Page 1

EPCTA100AM

Service&MaintenanceManual

MAEN043,2010-12

English

Page 2

Service&Maintenancemanual for EPCTA100AM

Foreword

This manual contains detailed information aboutEPC TA100 AM, including

descriptions of various actionsthat can be carried out in order to maintain or

update the PanelPC hardware and software.

The manual contains descriptions of basicmaintenance and replacement of

common parts in EPC TA100 AM.

The followingother manuals are available for EPC TA100 AM:

EPC TA100 AM installation manual (MAEN040x)for information regarding

installation.

Foreword

Order no: MAEN043

Copyright © 2010-12 Beijer Electronics AB. All rights reserved.

The information in this documentis subjectto changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics A B, including all its group companies, reserves the right to change any

information w ith ou t updating thispublication. Beijer ElectronicsAB assumes no responsibility for any

errors that may appear in this document. Read the entire installationmanual priorto i nstalling and using

this equipment. Only qualified perso nnel may install, operate or repair this equipment. Beijer Electronics

AB is not responsible for m odified, altered or renovated equipment. Because the equipment has a wide

range of applications, users must acquire the appropriateknowledgetousetheequipmentproperlyintheir

specific a pplications. Personsresponsible forthe application and the equipment must th emselves ensure

that each application isin compliance with all relevant requirements,standards and legislation in respect to

configuration and safety. Only partsand accessoriesmanufactured accordingto specifications set byBeijer

Electronics AB may be used.

BEIJER ELECTRONICSAB, INCLUDING ALL ITS GROUP

COMPANIES,SHALL NOT BE LIABLE TOANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTALOR CONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION,USE OR

REPAIROF THIS EQUIPMENT, WHETHER ARISING INTORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL BE

THE REPAIR,REPLACEMENT, OR REFUND OF PURCHASE PRICE,

AND THE CHOICE OF THEAPPLICABLE REMEDY SHALL BE AT

THE SOLE DISCRETION OFBEIJER ELECTRONICS AB .

BeijerElectronics, MAEN043

Page 3

Contents

Contents

1 Safety Precautions ....................................................... 5

1.1 General ...........................................................

1.2 During Installation ..............................................

1.3 During Use .......................................................

1.4 Service and Maintenance ........................................

1.5 Dismantling and Scrapping .....................................

2 Introduction ............................................................. 7

2.1 EPC TA100 AM .................................................

2.2 Maintenance .....................................................

2.3 Service andRepairs ..............................................

2.4 Dismantling and Scrapping .....................................

2.5 Contact andSupport ............................................

3 Installation ............................................................... 10

3.1 Space Requirements .............................................

3.2 Installation Process ..............................................

3.2.1 Other ConnectionsandPeripherals ................ .............

4 TechnicalData ........................................................... 13

5 ChemicalResistance .................................................... 14

5.1 Metal Casing .....................................................

5.2 Touch Screen and Overlay .......................................

5.2.1 AutotexF157/207 .......... .....................................

5.2.2 TouchScreenSurface ............. ...............................

5.2.3 AutoflexEB ........ ..............................................

6 Hardware Replacement ................................................. 17

6.1 Cables .............................................................

6.2 Replacing the Rear Cover ........................................

6.3 Replacing the Display/Display Cab

6.3.1 CalibratingtheTouch Screen ....................................

le ..........................

6.4 ReplacingtheCompleteFront ..................................

6.5 Replacing the Backlight .........................................

6.6 Available SpareParts for EPC TA

7 Additional Installation

Tips ............................................

100 AM ......................

7.1 GroundingthePanelPC ........................................

7.2 Ethernet Connection in t

7.3 To Achieve Better EMC Pr

he PanelPC ..........................

otection .............................

7.4 Ambient Temperature ...........................................

7.5 Safety .............................................................

7.6 Galvanic Isolati

7.7 Cable and Bus Term

on ................................................

ination RS485 .............................

8 Fault Tracing ............................................................. 32

9 Software .................................................................. 34

9.1 General Infor

9.1.1 Software Pro

9.2 Update or C

9.2.1 Backup a

mation about Software ...........................

ducts ...................... .........................

ustomize Software ..................................

ndRecovery ..................................... .......

10

10

12

14

15

15

16

16

17

18

19

20

22

23

24

25

25

26

27

28

29

30

31

34

34

35

35

5

5

6

6

6

7

8

8

8

9

BeijerElectronics, MAEN043

Page 4

Contents

10 EnvironmentalAspects ................................................. 36

10.1 General Environmental Aspects ................................

10.2 Environmental Impact of thePanelPCs ........................

10.2.1 MechanicalComponents ........................................

10.2.2 Electronics ............ ...........................................

10.3 Recycling .........................................................

10.4 Environmental Impact Report ..................................

36

36

36

36

37

37

BeijerElectronics, MAEN043

Page 5

Safety Precautions

1SafetyPrecautions

Both the installer and the ownerand/o r operator of the Panel PC must readand

understand this installation manual.

1.1 General

• Read the safety precautions carefully.

• Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

• Do not use the PanelPC in an environment with high explosive hazards.

• The supplier is not responsible for modified, altered or reconstructed

equipment.

• Use only parts and accessories manufactured accordingto specifications of

the supplier.

• Read the installation andoperating instructions carefully before installing,

using or repairingthe Panel PC.

• Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

PanelPC. This may cause fire or electrical shock.

• Only qualified personnel may operate thePanel PC.

• Storing the Panel PC where the temperatureis lower/higher than

recommended in this manual can causethe LCD display liquid to

congeal/become isotopic.

• The LCD display liquid contains apowerful irritant. In caseof skin contact,

wash immediately with plenty ofwater. In case of eye contact, hold theeye

open,flushwithplentyofwaterandgetmedicalattention.

• Thefiguresinthismanualservesanillustrativepurpose. Becauseofthemany

variables associated with any particular installation, the suppliercannot

assume responsibility for actual use based onthe figures.

• The supplier neither guarantees that the Panel PC is suitable for your

particular application, nor assumes responsibility for your productdesign,

installation or operation.

1.2 DuringInstallation

• The Panel PC is designed forstationary installation on a plane surface, where

the following conditions are fulfilled:

– no high explosive risks

– no strong magnetic fields

– no direct sunlight

– no large, sudden temperature changes

• Install the product accordingto the accompanying installation instructions.

• Ground the productaccording to the accompanying installation instructions.

• Only qualified personnel may install thePanel PC.

• Separate the high voltage, signal andsupply cables.

• Make sure thatthe voltage and polarity of the power sourceis correct before

connecting the productto the power outlet.

• Peripheralequipment must be appropriate for the application and location.

BeijerElectronics, MAEN043

5

Page 6

Safety Precautions

1.3 DuringUse

• Keep the Panel PC clean.

• Emergency stop and other safety functionsmay not be controlled from the

Panel PC.

• Do not use too muchforce or sharp objects when touching the keys, touch

screenetc.

1.4 ServiceandMaintenance

• Only qualified personnel should carry out repairs.

• The agreed warranty applies.

• Before carrying out any cleaning or maintenance operations,disconnect the

equipment from the electricalsupply.

• Clean the display and surrounding front coverwith a soft cloth and mild

detergent.

• Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier.

1.5 DismantlingandScrapping

• The PanelPC or parts thereof shall be recycledaccording

• The followingcomponents contain substances that migh

to health and theenvironment: lithium battery

display.

, electrolytic capacitor and

to local regulations.

t be hazardous

BeijerElectronics, MAEN043

6

Page 7

2Introduction

This manual describes howto maintain the EPC TA100 AM.

2.1 EPCTA100AM

Introduction

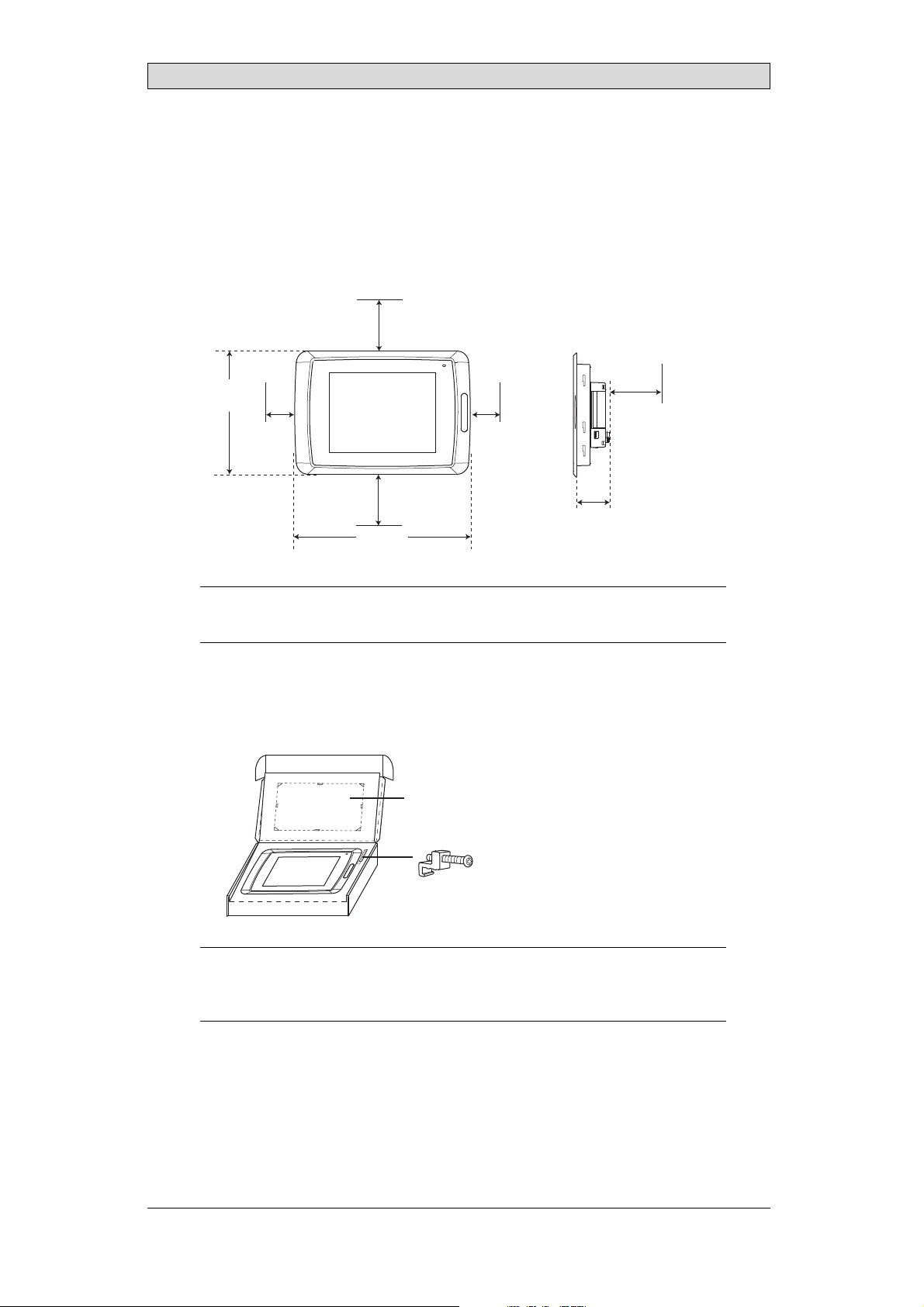

The following drawingsare available for EPC TA100 AM:

• Outline drawing

• Panelcut-out

BeijerElectronics, MAEN043

7

Page 8

Introduction

2.2 Maintenance

Carefully read the instructions beforebeginning maintenance on the Panel PC.

• Only qualified personnel shouldc arry out maintenance.

• The agreed warranty andlicense agreements apply.

• Any damage to thePanel PC caused by personnelinvalidates the warranty.

• Before carrying out any cleaning or maintenance operations,disconnect the

PanelPC from the power supply.

• Clean the display and surrounding front coverwith a soft cloth and mild

detergent. Recommended cleaning fluids for the display are water and IPA

(Isopropyl Alcohol or Hexane).

• Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier.

• A 6-month warranty onall service parts is provided.

Maintenance personnel are permitted to carry out the following actions:

• Replacing the Rear Cover

• Replacing the Display/Display Cable

• Replacing the Complete Front

• Replacing the Backlight

2.3 ServiceandRepairs

• Only accredited companies arepermitted to perform service and repairs.

• Ifanon-accreditedcompanyconductsanykindofserviceorrepair,theagreed

warranty will be invalidated.

• If training is required,c ontact the supplier.

• All maintenance should be performed in a 15-30°C temperature range.

• Any damage to thePanel PC caused by personnelinvalidates the warranty.

• Contracts with customers supersede theinformation in this document.

2.4 DismantlingandScrapping

• The PanelPC, or parts thereof, shall be recycled according to local

regulations.

• The followingcomponents contain substances that might be hazardousto

health and the environment: lithium battery, electrolytic capacitor, display.

BeijerElectronics, MAEN043

8

Page 9

Introduction

2.5 ContactandSupport

If you want toreport a fault or have a question about the Panel PC, please contact

your local supplier orfill out the form on the web site.

1.

Enter the web site www.beijerelectronics.com and select Support.

2.

Select Contact in themenu. Makesure to provide informationabout type

number, serial number, environment and aninstallation description.

The form will be sent tothe manufacturer’s help desk and they will answer your

question or register yourimprovement/fault.

To ensure quick resolution, provide asmany details as possible in your report.

Include the date and time whenthe problem occurred, a description of what you

were trying to do, the detailed steps you tookthat led up to the problem,and

details about any error messages received.

BeijerElectronics, MAEN043

9

Page 10

3Installation

3.1 SpaceRequirements

• Installation plate thickness: 1.5 - 9.0 mm (0.06- 0.35 inch)

• Space requirementswhen installing EPC TA100AM:

100 mm

(4.0 inch)

228 mm

(8.98 inch)

50 mm

(2.0 inch)

100 mm

(4.0 inch)

302 mm

(11.89 inch)

50 mm

(2.0 inch)

58 mm

(2.28 inch)

Installation

100 mm

(4.0 inch)

Caution:

Theo penings ontheenclosurearefor airconvection. Donotcovertheseopenings.

3.2 InstallationProcess

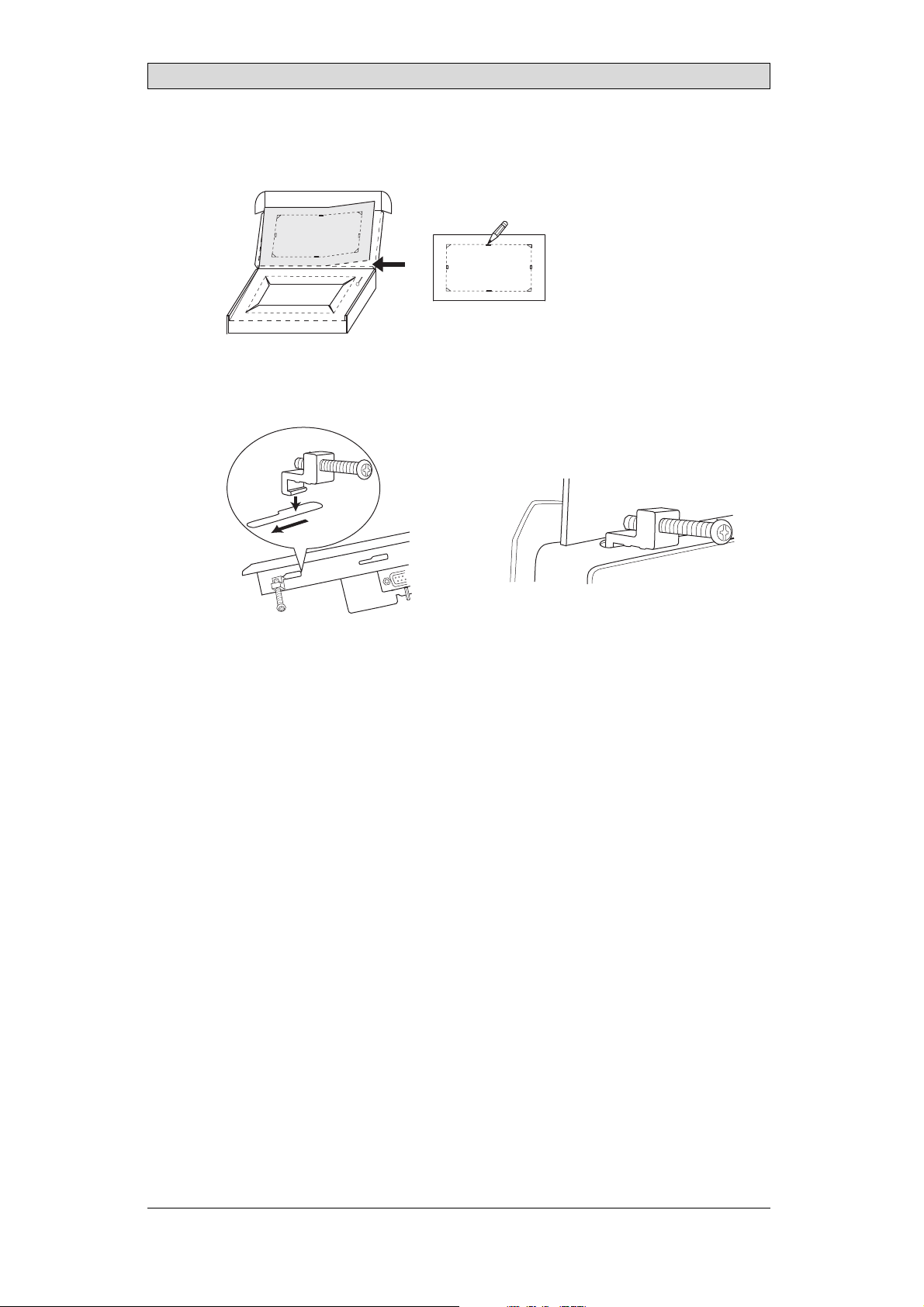

1.

Unpackand check the delivery. If damage is found, notify the supplier.

Panel cut out 264.5 x 206.0 mm

(10.41 x 8.11 inch)

x 13

Note:

Placethe PanelPConastablesurfaceduring installation.

Droppingitorlettingitfallmaycausedamage.

BeijerElectronics, MAEN043

10

Page 11

2.

Place the panel cut outwhere the Panel PC is to besituated, draw along the

outer sides of the holesand cut according to the markings.

3.

Secure the Panel PC in position, using all thefastening holes and the provided

brackets and screws:

x 13

Installation

0.5 - 1.0 Nm

BeijerElectronics, MAEN043

11

Page 12

Installation

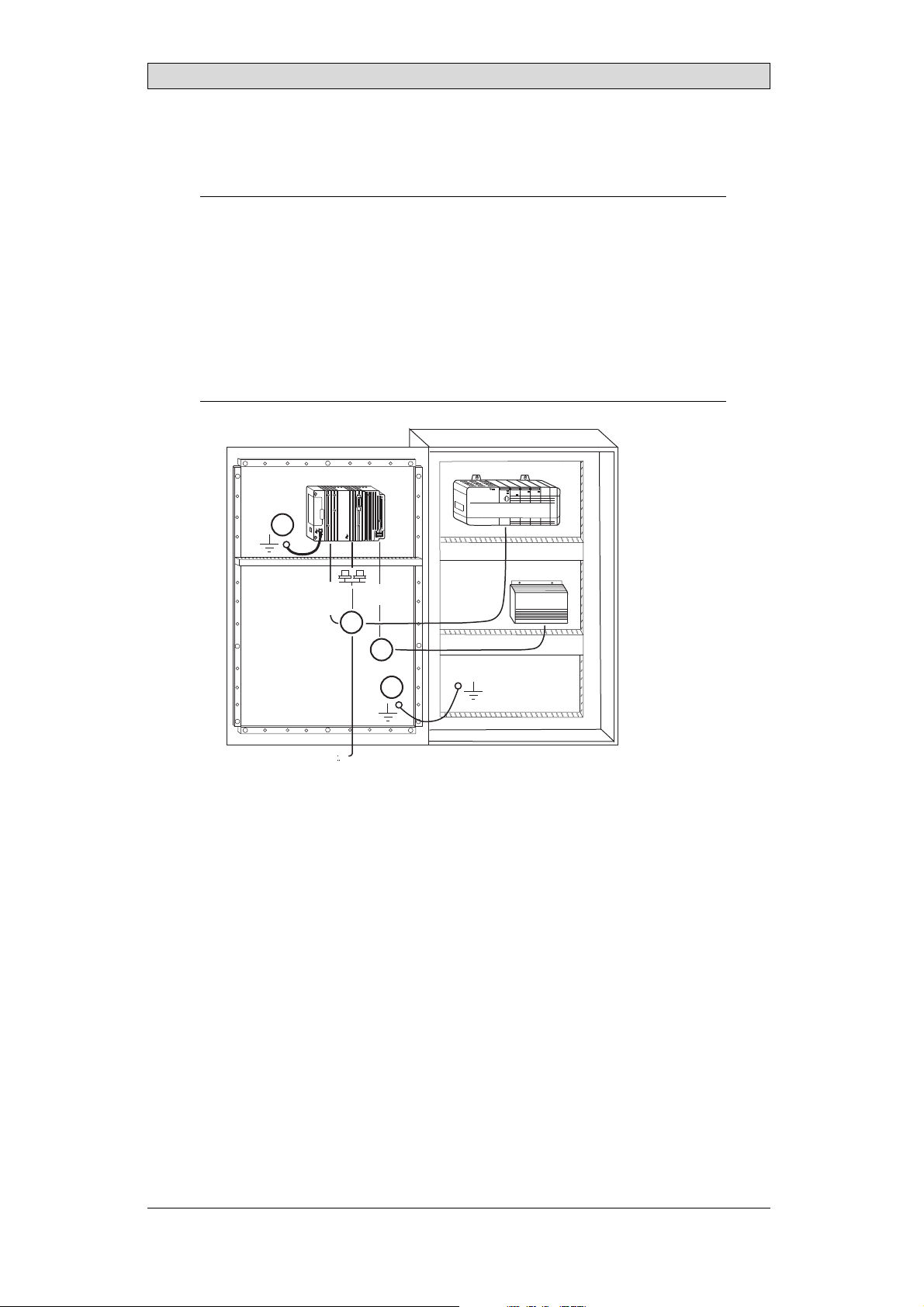

4.

Connect the cables in the specified order, according to the drawingand steps

below.

Caution:

• EnsurethatthePanelPCandthecontrollersystemhavethesameelectrical

grounding(referencevoltagelevel),otherwiseerrorsincommunicationmay

occur.

• ThePanelPCmustbebroughttoambienttemperaturebeforeitisstartedup. If

condensationforms,en surethatthePanelPCisdry beforeconnectingittothe

poweroutlet.

• Ensurethatthevoltageandpolarityofthepowersourceis correct.

• Useonlyshieldedcommunicationcables.

• Separatehighvoltagecablesfromsignalandsupplycables.

Power

CF CARD

B

1

Controller

RS422/RS485

RS232

24V DC

C

24V DC

D

A

Ethernet

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as short

as possible) with a cross-sectionof minimum 2.5 mm

– Connect cable C.

– Connect cable D.

5.

Carefully remove thelaminated film over thePanel PC display, to avoid static

2

.

electricity that could damage the panel.

3.2.1 OtherConnection

sandPeripherals

Cables, peripheral equipment and accessories must be suitable for theapplication

and its environment. Forfurther details or recommendations, please refer tothe

supplier.

BeijerElectronics, MAEN043

12

Page 13

Technical Data

4TechnicalData

Parameter EPCTA100 AM

Frontpanel,WxHxD 302x228x6mm

Mountingdepth 58m m (158mmincludingclearance)

Frontpanel seal IP66

Rear panel seal IP 20

Keyboard

material/Front

panel

Reverseside

material

Weight 2.1 kg

Serialport

RS422/RS485

SerialportRS232C 9-pinD-subcontact,malewith standardlockingscrews4-40

Ethernet 2x shieldedRJ45

USB Hosttype A(USB2.0),maxoutputcurrent500mA

Memoryslots 1x SDcard

Realtimeclock ±30PPM +errorbecauseofambienttemperature. Total

Power consumption

atrated voltage

Display TFT-LCD.800x600 pixels,64Kcolors.

Activeareaof

display,WxH

Fuse InternalDCfuse,3.15AT,5 x20mm

Powersupply +24VDC(20-30VDC).Powersupplyconnector.

Ambient

temperature

Storagetemperature -20°to +70°C

Relativehumidity 5- 85%non-condensed

Approvalsand

certifications

Touch screen: Polyesteronglass,1 millionfingertouch

operations. Overlay: AutotexF157orF207*.

Powder-coated aluminum

25-pinD-sub contact,chassis-mountedfemalewith

standardlockingscrews4-40UNC

UNC

maximumerror: 77seconds/monthat25°C.

Temperature coefficient: -0.034±0.006ppm/°C

Rechargeablebattery.

Normal: 0.5A

Maximum: 1.0A

CCFLbacklight lifetimeattheambienttemperatureof

+25°C:>50,000h.

211.2x 158.4mm

CE:Thepowersupplymustconformwiththerequirements

accordingtoIEC60950andIEC61558-2-4.

ULandcUL:Thepowersupplymustconformwiththe

requirementsfor classIIpowersupplies.

Verticalinstallation: 0°to+50°C

Horizontalinstallation: 0°to+40°C

Informationisavailableonthe website

www.beijerelectronics.com

2

*SeesectionChemicalResistance formoreinformation.

BeijerElectronics, MAEN043

13

Page 14

Chemical Resistance

5 ChemicalResistance

5.1 MetalCasing

The frame and casing material ispowder-coated aluminum. Thispowder paint

withstands exposure to thefollowing chemicals without visible change:

Aceticacid10% Phosphoricacid4%

Citricacid 10% Phosphoricacid10%

Diesel Seaw ater

Distilledwater Sodiumchloride2%

Edibleoil Sodiumchloride20%

Fueloil Sulphuricacid 20%

Hydrogenperoxide3% Tap water

The powder paintshows limited resistance to the f

ollowing chemicals at room

temperature:

Butanol Nitricacid3%

Hydrochloricacid5% Nitricacid 10%

Isopropylalcohol Phosphoricacid43%

Na-hypochlorite10% Turpentine

Note:

Ifexposuretoanyoftheabovechemicalsisdemanded,itisrecommendedtofirsttest

thechemical onan“invisible”spotof themetalcasing.

Thepowderpaintshowslittleornoresistancetothefollowingchemicalsatroom

temperature:

Aceticacid,conc. Methyl-ethylketone Toluene

Acetone Nitricacid 30% Trichlorethylene

Ammonia5% Phenol Xylene

Ammonia,conc. Sodiumhydroxide5% 97octanunleadedpetrol

Ethylacetate Sodiumhydroxide30% 98octanleadedpetrol

BeijerElectronics, MAEN043

14

Page 15

Chemical Resistance

5.2 TouchScreenandOverlay

5.2.1 AutotexF157/207

Autotex F157 or F207 coversthe overlay surrounding the touch screen.

SolventResistance

Autotex F157/F207 withstands exposure ofmore than 24 hours duration under

DIN42115Part2tothefollowingchemicalswithoutvisiblechange:

Acetonitrile DieselDowney/Lenor

Ajax/ Viminsolution EthanolPotassiumferricyanide

Alkalicarbonatesolution1Glycerine Potassiumhydroxide

Ammonia(<40%)

Aceticacid(<50%) Gumption

Arielpowderinsolution

1

Bleach

Castoroil Methanol Trichloroacetic acid

Causticsoda(<40%)

Cuttingoil Paraffinoil Windex

Cyclohexanol Persilpowderin solution1Wisk

Diacetonealcohol Petroleumspirit

1

Extremelyfaintglossingofthe texturewasnoted.

1

1

Glycol PureTurpentine

1

1

Hydrochloricacid(<36%) Sulfuricacid (<10%)

Linseedoil To ma to ketchup

Nitricacid (<10%) WhiteSpirit

1

Phosphoricacid(<30%)

(<30%)

SBP60/95

(<50%)

1

-

1

1

Autotex withstands DIN 42 115 Part 2 exposure of up to 1 hour duration to glacial

acetic acid without visiblechange.

Autotex is no

t resistant to high pressuresteam at over 100 °C or the following

chemicals:

Concentratedmineralacids Benzylalcohol

Concentratedcaustic solution Methylenechloride

OutdoorUse

In common with allpolyester based films Autotex F157/F207 is notsuitable for

use in conditions of longterm exposure to direct sunlight.

BeijerElectronics, MAEN043

15

Page 16

Chemical Resistance

5.2.2 TouchScreenSurface

Thetouchscreensurfaceonthepanelwithstandsexposuretothefollowing

solvents without visible change:

Solvents Time

Acetone 10minutes

Isopropanol 10minutes

Toluene 5 hours

5.2.3 AutoflexEB

It is recommendedto use the Autoflex EB touch display protection film, that can

be ordered from Beijer Electronics.

SolventResistance

Autoflex EB withstands exposureto the same chemicals as Autotex F157or F207

according to section AutotexF157/207.

OutdoorUse

In common with allpolyester based films Autotex EB is not suitable for usein

conditions of long term exposureto direct sunlight.

BeijerElectronics, MAEN043

16

Page 17

Hardware Replacement

6 HardwareReplacement

This section contains instructions on howto replace Panel PC hardware. Only

components included in the latest billof material and spare parts list are allowed.

See Available Spare Parts for EPC TA100 AM.

6.1 Cables

MostofthePanelPCsusethesametypeofflexcableconnectors.

connector flanges

Flex cable connector

To release the flex cables from the connector, gently push the

cable connector towards the flex cable.

Note:

Theconnectorsmustbeunlockedonbothsidesbeforeremovingthecable,otherwise

theflex cablem ay bedamaged.

two flanges on the

BeijerElectronics, MAEN043

17

Page 18

6.2 ReplacingtheRearCover

The following isneeded:

• Anewrearcover,seeAvailableSpare Parts forEPC TA100 AM

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Follow the stepsbelow to replace therear cover:

1.

Power off the Panel PC.

2.

Remove the rear coverof the Panel PC by loosening the 4 torx screws.

4 x torx screws

Hardware Replacement

3.

Re-assemble withthe new rear cover in reverseorder.

BeijerElectronics, MAEN043

18

Page 19

Hardware Replacement

6.3 ReplacingtheDisplay/Display Cable

The following isneeded:

• A new display/display cable, see Available SpareParts for EPC TA100 AM

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps below toreplace the display/display cable:

1.

Power off the Panel PC.

2.

Followthe instructions under Replacing the Rear Cover to removethe rear

cover.

3.

Disconnect the two flex cables the flex cable and the LED cable from the

power cardand remove the twoplastic nuts that hold the power cardin place.

LED cable

plastic nut

flex cable

plastic nut

4.

Lift the power cardand gently remove the backlight cables and the display

cablefromtherearsideofthepowercard.

display cable

backlight cables

BeijerElectronics, MAEN043

19

Page 20

Hardware Replacement

5.

Remove the mounting plate(9 torx screws). Gently lift the mounting plate

with the display and powercard.

9 x torx screws

6.

Flip the mounting plate andu nscrew the 4 torx screws.

4 x torx screws

7.

Re-assemble thepanel in reverse order.

6.3.1 CalibratingtheTouchScreen

Followthe steps below to calibrate the touch screen:

A touch calibration toolis pre-installed in the EPC TA100 AM. Itcan be started

from the desktop icon orfrom the Start menu.

Note:

Touch calibrationhasto becommencedwithin10secondsfromwhen thetouchscreen

toolwasstarted.

BeijerElectronics, MAEN043

20

Page 21

Hardware Replacement

1.

Press the first calibration point until the Releasemessage appears.

Touch calibration point

If you releaset he calibration point too early,an error message is displayed.

2.

Touch the following nine touch calibration points as they appear onthe

screen, and release themas the Releasemessages appear.

When touch calibration has beenperformed succes

sfully, a confirmation is

displayed.

BeijerElectronics, MAEN043

21

Page 22

Hardware Replacement

6.4 ReplacingtheCompleteFront

The following isneeded:

• Anewfront,seeAvailable Spare Parts for EPC TA100 AM

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps below toreplace the complete front of theEPC TA100AM:

1.

Power off the Panel PC.

2.

Followthe steps 1-3 and 5 in the Replacing the Display/Display Cable instructions, but in step 3, onlydisconnect the flex cables and the LEDcable (do not

remove the power card).

3.

Attach the new front.

4.

Re-assemble the unit.

BeijerElectronics, MAEN043

22

Page 23

Hardware Replacement

6.5 ReplacingtheBacklight

Note:

Alllampsinthedisplaymustbereplacedatthe sametime.

The following isneeded:

• A new backlight, see Available Spare Parts for EPC TA100 AM

• AtorxT10screwdriver

Note:

MakesuretouseadequateESDprotection.

Followthe steps below to replace the battery of the EPC TA100 AM:

1.

First,follow the steps 1–5 insection Replacing the Rear Cover.

2.

Gently move the backlight diagonally in directionfrom the display center to

release the snap-in closure thatkeeps the backlight in place.

3.

Remove the backlight from the display.

backlight

backlight snap lock

4.

Insert the new backlight. Be careful not to pull thecables of the new backlight

when inserting it, since pulling thecables will damage the backlight.

5.

Re-assemble the complete Panel PC.

connectors

BeijerElectronics, MAEN043

23

Page 24

Hardware Replacement

6.6 AvailableSparePartsforEPCTA100 AM

Ordernumber Description

601009276 COMPLETEFRONT

Includingfrontcover,touchoverlay,gasketsand labels

601009027 DISPLAY

Includingframe andcable

601009050 BACKLIGHT

601009028 DISPLAYCABLE

321099040 POWERCONNECTOR

601009011 REARCOVER

601009003 CFCOVER

601009001 MOUNTINGBRACKETS

601009039 TOUCHPROTECTIONSHEET

601009308 FRONTLABEL

601009135 COMPLETEBOX

601009008 TESTPLUGETHERNET

EthernetRJ45 testconnector

601009006 TESTPLUGRS232

RS232test connector

601009007 TESTPLUGRS422/485

RS422/485testconnector

601009069 TESTPLUGUSBH

USBHosttestconnector

BeijerElectronics, MAEN043

24

Page 25

Additional InstallationTips

7 AdditionalInstallationTips

When experiencing communication problems in for example noisy environments

or when operating close to temperaturelimits, the following recommendations

are to be noticed.

7.1 GroundingthePanelPC

Mounting plate in the cabinet

Power supply

24 V DC

5350

Panel PC

1

Door

Ferrite core

6

3

2

5

4

The PanelPC’smounting clamps do not provide a securegrounding connection

between the PanelPC and the device cabinet, see 1 in drawing above.

1.

Connect a 2.5 mm

panel chassis, see 2in drawing abov

2.

Connect a 6 or 4 mm

2

wire between thePan

el PC’s quick-connect plinth andthe

e.

2

wire or grounding braidbetween the panel’schassis and

the closest grounding point on thedoor, see 3 in drawingabove.

3.

Connect a strong but short groundingbraid between the door and the device

cabinet,see 4 in drawing above.

4.

Twist the cables onto the 24V DC feed, see 5 in drawing above.

2 turns around theferrite core provide 4 times the suppressionof 1 turn.

3 turns around theferrite core provide 9 times the suppressionof 1 turn.

A ferrite core suppresses disturbances to the 24 V feed, see 6 in drawing above.

Note:

Theg rounding wiresshouldbeshortandtheconductorshould havealargearea.

Along,thingroundingwirehasa veryhighimpedance(resistance)athighfrequencies

andwill notguidedisturbancestotheground.

Multi-wireconductors arebetterthansinglewireconductorswiththesamearea.

Abraidedconductorwirewiththe sameareaisevenbetter. Thebestisashort,thick

groundingbraid.

BeijerElectronics, MAEN043

25

Page 26

Additional InstallationTips

7.2 EthernetConnectioninthePanel PC

Industrial Ethernet

RJ45

RJ45

RJ45

RJ45

Panel PC

RJ45

1

2

Panel PC

RJ45

Panel PC

RJ45

Panel PC

RJ45

5351

Shielded

0.1 uF

250 V

3

4

1-1

2-2

3-3

8-8

Short and

unshielded

5

In some industrial units forEthernet, the RJ45 contact’s shield is connected to the

chassis via a capacitor, see 1 in drawing above.

The PanelPC’sEthernet shield is directly co

nnected to the chassis, see 2in

drawing above.

1.

Check whether the other Ethernetun it has its shield directly grounded or

grounded via a capacitor.

Note:

Inmany cases,connectingtheshieldedEthernetcablingtothechassisatbothendsis

inappropriate. Humo r groundingloopscanoccur. Unshieldedcablingmayevenresult

infewer communicationerrors.

A good solution may be to usea shielded Ethernet cable, but toconnect the shield

at one end only.

One option is to breakthe shield, see 3 in drawing above.

A more elegant method isto expand the shielded Ethernet cabling with a piece of

unshielded Ethernetcable, see 4 in drawing above.

You can groundthe shield via an external 0.1 uF/250 V plastic capacitor, see 5 in

drawing above. This will connect the HF transientsto the ground.

BeijerElectronics, MAEN043

26

Page 27

Additional InstallationTips

7.3 ToAchieveBetterEMCProtection

• Initially,use the original cabling from Beijer Electronicsprimarily.

• Use shielded cables for RS232 communication.

• Use twisted pair and shielded cabling forRS422 and RS485.

• Use the cabling intended for the bus type; Ethernet, Profibus, CC-Link,

CAN, Device Netetc.

• Install and connect according to applicable specifications for the relevantbus

standard.

• Use shielded cabling for Ethernet,preferably with foil + braided shield.

• D-sub covers should be shielded, and the shield shouldbe connected to the

cover 360 °where the cable comes in.

• Connect the shield at both ends.

Shielded cable

0.1 uF/250 V

Ground plane 1 Ground plane 2

Ground plate Ground plate

Not same potential

in another building

5352

With longer distances, there is arisk that the ground potential may be different.

In that case, theshield should only be connected at one end. A good alternative

is to connect the other end of theshield to the ground via a 0.1 uF/250 V plastic

capacitor. Both endsare then connected to the ground in terms ofHF, but only

connected to the groundat one end in terms of LF, thus avoiding the 50Hz

grounding loops.

Metal cabinet Metal cabinet

Terminal or connector Terminal or connector

Cable clamp

in steel

Short distance

EMC cable gland Plastic cable gland

Shielded cable Shielded cable

1.

Usean EMC cable gland or regular plastic cable gland, remove theouter jacket

5353

and connect the shieldto the installation plate with a 360 ° metal cable clamp.

2.

Place the 24 VD C and communications cabling in one cable trunk/cable duct

and 230/380 V ACin another. If the cables need to becrossed, cross them at

90 ° only. Avoidcombining the cabling for stronger 24 V DC outputs with

the communication cabling.

Ferritecores that are snapped ontothe shielded cabling may removeminor

disturbances. Large ferrite pieces that are snappedonto unshielded cabling and

where the wiresgo 2-4 times around the cores are approximately5-25 times more

efficient.

BeijerElectronics, MAEN043

27

Page 28

Additional InstallationTips

7.4 AmbientTemperature

The maximum ambient temperaturefor the Panel PC is provided inthe

specifications. The ambient temperature refers to the temperature in the device

cabinet which cools the PanelPC’s electronics.

Top

50 °C inside

Panel

PC

30 °C outside

Middle

45 °C inside

Bottom

40 °C inside

Power

Power

Power

Axial fan

120 x 120 mm

Airflow

5354

Inmostcases,theambienttemperatureforthePanelPCissignificantlyhigher

than the device cabinet’s ambient temperature.

If the cabinetis tall and there are a numbero f heat

temperature at the topof the cabinet will be cons

theoretical temperature increasethat would b

sensitivetoheat. Thelifespanofanelectrol

° increase in temperature. A 15-20 ° temperat

-generating devices, the

iderably higher than the

e expected. All electronics are

ytic capacitor is cut in half with an 8-10

ure increaseresults in a quarter of the

lifespan etc.

Rittal has a good programfor estimating the anticipated average temperature in

the cabinet as wellas a large program for controlling the temperature in the device

cabinet.

An enamel-coated steel cabinethas

a radiant heat value of5.5 W/m

2

and degrees

C.

Installing a fan insidethe cabinet will even out the temperature, while movingair

provides considerablybetter cooling than still air. Asuitable fan is a 120 x 120 mm

axial fan, available in24 V DC, 115 and 230 V AC.

Installthefansothatitsit

Panel PC. If the fan is mount

temperaturewillbehighe

s in the cooler areaand will blow cold air againstt he

ed at the top andsucks air upwards, the fan’s ambient

r=shorterlifespan.

Agoodfanwithaball-bearingmountinghasanexpectedlifespanofatleast

40,000 hours (not aguaranteed lifespan) at 40 °C. This correspondsto at least 4

years of continuous use. If a thermostat is installed,the fan only needs to come

on when needed.

Large graphic termi

lighting is off. The

nals draw only one fifth of the currentwhen the background

loss effect drops from e.g. 25 W to only 5 W.

The PanelPC’sloss effect = supply voltage x current. Virtually no power goes to

external users and no loss effectsdue to inputs.

BeijerElectronics, MAEN043

28

Page 29

7.5 Safety

Most of the Panel PCs are fed with 24 V DC.

Power supply

1

2

3

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

Power supply

230 V AC to 24 V DC

230 V AC

+24 V

0 V

4

+24 V

0 V

4

Distance?

+24 V

0 V

4

Panel PC

Panel PC

Panel PC

Small controller with expansion unit

COM1

COM100

Ch0

Ch1

Ch100

Ch101

5355

Additional InstallationTips

If you use apower supply that meets safety standardsandonlyfeedsthePanelPC,

there is noproblem. See 1in drawing above.

However,ifyouhavea24Vunitthatalsofeedsotherunits,thereisreasontobe

cautious, see 2 in drawing above. The Panel PCdoes not have insulation that

meets safety requirementsin the event of a potential short circuitbetween 230 V

AC and 24 V DC.It is assumed that the 24 V feed is secure, for example, SELV

according to EN60950 (protection against electric shock) and UL 950.

Example:

Hereisanexamplethatexplainswhyasecure24VDCfeedcanbe ruinedbymixing24

Vrelaycontactswith230VACrelaycontactsinasmallercontroller. Checkthatthe

“clearancesand creepagedistancesbetween24V DCand230VAC fulfillEN60950orUL

950”. Ifnot, inputaseparate 24VunitintothePanelP C.

If there is a substant

AC, it is OK to use the

ial distance between the relaycontacts for 24 V DC and 230 V

same 24 V devices forall feeds. See3 in drawing above.

Connect 0 V on the24 V feed to the ground,see 4 in drawing above. This offers

three advantages:

• Safety is increa

connection or s

• Tr an si e nt s o n t

• No risk that th

is not unusua

sed. The24Vfeedwillnotbeliveintheeventofafaulty

hortcircuitbetween0V(24V)and230Vphase.

he 24 V feed are connected to the ground.

e 24 V feed is ata high level in relationship to the ground. This

l since there is highstat ic electricity.

BeijerElectronics, MAEN043

29

Page 30

7.6 GalvanicIsolation

r

Additional InstallationTips

+24 V DC

DC/DC

galvanic isolation

Filter

0 V

1.5 m

Internal electronic

VCC

0 V (GND)

RS232RS422/485

USB

USB

DC/AC

Ethernet

CFL

5356

The PanelPC has galvanic isolation against the 24 VDC feed but no galvanic

isolation between the communication ports for RS232,RS422/485 and USB.

Only the Ethernetconnection has galvanic isolation.

Panel PC Modular controller Printe

RS422 RS232 USB

**

* *

Not same ground potential

* = Internal 0 V (GND) connection

When a PC is connected tothe panel, the panel’sinternal 0 V (G

*

Power CPU COM COM2

***

*

PCPC

5357

ND) will be

connected to the protective ground via the PC.

A number of USB devices canhave the shield connected together with the

protective ground. Here, the panel’s 0 V (GND) is connected to the protective

ground when, for example, aU SB memory stick, keyboard or similar device is

plugged in.

If a number of unitsare connected that have a 0 V a

these are connected to variousgrounding poin

problems. Grounding currents go through com

of the controller, and internally in th

e PanelPC, and can cause errors.

nd a ground connection, and

ts, there is asubstantial risk of

munication cables, the rearplate

Use external unitsto improve communication and achieve galvanic isolation.

Westermo has good industry-standard insulators that arealso insulated from the

24 V DC feed.

Note:

Itis veryimportanttomakesurethatthe24Vfeedin theexternalinsulationunitisnot

connectedtooneofthecommunication outlets. Ifitdoesnothave100%insulation

againstthe 24Vfeed,disturbancesandgroundingcurrentsfromthe0Vonthe24V

sidewilldisruptcommunication.

Usingthistypeofunitsolveso ne problembutcreates alargerproblem! A substandard

installationmayworknow,butproblemsmayarisewhenotherdevicesareconnected.

BeijerElectronics, MAEN043

30

Page 31

Additional InstallationTips

7.7 CableandBusTerminationRS485

• Use shieldedand twisted pair cable. The pair capacitance may not exceed 52.5

2

pF/m and areaat least 0.25 mm

(AWG 24), if you want to use themaximum

transfer distance and maximum transferspeed.

• 0 V, the reference voltage for communication should beincluded in

the cabling. With two-way communication use two pairs; onepair for

communication and one pair for 0V.

• The shield must be grounded at one end. The other end is usually grounded,

but with longer distances or whenthere is a difference in the ground potential,

theshieldshouldbeconnectedtothegroundvia0.1uF/250Vplastic

capacitor to preventground current in thebraided shield. A number of

manufacturers recommendthat the shield be grounded at each node. Various

manufacturers have different systemsfor bus termination. The RS485

standard does not describehow the “Fail Safe” function would be carried out,

justthatthesystemshouldbeabletohandletheerror.

Depending on the recipients’ design, the buswires may be on the same level or

require pull-up orpull-down to ensure that no faulty signals aredetected when the

bus is in restingmode (all transmitters are disconnected).

Inside Panel PC

+5 V

0 V

1 23

1 K

120 ohm 120 ohm

1 K

+5 V

(120 ohm)

14

1 K

2

15

6

19

1 K

7

8

0 V

0 V

4

55

17

50

Panel PC

RS422

1 2 3 4 5 6 7 8

CAB8CAB8 Bus

2

15

3

16

17

4

14

+5 V

VCC

8

0 V

7

0 V

VCC

1 K

120 ohm

1 K

RS485

1

2

3

4

5

6

7

8

Bus termination

Shield

0 V

0 V

5358

Some (older) operator panels hadpull-up and pull-down resistance except for

the actual bus termination at 120 ohm, similar toWestermo and Profibus. See 1

in drawing above.

The PanelPCs have another type of recipient, so-calledb uilt-in “Fail Safe”,where

simple bus termination resistance is sufficient. See 2 in drawing above.

If other nodes on theRS485 network require pull-up andpull-down and the Panel

PC is at one endof the loop, one of the followingprocedures can be carried out:

• Connect two 1k/0.25 W resistors in the25-pole D-sub contact. See 3 in

drawing above. Set jumper pins6-19.

• Use CAB8. It offers the option of bus terminationwith pull-up/-down. It

isalsoeasytoconnectthebuscableviathescrewterminalblock. See4in

drawing above.

BeijerElectronics, MAEN043

31

Page 32

Fault T racing

8FaultTracing

This section includes differentfault scenarios and steps to follow to trace the fault.

TheEPCTA100AMisnotworkingproperly,andthe

powerLEDisoff

1.

Isthepowervoltagecorrect?

2.

Does the powersupply deliver enough current?

3.

Check the fuse.

4.

Check the power card.

5.

Is thepower card correctly mounted?

TheEPCTA100AMisnotcommunicating

1.

Check the communication cable between the units.

2.

Check the communication ports onthe CPU board.

TheEPCTA100AMisworkingbutthebacklightisoff

1.

Check the backlight dimming.

2.

Check that the backlight is connected to the power card.

3.

Replace the backlight accordingto the Replacing the Backlight section.

4.

Check the DC/AC on the powercard.

TheEPCTA100AMisnotworking,thebacklightisoff

butthepower LEDison

1.

Check the backlight dimming.

2.

Check the CPU boardfor burned components.

3.

Download new firmwareto the Panel PC.

TheEPCTA100AMdoesnotincludethelatest

software

1.

Followthe instructions in section Updateor Customize Software.

BeijerElectronics, MAEN043

32

Page 33

Thetouchscreenismalfunctioningorisnot

respondingatall

1.

Re-calibrate the touch screen according tothe Calibrating the Touch Screen sec-

tion.

2.

Check that the flex cable is correctly fitted.

3.

Replace the display of the Panel PC according to the

Replacing theDisplay/Display Cable section.

4.

Check the touch interface on the power card.

Linesindisplay havewrongcolororthedisplay

pictureisshifted

1.

Check if the display has a wide vertical or horizontal areaacross the

display. It should be at least 2-3 cmwide with a grey or black color. See

Replacing theDisplay/Display Cable for instructions on how to correct this.

2.

Make sure the display cable is correctlyfitted.

3.

Make surethe display cable is not folded or damaged in anyway. Replace the

display cable accordingto the Replacing the Display/DisplayCable section.

Fault T racing

BeijerElectronics, MAEN043

33

Page 34

9Software

This chapter describes how to maintain andupdate the operating system in the

EPC TA100 AM, and instructions about howto recover the operating system.

9.1 GeneralInformationabout Software

The EPC TA100 AM is delivered with an image (operating system) pre-storedin

the NandFlash memory.

9.1.1 SoftwareProducts

The following softwareproduct is used:

• Operating System: Windows® XP Embedded SP3

Software

BeijerElectronics, MAEN043

34

Page 35

Software

9.2 UpdateorCustomizeSoftware

A customized operatingsystem image can be developed with theneeds of the

customer. Inthis case, please contact Beijer Electronics sales office for detailed

information.

9.2.1 BackupandRecovery

It isimportant to generate a backupimage of the operating system. In case of

emergency, a recoverycan be done in minutes using a backupimage. Several

programs on the market aresuitable for this.

A bootable device (such as aCD drive or USB Stick with a backupand recovery

program) as well a keyboardand mouse can easily be connected using a USB hub.

The default BIOS setting is set to boot automatically first from aUSB device.

RecoveringtheSystemUsingaUSBMe moryStickwith

aBeijerElectronics-PreparedBackupImage

Requirements:

• Acronis True Image Version 11 installed on the desktop PC

Performthe following steps to recover the system:

1.

Connect an empty USB memory stick (4 GB)to your PC. 8. . 9.

2.

Start Acronisand load the image (***.tib) to the USB stick.

3.

Connect the USB stick to the Panel PC and switch the powe

Windows XP Embedded is now loading from USB Device.

On the WindowsXP Embedded desktop you will find:

a) A program named EasyImage(in the Utility folder)

b) Animage (in the Image folder) to restore the

Windows XP Embedded

4.

Start the EasyImageprogram, select the Image file and start to restore the

internal NandFlash.

After finishing restoring, you can shutdownthe Panel PC via the Start menu.

5.

Disconnect the USB stickand power on the PanelPC.

Windows XP Embeddedw ill now be loaded from the internal flash.

internal NandFlash with

ron.

BeijerElectronics, MAEN043

35

Page 36

Environmental Aspects

10 EnvironmentalAspects

This chapter includes information about theenvironmental impact of the EPC

TA100 AM. More information can befound on the manufacturer’s web site.

10.1 GeneralEnvironmentalAspects

The manufacturer’s activities meet internal requirementsas well as those of the

SS-EN ISO 9001:2000and SS-EN ISO 14001:2004 international standards.

10.2 EnvironmentalImpactofthePanel PCs

10.2.1 MechanicalComponents

The aluminum and stainless steel usedin the mechanical components are judged

to be non-environmentally hazardous. The expanded rubber packing for the front

and the expanded polyethylene packing forthe display contain an adhesive that is

not classified as environmentally hazardous.

Screws may have undergone thefollowing surface treatments: Bright

nickel-plating or bright zinc-plating. Themembranekeyboardismadeof

polyester with silver wiring. On some models the keyboard contains LEDs.

Display frames andCF covers are made of halogen-free plastic, PC/ABS.

10.2.2 Electronics

CircuitBoard

Note:

AllPanelPCs areRoHScompliant.

The electronics are complex and almost all elements of the periodic table are

represented.

Display

There is a separatecircuit board for the display. The liquid crystals in the display

are cyclohexanecompounds. The fluorescent tubecontains mercury and lead

solder.

Batteries

The PanelPC

environme

contains a button cell lithium battery. The battery is not classified as

ntally hazardous bythe Swedish Battery Ordinance(1997:645).

BeijerElectronics, MAEN043

36

Page 37

Environmental Aspects

10.3 Recycling

The PanelPCs consist largely of aluminum. It is a greatadvantage in terms of both

resources and the environment ifit can be recycled. Make sure that Panel PCs

taken out of service are sent to facilitiesfor electronic scrap.

The manufacturer’s electronic waste is recycled by Stena Technoworld AB.

Aluminum front/rearcasings and other coverscan be removedand recycled.

Plastic display frames and CF coversmust be recycled as hard plastic. The circuit

board contains many valuablemetals and should therefore be recycled.

Remove the lithium battery. Electrolytic capacitors and displays are currently not

classified as hazardouswaste, but may be harmful to health and the environment.

The electrolytic capacitors should be handled asper Handbook 2001:7 (NFS)

and displays as perNFS 2001:8.

Thefluorescenttubemustbehandledashazardouswaste.

The packaging ismade from wood fiber and shouldberecycled. Thelargeprinted

label on the front, however, must firstbe removed as it is made of PVCvinyl. The

label and theplastic bag for the brackets are recycledas soft plastic.

The manufacturer is amember of the REPAregister. The protective film onthe

front is recycled assoft plastic. When the PanelPC is no longer useful it can be

returned to the manufacturer for environmentally responsiblerecycling. Contact

the company for further information.

10.4 EnvironmentalImpactReport

A PanelPC impacts the environment through its function,i.e., controlling

industrial equipment. The energy and the scrapped parts that can be saved

with efficient management mean thatthe PanelPC contributes to reduced

environmental impact.

Listed below areexamples of how you can reduce environmentalimpact during

Panel PC use.

• Switch thesystem off when not in use.

• Use g reen electricity.

• Use energy-savingoptions, e.g., turn off the backlight to both save energy and

reduce wearon the fluorescent tube.

• If possible, reduce the backlight brightness to reduceenergy consumption

and increase fluorescenttube service life.

Supplyt he Panel PC with 24 V DC.I

increases. Ensure that the Pan

environmentally responsible

manner.

f the input voltageis lower,the loss effect

el PC, battery, and packaging are recycledin an

BeijerElectronics, MAEN043

37

Page 38

Headoffice

BeijerElectronicsAB

Box426

20124Malmö,Swed

en

www.beijerelectronics.com/+4640358600

Loading...

Loading...