Page 1

Documentation

eXtended Transport System Start-Up

Version:

Date:

1.2

2016-02-18

Page 2

Page 3

Table of content

Table of content

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation............................................................................................................. 5

1.2 Documentation issue status.............................................................................................................. 6

1.3 Intended use ..................................................................................................................................... 6

2 Guidelines and Standards ........................................................................................................................7

3 Safety..........................................................................................................................................................8

3.1 General safety instructions ............................................................................................................... 8

3.1.1 Personnel qualification..........................................................................................................8

3.1.2 Description of safety symbols ...............................................................................................8

3.2 Special safety instructions ............................................................................................................... 9

3.3 Using in Ex environments ............................................................................................................... 10

4 Handling ...................................................................................................................................................11

4.1 Transport ........................................................................................................................................ 11

4.2 Packaging ....................................................................................................................................... 11

4.3 Storage ........................................................................................................................................... 12

4.4 Maintenance / Cleaning .................................................................................................................. 12

4.4.1 Replacement of the guide rollers ........................................................................................13

4.5 Disposal .......................................................................................................................................... 14

5 Product identification..............................................................................................................................15

5.1 Scope of supply .............................................................................................................................. 15

5.2 Type label ....................................................................................................................................... 15

5.3 Type key ......................................................................................................................................... 16

6 Technical description..............................................................................................................................18

6.1 General technical data.................................................................................................................... 18

6.1.1 Dimensions .........................................................................................................................19

6.1.2 Connection diagram XTS-Infeed.........................................................................................20

6.1.3 Connection overview...........................................................................................................21

6.2 Configuration ................................................................................................................................. 22

6.2.1 Basic functions....................................................................................................................22

6.2.2 Use of the basic functions...................................................................................................23

6.2.3 System length and curve function.......................................................................................23

6.3 Overview ........................................................................................................................................ 24

6.4 Overview of the components .......................................................................................................... 26

7 Installation................................................................................................................................................28

7.1 Mechanical installation.................................................................................................................... 28

7.2 Overview of the tightening torques ................................................................................................. 29

7.3 Mounting the movers on the guide rail............................................................................................ 31

7.4 The positioning system ................................................................................................................... 33

7.4.1 Zero point of the encoder system .......................................................................................33

7.4.2 Teaching the encoder system.............................................................................................34

7.4.3 Application simulation .........................................................................................................40

7.5 Collision avoidance......................................................................................................................... 41

7.5.1 Operating principle of collision avoidance........................................................................... 41

8 Technical data..........................................................................................................................................45

8.1 AT9011-0050-0550......................................................................................................................... 45

8.2 Technical drawing AT9011-0050-0550........................................................................................... 45

eXtended Transport System Start-Up 3

Version: 1.2

Page 4

Table of content

9 Support and Service................................................................................................................................46

Version: 1.2

eXtended Transport System Start-Up4

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics.

In the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC®and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

eXtended Transport System Start-Up 5

Version: 1.2

Page 6

Foreword

1.2 Documentation issue status

Issue Comment

1.2 Chapter update:

4.2; 4.5; 6.1.1; 6.1.2; 6.2.3; 6.4; 7.2; 7.5.1; 7.5.2

New and deleted chapter:

New: 4.4.1; 6.1.3

Deleted: 7.3

1.1 Chapter update:

3.2; 6.1; 6.1.1, 7.3

New chapter:

Technical data

1.0 First edition

1.3 Intended use

The linear eXtended Transport System (XTS) is designed for machines and equipment with the highest

demands on dynamics and positioning accuracy. All components of the eXtended Transport System (XTS)

are exclusively intended to be programmed and commissioned using the TwinCAT automation software

from Beckhoff Automation GmbH & Co. KG.

Caution - Risk of injury!

Electronic equipment is not fail-safe. In case of failure of the drive system, the machine

WARNING

manufacturer is responsible for ensuring that the connected components of the eXtended

Transport System (XTS) and the machine are brought into a safe state.

Commissioning of the eXtended Transport System (XTS)

The eXtended Transport System (XTS) must be commissioned based on the requirements

WARNING

All components of the eXtended Transport System (XTS) are installed exclusively in electrical systems or

machines. They may only be commissioned in connection with components of the eXtended Transport

System (XTS) and the previously designed plant. Furthermore, it is essential to take into account all

environmental conditions defined in this document before the eXtended Transport System (XTS) is

commissioned.

of the currently valid EU Machinery Directive. Furthermore, the client must ensure that all

components installed in the system have a valid serial number.

Version: 1.2

eXtended Transport System Start-Up6

Page 7

2 Guidelines and Standards

Danger for persons, the environment or equipment

The components of the XTS are not products within the meaning of the EC Machinery Di-

CAUTION

rective. Operation of the XTS components in machines or systems is only permitted once

the machine or system manufacturers has provided evidence of CE conformity of the complete machine or system.

Guidelines and Standards

eXtended Transport System Start-Up 7

Version: 1.2

Page 8

Safety

3 Safety

3.1 General safety instructions

3.1.1 Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

3.1.2 Description of safety symbols

The following safety symbols and associated safety instructions are used in this document. These safety

instructions must be read and followed.

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

DANGER

life and health of persons.

WARNING

CAUTION

Attention

Note

Caution - Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Damage to the environment or devices!

Failure to follow the safety instructions associated with this symbol can lead to damage to

the environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

Version: 1.2

eXtended Transport System Start-Up8

Page 9

Safety

3.2 Special safety instructions

The safety instructions are designed to avert danger and must be followed during installation,

commissioning, production, troubleshooting, maintenance and trial or test assemblies. The XTS can operate

independently. Installation in a machine or system is not mandatory. During independent commissioning or

installation of the XTS in a machine or system, the documentation and safety instructions provided by the

machine manufacturer must be read and applied.

Caution - Risk of injury!

The XTS may only be installed by trained and qualified personnel. The qualified personnel

WARNING

WARNING

DANGER

must know the national accident prevention regulations and be able to apply them.

When working on the XTS, personal protective equipment (PPE) must be worn. In particular, safety boots must be worn!

Caution - Risk of injury through electric shock!

Bring the electrical environment (XTS, cabinet, etc.) into a safe, de-energized state before

installing or working on the XTS.

Acute risk of injury due to improper earthing!

The XTS must be earthed in accordance with the statutory provisions. Non-compliant earthing can cause acute injuries or death by electric shock.

Attention

Attention

CAUTION

Intended use!

The XTS starter kit may only be put into operation under consideration of currently valid EU

directives and standards, as well as the EC Machinery Directive in force at the time of commissioning.

Destruction of the XTS starter kit!

Ensure adequate ventilation and proper earthing of the cabinet. The permissible ambient

conditions are specified in the “Technical data” section. Failure to observe the specified

ambient conditions and improper earthing may cause damage to components of the XTS

starter kit. Furthermore, EMC problems can arise.

Risk of burns from hot surfaces!

The XTS issues a warning via TwinCAT if the operating temperature exceeds 65 °C. If the

temperature exceeds 75 °C, the system switches off automatically. In the event of an automatic shutdown, the surface temperature of the coils may exceed 105 °C. Acute risk of

burns!

Do not touch the components of the XTS during operation and shortly after operation. Wait

until all components have cooled sufficiently.

Use a thermometer to check the surface temperature of the components.

In cases that require touching of components directly after operation, use suitable safety

gloves to protect from burns. Wear heat-resistant clothing.

Danger from magnetic fields!

The Beckhoff XTS is equipped with permanent magnets at the guide rails and movers. The

field strength of the XTS results solely from the magnetic fields of these components. A

limit range of < 0.5 mT is reached in energized state at a radius of 150 mm, in non-energized state at a radius of 130 mm. The magnetic field poses a danger to persons and the

environment. Observe the regulations for magnetic fields in air transportation (IATA Packing Instruction 902). This applies to already installed magnets. Permanent magnets must

be stored in humid conditions. The use of permanent magnets in humid conditions (up to

95% relative humidity) can lead to corrosion and destruction of the permanent magnets.

eXtended Transport System Start-Up 9

Version: 1.2

Page 10

Safety

Note

Danger from magnetic fields!

In particular, the magnetic field poses a danger to:

• Persons with cardiac pacemakers (the magnetic field may cause the pacemaker to

switch to test mode and thus cause a cardiac arrest!)

• Persons with magnetically conductive implants

• Magnetic data storage devices

• Chip cards with magnetic strips, and

• Electronic devices

• Also keep in mind that the magnetic fields can influence implanted defibrillators and

make external defibrillators inoperable.

• Ensure a safety distance of 500 mm to all magnetic parts. Also, make sure that there is

no direct contact with magnetic components near parts that are susceptible to interference.

The national regulations and guidelines applicable in other countries must be followed!

Also note the requirements of BGV B 11 in connection with magnetic fields (BGV B 11

Section 14).

Liability for further transport!

Please note that all components of the XTS starter kit may only be forwarded in the original

packaging supplied by Beckhoff. The use of other packaging for further transport would

void all liability and warranty claims against Beckhoff Automation GmbH & Co. KG.

3.3 Using in Ex environments

The use of the XTS in potentially explosive atmospheres – Directive 94/9/EC

– is not permitted!

WARNING

Version: 1.2

eXtended Transport System Start-Up10

Page 11

4 Handling

4.1 Transport

• The XTS starter kit may only be transported by qualified personnel and in the manufacturer's original

packaging.

• Avoid shocks, particularly at the corners of the packaging.

• If the packaging is damaged, check the XTS starter kit for visible damage. Inform the transport

company and, if necessary, the manufacturer.

Damage to the device due to improper transport!

When transporting the XTS starter kit ensure that all specifications are met. In particular,

jerky and fast movements should be avoided.

CAUTION

4.2 Packaging

• Motor modules in recyclable cardboard packaging*

• Magnet holders in recyclable cardboard packaging with foam inserts*

• Movers in recyclable cardboard packaging with bubble wrap*

Handling

*only single packaging.

Shipping of the XTS starter kit

Contents of the Starter Kit include

• Fully Assembled and tested XTS (item 4)

• Control Cabinet with all necessary equipment

(item 3)

Both are secured in the shipping crate to prevent

movement during transport.

Warning Pinch Point!

When opening/closing the case keep hands clear of

the area between the lid of the crate (1) and the side

of the crate (2) two People are required to lift/lower

the lid!

eXtended Transport System Start-Up 11

Version: 1.2

Page 12

Handling

4.3 Storage

Requirement Characteristic value

Climate category 2K3 according to EN 60721

Storage temperature -25°C to +85°C

Permissible relative humidity 15% - 95%, no condensation

Store only in the original recyclable manufacturer's packaging.

4.4 Maintenance / Cleaning

Maintenance

The XTS motor modules are maintenance-free!

Observe the ambient commissioning conditions!

Make sure that the XTS is stored and electrically operated only under the specified condi-

WARNING

tions.

The XTS movers are not maintenance-free!

Destruction of the rails!

The guide rollers of movers must be checked at regular intervals. Remove any dirt or other

WARNING

foreign material that may have accumulated on the guide rollers during operation. Failure to

comply with regular maintenance can lead to increased wear of the guide rollers, as well as

damage to the rails.

Rail maintenance

The rails can be lubricated lightly. This increases the life of the guide rollers. The following

Note

lubricants are suitable for this purpose:

• Vaseline according to DAB 10 (German Pharmacopoeia 10)

• Vaseline spray

• Silicone spray

• PTFE spray

• If the rails are cleaned for maintenance, re-lubricate them with one of the lubricants

listed above. For further specifications please contact the Beckhoff applications department.

Version: 1.2

eXtended Transport System Start-Up12

Page 13

Handling

Cleaning

The XTS modules are sealed according to protection class IP65. They are not protected against aggressive

substances. Clean the modules regularly to protect them against rust and corrosion. Use only Isopropanol.

Damage to motor modules

If damage to the motor modules has occurred, please contact Beckhoff Automation GmbH

WARNING

& Co. KG immediately!

Damage to the guide rollers

Make sure that the rails are free from dirt and metallic particles. A dirty rail can significantly

WARNING

reduce the service life of the guide rollers.

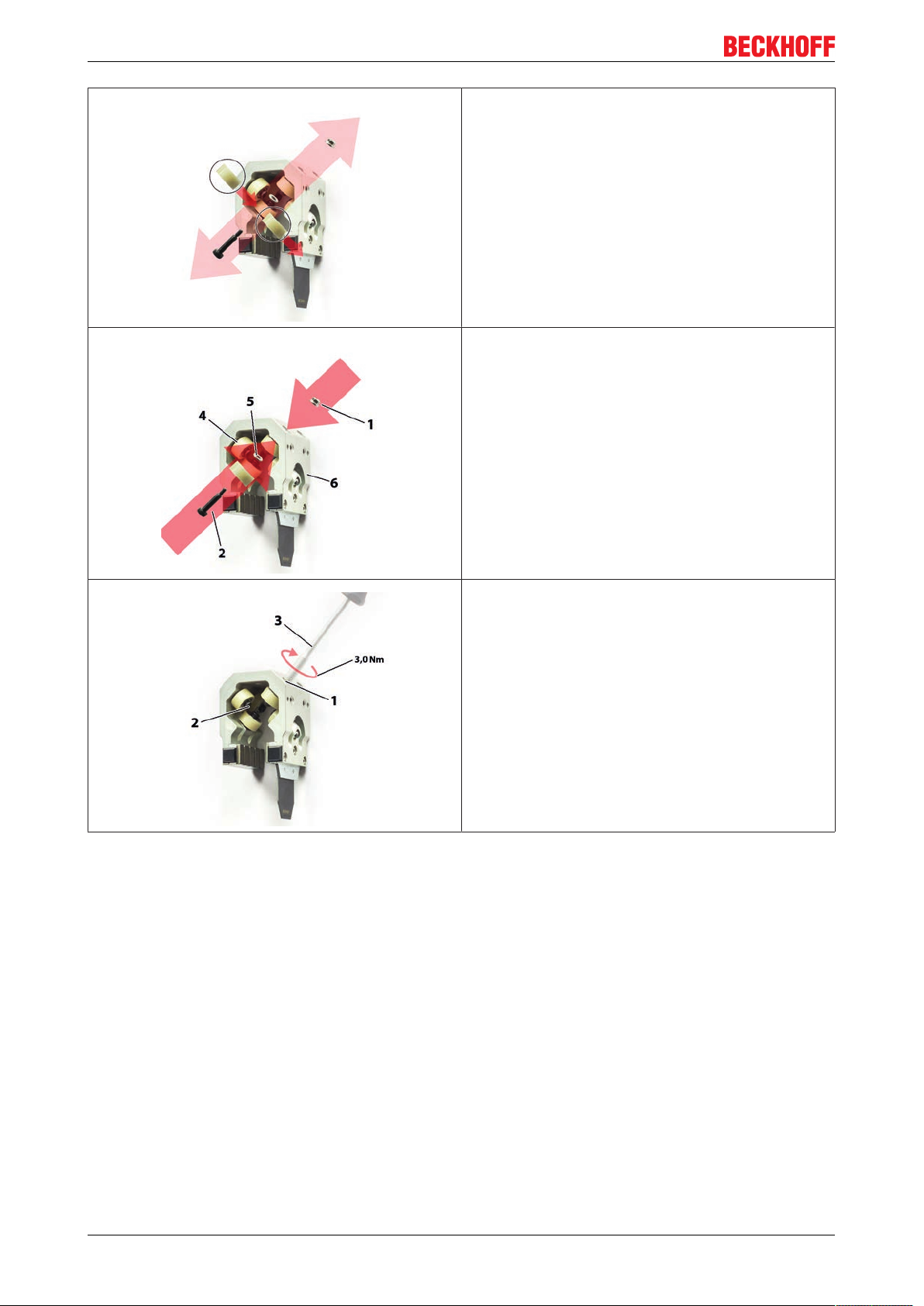

4.4.1 Replacement of the guide rollers

Installation manual

Loosen the roller axel nut

• Use a 1.5mm Allen Key hold to hold the screw

in place. (2)

• Loosen and remove the nut using a 5.5mm

socket wrench/spanner (1)

The Screw (2) must be held in place to prevent it

from turning with the Socket.

Removal of the components

• Pull out the screw that is the shaft of the roller

(2) and take with it

• the Roller (4)

• the washer (5)

• the nut (1)

Caution! When removing the screw (2) be sure to

pull it straight out from the hole in the mover body (6)

in order to prevent damage to the threads. Do not tilt

it.

eXtended Transport System Start-Up 13

Version: 1.2

Page 14

Handling

Exchange the Roller

After all the components have been removed, from

the mover body, the roller can be replaced.

Reassemble the Components

• Insert the screw (2) through

• the Roller (4) then

• the washer (5)

• Push the screw through the hole of the mover

body and fix it in place with the nut (6)

Caution! To prevent damage to the threads, take

care to insert the screw (2) straight into the mover

body (6). Do not tilt the screw.

Tighten the Roller axel nut.

• Use a 1.5mm Allen key hold the screw (2) in

place.

• With a 5.5mm Socket tighten the nut (1) to a

torque of 2.4Nm

The screw (2) must be held in place to prevent it from

turning with the nut.

4.5 Disposal

In accordance with the WEEE 2002/96/EC Directives we take old devices and accessories back for

professional disposal, provided the transport costs are taken over by the sender. Send the devices with the

note “For disposal” to:

Beckhoff Automation GmbH & Co. KG

Service-Center

Stahlstraße 31

33415 Verl

Version: 1.2

eXtended Transport System Start-Up14

Page 15

Product identification

5 Product identification

5.1 Scope of supply

Check the completeness of the delivery against your delivery note.

Missing parts or damage should be recorded immediately and reported to the carrier, the insurance and/or

Beckhoff Automation GmbH & Co. KG.

The standard scope of supply includes:

• XTS-Starter Kit

• Control cabinet

• Connection cables

• Control PC

• Switch mode power supply units for 24 V and 48 V

• Software licenses (TwinCAT/TC3/XTS Extension)

• Commissioning of the XTS (this manual)

5.2 Type label

eXtended Transport System Start-Up 15Version: 1.2

Page 16

Product identification

5.3 Type key

*Content of the XTS-Starterkit

Version: 1.2

eXtended Transport System Start-Up16

Page 17

Product identification

*Content of the XTS-Starterkit

eXtended Transport System Start-Up 17

Version: 1.2

Page 18

Technical description

6 Technical description

6.1 General technical data

Environmental influences XTS

Ambient temperature -10 °C – +40 °C

Transport and storage temperature -25 °C - +85 °C

Permissible relative humidity 15 % - +95 %, no condensation

Contamination level EN 60204 / EN 50178 Level 2

Corrosion protection Normally not required. Under extreme operating conditions, special measures

Installation altitude Between 1000 m and 2500 m, the performance reduces by 1.5% per 100 m.

Installation position Vertical installation position of the starter kit and housing

Ventilation XTS via convection

Protection class IP65

Ventilation of the machine bed!

To improve system utilization, it is strongly recommend to actively or passively cool the ma-

Note

chine bed of the XTS. For further information on cooling please contact the Beckhoff applications department!

If ambient temperatures exceeding +40 °C are expected, it is essential to contact

the Beckhoff applications department.

may be imposed by the production.

Other installation positions are possible for further individual XTS components

System properties XTS

Max. force 100 N at standstill

Payload 80 N at 2 m/s

Continuous force 30 N (at approx. 30 °C temperature increase between motor / mounting frame)

Velocity 4 m/s at 48 VDC supply

Acceleration > 100 m/s² (without payload)

Synchronization accuracy < ± 0.15

Absolute accuracy < ± 0.25

Repeatability (unidirectional) < ± 10 µm (standstill)

Mover length 50 mm in direction of movement (AT9011)

Mover weight Approx. 350 g (complete mover without attachments)

Maximum system length > 10 m (dependent on computing power, no system limit)

Occurring temperature during operation /

storage temperature

Protection class IP 65

Approvals CE

Vibration/shock resistance Conforms to EN60068-2-6/EN 60068-2-27

EMC immunity/emission Conforms to EN61000-6-2/EN 61000-6-4

1*)

The synchronization accuracy is primarily dependent on the mechanical stiffness and the load on the

1*)

mm at 1.5 m/s within a straight module

2*)

mm within a straight module

0…< +105 °C

3*)

/ -25 °C…+85 °C

mover. The controller setting and the mechanical offset between the modules must also be taken into

account.

2*)

Typically achievable absolute accuracy; this may be exceeded in case of significant thermal warming of

the module (∆ϑ ≥ 30°C) or lack of parallelism or orthogonality of the encoder flag to the motor module.

3*)

Please note the special safety instructions for the XTS on page 8 of this manual!

Version: 1.2

eXtended Transport System Start-Up18

Page 19

Technical description

Electrical data XTS

Supply voltage Control voltage 24 VDC, power supply 50 V

Current consumption Power supply: 16 A rated current

Power consumption control voltage (24 V) Motor modules: 30 W/m (communication, electronics,

displacement measurement)

Length per infeed Typically 1 m – max. 3 m (depending on computing power)

Power consumption per mover approx. 30 W at 2 m/s constant speed

approx. 60 W at 4 m/s constant speed

approx. 60 W at a peak acceleration of 10 m/s² and a mass

of 1 kg

approx. 300 W at a peak acceleration of 50 m/s² and a

mass of 1 kg

DC

Length per infeed!

The length per infeed is application-dependent. For precise dimensioning of the power sup-

Note

ply please contact the Beckhoff applications department.

Energy recovery from the XTS

The XTS is capable of energy recovery. If kinetic energy is fed back during an emergency

Note

stop, measures should be taken to avoid voltage overshoot, and associated premature

auto-shutdown of the motor modules. For further information please contact the Beckhoff

applications department.

6.1.1 Dimensions

Module Width at the ma-

chine bed

Straight motor module

AT2001-0250

Straight line motor module with power

supply

AT2001-0250

Curved motor module 180° (clothoid)

AT2050-0500

Distance between movers and modules

The air gap between the magnet and the motor should by 0.85 mm on each side. Important: The magnets

must not touch the motor modules of the XTS!

The air gap between the encoder flag and the sensor should be 0.9 mm. A tolerance range of 0.4 mm – 1.4

mm applies (as of December 2015).

Important: Under no circumstances must the encoder flag touch the sensors of the motor modules!

39.1 mm 22.1 mm 96 mm 250 mm

39.1 mm 22.1 mm 96 mm 250 mm

39.1 mm 22.1 mm 306.5 mm 204.2 mm

Width at the

track connection

Height Depth

eXtended Transport System Start-Up 19

Version: 1.2

Page 20

Technical description

24V Power supply

48V

GND

24V

PE connection port

of the module body

EtherCAT

line

48V Power supply

Control cabinet earth

6.1.2 Connection diagram XTS-Infeed

Circuit diagram 48 V negative not grounded:

Do not ground the negative side of the 48V DC Bus

Power Supply! The adjacent diagram describes the

current distribution in the individual conductors. Inside

the module the negative 24V and negative 48V

cables are connected together. If the 48V minus is

not grounded the current for each circuit remains on

its conductors. The current for the 24V control power

remains on the 0.75mm wires to and from the

module. The current for the 48V power remains on

the 2.5mm 48V wires to and from the module. The

grounding of the DC Bus circuit is not necessary. The

EN60204-1 Standard chapter 9.4.3.1 (ground faults)

describes that the control circuits must be grounded

to ensure a machine cannot start with a broken cable.

Load circuits are not affected.

Circuit diagram 48 V minus grounded:

If the negative side of the 48V power supply is

grounded, the following situation occurs as described

by the adjacent diagram. Again, the -48V and -24V

lines are connected internally in the modules. If the

negative side of the 48V power supply is also

grounded, -24V wire (0.75mm) and the -48V wire

(2.5mm) act in parallel for the return path. This will

overload the -24V (0.75mm) wire. The +48V wire

(2.5mm) will carry the 48V load circuit current to the

module, the +24V wire (0.75mm) will carry the 24V

Control circuit current to the module. On the return

side, the -24V (0.75mm) wire will carry half of the

sum of the 48V load circuit current and the 24V

control circuit current. The -48V (2.5mm) wire will

carry the other half of the sum of the currents. The

0.75mm wire does have a slightly higher resistance

(0.042Ohm/m) than the 2.5mm (0.013Ohm/m) wire

but the difference is so small it can be omitted.

Version: 1.2

eXtended Transport System Start-Up20

Page 21

Technical description

6.1.3 Connection overview

Slot assignment of the power voltage

For produce a power supply, connect the Harting plug of the starter kit with the Harting slots on the control

cabinet.

Line identification Slot Signal Wire cross section

Phase 1 Pin 1 +48 V 2.5 mm²

Phase 2 Pin 2 GND (48 V) 2.5 mm²

Phase 3 Pin 3 +24 V 0.75 mm²

Phase 4 Pin 4 GND (24 V) 0.75 mm²

green and yellow phase screwed to the side Functional earth 2.5 mm²

Design of the wire cross-sections

The cable length (supply voltage + EtherCAT) of the supply modules is 5 m. The cable end

Note

Slot assignment of the EtherCAT lines

of the supply voltage is pre-assembled with ferrules. The EtherCAT cable end is pre-assembled with an RJ45 connector.

For produce an EtherCAT connection, connect the EtherCAT cables with the corresponding labeled slots on

the control cabinet. If the cables are reversed, agree the teaching data of the respective modules will no

longer match.

• Pos. 1 shows the two places of assignment for

the Harting connector of the XTS.

• Pos. 2 shows the input and output slot for the

EtherCAT connection

eXtended Transport System Start-Up 21

Version: 1.2

Page 22

Technical description

6.2 Configuration

The linear XTS combines all drive technology functions in a single mechatronic system. Motor movement,

power electronics and displacement measurement form a technical unit, which can be used to implement a

wide range of complex movements. A user-friendly program interface enables different movements to be

realized simultaneously directly from TwinCAT with little effort. The modular XTS enables fast adaptation of a

transport concept to different geometries and applications. The XTS contains a fully integrated linear motor

with power electronics and position sensing in a single unit, a mover as moving part and a mechanical guide

rail. The desired geometries, lengths and radii are formed by the number and choice of the components.

6.2.1 Basic functions

The XTS enables a new class of functions that can be used at the same time in several places. Completely

new, particularly flexible: transport and positioning tasks are economically solvable with little effort.

6.2.1.1 Function of the linear motor with NC and further degrees of freedom

Free movement of the mover

The individual mover can be moved like a linear motor along the entire path, since it makes do without

cables. It can arbitrarily start, stop, brake, accelerate and drive to positions. Like a linear motor with NC

control, an individual mover can be synchronized to external motion profiles, thereby achieving maximum

flexibility.

Production speed

An individual mover can be addressed sensitively – without jerking and with maximum positioning accuracy.

The production speed may be up to 4 m/s over the entire track. The jerk-free acceleration profiles even allow

the transport of liquids.

Wear resistance

The use of XTS leads to less mechanical wear, since only the mover needs mechanical bearings. Gears,

belts, guide rollers and clamps are no necessary. Due to the high positioning accuracy, the compensation of

inaccuracies as required in common transport solutions is unnecessary: there is no stretching of chains due

to load and wear, re-tensioning of toothed belts or mechanical backlash during load changes. Apart from the

payload, only the small mass of the mover is moved.

6.2.1.2 Synchronous movement in the group

Movements with constant force

One mover follows another with a defined force. It can apply a clamping force and at the same time follow a

movement. For other applications the force can be limited so as not to place an unnecessary load on a

product under any conditions.

Synchronization in the group

Groups can be formed at any point on the track “on the fly” (during motion). The groups stop together or

move along processing stations with a specified velocity profile. The size of the group (number and spacing)

can be changed dynamically.

Free mobility of several movers

The movers can all be moved independently of one another. They can take up absolute positions along the

entire travel distance. In addition, they can be moved relatively to each other and always avoid a collision

with their neighbor.

Version: 1.2

eXtended Transport System Start-Up22

Page 23

Technical description

6.2.2 Use of the basic functions

Interruption-free production flow

From the combination of the basic functions, product flows can be kept constantly in motion with the XTS.

Since the movers in the XTS operate independently of each other, it is possible to stop and process

individual objects without having to interrupt the entire process; viewed from the outside the production flow

is maintained.

Pushing products, adjusting the product gap and product velocity

The movers of the XTS can always run with the flow of product. No return travel or return stroke against the

product flow is required. The transported material can be accumulated and grouped during the movement via

the dynamic buffering.

Clamp and move product

Through the combination of the synchronous movement of a group and the application of a near constant

force, a product can be clamped and moved in a clamped condition. Movement is controlled at all times and

at all places on the transport path.

6.2.3 System length and curve function

Due to the mechatronic concept, XTS combines functions and characteristics that are required for the

dynamic transport of goods of all kinds. Apart from the basic functions of the movers, the complex functions

of the XTS enable the gentle control of an endless product flow.

System length

There are no restrictions on the total length of the path, so that 10 m and much more are technically

possible. The system consists of individual modules, which when combined with one another create both

small, compact solutions and meter-long transport sections. Straight sections are made up of 250 mm

modules, which can be infinitely extended through curved sections. Motor cables must be provided at

maximum intervals of 3 meters. The electrical connection between the modules is automatically made when

assembling. The guide rail system offers individual lengths up to 2.5 m.

Curve function

The entire travel path becomes the utilizable path, since the outward and return path and also the curve

segments are available for the transport and processing of materials. Maximum possible utilization of the

transport movements results in very compact application solutions that enable completely new machine

concepts.

Movers

There are no system limits for the number of movers. The system can therefore be optimized to suit the

respective application. In practice the number is limited only by the available computing power of the PC.

eXtended Transport System Start-Up 23

Version: 1.2

Page 24

Technical description

6.3 Overview

Composition of the starter kit

This section exclusively deals with the XTS components of the starter kit.

Note

Basic components

• Stand and holder for all mechanical parts

• Industrial PC with all necessary interfaces and sufficient system performance

• TwinCAT NC PTP and XTS function package

• 24 V DC and 48 V DC power supply units

• CU2508 Real-time Ethernet port multiplier

XTS starter kit small AT2000-0500, 500 mm, straight length

Pos. Number Product description Item number

1 1 XTS straight module with connecting cable and EtherCAT

interface

2 3 XTS straight module AT2000-0250

3 2 XTS curved module 180° (clothoid) AT2050-0500

4 5 Movers including rollers, magnetic plates and encoder flag AT9011-0050-0550

5 1 Software license TwinCAT TC3 XTS Extension TF5850-0080

6 1 TwinCAT 3 PLC/ NC PTP 10 TC1250-0080

7 1 TwinCAT 3 Scope View Professional* TC1300-0080

8 1 TwinCAT 3 Scope Server* TF3300-0080

9 1 TwinCAT 3 CAM Design Tool* TE1510

10 1 TwinCAT 3 NC Camming* TF5050-0080

11 2 Guide rail, 180° (clothoid) AT9050-0500

12 1 Guide rail straight with lock AT9100-0500

13 1 Guide rail straight without lock AT9000-0500

AT2001-0250

XTS starter kit medium AT2000-1000, 1000 mm, straight length

Pos. Number Product description Item number

1 1 XTS straight module with connecting cable and EtherCAT

interface

2 7 XTS straight module AT2000-0250

3 2 XTS curved module 180° (clothoid) AT2050-0500

4 10 Movers including rollers, magnetic plates and encoder flag AT9011-0050-0550

5 1 Software license TwinCAT TC3 XTS Extension TF5850-0080

6 1 TwinCAT 3 PLC/ NC PTP 10 TC1250-0080

7 1 TwinCAT 3 Scope View Professional* TC1300-0080

8 1 TwinCAT 3 Scope Server* TF3300-0080

9 1 TwinCAT 3 CAM Design Tool* TE1510

10 1 TwinCAT 3 NC Camming* TF5050-0080

11 2 Guide rail, 180° (clothoid) AT9050-0500

12 1 Guide rail straight with lock AT9100-1000

13 1 Guide rail straight without lock AT9000-1000

AT2001-0250

Version: 1.2

eXtended Transport System Start-Up24

Page 25

Technical description

XTS starter kit large AT2000-1500, 1500 mm, straight length

Pos. Number Product description Item number

1 2 XTS straight module with connecting cable and EtherCAT

AT2001-0250

interface

2 10 XTS straight module AT2000-0250

3 2 XTS curved module 180° (clothoid) AT2050-0500

4 10 Movers including rollers, magnetic plates and encoder flag AT9011-0050-0550

5 1 Software license TwinCAT TC3 XTS Extension TF5850-0080

6 1 TwinCAT 3 PLC/ NC PTP 10 TC1250-0080

7 1 TwinCAT 3 Scope View Professional* TC1300-0080

8 1 TwinCAT 3 Scope Server* TF3300-0080

9 1 TwinCAT 3 CAM Design Tool* TE1510

10 1 TwinCAT 3 NC Camming* TF5050-0080

11 2 Guide rail, 180° (clothoid) AT9050-0500

12 1 Guide rail straight with lock AT9100-1500

13 1 Guide rail straight without lock AT9000-1500

*Subject to modification

eXtended Transport System Start-Up 25

Version: 1.2

Page 26

Technical description

6.4 Overview of the components

Mover 6 rollers Straight motor module

Position number Description

1 Mover body

2 Rollers

3 Rubber bumper

4 Magnet plates

5 Encoder flag for position measurement

6 Track mounting surface

7 Encoder flag detection surface

8 Motor coils

9 Dowel pin hole for alignment

10 Module to module connection card. Transmits control power (24 V) DC bus (50 V)

power and EtherCAT between modules.

11 Machine bed mounting surface

Alignment Dowel Pins

Exact locations and dimensions of the dowel pins are given in the 3D drawings (.stp files) of

Note

the motor modules. For further information please contact the Beckhoff applications department.

Version: 1.2

eXtended Transport System Start-Up26

Page 27

Technical description

Curved motor module 180° (clothoid) Guide rails with and without lock cover

Position number Description

12 Slot for Module to Module connection card (10)

13 Motor Coils

14 Slot for Module to Module connection card (10)

15 Track Mounting Surface

16 Encoder Flag detection surface

17 Straight track without gate

18 Gate which can be removed to allow movers to be added/removed from the track.

19 Motor Module mounting surface

eXtended Transport System Start-Up 27

Version: 1.2

Page 28

Installation

7 Installation

7.1 Mechanical installation

Acute risk of injury or death by electric shock!

Before assembly or disassembly of the XTS, make sure all electrical components are in a

DANGER

de-energized idle state! Failure to observe this instruction may result in serious bodily injury

or death!

Danger from magnetic fields!

In particular, the magnetic field poses a danger to:

• Persons with cardiac pacemakers (the magnetic field may cause the pacemaker to

switch to test mode and thus cause a cardiac arrest!)

• Persons with magnetically conductive implants

• Magnetic data storage devices

• Chip cards with magnetic strips, and

• Electronic devices

• Also keep in mind that the magnetic fields can influence implanted defibrillators and

make external defibrillators inoperable.

• Ensure a safety distance of 500 mm to all magnetic parts. Also, make sure that there is

no direct contact with magnetic components near parts that are susceptible to interference.

The national regulations and guidelines applicable in other countries must be followed!

Also note the requirements of BGV B 11 in connection with magnetic fields (BGV B 11

Section 14).

Attention

Danger from magnetic attraction forces!

The Beckhoff XTS is equipped with permanent magnets at the guide rails and movers. During the installation and commissioning of components, magnetic attraction forces may result in bruising or injuries of body parts. Therefore, please observe the following safety information:

• Move the magnetic components together slowly. Never leave magnetic components unsecured next to each other. Wear protective gloves.

• Avoid shocks or jerky contact between magnets. This could lead to splintering and eye

injuries. Wear safety goggles.

• Make sure that your working environment is free from ferrous tools or materials. These

could be attracted by the magnetic field and cause injuries to body parts. Do not wear

magnetisable objects such as watches, necklaces, earrings, etc.

• Always work in pairs

• Always wear personal protective equipment (PPE)!

Changes to system components

Machining (milling, drilling, etc.) of individual components of the XTS and associated modification of the overall configuration can lead to deformation of system components.

Please note: Any unauthorized modifications of the XTS would void any warranty claims

against Beckhoff Automation GmbH & Co. KG.

Version: 1.2

eXtended Transport System Start-Up28

Page 29

7.2 Overview of the tightening torques

Screw sizes and tightening torques

Motor modules

Straight motor module Curve motor module 180° (Clothoide)

Installation

Position number Description

1 Screw: M5 x 20 DIN EN ISO 4762-A2 tightening torque 6Nm

2 Screw: M6 x 12 ISO 7380-A2 Tightening Torque 8Nm

3 Screw: M5x30 DIN EN ISO 4762-A2 Tightening Torque 6Nm

Screw Tightening Torque

Please note the tightening torque values given are those recommended by Beckhoff Auto-

Note

mation GmbH & Co. KG. Use of other tightening torques can result in damage to the components.

eXtended Transport System Start-Up 29

Version: 1.2

Page 30

Installation

Guide rail with mover 6 rollers

Guide rail with lock Mover 6 rollers

Position number Description

4 Screw: M4 x 10 DIN EN ISO 4762-A2 Tightening Torque 3Nm

5 Screw: M3 x 30 DIN EN ISO 4762-A2 Nut: M3 DIN 985 Tightening Torque 2Nm

6 Screw M4 x 40 DIN EN ISO 4762-A2 Tightening Torque 4Nm.

7 Screw: M3 x 6 DIN EN ISO 4026 Tightening Torque 0.5Nm

8 M6 (see full description below)

9 Screw: M3 x 12 DIN EN ISO 4762-A2 , Nut: M3 Tightening Torque 1.5Nm

10 Screw: M3 x 6 DIN EN ISO 4762-A2 Tightening Torque 1.5Nm

11 Screw M3 x 4 ISO 7380-A2 Tightening Torque 0.8Nm

Maximum Screw Depth for the threaded through hole

The M6 threaded through holes (Pos 8) are located directly behind the upper rollers of the

Note

mover. When mounting equipment using these M6 threaded holes a screw depth of 6.5mm

must not be exceeded. Exceeding this depth will drive the screw into the roller damaging it.

Version: 1.2

eXtended Transport System Start-Up30

Page 31

7.3 Mounting the movers on the guide rail

Installation instructions

1.) First release both socket head screws at the motor module

lock with an Allen key (size 3) by turning them clockwise.

2.) Remove the lock cover by lifting it. Avoid contaminating or

damaging the released screws or the lock cover. Work in a

clean and largely dust-free environment.

Attention: Please note that the edges that are now

accessible are very sharp and not chamfered. Risk of cuts!

Installation

3.) The three alignment pins on the lock module can be

removed and put to one side if necessary. Next, place the red

feed aid on the guide rail. Fasten it with the two socket head

screws (size 3) and an Allen key.

4.) Now place the mover on the guide rail. Hold the mover

straight over the motor module and insert it slowly onto the

guide rail, without forcing it. If the permanent magnets of the

movers and the motor modules have a magnetic field, both

components will automatically attract each other.

Attention: Risk of injury by crushing

eXtended Transport System Start-Up 31

Version: 1.2

Page 32

Installation

5.) The mover is now mounted on the guide rail. Slowly push

the mover out of the work area by hand.

Attention: Please take care when rerailing the mover to

avoid damaging the plastic rollers on the sharp edges.

6.) Remove the red feed aid, once all movers were replaced

or rerailed. To this end release the two socket head screws

(size 3) with an Allen key and lift off the feed aid.

7.) Now place the lock cover onto the alignment pins from

above. Check the exact position and ensure that the lock

cover sits tightly on the alignment pins.

Attention: If the lock cover does not sit properly on the

alignment pins, the guide rails and movers may become

damaged!

8.) Finally, fasten the lock cover with the two socket head

screws and an Allen key (size 3). The screw-in direction is

anti-clockwise.

Version: 1.2

eXtended Transport System Start-Up32

Page 33

Installation

7.4 The positioning system

Before the movers are set in motion at the new XTS, the offset levels of the encoder sensors have to be

calibrated. In ready-made starter kits the system sensors are already calibrated, and the sensor values are

stored in a file. New systems or systems, in which motor modules were replaced or regrouped, have to be

recalibrated. The calibration is straightforward and can be performed without damage to the system.

7.4.1 Zero point of the encoder system

The zero point of the encoder system is at the

module edge (at the side of the cable joint) of the first

feed module.

The arrow in the image (item 1) figure shows the

positive count direction of the system.

eXtended Transport System Start-Up 33

Version: 1.2

Page 34

Installation

7.4.2 Teaching the encoder system

Before January 2014 it was still necessary to carry out a measurement at standstill (to determine the zero

offset) and a measurement in operation (to determine peak values). With the new CTcolXstDrv, only still the

measurement at standstill is required. Measurements should generally be carried out when the motor

modules are assembled. XTS starter kits come with a ready-made calibration file, which can be found under

\TwinCAT3.1\Boot folder.

1.

Once the configuration and the TwinCAT system have been activated, the Run mode can be started.

The TwinCAT toolbar should now be green. The standstill measurement can now commence. The

parameters to be adjusted as part of the calibration can be found in the CTcloXTSDriver under

TcCom Objects.

2.

The idea behind the standstill measurement is to capture all values without interference. To this end,

in a first step all movers are moved to motor modules 1, 2 and 3, in order to exclude them from the

teaching process. Only the remaining motor modules are set to zero in this step.

Version: 1.2

eXtended Transport System Start-Up34

Page 35

3.

Installation

In this example image, up to 10 motor modules can be selected. Modules 1, 2 and 3 are not part of the

teaching procedure, since there are still movers on these motor modules. The other motor modules

are part of the teaching process. The zero point is now set for the motor modules.

4.

Use the command “Online Write” to start the teaching process. The lower output window with the

setting TwinCAT opens and displays the teaching history.

5.

This window shows that the motor modules 1, 2 and 3 were excluded from the teaching, and that the

process was started.

eXtended Transport System Start-Up 35

Version: 1.2

Page 36

Installation

6.

The teaching process can now be stopped by repeating the command “Online Write”.

7.

The process is now stopped. This display window also shows that the technical data of modules 1, 2

and 3 are invalid, because they were excluded from the teaching process.

8.

Now, all movers are manually pushed to motor modules 7, 8 and 9. The previously excluded motor

modules 1, 2 and 3 can now take part in the teaching process. Since the movers are now on modules

7, 8 and 9, these modules are now also excluded from teaching.

Version: 1.2

eXtended Transport System Start-Up36

Page 37

9.

Installation

The teaching process is identical to the already completed process for motor modules 1, 2 and 3. The

modules that are blocked/excluded from the teaching process are 7, 8 and 9.

10.

Repeat the command “Online Write” to start a new teaching process.

11.

The output window with the setting TwinCAT now shows the values again, which were set in the

previous steps. 7, 8 and 9 are now excluded from the teaching process.

eXtended Transport System Start-Up 37

Version: 1.2

Page 38

Installation

12.

Repeat the command “Online Write” to end the teaching process.

13.

The final output window with the setting TwinCAT now indicates that the teaching process was

stopped and that all movers were found and can be started.

14. When the XTS is started for the first time, the system returns the error “Initial Axis Fault”. This is a step

error, which occurs only once. Restart the system to rectify the error. No further errors should occur.

Version: 1.2

eXtended Transport System Start-Up38

Page 39

15.

Installation

Now that all motor modules have completed the teaching process, you can use this operation screen

to move the movers on the XTS. Please note that all three fields should be ticked under “Enabling”.

The value in the field “Override” should be set to a value greater than zero. You can now use the

function keys F1 – F9 to move the movers on the system.

Important: Collision avoidance has not yet been set. Collisions between movers can therefore

not be ruled out! Activate collision avoidance before commissioning and moving the movers.

This is described in the next section.

Risk of injury from moving movers!

When the XTS is started up, the movers start moving on the guide rails. There is a risk of

WARNING

injury to body parts. Keep an appropriate safety distance, and stay clear of the operating

space.

eXtended Transport System Start-Up 39

Version: 1.2

Page 40

Installation

7.4.3 Application simulation

1.

The XTS system also enables simulation of the mover movements. It is therefore not imperative to

involve real movers on the XTS system. The simulation process is started in the Solution Explorer via

SoftDriveEncoder_Obj2. The tab is called Parameter (Init), where the PositionsFeedbackMode can

be set to simulation.

2.

Once this is done, all the movers have to be declared with a starting position for the simulation. To

simulate a precise practical application, we recommend setting the distance between movers to 100

mm. This parameter must be set for each simulated mover. The value for the starting position

indicates at which position the movers start in the simulation.

3.

To ensure the simulation runs smoothly, the trees Device 1 (EtherCAT) and Object1 (CTcIoXtsDrv)

should be expanded in the Solution Explorer.

4. Restart the system, once all parameters have been set. The simulation can then be started.

Version: 1.2

eXtended Transport System Start-Up40

Page 41

Installation

7.5 Collision avoidance

7.5.1 Operating principle of collision avoidance

In collision avoidance mode, the parameters “InTarget”, “InPosition” and “HasJob” are disabled, even if they

were configured. Collision avoidance is intended to assign all movers concrete travel paths, velocities and

gaps. These settings prevent collisions of the movers during motion.

1a.

1b.

All movers are positioned at the zero point (feed-in motor module). Various settings are now

implemented via the PLC blocks of the movers, which prevent collisions between the movers.

This window shows the PLC block for mover no. 9. We now instruct this mover to move to position

2000 with a velocity of 1000. The gap of mover in traversing direction is set to 100.

eXtended Transport System Start-Up 41

Version: 1.2

Page 42

Installation

1c.

The diagram now indicates that the mover is active and has assumed the specified velocity over the

travel path. At target position (2000) the velocity has reduced, and the activity of the mover has

ceased.

1d.

2a.

The mover no. 9 has now arrived at the previously set position.

A further mover is now parameterized. Mover 8 is also instructed to move to position 2000, with a

velocity of 1000. The distance of 100 remains the same. Since mover 9 is already at this position, a

typical collision scenario would arise. However, both movers are declared with a gap of 100. This

means that mover 8 moves to position 1800 and keeps a distance of 100 to mover 9.

Version: 1.2

eXtended Transport System Start-Up42

Page 43

2b.

2c.

Installation

Since mover 8 has not yet reached its final position 2000, but remains at 1800, the mover remains

active. The diagram shows that the busy and active straight section remains active when the

position 1800 is reached.

3a.

The diagram also illustrates the positioning of the two movers on the XTS system. Mover 8 stops

behind mover 9.

We now instruct mover 9 to move to position 2500. The velocity and the gap remain the same.

eXtended Transport System Start-Up 43

Version: 1.2

Page 44

Installation

3b.

Changing the commands for mover 9 also changes the diagram. It shows that mover 9 is again

active and has assumed a velocity, which decreases to zero at position 2500. Mover 8 has also

assumed a velocity, which falls to zero at position 2000. The active and busy straight sections also

finish at this position.

4.

Mover 9 has now moved to position 2500 and mover 8 to position 2000 without colliding. Once the

positions have been reached, the activity of the movers is completed until new values or cycles are

entered.

Version: 1.2

eXtended Transport System Start-Up44

Page 45

8 Technical data

8.1 AT9011-0050-0550

Technical data Symbol [Unit] AT9011-0050-0550

Length mm 50.00

Width mm 62.00

Height mm 78.50

Weight g 410.00

Center of gravity mm from above appr. 42.5

Roll 6 x D19 cylindrical

8.2 Technical drawing AT9011-0050-0550

Technical data

eXtended Transport System Start-Up 45Version: 1.2

Page 46

Support and Service

9 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

on Beckhoff

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

Version: 1.2

eXtended Transport System Start-Up46

Loading...

Loading...