Page 1

G

CANopen network adapter

GN-9261

User manual

-series GN-9261 CANopen Rev. 1.01.docx

Page 1 of (52)

Page 2

GN-9261 User Manual

G

REV.

PAGES

REMARKS

DATE

Editor

1.00

New Document

2018/7/30

1.01

First release

2019/01/29

NJL

DOCUMENT CHANGE SUMMARY

-series GN-9261 CANopen Rev. 1.01.docx

Page 2 of (52)

Page 3

GN-9261 User Manual

G

Contents

1. Important Notes ............................................................................................................................................................. 5

1.1.1 Symbols.............................................................................................................................................................. 6

1.1.2 Safety Notes .................................................................................................................................................... 6

1.1.3 Certification ..................................................................................................................................................... 6

3.1 GN-9261 Specification ........................................................................................................................................ 8

3.2 GN-9261 Wiring Diagram ..................................................................................................................................... 9

3.3 GN-9261 LED Indicator ....................................................................................................................................... 10

3.3.1 LED Indicator................................................................................................................................................. 10

3.3.2 MOD(Module Status LED) ...................................................................................................................... 10

3.3.3 RUN(Module Status LED) ....................................................................................................................... 10

3.3.4 ERROR(CANopen Error LED)................................................................................................................. 10

3.3.6 Field Power, System Power LED(Field Power, System Power Status LED) ................... 11

3.3.7 Indicator states and flash rates .......................................................................................................... 11

3.4. GN-9261 Electrical Interface ............................................................................................................................ 12

3.4.1 5pin Open Connector ............................................................................................................................... 12

3.4.2 Dip Switch ...................................................................................................................................................... 12

3.4.4 RS232 Port for MODBUS/RTU, Touch Panel or I/O Guide .................................................. 13

4. Dimension ........................................................................................................................................................................ 14

4.1 GN-9261 .................................................................................................................................................................... 14

5. Communication .............................................................................................................................................................. 15

5.1 Device Model

......................................................................................................................................................... 15

5.1.1 Structure of the device model ............................................................................................................ 15

5.2 PDO (Process Data) ........................................................................................................................................... 15

5.2.1 Introduction ................................................................................................................................................... 15

5.2.2 PDO Mapping ............................................................................................................................................... 16

5.2.3 PDO Identifier .............................................................................................................................................. 16

5.2.4 PDO Communication Type .................................................................................................................... 17

-series GN-9261 CANopen Rev. 1.01.docx

Page 3 of (52)

Page 4

GN-9261 User Manual

G

5.3 SDO (Service Data) ............................................................................................................................................. 19

5.3.1 Introduction ................................................................................................................................................... 19

5.4 Emergency (Error Message) .......................................................................................................................... 20

5.5 NMT (Network Management) ......................................................................................................................... 20

5.5.1 Network Start-up ........................................................................................................................................ 20

5.5.2 Boot-up Message ....................................................................................................................................... 21

5.5.3 Node Guarding ............................................................................................................................................ 21

5.5.4 Life Guarding ................................................................................................................................................ 23

6. Object Directory ............................................................................................................................................................. 26

6.1 Communication Profile Area ......................................................................................................................... 26

6.2. Manufacturer Specific Profile Area ........................................................................................................... 33

6.3 Standard Device Profile Area – DS401 ..................................................................................................... 35

7. MODBUS Interface ....................................................................................................................................................... 39

7.1 MODBUS Interface Register/Bit Map......................................................................................................... 39

7.2 Supported MODBUS Function Codes ...................................................................................................... 39

7.2.1 8(0x08)Diagnostics .................................................................................................................................... 40

7.2.2 Error Response ............................................................................................................................................. 41

7.3 MODBUS Special Register Map ..................................................................................................... 42

7.3.1 Adapter Identification Special Register (0x1000, 4096) ....................................................... 42

7.3.3 Expansion Slot Information Special Register (0x2000, 8192)....................................... 43

APPENDIX A .................................................................................................................................................................. 48

A.1 Pr oduct List ........................................................................................................................................................... 48

A.2 Glossary .................................................................................................................................................................. 50

APPENDIX B .................................................................................................................................................................. 51

-series GN-9261 CANopen Rev. 1.01.docx

Page 4 of (52)

Page 5

GN-9261 User Manual

G

Warning!

Caution!

1. Important Notes

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls describes some

important differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also becaus e of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves that each intended application of

this equipment is acceptable.

In no event will CREVIS be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, CREVIS cannot assume responsibility

or liability for actual use based on the examples and diagrams.

If you don’t follow the directions, it could cause a personal injury, damage to the equipment or

explosion

Do not assemble the products and wire with power applied to the system. Else it may cause an electric

arc, which can result into unexpected and potentially dangerous action by field devices. Arching is

explosion risk in hazardous locations. Be sure that the area is non-hazardous or remove system power

appropriately before assembling or wiring the modules.

Do not touch any terminal blocks or IO modules when system is running. Else it may cause the unit to

an electric shock or malfunction.

Keep away from the strange metallic materials not related to the unit and wiring works should be

controlled by the electric expert engineer. Else it may cause the unit to a fire, electric shock or

malfunction.

If you disobey the instructions, there may be possibility of personal injury, damage to equipment

or explosion. Please follow below Instructions.

Check the rated voltage and terminal array before wiring. Avoid the circumstances over 55℃ of

temperature. Avoid placing it directly in the sunlight.

Avoid the place under circumstances over 85% of humidity.

Do not place Modules near by the inflammable material. Else it may cause a fire.

Do not permit any vibration approaching it directly.

Go through module specification carefully, ensure inputs, output connections are made with the

specifications. Use standard cables for wiring.

Use Product under pollution degree 2 environment.

-series GN-9261 CANopen Rev. 1.01.docx

Page 5 of (52)

Page 6

GN-9261 User Manual

G

1.1. Safety Instruction

1.1.1 Symbols

Identifies information about practices or circumstances that can cause an explosion

in a hazardous environment, which may lead to personal injury

or death property damage, or economic loss

Identifies information that is critical for successful application and understanding of

the product

Identifies information about practices or circumstances that can lead to personal

injury, property damage, or economic loss.

Attentions help you to identity a hazard, avoid a hazard, and recognize

the consequences

1.1.2 Safety Notes

The modules are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the modules, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, G-BUS Pin.

1.1.3 Certification

c-UL-us UL Listed Industrial Control Equipment, certified for U.S. and Canada

See UL File E235505

FCC, Reach, RoHS- II, China RoHS

CE Certificate

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

-series GN-9261 CANopen Rev. 1.01.docx

Page 6 of (52)

Page 7

GN-9261 User Manual

G

Environment Specification

Operating T emperature

-40℃~70℃

UL Temperature

-20℃~60℃

Storage T e mperature

-40℃~85℃

Relative Humidity

5% ~ 90% non-condensing

Operating Altitude

2000m

Mounting

DIN rail

General Specification

Shock Operating

IEC 60068-2-6

Vibration resistance

Based on IEC 60068-2-6

Test time : 1hrs for each test

EMC resistance burst/ESD

EN 61000-6-2 : 2005

EN 61000-6-4/ALL : 2011

Installation Pos. / Protect. Class

Vertical and horizontal installation is available.

Product Certifications

CE, UL

2. Environment Specification

Sine Vibration

5 ~ 25Hz : 1.6mm

25 ~ 300Hz : 4g

Sweep Rate : 1 Oct/min, 20 cycles

Random Vibration

10 ~ 40Hz : 0.0125g²/Hz

40 ~ 100Hz : 0.0125 → 0.002g²/Hz

100 ~ 500Hz : 0.002g²/Hz

500 ~ 2000Hz : 0.002 → 1.3 x 10-⁴g²/Hz

-series GN-9261 CANopen Rev. 1.01.docx

Page 7 of (52)

Page 8

GN-9261 User Manual

G

Interface Specifications, GN-9261

Adapter Type

Slave node (CANopen, CiA 301)

Max. PDO Number

32 TPDO / 32 RPDO

Max. SDO Number

1 Standard SDOs

PDO Mapping Method

Auto Mapping : CiA 301 (default), Sequential

Max. Expansion Module

63 slots

Max. Input size

252 bytes

Max. Output size

252 bytes

Nodes

1~99

Baudrate

10, 20, 50, 100, 125, 250, 500, 800, 1000 Kbps(default 1000Kbps)

Interface Connector

5pin Open Connector

Other Serial Port

RS232 for MODBUS/RTU(Touch Panel, I/O Guide ...)

Serial Configuration (RS232)

Node : 1 (Fixed)

Stop bit : 1 (Fixed)

Indicator

6 LEDs

1 Green, Field Power Status

Module Location

Starter module left side of G-Series system

Field Power Detection

About 14Vdc

General Specification

System Power

Supply voltage : 24Vdc nominal

Reverse polarity protection

Power dissipation

70mA typical @ 24Vdc

Current for I/O module

1.5A @ 5Vdc

Isolation

System power to internal logic : Non-isolation

System power I/O driver : Isolation

Field Power

Supply voltage : 24Vdc typical(Max. 32Vdc)

Refer to IO Module`s Specification.

Max. Current Field Power Contact

DC 10A Max

Weight

162g

Module Size

54mm x 99mm x 70mm

Environment Condition

Refer to ‘2. Environment Specification’

3. General Description

3.1 GN-9261 Specification

Manual Mapping (Reference to Index : 0x20F0, Sub Index : 6)

Baud Rate : 115200 (Fixed)

Data bit : 8 (Fixed)

Parity bit : No parity (Fixed)

1 Green/Red, Module Status (MOD)

1 Green, Network Status(RUN)

1 Red, Error Status (ERROR)

1 Green/Red, Expansion I/O Module Status (IOS)

1 Green, System Power Status

Supply voltage range : 15~32Vdc

Protection : Output current limit (Min. 1.5A)

* Field Power Range is different depending on IO Module series.

-series GN-9261 CANopen Rev. 1.01.docx

Page 8 of (52)

Page 9

GN-9261 User Manual

G

3.2 GN-9261 Wiring Diagram

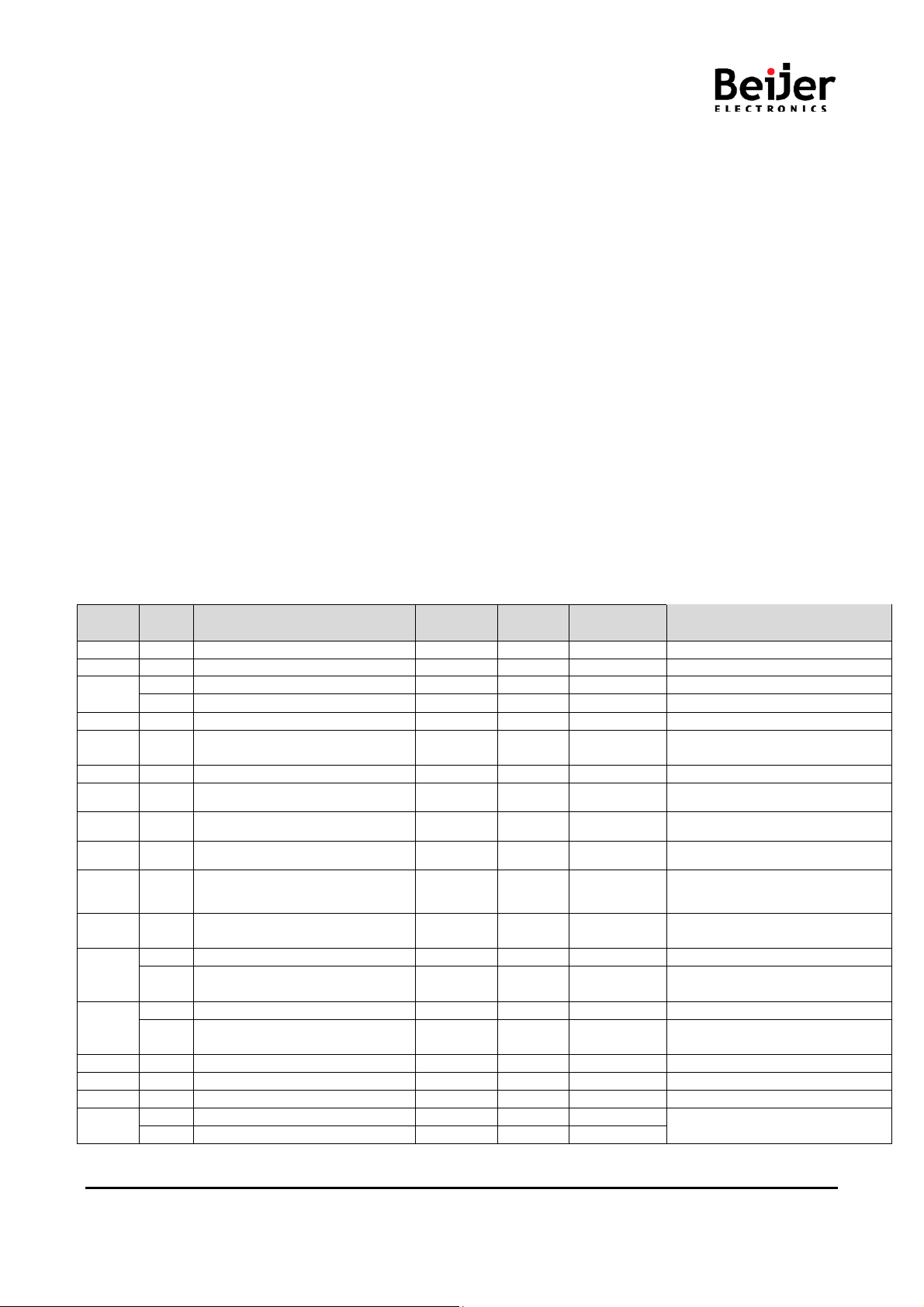

Pin No. Signal Description Signal Description Pin No.

0 System Power, 24V System Power, Ground 1

2 System Power, 24V System Power, Ground 3

4 F.G F.G 5

6 Field Power, Ground Field Power, Ground 7

8 Field Power, 24V Field Power, 24V 9

-series GN-9261 CANopen Rev. 1.01.docx

Page 9 of (52)

Page 10

GN-9261 User Manual

G

Status

LED

To indicate

At least one of the error counters of the CAN controller has

reached or exceeded the warning limit.

A guard event (NMT-Slave or NMT-Master) or a Heartbeat event

has occurred.

The SYNC message has not been received within then

0x1006)

3.3 GN-9261 LED Indicator

3.3.1 LED Indicator

LED No. LED Function / Description LED Color

MOD Module Status Green/Red

RUN CANopen Status Green/Red

ERROR CANopen Error Status Red

I.O Extension Module Status Green/Red

Field Power Field Power Enable Green

3.3.2 MOD(Module Status LED)

Not Powered OFF Not power is supplied to the unit.

Normal Operational Green The unit is operating in normal condition.

Unrecoverable Fault Red

The device has an unrecoverable fault.

- Memory error or CPU watchdog error.

3.3.3 RUN(Module Status LED)

Status LED To indicate

Not Powered OFF

Stopped Single flash Green Module is stopped

Pre-Operational Blinking Green Module is in PRE-OPERATIONAL

Operational Green Module is in OPENRATIONAL

Module is either not getting power, or it is NOT_ACTIVE status.

Module is initializing.

3.3.4 ERROR(CANopen Error LED)

Status LED To indicate

Not Powered OFF Module is not getting powered or No error.

Warning limit reached Single flash

Error control Event Double flash

Sync. Error Triple flash

Bus Off ON The CAN controller is bus off.

-series GN-9261 CANopen Rev. 1.01.docx

configured communication cycle period time out (see index

Page 10 of (52)

Page 11

GN-9261 User Manual

G

Red

Status

LED

To indicate

Equal ON and OFF times with a frequency of approximately 10 Hz: ON for

approximately 50ms and OFF for approximately 50ms.

3.3.5 IOS LED(Extension Module Status LED)

Status LED To indicate

Not Powered OFF Device may not be powered.

No Expansion Module Flashing Red Adapter has no expansion module

Internal Bus Connection,

Run Exchanging I/O

Expansion Configuration

Failed - Detected invalid expansion module ID.

- Overflowed Input/Output Size

- Too many expansion module

- Initialization failure

- Communication failure.

- Changed expansion module configuration.

- Mismatch vendor code between adapter and expansion module.

Green Exchanging I/O data.

One or more expansion module occurred in fault state.

3.3.6 Field Power, System Power LED(Field Power, System Power Status LED)

Not Powered OFF Not power is supplied to the unit.

Normal Operational Green The unit is operating in normal condition.

Unrecoverable Fault Red

The device has an unrecoverable fault.

- Memory error or CPU watchdog error.

3.3.7 Indicator states and flash rates

LED ON Constantly ON

LED OFF Constantly OFF.

LED Blinking

LED Single flash

LED Double flash

LED Triple flash

-series GN-9261 CANopen Rev. 1.01.docx

One short flash (approximately 200ms) followed by a long OFF phase

(approximately 1000ms)

A sequence of two short flashes (approximately 200ms), separated by an OFF phase

(approximately 200ms).

The sequence is finished by a long OFF phase (approximately 1000ms)

A sequence of three short flashes (approximately 200ms), separated by an OFF phase

(approximately 200ms).

The sequence is finished by a long OFF phase (approximately 1000ms)

Page 11 of (52)

Page 12

GN-9261 User Manual

G

1

Terminal Resister

On : Terminal Resister On

Default : 0 (1000kbps)

8

Baudrate #1

3.4. GN-9261 Electrical Interface

3.4.1 5pin Open Connector

No. Signal Name Description

3.4.2 Dip Switch

1 -

2 CAN H CAN High

3 Shield F.G

4 CAN L CAN Low

5 CAN G CAN GND

DIP Pole# Description

2

3

4

5 Baudrate #4

6 Baudrate #3

7 Baudrate #2

Reserved

5 6 7 8 (ex.)

0 0 0 1 : 10Kbps

0 0 1 0 : 20Kbps

0 0 1 1 : 50Kbps

0 1 0 0 : 100Kbps

0 1 0 1 : 125Kbps

0 1 1 0 : 250Kbps

0 1 1 1 : 500Kbps

1 0 0 0 : 800Kbps

1 0 0 1 : 1000Kbps

-series GN-9261 CANopen Rev. 1.01.docx

Page 12 of (52)

Page 13

GN-9261 User Manual

G

3.4.3 Address setup

Each Adapter could have an unique address (from 1 to 99)

so that it can be addressed independently from other nodes.

The address 0 is reserved.

3.4.4 RS232 Port for MODBUS/RTU, Touch Panel or I/O Guide

RS232 (37204-64A3-004PL/3M

Pin# Signal Name Description

1 Reserved ---2 TXD RS232 TXD

3 RXD RS232 RXD

4 GND RS232 GND

-series GN-9261 CANopen Rev. 1.01.docx

Page 13 of (52)

Page 14

GN-9261 User Manual

G

4. Dimension

4.1 GN-9261

(mm)

-series GN-9261 CANopen Rev. 1.01.docx

Page 14 of (52)

Page 15

GN-9261 User Manual

G

5. Communication

5.1 Device Model

5.1.1 Structure of the device model

Communication. This functional unit makes the communication data objects and the associated functionality

for data exchange over the CANopen network available. The network status machine is part of this.

Object directory. This contains all the data objects (application data + parameters) that are accessible from

outside and that affect the behavior of communication, application and status machines. The object directory

is organized as a two-dimensional table in which the data are addressed by their index and sub-index.

The data exchange with CANopen devices takes place by means of data objects. In the CANopen

communication profile, two types of standard object (PDO and SDO) and special objects (for network

management etc.) are defined. The GN-9261 supports the following objects:

• 32 transmit PDOs

• 32 receive PDOs

• 1 standard SDO (server)

• Node guarding

• NMT objects

Every CANopen device possesses a CANopen object directory in which

The parameters for all the CANopen objects are entered.

5.2 PDO (Process Data)

5.2.1 Introduction

In many fieldbus systems the entire process image is continuously transferred - usually in a more or less

cyclic manner. CANopen is not limited to this communication principle, since the multi-master bus access

protocol allows CAN to offer other methods.

The process data in CANopen is divided into segments with a maximum of 8 bytes. These segments are

known as process data objects (PDOs). The PDOs each corresponds to a CAN telegram, whose specific

CAN identifier is used to allocate them and to determine their priority.

The PDOs are named from the point of view of the Network Adapter: receive PDOs (RxPDOs) are received

by the coupler and contain output data, while transmit PDOs (TxPDOs) are sent by the coupler and contain

input data.

-series GN-9261 CANopen Rev. 1.01.docx

Page 15 of (52)

Page 16

GN-9261 User Manual

G

5.2.2 PDO Mapping

CANopen specifies the data assignment for the first two PDOs in the device profile for input/output groups

(DS401) (“default mapping”). The first PDO is provided for digital inputs (TxPDO1) or outputs (RxPDO1). The

first 4 analog inputs or outputs are located in the second PDO. These PDOs are accordingly occupied by the

Network Adapters - if, for instance, no digital output terminals are plugged in, RxPDO1 remains empty.

Once the first PDOs have been occupied, the next PDOs are filled with process data in the following

sequence:

1. Digital I/O (1-byte)

2. Digital I/O (2-byte)

3. Analog I/O

5.2.3 PDO Identifier

For the first two PDOs (PDO1 + PDO2) CANopen provides default identifiers depending on the node

address, but all other PDOs must have identifiers assigned to them. The principle of the default identifiers is

explained in the section on “Network Management”, and there is a list of all the CANopen default identifiers

in the appendix.

Pre-Define Connection Set

In the system of default identifiers, all the nodes (here: slaves) communicate with one central station (the

master), since slave nodes do not listen by default to the send identifier of other slave nodes:

PDO Linking

If the consumer-producer model of CANopen PDOs is to be used for direct data exchange between nodes

(without a master), the distribution of identifiers must be appropriately adapted, so that the TxPDO identifier

of the producer agrees with the RxPDO identifier of the consumer:

-series GN-9261 CANopen Rev. 1.01.docx

Page 16 of (52)

Page 17

GN-9261 User Manual

G

This procedure is known as PDO linking. It permits, for example, easy construction of electronic drives in

which several slave axes simultaneously listen to the actual value in the master axis TxPDO.

5.2.4 PDO Communication Type

Event driven

The “event” is the alteration of an input value, the data being transmitted immediately after this change. The

event-driven flow can make optimal use of the bus bandwidth, since instead of the whole process image it is

only the changes in it that are transmitted. A short reaction time is achieved at the same time, since when an

input value changes it is not necessary to wait for the next interrogation from a master.

Polling

The PDOs can also be polled by data request telegrams (remote frames). In this way it is possible to get the

input process image of event-driven inputs onto the bus, even when the inputs have not changed, for

instance by a monitoring or diagnostic device brought into the network while it is running.

The Crevis CANopen bus Adapter supports the interrogation of PDOs by means of remote frames.

Synchronized

It is not only for drive applications that it is worthwhile to synchronize the determination of the input

information and the setting the outputs. For this purpose CANopen provides the SYNC object, a CAN

telegram of high priority but containing no user data, whose reception is used by the synchronized nodes as

a trigger for reading the inputs or for setting the outputs:

PDO transmission type

The “PDO transmission type” parameter specifies how the transmission of the PDO is triggered, or how

received PDOs are handled:

-series GN-9261 CANopen Rev. 1.01.docx

Page 17 of (52)

Page 18

GN-9261 User Manual

G

X

X

X

Transmission type PDO transmission

cyclic acyclic synchronous asynchronous RTR only

0

1-240 X

241-251 reserved

252

253

254

255

Synchronous

Transmission type 0 is only useful for RxPDOs: the PDO is only used when the next SYNC telegram is

received. In transmission types 1-240 the PDO is cyclically transmitted or expected: after every “nth” SYNC

(n = 1...240).

Since transmission types can be combined on a coupler as well as in the network, it is possible, for example,

for a fast cycle to be agreed for digital inputs (n = 1), whereas the data for analog inputs is transmitted in a

slower cycle (e.g. n = 10). The cycle time (SYNC rate) can be monitored (object 0x1006), so that if the SYNC

fails the Adapter switches its outputs into the fault state.

Asynchronous

X X

X

X X

X

The transmission types 254 + 255 are asynchronous, but may also be event-driven. In transmission type

254, the event is specific to the manufactur er, where as for type 255 it is defined in the device pr of ile. Sinc e

the Beckhoff CANopen Network Adapters support device profile DS401 no distinction is made here between

the two transmission types.

Inhibit Time

The “inhibit time” parameter can be used to implement a “transmit filter” that does not increase the reaction

time for relatively new input alterations, but is active for changes that follow immediately afterwards. The

inhibit time (transmit delay time) specifies the minimum length of time that must be allowed to elapse

between the transmission of two of the same telegrams. If the inhibit time is used, the maximum bus loading

can be determined, so that the worst case latency can then be found.

-series GN-9261 CANopen Rev. 1.01.docx

Page 18 of (52)

Page 19

GN-9261 User Manual

G

5.3 SDO (Service Data)

5.3.1 Introduction

The parameters listed in the object directory are read and written by means of service data objects. These

SDOs are multiplexed domains, i.e. structures of any size that have a multiplexer (address). The multiplexer

consists of a 16-bit index and an 8-bit sub-index that address the corresponding entries in the object

directory.

The CANopen Network Adapters are servers for the SDO, which means that at the request of a client they

make data available (upload), or they receive data from the client (download).

This involves a handshake between the client and the server. When the size of the parameter to be

transferred is not more than 4 bytes, a single handshake is sufficient (one telegram pair).

For a download, the client sends the data together with its index and sub-index, and the server confirms

reception. For an upload, the client requests the data by transmitting the index and sub-index of the desired

parameter and the server sends the parameter (including index and sub-index) in its answer telegram. The

same pair of identifiers is used for both upload and download. The telegrams, which are always 8 bytes long,

encode the various services in the first data byte.

All parameters with the exception of objects 1008h, 1009h and 100Ah (device name, hardware and software

versions) are only at most 4 bytes long, so this description is restricted to transmission in expedited transfer.

-series GN-9261 CANopen Rev. 1.01.docx

Page 19 of (52)

Page 20

GN-9261 User Manual

G

5.4 Emergency (Error Message)

Emergency messages are always sent in the event of a critical error situation having occurred/overcome in

the device, or if important information has to be communicated to other devices.

Structure and meaning of the entries in the emergency object are explained in the table .EMCY-CODE., they

are coded in the bus message in a ‘Low byte’ / ‘High byte’ order.

An emergency object is also sent, after an error is remedied (Error Code = 0x0000, the Error Register and

the Additional Code behave as described in the table .EMCY-CODE.).

Following Power On an emergency object is sent if the loaded settings are the default settings. This occurs

for two reasons:

• No settings have yet been saved (Index 0x1010).

• The saved setting was discarded by the Network Adapter, because modules were connected or

disconnected.

5.5 NMT (Network Management)

5.5.1 Network Start-up

CANopen defines a state machine that controls the functionality of a device. Transition between the

individual states is initiated by internal events or services from the NMT master. These devices states can be

connected to application processes.

In Initialization state, the CANopen data structures of a node are initialized by the application. The CiA DS301 standard defines various mandatory OD entries for this task as well as specific communication objects

required for that. In the minimum device configuration, the identifier for these communication objects must

correspond to the so-called Pre-Defined Connection-Set. The device profiles define further settings for the

applicable device class. The pre-defined settings for identifier for emergency, PDOs and SDOs are

calculated based on the node address (Node ID) that can be in the range from 1 to 99, added to a base

identifier that determines the function of the individual object.

-series GN-9261 CANopen Rev. 1.01.docx

Page 20 of (52)

Page 21

GN-9261 User Manual

G

After Initialization is completed the node automatically switches into PRE-OPERATIONAL (12) state. The

NMT master will be informed about this state change with the BOOT-UP message sent by the corresponding

node. In this state it is not possible to communicate with the node using PDOs. However, the node can be

configured over the CAN bus using SDOs in PRE-OPERATIONAL state. NMT services and Life Guarding

are also available in this state.

The application as well as the available resources of the CANopen device determine to what extend

configuration over the CAN bus with the help of SDOs must take place. For example, if the CANopen device

does not provide a non-volatile memory to store mapping and communication parameters for PDOs and

these parameters differ from the default values, then these parameters must be transmitted to the node over

the network after initialization is completed.

After the configuration of these parameters by the application or the NMT master is completed, the NMT

service Start_Remote_Node (6) can be used to render the node from PRE-OPERATIONAL state into

OPERATIONAL state. This state change also causes the initial transmission of all TPDOs independently of

whether an event for it is present. Each subsequent transmission of PDOs then always takes place as a

function of an event.

All CANopen devices also support the Stop_Remote_Node (7), Enter_PRE-OPERATIONAL_State (8),

Reset_Node (10), Reset_Communication (11) services. Reset_Node is used to reset the application-specific

data and the communication parameter of the node. The CANopen data structures are loaded with their

initial values. Data stored in a non-volatile memory are rejected. This state change is comparable with an

initial operation of the node.

If the NMT service Reset_Communication is used to change the state of a node, then loading initial values

exclusive for the communication parameters in the CANopen stack takes place.

No communication via PDO and SDO is possible if the device is in STOPPED state. Only NMT services,

Node Guarding, Life Guarding as well as Heartbeat are possible in this state.

5.5.2 Boot-up Message

After the initialization phase and the self-test, the Network Adapter sends the boot-up message, a CAN

message with no data bytes and with the identifier of the emergency message: CAN-ID = 0x80 + node ID.

5.5.3 Node Guarding

Node Guarding represents a means of node supervision that is initiated by the NMT master. This service is

used to request the node’s operational state and to determine whether the node is functioning correctly. The

NMT master transmits a single Node Guard message to the slave in the form of a remote frame with the

CAN identifier 0x700 plus the node address of the NMT slave. As a response to this remote frame, the NMT

slave sends a CAN message back containing its current NMT state and a one bit that toggles between two

subsequent messages.

Response from the NMT Slave to a Node Guard Remote Frame:

Identifier DLC

0x700 + Node Address 1 Status Byte

-series GN-9261 CANopen Rev. 1.01.docx

Data

0

Page 21 of (52)

Page 22

GN-9261 User Manual

G

Node state of a CANopen Device

Status Byte Node State

0x00 BOOT-UP

0x04 STOPED

0x05 OPERATIONAL

0x7F PRE-OPERATIONAL

Bit 7 of the status byte always starts with a 0 and changes its value after each transmission. The application

is responsible for actively toggling this bit. This ensures that the Node Guard response message from a

slave is not just stored in one of the Full-CAN channels. Thus the NMT master will get the confirmation from

the NMT slave node that the application is still running.

-series GN-9261 CANopen Rev. 1.01.docx

Page 22 of (52)

Page 23

GN-9261 User Manual

G

5.5.4 Life Guarding

As an alternative to Node Guarding node supervision can also be performed by Life Guarding services. In

contrast to the Node Guarding the NMT master cyclically sends a Life Guard message to the slave in the

form of a remote frame with the CAN identifier 0x700 plus the node address of the NMT slave. As a

response to this remote frame, the NMT slave sends a CAN message back containing its current NMT state

and a one bit that toggles between two subsequent messages. With being missing the answer or unexpected

status of the slave the NMT masters application is informed. Further the slave can detect the loss of the

masters. The Life Guarding is started with the transmission of the first Life Guard message of the masters.

Response from the NMT Slave to a Life Guard Remote Frame

Identifier DLC

0x700 + Node Address 1 Status Byte

Meaning of the status byte corresponds to that of the Node Guarding message The Life Guarding

supervision on the NMT slave node is deactivated, if the Life Guard time (object entry 0x100C in the object

dictionary) or the Life time factor (object entry 0x100D in the object dictionary) are equal to zero.I/O Process

Image Map

Data

0

An expansion module may have 3 types of data as I/O data, configuration parameter and memory register.

The data exchange between network adapter and expansion modules is done via an I/O process image data

by FnBus protocol. The following figure shows the data flow of process image between network adapter and

expansion modules.

-series GN-9261 CANopen Rev. 1.01.docx

Page 23 of (52)

Page 24

GN-9261 User Manual

G

5.6 Example of Input and Output Proce s s Im a ge Ma p

Input image data depends on slot position and expansion slot data type. Input process image data is only

ordered by expansion slot position when input image mode is uncompressed (mode 0). But, when input image

mode is compr essed (m ode 1), input proces s im age data is or dered b y expans ion slo t pos ition and slot d ata

type.

Input process image mode can be set by Object Index 0x4500

For example slot configuration

Slot Address Module Description

#0 CANopen Adapter

#1 8-discrete output

#2 8-dis cr ete inp ut

#3 4-analog output

#4 2ch, high speed counter

#5 4-relay output

#6 16-dis c rete in put

#7 4-analog input

#8 16-dis c rete out put

Non-compress mode data format

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Index Sub-Index

0 Analog Output Ch0 low byte (Slot#3) 0x6411 0x01

1 Analog Output Ch0 high byte (Slot#3) 0x6411 0x01

2 Analog Output Ch1 low byte (Slot#3) 0x6411 0x02

3 Analog Output Ch1 high byte (Slot#3) 0x6411 0x02

4 Analog Output Ch2 low byte (Slot#3) 0x6411 0x03

5 Analog Output Ch2 high byte (Slot#3) 0x6411 0x03

6 Analog Output Ch3 low byte (Slot#3) 0x6411 0x04

7 Analog Output Ch3 high byte (Slot#3) 0x6411 0x04

8 Discrete Output 8 pts. (Slot#1) 0x6200 0x01

9 Reserved Discrete Output 4 pts. (Slot#5) 0x6200 0x02

10 Discrete Output low 8 pts. (Slot#8) 0x6200 0x03

11 Discrete Output high 8 pts. (Slot#8) 0x6200 0x04

12 Discrete Input 8 pts. (Slot#2) 0x6000 0x01

13 Discrete Input low 8 pts. (Slot#6) 0x6000 0x02

14 Discrete Input high 8 pts. (Slot#6) 0x6000 0x03

-series GN-9261 CANopen Rev. 1.01.docx

Page 24 of (52)

Page 25

GN-9261 User Manual

G

15 Discrete Input low 8 pts. (Slot#9) 0x6000 0x08

16 Discrete Input high 8 pts. (Slot#9) 0x6000 0x09

17 Analog Output Ch0 low byte (Slot#7) 0x6400 0x01

18 Analog Output Ch0 high byte (Slot#7) 0x6400 0x01

19 Analog Output Ch1 low byte (Slot#7) 0x6400 0x02

20 Analog Output Ch1 high byte (Slot#7) 0x6400 0x02

21 Analog Output Ch2 low byte (Slot#7) 0x6400 0x03

22 Analog Output Ch2 high byte (Slot#7) 0x6400 0x03

23 Analog Output Ch3 low byte (Slot#7) 0x6400 0x04

24 Analog Output Ch3 high byte (Slot#7) 0x6400 0x04

25 Special Input LL byte Ch#0 (Slot#4) 0x3000 0x01

26 Special Input LH byte Ch#0 (Slot#4) 0x3000 0x02

27 Special Input HL byte Ch#0 (Slot#4) 0x3000 0x03

28 Special Input HH byte Ch#0 (Slot#4) 0x3000 0x04

29 Special Input LL byte Ch#1 (Slot#4) 0x3000 0x05

30 Special Input LH byte Ch#1 (Slot#4) 0x3000 0x06

31 Special Input HL byte Ch#1 (Slot#4) 0x3000 0x07

32 Special Input HH byte Ch#1 (Slot#4) 0x3000 0x08

33 Special Output byte Ch#0 (Slot#4) 0x3200 0x01

34 Special Output byte Ch#1 (Slot#4) 0x3200 0x02

-series GN-9261 CANopen Rev. 1.01.docx

Page 25 of (52)

Page 26

GN-9261 User Manual

G

Sub-

Index

0x1000

0x00

Device type

unsigned32

ro

Statement of device type

0x1001

0x00

Error register

unsgined8

ro

Error register

0x00

Predefine error field

unsgined8

rw

0

Number of error states stored

0x01

Standard error filed

unsigned32

ro

0

Error state are stored

0x1005

0x00

COB-ID sync message

unsigned32

rw

0x80000080

Identifier of the Sync message

0x1007

0x00

Synchronous Window Length

unsigned32

rw

0

Synchronous Window Length

visible

string

visible

string

visible

string

Interval between two guard

Is set by the NMTmaster.(ms)

0x00

Largest sub-index supported

unsigned32

ro

1

Number of store options

0x00

Restore default parameters

unsgined8

ro

1

Number of restore options

0x1012

0x00

COB-ID Time Stamp

unsigned32

rw

100

COB-ID Time Stamp

0x1014

0x00

COB-ID emergency message

unsigned32

ro

0x80+node ID

COB-ID of the emergency object

0x1015

0x00

Inhibit time EMCY

unsigned16

rw

0

COB-ID SYNC

0x00

Number of entries

unsgined8

ro

5

Heartbeat time value

0x01

Consumer Heartbeat time1

unsigned32

rw

0

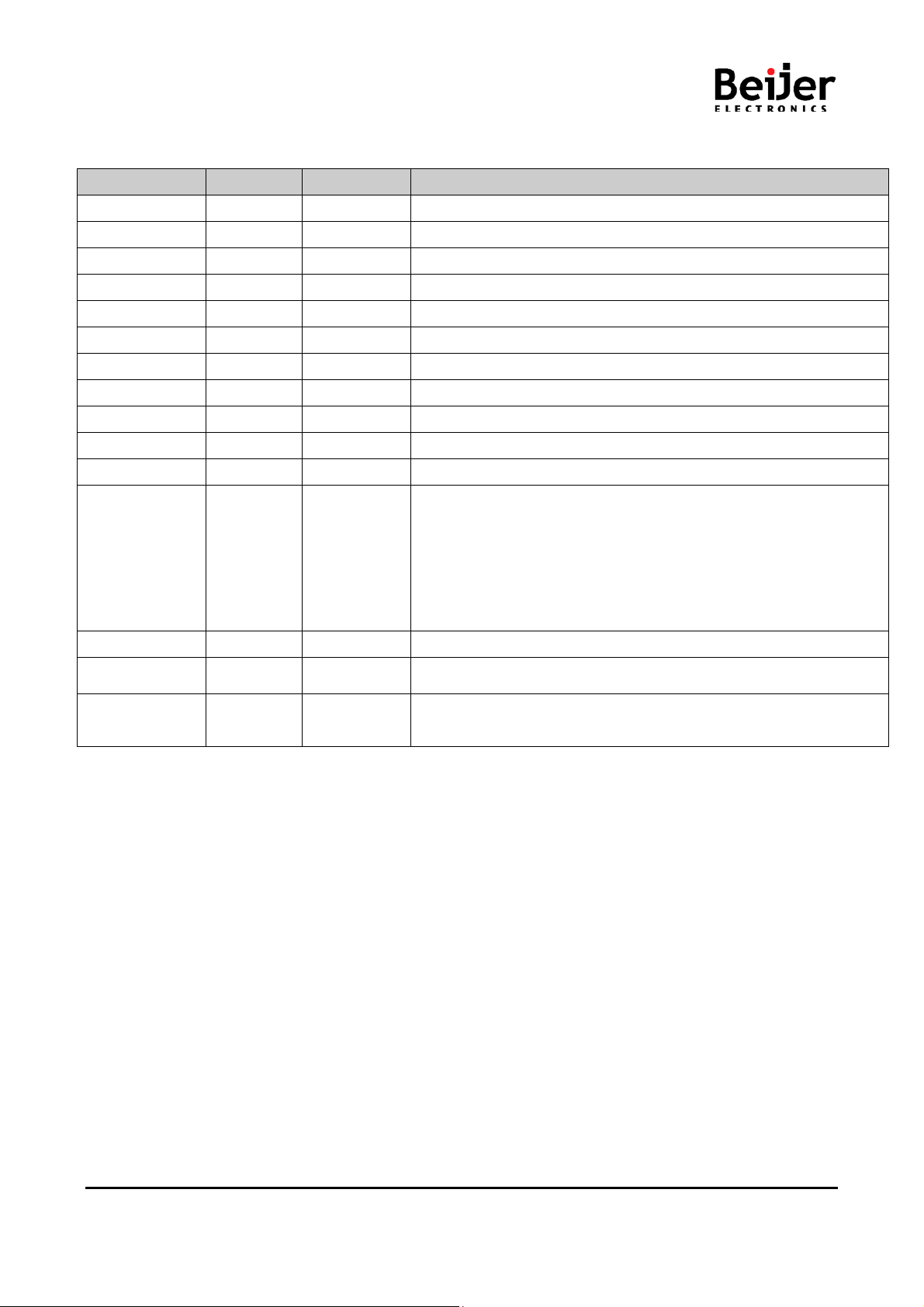

6. Object Directory

All the CANopen objects relevant for the Network Adapter are entered into the CANopen object directory.

The object directory is divided into three different regions:

1) communication-specific profile region (index 0x1000 – 0x1FFF)

2) manufacturer-specific profile region (index 0x2000 – 0x5FFF)

3) standardized device profile region (0x6000 – 0x9FFF)

Region 1 thus contains the description of all the parameters particular to communication, the manufacturerspecific entries are described in region 2, and region 3 stores the objects for the device profile according to

DS-401. Every entry in the object directory is identified by a 16 bit index.

6.1 Communication Profile Area

The following table contains all objects of the communication profile supported by the Network adapter

Index

0x1003

0x1006 0x00 Communication cycle period unsigned32 rw 0

0x1008 0x00 Manufacturer device name

0x1009 0x00 Manufacturer hardware version

0x100A 0x00 Manufacturer software version

0x100C 0x00 Guard time unsigned16 rw 0x00C8

0x100D 0x00 Life time factor unsgined8 rw 2

0x1010

0x1011

0x01 Save all parameters unsigned32 rw 1

0x01 Restore all default unsigned32 rw 1

Name Type Attribute Default Meaning

ro GN-9261 Device name of the Adapter

ro 100 H/W version description

ro 100 Software version number

Communication cycle period in.

’0’ if not used

telegrams.

Life time factor * guard time =

life time(watchdog for life guarding)

Store all parameters

0x65766173(ASCII : save)

Restore all default parameters

0x64616F6C(ASCII : load)

0x1016

-series GN-9261 CANopen Rev. 1.01.docx

Page 26 of (52)

Page 27

GN-9261 User Manual

G

...

...

...

...

...

0x05

Consumer Heartbeat time5

unsigned32

rw

0

0x1017

0x00

Producer Heartbeat time

unsigned16

rw

Producer Heartbeat time (0~127)

0x00

Identity object

unsgined8

ro

4

Identity Object

0x01

Manufacturer ID

unsigned32

ro

0x0000029D

0x03

Revision number

unsigned32

ro

0x00000100

0x04

Serial number

unsigned32

ro

0x1019

0x00

Synchronous counter overflow value

unsigned16

rw

0

Synchronous counter overflow value

Error Behavior

0x01

Communication Error

unsgined8

rw

0

0x01

COB-ID used by PDO

unsigned32

rw

0x200+nodeID

Parameter 1-32

0x02

Transfer type

unsgined8

rw

… …

…

0x00

Number of entries

unsgined8

ro

5

0x01

COB-ID used by PDO

unsigned32

rw

0x00

Number of entries

unsgined8

rw

8

Receive PDO Mapping

0x01

1. Mapping Entry 1

unsigned32

rw

Parameter 1-32

…

…

0x08

8. Mapping Entry 8

unsigned32

rw

… …

…

0x01

1. Mapping Entry 1

unsigned32

rw

… …

0x08

8. Mapping Entry 8

unsigned32

rw

0x01

COB-ID used by PDO

unsigned32

rw

0x180+nodeID

Parameter 1-32

…

…

…

0x00

Number of entries

unsgined8

ro

5

0x01

COB-ID used by PDO

unsigned32

rw

0x02

Transfer type

unsgined8

rw

0x00

Number of entries

unsgined8

rw

8

Transmit PDO Mapping

…

…

0x08

8. Mapping Entry 8

unsigned32

rw

… …

…

0x00

Number of entries

unsgined8

rw

8

0x01

1. Mapping Entry 1

unsigned32

rw

0x08

8. Mapping Entry 8

unsigned32

rw

0x02 Consumer Heartbeat time2 unsigned32 rw 0

0x1018

0x1029

0x1400

0x141F

0x1600

0x161F

0x1800

0x02 Product code unsigned32 ro 0x00009060

0x00 Number of error unsgined8 ro 1

0x00 Number of entries unsgined8 ro 5 Receive PDO Communication

0x02 Transfer type unsgined8 rw

0x00 Number of entries unsgined8 rw 8

0x00 Number of entries unsgined8 ro 5 Transmit PDO Communication

0x02 Transfer type unsgined8 rw

0x181F

0x1A00

0x1A1F

0x01 1. Mapping Entry 1 unsigned32 rw

… …

Parameter 1-32

• Object 0x1000, Device Type

The object indicates the implemented device profile. The CANopen Network Adapter has implemented the

Device Profile for Generic I/O Modules" (device profile No. 401). Moreover, in the index 0x1000 the value

informs about the type of modules connected.

-series GN-9261 CANopen Rev. 1.01.docx

Page 27 of (52)

Page 28

GN-9261 User Manual

G

Bit

Meaning

Format:

MSB

4 byte 3 byte 2 byte 1 byte 0 byte

0x00 0x00 0000.4321 (bit) 0x01 0x91

Device connect Number Device Profile Number

This register contains internal errors. This register is also part of the emergency message

1 1 = 1, if at least one digital input is connected.

2 2 = 1, if at least one digital output is connected.

3 3 = 1, if at least one analog input is connected.

4 4 = 1, if at least one analog output is connected.

• Object 0x1001, Error Register

Format:

Bit Meaning

0 General Error

1 Reserved

2 Reserved

3 Reserved

4 Communication

5 Device profile specific

6 Reserved

7 Manufacturer specific

In the event of an error, bit 0 is always set. Additional bits used specify the error in more detail.

• Object 0x1003, Pre-defined Error Field

The sub-index 0 contains the errors currently stored in the field. If a new error occurs, it will be entered in

sub-index 1, and all errors already existing moved down by one sub-index. A max. Of 20 error entries are

supported. Should more than 20 errors occur, each time the error contained in sub-index 20 is written over?

Format:

The additional information corresponds to the first 2 bytes of the additional code of the Emergency telegram.

The error code coincides with the error code in the Emergency telegram.

The complete error memory is deleted by writing a .0" in sub-index 0.

-series GN-9261 CANopen Rev. 1.01.docx

Page 28 of (52)

Page 29

GN-9261 User Manual

G

• Object 0x1005, COB-ID SYNC message

The object defines the COB ID for the synchronization message.

• Object 0x1006, Communication Cycle Period

The object defines the max. Time in µs for two subsequent SYNC messages.

The internal resolution is 2ms. If the value is 0, no SYNC monitoring is performed.

• Object 0x1008, Manufacturer Device Name

The object indicates the device name of the Network Adapter.

• Object 0x1008, Manufacturer Device Name

The object contains the length of the time window for synchronous PDOs in us. It is 0 if not used.

• Object 0x1009, Manufacturer Hardware Version

The object indicates the current hardware version of the Network Adapter

• Object 0x100A, Manufacturer Software Version

The object indicates the current software version of the Network Adapter

• Object 0x100C, Guard Time

The object indicates the Guarding Time in milliseconds. An NMT master cyclically interrogates the NMT

slave for its status. The time between two interrogations is termed Guard Time.

• Object 0x100D, Life Time Factor

The life Time Factor is part of the Node Guarding Protocol. The NMT slave checks if it was interrogated

within the Node Life Time (Guard time multiplied with the life time factor). If not, the slave works on the basis

that the NMT master is no longer in its normal operation. It then triggers a Life Guarding Event.

If the node life time is zero, no monitoring will take place.

• Object 0x1010, Store Parameters

This object allows to permanently storing the settings made by the user. For this purpose, the

signature .save" (lower case letters ASCII - MSB. 0x65 76 61 73 - LSB) must be written into the index

0x1010 sub index 1. The storing process runs in the background and takes approx. 2-3 seconds. When the

storing process is finished, the SDO reply telegram is sent. Communication remains possible during storage

by means of SDOs. An error message as a result of a new storage attempt only occurs, when the previous

one was not yet finished.

It is also not possible to trigger the storage function for as long as .Restore" is active.

As soon as a setting is stored, the Emergency .Changed HW configuration. Is not sent any longer if the

Network Adapter is started up again without changing the module configuration.

-series GN-9261 CANopen Rev. 1.01.docx

Page 29 of (52)

Page 30

GN-9261 User Manual

G

Object 0x1011, Restore default Parameters

This object allows resetting the user stored parameters to the original default values.

Sub-indexes 2 and 3 are not supported.

The load command is processed in the background and takes approx. 2-3 seconds. When the performance

is finished, the SDO reply message is sent. Communication can be continued during performance using

SDOs. An error message is only tripped with another attempt to send a load command, if the previous one is

not yet completed. It is also not possible to trigger a load command for as long as .Save" is active.

Sub-index 1 - Permanent entry of default parameters:

Writing the signature .load" (lower case letters ASCII - MSB 0x64 0x61 0x6F 0x6C LSB) into the index

0x1011 sub-index 1 entails loading of the standard factory settings after the following Power ON and each

further Power On (until the next SAVE command is given).

• Object 0x1014, COB-ID Emergency Object

The object defines the COB ID for the EMCY message.

If a new COB ID is to be entered, set bit 31 to 1 first, because standard DS301 does not allow to change a

valid COB ID (Bit31=0).

• Object 0x1015, Inhibit Time Emergency Object

This object indicates the time in minutes which must be allowed to elapse prior to another Emer genc y

to be sent.

An entry of zero deactivates the delayed transmission.

Due to the fact that with delayed transmission the entries are entered in a queue, the max. number of

Emergencies in quick succession is limited to the queue size (20 entries). If this number is exceeded, an

Emergency is sent immediately indicating the overf lo w.

One time unit is 100µs.

• Object 0x1016, Consumer Heartbeat Time

This entry allows the monitoring of a maximum of 1modules. The system checks whether each module

defined in this object has created a Heartbeat within the set time. If the set time was exceeded, a HeartbeatEvent is triggered. The Heartbeat-Time is entered in milliseconds. The monitoring is deactivated, if the time

value is 0.

• Object 0x1017, Producer Heartbeat Time

The object defines the time between two Heartbeat messages sent in milliseconds. If the time is 0, no

Heartbeat is sent. The Heartbeat transmission starts as soon as a value other than 0 is entered.

-series GN-9261 CANopen Rev. 1.01.docx

Page 30 of (52)

Page 31

GN-9261 User Manual

G

• Object 0x1018, Identity Object

The object specifies the device used.

• Object 0x1029, Error behavior

The object specifies to which state an I/O module shall be set, when a communication error, output error or

input error is detected.

• Object 0x1400 ~ 0x141F Receive PDO Communication Parameter

This object is used to set the communication parameters of the RxPDOs. 8 RxPDOs are supported. The

default COB IDs of the first four PDOs is resigned according to the DS301 standard. All further PDOs are

deactivated. If not all default PDOs are used (i.e. a smaller number of modules is connected), also the

default PDOs not used are deactivated.

If a new COB ID is to be entered, bit 31 must be set to 1 first,

because the DS301 standard does not permit to change a valid COB ID (Bit31=0).

• Object 0x1600 ~ 0x161F, Receive PDO Mapping Parameter

This object is used to define the data, which is to be transmitted by means of the PDO.

Sub-index 0 contains the number of objects valid for the PDO.

Index: Index of the object to be transmitted

Sub-Index: Sub-index of the object to be transmitted

Size: Object size in bits Due to the fact that max. 32 bytes can be transmitted in a PDO, the sum of the valid

object lengths must not exceed 252 (32Byte*8Bit = 256 but, Fn-bus specification is Max.252bytes)

• Object 0x1800 ~ 0x181F, Transmit PDO Communication Parameter

This object is used to set the communication parameters of the TxPDOs. 8 TxPDOs are supported. The

default COB IDs of the first four PDOs is reassigned according to the DS301 standard. All other PDOs are

de-activated. If not all default PDOs are used (i.e. a smaller number of modules is connected), also the

default PDOs not used are de-activated.

-series GN-9261 CANopen Rev. 1.01.docx

Page 31 of (52)

Page 32

GN-9261 User Manual

G

• Object 0x1A00 ~ 0x1A1F, Transmit PDO Mapping Parameter

This object is used to define the data, which is transmitted using the PDO. Sub-index 0 contains the number

of objects valid for the PDO.

Index: Index of the object to be transmitted

Sub-Index: Sub-index of the object to be transmitted

Size: Object size in bits Due to the fact that max. 8 bytes can be transmitted in a PDO, the sum of the valid

object lengths must not exceed 252

-series GN-9261 CANopen Rev. 1.01.docx

Page 32 of (52)

Page 33

GN-9261 User Manual

G

Sub-

Index

unsigned16

ro

0

unsigned16*n

ro

All module name

unsigned16

ro

Baudrate Setting value

0x03E8 : 1000(default)

unsigned8

rw

0

unsigned32

ro

0x00000003

unsigned16

ro

unsigned16

ro

unsigned16

ro

unsigned16

ro

unsigned16

ro

unsigned16

ro

unsigned32

ro

unsigned32

ro

unsigned16

ro

unsigned16

ro

unsigned8*n

rw

unsigned8*n

ro

unsigned16

ro

unsigned8*n

rw

unsigned32

ro

unsigned32

ro

unsigned32

ro

unsigned16

ro

unsigned8*n

ro

6.2. Manufacturer Specific Profile Area

The following table shows all objects of the manufacturer profile supported by the Network Adapter.

*0x2100(Slot#0=NA), 0x2101(Slot#1), 0x2102(Slot#2)...

Index

0x20F0

0x21xx

0x00 Number of entries unsigned8 ro 0x4F

0x01 Node id current switch value unsigned8 ro

0x02 Number of module unsigned16 ro

Run command

0 : IO_Available

1 : IO_Ready

2 : IO_Idle

0x03

0x04 All module id

0x05 Baudrate

0x06

0x0C Status, error inf orm ation

0x0E All size of output bit

0x0F All size of input bit

0x10 All size of output byte

0x11 All size of input byte

0x04 Module ID

0x08 Address of output byte

0x09 Address of input byte

0x0C Fnbus Status, error inf ormati on

0x0E Size of output bit

0x0F Size of input bit

0x12 IO Data output#0

0x13 IO Data input#0

0x16 Parameter length

0x17 Parameter data

0x18 Hardware Rev

0x19 Firmware Rev

0x1A Firmware release date

0x1B Inspection date

0x20 String, Module description

3 : IO_Run

4 : IO_Timeout

5 : IO_Minorfault

6 : IO_Unrecoveryfault

7 : Reset

PDO Mapping Method

0 : DS301(Auto) (default)

2 : Manual

Name Type Attribute Default Meaning

Node ID value

Number of Module

-series GN-9261 CANopen Rev. 1.01.docx

Page 33 of (52)

Page 34

GN-9261 User Manual

G

unsigned8

ro

0xFE

Read Special Input 8 bit

unsigned8

ro

...

...

...

unsigned8

ro

unsigned8

rw

1

unsigned8

ro

0xFE

Special input Interrupt Mask any

unsigned8

rw

0xFF

...

...

...

unsigned8

rw

0xFF

unsigned8

ro

0xFE

number of entries

unsigned8

rw

0

1st special output block

...

...

...

unsigned8

rw

0

64st special output block

unsigned8

ro

0xFE

Error Mode 8 Special output

unsigned8

rw

0xFF

...

...

...

unsigned8

rw

0xFF

unsigned8

ro

0xFE

Fault State 8 output lines

unsigned8

rw

0

...

...

...

unsigned8

rw

0

0x2100

0x213F

0x00 Read special input data

0x3000

0x3005 0x00 Enable speci al input int errupts

0x3006

0x3200

0x3206

0x3207

0x1 8-bit special input 1

… …

0xFE 8-bit special input 254

0x00 Number of entries

0x01

0xFE

0x00 Number of entries

0x01 8-bit special output 1

0xFE 8-bit special output 254

0x00 Number of entries

0x01 Faultmode for special output 1

0xFE Faultmode for special output 254

0x00 Number of entries

0x01 Fault state for spec i al output 1

0xFE Fault state for special output 254

Special input interrupt mask any

change for special input 1

... ...

Special input interrupt mask any

change for special input 254

… …

... ...

... ...

change for Special Inputs

• Object 0x2100(Slot#0=NA), Manufacture Information.

Index Sub Name Type Attribute Default Meaning

0x00 number of entries unsigned8 ro 0x4F number of entries(slot number)

0x04 module id unsigned16 ro 0

• Object 0x2101(Slot#1=IO), ... , 0x213F(Slot#63=IO), IO Module Inform ation.

Index Sub Name Type Attribute Default Meaning

0x00 number of entries unsigned8 ro 0x4F number of entries(slot number)

0x04 module id unsigned16 ro 0

• Object 0x20F0, Network Adapter Status.

This object contains the Network Adapter status.

- Sub-index 2 contains rotary switch value set Node ID from NA.

- Sub-index 5 contains Dip switch value set baudrate from NA. If you write 5(125), you can read 7D

h.

- Sub-index 6 set Master's PDO mapping method. By default, DS301 Auto mapping. PDO1 is digital IO and

PDO2~3 analog IO fixed. From PDO4 additional IO slot is used in sequence. Manual mapping set all digital

IO, second analog IO and Special IO lastly. So you need separate master.

-series GN-9261 CANopen Rev. 1.01.docx

Page 34 of (52)

Page 35

GN-9261 User Manual

G

• Object 0x3000, Special Modules, Inputs.

This object contains the process data of the special input modules. Sub-index 1 contains the first 8 special

input channels from the left to the right, counted from starting with the Network Adapter. Sub-index 2 the next

etc.

• Object 0x3005, Special Inputs Interrupt.

This object shall enable and disable special module the interrupt behavior without changing the interrupt

mask. By default, special input activates an interrupt.

• Object 0x3005, Special Inputs Interrupt.

This object determines, which input port lines shall activate an interrupt by positive or/and negative edge

detection.

• Object 0x3200, Special Modules, Outputs.

This object contains the process data of the special output modules. Sub-index 1 contains the first 8 special

output channels from the left to the right, counted from starting with the Network Adapter. Sub-index 2 the

next etc.

• Object 0x3206, Special Output Error Mode

This object is used to define whether the outputs change to a pre-defined error status (see object 0x3207) in

the event of an

error (i.e. Adapter changes to the Stopped status, Node guarding has failed,). Once the error is remedied,

the outputs retain

their momentary status, i, e. the set error status of the output channels remains unchanged.

All analog outputs that are not covered by the object 0x3207 are always set to 0 in the event of an error.

0 = The output remains unchanged

1 = The output changes to a pre-defined error status

• Object 0x3207, Special Output Error Value integer

This object is used to define values that they are to assume in the event of an error. Prerequisite being that

the corresponding bit is set in object 0x3206

6.3 Standard Device Profile Area – DS401

• Object 0x6000, Digital Inputs

This object contains the process data of the digital input modules. Sub-index 1 contains th e fi r st 8 di gi t al in pu t

channels from the left to the right, counted from starting with the Network Adapter. Sub-index 2 the next etc.

• Object 0x6005, Global Interrupt Enable Digital 8-bit

This object shall enable an d disable globally the interr upt behavior without chan ging the interrupt mask s. In

event-driven mode th e device tr ansmits the i nput values depending o n the interrupt masks in objects 6006

h, and 6008h. If the object is not supported, the device shall behave accordingly to the default value.

6007

h,

• Object 0x6006, Interrupt Mask Any Change 8-bit

-series GN-9261 CANopen Rev. 1.01.docx

Page 35 of (52)

Page 36

GN-9261 User Manual

G

This object determines, which input port lines shall activate an interrupt by positive or/and negative edge

detection.

If the object is not supported the device shall behave accordingly to the default value.

• Object 0x6007, Interrupt Mask Low-to-High 8-bit

This object determ ines, which input port l ines shall acti vate an interru pt by positive edg e detection (lo gical 0

to 1). Done for groups of 8 lines. The values shall be in an ”OR” connect ion to the values of 6006

(Interrupt mask any change 8-bit). If inputs are inverted by 6002

h object (polarity input 8-bit), the positive logical

h object

edge shall correspond to negative physical edge.

0 = Interrupt Disabled

1 = Interrupt Enabled

• Object 0x6008, Interrupt Mask High-to-Low 8-bit

This object determ ines, whi ch input por t lines shal l activat e an interr upt b y negativ e edge det ectio n (logic al 1

to 0). Done for groups of 8 lines. The values shall be in an ”OR” connect ion to the values of 6006

h object

(Interrupt mask an y change 8-bit). If inputs are inverted by 6002h o bject (polarity input 8-bit), the negat ive

logical edge shall correspond to positive physical edge.

0 = Interrupt Disabled

1 = Interrupt Enabled

• Object 0x6200, Digital Outputs

This object contai ns the process data of t he digital output m odules. Sub-index 1 contai ns the first 8 digital

output channels from left to right, counting starting from the Network Adapter. Sub-index 2 the next etc.

• Object 0x6206, Error Mode Output 8-Bit

This object defines whether the out puts change to a pre-defined error status i n the event of an error (i.e.

Adapter changes to the Stopped status, Node guarding has failed,) (see object 0x6207). If the error is remedied,

the outputs remain in their momentary status, i.e. the set error status of the output channels remains

unchanged.

0 = Outputs remain unchanged (per channel)

1 = Outputs change to a pre-defined error status (per channel)

• Object 0x6207, Error Value Output 8-Bit

This object is used to define the values, which the outputs should assume in the event of an error. Prerequisite

being that the corresponding bit in object 0x6206 is set.

0 = Output to 0 (per channel)

1 = Output to 1 (per channel)

Example: Index 0x6206 sub-index 0 = 1, sub-index 1 = 65 = 0x41

Index 0x6207 sub-index 0 = 1 sub-index 1 = 33 = 0x21

Channel 1 is set to 1, channel 7 is set to 0, and all other output channels remain unchanged in the event of an

error

• Object 0x6401, Analog Inputs 16 Bit

This object contains the process data of the analog input modules. Sub-index 1 contains the first analog input

channel from left to right, counting starting with the Network Adapter. Sub-index 2 the second, etc.

• Object 0x6411, Analog Outputs 16 Bit

This object contains t he process data of the an alog output modules. Sub-in dex 1 contains the first an alog

output channel from left to right, counting starting with the Network Adapter. Sub-index 2 the second, etc.

-series GN-9261 CANopen Rev. 1.01.docx

Page 36 of (52)

Page 37

GN-9261 User Manual

G

• Object 0x6421, Analog Input Interrupt Trigger Selection

This object determ ines, which events shall cause an interrupt f or a specific channel. All bits set to 1b shall

trigger the correspond ing analog input. If the objec t is not suppor ted, the dev ice shall beha ve accordingl y to

the default value.

Format:

Bit Value Meaning

0

0b Upper limit not exceeded

1b Upper limit exceeded

1

2

3

4

reversed 0b Reserved for future use

• Object 0x6423, Analog Input Global Interrupt Enable

This object shall e nable and disab le globally the interrupt behavior without changing the interrupt mask . By

default, no analog input activates an interrupt.

0 = global interrupt disabled

1 = global interrupt enabled

• Object 0x6424, Analog Input Interrupt Up per Limit Integer

If enabled (see 6423h object), an interrupt is triggered when the analog input is equal or rises above the given

value. The value shall be always left adjusted. As long as the trig ger condition is m et, every change of the

analog input data generate s a new interrupt, if there i s no additional trigger condition, e.g. an inpu t interrupt

delta (6426h).

• Object 0x6425, Analog Input Interrupt Lower Limit Integer

0b Input not below lower limit

1b Input below lower limit

0b Input not changed by more than delta

1b Input changed by more than delta

0b Input not reduced by more than negative delta

1b Input reduced by more than negative delta

0b Input not increased by more than positive delta

1b Input increased by more than positive delta

If enabled (see 6423h obje c t), an inter rup t is tr igg ered when t h e analog input falls below the given value. T he

value shall be always left adjusted. As long as the trigger conditi on is met, ever y change of the analog inp ut

data generates a new interrupt, if there is no addit ional tr igger co nd iti on, e.g. an in put interr u pt delt a (64 26h).

• Object 0x6426, Analog Input Interrupt Delta Limit Integer

This object shall set the delta value (rising or falling above or below the last communicated value) for interruptenabled analog inputs (see 6423h object).

• Object 0x6427, Analog Input Interrupt Negative Delta Unsigned

This object shall set the negative delta value (falling below the last communicated value) for interrupt-enabled

analog inputs (see 6423h object).

-series GN-9261 CANopen Rev. 1.01.docx

Page 37 of (52)

Page 38

GN-9261 User Manual

G

• Object 0x6428, Analog Input Interrupt Positive Delta Unsigned

This object shall set the ne gat ive d elt a v alu e (r ising be lo w the las t c om municated value) for interrupt-enabled

analog inputs (see 6423h object).

• Object 0x6443, Analog Output Error Mode

This object is used to d ef ine whether t he outp uts chan ge to a pre-defined error status (s ee objec t 0x64 44) in

the event of an error (i.e. Adapter changes to the Stopped status , Node guarding has failed,). Once the err or

is remedied, the outputs retain their momentary status, i, e. the set error status of the output channels remains

unchanged.

All analog outputs that are not covered by the object 0x6444 are always set to 0 in the event of an error.

0 = The output remains unchanged

1 = The output changes to a pre-defined error status

• Object 0x6444, Analog Output Error Value Integer

This object is used to defin e values that they are to assum e in the event of an error. Prerequisite being that

the corresponding bit is set in object 0x6443

-series GN-9261 CANopen Rev. 1.01.docx

Page 38 of (52)

Page 39

GN-9261 User Manual

G

0x0000~

Read

Process input image bits

2

All input registers area are addressable by bit address.

Size of input image bit is size of input image register * 16.

0x1000~

Read/Write

Process output image bits

1,5,15

All output registers area are addressable by bit address.

Size of output image bit is size of output image register * 16.

Code

1(0x01)

Read Coils

This function code is used to read from 1 to 2000 contiguous

7. MODBUS Interface

7.1 MODBUS Interface Register/Bit Map

• Register Map

Start Address Read/Write Description Func. Code

0x0000 ~ 0x007E Read Process input image registers (Real Input Register) 3,4,23

0x0800 ~ 0x087E Read/Write Process output image registers (Real Output Register) 3,16,23

0x1000 * Read Adapter Identification special registers. 3,4,23

0x1020 * Read/Write Adapter Watchdog, other time special register. 3,4,6,16,23

0x1100 * Read/Write Adapter Information special registers. 3,4,6,16,23

0x2000 * Read/Write Expansion Slot Information special registers. 3,4,6,16,23

* The special register map must be accessed by read/write of every each address (one address).

• Register Bit Map

Start Address Read/Write Description Func. Code

7.2 Supported MODBUS Function Codes

Function

-series GN-9261 CANopen Rev. 1.01.docx

Function Description

(Read output bit)

status of coils in a remote device. The Request PDU specifies the

starting address, i.e. the address of the first coil specified, and the

number of coils. In the PDU Coils are addressed starting at zero.

Therefore coils numbered 1-16 are addressed as 0-15. The coils in the

response message are packed as one coil per bit of the data field. Status

is indicated as 1= ON and 0= OFF.

Page 39 of (52)

Page 40

GN-9261 User Manual

G

2(0x02)

Read Discrete Inputs

This function code is used to read from 1 to 2000 contiguous status of

3(0x03)

Read Holding Registers

This function code is used to read the contents of a contiguous block of

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0000(0)

Any

Echo Request Data

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x0001(1)

0x0000, 0xFF00

Echo Request Data

Reset Only

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000B(11)

0x0000

Total Message Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000C(12)

0x0000

CRC Error Count

Sub-function

Data Field (Request)

Data Field (Response)

Description

0x000D(13)

0x0000

Exception Error Count

(Read input bit)

(Read output word)

discrete inputs in a remote device. The Request PDU specifies the

starting address, i.e. the address of the first input specified, and the

number of inputs. In the PDU Discrete Inputs are addressed starting at

zero. Therefore Discrete inputs numbered 1-16 are addressed as 0-15.

The discrete inputs in the response message are packed as one input

per bit of the data field.

Status is indicated as 1= ON; 0= OFF.

holding registers in a remote device. The Request PDU specifies the

starting register address and the number of registers. The register data

in the response message are packed as two bytes per register, with the

binary contents right justified within each byte. For each register, the first

byte contains the high order bits and the second contains the low order

bits.

7.2.1 8(0x08)Diagnostics

Sub-function 0x0000(0) Return Query Data

The data passed in the request data field is to be returned (looped back) in the response.

The entire response message should be identical to the request.

Sub-function 0x0001(1) Restart Communications Option

The remote device could be initialized and restarted, and all of its communications event counters are

cleared.

Especially, data field 0x55AA make the remote device to restart with factory default setup of EEPROM.

Sub-function 0x000B(1 1) Return Bus Message Count

The response data field returns the quantity of messages that the remote device has detected on the

communications system since its last restart, clear counters operation, or power-up.

Sub-function 0x000C(12) Return Bus Communication Error Count

The response data field returns the quantity of CRC errors encountered by the remote device since its last

restart, clear counters operation, or power-up.

Sub-function 0x000D(13) Return Bus Exception Error Count

The response data field returns the quantity of MODBUS exception responses returned by the remote device

since its last restart, clear counters operation, or power-up.

Exception responses are described and listed in section 3.2.11.

Sub-function 0x000E(14) Return Slave Message Count

The response data field returns the quantity of messages addressed to the remote device, or broadcast, that

the remote device has processed since its last restart, clear counters operation, or power–up.

-series GN-9261 CANopen Rev. 1.01.docx