Page 1

Documentation | EN

TwinSAFE Loader

Tool to load and adapt a TwinSAFE project

2020-08-10 | Version: 2.4.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.2.1 Delivery state ..................................................................................................................... 6

1.2.2 Operator's obligation to exercise diligence ........................................................................ 6

1.2.3 Description of instructions.................................................................................................. 7

1.3 Documentation issue status ..............................................................................................................8

2 System description ...................................................................................................................................9

2.1 General..............................................................................................................................................9

2.2 System limits......................................................................................................................................9

3 Product description.................................................................................................................................10

3.1 System requirements.......................................................................................................................10

3.1.1 Operating System ............................................................................................................ 10

3.1.2 Target system .................................................................................................................. 11

3.1.3 Communication with the TwinSAFE logic component ..................................................... 12

3.2 Intended use....................................................................................................................................13

3.3 Functioning ......................................................................................................................................13

3.3.1 Communication................................................................................................................ 13

3.3.2 Authentication .................................................................................................................. 13

3.3.3 Loading a safety project................................................................................................... 14

3.3.4 Activation of a safety project............................................................................................ 14

3.3.5 Deleting a safety project .................................................................................................. 15

3.3.6 Customizing a safety project............................................................................................ 15

3.3.7 List of the current group configuration ............................................................................. 17

3.3.8 Additional functions.......................................................................................................... 17

3.4 List of all available parameters ........................................................................................................18

3.5 Safety parameters ...........................................................................................................................19

3.6 Error codes ......................................................................................................................................20

3.7 FMEDA ............................................................................................................................................20

4 EtherCAT Mailbox Gateway....................................................................................................................23

4.1 Settings EtherCAT Mailbox Gateway ..............................................................................................23

4.2 Beckhoff Virtual Ethernet Adapter ...................................................................................................24

4.3 Adding a route .................................................................................................................................26

5 Appendix ..................................................................................................................................................28

5.1 Support and Service ........................................................................................................................28

5.2 Certificates.......................................................................................................................................29

5.2.1 Letter of Confirmation ...................................................................................................... 29

TwinSAFE Loader 3Version: 2.4.0

Page 4

Table of contents

TwinSAFE Loader4 Version: 2.4.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Origin of the document

This original documentation is written in German. All other languages are derived from the German original.

Currentness

Please check whether you are using the current and valid version of this document. The current version can

be downloaded from the Beckhoff homepage at http://www.beckhoff.com/english/download/twinsafe.htm.

In case of doubt, please contact Technical Support [}28].

Product features

Only the product features specified in the current user documentation are valid. Further information given on

the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative.

Disclaimer

The documentation has been prepared with care. The products described are subject to cyclical revision. For

that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. We reserve the right to revise and change the documentation at any time

and without prior announcement. No claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

TwinSAFE Loader 5Version: 2.4.0

Page 6

Foreword

EtherCAT® and Safety over EtherCAT® are registered trademarks and patented technologies, licensed by

Beckhoff Automation GmbH, Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see chapter Product description);

• the TwinSAFE products are only operated in sound condition and in working order.

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental protection

aspects, and is familiar with the operating instructions and in particular the safety instructions contained

herein.

• the operating instructions are in good condition and complete, and always available for reference at the

location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all notes

remain legible.

TwinSAFE Loader6 Version: 2.4.0

Page 7

1.2.3 Description of instructions

In these operating instructions the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to the environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Foreword

Tip or pointer

This symbol indicates information that contributes to better understanding.

TwinSAFE Loader 7Version: 2.4.0

Page 8

Foreword

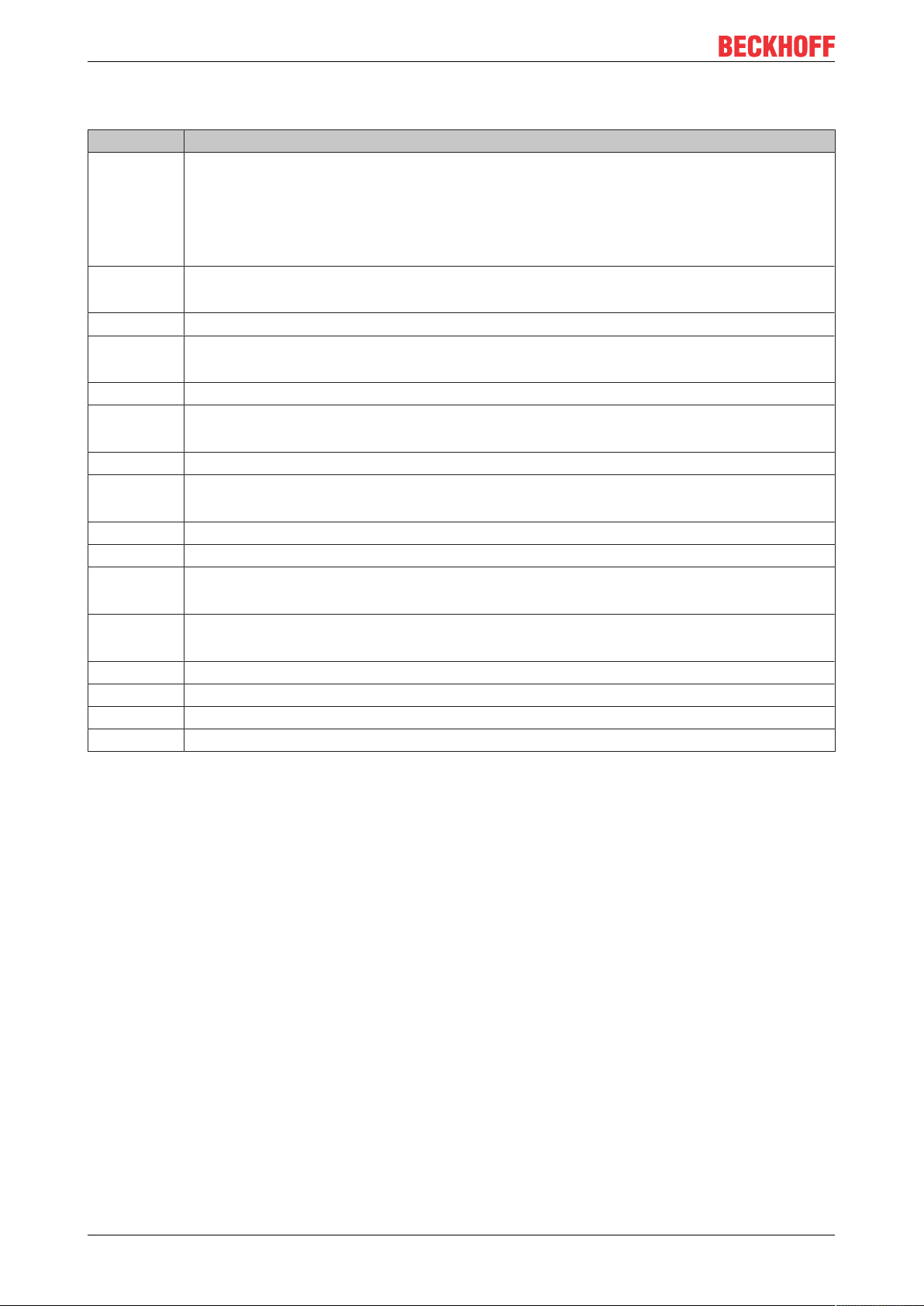

1.3 Documentation issue status

Version Comment

2.4.0 • Semicolons removed from the csv tables

• Note on the different indexing in the Loader compared to the Safety Editor with regards to

the groups

• Added another example for the customizing

• Description of operating system extended

2.3.0 • Description of target system extended

• Added TwinSAFE Loader Version v7

2.2.0 • Added TwinSAFE Loader Version v6

2.1.1 • Note to Virtual Ethernet Adpater added

• Parameter --localams added

2.1.0 • Added extensions for TwinSAFE Loader, version v5

2.0.0 • Migration

• List of supported hardware updated

1.2.0 • Setting up EtherCAT Mailbox Gateway added

1.1.0 • Expanding system requirements

• Foreword updated

1.0.0 • First released version

0.0.7 • Functions Delete and Customize added

0.0.6 • Note added to FMEDA chapter

• Graphic added to Chapter 2.1

0.0.5 • Addition of the FMEDA

• Exchange of Chapters 3.2 and 3.3

0.0.4 • Resorting of chapters

0.0.3 • Chapter 3.7, CSV format added

0.0.2 • Revision of call parameters

0.0.1 • First draft

TwinSAFE Loader8 Version: 2.4.0

Page 9

System description

2 System description

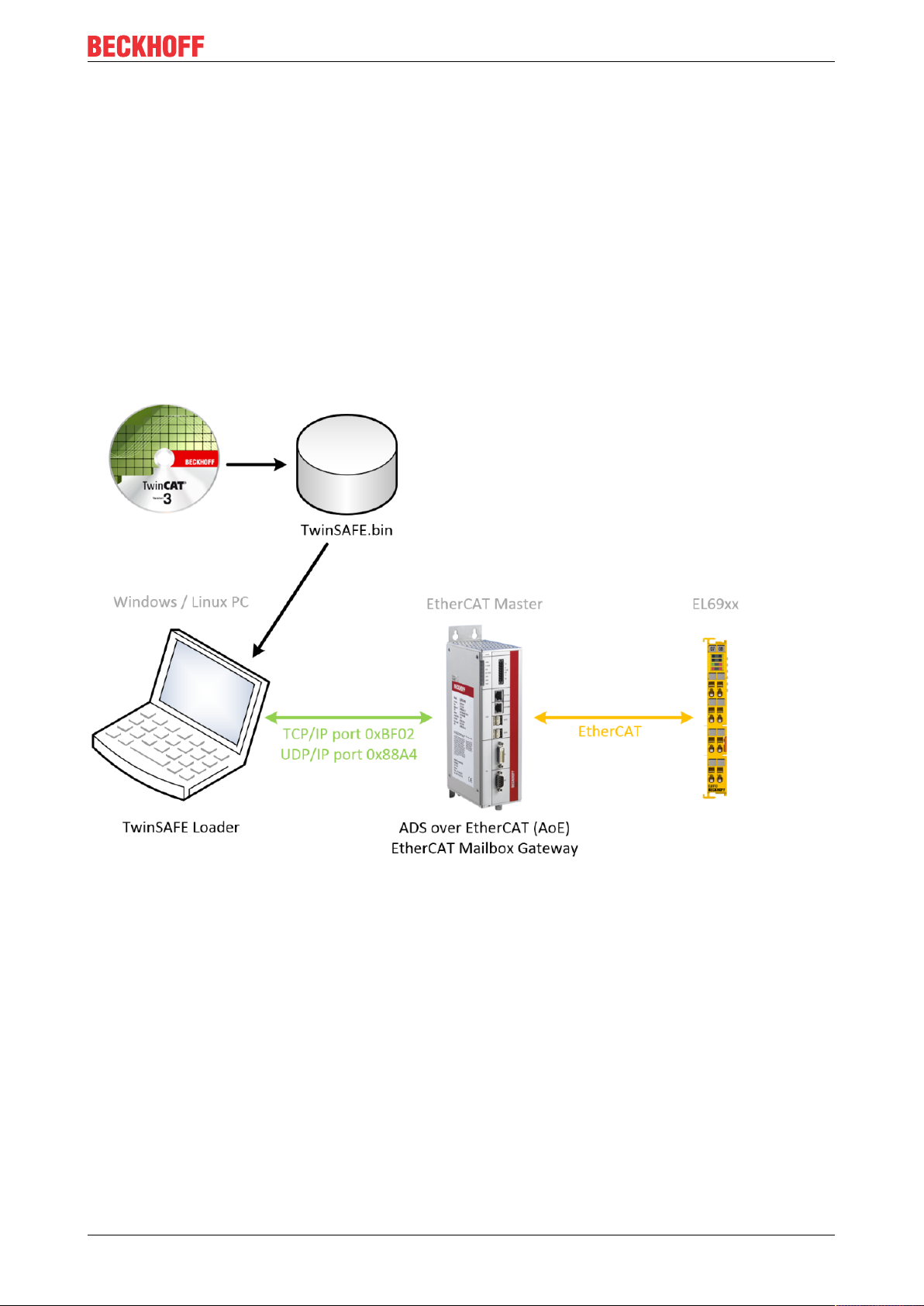

2.1 General

The TwinSAFE Loader is a software for loading a safety project to an EL69xx or EK19x0 safety controller

independently of the TwinCAT development environment. The starting point of a loading procedure is a

binary file that is exported in advance from the TwinCAT development environment.

Following the actual loading procedure, it is possible to adapt the safety project. To perform an adaptation,

the safety project must be configured accordingly in the TwinCAT development environment. The TwinSAFE

groups that are to be activated, deactivated or be passivated must be parametrized accordingly and the safe

substitute values for the outputs of the groups must be defined during the development by the programmer.

These substitute values are also part of the binary file that the programmer created after completion of the

safety program.

Fig.1: TwinSAFE Loader - Overview

2.2 System limits

The TwinSAFE Loader software is delivered as an executable program library and is available for the

Windows and Linux operating systems. This library can be integrated into applications. The various functions

of the program library are controlled by corresponding command line parameters.

The safety project can only be loaded for the EL6900 TwinSAFE logic terminal. It is not possible to adapt the

safety project here.

The safety project can be loaded and adapted for the EL6910 TwinSAFE logic terminal, the EK1960

TwinSAFE controller and any future TwinSAFE products.

A TwinCAT version 3.1 or higher is required to create a corresponding safety project.

TwinSAFE Loader 9Version: 2.4.0

Page 10

Product description

3 Product description

The TwinSAFE Loader is a program library for the loading and adaptation of a safety project for TwinSAFE

logic components. Before describing the functional mode of the product in detail, the system requirements

for the successful use of the TwinSAFE Loader are dealt with in the following section.

3.1 System requirements

3.1.1 Operating System

To run the TwinSAFE Loader, the following system requirements must be met depending on the operating

system.

3.1.1.1 Windows

No additional components are required for the operating systems Windows7 (32/64bit) and Windows 10

(32/64 bit).

The following table lists the different versions of the TwinSAFE Loader and the associated SHA checksums.

File name Operating system Version SHA Checksum

TwinSAFE_Loader.exe Win32 v1 SHA1:

3dfc76aca223f04a0e91677f2c6452df8a39a8f9

v5 SHA256:

970a4ee096e181d20cea42d700c6ded1253a61a

34c9ea00a5db6cc9ee99693f6

v6 SHA256:

177f74ae6ce036ecc0f747f1f1324cfd890c627be9

1c111429a4bf124a3a1a1d

v7 SHA256:

e8287a0c23229cedb821e3a5b56459101ca45aa

badaa185e4313bd7ad3a92d47

TwinSAFE Loader10 Version: 2.4.0

Page 11

Product description

3.1.1.2 Linux

No additional components are required for the operating system Ubuntu16.04.

The following table lists the different versions of the TwinSAFE Loader and the associated SHA checksums.

Filename Operating system Version SHA Checksum

TwinSAFE_Loader.bin Linux x86 64-Bit v1 SHA1:

c37f52a2fb8e3609346671feb2f60c9cba2bd2f9

v5 SHA256:

462a9f652eab4ad43fb0dbf487bb3db9fa71a596c

e339fb9fd5990f544d0a808

v6 SHA256:

972391f4aa88322dc8ffad415919ae814095ab73

49f059ffcb03e8a8c5d0f8a5

v7 SHA256:

b184816a9a17caeb1d7baca2395d30207cac463

b63638930de0dc4f20539bedf

TwinSAFE_Loader-i386.bin Linux x86 32-Bit v5 SHA256:

4b25dbd486cd56a3da411e7b1643be6834b7db5

1c3cb58bfb9caecdd36bdc9e1

v6 SHA256:

11ed882fd06dd28f19ec3a7c458fdebf87b8fdd26

9bec930a145056ece4dc835

v7 SHA256:

3af9a3a22fffa7a399c9aa5c1763ba588bc2680be

b8d3cadfd165739f4dca099

3.1.2 Target system

The supported TwinSAFE logic components can be taken from the following list:

Product name SW version

EL6900 05 or newer (Production from week 02/2014)

EL6910 01 or newer

EK1960 01 or newer

EL1918 01 or newer

EL2911 01 or newer

EP1957-0022 01 or newer

EJ6910 01 or newer

EJ1914 01 or newer

EJ1918 01 or newer

EJ2914 01 or newer

EJ2918 01 or newer

EJ1957 01 or newer

The components listed in the table above are directly supported in the current version of the TwinSAFE

loader.

NOTE

Integration of new TwinSAFE logic components

If a new TwinSAFE logic component is available which is not directly supported in the current version of the

TwinSAFE loader, it can be included by an additional configuration file.

TwinSAFE Loader 11Version: 2.4.0

Page 12

Product description

To integrate a new TwinSAFE logic component, an additional file "custom_terminals.csv" must be created in

the directory of the TwinSAFE Loader execution file. This file can then be filled in the following syntax so that

new components can be supported (lines 1 and 2 are fixed). Using the example of a new logic component

ELxxxx, which is based on the TwinSAFE Logic EL6910, the file would have to be extended as shown in line

5.

File: custom_terminals.csv

1

class;type

EL6910;EL6910

EL6910;EP1957-0022

EL6910;ELxxxx

Furthermore, an updated version of this configuration file can always be found on the Beckhoff website when

new components are introduced without direct support from the TwinSAFE Loader.

3.1.3 Communication with the TwinSAFE logic component

The TwinSAFE Loader supports the following protocols for the loading or adaptation of a safety project to a

TwinSAFE logic component.

ADS over EtherCAT (AoE)

EtherCAT Mailbox Gateway

For successful communication with the TwinSAFE logic component, the TwinSAFE Loader must be able to

establish a connection with the EtherCAT master existing in the system. The following system requirements

must be fulfilled for this:

3.1.3.1 ADS over EtherCAT (AoE)

The EtherCAT master must be configured so that it accepts AoE connections (according to ETG.1020) on

port 0xBF02 (TCP/IP).

3.1.3.2 EtherCAT Mailbox Gateway

The EtherCAT master must be configured so that it accepts packets of the EtherCAT mailbox gateway

(according to ETG.8200) on port 0x88A4 (UDP/IP).

TwinSAFE Loader12 Version: 2.4.0

Page 13

Product description

3.2 Intended use

WARNING

Risk of injury!

TwinSAFE terminals may only be used for the purposes described below!

CAUTION

Follow the machinery directive!

The TwinSAFE terminals may only be used in machines according to the machinery directive.

WARNING

Loading and adapting the project - workflow!

For loading and adapting a safety project, the user must specify a workflow in order to ensure that the correct safety project for the application is activated on the TwinSAFE logic component.

WARNING

Loading and adapting the project - authentication!

The user must ensure that only authorized persons are able to load or adapt the safety project.

3.3 Functioning

The task of the TwinSAFE Loader is to load a safety project to a TwinSAFE logic component independently

of the TwinCAT development environment or to adapt a safety project already existing on a TwinSAFE logic

component.

The data packets necessary for this are transmitted via the EtherCAT master existing in the system to the

corresponding component. The functions of the TwinSAFE Loader are controlled by command line

parameters.

3.3.1 Communication

The following parameters must be used to control communication.

Command line parameters Description

--gw <IPv4 address> Specification of the IPv4 address of the EtherCAT

mailbox gateway or, in AoE mode, the IPv4 address

of the EtherCAT master. As of version v5, the

EtherCAT master can also be addressed via the host

name in AoE mode.

--ams <NetId> Specification of the AmsNetID, if ADS over EtherCAT

(AoE) is to be used.

--localams <NetId> if --ams is used the local AMSNetID can be specified.

If the parameter is not used, the AmsNetID is formed

from its own IP address + ".1.1".

3.3.2 Authentication

The following parameters must be used to authenticate a user on the TwinSAFE logic.

Command line parameters Description

--user <user name> Name of the user with the appropriate rights to

perform the desired function.

--pass <password> Password of the user.

TwinSAFE Loader 13Version: 2.4.0

Page 14

Product description

User management

Each TwinSAFE logic component has its own user administration. Only users registered in the

TwinSAFE logic component can perform certain functions.

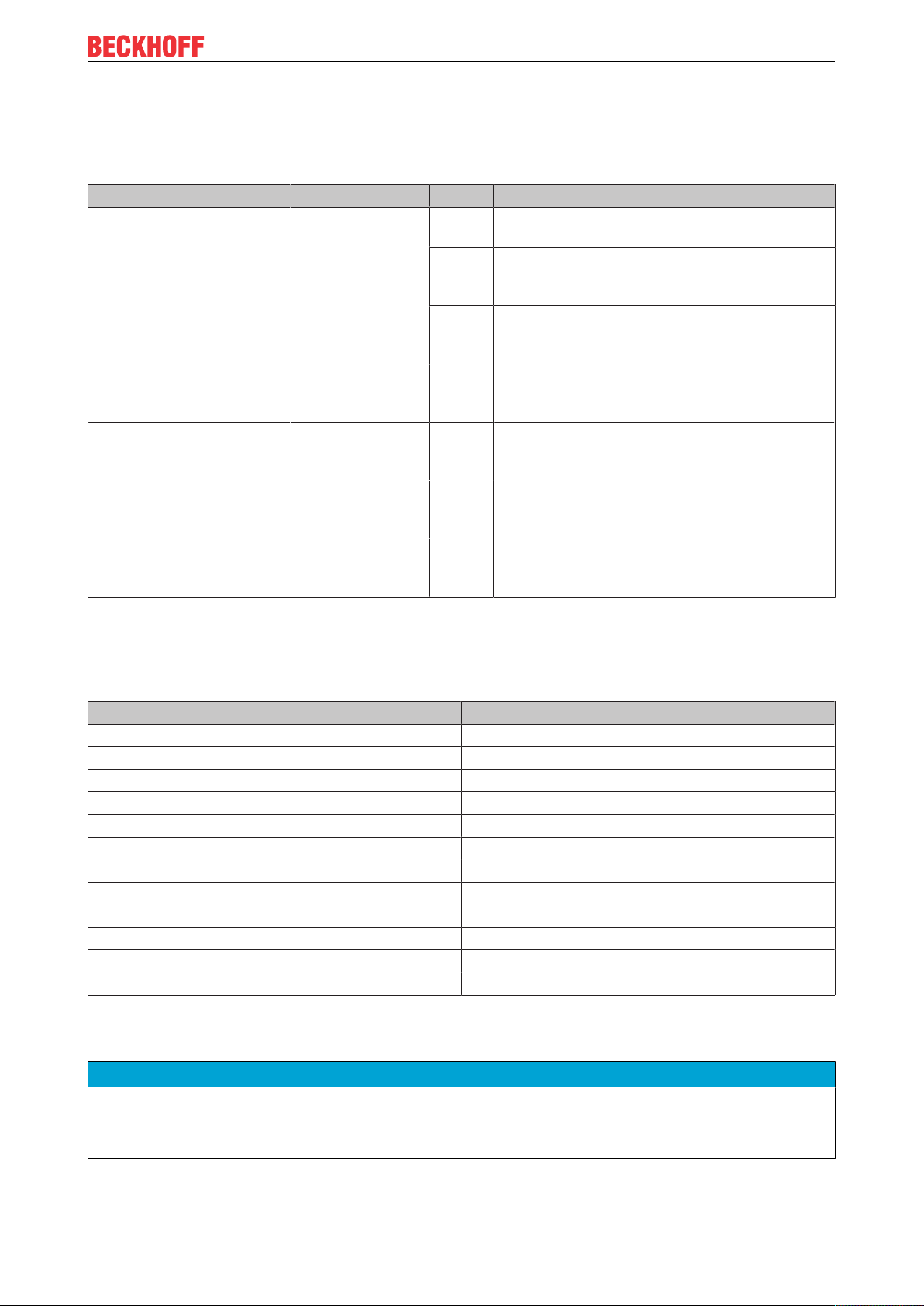

3.3.3 Loading a safety project

The following parameters must be used to load a safety project.

Command line parameters Description

--slave <EtherCat address of the EtherCAT

slave>

--proj <path to the binary file> Specification of the path to the binary file of the safety

Loading a safety project

The loading of a safety project typically consists of a two-step process. The safety project must be activated

after loading it to the TwinSAFE logic component.

This division of the process enables measures to be taken to ensure that the correct safety project for the

respective application on the TwinSAFE logic component is switched to active. The user must define these

measures. The user shall bear full responsibility to provide proof for the accuracy and efficacy of these

measures. See also Chapter FMEDA [}20].

In the TwinCAT development environment, for example, the checksum of the transferred safety project is

checked and a repeat login carried out before the safety project is really enabled (see chapter Intended use

[}13]).

Specification of the EtherCAT slave address of the

TwinSAFE logic component.

project.

WARNING

The loading of a safety project takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.254 --user Administrator --pass TwinSAFE --slave 1007 --proj ./

example.bin

Fig.2: Call to load a safety project

3.3.4 Activation of a safety project

The following parameters must be used to activate a safety project.

Command line parameters Description

--slave <EtherCat address of the EtherCAT slave> Specification of the EtherCAT slave address of the

TwinSAFE logic component.

--proj <path to the binary file> Specification of the path to the binary file of the safety

project.

--crc <project CRC of the safety project to be

activated>

The activation of a safety project takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.117 --ams 192.168.1.117.2.1 --user Administrator --pass TwinSAFE -slave 1007 --proj ./example.bin --crc 0x4273

Specification of the project CRC of the safety project

to be activated.

TwinSAFE Loader14 Version: 2.4.0

Page 15

Product description

Fig.3: Call to activate a safety project

3.3.5 Deleting a safety project

The following parameters must be used to delete a safety project.

Command line parameters Description

--slave <EtherCat address of the EtherCAT slave> Specification of the EtherCAT slave address of the

TwinSAFE logic component.

--delete Command to delete the project

The deletion of a safety project takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.254 --user Administrator --pass TwinSAFE --slave 1007 --delete

Fig.4: Call to delete a safety project

3.3.6 Customizing a safety project

The following parameters must be used to customize a safety project.

Command line parameters Description

--slave <EtherCat address of the EtherCAT slave> Specification of the EtherCAT slave address of the

TwinSAFE logic component.

--customize <path to csv file> Specification of the path to the csv file for the group

configuration

The customizing of a safety project takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.254 --user Administrator --pass TwinSAFE --slave 1007 --customize ./

groupconfig.csv

Fig.5: Call to customize a safety project

Using the function block NT_StartProcess from the library Tc2_Utilities, customizing can also be started via

the PLC, for example:

NT_StartProcess_Customizing:NT_StartProcess;

NT_StartProcess_NetId:T_AmsNetID:='';

NT_StartProcess_Err:BOOL;

NT_StartProcess_ErrId:UDINT;

NT_StartProcess_Start:BOOL;

NT_StartProcess_Tmout:TIME;

NT_StartProcess_Busy:BOOL;

TwinSAFE Loader 15Version: 2.4.0

Page 16

Product description

Fig.6: Call of the function block NT_StartProcess for customizing

3.3.6.1 CSV format of the group configuration

The CSV file for the customization consists of several lines of ASCII text, whose columns are separated by

semicolons. The column order is fixed and includes the following information:

1st column: ID of the TwinSAFE group

(Please note that the index starts with 1, whereas the execution order of the groups in the TwinSAFE Editor

is zero-based)

2nd column: Indicates whether the group should be activated

3rd column: Indicates whether the group can and should be passivated

4th column: Indicates whether the group can and should be temporarily deactivated

5th column: Indicates whether the group can and should be permanently deactivated

The first line contains an unsigned integer, which is interpreted as the version number of the csv format:

"1"

The second line contains the header:

"id;activate;passivate;temporarily;permanent"

The (2+n)th line contains the configuration of the nth TwinSAFE group in the format:

<id>;[AE];[ADE]; [ADE]; [ADE]

A: Active

D: cannot be activated

E: can be activated, but is currently inactive

Example Logic Terminal Listing (Tabular form)

1

id activate passivate temporarily permanent

1 E E E A

2 E A D D

Example of TwinSAFE group configuration (plain text)

1

id;activate;passivate;temporarily;permanent

1;E;E;E;A

2;E;A;D;D

This is a version-1 csv format.

The file contains a configuration for a TwinSAFE project with 2 groups:

1. The first group can be activated, passivated, temporarily deactivated and permanently deactivated. Its

current state is permanently deactivated.

2. The second group can only be activated or passivated. Its current state is passivated.

TwinSAFE Loader16 Version: 2.4.0

Page 17

Product description

3.3.7 List of the current group configuration

The following parameters must be used to list the groups of a safety project.

Command line parameters Description

--slave <EtherCat address of the EtherCAT slave> Specification of the EtherCAT slave address of the

TwinSAFE logic component.

--list <file name> Saves the list of the group configuration as a CSV list

in the specified file.

The listing of the groups of a safety project takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.254 --user Administrator --pass TwinSAFE --slave 1007 --list ./

groupconfig.csv

Fig.7: Call to list the groups of a safety project

3.3.7.1 CSV format of the group configuration

The csv format corresponds to the csv format from chapter 3.3.6.1 [}16].

3.3.8 Additional functions

The following additional functions can be used via parameters.

Command line parameters Description

--list <file name> Saves the list of all available slaves as a CSV list in

the specified file.

The listing of the available slaves takes place, for example, as shown in the following call:

TwinSAFE_Loader --gw 192.168.1.254 --list ./safetyterminals.csv

3.3.8.1 CSV format of the list of all available slaves

The CSV file listing the compatible EtherCAT slaves consists of several lines of ASCII text, whose columns

are separated by semicolons. The column order is fixed and includes the following information

1st column: EtherCat address of the slave

2nd column: FsoE address of the slave

3rd column: Terminal type of the slave

4th column: Project CRC of the project currently active on the slave

5th column: Name of the EtherCAT slave in TwinCAT

The first line contains the header:

"EtherCAT address; "FSoE address; type; project crc; name"

The (1+n)th row contains the configuration of the nth EtherCAT slave in the format:

TwinSAFE Loader 17Version: 2.4.0

Page 18

Product description

<EtherCAT address>;<FSoE address>;<Type>;<Project CRC>;<Name>

Sample Logic Terminal Listing (Tabular form)

EtherCAT address FSoE address type project crc name;

1001 1 EL6900 0x0 Term 2 (EL6900)

1003 3 EL6910 0x0 Term 4 (EL6910)

1004 50 EL6930 0x4539 Term 5 (EL6930)

Sample Logic Terminal Listing (Clear text)

EtherCAT address;FSoE address;type;project crc;name

1001;1;EL6900;0x0;Term 2 (EL6900)

1003;3;EL6910;0x0;Term 4 (EL6910)

1004;50;EL6930;0x4539;Term 5 (EL6930)

The file contains a listing of three logic terminals

1. The first logic terminal is accessible via the EtherCAT address "1001", it has the FSoE address "1", it

is of the type "EL6900", no project is currently active on it ("0x0") and it is called "Term 2 (EL6900)"

2. The second logic terminal is accessible via the EtherCAT address "1003", it has the FSoE address "3",

it is of the type "EL6910", no project is currently active on it ("0x0") and it is called "Term 4 (EL6910)"

3. The third logic terminal is accessible via the EtherCAT address "1004", it has the FSoE address "50",

it is of the type "EL6930", the project with the CRC "0x4539" is currently active on it and it is called

"Term 5 (EL6930)"

3.4 List of all available parameters

Command line parameters Description

--gw <IPv4 address> Specification of the IPv4 address of the EtherCAT

mailbox gateway or, in AoE mode, the IPv4 address

of the EtherCAT master.

--ams <NetId> Specification of the AmsNetID, if ADS over EtherCAT

(AoE) is to be used.

--localams <local AMSNetID> if --ams is used the local AMSNetID can be specified.

If the parameter is not used, the AmsNetID is formed

from its own IP address + ".1.1".

--user <user name> Name of the user with the appropriate rights to

perform the desired function.

--pass <password> Password of the user.

--slave <EtherCat address of the EtherCAT slave> Specification of the EtherCAT slave address of the

TwinSAFE logic component.

--proj <path to the binary file> Specification of the path to the binary file of the safety

project.

--crc <project CRC of the safety project to be

activated>

--list <file name> Together with the command parameter --gw:

--list <file name> Together with the command parameters --gw and --

--customize <path to csv file> Specification of the path to the csv file for the group

--delete Command to delete the project

Specification of the project CRC of the safety project

to be activated.

Saves the list of all available slaves as a CSV list in

the specified file.

slave:

saves the list of the group configuration as a CSV list

in the specified file.

configuration

TwinSAFE Loader18 Version: 2.4.0

Page 19

3.5 Safety parameters

The product is classified in accordance with IEC 61508:2010 as a T2 tool.

Product description

TwinSAFE Loader 19Version: 2.4.0

Page 20

Product description

3.6 Error codes

The product has the following error codes.

Error code Meaning Possible cause

0x0000 No error Action successfully carried out

0x0001 Invalid parameter Command-line parameter was incorrect

0x0002 File does not exist or is corrupted Project file is corrupted or the specified path is invalid

0x0003 Login failed The specified user name or password is invalid on the logic

terminal

0x0004 Unknown EtherCAT slave No slave could be found for the specified EtherCAT

address

0x0005 Error during the data transmission The communication connection was disconnected

3.7 FMEDA

The following table contains the FMEDA for the TwinSAFE loader. The errors are described in the

FailureMode column, in Effect the effect and in Diagnostics how the errors are detected or not detected.

CAUTION

FMEDA

The last column, User measures required of the following table indicates whether the user has to take action to handle the errors described under FailureMode in a safe manner. These measures must be defined

and implemented by the user in the form of e.g. process descriptions or software specifications. The user

shall bear full responsibility to provide proof for the accuracy and efficacy of these measures.

TwinSAFE Loader20 Version: 2.4.0

Page 21

Product description

FMEDAIDFailureMode Effect Diagnostics User mea-

1 A download with a defec-

tive project file is starting.

2 A download with a project

file is starting which does

not contain the expect

project.

11 A download and an acti-

vation of the project are

being carried out on a target system which was not

intended from the point of

view of the secure address.

3 The download and the

activation are being carried out with an unexpected project.

5 A user is attempting to

carry out a download with

false access data.

7 An unauthorized user is

attempting to carry out a

download with valid access data.

Prior to the actual download the current

safety project is deleted by the tool. The

download with the new project file is carried out by the tool.

Download will be carried out completely

and validly by the tool, but it won’t be activated yet.

Download will be carried out completely

and validly by the tool, but it won’t be activated yet.

Download is carried out completely and

validly by the tool.

Prior to start of the actual download

process a login is carried out with the invalid access data on the target system.

The download is successfully carried out. Error is not detected by the tool. Yes

During the download the checksums

of the download packages are

checked by the target system. The

download is canceled in the event of

discrepancy of the checksums..

Activation only occurs if the project

CRC of the activation record matches

the project CRC of the target system.

A discrepancy leads to cancellation

of the activation.

Activation only occurs if the secure

address in the activation record

matches the secure address of the

target system. A discrepancy leads to

cancellation of the activation.

Error is not detected by the tool. Yes

Invalid access data is detected on the

target system during the login, the

download is refused and a feedback

is given to the tool.

sures required

No

Yes

No

No

13 Customizing is being car-

ried out by an unauthorized user with valid access data.

14 Customizing is being car-

ried out by a user with

false access data.

8 Customizing record is be-

ing incorrectly transmitted.

12 The wrong customizing

record is being transmitted.

9 A communication connec-

tion cannot be established with the target system.

15 While carrying out the

download the communication connection to the

target system is canceled.

16 While carrying out the

customizing the communication connection to the

target system is canceled.

The customizing is successfully carried

out.

Prior to starting the actual customizing

process a login is carried out on the target

system with the invalid access data.

The customizing is successfully carried

out.

Customizing action is carried out completely and validly by the tool.

No action is executed on the target system.

Prior to the actual download the current

safety project is deleted by the tool. The

download of a safety project only leads to

a successful change of the active safety

project if all steps of the download were

correctly carried out and the safety project

was activated. A cancellation of this

process leads to an empty target system.

The customizing is carried out by a single

transaction. If this transaction is interrupted, no action will be carried out on the

target system. If the transaction is carried

out, the correct action takes place on the

target system (provided there are no further errors such as e.g. FMEDA ID 8).

Error is not detected by the tool. Yes

Invalid access data is detected on the

target system during the login, customizing is refused and a feedback is

given to the tool.

Error is not detected by the tool. Yes

Error is not detected by the tool. Yes

An error code indicates a communication error.

An error code indicates the cancellation of the action.

An error code indicates the cancellation of the action.

No

No

No

No

TwinSAFE Loader 21Version: 2.4.0

Page 22

Product description

FMEDAIDFailureMode Effect Diagnostics User mea-

10 The execution of the tool

is unexpectedly interrupted during the download of a safety project.

18 The execution of the tool

is unexpectedly interrupted during the customizing of a safety

project.

24 A file is being specified

for the customizing that

does not correspond to

the CSV format.

Prior to the actual download the current

safety project is deleted by the tool. The

download of a safety project only leads to

a successful change of the active safety

project if all steps of the download were

correctly carried out and the safety project

was activated. A cancellation of this

process leads to an empty target system.

The customizing is carried out by a single

transaction. If this transaction is interrupted, no action will be carried out on the

target system. If the transaction is carried

out, the correct action takes place on the

target system (provided there are no further errors such as e.g. FMEDA ID 8).

No action is executed on the target system.

A successful download includes the

login on the target system, the deletion of the existing safety project, the

download of the new safety project

and the activation of the new safety

project. Only the successful execution of all of the steps results in a

valid change of the safety project.

Current configuration data of the target system.

If the tool detects an unexpected

character during the processing of a

CSV file, further processing is canceled and an error is reported.

sures required

Yes

Yes

No

TwinSAFE Loader22 Version: 2.4.0

Page 23

EtherCAT Mailbox Gateway

4 EtherCAT Mailbox Gateway

The EtherCAT Mailbox Gateway is required to access TwinSAFE logic components when ADS cannot be

used for communication.

The following description shows which settings must be made by way of example in order to be able to

communicate via the EtherCAT Mailbox Gateway.

The configuration for using the EtherCAT Mailbox Gateway consists of a TwinSAFE Loader PC on which the

TwinSAFE Loader is installed and a TwinCAT PC which serves as a gateway to route the requests from the

TwinSAFE Loader PC to the EtherCAT network and to the TwinSAFE logic components.

Fig.8: EtherCAT Mailbox Gateway

4.1 Settings EtherCAT Mailbox Gateway

Activation of the EtherCAT Mailbox Gateway is performed via the advanced settings of the EtherCAT master.

These can be found under the EtherCAT tab when the EtherCAT master is selected in the TwinCAT tree

structure.

The settings for the EtherCAT Mailbox Gateway are summarized under the entry EoE Support. The Virtual

Ethernet Switch, Connect to TCP / IP Stack, and IP Enable Router must be enabled. In addition, the

EtherCAT Mailbox Gateway must be activated and an IP address outside the existing networks must be

selected. These settings require a restart of the TwinCAT PC.

TwinSAFE Loader 23Version: 2.4.0

Page 24

EtherCAT Mailbox Gateway

Fig.9: EoE Support

Whether these settings are correct should be checked locally with the ping command on the TwinCAT

computer. In this case, the command would read as follows:

ping 192.198.67.254

Fig.10: The command ping 192.198.67.254

4.2 Beckhoff Virtual Ethernet Adapter

If the ping command has not yet delivered a positive result, it may be that the Beckhoff Virtual Ethernet

Adapter has yet to be configured.

To do this, open the network settings and select the Properties via the context menu of the Beckhoff Virtual

Ethernet Adapter.

TwinSAFE Loader24 Version: 2.4.0

Page 25

Fig.11: Network settings - context menu of the Beckhoff virtual Ethernet adapter

Beckhoff Virtual Ethernet Adapter

If there is no Virtual Ethernet adapter in the system listed, an EoE device (e.g. EL6601) can be

added under TwinCAT. Under the Extended EtherCAT settings of this device, under EoE the Virtual

Ethernet port can be activated.

EtherCAT Mailbox Gateway

In the properties of this network adapter, you set a fixed IP address that is within the network area of the

EtherCAT Mailbox Gateway. In the example, this is the IP address 192.198.67.13 with the subnet mask

255.255.255.0.

Fig.12: Properties of the Beckhoff virtual Ethernet adapter

TwinSAFE Loader 25Version: 2.4.0

Page 26

EtherCAT Mailbox Gateway

Whether this setting is correct should be checked again with the ping command locally on the TwinCAT

computer. The command would again be as follows:

ping 192.198.67.254

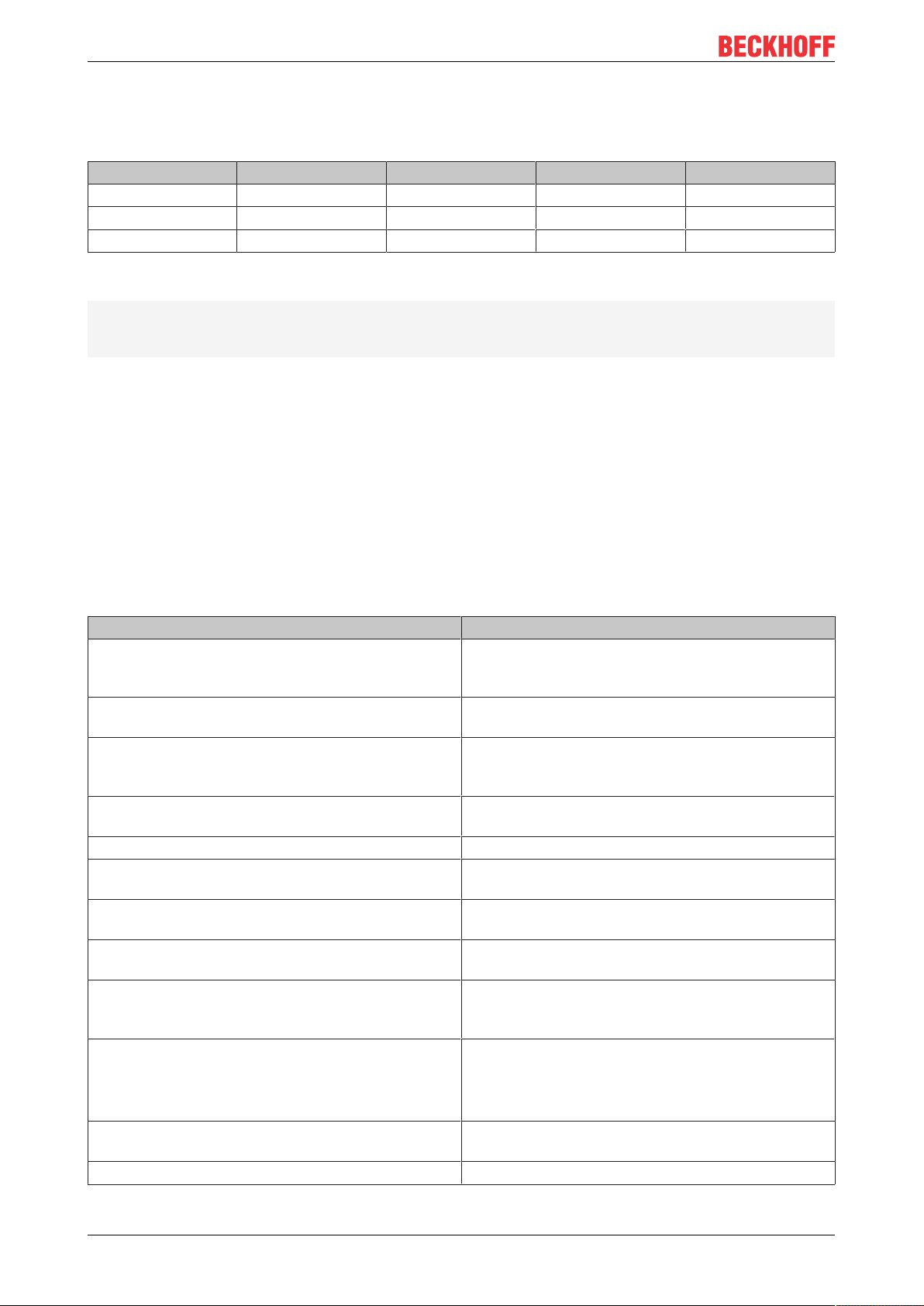

4.3 Adding a route

After all settings on the TwinCAT PC have been carried out and the local execution of the ping command

has been successful, an IP route has to be added to the TwinSAFE Loader PC.

The route is added by command route add from the command line.

The command prompt to add a route must be started as an administrator.

Fig.13: Start the Windows command prompt as administrator

The route is then added using the following command:

route add 192.198.67.0 mask 255.255.255.0 172.17.42.29

The command returns an OK! when adding the route was successful.

The current routes can be displayed using the route print 192.198.* command.

TwinSAFE Loader26 Version: 2.4.0

Page 27

EtherCAT Mailbox Gateway

Fig.14: Windows command prompt

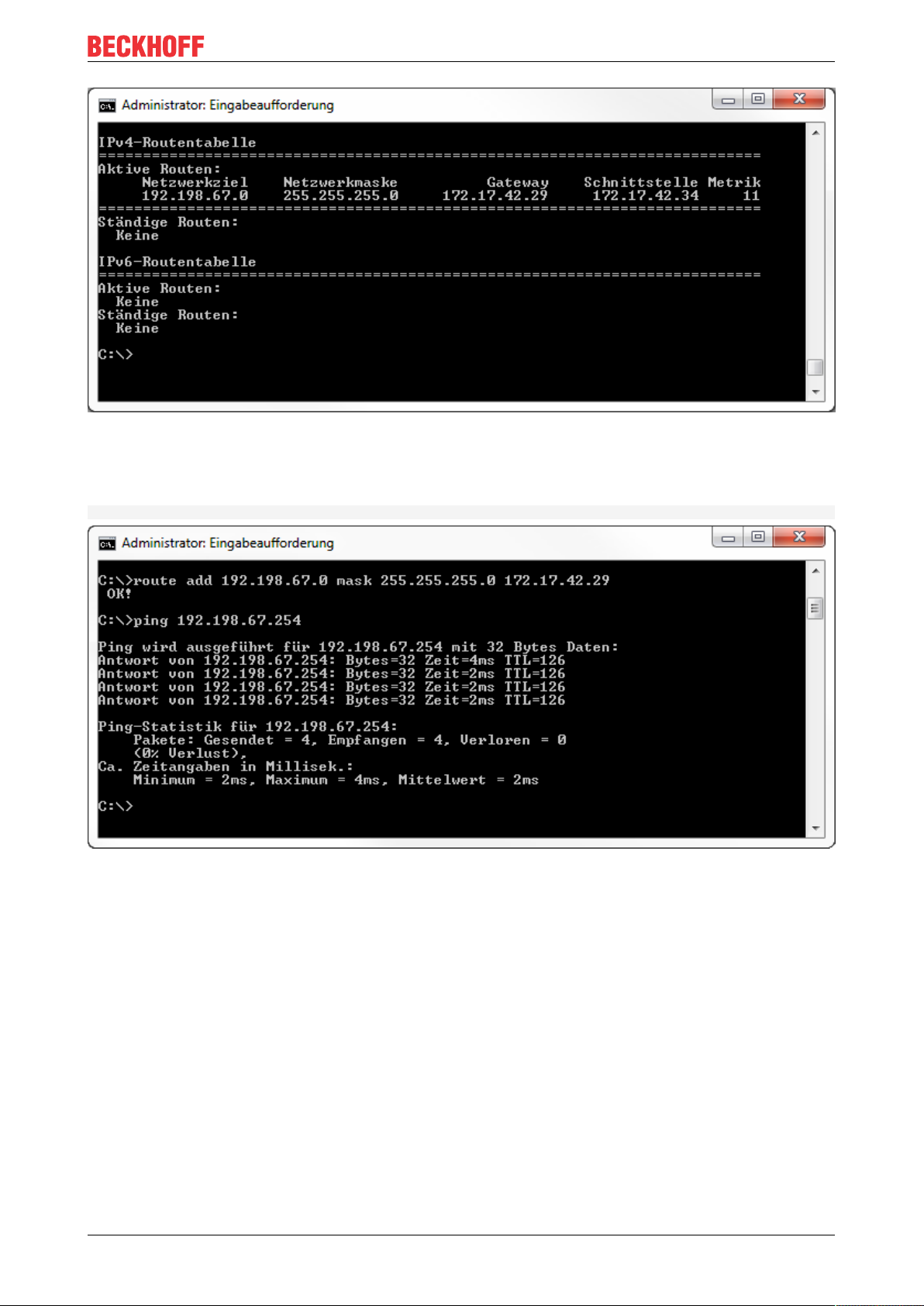

To check the function, a ping command should now be sent from the TwinSAFE Loader PC to the EtherCAT

Mailbox Gateway.

ping 192.198.67.254

Fig.15: Windows command prompt - command ping 192.198.67.254

If the ping command returns a positive result, the EtherCAT Mailbox Gateway can also be used with the

TwinSAFE Loader.

TwinSAFE Loader 27Version: 2.4.0

Page 28

Appendix

5 Appendix

5.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49 5246 963 0

Fax: +49 5246 963 198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49 5246 963 157

Fax: +49 5246 963 9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49 5246 963 460

Fax: +49 5246 963 479

e-mail: service@beckhoff.com

TwinSAFE Loader28 Version: 2.4.0

Page 29

5.2 Certificates

5.2.1 Letter of Confirmation

Appendix

TwinSAFE Loader 29Version: 2.4.0

Page 30

Table of figures

Table of figures

Fig. 1 TwinSAFE Loader - Overview ..................................................................................................... 9

Fig. 2 Call to load a safety project ......................................................................................................... 14

Fig. 3 Call to activate a safety project.................................................................................................... 15

Fig. 4 Call to delete a safety project ...................................................................................................... 15

Fig. 5 Call to customize a safety project................................................................................................ 15

Fig. 6 Call of the function block NT_StartProcess for customizing........................................................ 16

Fig. 7 Call to list the groups of a safety project...................................................................................... 17

Fig. 8 EtherCAT Mailbox Gateway ........................................................................................................ 23

Fig. 9 EoE Support ................................................................................................................................ 24

Fig. 10 The command ping 192.198.67.254 ............................................................................................ 24

Fig. 11 Network settings - context menu of the Beckhoff virtual Ethernet adapter .................................. 25

Fig. 12 Properties of the Beckhoff virtual Ethernet adapter ..................................................................... 25

Fig. 13 Start the Windows command prompt as administrator ................................................................ 26

Fig. 14 Windows command prompt ......................................................................................................... 27

Fig. 15 Windows command prompt - command ping 192.198.67.254 .................................................... 27

TwinSAFE Loader30 Version: 2.4.0

Page 31

Page 32

More Information:

www.beckhoff.de/english/twinsafe/default.htm

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

Phone: +49 5246 9630

info@beckhoff.com

www.beckhoff.com

Loading...

Loading...