Page 1

User manual

EPC X Device series

8,4“

10,4“

5,7“

EPC X 550

6,4“

EPC X 1000

EPC X 840

EPC X 640

CiS-Nr.: 360.610.0150

Reg 10517/0606

Version 1/06.06

© Elektronik-Systeme LAUER GmbH & Co. KG

Page 2

Elektronik Systeme LAUER GmbH & Co. KG

P.O Box 1465

D-72604 Nürtingen

Operating instructions: Embedded XScale

issue: 13. Juni 2006

editor: Jung

Operating instructions, manuals and software are copyrighted. All rights

are reserved. Copying, duplicating, translating, transcribing en bloc or

partially is prohibited. An exception is the making of a software back up

copy for private use.

• We reserve the right to make amendments to the manual without

prior notice.

• We can not guarantee the accuracy and correctness of the

programmes and data stored on the CD-ROM.

• Helpful suggestions, improvements as well as references to errors

are welcome at any time.

0-2

• The stipulations are also valid for any special annexes to this manual.

Microsoft, Windows 2000, Windows XP and the Windows Logo are either

registered trademarks or trademarks of the Microsoft Corporation in the

USA and/or other countries.

The above terms in this documentation can be brands, whose use by

third parties can breach the rights of the proprietor.

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 3

User tips

Please read the manual prior to using for the first time and keep it in a

safe place for future use.

Target group The documented information in this manual refers to the appliance, place

of use, transport, storage, assembly, use and maintenance.

This manual is directed to the following target groups:

• User

• Service technicians/maintenance technicians

Especially observe the chapter „safety instructions and general

instructions“.

Knowledge of PC and Microsoft-operating systems are assumed. General knowledge in the area of automation technology is recommended.

Diagram convention [Key] Key entries by the user are shown in squared brackets, for

example [CTRL] or [DEL]

italic

Necessary basic knowledge A solid Knowledge of the personal computer and Microsoft-operating

systems is assumed and a general knowledge in the area of automation

technology is recommended.

Approbation’s & standards You will find information in the annex, chapter „certificate and guide lines“.

Safety instructions Anywhere in the automation equipment, where dangerous errors may

occur, i.e. that an occurring error may cause major material or personal

damage, additional external precautions or facilities have to be made (for

example by means of independent limit switches, mechanical interlocks

etc.), which in case of an error guarantee or enforce a secure operating

condition.

The test and aptitude of the intended usage by the user res. the usage

under operational conditions is the responsibility of the user. Therefore

Elektronik-Systeme LAUER does not assume liability.

Names of pushbuttons to be used, menus or other screen

elements as well as brand names are shown in italic letters.

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

0-3

Page 4

User tips

Icons The following icons are used in the manual to mark certain paragraphs:

Danger

Means that death or severe injury will occur when the relevant

precautionary measures are not taken

Caution

Means that death or severe injury may occur when the relevant

precautionary measures are not taken.

Warning

With warning triangle means that a light injury may occur when the rele-

vant precautionary measures are not taken

Precaution

Without warning triangle means that material damage may occur when

the relevant precautionary measures are not taken

Attention

Means that an undesirable effect or situation may occur if the respective

advise is ignored.

The warning advise for the highest level is used if various danger levels

occur. When a warning advise with a warning triangle warns about personal damage then an additional warning for material damage can be

added.

Qualified personnel The described appliance may only be installed and operated in

accordance with this documentation. Only qualified personnel may put it

into operation and operate this appliance. Qualified personnel are persons,

who in accordance with the safety regulations contained in this

documentation, are authorised to put into operation, earth and stamp

appliances, systems and circuits.

Intended use

The appliance can only be used for the designated purposes as described

in the catalogue and the technical write up and only in conjunction with

external devises i.e. components recommended and authorised by Elektronik-Systeme LAUER GmbH & Co. KG. The efficient and safe operation

of the appliance presupposes appropriate transport, storage, assembly

and installation as well as accurate handling and maintenance.

0-4

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 5

Table of contents

User tips 3

Table of contents 5

Preamble 6

Certificates and guide lines 7

1 Description of the product 1-1

1.1 Operating side .................................................................. 1-1

1.2 Side of slot ........................................................................ 1-2

2 How to commission the appliance 2-1

2.1 Current supply ...................................................................... 2-1

2.2 Earthing scheme............................................................... 2-2

2.3 Installation ........................................................................ 2-2

2.4 How to switch on the appliance......................................... 2-2

T Technical Datas T-1

T1 Dimensions of the machine ............................................... T-1

T1.1 EPC X 550 overall sizes/ assembly dimensions ................ T-1

T1.2 EPC X 550 unit measures ................................................ T-2

T1.3 EPC X 640 overall sizes/locating distances ...................... T-3

T1.4 EPC X 640 unit measures ................................................ T-4

T1.5 EPC X 840 overall sizes/locating distances ...................... T-5

T1.6 EPC X 840 unit measures ................................................ T-6

T1.7 EPC X 1000 overall sizes/assembly dimensions ............... T-7

T1.8 EPC X 1000 unit dimensions ............................................ T-8

T2 Data of the electrical system ............................................. T-9

T3 Environmental conditions ................................................ T-10

T4 Intersections ................................................................... T-11

T5 Options for the BUS module (COM 2) ............................. T-12

T6 Maintenance and attendance .......................................... T-14

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

0-5

Page 6

Preamble

Elektronik-Systeme LAUER GmbH & Co. KG

Kelterstraße 59

D-72669 Unterensingen

Tel. +49 (0) 7022 / 9660-0

Fax +49 (0) 7022 / 9660-274

http://www.lauer-systeme.net

our philosophy Elektronik-Systeme LAUER is a reliable internationally orientated partner.

From the text display LCA, the high-tech operating console PCS, to the

industrial computer we supply a complete range to:

• operate, observe a nd control

Systeme LAUER stands for an almost unlimited product range and

competent service, under the umbrella of AUGUSTA Technologie AG – a

global group of companies.

Through active co-operation with our customers, persuasive concepts

are developed harmonising efficiently man, and interface. Proximity to

customers – the direct dialog – is the basis of our success.

Support contact Telephone: +49 (0) 7022 / 9660 -132, -209, -221

eMail: Support@systeme-lauer.de

for support inquiries always have the serial number of your appliance at

hand!

Actual drivers, software, manuals, ... can be found on our Website:

http://www.systeme-lauer.de

Sales contact Telephone: +49 (0) 7022 / 9660 -0

eMail: Sales@systeme-lauer.de

0-6

additionally on offer ... ... courses and technical training in our modern equipped training centre

or alternatively at your place of business. Please ask your distribution

agent for the latest training course schedule.

... not only demo-appliances but also specialists who will personally assist

you when you first take your appliance into operation.

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 7

Certificates and guide lines

The following applies for the products described in this documentation:

EMV-directives Direct current –DC supply

The appliances running on DC supply comply with the EC-directive „89/

336/EEC electromagnetic compatibility“ and are according to the CEmarking designed for following applications:

Application Standard

Emitted interference interference resistant

industrial EN 61000-6-4: 2001 EN 61000-6-2: 2001

low voltage directive 230V The appliances running on AC supply comply with the EC-directive 73/

23/EEC, low voltage directive. Compliance with this standard was tested

in accordance with EN 60950.

Declaration of conformity The EC- declaration of conformity and the associated documentation

and are kept at the disposal of the responsible authorities. Your distribution

agent can make these available on demand.

Assembly directives Please note the assembly directives and safety instructions mentioned

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

0-7

Page 8

0-8

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 9

1 Description of the product

1 Description of the product

The EPC X-series is suitable for the visualization of process data of

simple to moderate complexity. Due to the process architecture used

(Intel XScale) the machines produce less failures and are suitable for

higher temperatures than normal x86 systems, and additionally, they

combine this factor with lower machine costs.

The appliances were developed to be used in connection with the operating

systems Windows CE, LINUX, and VxWorks. Via the 2 USB interface, a

connection of external keyboards, mice, USB-sticks, or of certain printers

is possible. Via the integrated Ethernet-intersection, the appliances can

easily either be embedded in existing computer networks, or be used as

Web-panels

In connection with the (optional) visualizing software WOP-iT, or zenOn

CE, and the bus module option, the appliances can be used to visualize

SPS-data provided by different manufacturers.

The series includes the versions EPC X 550tm, EPC X 550tc, EPC X

640tc, EPC X 840tc, and EPC 1000tc.

1.1 Operating side

1 Monochrome/Color STN-Display

with Resistive Touch

(EPC X 550)

Color TFT-Display with Resistive

Touch

(EPC X 640/EPC X 840/

EPC X 1000)

1

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

1-1

Page 10

1 Description of the product

1.2 Side of slot

Without option for bus module.

(at request)

With option for bus module

(standard)

1-2

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 11

2 How to commission the appliance

2 How to commission the appliance

2.1 Current supply

Caution!

The EPC X may only be operated when using an extra-low voltage

combined with a safe separation according to the regulation EN60950!

The control transformer must correspond to the regulation EN60742!

Please check the distribution supply according to the type plate.

When wiring the voltage supply, and the a.c. voltage, please observe the

information on the type plate.

Please check all cable connections before operating the appliance.

The connection to the 0V distribution voltage shows low impedance when

connected to the casket (the earth)!

1 Power supply 24 V

2 Grounding screw

Build-up of supply

2

The current supply is effected via a bipole connector (Phoenix MST BT

2.5/2-STF-5.08)

230 VAC

1

230 VAC

+ 24 V

0 V

24 V DC

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

2-1

Page 12

2 How to commission the appliance

2.2 Earthing scheme

In order to guarantee a safe derivation of electrical interferences, please

observe the following points:

• Please choose the shortest possible way to connect the appliance

and the switch cupboard to a central earthing point.

• Please pay attention to choose the connection with the lowest

possible induction between the appliance and the switch cupboard.

• All data-cables connected to the appliance have to be equipped with

closed lines.

• Please earth the screens on both sides. The connection between

the connected systems has to be of low impedance. Please eliminate

the transfer of high compensating currents via the conducting screen

due to differences of potential.

• Please earth the appliance with a green and yellow cable with a

cross-section of at least 4 mm².

2.3 Installation

Installation The appliance has to be installed into a HF-tight casket or switch cupboard

made of metal.

Please make sure that sufficient air can circulate. Please provide a space

for circulating air of 100 mm around the appliance, so that the heat

produced in the appliance can vanish into the surroundings!

When installing or dismantling the appliance, it must be stressfree.

When assembling the appliance in the casket, please do only use the

parts supplied with the appliance. Both kind and number of the assembly

parts depend on the appliance (cf. ratings).

Caution!

Damages at the appliance are possible!

The front protection IP65 is only guaranteed if the seal is attached correctly

to the front plate.

2.4 How to switch on the appliance

Starting process The EPC X boots and loads the Operating System.

2-2

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 13

T Technical Datas

T Technical Datas

T1 Dimensions of the machine

T1.1 EPC X 550 overall sizes/ assembly dimensions

Front plate width 215.0 mm

height 160.0 mm

Dimensions of section width 197.0 mm

height 142.4 mm

Depth of installation 53 mm

Weight approx. 1.2 kg

Opening in the front plate for installation

Opening W x H

197.0 mm x 142.4 mm

Manner of fastening:

with 4 aluminium or plastic retainer

blocks with set screws

M5x30, DIN 914, with pin and

hexagon socket, zinced.

(LAUER assembly set no 37)

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-1

Page 14

T Technical Datas

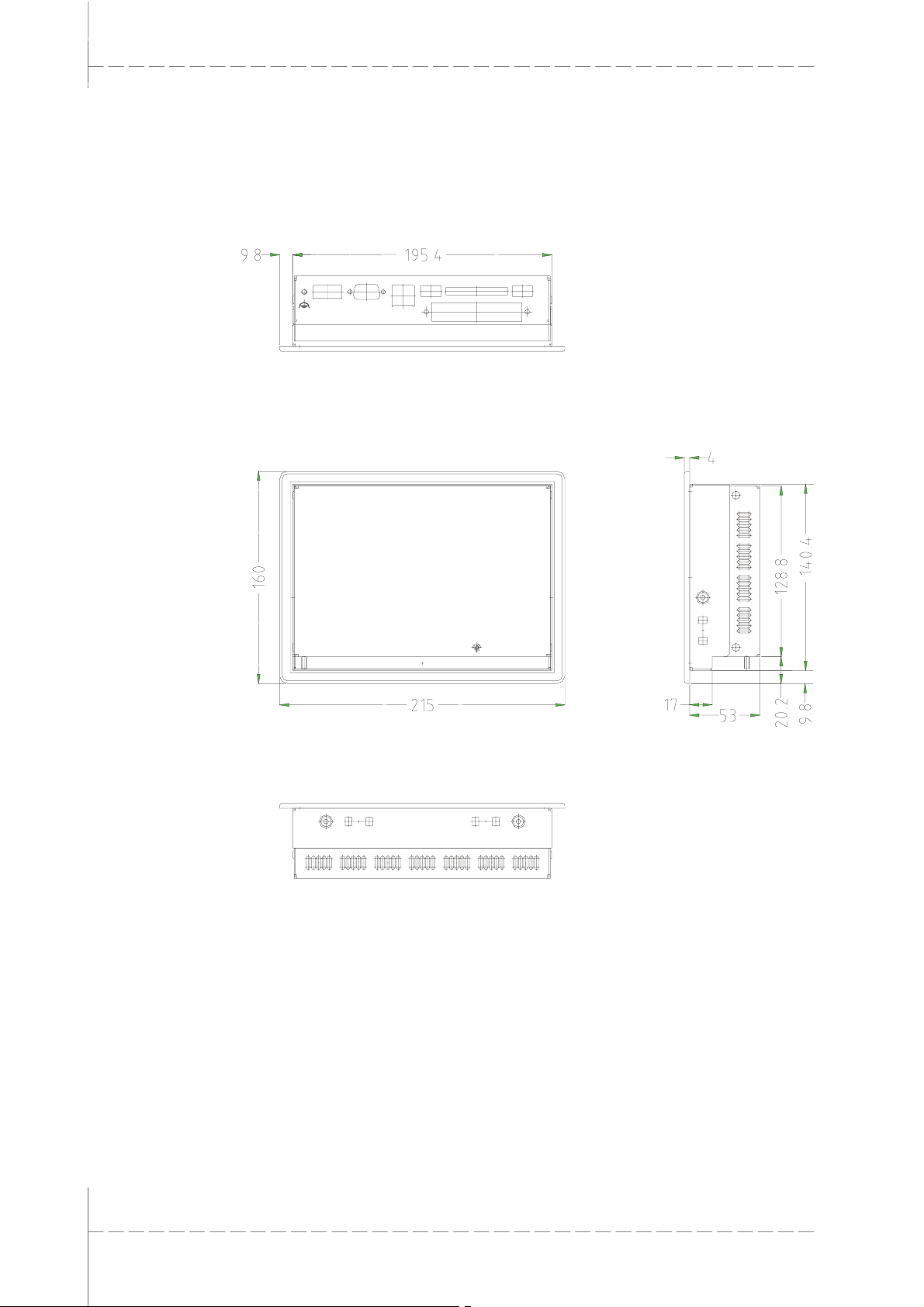

T1.2 EPC X 550 unit measures

View of the appliance’s lower side

View of the appliance’s back side Side view

View of the appliance’s upper side

T-2

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 15

T Technical Datas

T1.3 EPC X 640 overall sizes/locating distances

Front plate width 211.0 mm

height 158.0 mm

Cutout measures width 197.0 mm

height 142.0 mm

Assembly depth 57 mm (without BUS-module option)

65 mm (with BUS-module option)

Opening in the front plate for installation

Opening W x H

197.0 mm x 142.0 mm

Manner of fastening: with 6

aluminium or plastic retainer blocks

with set screws M 5x30, DIN 914,

with pin and hexagon socket,

zinced

(LAUER assembly set no 33)

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-3

Page 16

T Technical Datas

T1.4 EPC X 640 unit measures

View of appliance’s lower side

Side view of the appliance’s back side side view

T-4

view of the appliance’s upper side

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 17

T Technical Datas

T1.5 EPC X 840 overall sizes/locating distances

Front plate width 252.0 mm

height 190.0 mm

Cutout measures width 232.0 mm

height 170.0 mm

Assembly depth 61 mm (without BUS-module option)

69 mm (with BUS-module option)

Weight approx. 1.9 kg

Opening in the front plate for installation

Opening W x H

232.0 mm x 170.0 mm

Manner of fastening:

with 6 aluminium or plastic retainer

blocks with set screws M 5x30,

DIN 914, with pin and hexagon

socket, zinced

(LAUER assembly set no 33)

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-5

Page 18

T Technical Datas

T1.6 EPC X 840 unit measures

View of the appliance’s lower side

View of the appliance’s back side side view

View of the appliance’s upper side

T-6

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 19

T Technical Datas

T1.7 EPC X 1000 overall sizes/assembly dimensions

Front plate width 318.0 mm

height 244.0 mm

Cutout measurements width 303.0 mm

height 228.0 mm

Assembly depth 63 mm (without BUS-module option)

71 mm (with BUS-module option)

Weight approx. 2.7 kg

Opening in the front plate for installation

Opening W x H

303.0 mm x 229.0 mm

Manner of fastening:

with 6 aluminium or plastic retainer

blocks with set screws M 5x30,

DIN 914, with pin and hexagon

socket, zinced

(LAUER assembly set no 33)

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-7

Page 20

T Technical Datas

T1.8 EPC X 1000 unit dimensions

View of appliance’s lower side

Side view View of appliance’s rear end Side view

T-8

View of appliance’s upper

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 21

T Technical Datas

T2 Data of the electrical system

Current supply operating voltage 24 V ± 20% reverse battery protection

drawing of current EPC X 550 approx. 0.5 A

EPC X 640 approx. 1.0 A

EPC X 840 approx. 1.0 A

EPC X 1000 approx. 1.0 A

fuse 2.5 A inert

bypassing time 1 ms at 19.2 V (Ub-20%)

Properties of the display

Type of appliance (EPC X) 550tm 550tc 640tc 840tc 1000tc

Diagonal of display (inches) 5,7 5,7 6,4 8,4 10,4

Active area (mm) 115,2x86,4 115,2x86,4 132,5x99,4 170,9x128,2 211,2x158,4

Resolution (pixels) 320x240 320x240 640x480 640x480 640x480

Max. colours 256(Graustufen) 65536 65536 65536 65536

Angle of view (H)/(V) 46°/60° 100°/95° 110°/90° 130°/110° 130°/110°

Max. luminosity (cd/m²) 180 180 400 450 430

Contrast ratio 10 40 300 450 500

Reaction period (25°C, tr/tf, ms) 150/250 450/100 15/16 8/27 10/30

Technology of the display STN STN TFT TFT TFT

Life of tube 40 000 25 000 30 000 50 000 50 000

Touchscreen resistive resistive resistive resistive resistive

Range of operational temperature 0…50°C

Memory operating system 64 MB Compact-FLASH (external)

working memory 64 MB SDRAM, 32 bits

optional 128 MB SDRAM, 32 bits

residual memory 512 KB SDRAM battery-buffered

(use depends on software)

Processor Intel Xscale PXA255 with 400 MHz

Intersections serial 1 RS232 ad lib.

serial 2 option of intersection for communcation modules

USB 2x USB 1.1

(max. 0.5 A per port)

LAN Ethernet 10/100 MBit

Real time clock battery-buffered, with date and calendar

Time resolution 1 second

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-9

Page 22

T Technical Datas

T3 Environmental conditions

Ambient temperature: operation0…50° C

storage -20…60° C

Air moisture according to DIN EN60068-2-3

operation10…75%, not condensing

storage 10…75%, not condensing

Vibration during operation according to DIN EN50058-2-6

0.075 mm (10…58 Hz), sine

1G (58…500 Hz), sine

Shock during operation according to DIN EN60068-2-27

15 g, 11ms, half-sine

Protection type according to DIN EN60529

Front IP 65

Back IP 20

T-10

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 23

T Technical Datas

T4 Intersections

Compact-Flash-Slot As a standard, EPC X-appliances are equipped with a Compact-Flash-

Slot according to CFA-standard (type 1).

1 Compact Flash Slot

2 COM 1

3 Ethernet

4 USB 1

5 USB 2

6 Plug for bus module (opt.)

3

4

6

2

Caution!

Caution! In connection with EPC X only the Compact FLASH Cards

authorized by „Elektronik Systeme Lauer GmbH & Co KG“ may be used.

Only when the appliance is switched off, is it permitted to change the

Compact FLASH Card!

1

5

Serial intersection (COM 1) The serial intersection is occupied according to PC XT/AT standard!

The intersection’s potential is not separated.

DSUB-plug 9 channel plug

USB-intersections Both USB connections correspond to the USB 1.1 standard, and permit

a data transfer rate of 10 MBit/s.

Caution!

From the two USB-intersections there may be taken a current potential

of only 0.5 A each.

External USB-appliances needing a higher current supply must provide

it by themselves!

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-11

Page 24

T Technical Datas

T5 Options for the BUS module (COM 2)

„S1“ – RS 232/TTY The potential of the intersection RS 232 is not separated.

The potential of the intersection TTY is separated.

DSUB-socket with 25 channels

Shielding/housing

power source 1 (20 mA)

power source2 (20 mA)

„S2“ – RS 485/RS 422 The potential of the intersection RS 485/RS 422 is separated.

DSUB-plug: 15 channel plug

Shielding/housing

„P“ – Profibus-DP The potentials of the profibus intersection are separated.

DSUB-socket: 9 channel socket

T-12

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 25

T Technical Datas

„M“- MPI The potentials of the MPI intersection are separated.

DSUB-socket: 9 channel socket

„C“ – CAN The potentials of the CAN intersection are separated. At request, 2 diffe-

rent CAN protocols are available.

DSUB plug: 9 channel plug

Shielding/housing

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-13

Page 26

T Technical Datas

T6 Maintenance and attendance

Lauer EPC X appliances only need minimal maintenance and attendance.

Nevertheless, please observe the following information:

Changing the batteries The appliance is equipped with an integrated lithium battery to buffer the

data of both the real-time clock, and the integrated SRAM storage.

Type of battery: CR2032, 3V/230mAh

Manufacturer: Varta, type 6032

Buffer current: 2µA typ / 15 µA max

Control of battery voltage: yes (functionality depends on the software)

Lasting of battery (typ.): 5 years

The lasting of the battery always depends on the ambiance conditions

(working temperature, connecting/disconnecting time, air moisture). The

indicated lasting is based on the fact that the appliance is switched on

regularly (several days per week, resp. at least 1 500 hours per year.

The battery may only be changed by trained experts. Please observe the

ESD protection measures. We recommend to always have the battery

changed by „Elektronik-Systeme LAUER GmbH & Co. KG.“

Please switch off the appliance’s tension before changing the battery.

Before changing the batteries, the EPCX 550-appliances have to be

removed from the switch cupboard’s casket. Afterwards, you must loosen

the four flange-head screws (hexagon socket screw, 2.0 mm).

The appliances EPCX 640 to EPCX 1000 need not necessarily be

removed from the switch cupboard. In their case, it suffices to loosen the

screws at the rear sheet metal (hexagon socket screw, size 2.0), and to

tilt the rear sheet metal downwards. Please hold the rear sheet metal

approximately horizontally with one hand.

Please use a plastic part (e.g. Touch pen) to press the battery’s contact

spring backwards until the battery springs out of the holding device.

Remove the battery. Insert the new battery into the battery tray, and lock

it. While doing so, the battery’s positive pole must show upwards,

respectively be visible!!

Caution!

When the battery is changed, the data in the SRAM-dump and in the

real-time clock get lost.

T-14

NO manipulations at the appliance are permitted during the period of

liability for defects!

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Page 27

T Technical Datas

Caution!

Do not short-out the battery contacts! Explosion hasard! Always replace

the battery by the same type from the same manufacturer!

Lithium batteries are hazardous waste. Please dispose of used batteries

according to the respective national regulations!

Changing the display tubes We recommend to have the display tubes changed by „Systeme Lauer.“

With respect to the tubes’ service lives, please refer to the ratings.

Display tubes contain traces of mercury, and are hazardous waste. They

are to be disposed of according to the respective national regulations!

Cleaning Please do always use mild detergents (e.g. neutral soap solution or diluted

washing-up liquid). Please do always use a soft, clean cloth to clean the

appliance.

Caution!

Please, do not use any detergents containing abrasive substances (e.g.

scouring powder or cleansing milk. They can either spoil the readability

of the representation on the display, or they can damage the touch screen!

Please, do not use any acetone or petroleum ether!

How to operate the touch screen The touch screen may only be operated by hand, or with especially

designed touch-pens. When using pointed metal parts (e.g. screw drivers)

can damage the touch screen!

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

T-15

Page 28

T Technical Datas

T-16

© Elektronik-Systeme LAUER GmbH & Co. KG • Kelterstr. 59 • 72669 Unterensingen • Tel. 07022/9660-0 • Fax 07022/9660-103

Loading...

Loading...