Page 1

Users Manual

Version 1.0 November 2003

ENGLISH

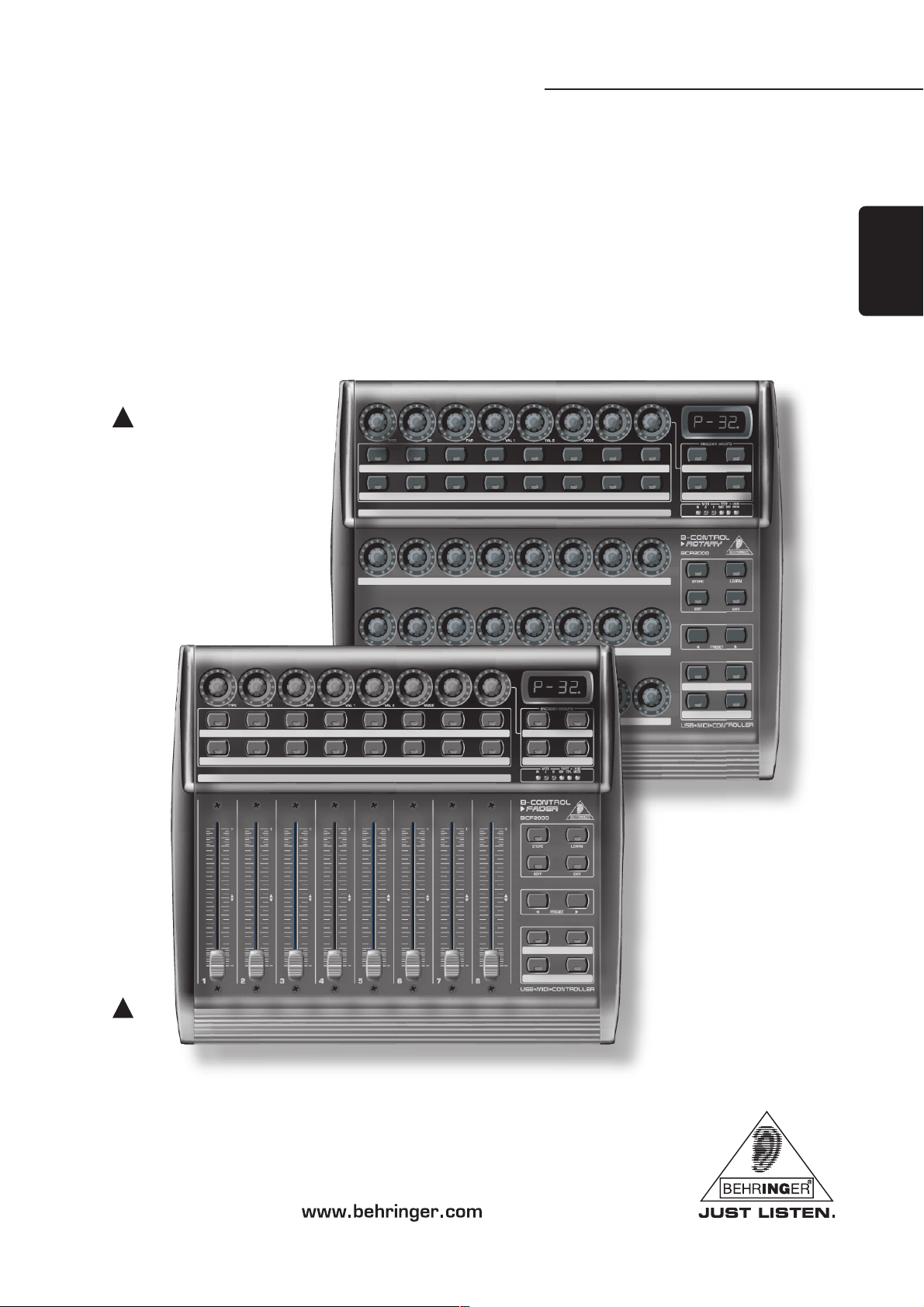

B-CONTROL FADER BCF2000 B-CONTROL ROTARY BCR2000

Page 2

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

IMPORTANT SAFETY INSTRUCTIONS

CAUTION: To reduce the risk of electric shock, do not remove

the top cover (or the rear section). No user

serviceable parts inside; refer servicing to qualified

personnel.

WARNING: To reduce the risk of fire or electric shock, do not

expose this appliance to rain and moisture.

This symbol, wherever it appears, alerts you to the

presence of uninsulated dangerous voltage inside

the enclosurevoltage that may be sufficient to

constitute a risk of shock.

This symbol, wherever it appears, alerts you to

important operating and maintenance instructions

in the accompanying literature. Please read the

manual.

DETAILED SAFETY INSTRUCTIONS:

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this device near water.

6) Clean only with a dry cloth.

7) Do not block any ventilation openings. Install in accordance

with the manufacturers instructions.

8) Do not install near any heat sources such as radiators,

heat registers, stoves, or other apparatus (including

amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades with

one wider than the other. A grounding type plug has two

blades and a third grounding prong. The wide blade or the

third prong are provided for your safety. If the provided plug

does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

10) Protect the power cord from being walked on or pinched

particularly at plugs, extension cords, and the point at which

they exit the unit.

11) Only use attachments/accessories specified by the

manufacturer.

12) Use only with the cart, stand, tripod, bracket, or table

specified by the manufacturer, or sold with the device. When

a cart is used, use caution when moving the cart/device

combination to avoid injury from stumbling over it.

13) Unplug this device during lightning storms or when not

used for long periods of time.

14) Refer all servicing to qualified service personnel.

Servicing is required when the unit has been damaged in

any way, such as power supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the device,

the unit has been exposed to rain or moisture, does not

operate normally, or has been dropped.

2

Page 3

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

FOREWORD

Dear Customer,

welcome to the team of

BEHRINGER users, and

thank you very much for

expressing your confidence in us by purchasing the B-CONTROL.

Writing this foreword

for you gives me great

pleasure, because it

represents the culmination of many months of

hard work delivered by

our engineering team to

achieve a very ambitious

goal: to present two

outstanding USB MIDI

CONTROLLERS. Due to

their extreme flexibility

they can be used as a

central control unit with USB/MIDI interface as well as for mere

MIDI control applications. The task of designing our new

B-CONTROLs certainly meant a great deal of responsibility, which

we assumed by focusing on you, the discerning user and musician.

Meeting your expectations also meant a lot of work and night

shifts. But it was fun, too. Developing a product usually brings a

lot of people together, and what a great feeling it is when all who

participated in such a project can be proud of what theyve

achieved.

It is our philosophy to share our enjoyment with you, because

you are the most important member of the BEHRINGER team.

With your highly competent suggestions for new products youve

made a significant contribution to shaping our company and

making it successful. In return, we guarantee you uncompromising

quality as well as excellent technical and audio properties at an

extremely reasonable price. All of this will enable you to give free

rein to your creativity without being hampered by budget

constraints.

We are often asked how we manage to produce such highquality devices at such unbelievably low prices. The answer is

quite simple: its you, our customers! Many satisfied customers

mean large sales volumes enabling us to get better purchasing

terms for components, etc. Isnt it only fair to pass this benefit on

to you? Because we know that your success is our success too!

I would like to thank all of you who have made the B-CONTROL

possible. You have all made your own personal contributions,

from the developers to the many other employees at this company,

and to you, the BEHRINGER user.

TABLE OF CONTENTS

1. INTRODUCTION ........................................................ 4

1.1 Before you get started .................................................... 4

1.1.1 Shipment .............................................................. 4

1.1.2 Initial operation ..................................................... 4

1.1.3 Warranty ............................................................... 4

1.2 System requirements ..................................................... 4

2. INTRODUCTION TO MIDI ......................................... 4

2.1 MIDI control for beginners .............................................. 4

2.2 The MIDI standard .......................................................... 5

2.3 MIDI connections ............................................................ 5

2.4 The MIDI format .............................................................. 5

3. CONTROL ELEMENTS AND CONNECTIONS ......... 6

4. CONTROLS ............................................................... 8

4.1 The operating modes ..................................................... 8

4.1.1 USB modes .......................................................... 8

4.1.2 Stand-alone modes ............................................ 10

4.2 Play mode menu ........................................................ 12

4.2.1 Selecting a preset .............................................. 12

4.2.2 Copy/store presets ............................................. 13

4.2.3 Copying encoder groups .................................... 13

4.3 Programming ................................................................ 13

4.3.1 The LEARN function .......................................... 13

4.3.2 Programming in EDIT mode .............................. 13

4.3.3 Settings in the global setup menu ..................... 16

4.3.4 Additional functions ............................................ 16

5. APPENDIX ............................................................... 17

6. SPECIFICATIONS ................................................... 18

7. WARRANTY ............................................................ 19

My friends, its been worth the effort!

Thank you very much,

Uli Behringer

3

Page 4

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

1. INTRODUCTION

Thank you very much for expressing your confidence in

BEHRINGER products by purchasing the B-CONTROL.

The B-CONTROL is an extremely flexible control surface

suitable for a wide array of applications. Regardless of whether

you want to intuitively control your sequencer software with mixers,

plug-ins and virtual instruments, or if you wish to use its broad

MIDI functions for controlling rack synthesizers, general MIDI

sound generators or effect processors, the B-CONTROL offers

you tremendous ease of use that leaves no wishes open.

To ensure the highest possible operating safety, our equipment

is manufactured according to the highest quality standards in the

audio industry. Additionally, we produce our equipment adhering

to the ISO9000 certified management system.

+ The following users manual is intended to familiarize

you with the units control elements, so that you can

master all the functions. After having thoroughly read

the users manual, store it at a safe place for future

reference.

1.1 Before you get started

1.1.1 Shipment

The B-CONTROL was carefully packed at the assembly plant

to assure secure transport. Should the condition of the cardboard

box suggest that damage may have taken place, please inspect

the unit immediately and look for physical indications of damage.

+ Damaged equipment should NEVER be sent directly to

us. Please inform the dealer from whom you acquired

the unit immediately as well as the transportation

company from which you took delivery of the unit.

Otherwise, all claims for replacement/repair may be

rendered invalid.

+ To assure optimal protection of your B-CONTROL during

use or transport, we recommend utilizing a carrying

case.

+ Please always use the original packaging to avoid

damage due to storage or shipping.

+ Never let unsupervised children play with the

B-CONTROL or with its packaging.

+ Please dispose of all packaging materials in an

environmentally-friendly fashion.

1.1.2 Initial operation

Please make sure the unit is provided with sufficient ventilation,

and never place the B-CONTROL on top of an amplifier or in the

vicinity of a heater to avoid the risk of overheating.

A power supply unit which meets the necessary safety

requirements is enclosed for connecting the B-CONTROL to the

mains.

1.1.3 Warranty

Please take a few minutes and send us the completely filled

out warranty card within 14 days of the date of purchase to assure

unproblematic warranty processing in the future. You may also

register online at www.behringer.com. The serial number needed

for the registration is located at the top of the unit. Failure to

register your product may void future warranty claims.

1.2 System requirements

for USB operation:

Up-to-date WINDOWS® PC or MAC® with a USB connection

+ The B-CONTROL supports WINDOWS

OSX® USB MIDI compatibility. Soon, you will be able

to download drivers for other operating systems, for

multi unit support, new presets as well as a WINDOWS

editor software free of charge. Just click

www.behringer.com to get it for free.

®

XP and MAC

+ The BCF2000/BCR2000 can also be operated stand-

alone without a PC as a pure MIDI controller. Software

control via MIDI is also possible, provided your

computer has a MIDI interface.

2. INTRODUCTION TO MIDI

2.1 MIDI control for beginners

Application possibilities for both B-CONTROL models, the

BCF2000 and the BCR2000, are truly wide-ranging. Well start

with a couple of general explanations and examples that should

quickly let you get a good understanding of MIDI basics.

What exactly does the B-CONTROL do?

Simply put, this a remote control for all kinds of MIDI equipment.

Using the faders (BCF2000 only), encoders (infinitely variable

rotary controls) and keys, an entire array of control functions can

be performed. Adjusting these parameters, you can control various

functions of external (hardware or software) equipment in real

time. For example, countless software mixers, sound generators

or effects can be remotely controlled. With these software

applications, you are dealing with simulations of real equipment

in your computer, whereby they are visually represented on the

computer screen, while the computer takes over the function of

replicating their respective functions.

And how does it work?

You can assign particular MIDI data to each control element on

the B-CONTROL; for example, you can assign the so-called MIDIController 7 (CC 07) that adjusts the volume of a MIDI device to

one of the controls on your BCF2000/BCR2000. If you move/

turn the corresponding control on your B-CONTROL, you can

hear how the volume on the receiving MIDI device also changes

(provided it is also connected to an audio output). Keep the

following in mind:

+ MIDI data is only control data and contains no audio

information!

What settings do I have to make? Where? How?

Often, you can assign MIDI control data numbers, the so-called

control change or CC numbers, to individual MIDI parameters.

Thats particularly the case with music software such as software

sequencers, mixers and sound generators as well as the so-called

plug-ins (effect units or sound generators integrated into the

software).

Basically, you have 2 options:

You either set the desired control numbers at the B-CONTROL

and transmit them to the software you are controlling, or you can

set the desired control data directly on your MIDI device and let

the B-CONTROL receive the information about number

assignment using the LEARN procedure.

Example:

On a software synthesizer, you want to control filter frequency,

filter resonance and volume using the MIDI controllers 5, 6 and 7.

To receive MIDI data, youll need to perform the following

settings on your software synthesizer:

4

2. INTRODUCTION TO MIDI

Page 5

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

2

&8n (n = channel #)

&9n (n = channel #)

s set filter frequency to CC 05

s set filter resonance to CC 06 (receive)

s set volume to CC 07 (receive)

To get detailed information on how to assign them, please refer

to chapter 4.3.2 Programming in the EDIT mode on page 13.

Now, define in the B-CONTROL the control elements that will

control these 3 parameters. You can either use the LEARN

function if the software synthesizer gives you the option to send

its CC data via MIDI, or you can implement the following settings

manually:

s Assign the push encoder 1 CC 05 to filter frequency control

via dial rotation.

s Assign the push encoder 2 CC 06 to filter resonance control

via dial rotation.

s Assign the push encoder 3 CC 07 to volume control

via dial rotation.

How do I wire the B-CONTROL?

Several classic examples can be found in the explanations of

different operating modes (see chapter 4.1 The Operating

Modes). Basically, the following applies:

s If you want to control hardware MIDI equipment, use the

MIDI connectors.

s To control software MIDI equipment, you can either use the

MIDI connectors on your B-CONTROL provided your

computer has a MIDI interface or you can use a USB

connection.

s To remotely control both hardware and software equipment,

several combination modes are available. These are

explained in chapter 4.1.

What kinds of equipment can I control with the B-CONTROL?

You can basically control any device supporting the MIDI format.

Both hardware and software MIDI devices are controlled exactly

the same. The only difference is in the wiring.

Here are a couple of suggestions on how you can use your

B-CONTROL:

s Editing sound parameters of (virtual) synthesizers, sound

samplers, GM/GS/XG sound generators

s Controlling parameters on effects equipment/software

plug-ins such as effects processors, reverbs, compressors,

equalizers etc.

s Remotely controlling software mixers (volume, panorama,

equalizers etc.)

s Remotely controlling transport functions (playback, forward,

stop etc.) on sequencers, hard disk recorders, drum

computers etc.

s Using BCF2000 faders as drawbar control for virtual or digital

organ expanders

s Controlling MIDI-enabled lighting equipment

s Live control of volume and sound parameters on expanders

s Triggering (i.e. playing live) short samples, drum loops,

shouts, effects etc.

s Remotely controlling groove boxes, step sequencers, MIDI

generators (such as arpeggiators etc.), DJ software and

other live software

s Program changes and volume control on sound generators

(just like on a master keyboard)

s Likewise, applicable to band keyboardists, solo entertainers,

organists, electronic music performers, DJs, sound

engineers, home/project studio owners, theater technicians

etc.

2.2 The MIDI standard

The MIDI standard (Musical Instruments Digital Interface) was

developed in the early 80s to make communication between

equipment from different manufacturers possible. Over the years,

the MIDI interface has become hugely popular; it has become a

matter of fact that complete studios can be connected via MIDI.

At the center of any such network is at least one computer that

controls peripheral equipment. You can use the B-CONTROL in

such a studio to control your sequencer or other software tools

running on your computer (e.g. software mixers, VST instruments,

effect plug-ins). But even if you dont use a computer, you can

use the B-CONTROL as a central control surface in your studio

for comfortably editing your rack synthesizers, GM/GS/XG sound

generators and effects equipment.

2.3 MIDI connections

The MIDI connections in the back of your B-CONTROL feature

the standard 5-pin DIN connectors. You will require MIDI cables

to connect your B-CONTROL to other MIDI equipment. In general,

commercially available ready-to-use cables can and should be

used. Their length should not exceed 15 m (50 ft.).

MIDI IN: Used for receiving MIDI data (parameter feedback,

SysEx data), or to mix MIDI signals with the B-CONTROL signals

(merge function).

MIDI OUT A/B: Data for controlling other MIDI equipment can

be sent through the MIDI outputs.

+ The B-CONTROL has two MIDI outputs. MIDI

OUT B can be configured as MIDI THRU, so that the

incoming data at MIDI IN can be passed through

unaffected.

2.4 The MIDI format

Although your B-CONTROL is very easy to use, it still makes

sense to review some information about this data format. Each

MIDI command, also called message, consists of a status byte

and up to two data bytes. The status byte defines the command

type, and the data bytes contain the corresponding values.

Different types of MIDI messages used by the B-CONTROL are

explained next:

Note messages:

Among keyboard hotshots, Note On and Note Off messages are

among the essential MIDI messages. Playing MIDI instruments

from a master keyboard or computer is only possible with these

messages. The B-CONTROL can also send Note Messages;

however, this is not absolutely necessary to play music. This way,

note events are also used to trigger drumloops or individual notes

from a sampler. Many effects processors also allow rhythmic

entering of delay times or song tempos with note commands.

Note On and Note Off messages have the following data format:

Status Byte Data Byte 1 Data Byte

Note Off

Note On

Table 2.1: Data format of Note On and Note Off messages

The value range for channel numbers is between 1 and 16; for

data bytes it is 0 to 127. Even though Note Off messages are not

really used by keyboarders anymore, the B-CONTROLs support

sending this status information.

Velocity corresponds to the key pressure, and therefore to the

volume of a touch-sensitive keyboard (piano). Since the

B-CONTROL does not feature touch-sensitive keys, the velocity

value is transmitted with a fixed value that can be set during

programming.

Note # Velo c it y

Note # Velo c it y

+ A note command can only be assigned to keys,

footswitches and push functions of the encoder.

2. INTRODUCTION TO MIDI

5

Page 6

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

Control Change (CC):

Control Change Messages are some of the most powerful MIDI

messages. Using them, a vast number of parameters and functions

can be recalled and automated. Individual control elements (faders,

rotary dials, keys etc.) can be assigned to CC messages on your

B-CONTROL. Because not only keys but also faders and rotary

dials can be used, control values can be controlled in real time

either statically or dynamically. A list with the standard controller

numbers can be found in this user manuals appendix.

NRPN:

Additionally, controllers that have no standardized assignment

can also be used, and can therefore be assigned according to no

predetermined rule. These controllers are called NRPNs (NonRegistered Parameter Numbers). NRPNs are further subdivided

into MSB (Most Significant Byte) and LSB (Least Significant Byte)

in order to achieve a higher resolution. A lower resolution is

particularly easy to observe during fader movement of a mixer, in

which 7-bit (= 128 values) jumps in the signal level can be heard.

By subdividing NRPNs into MSB and LSB, you can achieve

14-bit resolution of faders and rotary dials, which means that the

movement of a fader is divided into more than 16,000 steps (214)!

In addition to NRPNs, there are also RPNs (Registered Parameter

Numbers). RPN commands are defined as GM (general MIDI),

GS (Roland) and XG (Yamaha) MIDI standards.

Pitch Bend

The pitch-bend wheel of a keyboard is used for tone modulation

and has its own commands in the MIDI format.

After Touch

MIDI keyboards featuring After Touch can respond to varying

key pressure even after you release the key (i.e. after the keystroke

is over) and can send this data via MIDI. This function either

reacts key-specific (key pressure) or it reacts to all notes at the

same time (channel pressure).

MIDI Machine Control (MMC):

With MIDI Machine Control, you can assign transport functions

of a sequencer or drum computer (e.g. start, stop, FFW/RWD)

and locator points to individual keys with a permanently adjustable

time position (locate, punch in/out points).

Program Change Messages and MIDI Bank Select:

Program change messages are used to recall programs/presets

in MIDI devices connected to your B-CONTROL. 128 program

numbers can be recalled. For devices with more than 128 presets,

use the bank select function, which lets you select a storage bank

before sending a program change.

Running Status:

Because the MIDI interface is a serial data transmission format

(meaning that its data is transmitted as a succession of individual

data segments), it became apparent very quickly that it may not

be fast enough. To avoid perceptible delays in the output of MIDI

data, Running Status was designed. It suppresses the

transmission of the status byte when the same MIDI messages

are transmitted in succession. This means that, for example,

during a continuous change of the data byte of a controller (e.g.

volume), the status byte is only sent once. The only thing that is

transmitted are the changes in the data byte. This goes on until

another status byte is sent. 8 bits are saved for each message

sent.

SysEx Dump:

System-Exclusive data refer to a function that makes

transmission of nonspecific data via MIDI possible. This is often

used for reading out memory contents and storing them externally.

The status byte notes the data type (SysEx); the first three data

bytes are a manufacturer ID, so that when you have a large MIDI

network, you can still talk to the correct MIDI device.

To make using several identical B-CONTROLs at the same

time possible, you can assign a device number (device ID) in the

global setup menu to each B-CONTROL, which assures that only

the correct device receives the data intended for it.

3. CONTROL ELEMENTS AND

CONNECTIONS

In this chapter, we will describe various control elements of

your B-CONTROL. All controls and connectors are explained in

detail, and well give you useful tips on how to use them.

The 8 infinitely variable push encoders are used to send

MIDI data. They have two functions (turn and press) that

can be assigned to different MIDI commands.

Each of these 16 keys can send one MIDI command.

The four-digit LED display indicates the current operating

software version briefly during startup. After that, it shows

the selected preset number. When in play mode, activating

one of the control elements indicates value changes on the

LED in real time. When in programming mode, it indicates

the type of MIDI commands, program/channel numbers and

parameter values.

Using the ENCODER GROUP keys, four so-called encoder

groups per preset can be recalled, so that eight PUSH

encoders for a total of 64 different MIDI functions are at

your disposal.

These LEDs indicate the following:

MIDI IN, OUT A and OUT B illuminate if MIDI data flows

through the respective connectors.

USB Mode illuminates if a USB connection to a computer is

active (your computer must be on).

The FOOT SW LEDs illuminate if the footswitch is actuated.

FOOT CTRL (BCF2000 only) illuminates when the footswitch

pedal is pressed (MIDI data is sent).

Permanently fixed functions are assigned to this key section:

STORE saves presets.

LEARN gets you to the LEARN mode.

EDIT gets you to the EDIT mode.

Using the EXIT key, you exit a programming level (edit mode/

global setup). Use it also to cancel a store or copy procedure.

The eight 100-mm faders of the BCF2000 are freely

assignable for controlling MIDI commands. They are

motorized, so they automatically slide into the predetermined

position when you switch to another preset. If the software

you are controlling or the MIDI device to which your

B-CONTROL is connected support parameter feedback, the

fader positions change automatically.

Using the PRESET keys, 32 presets can be recalled. The

preset number is shown in the display.

These four keys can be assigned to any MIDI command of

your choice.

The 24 infinitely variable rotary controls (encoders) of the

BCR2000 can be programmed to send MIDI control

commands. The LED circle show the current value.

These are the SWITCH connectors for connecting a

footswitch. Its polarity is automatically detected. On the

BCR2000, the first connector (SWITCH 1) can also be used

to connect a double footswitch with stereo jacks. In this

case, SWITCH 2 must remain unused.

6

3. CONTROL ELEMENTS AND CONNECTIONS

Page 7

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

Fig. 3.1: The control surface of the B-CONTROLs

Fig.3.2: The back of the BCF2000 (control elements to coincide with the BCR2000)

CONTROLLER connector (BCF2000 only). Here, you can

connect a footswitch that can be used for controlling

assignable MIDI data.

The POWER switch turns your B-CONTROL on. The

POWER switch should always be in its Off position when

connecting the unit to the mains.

+ Please keep in mind: The POWER switch does not fully

disconnect your B-CONTROL from the mains. Always

unplug the power cord from the mains if you dont intend

to use your B-CONTROL for longer periods of time.

The connection to the mains is established using a standard

connection socket. A matching cable is included in the

shipment.

SERIAL NUMBER. Please take the time to fill out and return

the warranty card within 14 days after the date of purchase

to benefit from our extended warranty. The serial number is

located on the top side of your REV2496. You can also

register online at www.behringer.com.

3. CONTROL ELEMENTS AND CONNECTIONS

7

Page 8

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

4.1.1 USB modes

USB mode U-1:

Fig. 3.3: The footswitch connectors on the BCR2000

The USB connector is used for connecting to a computer

with a compatible USB input.

These are the MIDI connectors of your B-CONTROL.

Depending on the operating mode, MIDI OUT B doubles as

MIDI THRU.

4. CONTROLS

4.1 The operating modes

Depending on how you want to use your B-CONTROL, you

should first select an operating mode.

You can use it as a pure USB controller for your computer

applications (software mixers, sequencers, soft synths, VSTeffects etc.), as a stand-alone MIDI controller, or as a combination

of both with different MIDI interface configuration possibilities.

Here is how you select an operating mode:

s Keep the EDIT key pressed, and press the STORE key at

the same time.

s You are now in the global setup menu and you can let go of

both keys.

s Now, select an operating mode by turning the PUSH encoder 1.

You can select USB modes U-1 to U-4 and stand-alone

modes S-1 to S-3. The modes are described in detail in

chapter 4.1.1 and further, and examples about their use

are also given there. Please see also chapter 4.3.3.

s To exit global setup, please press the EXIT key.

+ The settings made in the global setup menu are

automatically stored and do not have to be separately

saved.

The USB connection is briefly interrupted if you switch within a

USB mode, or when you switch from a USB mode to a standalone mode and vice versa.

If a USB connection is made or lost while your

B-CONTROL is on, the selected operating mode is retained.

8

4. CONTROLS

Fig. 4.1: Routing and use in USB mode 1

In USB mode 1, the B-CONTROL is connected to your PC by

using a USB cable. It sends MIDI data and receives parameter

feedback from the computer, provided that the music software

you are controlling supports these functions. This way, current

parameter values can be shown on the LED, or can be indicated

by the fader position.

All MIDI ports of the B-CONTROL are off. This mode is optimal

for controlling software tools (mixers, sequencers, synths, VSTeffects etc.) if you dont need any additional MIDI ports. This mode

is also very useful if you are already using other multi-channel

MIDI interfaces on your computer and cant address any additional

ones.

Page 9

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

USB-Mode U-2:

USB-Mode U-3:

Fig. 4.2: Routing and use in USB mode 2

Your B-CONTROL sends MIDI data to the computer and

receives parameter feedback, provided that the software you are

controlling supports this function. MIDI IN and OUT A are available

as a 16-channel MIDI interface for your computer. OUT B functions

as MIDI THRU and forwards MIDI IN data unchanged. OUT B is

not accessible from the computer, and doesnt send any control

data from the B-CONTROL. This mode is ideal for applications in

which you control music software on your computer and at the

same time need a USB MIDI interface with one IN and one OUT.

Additionally, a MIDI keyboard can be tapped into at the MIDI THRU

(OUT B) connector. This way, you can use a master keyboard to

import your arrangements into the sequencer, or to play back

software synths. OUT A controls a hardware sampler, while a

MIDI expander (sound generator without a keyboard; e.g. a rack

synthesizer or a pure preset unit), an effects processor or similar

can be connected at OUT B, whereby it is directly controlled only

from the keyboard or is controlled only via program changes.

4. CONTROLS

Fig. 4.3: Routing and use in USB mode 3

This is surely the most often used standard mode with

computer applications.

This setting is optimal for controlling software while all MIDI

connectors are used as a USB-MIDI interface for the computer. With

this function, there are 16 input channels and 32 output channels

available to your music software (IN and OUT A + OUT B).

The B-CONTROL transmits its data via USB to the computer.

The availability of parameter feedback from the computer to the

B-CONTROL depends on the software your are controlling. MIDI

expanders can not be directly accessed from the keyboard in this

operating mode. This operating mode is only used to import MIDI

tracks into the sequencer.

9

Page 10

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

USB-Mode U-4 (expanded):

Fig. 4.4: Application in USB mode 4 (expanded)

Fig. 4.5: Routing in USB mode 4

This operating mode should be selected if you want to couple

two B-CONTROLs (e.g. 1x BCF2000 & 1x BCR2000) to control

your software using both B-CONTROLS through a common USB

port. Additionally, MIDI OUT B of the first controller (unit 1) can

be used from the computer as a 16-channel MIDI output. The

data of both B-CONTROLs is mixed and is sent to the host

computer via USB. Select stand-alone mode 3 for the second

unit (unit 2).

4.1.2 Stand-alone modes

The stand-alone modes come into play when the B-CONTROL

is not used as a USB-controller for controlling PC applications

but as a pure MIDI controller. With all stand-alone modes, all

MIDI connectors can be used simultaneously, and these modes

differ only in how the data is transmitted on the MIDI outputs. Of

course, not only sound generators can be remotely controlled

(as shown in the illustrations) but also effects processors, groove

boxes, hardware sequencers, lighting equipment, compact

studios, portable keyboards, e-pianos etc. basically any

equipment with a MIDI input. This can also be your computer

with its own MIDI interface. The USB connector can not be used

while your B-CONTROL is in one of the stand-alone modes. A

merge function that makes mixing MIDI data from two different

sources to one output possible is active at output A in all standalone modes.

10

4. CONTROLS

Page 11

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

Stand Alone-Mode S-1:

Stand Alone-Mode S-2:

Fig. 4.6: Routing and use in stand-alone mode 1

S-1 is probably the most frequently used standard operating

mode among the stand-alone applications. We recommend using

it when you for example want to control two sound generators

from your B-CONTROL, whereby both sound generators are

played simultaneously from a master keyboard. To do this, MIDI

data from the B-CONTROL and the keyboard have to be mixed

and transmitted on both MIDI OUTs. This is done using the

integrated merge function. The master keyboard is connected to

the MIDI input of the B-CONTROL. Both expanders played from

the master keyboard and controlled by the B-CONTROL are

connected at the MIDI outputs. Control data for the BCF2000/

BCR2000 will probably be program change and real-time

controller commands, while the keyboard will typically transmit

keyboard commands (note on/off, velocity, after touch, pitch bend).

Fig. 4.7: Routing and use in stand-alone mode 2

Say you want to control just one sound generator from your

B-CONTROL because the tone generator allows extensive editing

(e.g. its a rack synthesizer or a sampler, as shown above). The

MIDI keyboard should be able to play both sound generators. In

this case, S-2 is the optimal setup. The second sound module

can be a pure preset unit that doesnt allow any programming.

However, it can also be an effects unit that only receives program

commands from the keyboard. This operating mode is also very

useful when the data received by the second unit is undesired

and could otherwise disrupt operation (e.g. to MIDI functions that

cannot be switched off or the MIDI channel can not be changed).

4. CONTROLS

11

Page 12

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

Stand Alone-Mode S-3:

Fig. 4.8: Routing and use in stand-alone mode 3

In this mode, MIDI data from the BCF2000/BCR2000 is mixed

with the data coming in at the MIDI input (merge function), but is

exported exclusively on output A. Only control data of the

B-CONTROL is available at output B.

This way, you can control two MIDI devices from your

B-CONTROL, but only the device connected at OUT A can

additionally be played from the MIDI keyboard.

Important information about stand-alone modes:

When connecting this way, parameter values of the controlled

devices can be shown by the LEDs of your B-CONTROL. If

parameter feedback is important, connect MIDI IN to MIDI OUT

of the device you want to control. Of course, the hardware has to

be capable of sending a response about the current parameter

values. If you are not sure, check the equipments user manual.

Parameter feedback in stand-alone mode 3 functions when MIDI

output B is used. In all other stand-alone modes, undesired MIDI

loops can occur; control data of the B-CONTROL are transmitted

via MIDI OUT B only in stand-alone mode 3.

If you want to daisy-chain two B-CONTROLs to jointly control

several MIDI devices, you need to connect OUT A of the first

B-CONTROL to MIDI IN of the second B-CONTROL. OUT A of

the second B-CONTROL needs to be connected to the MIDI input

of the effects unit. If additional MIDI devices need to be talked

to, please connect the THRU port of one MIDI device to the IN

port of the next MIDI device. This way, with different MIDI channel

assignments, each MIDI device can be controlled from each one

of the B-CONTROLs.

If additional MIDI inputs are needed, then external MIDI merge

boxes must be used. For example, if your sound module only has

one MIDI IN connector, and you want to control if from several

MIDI controllers and from a keyboard, you will need a 2-in/1-out

merge box.

If additional MIDI outputs are required, you will need external

thru boxes. With more complex MIDI setups, thru boxes are

preferred to using longer thru chains to prevent data transmission

problems.

Your B-CONTROL can also control your computer via MIDI

(without a USB connection) as long as your computer features a

MIDI interface. In this case, all stand-alone modes can be used.

When using parameter feedback, you must use stand-alone mode 3,

and should connect your computer via MIDI IN and MIDI OUT B,

so that no feedback loop occurs.

If you dont require the response function during software control,

you can connect as many BCF2000/BCR2000s as you want per

MIDI. The last B-CONTROL in the chain is then connected to the

MIDI IN input of your computer. This way, you can control nearly

as many channels of a software mixer as you wish. However,

keep in mind that all devices must share 16 MIDI channels.

4.2 Play mode menu

The Play mode menu is the highest menu level in the

B-CONTROL. Use it during normal operation for real-time control

of MIDI data.

Display:

After switching on the unit, the current system software version

is briefly displayed. Value changes are shown when using one of

the control elements.

Control elements:

You can use several keys, encoders and faders simultaneously

and send their MIDI data. The classification of MIDI data types is

explained in chapter 4.3. According to its assigned MIDI data

type, each control element shows the current parameter value in

the corresponding LED or LED ring.

The position of the faders changes automatically as soon as

you choose another preset or during incoming parameter

messages.

LED display:

The encoder LED ring displays or the status LEDs of the

buttons change automatically when running controller recordings

in a sequencer, provided, of course, all connections have been

made correctly, the correct operating mode is enabled and the

software sequencer supports sending parameter values.

Button illumination varies according to the controller mode: if a

button is in Toggle on mode, the button LED illuminates as

soon as the button is pressed. Only when you press the button

once again, the LED goes out. If a button is in Toggle off mode,

the corresponding LED will be lit only for the time the button is

pressed.

The LED rings of the encoders are normally displayed in a

multi-step manner, i.e. turning the encoder from left to right lights

the first LED followed by the next, whereby the first LED goes out

etc. This way, even small value changes can be displayed

accurately.

12

4. CONTROLS

Page 13

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

4.2.1 Selecting a preset

s Select a preset with the PRESET button . The new

preset number is indicated in the display.

s Alternatively, you may select a preset by pressing and

holding down the preset button while moving one of the

push encoders .

s As soon as you release the PRESET button, the new preset

is active.

4.2.2 Copy/store presets

s Press the STORE button to save a preset. The button LED

starts to flash.

s Select a memory number using the PRESET buttons or by

holding down one of the PRESET buttons while moving a

push encoder at the same time. The new preset number

flashes in the display.

s By pressing STORE again, the STORE LED and the display

stop flashing.

s If you want to overwrite the current preset, press the STORE

button twice (step 2 can be cancelled).

s Cancel the store procedure by pressing the EXIT button.

We deliberately did not include an autostore function. That way,

you can assign a new MIDI control to a control element without

changing the current preset. If you want to restore a preset, just

select another preset briefly and again return to editing. Now, the

old data has been restored.

4.2.3 Copying encoder groups

With this function you are able to copy an entire encoder group

within a preset. This saves a lot of programming effort if all encoder

groups within a preset consist of the same basic functions (e.g.

MIDI channel, CC number for turn and push function).

s Press the encoder group button of the group you want to

copy.

s Press STORE; the STORE button LED flashes.

s Now select the destination encoder group. The destination

encoder button LED flashes.

s Press STORE again, the STORE button LED is no longer

lit.

s Cancel the store procedure at any time by pressing EXIT.

+ To permanently store encoder group settings, carry out

the preset store function as explained in chapter 4.2.2.

+ To copy an encoder group into a different preset, you

have to copy an entire preset! After that, you can copy

or rearrange the encoder groups in the new preset as

described above.

4.3 Programming

4.3.1 The LEARN function

The easiest way to assign MIDI functions to individual control

elements is to use the LEARN function. Here, the MIDI data is

assigned remotely. For example, MIDI data sent from a MIDI

sequencer to your B-CONTROL is assigned to a control element

selected beforehand.

With LEARN, not only CC, NRPN and note commands can be

received but almost any type of MIDI data, including short SysEx

strings.

s Press and hold the LEARN button while operating any control

element. This can be a fader (BCF2000 only), an encoder

BCR2000 only), a PUSH encoder, button, footswitch or

sustain pedal (BCF2000 only). The control element is shown

in the display (e.g. E 24 or Fd 8).

+ When using push encoders, select an encoder group

beforehand. In addition, you have to differentiate

between turn and push function.

s Now, release the LEARN button. The B-CONTROL is waiting

to receive MIDI data.

s Start transmitting MIDI data from your sequencer. As soon

as the data is received by the BCF2000/BCR2000, it is

shown in the display.

s After correct data transmission, the display shows GOOD

or bAd if wrong, faulty or too extensive data has been

sent.

s To leave or cancel LEARN, press the EXIT button.

4.3.2 Programming in EDIT mode

The detailed programming of all MIDI commands (e.g. pitch

bend, After Touch, MMC, etc.) can be done in the EDIT mode.

s To activate the EDIT mode, press and hold the EDIT button

and operate a control element. This can be a fader (BCF2000

only), an encoder (BCR2000 only), a push encoder, a button,

footswitch or sustain pedal (BCF2000 only). The control

element is indicated in the display (e.g. E 24 or Fd 8).

+ When using push encoders, select an encoder group

beforehand. In addition, you have to differentiate

between turn and push function.

s Release EDIT; you are now in the EDIT mode.

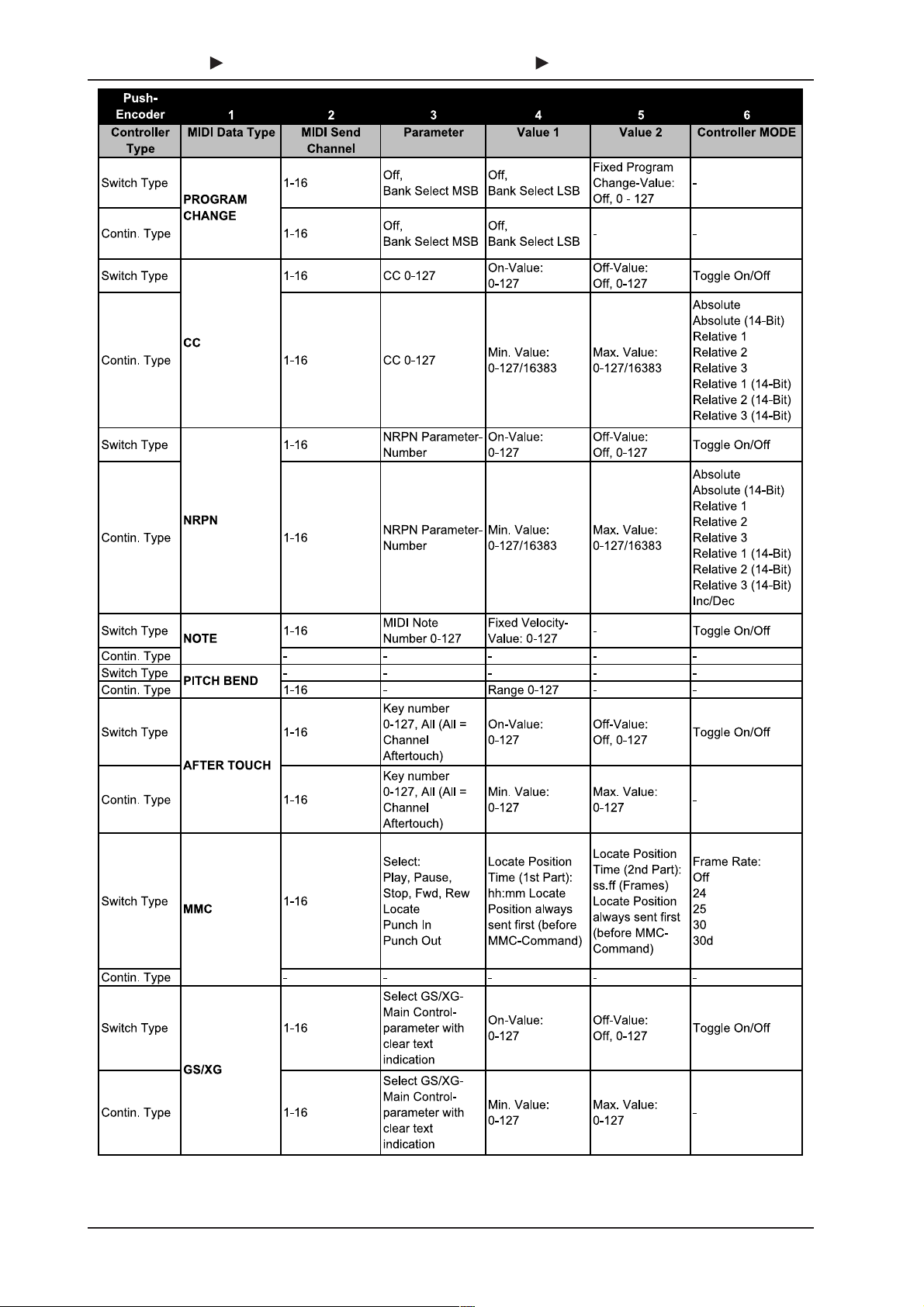

s Using the push encoders 1 to 6, you can now assign MIDI

commands to the selected control element. You will find all

possible MIDI function in table 4.1, including all

accompanying explanations.

s If you want to assign MIDI data to additional control

elements, just press and hold the EDIT button and move

one of the control elements. Now, let go of both controls

and use the push encoders to assign a function to it (see

table 4.1).

s To leave the EDIT mode, press EXIT.

+ Initially, all settings made here are stored temporarily!

More detailed EDIT functions are described in the following

table:

4. CONTROLS

If you intend to store them in a preset, please see chapter

4.2.2.

13

Page 14

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

14

Tab. 4.1: Assignment of the push encoders in EDIT mode

4. CONTROLS

Page 15

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

Table explanation:

All settings in the EDIT mode are made by turning the first six

push encoders. Pressing the push encoder displays its current

value. In addition, the setting options depend on whether the

selected control element is a SWITCH type or CONTINUOUS

type.

s SWITCH-type control elements are buttons, press functions

for push encoders and footswitches.

s CONTINUOUS-type control elements include the eight

BCF2000 faders, the 24 encoders of the BCR2000, the turn

function of the push encoders and the sustain pedal

(BCF2000 only).

In the EDIT mode, Push Encoder 1 selects (by turning) the

type of command assigned to a control element.

With Push Encoder 2, select a MIDI channel through which

that control elements data is sent.

Push Encoders 3 - 5 set parameters and values for the selected

MIDI type. They vary depending on the MIDI function. More details

about this subject can be found later in this chapter.

Push Encoder 6 (Controller Mode) selects how the previously

selected control element behaves, depending on whether it is a

SWITCH or a CONTINUOUS type.

SWITCH-type control elements have two different modes:

Toggle On and Toggle Off. Toggle On is similar to a switching

function (e.g. a light switch). Each time you press the switch, the

value sent alternates between the on value (set by encoder 4)

and the off value (set by encoder 5). This setting is perfect for

triggering drum loops from a sampler (press once = start, press

again = stop).

The Toggle Off mode corresponds to a momentary-contact

button, comparable to the switch of an electric door opener. The

on value is sent only as long as the button is pressed. After

releasing the button, the off value is sent. Use this control type

to trigger short sound FX or samples (similar to using a keyboard)

by sending Note On and Offs.

CONTINUOUS-type element controls are divided into

Absolute, Absolute (14 bit), Relative 1 (2nd complement),

Relative 2 (binary offset), Relative 3 (MSB, most significant

bit), Relative 1 (14 bit), Relative 2 (14 bit), Relative 3 (14 bit)

and Increment/Decrement. Absolute means absolute data

values although jumps may occur when changing values. With

Relative, the current parameter value is continued independently

from the position of the control. Absolute (14-Bit) or one of the

Relative (14-Bit) modes are standard modes for value changes

at NRPNs with high resolution. This is necessary with some

software mixers if more than 128 steps are needed. Increment/

Decrement serves as a step-by-step increase or decrease of

values by using the Data Increment/Decrement commands

(see list 5.1 in the appendix).

+ The classic controler mode for most applications is

absolute. All other modes have to be supported by

the MIDI software or the device to be controlled.

Program Change:

With the encoders 3 and 4 you can select bank numbers. If a

MIDI device contains more than 128 presets/programs, first a

bank change command has to be sent. Even though this is a

controller command, it has to be sent before the program change

(and is therefore adjustable) since it is linked to the preset change.

If the bank select message is not needed, simply select off.

Encoder 5 selects the program number. If the selected

control element is a control dial (continuous type), the

program number is directly selected when turning the dial.

Pressing the switch directly selects the assigned program

number. This can be useful if you always want to start from

the same preset.

Control Change CC:

A control change consists of a controller number and its

respective value. Encoder 3 sets the controller number. With

buttons, different values can be sent when pressing and releasing

(to be set with encoders 4 and 5). This function is useful if fixed

parameter settings are to be sent.

With faders and control dials (continuous type), the value range

can be determined by using encoders 4 (minimum value) and 5

(maximum value).

+ Alternatively, you can invert the value scale by assigning

127 as the minimum value and 0 as maximum value

(scale inversion). A classic application is the draw bar

control of virtual or digital organs or organ expanders.

If assigning controller 7 (volume) to the faders of the

BCF2000 this way, the signal becomes quieter when

moving up the fader. Moving down the fader is similar

to moving out the draw bars, and the volume increases.

NRPN:

A NRPN is needed if none of the 127 standardized controller

numbers are available for a certain function.

Encoder 3 selects the parameter number. For assigning mixer

faders, we recommend the high resolution (Absolute 14 bit),

provided that the control hardware/software supports it.

Note:

Of course, a note can only be assigned to one SWITCH element.

The note is set with encoder 3. Note C3 (C key) corresponds with

note number 60. Encoder 4 sets the note velocity (note volume).

Pitch Bend:

Pitch bend is assignable to only one CONTINUOUS element.

Since this is a type of command with its own status byte, selecting

a MIDI channel (Encoder 2) and Range (Encoder 4) is sufficient.

After Touch:

Normally, ALL is selected here. This means that After Touch

affects all notes equally (Channel Pressure). If you want to use

a polyphonic After Touch (Key Pressure), the single note on

which After Touch should have an effect can be selected using

encoder 3. Since this process is only supported by a few tone

generators, channel After Touch will be best most of the time.

When a switch element has been selected, an on and off value

can also be set (release dynamic). Therefore, you can limit the

modulation range (FX depth) using After Touch.

MMC:

MIDI Machine Control data is only assignable to button

elements.

Encoder 4 (Value 1) sets Locate Time hour and minute values,

while encoder 5 (Value 2) sets seconds and frames. The Locate

Position is always sent before the MMC command. We therefore

have the following logic-switching sequence:

If the Locate parameter has been selected, the sequencer or

hard drive recorder always jumps to the set position. If Play has

been selected as the parameter (for a button), the sequencer

always starts from the set locator point as soon as the button is

pressed. Rewind always begins at the chosen locator point.

Select the frame rate with encoder 6: 24, 25, 30 (non-drop), 30d

(drop frame) or off (in this case only the MMC message is sent,

without any information of the locate position).

4. CONTROLS

15

Page 16

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

3

GS/XG:

Encoder 3 directly selects the most important Main Control

parameters. The display indicates them as a (shortened) text

(table 4.2). In this case, these are CCs or NRPNs (no SysEx

data).

Table 4.2: GS/XG Parameter Main Controls

Encoders 5 and 6 let you confine or invert each controllers

value range.

4.3.3 Settings in the global setup menu

Settings that have an effect on all presets are made in the global

setup menu.

s Keep the EDIT key pressed and at the same time press the

STORE key.

s You are now in the global setup menu, and can let go of

both keys.

s Now, turn the push encoders 1 to 6 to get the desired setting.

This is how the push encoders are allocated:

(QFRGH U )XQFWLRQ 6HOHFW

1 Operating Mode U-1 ... U-4, S-1 ... S2 Global RX Channel Of f, 1 ... 16

3 Footsw itch Auto/Normal/In verted

4 Start Prese t 1 ... 32, Last

5 Device ID 1 ... 16

6 SysEx Dump Single/All

Table 4.3: Push encoder allocation in global setup menu

Operating Mode:

The operating modes are described in chapter 4.1. You can

select USB modes U-1 to U-4 and stand-alone modes S-1 to S-

3.

Global RX Channel:

The B-CONTROL receives program change commands on this

channel.

Footswitch type:

Because there are different kinds of footswitches (depending

on their switching behavior), the polarity of the footswitch connector

can be set (normal/inverted), or it can be automatically detected

during power startup (auto recognition).

Start Preset Number:

Each of the 32 presets can be selected as the startup preset.

Additionally, with the Last function, at startup you have the option

to always load the preset that was used last.

Device ID Number:

You should change the ID number settings only if you work

with several BCF2000s or BCR2000s at the same time, and

problems with recognizing the correct device start occurring during

a SysEx Dump procedure.

+ Please keep in mind that SysEx Dumps can only be

received at the device number to which they were sent!

SysEx Dump Select:

Turning push encoder 6 lets you select between the current

preset (single) or the entire memory contents of the 32 presets

(all) should be sent as a SysEx dump. One press on encoder 6

triggers the dump.

s To exit the global setup menu, press EXIT.

+ The settings in the global setup menu take effect

immediately and do not have to be separately stored.

4.3.4 Additional functions

Panic Reset:

This function resets the most important MIDI data to their factory

settings.

s Press EDIT and keep it pressed.

s Now press EXIT. The reset is performed as soon as you

press EXIT. PAnC (for Panic) appears in the display.

s As soon as the reset is over, your B-CONTROL goes

automatically into the play mode, and the current preset is

shown in the display.

Data Request:

Current value settings of the MIDI device connected to your

B-CONTROL can be transmitted to your B-CONTROL using the

data request function (provided that the MIDI device supports

this function, and a request command was defined using the editor

software). In this case, the MIDI device doesnt send data; the BCONTROL requests them instead.

s Press the LEARN key while the EDIT key is kept pressed.

The request takes place, and the B-CONTROL indicates

the controller values of the receiving MIDI device on the

LED ring or through fader positions.

Snapshot Send:

A Snapshot Send lets you send all current controller values in

order to transmit the B-CONTROL settings to the connected MIDI

device.

s Press the PRESET key while the EDIT key is kept

pressed. The B-CONTROL now sends the current controller

settings.

Single Preset Dump:

In addition to the SysEx Dump function in the global setup menu,

the following key combination lets you send all settings of the

current presets:

s Press the PRESET key while the EDIT key is kept

pressed.

+ Snapshot Send and Single Preset Dump differ in the

kind of data that is being sent: With Snapshot Send,

only current control values are transmitted in order to

synchronize them with the connected MIDI device. With

Single Preset Dump, the entire contents of the current

preset including the current control assignments are

sent. With this function, you can easily archive certain

presets, or swap them with other B-CONTROL users.

16

4. CONTROLS

Page 17

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

5. APPENDIX

Table 5.1: Standard MIDI Controller

5. APPENDIX

17

Page 18

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

6. SPECIFICATIONS

USB INTERFACE

Table 5.2: GS/XG Parameter Main Controls

0XVLFDO1RWH 0,',1RWH1XPEHU

C-2 0

&'E

'

'(E

(

)

)*E

*

*$E

$

$%E

+

C-1 12

C0 24

C1 36

C2 48

C3 (Clef C) 60 (Yamaha Convention)

C4 72

C5 84

C6 96

C7 108

C8 120

G8 127

Table 5.3: MIDI note number assignment

Type Full-speed 12 MBit/sec.

MIDI INTERFACE

Type 5-pin DIN connectors IN, OUT A,

CONTROL ELEMENTS

BCF2000

Controls 8 motorized 100-mm faders

Keys 20 keys

BCR2000

Controls 24 infinitely variable encoders

Keys 20 keys

DISPLAY

Type 4-digit 7-segment LED display

SWITCHED INPUTS

BCF2000

Footswitch 1 x 1/4" TS connector

Foot pedal 1 x 1/4" TRS connector

BCR2000

Footswitch

Input 1 1/4" TRS stereo connector for

Input 2: 1/4" TS connector

POWER SUPPLY

Voltage 85 - 250 V~, 50 - 60 Hz

Power consumption max. 10 W

Fuse T 1 A H

Mains connection Standard IEC receptacle

DIMENSIONS/WEIGHT

Dimensions

(H x W x D) 13" x 4" x 11 4/5"

Weight

BCR2000 approx. 2,15 kg (4 ¾ lbs.)

BCF2000 approx. 2,60 kg (5 ¾ lbs.)

USB MIDI class-compliant

OUT B/THR U

8 infinitely variable push encoders

with LED rings

10 system keys (4x Encoder Group,

4x programming, 2x Preset)

with LED rings

8 infinitely variable push

encoders with LED rings

10 system keys (4x Encoder Group,

4x programming, 2x Preset)

with automatic polarity detection

dual-footswitch

both with automatic polarity

detection

(330 mm x 100 mm x 300 mm)

18

BEHRINGER is constantly striving to manintain the highest professional

standards. As a result of these efforts, modifications may be made from

time to time to existing products without prior notice. Specifications and

appearance may differ from those listed or illustrated.

6. SPECIFICATIONS

Page 19

B-CONTROL FADER BCF2000/B-CONTROL ROTARY BCR2000

7. WARRANTY

§ 1 WARRANTY CARD/ONLINE REGISTRATION

To be protected by the extended warranty, the buyer must

complete and return the enclosed warranty card within 14 days

of the date of purchase to BEHRINGER Spezielle Studiotechnik

GmbH, in accordance with the conditions stipulated in § 3. Failure

to return the card in due time (date as per postmark) will void any

extended warranty claims. Based on the conditions herein, the

buyer may also choose to use the online registration option via

the Internet (www.behringer.com or www.behringer.de).

§ 2 WARRANTY

1. BEHRINGER (BEHRINGER Spezielle Studiotechnik GmbH

including all BEHRINGER subsidiaries listed on the enclosed

page, except BEHRINGER Japan) warrants the mechanical and

electronic components of this product to be free of defects in

material and workmanship for a period of one (1) year* from the

original date of purchase, in accordance with the warranty

regulations described below. If the product shows any defects

within the specified warranty period that are not excluded from

this warranty as described under § 4, BEHRINGER shall, at its

discretion, either replace or repair the product using suitable new

or reconditioned parts. In the case that other parts are used which

constitute an improvement, BEHRINGER may, at its discretion,

charge the customer for the additional cost of these parts.

2. If the warranty claim proves to be justified, the product will

be returned to the user freight prepaid.

3. Warranty claims other than those indicated above are

expressly excluded.

§ 3 RETURN AUTHORIZATION NUMBER

1. To obtain warranty service, the buyer (or his authorized dealer)

must call BEHRINGER (see enclosed list) during normal business

hours BEFORE returning the product. All inquiries must be

accompanied by a description of the problem. BEHRINGER will

then issue a return authorization number.

2. Subsequently, the product must be returned in its original

shipping carton, together with the return authorization number to

the address indicated by BEHRINGER.

3. Shipments without freight prepaid will not be accepted.

§ 4 WARRANTY REGULATIONS

1. Warranty services will be furnished only if the product is

accompanied by a copy of the original retail dealers invoice. Any

product deemed eligible for repair or replacement under the terms

of this warranty will be repaired or replaced.

2. If the product needs to be modified or adapted in order to

comply with applicable technical or safety standards on a national

or local level, in any country which is not the country for which the

product was originally developed and manufactured, this

modification/adaptation shall not be considered a defect in

materials or workmanship. The warranty does not cover any such

modification/adaptation, irrespective of whether it was carried out

properly or not. Under the terms of this warranty, BEHRINGER

shall not be held responsible for any cost resulting from such a

modification/adaptation.

3. Free inspections and maintenance/repair work are expressly

excluded from this warranty, in particular, if caused by improper

handling of the product by the user. This also applies to defects

caused by normal wear and tear, in particular, of faders,

crossfaders, potentiometers, keys/buttons, tubes and similar parts.

4. Damages/defects caused by the following conditions are not

covered by this warranty:

s improper handling, neglect or failure to operate the unit in

compliance with the instructions given in BEHRINGER user

or service manuals.

s connection or operation of the unit in any way that does not

comply with the technical or safety regulations applicable in

the country where the product is used.

s damages/defects caused by force majeure or any other

condition that is beyond the control of BEHRINGER.

5. Any repair or opening of the unit carried out by unauthorized

personnel (user included) will void the warranty.

6. If an inspection of the product by BEHRINGER shows that

the defect in question is not covered by the warranty, the inspection

costs are payable by the customer.

7. Products which do not meet the terms of this warranty will be

repaired exclusively at the buyers expense. BEHRINGER will

inform the buyer of any such circumstance. If the buyer fails to

submit a written repair order within 6 weeks after notification,

BEHRINGER will return the unit C.O.D. with a separate invoice

for freight and packing. Such costs will also be invoiced separately

when the buyer has sent in a written repair order.

§ 5 WARRANTY TRANSFERABILITY

This warranty is extended exclusively to the original buyer

(customer of retail dealer) and is not transferable to anyone who

may subsequently purchase this product. No other person (retail

dealer, etc.) shall be entitled to give any warranty promise on

behalf of BEHRINGER.

§ 6 CLAIM FOR DAMAGES

Failure of BEHRINGER to provide proper warranty service shall

not entitle the buyer to claim (consequential) damages. In no

event shall the liability of BEHRINGER exceed the invoiced value

of the product.

§ 7 OTHER WARRANTY RIGHTS AND NATIONAL LAW

1. This warranty does not exclude or limit the buyers statutory

rights provided by national law, in particular, any such rights

against the seller that arise from a legally effective purchase

contract.

2. The warranty regulations mentioned herein are applicable

unless they constitute an infringement of national warranty law.

* Customers in the European Union please contact

BEHRINGER Germany Support for further details.

Technical specifications and appearance subject to change without notice. The information contained herein is correct at the time of printing.

WINDOWS®, MAC OS X® as well as the names of companies, institutions or publications pictured or mentioned and their respective logos are

registered trademarks of their respective owners. Their use neither constitutes a claim of the trademarks by BEHRINGER® nor affiliation of the

trademark owners with BEHRINGER®. BEHRINGER® accepts no liability for any loss which may be suffered by any person who relies either wholly

or in part upon any description, photograph or statement contained herein. Colors and specifications depicted may vary slightly from product. No part

of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording of any

kind, for any purpose, without the express written permission of BEHRINGER Spezielle Studiotechnik GmbH. BEHRINGER® is a registered

© 2003 BEHRINGER Spezielle Studiotechnik GmbH.

BEHRINGER Spezielle Studiotechnik GmbH, Hanns-Martin-Schleyer-Str. 36-38,

47877 Willich-Münchheide II, Germany

Tel. +49 2154 9206 0, Fax +49 2154 9206 4903

trademark.

ALL RIGHTS RESERVED.

7. WARRANTY

19

Loading...

Loading...