x000D(13) Return Bus Exception Error Count

The response data field returns the quantity of MODBUS exception responses returned by the remote device

since its last restart, clear counters operation, or power–up.

Exception responses are described and listed in section 3.2.11.

0x000D(13) 0x0000 Exception Error Count

Sub-function 0x000E(14) Return Slave Message Count

The response data field returns the quantity of messages addressed to the remote device, or broadcast, that

the remote device has processed since its last restart, clear counters operation, or power–up.

0x000E(14) 0x0000 Slave Message Count

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 32 of (44)

Page 33

GN-9386 User Manual

G

Sub-function

Data Field (Request)

Data Field (Response)

Description

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0064(100)

0x0000

ModBus, Internal Bus Status

Same as status 1word

Sub-function 0x000F(15) Return Slave No Response Count

The response data field returns the quantity of messages addressed to the remote device for which it has

returned no response (neither a normal response nor an exception response), since its last restart, clear

counters operation, or power–up.

0x000F(15) 0x0000 Slave No Response Count

Sub-function 0x0064(100) Return Slave ModBus, G-Series internal bus Status

The response data field returns the status of ModBus and Internal Bus addressed to the remote device.

This status values are identical with status 1word of input process image. Refer to 2.4.2.

6.2.2. Error Response

In an exception response, the server sets the MSB of the function code to 1. This makes the function code

value in an exception response exactly 80 hexadecimal higher than the value would be for a normal response.

• Exception Codes

Exception

Code

Name Description

01 Illegal Function

02 Illegal Data Address

03 Illegal Data Value

04 Slave Device Failur e

05 Acknowledge

06 Slave Device Busy

08 Memory Parity Error

0A

Gateway Path

Unavailable

The function code received in the query is not an allowable action for

the server (or slave).

The data address received in the query is not an allowable address

for the server (or slave).

A value contained in the query data field is not an allowable value for

server (or slave).

An unrecoverable error occurred while the server (or slave) was

attempting to perform the requested action.

The server (or slave) has accepted the request and is proc es sing it,

but a long duration of time will be required to do so.

Specialized use in conjunction with programming commands.

The server (or slave) is engaged in processing a long–duration

program command. The client (or master) should retransmit the

message later when the server (or slave) is free.

The server (or slave) attempted to read record file, but detected a

parity error in the memory. The client (or master) can retry the

request, but service may be required on the server (or slave) device.

Specialized use in conjunction with gateways, indicates that the

gateway was unable to allocate an internal communication path from

the input port to the output port for processing the request.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 33 of (44)

Page 34

GN-9386 User Manual

G

6.3. MODBUS Special Register Map

The special register map can be accessed by function code 3, 4, 6 and 16. Also the special register map must

be accessed by read/write of every each address (one address).

6.3.1. Adapter Identification Special Register (0x1000, 4096)

Address Access Type, Size Description

0x1000(4096) Read 1word Vendor ID = 0x029D(669), Crevis. Co., Ltd.

0x1001(4097) Read 1word Device type = 0x000C, Network Adapter

0x1002(4098) Read 1word Product Code = 0x9010

0x1003(4099) Read 1word Firmware revision, if 0x0100, revision 1.00

0x1004(4100) Read 2word Product unique serial number

0x1005(4101) Read

0x1006(4102) Read 1word Sum check of EEPROM

0x1010(4112) Read 2word Firmware release date

String Product name string (ASCII)

up to 36byte “GN-9386,EtherCAT ID Type,G-Series”

7word Composite Id of following address

- 1word 0x1100(4352), Modbus RS232 Node. (Fixed 0x0001)

- 1word 0x1000(4096), Vendor ID

0x101E(4126) Read

- String Type consists of valid string length (first 1word) and array of characters.

- 1word 0x1001(4097), Device type

- 1word 0x1002(4098), Product code

- 1word 0x1003(4099), Firmware revision

- 2word 0x1004(4100), Product serial number

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 34 of (44)

Page 35

GN-9386 User Manual

G

6.3.2. Adapter Information Special Register (0x1100, 4352)

Address Access Type, Size Description

Master fault action option.

- 0x00 : Normal option

- 0x01 : Master fault action

0x1100(4352) Read/Write 1word

0x1102(4354) Read 1word Start address of input image word register . = 0x000 0

0x1103(4355) Read 1word Start address of output image word reg is ter. =0x 08 00

0x1104(4356) Read 1word Size of input image word register.

0x1105(4357) Read 1word Size of output image word register.

0x1106(4358) Read 1word Start address of input image bit. = 0x0000

0x1107(4359) Read 1word Start address of output image bit. =0x1000

This option can enable Master fault action option.

With master fault action, fault action can be activated with

master communication failure. Also, can activate hold last

state as IO parameter.

0x1108(4360) Read 1word Size of input image bit.

0x1109(4361) Read 1word Size of output image bit.

0x110D(4365) Read 1word

0x110E(4366) Read up to 33word

0x1110(4368) Read 1word Number of expansion slot

- After the system is reset, the new “Set Value” action is applied.

Current Dip Switch Value and Field Power Status (MSB)

ex) Field Power ON, Dip Switch 0x03 = 0x8003

Expansion slot’s GT-number including GN

First 1word is adapter’s number, if GN-9386, then 0x9386

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 35 of (44)

Page 36

GN-9386 User Manual

G

6.3.3. Expansion Slot Information Special Resister (0x2000, 8192)

Each expansion slot has 0x20(32) address offset and same information structure.

Slot#1 0x2000(8192)~0x201F(8223) Slot#2 0x2020(8224)~0x203F(8255)

Slot#3 0x2040(8256)~0x205F(8287) Slot#4 0x2060(8288)~0x207F(8319)

Slot#5 0x2080(8320)~0x209F(8351) Slot#6 0x20A0(8352)~0x20BF(8383)

Slot#7 0x20C0(8384)~0x20DF(8415) Slot#8 0x20E0(8416)~0x20FF(8447)

Slot#9 0x2100(8448)~0x211F(8479) Slot#10 0x2120(8480)~0x213F(8511)

Slot#11 0x2140(8512)~0x215F(8543) Slot#12 0x2160(8544)~0x217F(8575)

Slot#13 0x2180(8576)~0x219F(8607) Slot#14 0x21A0(8608)~0x21BF(8639)

Slot#15 0x21C0(8640)~0x21DF(8671) Slot#16 0x21E0(8672)~0x21FF(8703)

Slot#17 0x2200(8704)~0x221F(8735) Slot#18 0x2220(8736)~0x223F(8767)

Slot#19 0x2240(8768)~0x225F(8799) Slot#20 0x2260(8800)~0x227F(8831)

Slot#21 0x2280(8832)~0x229F(8863) Slot#22 0x22A0(8864)~0x22BF(8895)

Slot#23 0x22C0(8896)~0x22DF(8927) Slot#24 0x22E0(8928)~0x22FF(8959)

Slot#25 0x2300(8960)~0x231F(8991) Slot#26 0x2320(8992)~0x233F(9023)

Slot#27 0x2340(9024)~0x235F(9055) Slot#28 0x2360(9056)~0x237F(9087)

Slot#29 0x2380(9088)~0x239F(9119) Slot#30 0x23A0(9120)~0x23BF(9151)

Slot#31 0x23C0(9152)~0x23DF(9183) Slot#32 0x23E0(9184)~0x23FF(9215)

Slot#33 0x2400(9216)~0x241F(9247) Slot#34 0x2420(9248)~0x243F(9279)

…..

Slot#63 0x27C0(10176)~0x27DF(10207)

Address Expansion Expansion Expansion Expansion

……..

Offset Slot#1 Slot#2 Slot#3 Slot#4 Slot#63

+ 0x00(+0) 0x2000(8192) 0x2020(8224) 0x2040(8256) 0x2060(8288) ……. 0x27C0(10176)

Expansion

+ 0x01(+1) 0x2001(8193) 0x2021(8225) 0x2041(8257) 0x2061(8289) ……. 0x27C1(10177)

+ 0x02(+2) 0x2002(8194) 0x2022(8226) 0x2042(8258) 0x2062(8290) ……. 0x27C2(10178)

+ 0x03(+3) 0x2003(8195) 0x2023(8227) 0x2043(8259) 0x2063(8291) ……. 0x27C3(10179)

+ 0x04(+4) 0x2004(8196) 0x2024(8228) 0x2044(8260) 0x2064(8292) ……. 0x27C4(10180)

+ 0x05(+5) 0x2005(8197) 0x2025(8229) 0x2045(8261) 0x2065(8293) ……. 0x27C5(10181)

+ 0x06(+6) 0x2006(8198) 0x2026(8230) 0x2046(8262) 0x2066(8294) ……. 0x27C6(10182)

+ 0x07(+7) 0x2007(8199) 0x2027(8231) 0x2047(8263) 0x2067(8295) ……. 0x27C7(10183)

+ 0x08(+8) 0x2008(8200) 0x2028(8232) 0x2048(8264) 0x2068(8296) ……. 0x27C8(10184)

+ 0x09(+9) 0x2009(8201) 0x2029(8233) 0x2049(8265) 0x2069(8297) ……. 0x27C9(10185)

+ 0x0A(+10) 0x200A(8202) 0x202A(8234) 0x204A(8266) 0x206A(8298) ……. 0x27CA(10186)

+ 0x0B(+11) 0x200B(8203) 0x202B(8235) 0x204B(8267) 0x206B(8299) ……. 0x27CB(10187)

+ 0x0C(+12) 0x200C(8204) 0x202C(8236) 0x204C(8268) 0x206C(8300) ……. 0x27CC(10188)

+ 0x0D(+13) 0x200D(8205) 0x202D(8237) 0x204D(8269) 0x206D(8301) ……. 0x27CD(10189)

+ 0x0E(+14) 0x200E(8206) 0x202E(8238) 0x204E(8270) 0x206E(8302) ……. 0x27CE(10190)

+ 0x0F(+15) 0x200F(8207) 0x202F(8239) 0x204F(8271) 0x206F(8303) ……. 0x27CF(10191)

+ 0x10(+16) 0x2010(8208) 0x2030(8240) 0x2050(8272) 0x2070(8304) ……. 0x27D0(10192)

+ 0x11(+17) 0x2011(8209) 0x2031(8241) 0x2051(8273) 0x2071(8305) ……. 0x27D1(10193)

+ 0x12(+18) 0x2012(8210) 0x2032(8242) 0x2052(8274) 0x2072(8306) ……. 0x27D2(10194)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 36 of (44)

Page 37

GN-9386 User Manual

G

+ 0x13(+19) 0x2013(8211) 0x2033(8243) 0x2053(8275) 0x2073(8307) ……. 0x27D3(10195)

+ 0x14(+20) 0x2014(8212) 0x2034(8244) 0x2054(8276) 0x2074(8308) ……. 0x27D4(10196)

+ 0x15(+21) 0x2015(8213) 0x2035(8245) 0x2055(8277) 0x2075(8309) ……. 0x27D5(10197)

+ 0x16(+22) 0x2016(8214) 0x2036(8246) 0x2056(8278) 0x2076(8310) ……. 0x27D6(10198)

+ 0x17(+23) 0x2017(8215) 0x2037(8247) 0x2057(8279) 0x2077(8311) ……. 0x27D7(10199)

+ 0x18(+24) 0x2018(8216) 0x2038(8248) 0x2058(8280) 0x2078(8312) ……. 0x27D8(10200)

+ 0x19(+25) 0x2018(8217) 0x2038(8249) 0x2058(8281) 0x2078(8313) ……. 0x27D9(10201)

+ 0x1A(+26) 0x201A(8218) 0x203A(8250) 0x205A(8282) 0x207A(8314) ……. 0x27DA(10202)

+ 0x1B(+27) 0x201B(8219) 0x203B(8251) 0x205B(8283) 0x207B(8315) ……. 0x27DB(10203)

+ 0x1C(+28) 0x201C(8220) 0x203C(8252) 0x205C(8284) 0x207C(8316) ……. 0x27DC(10204)

+ 0x1D(+29) 0x201D(8221) 0x203D(8253) 0x205D(8285) 0x207D(8317) ……. 0x27DD(10205)

+ 0x1E(+30) 0x201E(8222) 0x203E(8254) 0x205E(8286) 0x207E(8318) ……. 0x27DE(10206)

+ 0x1F(+31) 0x201F(8223) 0x203F(8255) 0x205F(8287) 0x207F(8319) ……. 0x27DF(10207)

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 37 of (44)

Page 38

GN-9386 User Manual

G

Address Offset Access Type, Size Description

+ 0x02(+2) ** Read 1word Input start register address of input image word this slot.

+ 0x03(+3) ** Read 1word Input word’s bit offset of input image word this slot.

+ 0x04(+4) ** Read 1word Output start register address of output image word this slot.

+ 0x05(+5) ** Read 1word Output word’s bit offset of output image word this sl ot.

+ 0x06(+6) ** Read 1word Input bit start address of input image bit this slot.

+ 0x07(+7) ** Read 1word Output bit start address of output image bit this slot.

+ 0x08(+8) ** Read 1word Size of input bit this slot

+ 0x09(+9) ** Read 1word Size of output bit this slot

+ 0x0A(+10)** Read n word Read input data this slot

+ 0x0B(+11)** Read/Write n word Read/write output data this slot

+ 0x0E(+14) Read 1word GT-number, if GT-1238, returns 0x1238

String First 1word is length of valid character string.

up to 74byte If GT-1238, returns

+ 0x0F(+15) Read

+ 0x10(+16) Read 1word Size of configuration parameter byte

+ 0x11(+17)** Read/Write n word

+ 0x17(+23) Read 2word

+ 0x19(+25) Read 2word Firmware release date.

* After the system is reset, the new “Set Value” action is applied.

** Nothing of output, input, memory or configuration parameter corresponding slot returns Exception 02.

Valid character size = 0x001E =30 characters,

“GT-1238, 8DI, 24Vdc, Universal”

“00 1E 52 54 2D 31 32 33 38 2C 20 38 44 49 2C 20 32 34 56 64 63

2C 20 55 6E 69 76 65 72 73 61 6C 00 00”

Read/write Configuration parameter data, up to 8byte. Refer to A.2

***

Firmware Revision

ex) 0x00010010 (Major revision 1 / Minor revision 1, Rev 1.001)

6.4. Supported MODBUS Function Code s

MODBUS Reference Documents

http://www.modbus.org

MODBUS Tools

http://www.modbustools.com

http://www.win-tech.com, modscan32

, modbus poll

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 38 of (44)

Page 39

GN-9386 User Manual

G

All LED turns off

- No power

- Check main power Cable

- Contact Sales team and send module

for repair.

ERROR LED blinking red

- Invalid Configuration

- Check I/O size configuration

IOS LED turns off

- Device may not be powered.

- Check main power Cable

IOS LED flashes red

- Adapter has no expansion module

- Add one or more expansion modules.

One or more expansion module

- Check main power Cable

for repair.

- Check main power Cable

for repair.

7. TROUBLE SHOOTING

How to diagnose by LED indicator

LED Status Cause Action

MOD LED is red - Occurrence critical error in firmware

occurred in fault state.

IOS LED is red

- Detected invalid expansion module ID.

- Overflowed Input/Output Size

- Too many expansion module

- Initialization failure

- Communication failure.

- Changed expansion module

configuration.

- Mismatch vendor code between

adapter and expansion module.

- Use expansion slot up to 63.

- Compose that IO total size is not

excess.

- Check status of expansion IO

connection.

- Check the vendor code of module.

Field Power LED

turns off

System Power LED

turns off

- Field power is not supplied.

- System power is not supplied.

- Contact Sales team and send module

- Contact Sales team and send module

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 39 of (44)

Page 40

GN-9386 User Manual

G

How to diagnose when device couldn’t communicate network

Inspection of wrong or omission cable connection

- Check status of cable connection for each node.

- Check that all color matches between connector and cable.

- Check wire omission.

Terminator resistor

- If terminator resistor is not installed, install terminator resistor

- Check location of terminator resistor

Configuration of Node address

- Check duplication node address.

Configuration of Master

- Check configuration of master

- Check whether to do download or don’t

- Check composition is right as below Configuration of communication baud rate I/O size

Configuration of each nod e

Ground and environment

- Check ground is contacted

- Check environment factor (temperature, humidity, etc.) is in less than regular limit

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 40 of (44)

Page 41

GN-9386 User Manual

G

No.

GT-Number

Description

ID(hex)

Digital Input Module

1

GT-1238

8 Points, Universal, 24Vdc, 10RTB

1238

2

GT-123F

16 Points, Universal, 24Vdc, 20P connector

123F

3

GT-12DF

16 Points, Universal, 24Vdc, 18RTB

12DF

4

GT-12FA

32 Points, Universal, 24Vdc, 40P connector

12FA

5

GT-1804

4 Points, 120Vac, 10RTB

1804

6

GT-1904

4 Points, 240Vac, 10RTB

1904

Digital Output Module

7

GT-2318

8 Points, Sink, 24Vdc/0.5A, 10RTB

2318

8

GT-2328

8 Points, Source, 24Vdc/0.5A, 10RTB

2328

9

GT-221F

16 Points, Sink, 24Vdc/0.3A, 20P connector

221F

10

GT-222F

16 Points, Source, 24Vdc/0.3A, 20P connector

222F

11

GT-225F

16 Points, Sink, 24Vdc/0.3A, 18RTB

225F

12

GT-226F

16 Points, Source, 24Vdc/0.3A, 18RTB

226F

13

GT-22BA

32 Points, Sink, 24Vdc/0.3A, 40P connector

22BA

14

GT-22CA

32 Points, Source, 24Vdc/0.3A, 40P connector

22CA

15

GT-2618

8 Points, Sink, 24Vdc/2A, 10RTB

2618

16

GT-2628

8 Points, Source, 24Vdc/2A, 10RTB

2628

17

GT-2734

4 Points, MOS Relay, 240Vdc/ac, 0.5A, 10RTB

2734

18

GT-2744

4 Points, Relay, 24Vdc/2A, 240Vac/2A, 10RTB

2744

19

GT-2764

4 Points, MOS Relay, 24Vdc/ac, 2A, 10RTB

2764

20

GT-2784

4 Points, MOS Relay, 110Vdc/ac, 1A, 10RTB

2784

Analog Input Module

21

GT-3001

LoadCell (TBD)

3001

22

GT-3114

4 Channels, 0~20, 4~20mA, 12bits, 10RTB

3114

23

GT-3154

4 Channels, 0~20, 4~20mA, 16bits, 10RTB

3154

24

GT-3118

8 Channels, 0~20, 4~20mA, 12bits, 10RTB

3118

25

GT-3158

8 Channels, 0~20, 4~20mA, 16bits, 10RTB

3158

26

GT-311F

16 Channels, 0~20, 4~20mA, 12bits, 20P connector

311F

27

GT-315F

16 Channels, 0~20, 4~20mA, 16bits, 20P connector

315F

28

GT-317F

16 Channels, 0~20, 4~20mA, 12bits, 18RTB

317F

29

GT-319F

16 Channels, 0~20, 4~20mA, 16bits, 18RTB

319F

30

GT-3424

4 Channels, 0~10, 0~5, 1~5Vdc, 12bits, 10RTB

3424

31

GT-3464

4 Channels, 0~10, 0~5, 1~5Vdc, 16bits, 10RTB

3464

32

GT-3428

8 Channels, 0~10, 0~5, 1~5Vdc, 12bits, 10RTB

3428

33

GT-3468

8 Channels, 0~10, 0~5, 1~5Vdc, 16bits, 10RTB

3468

34

GT-342F

16 Channels, 0~10, 0~5, 1~5Vdc, 12bits, 20P connector

342F

35

GT-346F

16 Channels, 0~10, 0~5, 1~5Vdc, 16bits, 20P connector

346F

36

GT-347F

16 Channels, 0~10, 0~5, 1~5Vdc, 12bits, 18RTB

347F

37

GT-349F

16 Channels, 0~10, 0~5, 1~5Vdc, 16bits, 18RTB

349F

38

GT-3704

4 Channels, RTD, 10RTB

3704

39

GT-3708

8 Channels, RTD, 20P connector

3708

APPENDIX A

A.1. Product List

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 41 of (44)

Page 42

GN-9386 User Manual

G

40

GT-3804

4 Channels, Thermocouple, 10RTB

3804

41

GT-3808

8 Channels, Thermocouple, 20P connector

3808

42

GT-3901

AC Measurement

3901

43

GT-3914

4 Channels, Differential, 0~20, 4~20, +/-20mA, 12Bits, 10RTB

3914

44

GT-3934

4 Channels, Differential, 0~20, 4~20, +/-20mA, 16Bits, 10RTB

3934

45

GT-3918

8 Channels, Differential, 0~20, 4~20, +/-20mA, 12Bits, 18RTB

3918

46

GT-3938

8 Channels, Differential, 0~20, 4~20, +/-20mA, 16Bits, 18RTB

3938

47

GT-3924

4 Channels, Differential, 0~5, 0~10, +/-5, +/-10Vdc, 12B its, 10RTB

3924

48

GT-3944

4 Channels, Differential, 0~5, 0~10, +/-5, +/-10Vdc, 16B its, 10RTB

3944

49

GT-3928

8 Channels, Differential, 0~5, 0~10, +/-5, +/-10Vdc, 12B its, 18RTB

3928

50

GT-3948

8 Channels, Differential, 0~5, 0~10, +/-5, +/-10Vdc, 16B its, 18RTB

3948

Analog Output Module

51

GT-4114

4CH, 0~20mA, 12Bits, 10RTB

4114

52

GT-4154

4CH, 0~20mA, 16Bits, 10RTB

4154

53

GT-4118

8CH, 0~20mA, 12Bits, 10RTB

4118

54

GT-4158

8CH, 0~20mA, 16Bits, 10RTB

4158

55

GT-4424

4CH, 0~10Vdc, 12Bits, 10RTB

4424

56

GT-4464

4CH, 0~10Vdc, 16Bits, 10RTB

4464

57

GT-4428

8CH, 0~10Vdc, 12Bits, 10RTB

4428

58

GT-4468

8CH, 0~10Vdc, 16Bits, 10RTB

4468

59

GT-417F

16CH, 0~20mA, 12Bits, 18RTB

417F

60

GT-419F

16CH, 0~20mA, 16Bits, 18RTB

419F

61

GT-442F

16CH, 0~10Vdc, 12Bits, 20P Connector

442F

62

GT-446F

6CH, 0~10Vdc, 16Bits, 20P Connector

446F

63

GT-447F

16CH, 0~10Vdc, 12Bits, 18RTB

447F

64

GT-449F

16CH, 0~10Vdc, 16Bits, 18RTB

449F

Special Module

65

GT-5102

2CH, Encoder, Input, 5Vdc, 10RTB

5102

66

GT-5211

1CH, RS 232, RTS/CTS, Full Duplex Type, 10RTB

5211

67

GT-5212

2CH, RS 232, Full Duplex Type, 10RTB

5212

68

GT-5221

1CH, RS 485, Full Duplex Type, 10RTB

5221

69

GT-5231

1CH, RS 485, Half Full Duplex Type, 10RTB

5231

70

GT-5232

2CH, RS 485, Half Full Duplex Type, 10RTB

5232

71

GT-5352

2CH, Synchronous Serial Interface Input, 10RTB

5352

72

GT-5521

1CH, Stepper Module (TBD)

5521

Power Module

73

GT-7408

Shield Module

7408

74

GT-7508

Common for 0Vdc

7508

75

GT-7511

Power Expansion, In 24Vdc, Out 1A/5Vdc

7511

76

GT-7518

Common for 24Vdc

7518

77

GT-7588

Common for 0Vdc, 24Vdc

7588

78

GT-7641

Field Power, 5/24/48 Vdc, 110/220 Vac

7641

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 42 of (44)

Page 43

GN-9386 User Manual

G

A.2. Glossary

- System Power : The power for starting up CPU.

- Field Power : The power for input and output line.

- Terminator Resistor : Resistor for prevention reflected wave.

- EDS : Electronic Data Sheet.

- Sink : The method of in/output power supply if a device has no power source.

- Source : The method of in/output power supply if a device has the power source.

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 43 of (44)

Page 44

GN-9386 User Manual

G

Head office

Beijer Electronics AB

Box 426

20124 Malmö, Sweden

Phone +46 40 358600

www.beijerelectronics.com

-series GN-9386 EtherCAT Rev. 1.01.docx

Page 44 of (44)

Loading...

Loading...