Page 1

Manual | EN

TF6610

TwinCAT 3 | S5/S7 Communication

11/10/2020 | Version: 1.1

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

2 Overview.....................................................................................................................................................7

3 Installation..................................................................................................................................................8

3.1 Installation .........................................................................................................................................8

3.2 Installation WindowsCE..................................................................................................................11

3.3 Licensing .........................................................................................................................................13

4 Configuration of an IBH Link S5/S7 ++ adapter....................................................................................16

5 Description of the PLC data area parameter values ............................................................................18

6 API.............................................................................................................................................................20

6.1 PLC Reference ................................................................................................................................20

6.1.1 Function blocks................................................................................................................ 20

6.1.2 Functions [obsolete]......................................................................................................... 25

6.1.3 Data Types ...................................................................................................................... 26

6.1.4 Global Constants ............................................................................................................. 29

7 Samples....................................................................................................................................................31

8 Appendix ..................................................................................................................................................32

8.1 Error codes overview.......................................................................................................................32

8.2 Internal S5/S7 communication error codes .....................................................................................33

8.3 ADS Return Codes ..........................................................................................................................35

8.4 Win32 Error Codes ..........................................................................................................................40

8.5 Troubleshooting/diagnostics............................................................................................................95

TF6610 3Version: 1.1

Page 4

Table of contents

TF66104 Version: 1.1

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702

with corresponding applications or registrations in various other countries.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

TF6610 5Version: 1.1

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life and health of

persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to persons.

NOTE

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or

equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

TF66106 Version: 1.1

Page 7

Overview

2 Overview

The function blocks of the PLC library Tc2_S5S7Com can be used to realise data exchange between the

local TwinCAT PLC and a S5/S7 controller via an Ethernet LAN adapter from IBHsoftec.

The adapter is not part of the Beckhoff product and must be bought from IBHsoftec.

Product components

The function TF6610 | S5/S7 consists of the following components which are automatically installed during

setup:

• Functions: TF6310

• PLC library Tc2_S5S7Com (Tc2_TcpIp installed with TF6310)

• Background program:TwinCAT TCP/IP connection server (for communication, installed with

TF6310);.

System requirements

Supported adapters:

• IBH Link S5++ adapter from IBHsoftec (from firmware version 1.39; the firmware version can be

read via the configuration software provided).

Older adapters (without ++) are currently not supported.

• IBH Link S7++ adapter from IBHsoftec (from firmware version NL50MPI V02.004 05.06.09; the

firmware version can be read via the configuration software provided).

The following article describes the minimum requirements for the engineering or runtime system.

Development environment

A development environment describes a computer developing PLC program, but not running. On a

development computer, the following have to be installed:

• TwinCAT v3.1.4016.0 XAE (engineering) or higher;

• TwinCAT 3 Function TF6610 S5 / S7 Communication;

Run-time environment

A runtime environment describes a computer running PLC programs. On a runtime computer, the following

have to be installed:

• TwinCAT v3.1.4016.0 XAR (runtime) or higher;

• TwinCAT 3 Function TF6610 S5 / S7 Communication;

• Licenses for TC1200 PLC and TF6610;

Developer and run-time version on a computer

To run a runtime and development environment on a computer (for example, to test a PLC program before

loading it to the target computer), the following requirements must be fullfilled:

• TwinCAT v3.1.4016.0 XAE (Engineering) or higher;

• TwinCAT 3 function TF6610 S5 / S7 communication;

• Licenses for TC1200 PLC, TF6610;;

Please note: For test purposes a 7-day trial license can be generated, see licensing.

TF6610 7Version: 1.1

Page 8

Installation

3 Installation

The function TF6610 can be installed with the Operating System XP and CE.

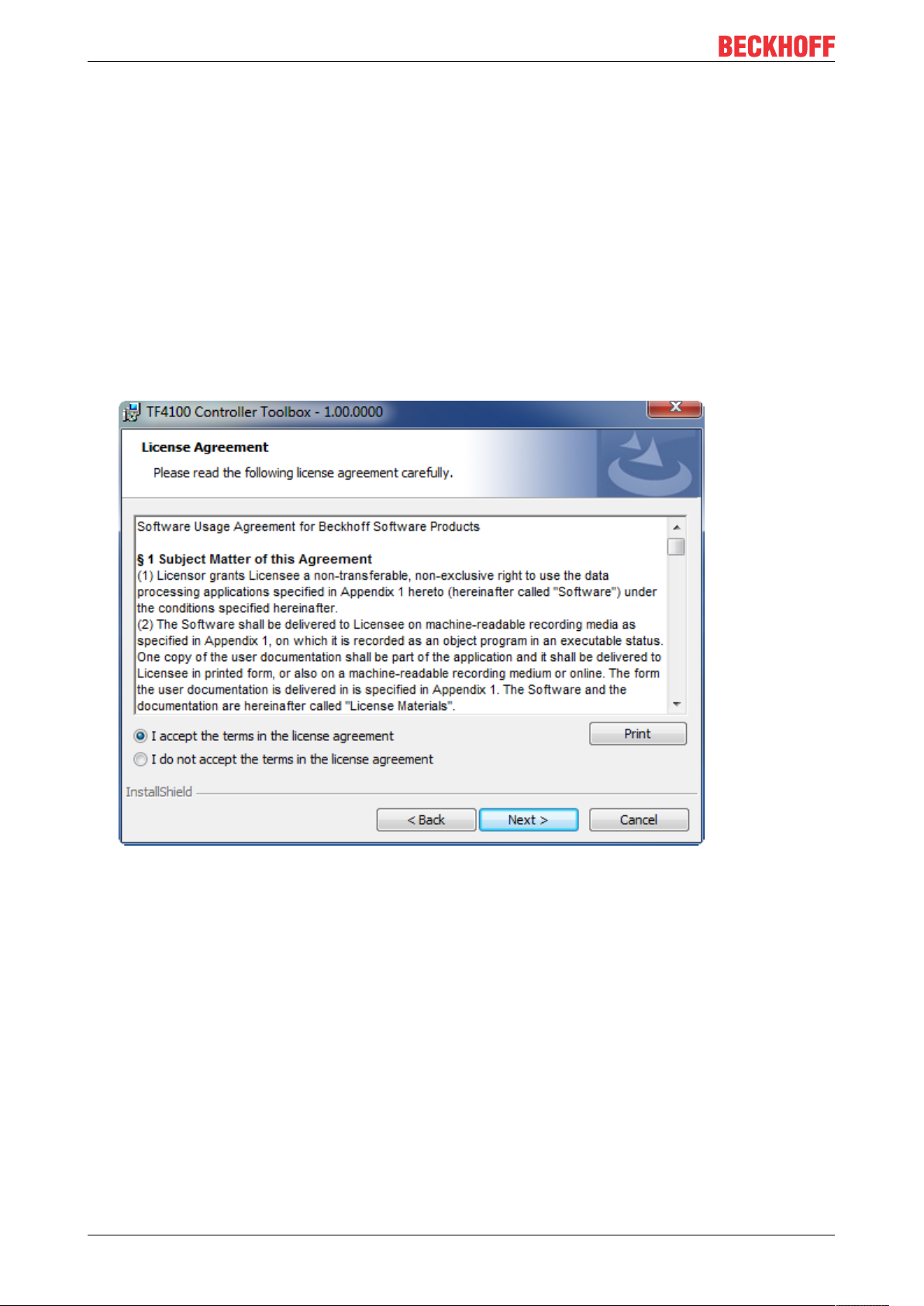

3.1 Installation

The following section describes how to install the TwinCAT3Function for Windows-based operating

systems.

ü The TwinCAT3Function setup file was downloaded from the Beckhoff website.

1. Run the setup file as administrator. To do this, select the command Run as administrator in the context

menu of the file.

ð The installation dialog opens.

2. Accept the end user licensing agreement and click Next.

TF66108 Version: 1.1

Page 9

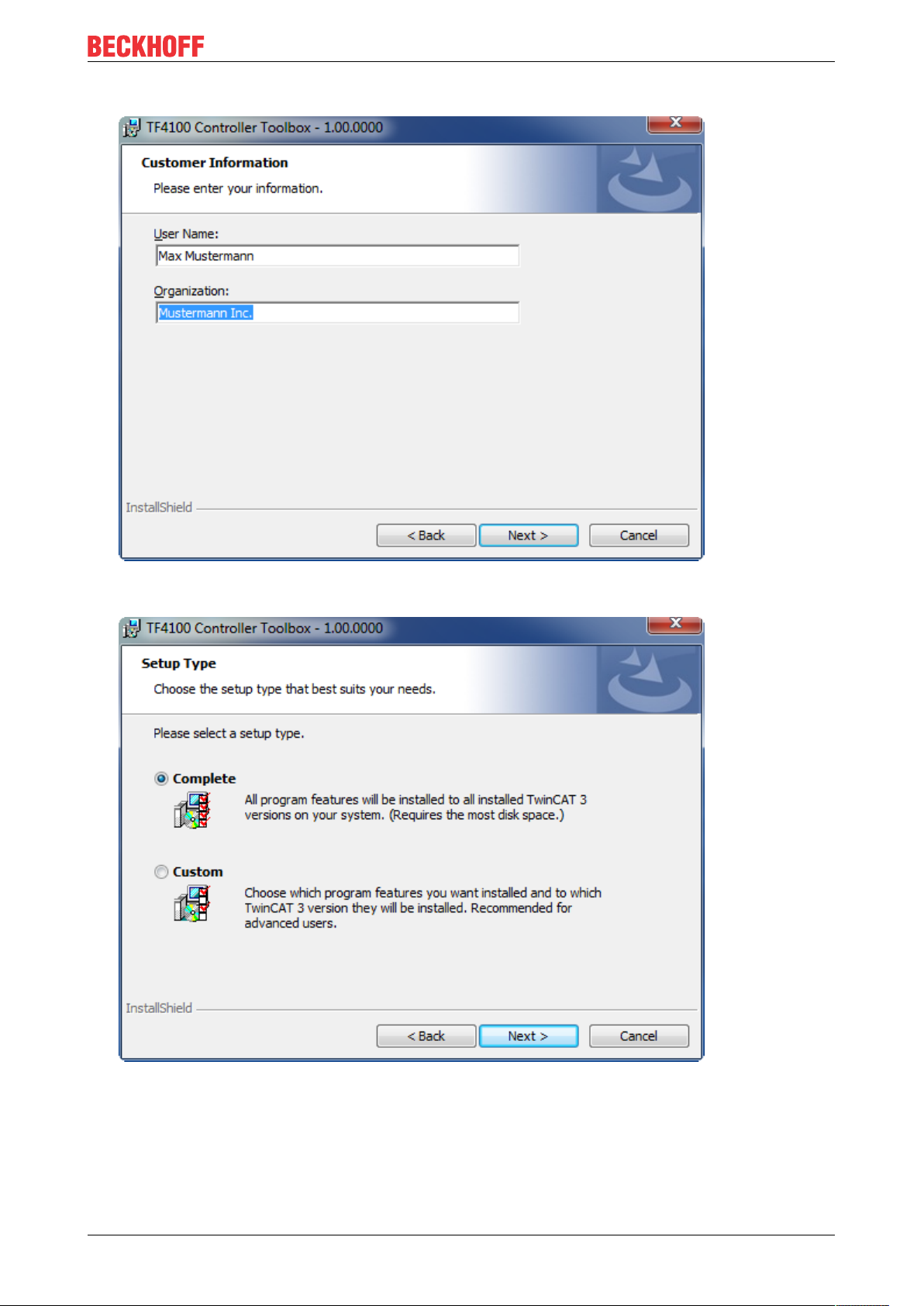

3. Enter your user data.

Installation

4. If you want to install the full version of the TwinCAT3Function, select Complete as installation type. If

you want to install the TwinCAT3Function components separately, select Custom.

TF6610 9Version: 1.1

Page 10

Installation

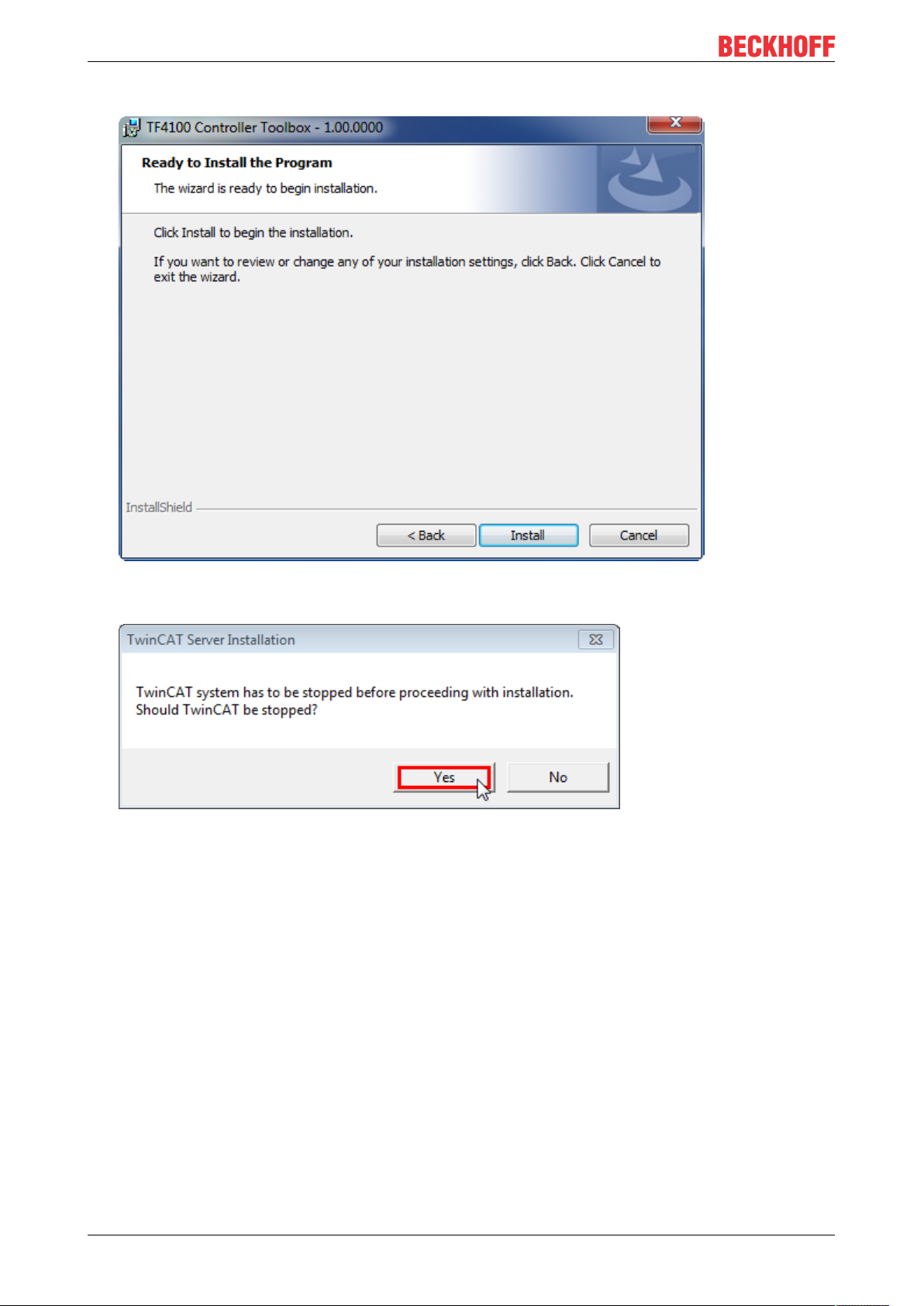

5. Select Next, then Install to start the installation.

ð A dialog box informs you that the TwinCAT system must be stopped to proceed with the installation.

6. Confirm the dialog with Yes.

TF661010 Version: 1.1

Page 11

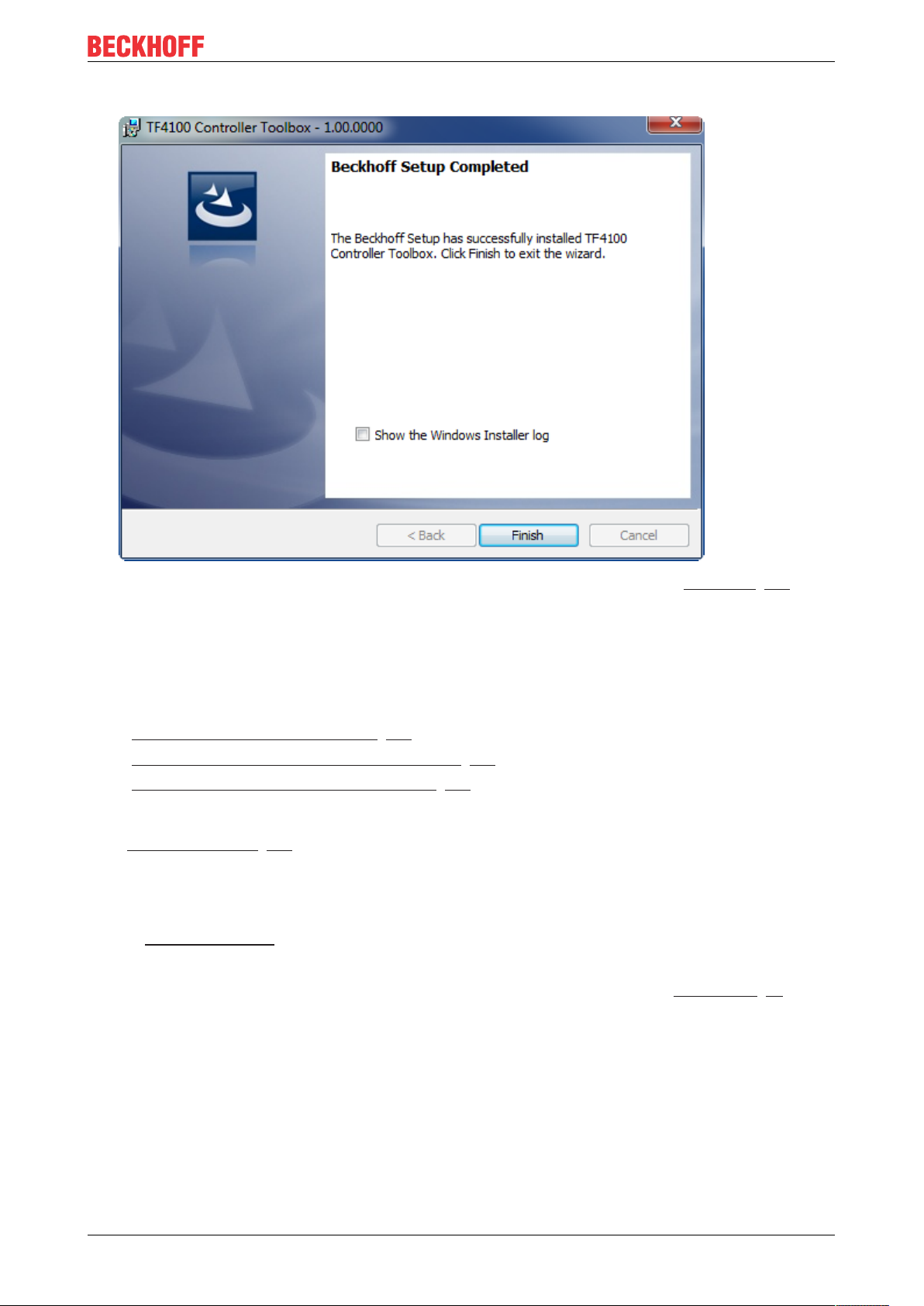

7. Select Finish to exit the setup.

Installation

ð The TwinCAT3Function has been successfully installed and can be licensed (see Licensing [}13]).

3.2 Installation WindowsCE

The following section describes how to install a TwinCAT3function (TFxxx) on a Beckhoff Embedded PC

with WindowsCE.

1. Download and install the setup file [}11]

2. Transfer the CAB file to the WindowsCE device [}12]

3. Run the CAB file on the WindowsCE device [}12]

If an older TFxxx version is already installed on the WindowsCE device, it can be updated:

• Software upgrade [}12]

Download and install the setup file

The CAB installation file for WindowsCE is part of the TFxxx setup. This is made available on the Beckhoff

website www.beckhoff.com and automatically contains all versions for Windows XP, Windows 7 and

Windows CE (x86 and ARM).

Download the TFxxx setup file and install the TwinCAT3function as described in the Installation [}8]

section.

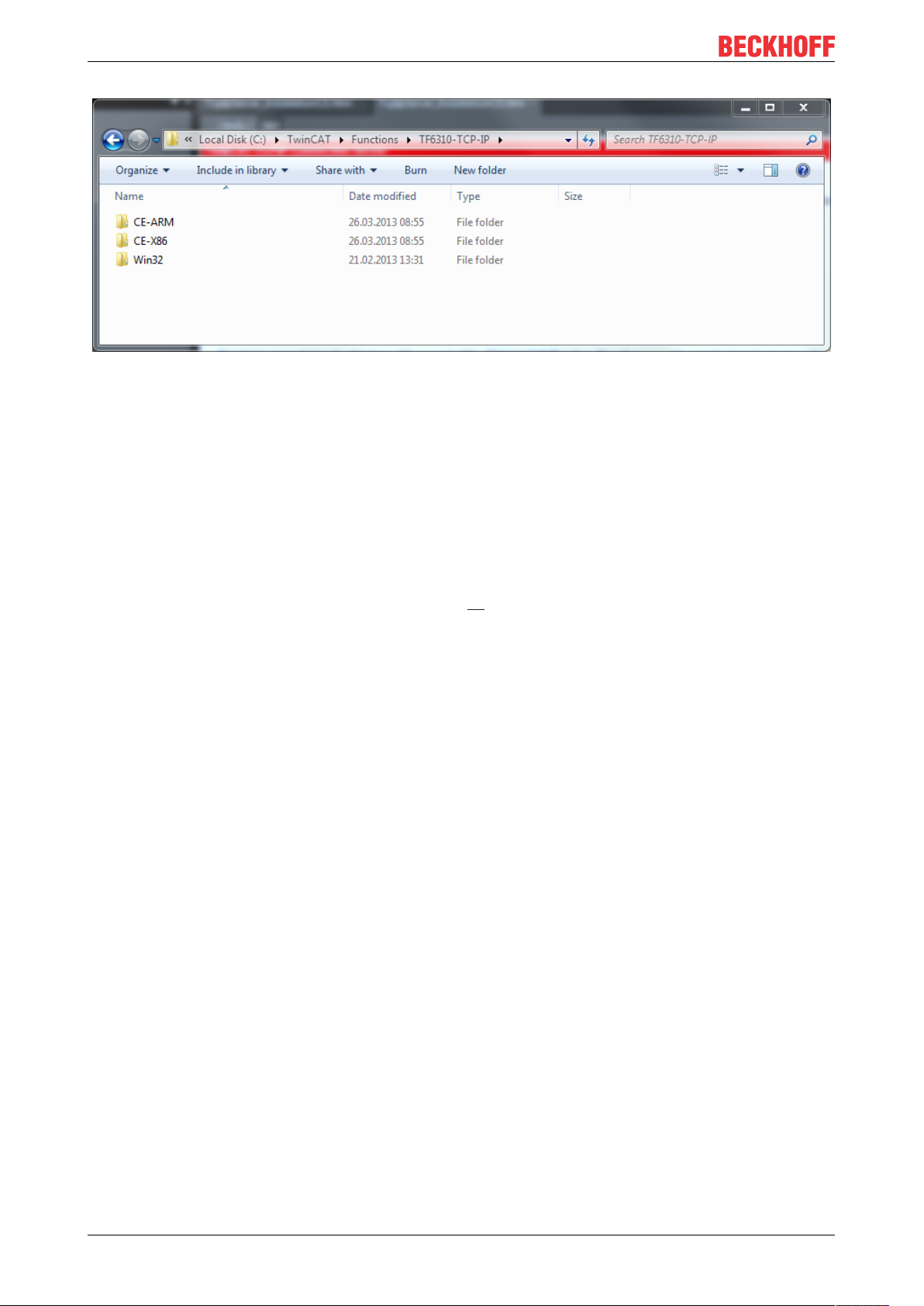

After the installation, the installation folder contains three directories (one directory per hardware platform):

• CE-ARM: ARM-based Embedded PCs running WindowsCE, e.g. CX8090, CX9020

• CE-X86: X86-based Embedded PCs running WindowsCE, e.g. CX50xx, CX20x0

• Win32: Embedded PCs running WindowsXP, Windows7 or WindowsEmbeddedStandard

The CE-ARM and CE-X86 directories contain the CAB files of the TwinCAT3function for WindowsCE in

relation to the respective hardware platform of the WindowsCE device.

Example: "TF6310" installation folder

TF6610 11Version: 1.1

Page 12

Installation

Transfer the CAB file to the WindowsCE device

Transfer the corresponding CAB file to the WindowsCE device.

There are various options for transferring the executable file:

• via network shares

• via the integrated FTP server

• via ActiveSync

• via CF/SD cards

Further information can be found in the Beckhoff Information System in the "Operating Systems"

documentation (EmbeddedPC>Operating Systems>CE).

Run the CAB file on the WindowsCE device

After transferring the CAB file to the WindowsCE device, double-click the file there. Confirm the installation

dialog with OK. Then restart the WindowsCE device.

After restarting the device, the files of the TwinCAT3function (TFxxxx) are automatically loaded in the

background and are then available.

The software is installed in the following directory on the WindowsCE device:

\Hard Disk\TwinCAT\Functions\TFxxxx

Software upgrade

If an older version of the TwinCAT3function is already installed on the WindowsCE device, carry out the

following steps on the WindowsCE device to upgrade to a new version:

1. Open the CE Explorer by clicking Start>Run and entering "Explorer".

2. Navigate to \Hard Disk\TwinCAT\Functions\TFxxx\xxxx.

3. Rename the file Tc*.exe to Tc*.old.

4. Restart the WindowsCE device.

5. Transfer the new CAB file to the WindowsCE device.

6. Run the CAB file on the WindowsCE device and install the new version.

7. Delete the file Tc*.old.

8. Restart the WindowsCE device.

ð The new version is active after the restart.

TF661012 Version: 1.1

Page 13

Installation

3.3 Licensing

The TwinCAT3function can be activated as a full version or as a 7-day test version. Both license types can

be activated via the TwinCAT 3 development environment (XAE).

Licensing the full version of a TwinCAT3Function

A description of the procedure to license a full version can be found in the Beckhoff Information System in

the documentation "TwinCAT3Licensing".

Licensing the 7-day test version of a TwinCAT3Function

A 7-day test version cannot be enabled for a TwinCAT 3 license dongle.

1. Start the TwinCAT 3 development environment (XAE).

2. Open an existing TwinCAT 3 project or create a new project.

3. If you want to activate the license for a remote device, set the desired target system. To do this, select

the target system from the Choose Target System drop-down list in the toolbar.

ð The licensing settings always refer to the selected target system. When the project is activated on

the target system, the corresponding TwinCAT 3 licenses are automatically copied to this system.

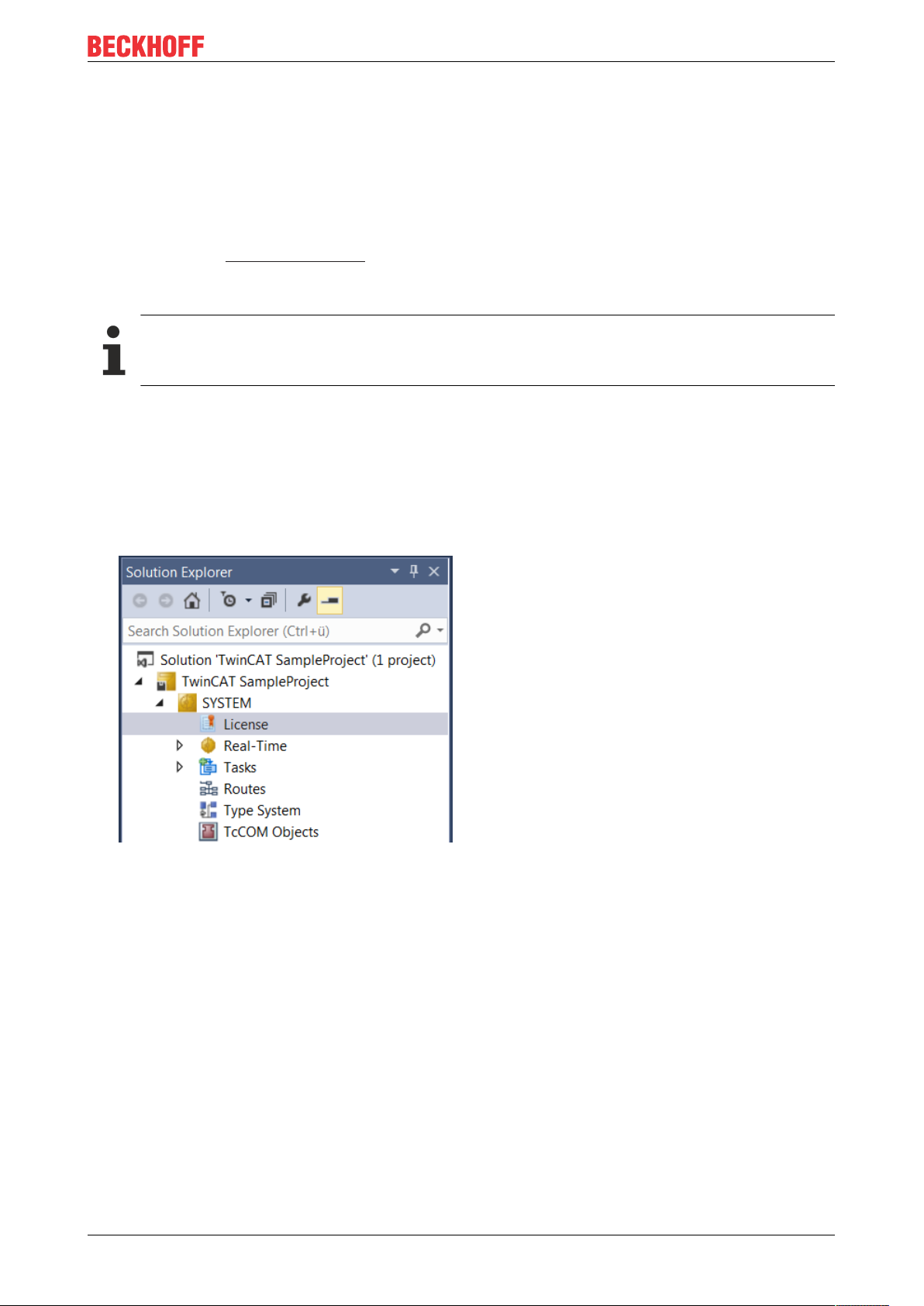

4. In the Solution Explorer, double-click License in the SYSTEM subtree.

ð The TwinCAT 3 license manager opens.

TF6610 13Version: 1.1

Page 14

Installation

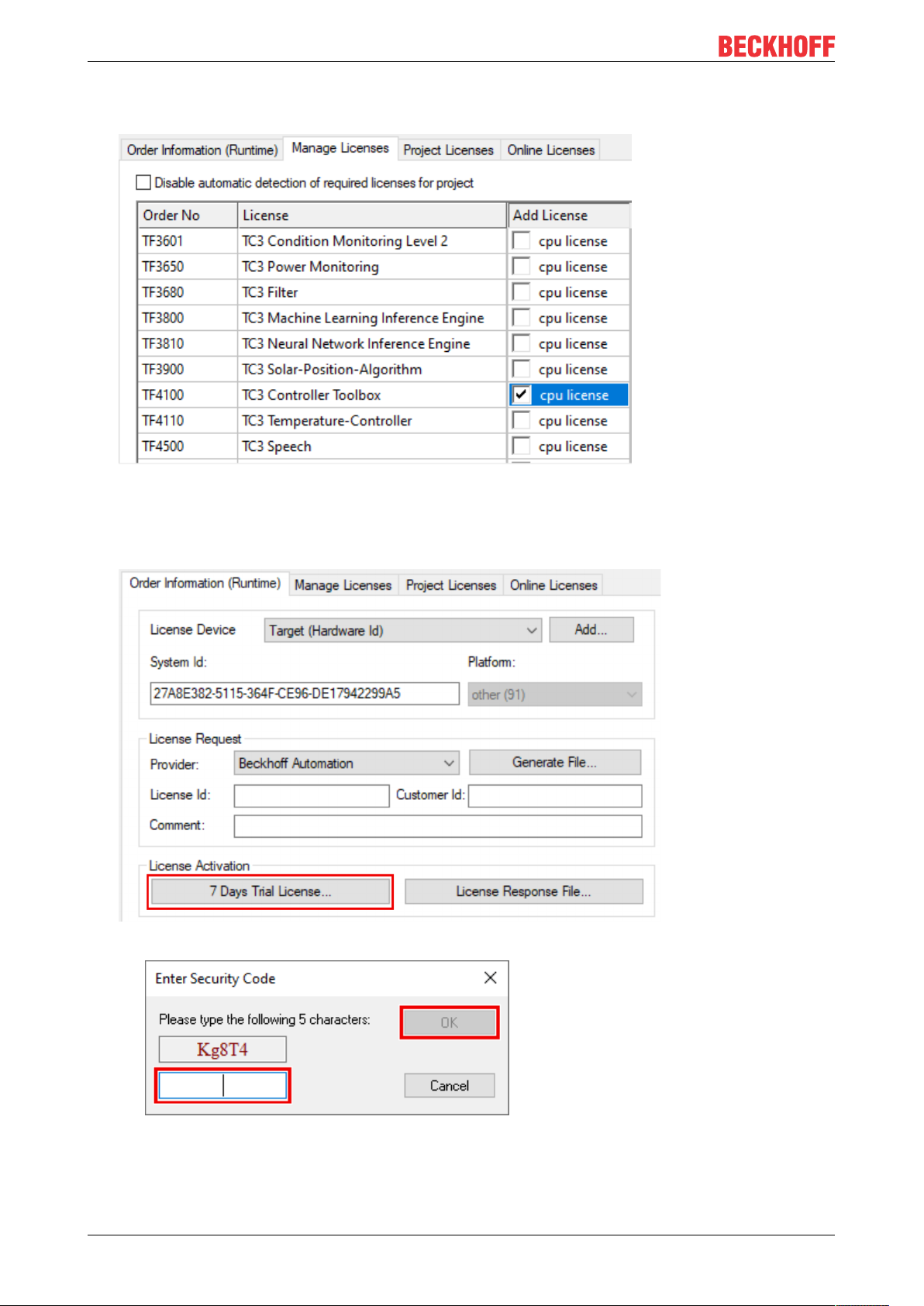

5. Open the Manage Licenses tab. In the AddLicense column, check the check box for the license you

want to add to your project (e.g."TF6420:TC3DatabaseServer").

6. Open the Order Information (Runtime) tab.

ð In the tabular overview of licenses, the previously selected license is displayed with the status

“missing”.

7. Click7-DayTrialLicense... to activate the 7-day trial license.

ð A dialog box opens, prompting you to enter the security code displayed in the dialog.

8. Enter the code exactly as it is displayed and confirm the entry.

9. Confirm the subsequent dialog, which indicates the successful activation.

ð In the tabular overview of licenses, the license status now indicates the expiry date of the license.

10. Restart the TwinCAT system.

TF661014 Version: 1.1

Page 15

ð The 7-day trial version is enabled.

Installation

TF6610 15Version: 1.1

Page 16

Configuration of an IBH Link S5/S7 ++ adapter

4 Configuration of an IBH Link S5/S7 ++ adapter

The adapter configuration software is provided by the manufacturer of the adapter. It is not part of the

TwinCAT function. A detailed description of the module configuration can be found in the manufacturer

documentation.

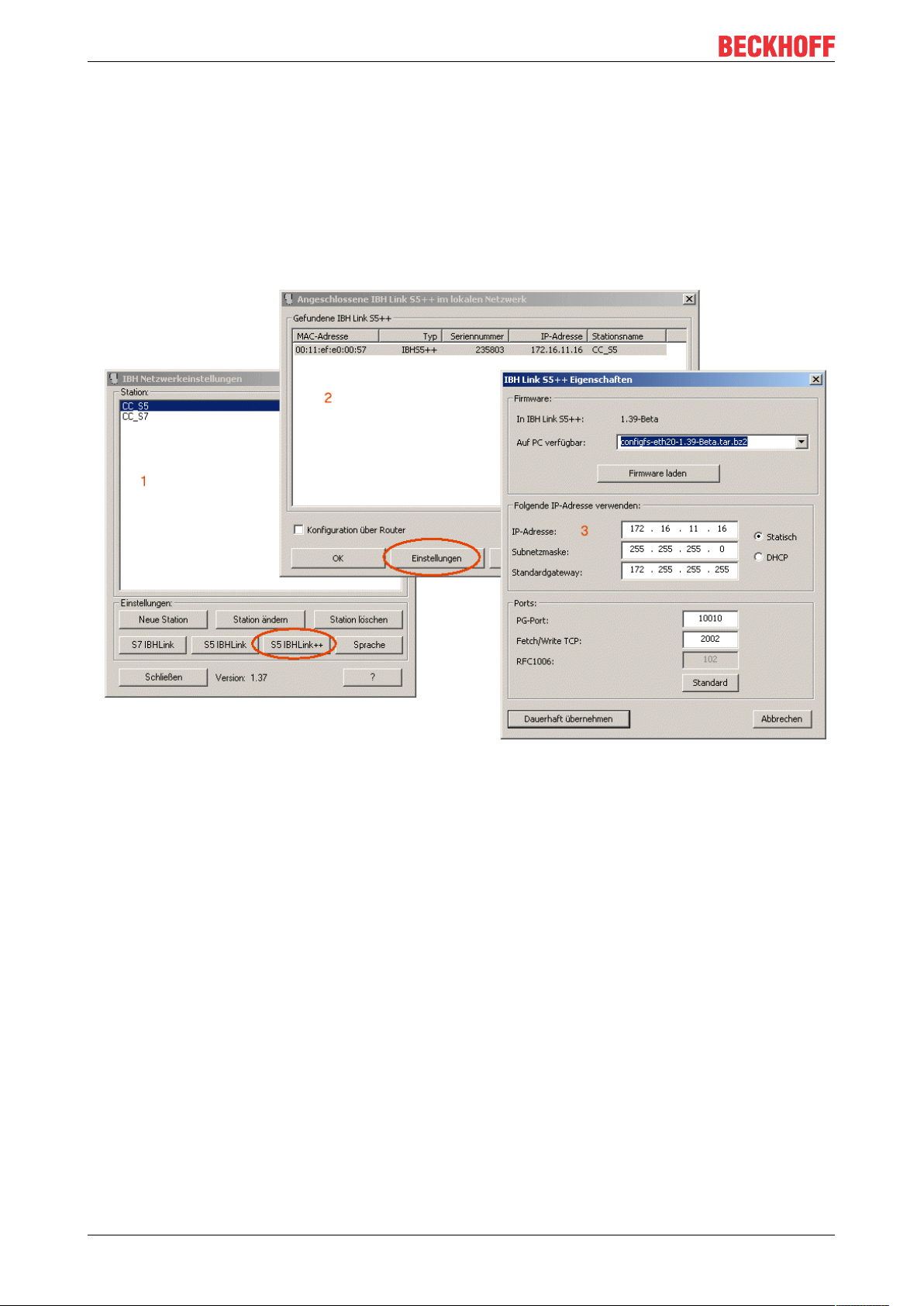

Configuration of an IBH Link S5++ adapter

In the following example a fixed IP address 172.16.11.16 was set:

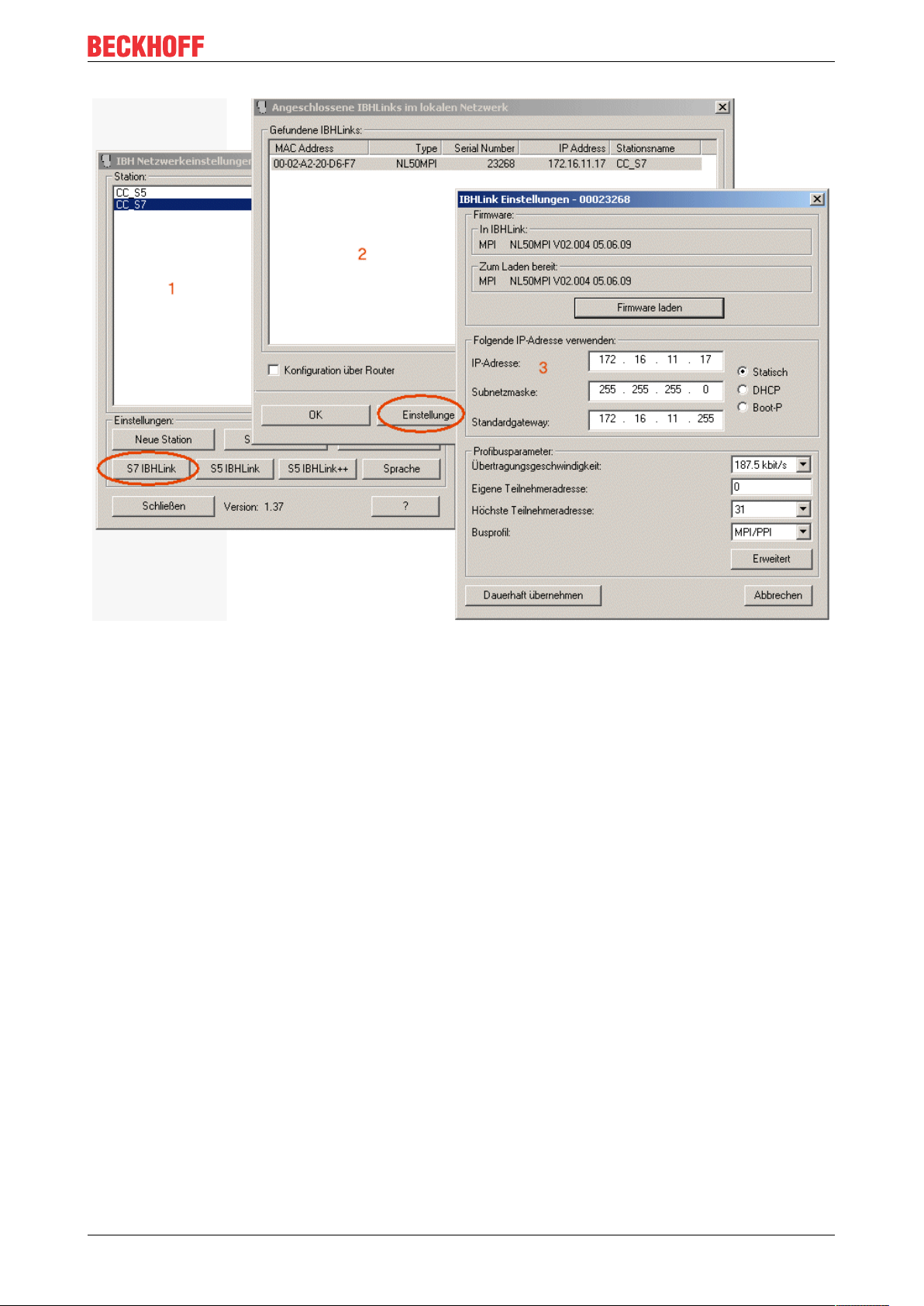

Configuration of an IBH Link S7++ adapter

In the following example a fixed IP address 172.16.11.17 was set:

TF661016 Version: 1.1

Page 17

Configuration of an IBH Link S5/S7 ++ adapter

TF6610 17Version: 1.1

Page 18

Description of the PLC data area parameter values

5 Description of the PLC data area parameter

values

The parameter values to be used for the write/read command differ depending on the type of external control

used, the adapter or the communication protocol. Some data areas may not be available, or the data have to

be read/written word by word instead of byte by byte. Further information can be found in the documentation

for the external control.

Data type

Read access to word variables in the S5/S7 controller returns data in Motorola format (Hi and Lo

bytes interchanged). For the evaluation the read data first have to be converted to the common Intel

format used in the TwinCAT system. Data to be written from the TwinCAT system to the S5/S7 controller must be converted to the Motorola format before the write access.

The BCD number system is used in the S5/S7 controller for representing the counter/timer variables. The

data may have to be converted, if necessary.

The TwinCAT PLC library: TcUtilities.Lib offers functions for conversion between Motorola and Intel format

(e.g. BE16_TO_host, host_TO_BE16...).

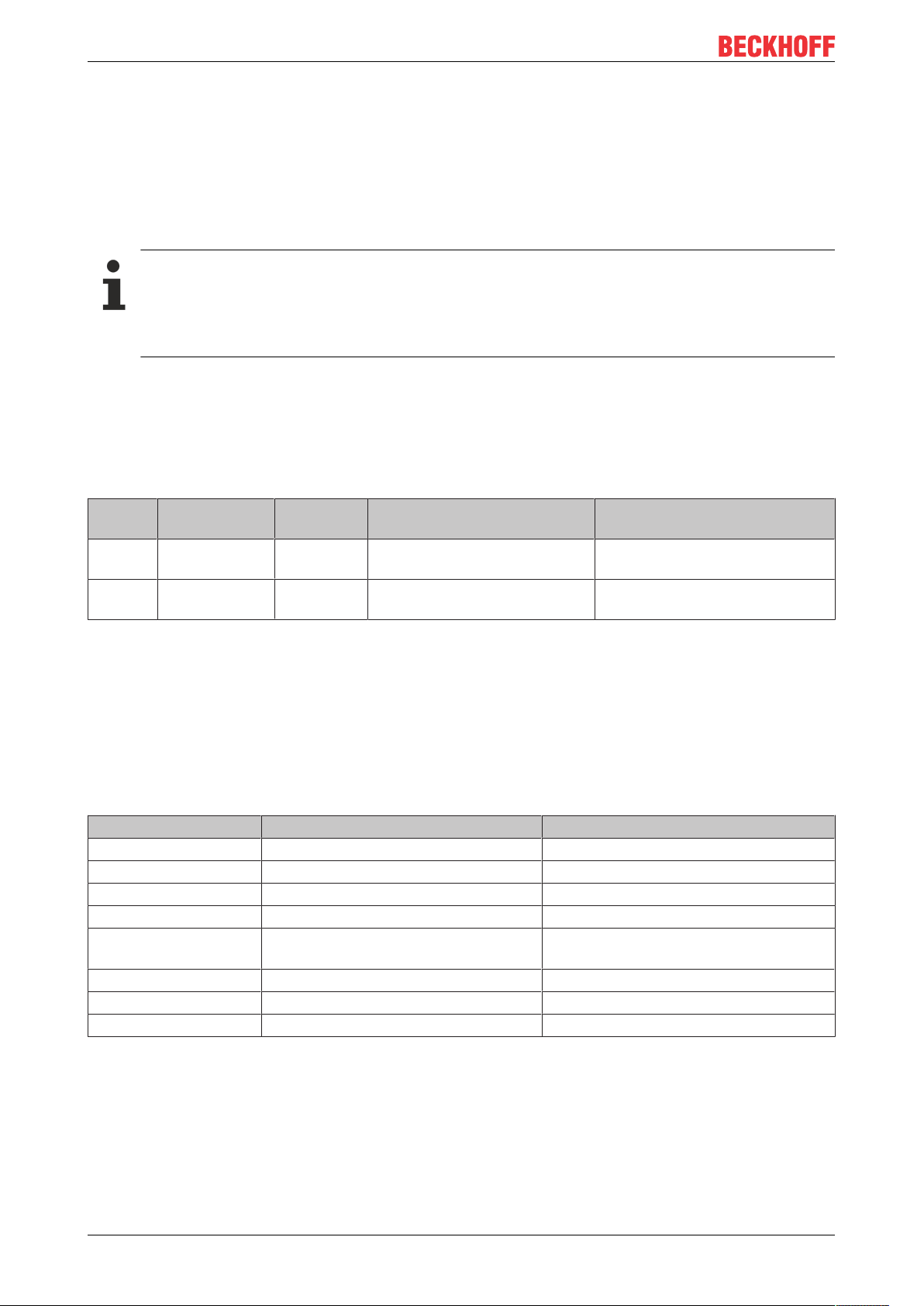

The following table provides an overview of the available communication routes:

Control LAN adapter Transport

protocol

S5 IBH Link S5++ TCP/IP IBH S5 LAN link protocol =

S7 IBH Link S7++ TCP/IP NetLink MPI protocol (NL-MPI)

IBH S5 LAN link protocol = FETCH/WRITE telegrams

• Currently this protocol can only be used with S5 controllers.

• The TCP/IP port number has the default value 2002;

• The parameter devAddr is not evaluated.

• The data block number (nDB) is only evaluated when the areas data blocks (DB) and extended data

blocks (DX) are accessed. Permitted range: 1..255;

• The areas P (periphery) and OS (operating state) are not supported.

Data area (eArea) Start address (nOffset) Permitted data length (cbBuffer)

DB Data word offset: 0..2047 read/write 1..2048 words

M Flag byte offset: 0..255 read/write 1..256 bytes

I Input byte offset: 0..127 read 1..128 bytes

Q Output byte offset: 0..127 write 1..128 bytes

P I/O periphery byte offset: 0..127 (digital

I/Os), 128..255 (analog I/Os)

C Counter start offset: 0..255 read/write 1 word

T Timer start offset: 0..255 read/write 1 word

DX Data word offset: read/write 1..2048 words

LAN adapter communication

protocol

FETCH/WRITE telegrams

from Hilscher

read/write 1..256 bytes

Notes

No connection parameterisation

required in the external controller.

No connection parameterisation

required in the external controller.

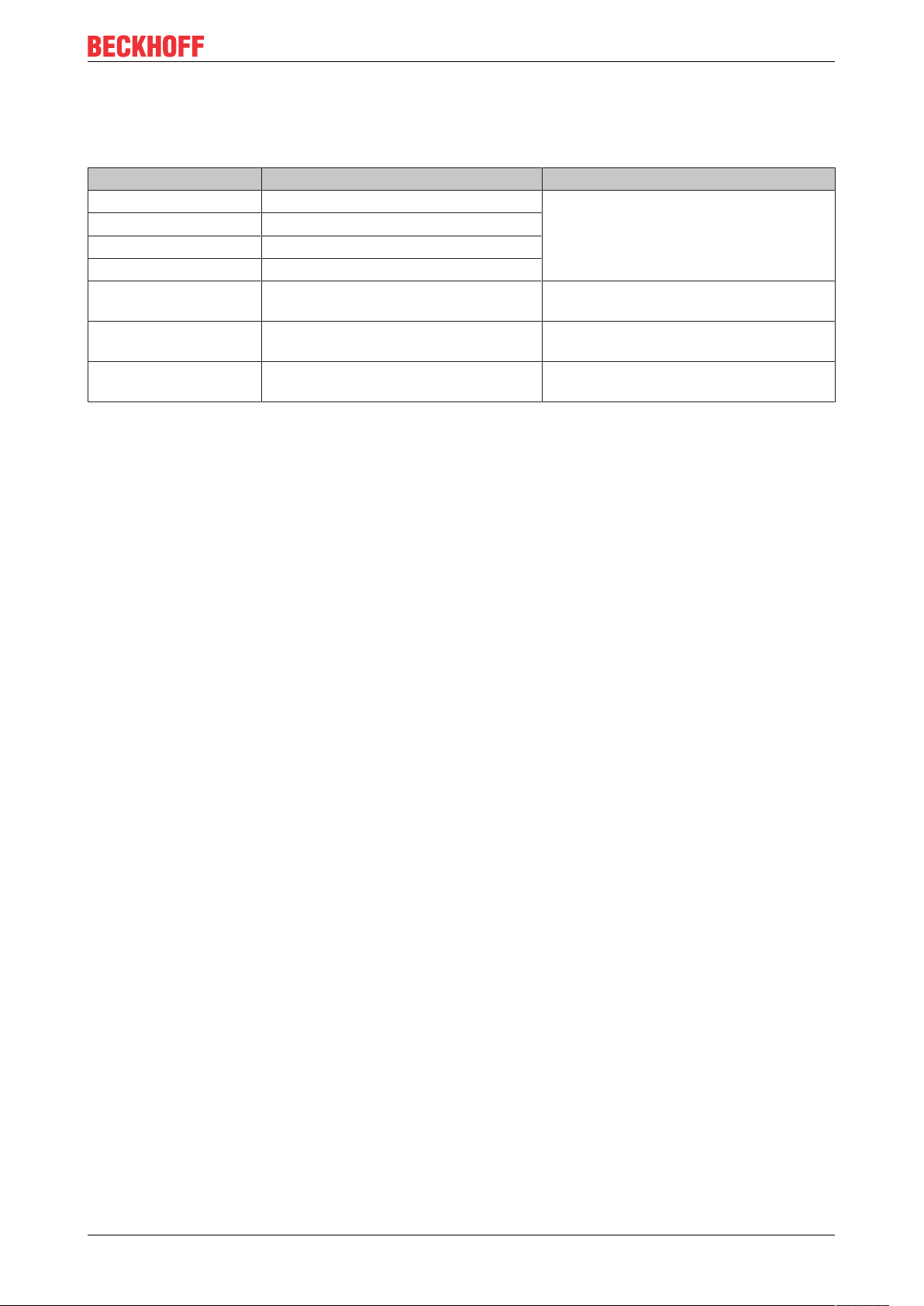

NetLink MPI protocol (NL-MPI) from Hilscher

• This protocol can only be used with S7 controllers.

• The TCP/IP port number has the default value 1099

• The MPI address (devAddr) has the default value 2. Permissible values: 1..126;

• The data block number (nDB) is only evaluated when the data blocks (DB) data area is accessed.

Permissible values: 0..65534;

TF661018 Version: 1.1

Page 19

Description of the PLC data area parameter values

• The areas P (periphery) and DX (extended data block) are not supported.

• The byte length has to be specified for the data length parameter (cbBuffer).

• The OS area (operating state) is only available for read access.

Data area (eArea) Start address (nOffset) Permitted data length (cbBuffer)

DB Data byte offset: 0..65534 Read: max. 222 bytes, write: max. 216

M Flag byte offset: 0..65534

I Input byte offset: 0..65534

Q Output byte offset: 0..65534

C Counter start offset: 0..65534 Read: max. 111 word counters, write:

T Timer start offset: 0..65534 Read: max. 111 word timers, write: max.

OS Operating state: Irrelevant 1 word (0=STOP, 1=START, 2=RUN,

bytes

max. 108 counters

108 timers

3=UNKNOWN)

TF6610 19Version: 1.1

Page 20

API

6 API

6.1 PLC Reference

6.1.1 Function blocks

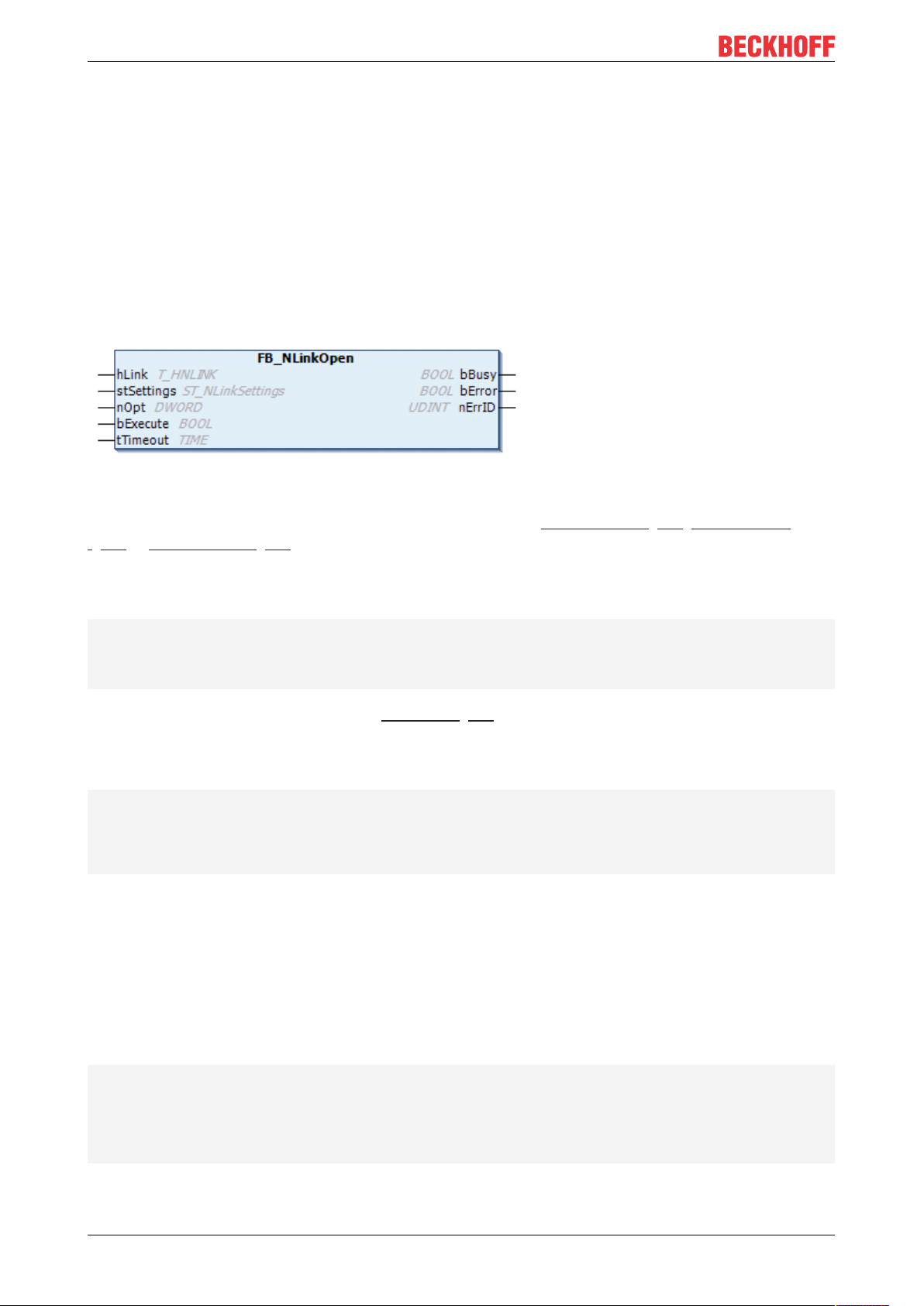

6.1.1.1 FB_NLinkOpen

This function block (actively) establishes a network connection to the third-party system. If successful, the

internal parameters of the hLink variable are initialised. The same instance of the hLink variable must then

be transferred to the other instances of the communication blocks FB_NLinkFetch [}22], FB_NLinkWrite

[}24] or FB_NLinkClose [}21]. In a PLC application one instance of this variables is required for each

network connection (TwinCAT system<->Ethernet LAN adapter<->external controller).

VAR_IN_OUT

VAR_IN_OUT

hLink : T_HNLINK;

END_VAR

hLink : Network connection handle ( Type:T_HNLINK [}29]). The instance of this variable is required by the

other communication blocks and is transferred to them via VAR_IN_OUT.

VAR_INPUT

VAR_INPUT

stSettings:ST_NLinkSettings:=(sHost:='127.0.0.1',nPort:=2002);

nOpt:DWORD:=0;

bExecute:BOOL;

tTimeout:TIME:=T#45s;

END_VAR

stSettings: Structure with configuration settings for the communication connection. The member variables of

this structure should contain parameters such as port number, host name, etc.

nOpt: Reserved for future applications.

bExecute: The block is activated by a rising edge at this input.

tTimeout: Specifies the timeout that must not be exceeded on receipt of the command.

VAR_OUTPUT

VAR_OUTPUT

bBusy : BOOL;

bError : BOOL;

nErrID : UDINT;

END_VAR

TF661020 Version: 1.1

Page 21

API

bBusy: When the function block is activated this output is set. It remains set until a feedback is received.

While Busy = TRUE, no new command will be accepted at the inputs. Please note that it is not the command

execution but the receipt of the command that is monitored.

bError: In the event of an error during the command transfer, this output is set once the bBusy output has

been reset.

nErrID: Supplies the error number [}32] when the bError output is set.

Example:

See examples [}31].

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

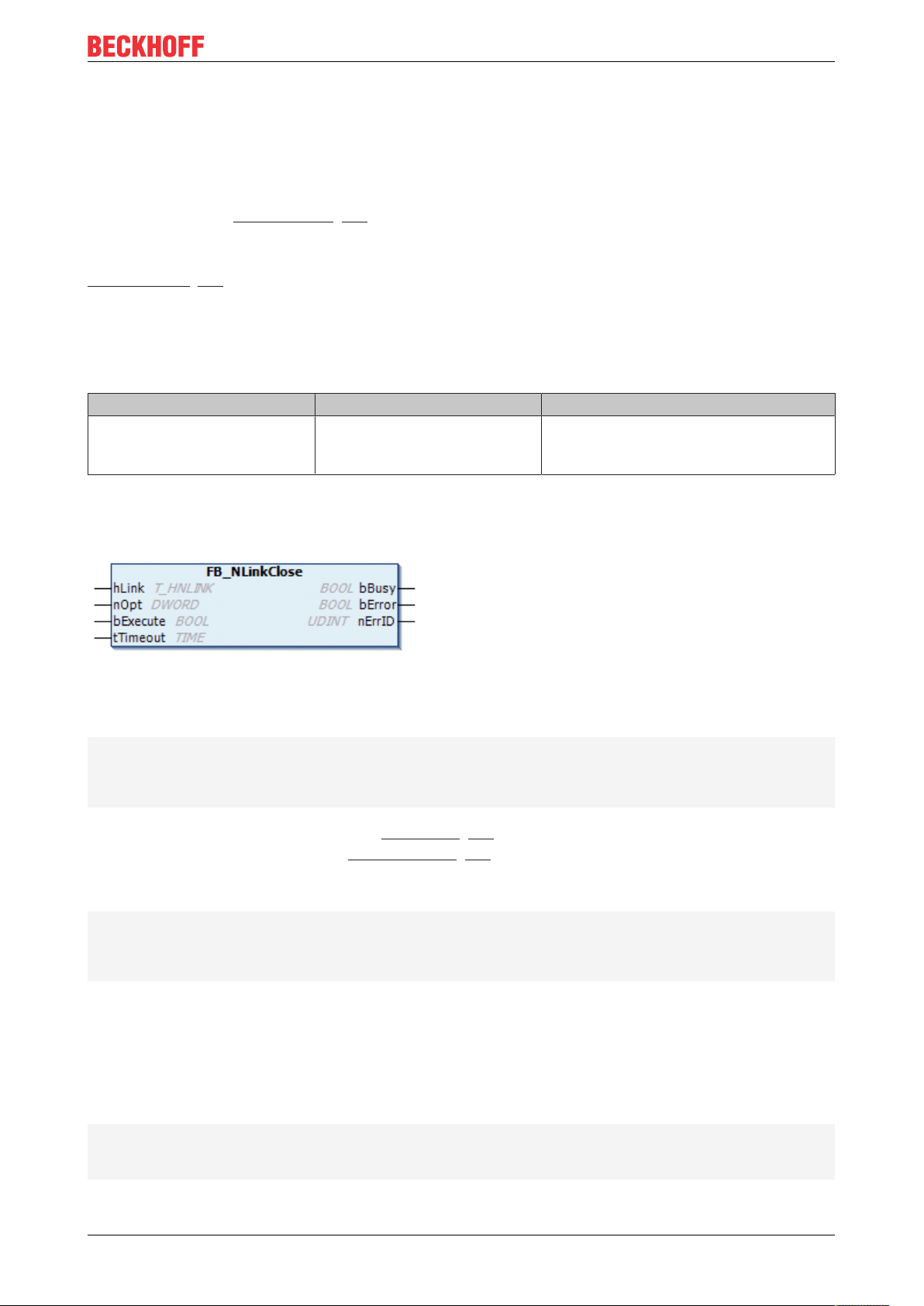

6.1.1.2 FB_NLinkClose

This function block closes the network connection to the third-party system.

VAR_IN_OUT

VAR_IN_OUT

hLink : T_HNLINK;

END_VAR

hLink : Network connection handle ( Type:T_HNLINK [}29]). This is where the instance of the variable used

for establishing the connection by the FB_NLinkOpen [}20] function block is transferred.

VAR_INPUT

VAR_INPUT

nOpt:DWORD:=0;

bExecute:BOOL;

tTimeout:TIME:=DEFAULT_ADS_TIMEOUT;

END_VAR

nOpt: Reserved for future applications.

bExecute: The block is activated by a rising edge at this input.

tTimeout: Specifies the timeout that must not be exceeded on receipt of the command.

VAR_OUTPUT

VAR_OUTPUT

bBusy : BOOL;

bError : BOOL;

TF6610 21Version: 1.1

Page 22

API

nErrID : UDINT;

END_VAR

bBusy: When the function block is activated this output is set. It remains set until a feedback is received.

While Busy = TRUE, no new command will be accepted at the inputs. Please note that it is not the command

execution but the receipt of the command that is monitored.

bError: In the event of an error during the command transfer, this output is set once the bBusy output has

been reset.

nErrID: Supplies the error number [}32] when the bError output is set.

Example:

See examples [}31].

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

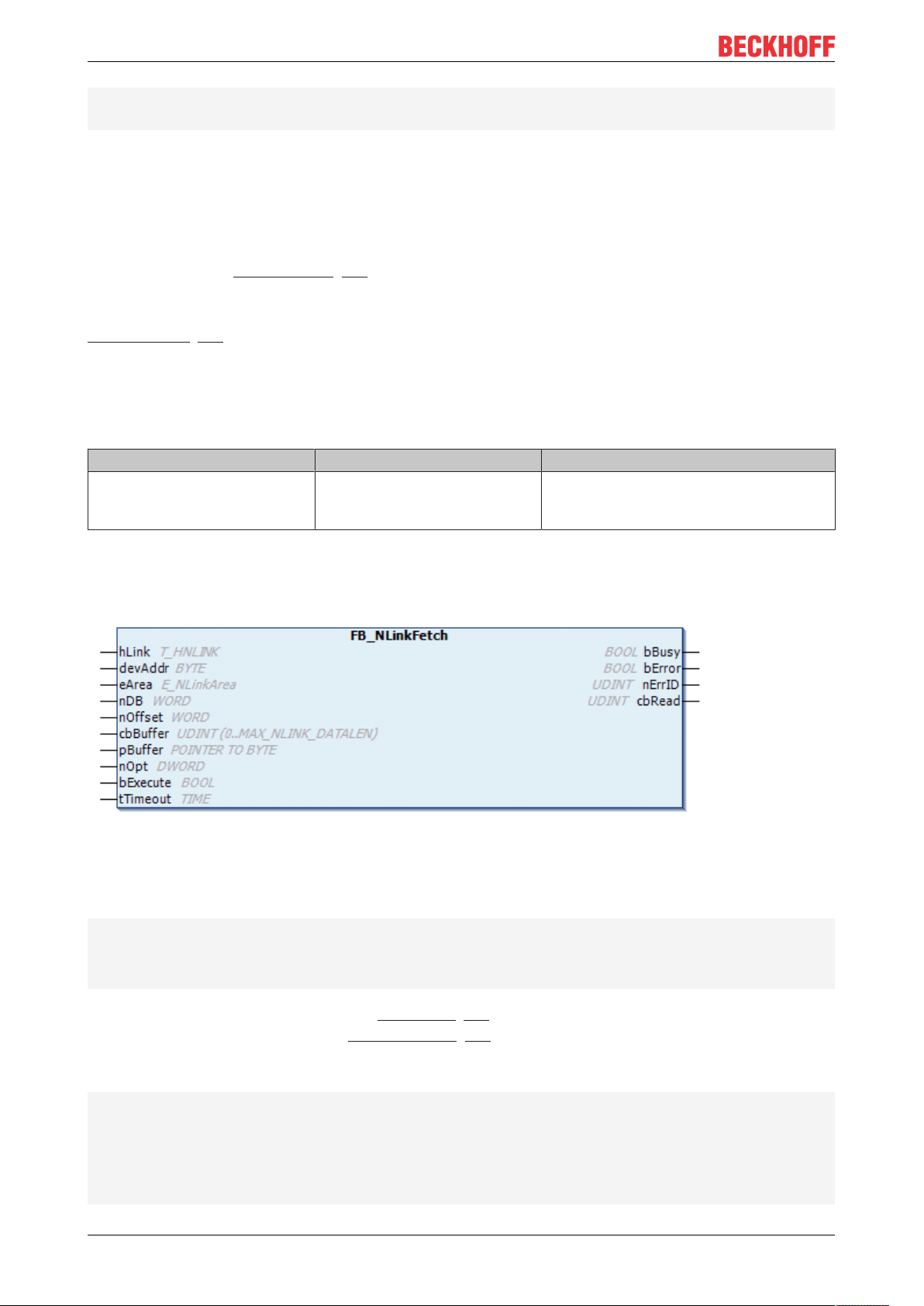

6.1.1.3 FB_NLinkFetch

This function block reads data from the third-party system and writes them to the local TwinCAT system

(FETCH service).

VAR_IN_OUT

VAR_IN_OUT

hLink : T_HNLINK;

END_VAR

hLink : Network connection handle (Type:T_HNLINK [}29]). This is where the instance of the variable used

for establishing the connection by the FB_NLinkOpen [}20] function block is transferred.

VAR_INPUT

VAR_INPUT

devAddr:BYTE:=2;

eArea:E_NLinkArea:=eNLinkArea_DB;

nDB:WORD:=0;

nOffset:WORD:=0;

cbBuffer:UDINT(0..MAX_NLink_DATALENGTH):=0;

pBuffer:POINTERTOBYTE:=0;

nOpt:DWORD:=0;

TF661022 Version: 1.1

Page 23

API

bExecute:BOOL;

tTimeout:TIME:=DEFAULT_ADS_TIMEOUT;

END_VAR

devAddr: Device address, MPI address of the component on the third-party system.

eArea: PLC data area in the third-party system (inputs, outputs, data block etc.) from which data are to be

read (type:E_NLinkArea [}26]).

nDB: Data block number in the third-party system. Data are to be read from this data block (only relevant for

access to data blocks and extended data blocks).

nOffset: The start byte address or word address from which data are to be read in the third-party system.

Whether a byte or word address is to be specified depends on the type of external controller/protocol used

and the data area to be accessed. Further information can be found here: Description of the PLC data area

parameter values [}18].

cbBuffer: Maximum number of data bytes to be read. The byte length is specified even for access to word

addresses.

pBuffer: Pointer/address of the target data buffer in the TwinCAT system. The read data are written into this

buffer. The address can be determined with the ADR operator. The target data buffer must not be smaller

than the specified length of the data to be read.

nOpt: Reserved for future applications.

bExecute: The block is activated by a rising edge at this input.

tTimeout: Specifies the timeout that must not be exceeded on receipt of the command.

VAR_OUTPUT

VAR_OUTPUT

bBusy : BOOL;

bError : BOOL;

nErrID : UDINT;

cbRead : UDINT := 0; (* Number of recend realy returned data bytes *)

END_VAR

bBusy: When the function block is activated this output is set. It remains set until a feedback is received.

While Busy = TRUE, no new command will be accepted at the inputs. Please note that it is not the command

execution but the receipt of the command that is monitored.

bError: In the event of an error during the command transfer, this output is set once the bBusy output has

been reset.

nErrID: Supplies the error number [}32] when the bError output is set.

cbRead: Number of successfully read data bytes.

Example:

See examples [}31].

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

TF6610 23Version: 1.1

Page 24

API

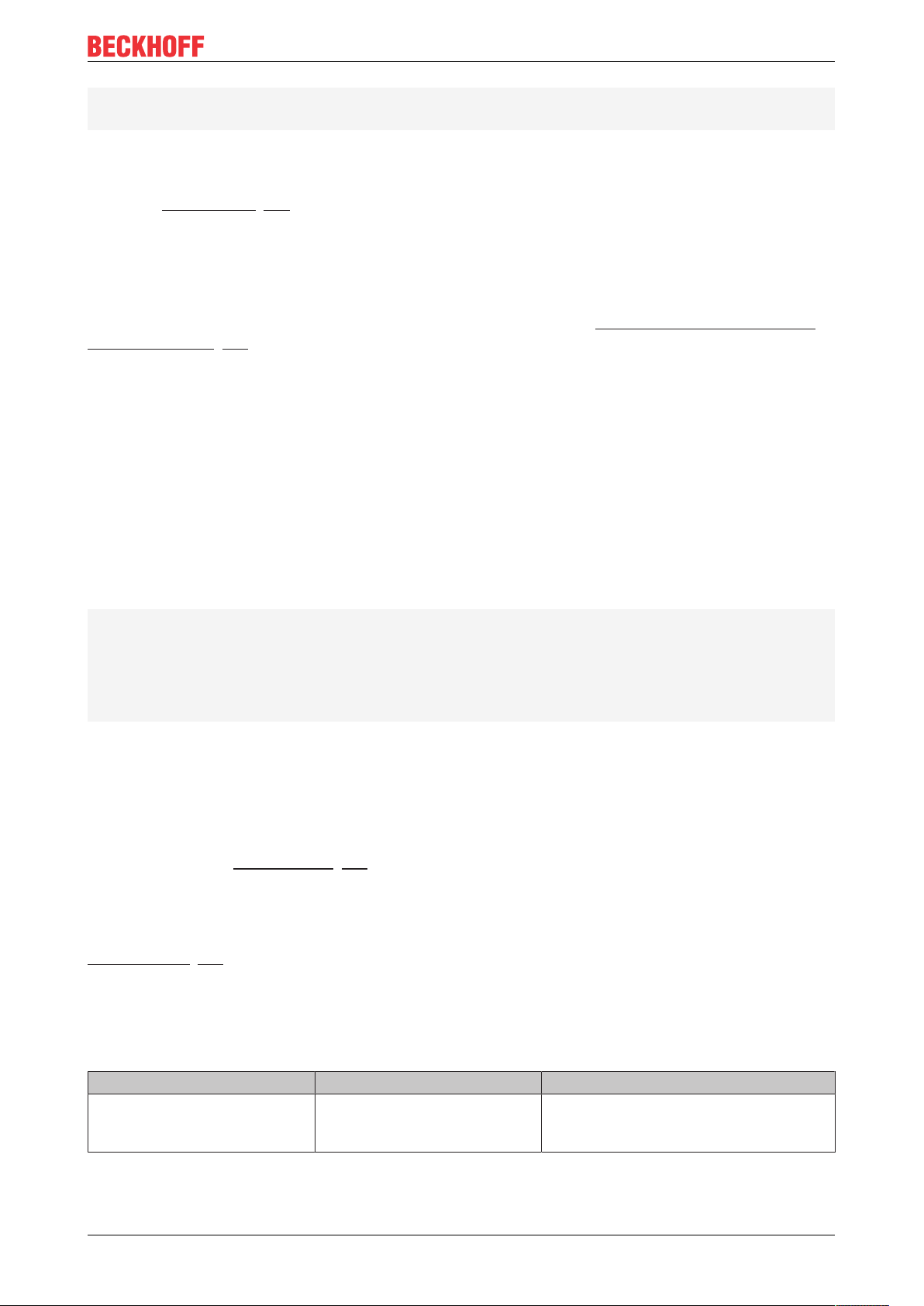

6.1.1.4 FB_NLinkWrite

This function block sends data from the local TwinCAT system to the third-party system (WRITE service).

VAR_IN_OUT

VAR_IN_OUT

hLink : T_HNLINK;

END_VAR

hLink : Network connection handle ( Type:T_HNLINK [}29]). This is where the instance of the variable used

for establishing the connection by the FB_NLinkOpen [}20] function block is transferred.

VAR_INPUT

VAR_INPUT

devAddr:BYTE:=2;

eArea:E_NLinkArea:=eNLinkArea_DB;

nDB:WORD:=0;

nOffset:WORD:=0;

cbBuffer:UDINT(0..MAX_NLink_DATALENGTH):=0;

pBuffer:POINTERTOBYTE:=0;

nOpt:DWORD:=0;

bExecute:BOOL;

tTimeout:TIME:=DEFAULT_ADS_TIMEOUT;

END_VAR

devAddr: Device address, MPI address of the component on the third-party system.

eArea: PLC data area in the third-party system (inputs, outputs, data block, etc.) to which data are to be

written (type:E_NLinkArea [}26])

nDB: Data block number in the third-party system. Block in which data are to be written (only relevant for

access to data blocks and extended data blocks).

nOffset: The start byte address or word address from which data are to be written to the third-party system.

Whether a byte or word address is to be specified depends on the type of external controller/protocol used

and the data area to be accessed. Further information can be found here: Description of the PLC data area

parameter values [}18].

cbBuffer: Maximum byte length of the data to be transferred from the source data buffer in the local

TwinCAT system to the third-party system. The byte length is specified even for access to word addresses.

pBuffer: Pointer/address for the source data buffer. Data from this buffer are transferred to the third-party

system. The address can be determined with the ADR operator. The source data buffer must not be smaller

than the specified length of the data to be sent.

nOpt: Reserved for future applications.

bExecute: The block is activated by a rising edge at this input.

tTimeout: Specifies the timeout that must not be exceeded on receipt of the command.

TF661024 Version: 1.1

Page 25

API

VAR_OUTPUT

VAR_OUTPUT

bBusy : BOOL;

bError : BOOL;

nErrID : UDINT;

cbWrite : UDINT := 0;(* Number of successfull written data bytes *)

END_VAR

bBusy: When the function block is activated this output is set. It remains set until a feedback is received.

While Busy = TRUE, no new command will be accepted at the inputs. Please note that it is not the command

execution but the receipt of the command that is monitored.

bError: In the event of an error during the command transfer, this output is set once the bBusy output has

been reset.

nErrID: Supplies the error number [}32] when the bError output is set.

cbWrite: In case of success: Number of successfully written data bytes.

Example:

See examples [}31].

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

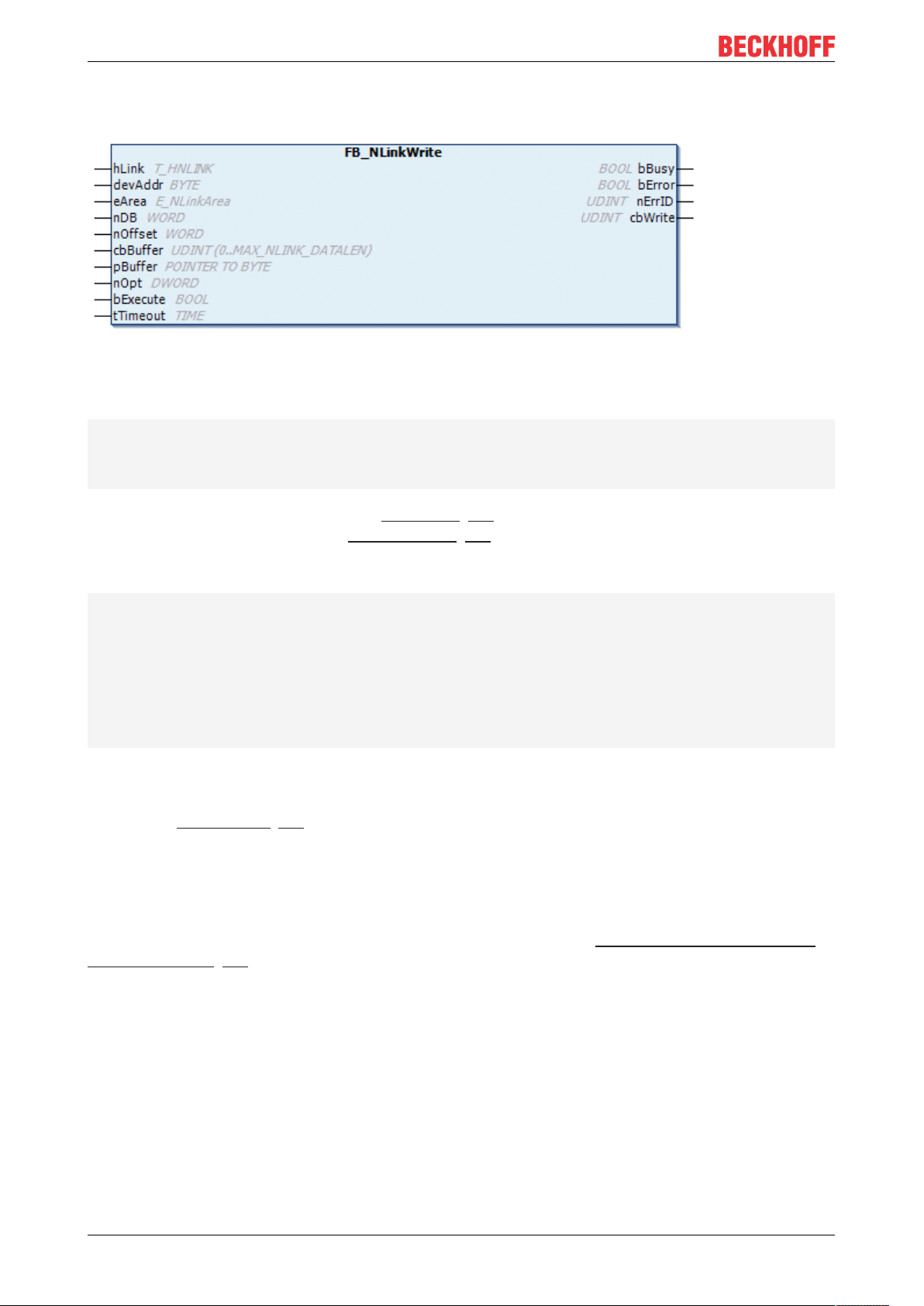

6.1.2 Functions [obsolete]

6.1.2.1 F_GetVersionTcS5S7Comm

This function can be used to read PLC library version information.

FUNCTION F_GetVersionTcS5S7Comm : UINT

VAR_INPUT

nVersionElement:INT;

END_VAR

nVersionElement : Version element to be read. Possible parameter:

• 1 : major number;

• 2 : minor number;

• 3 : revision number;

TF6610 25Version: 1.1

Page 26

API

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3 Data Types

6.1.3.1 E_NLinkArea

TYPEE_NLinkArea:

(

eNLinkArea_DB:=16#01,(* Source/dest. data from/to data block in main memory. *)

eNLinkArea_M:=16#02,(* Source/dest. data from/to flag area. *)

eNLinkArea_I:=16#03,(* Source/dest. data from/to process image of the inputs. *)

eNLinkArea_Q:=16#04,(* Source/dest. data from/to process image of the outputs. *)

eNLinkArea_P:=16#05,(* Source/dest. data from/to in I/O modules (S7 only PI, PQ). *)

eNLinkArea_C:=16#06,(* Source/dest. data from/to counter cells. *)

eNLinkArea_T:=16#07,(* Source/dest. data from/to timer cells. *)

eNLinkArea_DX:=16#0A,(* Source/dest. data from/to extended data block. *)

eNLinkArea_OS:=16#100(* Read PLC operational status information *)

);

END_TYPE

PLC data area (inputs, outputs, flag, data block etc.) to be accessed. The parameter values differ depending

on the type of external control used, the adapter or the communication protocol. Some data areas may not

be available, or the data have to be read/written word by word instead of byte by byte .

More detailed information on this topic can be found under: S5/S7 data area parameter values [}18].

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3.2 E_NLinkProtocol

TYPE E_NLinkProtocol:

(

eNLinkProtocol_IBH_SX_PP := 0, (* IBH Link protocol (used by IBH Link S5++ adater) *)

eNLinkProtocol_MPI (* Hilscher NL-MPI protocol (used only by IBH Link S7++ adapter) *)

);

END_TYPE

Communication protocol (depends on the hardware used).

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

TF661026 Version: 1.1

Page 27

6.1.3.3 E_NLinkTransport

TYPE E_NLinkTransport:

(

eNLinkTransport_TCPIP:=0

);

END_TYPE

Transport protocol (determines how the data are to be transported). Only the stream-oriented TCP/IP

protocol is supported at present.

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3.4 E_NLinkOpState

TYPE E_NLinkOpState:

(

eNLinkOpState_STOP:=0,

eNLinkOpState_START:=1,

eNLinkOpState_RUN:=2,

eNLinkOpState_UNKNOWN:=3

);

END_TYPE

API

Operational state (only S7);

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3.5 ST_NLinkDebug

Via these parameters the debug outputs can be activated/deactivated during troubleshooting (standard

setting: inactive)

The debug outputs are shown in the log view of the TwinCAT System Manager.

TYPEST_NLinkDebug:

STRUCT

eTx:E_DbgDirection:=eDbgDirection_OFF;

eRx:E_DbgDirection:=eDbgDirection_OFF;

bState:BOOL:=TRUE;

END_STRUCT

END_TYPE

eTx: Activates/deactivates the debug output for the send buffer (Type: E_DbgDirection).

eRx: Activates/deactivates the debug output for the receive buffer (Type: E_DbgDirection).

bState: Activates/deactivates status messages when establishing or closing the socket connection.

TF6610 27Version: 1.1

Page 28

API

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3.6 ST_NLinkSettings

TYPE ST_NLinkSettings:

STRUCT

sSrvNetID:T_AmsNetID:='';

eProtocol:E_NLinkProtocol:=eNLinkProtocol_IBH_SX_PP;

eTransport:E_NLinkTransport:=eNLinkTransport_TCPIP;

sHost:T_IPv4Addr:='127.0.0.1';

nPort:UDINT:=2002;

local_T_selector:STRING:='00 01';

remote_T_selector:STRING:='00 01';

bServer:BOOL:=FALSE;

bThrottle:BOOL:=FALSE;

debug:ST_NLinkDebug;

END_STRUCT

END_TYPE

sSrvNetID: TwinCAT network address of the TwinCAT TCP/IP connection server (default = empty string,

type: T_AmsNetId).

eProtocol: The communication protocol to be used is set via this parameter (type: E_NLinkProtocol [}26]).

eTransport: The transport protocol to be used is set via this parameter (type: E_NLinkTransport [}27]).

sHost: String containing the network address (Ipv4) of the communication partner (default = ‘127.0.0.1’,

type: T_IPv4Addr).

nPort: Internet Protocol (IP) port (default = 2002).

local_T_selector : Local TSAP address (reserved).

remote_T_selector : Remote TSAP address (reserved).

bServer: FALSE = client (active) connection. TRUE = server (passive) connection. Currently only client

connections are permitted.

bThrottle: If this parameter is set, the number of polling socket calls is reduced if no or few data are

received, i.e. the poll cycle is slowed down, thereby reducing the system load (default = FALSE).

debug: Optional debug output settings(type:ST_NLinkDebug [}27]).

Hint!

Background information about the configuration of eProtocol- and eTransport parameter:

The IBHsoftec S7++ adapter is supporting more than one communication protocol (channel) to S7 controller.

• Using the Hilscher MPI-Protokoll + TCP/IP as transport protocol.

• Using the IBHsoftec S5++/S7++ protocol + RFC1006 as transport protocol.

The TwinCAT S5/S7 communication library is supporting only the first communication channel (using TCP/IP

transport protocol).

If you want to communicate with S7 controller then use this settings:

eProtocol := eNLinkProtocol_MPI;

eTransport := eNLinkTransport_TCPIP;

If you want to communicate with S5 controller then use this settings:

TF661028 Version: 1.1

Page 29

API

eProtocol := eNLinkProtocol_IBH_SX_PP;

eTransport := eNLinkTransport_TCPIP;

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.3.7 T_HNLINK

A variable of this type represents a network connection handle. The structural elements should not be written

to or modified directly. Variables of this type are used for internal data exchange.

One instance is required for each network connection (TwinCAT system<->Ethernet LAN adapter<->external

controller). The same instance is then transferred to other communication blocks as VAR_IN_OUT

parameter.

TYPE T_HNLINK :

STRUCT

END_STRUCT

END_TYPE

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.4 Global Constants

6.1.4.1 Overview

Name Value Description

MAX_NLINK_BUFFER_SIZE 16#FFFF Max. internal buffer size for RX/TX (64k)

MAX_NLINK_DATALEN 2048 Max. data length supported by the PLC blocks for

transfers. The actual max. length may be smaller due to

specific device characteristics.

MAX_NLINK_HEADERLEN 16 Max. length of the frame header for the NL-MPI and

IBHNet protocols.

MAX_NLINK_MPI_CONNECTIONS16 Max. number of open MPI connections. If this number is

exceeded, the oldest connections are closed

automatically.

TF6610 29Version: 1.1

Page 30

API

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

6.1.4.2 Library version

All libraries have a specific version. This version is shown in the PLC library repository too.

A global constant contains the library version information:

Global_Version

VAR_GLOBAL CONSTANT

stLibVersion_Tc2_S5S7Com : ST_LibVersion;

END_VAR

stLibVersion_Tc2_S5S7Com: version information of Tc2_S5S7Com library (type: ST_LibVersion).To

compare the existing version to a required version the function F_CmpLibVersion (defined in Tc2_System

library) is offered.

Hint: All other possibilities known from TwinCAT2 libraries to query a library version are obsolete!

Requirements

Development environment Target platform PLC libraries to include

TwinCAT V3.1.4016 or higher PC oder CX (x86, x64, ARM) Tc2_S5S7Com (Communication->TcpIp)

Tc2_TcpIp (Communication->TcpIp)

Tc2_Utilities (System)

TF661030 Version: 1.1

Page 31

7 Samples

The communication parameters in the project examples must be set to match your configuration.

Samples

PLC project Third-party

system

https://

infosys.beckh

off.com/

content/1033/

tf6610_tc3_s5

s7communicat

ion/

Resources/

zip/70701953

1.zip

https://

infosys.beckh

off.com/

content/1033/

tf6610_tc3_s5

s7communicat

ion/

Resources/

zip/70702260

3.zip

S5 Ethernet adapter:

S7 Ethernet adapter:

Adapter Communication

parameters

• Protocol: IBH S5

IBH Link S5++

IBH Link S7++

LAN Link

protocol

• Transport: TCP/

IP

• IP address:

'172.17.60.243'

• Port number:

2002

• Protocol:

NetLink MPI

protocol (NLMPI)

• Transport: TCP/

IP

• IP address:

'172.17.60.243'

• Port number:

1099

• MPI address: 2

Data area parameter values

• Data area: DB

• Data block

number: 16

• Write 1 word (2

bytes) from the

start address

(word offset): 9

• Read 10 words

(20 bytes) from

the start address

(word offset): 0

• Data area: DB

• Data block

number: 1

• Write 10 bytes

from the start

address (byte

offset): 0

• Read 10 bytes

from the start

address (byte

offset): 0

Description

The data in the

data block are

accessed word

by word.

The data in the

data block are

accessed byte

by byte. In

addition to the

selected data

area the

operating status

of the controller

is read (STOP,

RUN, START...).

TF6610 31Version: 1.1

Page 32

Appendix

8 Appendix

8.1 Error codes overview

Codes (hex) Codes (dec) Error source Description

0x00000000-0x00007800 0-30720

0x00008000-0x000080FF 32768-33023 Internal TwinCAT TCP/IP

0x00008300-0x000085FF 33536-34303

0x80070000-0x8007FFFF 2147942400-2148007935 Error source = Code -

TwinCAT system error

codes [}35]

Connection Server error

codes

Internal TwinCAT S5/S7

communication error

codes [}33]

0x80070000 = Win32

system error codes.

The low word of the error

code includes the Win32

Error Codes [}40]

TwinCAT system error

(including ADS error

codes)

Internal error of the

TwinCAT TCP/IP

Connection Server

Internal error in the S5/S7

Ethernet/LAN module or

the TwinCAT PLC library

Win32 system error

(including Windows

sockets error codes).

Please seach in the

Win32 Error Codes list for

the low word of the error

code.

TF661032 Version: 1.1

Page 33

8.2 Internal S5/S7 communication error codes

Appendix

TF6610 33Version: 1.1

Page 34

Appendix

Code

(hex)

0x00000000 0 NLINK_COMMERR_NOERROR No error.

0x00008300 33536 NLINK_COMMERR_TIMEOUT Timeout during communication

0x00008301 33537 NLINK_COMMERR_TXOVERFLOW Send buffer overflow

0x00008302 33538 NLINK_COMMERR_RXOVERFLOW Receive buffer overflow

0x00008303 33539 NLINK_COMMERR_FATAL Fatal internal error

0x00008304 33540 NLINK_COMMERR_SYSTEMID Invalid system ID

0x00008305 33541 NLINK_COMMERR_HEADERLEN Invalid header length parameter

0x00008306 33542 NLINK_COMMERR_OPCODE Invalid OP code, OP code length or OP

0x00008307 33543 NLINK_COMMERR_INVALIDSIZE Invalid data length

0x00008308 33544 NLINK_COMMERR_INVALIDSTATE Device or connection is in a faulty/invalid

0x00008309 33545 NLINK_COMMERR_INVALIDVALUE An invalid parameter value was specified

0x0000830A 33546 NLINK_COMMERR_INVALIDAREA Invalid/unsupported data area

0x0000830B 33547 NLINK_COMMERR_UNEXPTECTED Unexpected error

0x00008402 33794 NLINK_COMMERR_IBH_AREA_NOT_

0x00008403 33795 NLINK_COMMERR_IBH_AREA_TO_S

0x00008406 33798 NLINK_COMMERR_IBH_INVALID_HE

0x00008407 33799 NLINK_COMMERR_IBH_DATA_OVER

0x00008409 33801 NLINK_COMMERR_IBH_TIMEOUT Timeout during communication with the

0x0000840A 33802 NLINK_COMMERR_IBH_DATA_UNDE

0x00008501 34049 NLINK_COMMERR_MPI_UE Timeout from remote station remote

0x00008502 34050 NLINK_COMMERR_MPI_RR Resource unavailable remote station

0x00008503 34051 NLINK_COMMERR_MPI_RS Requested function of master is not

0x00008511 34065 NLINK_COMMERR_MPI_NA No response of the remote station remote

0x00008512 34066 NLINK_COMMERR_MPI_DS Master not into the logical token ring

Code

(dec)

Symbolic constant Description

General error codes Offset 0x8300 + error code

(transaction)

code word

state

IBH Link S5++ specific error codes Offset 0x8400 + error code

Data area not available in the controller,

AVAILABLE

MALL

ADER

FLOW

RFLOW

Hilscher NL-MPI interface error

codes

data block not available

Requested area is too small

Invalid frame/header format

Permitted data size exceeded, data buffer

too small

controller

Too few data were received

Offset 0x8500 + MPI response

message error code

station remote station has not responded

within 1 sec.timeout

remote station has no left buffer space for

the requested service

activated within the remote station. The

connection seems to be closed in the

remote station. Try to send command

again

station check network wiring, check

remote address, check baud rate

network in general check master DPAddress or highest-station-Addres s of

other masters. Examine bus wiring to bus

short circuits

TF661034 Version: 1.1

Page 35

Appendix

Code

(hex)

0x00008514 34068 NLINK_COMMERR_MPI_LR Resource of the local FDL controller not

0x00008515 34069 NLINK_COMMERR_MPI_IV The specified msg.data_cnt parameter

0x00008530 34096 NLINK_COMMERR_MPI_TO Timeout, the request message was

0x00008539 34105 NLINK_COMMERR_MPI_SE Sequence fault, internal state machine

0x00008585 34181 NLINK_COMMERR_MPI_REJ_IV Specified offset address out of limits or

0x00008586 34182 NLINK_COMMERR_MPI_REJ_PDU Wrong PDU coding in the MPI response

0x00008587 34183 NLINK_COMMERR_MPI_REJ_OP Specified length to write or to read results

0x00008588 34184 NLINK_COMMERR_MPI_REJ_OP Specified address not defined in the

0x00008589 34185 NLINK_COMMERR_MPI_REJ_OP MPI remote station not in the right

Code

(dec)

Symbolic constant Description

General error codes Offset 0x8300 + error code

available or not sifficient. HOST too many

messages. no more segments in DEVICE

free

invalid HOST check the limit of 222 bytes

(read) respectively 216 bytes (write) in

msg.data_cnt

accepted but no indication is sent back by

the remote station remote station MPI

protocol error, or station not presentor

error. Remote station does not react like

awaited or a reconnection was retried

while connection is already open or

device has no SAPs left to open

connection channel

not known in the remote station HOST

please check msg.data_adr if present or

offset parameter in request message

of the remote station DEVICE contact

hotline

in an access outside the limits HOST

please check msg.data_cnt length in

request message

remote station, please check

msg.data_adr in the request message

operational mode, bring S7 into RUN-P

Mode

8.3 ADS Return Codes

Grouping of error codes: 0x000 [}35]..., 0x500 [}36]..., 0x700 [}37]..., 0x1000 [}39]...

Global error codes

TF6610 35Version: 1.1

Page 36

Appendix

Hex Dec HRESULT Name Description

0x0 0 0x9811 0000 ERR_NOERROR No error.

0x1 1 0x9811 0001 ERR_INTERNAL Internal error.

0x2 2 0x9811 0002 ERR_NORTIME No real-time.

0x3 3 0x9811 0003 ERR_ALLOCLOCKEDMEM Allocation locked – memory error.

0x4 4 0x9811 0004 ERR_INSERTMAILBOX Mailbox full – the ADS message could not be sent.

0x5 5 0x9811 0005 ERR_WRONGRECEIVEHMSG Wrong HMSG.

0x6 6 0x9811 0006 ERR_TARGETPORTNOTFOUND Target port not found – ADS server is not started or

0x7 7 0x9811 0007 ERR_TARGETMACHINENOTFOUND Target computer not found – AMS route was not

0x8 8 0x9811 0008 ERR_UNKNOWNCMDID Unknown command ID.

0x9 9 0x9811 0009 ERR_BADTASKID Invalid task ID.

0xA 10 0x9811 000A ERR_NOIO No IO.

0xB 11 0x9811 000B ERR_UNKNOWNAMSCMD Unknown AMS command.

0xC 12 0x9811 000C ERR_WIN32ERROR Win32 error.

0xD 13 0x9811 000D ERR_PORTNOTCONNECTED Port not connected.

0xE 14 0x9811 000E ERR_INVALIDAMSLENGTH Invalid AMS length.

0xF 15 0x9811 000F ERR_INVALIDAMSNETID Invalid AMS Net ID.

0x10 16 0x9811 0010 ERR_LOWINSTLEVEL Installation level is too low –TwinCAT 2 license er-

0x11 17 0x9811 0011 ERR_NODEBUGINTAVAILABLE No debugging available.

0x12 18 0x9811 0012 ERR_PORTDISABLED Port disabled – TwinCAT system service not

0x13 19 0x9811 0013 ERR_PORTALREADYCONNECTED Port already connected.

0x14 20 0x9811 0014 ERR_AMSSYNC_W32ERROR AMS Sync Win32 error.

0x15 21 0x9811 0015 ERR_AMSSYNC_TIMEOUT AMS Sync Timeout.

0x16 22 0x9811 0016 ERR_AMSSYNC_AMSERROR AMS Sync error.

0x17 23 0x9811 0017 ERR_AMSSYNC_NOINDEXINMAP No index map for AMS Sync available.

0x18 24 0x9811 0018 ERR_INVALIDAMSPORT Invalid AMS port.

0x19 25 0x9811 0019 ERR_NOMEMORY No memory.

0x1A 26 0x9811 001A ERR_TCPSEND TCP send error.

0x1B 27 0x9811 001B ERR_HOSTUNREACHABLE Host unreachable.

0x1C 28 0x9811 001C ERR_INVALIDAMSFRAGMENT Invalid AMS fragment.

0x1D 29 0x9811 001D ERR_TLSSEND TLS send error – secure ADS connection failed.

0x1E 30 0x9811 001E ERR_ACCESSDENIED Access denied – secure ADS access denied.

Reducing the number of ADS messages per cycle

will help.

is not reachable.

found.

ror.

started.

Router error codes

Hex Dec HRESULT Name Description

0x500 1280 0x9811 0500 ROUTERERR_NOLOCKEDMEMORY Locked memory cannot be allocated.

0x501 1281 0x9811 0501 ROUTERERR_RESIZEMEMORY The router memory size could not be changed.

0x502 1282 0x9811 0502 ROUTERERR_MAILBOXFULL The mailbox has reached the maximum number of

0x503 1283 0x9811 0503 ROUTERERR_DEBUGBOXFULL The Debug mailbox has reached the maximum

0x504 1284 0x9811 0504 ROUTERERR_UNKNOWNPORTTYPE The port type is unknown.

0x505 1285 0x9811 0505 ROUTERERR_NOTINITIALIZED The router is not initialized.

0x506 1286 0x9811 0506 ROUTERERR_PORTALREADYINUSE The port number is already assigned.

0x507 1287 0x9811 0507 ROUTERERR_NOTREGISTERED The port is not registered.

0x508 1288 0x9811 0508 ROUTERERR_NOMOREQUEUES The maximum number of ports has been reached.

0x509 1289 0x9811 0509 ROUTERERR_INVALIDPORT The port is invalid.

0x50A 1290 0x9811 050A ROUTERERR_NOTACTIVATED The router is not active.

0x50B 1291 0x9811 050B ROUTERERR_FRAGMENTBOXFULL The mailbox has reached the maximum number for

0x50C 1292 0x9811 050C ROUTERERR_FRAGMENTTIMEOUT A fragment timeout has occurred.

0x50D 1293 0x9811 050D ROUTERERR_TOBEREMOVED The port is removed.

possible messages.

number of possible messages.

fragmented messages.

TF661036 Version: 1.1

Page 37

General ADS error codes

Appendix

TF6610 37Version: 1.1

Page 38

Appendix

Hex Dec HRESULT Name Description

0x700 1792 0x9811 0700 ADSERR_DEVICE_ERROR General device error.

0x701 1793 0x9811 0701 ADSERR_DEVICE_SRVNOTSUPP Service is not supported by the server.

0x702 1794 0x9811 0702 ADSERR_DEVICE_INVALIDGRP Invalid index group.

0x703 1795 0x9811 0703 ADSERR_DEVICE_INVALIDOFFSET Invalid index offset.

0x704 1796 0x9811 0704 ADSERR_DEVICE_INVALIDACCESS Reading or writing not permitted.

0x705 1797 0x9811 0705 ADSERR_DEVICE_INVALIDSIZE Parameter size not correct.

0x706 1798 0x9811 0706 ADSERR_DEVICE_INVALIDDATA Invalid data values.

0x707 1799 0x9811 0707 ADSERR_DEVICE_NOTREADY Device is not ready to operate.

0x708 1800 0x9811 0708 ADSERR_DEVICE_BUSY Device is busy.

0x709 1801 0x9811 0709 ADSERR_DEVICE_INVALIDCONTEXT Invalid operating system context. This can result

0x70A 1802 0x9811 070A ADSERR_DEVICE_NOMEMORY Insufficient memory.

0x70B 1803 0x9811 070B ADSERR_DEVICE_INVALIDPARM Invalid parameter values.

0x70C 1804 0x9811 070C ADSERR_DEVICE_NOTFOUND Not found (files, ...).

0x70D 1805 0x9811 070D ADSERR_DEVICE_SYNTAX Syntax error in file or command.

0x70E 1806 0x9811 070E ADSERR_DEVICE_INCOMPATIBLE Objects do not match.

0x70F 1807 0x9811 070F ADSERR_DEVICE_EXISTS Object already exists.

0x710 1808 0x9811 0710 ADSERR_DEVICE_SYMBOLNOTFOUND Symbol not found.

0x711 1809 0x9811 0711 ADSERR_DEVICE_SYMBOLVERSIONIN-

VALID

0x712 1810 0x9811 0712 ADSERR_DEVICE_INVALIDSTATE Device (server) is in invalid state.

0x713 1811 0x9811 0713 ADSERR_DEVICE_TRANSMODENOTSUPP AdsTransMode not supported.

0x714 1812 0x9811 0714 ADSERR_DEVICE_NOTIFYHNDINVALID Notification handle is invalid.

0x715 1813 0x9811 0715 ADSERR_DEVICE_CLIENTUNKNOWN Notification client not registered.

0x716 1814 0x9811 0716 ADSERR_DEVICE_NOMOREHDLS No further notification handle available.

0x717 1815 0x9811 0717 ADSERR_DEVICE_INVALIDWATCHSIZE Notification size too large.

0x718 1816 0x9811 0718 ADSERR_DEVICE_NOTINIT Device not initialized.

0x719 1817 0x9811 0719 ADSERR_DEVICE_TIMEOUT Device has a timeout.

0x71A 1818 0x9811 071A ADSERR_DEVICE_NOINTERFACE Interface query failed.

0x71B 1819 0x9811 071B ADSERR_DEVICE_INVALIDINTERFACE Wrong interface requested.

0x71C 1820 0x9811 071C ADSERR_DEVICE_INVALIDCLSID Class ID is invalid.

0x71D 1821 0x9811 071D ADSERR_DEVICE_INVALIDOBJID Object ID is invalid.

0x71E 1822 0x9811 071E ADSERR_DEVICE_PENDING Request pending.

0x71F 1823 0x9811 071F ADSERR_DEVICE_ABORTED Request is aborted.

0x720 1824 0x9811 0720 ADSERR_DEVICE_WARNING Signal warning.

0x721 1825 0x9811 0721 ADSERR_DEVICE_INVALIDARRAYIDX Invalid array index.

0x722 1826 0x9811 0722 ADSERR_DEVICE_SYMBOLNOTACTIVE Symbol not active.

0x723 1827 0x9811 0723 ADSERR_DEVICE_ACCESSDENIED Access denied.

0x724 1828 0x9811 0724 ADSERR_DEVICE_LICENSENOTFOUND Missing license.

0x725 1829 0x9811 0725 ADSERR_DEVICE_LICENSEEXPIRED License expired.

0x726 1830 0x9811 0726 ADSERR_DEVICE_LICENSEEXCEEDED License exceeded.

0x727 1831 0x9811 0727 ADSERR_DEVICE_LICENSEINVALID Invalid license.

0x728 1832 0x9811 0728 ADSERR_DEVICE_LICENSESYSTEMID License problem: System ID is invalid.

0x729 1833 0x9811 0729 ADSERR_DEVICE_LICENSENOTIMELIMIT License not limited in time.

0x72A 1834 0x9811 072A ADSERR_DEVICE_LICENSEFUTUREISSUE License problem: Time in the future.

0x72B 1835 0x9811 072B ADSERR_DEVICE_LICENSETIMETOLONG License period too long.

0x72C 1836 0x9811 072C ADSERR_DEVICE_EXCEPTION Exception at system startup.

0x72D 1837 0x9811 072D ADSERR_DEVICE_LICENSEDUPLICATED License file read twice.

0x72E 1838 0x9811 072E ADSERR_DEVICE_SIGNATUREINVALID Invalid signature.

0x72F 1839 0x9811 072F ADSERR_DEVICE_CERTIFICATEINVALID Invalid certificate.

0x730 1840 0x9811 0730 ADSERR_DEVICE_LICENSEOEMNOT-

FOUND

0x731 1841 0x9811 0731 ADSERR_DEVICE_LICENSERESTRICTED License not valid for this system ID.

0x732 1842 0x9811 0732 ADSERR_DEVICE_LICENSEDEMODENIED Demo license prohibited.

0x733 1843 0x9811 0733 ADSERR_DEVICE_INVALIDFNCID Invalid function ID.

0x734 1844 0x9811 0734 ADSERR_DEVICE_OUTOFRANGE Outside the valid range.

0x735 1845 0x9811 0735 ADSERR_DEVICE_INVALIDALIGNMENT Invalid alignment.

from use of ADS function blocks in different tasks. It

may be possible to resolve this through multitasking

synchronization in the PLC.

Invalid symbol version. This can occur due to an online change. Create a new handle.

Public key not known from OEM.

TF661038 Version: 1.1

Page 39

Appendix

Hex Dec HRESULT Name Description

0x736 1846 0x9811 0736 ADSERR_DEVICE_LICENSEPLATFORM Invalid platform level.

0x737 1847 0x9811 0737 ADSERR_DEVICE_FORWARD_PL Context – forward to passive level.

0x738 1848 0x9811 0738 ADSERR_DEVICE_FORWARD_DL Context – forward to dispatch level.

0x739 1849 0x9811 0739 ADSERR_DEVICE_FORWARD_RT Context – forward to real-time.

0x740 1856 0x9811 0740 ADSERR_CLIENT_ERROR Client error.

0x741 1857 0x9811 0741 ADSERR_CLIENT_INVALIDPARM Service contains an invalid parameter.

0x742 1858 0x9811 0742 ADSERR_CLIENT_LISTEMPTY Polling list is empty.

0x743 1859 0x9811 0743 ADSERR_CLIENT_VARUSED Var connection already in use.

0x744 1860 0x9811 0744 ADSERR_CLIENT_DUPLINVOKEID The called ID is already in use.

0x745 1861 0x9811 0745 ADSERR_CLIENT_SYNCTIMEOUT Timeout has occurred – the remote terminal is not

0x746 1862 0x9811 0746 ADSERR_CLIENT_W32ERROR Error in Win32 subsystem.

0x747 1863 0x9811 0747 ADSERR_CLIENT_TIMEOUTINVALID Invalid client timeout value.

0x748 1864 0x9811 0748 ADSERR_CLIENT_PORTNOTOPEN Port not open.

0x749 1865 0x9811 0749 ADSERR_CLIENT_NOAMSADDR No AMS address.

0x750 1872 0x9811 0750 ADSERR_CLIENT_SYNCINTERNAL Internal error in Ads sync.

0x751 1873 0x9811 0751 ADSERR_CLIENT_ADDHASH Hash table overflow.

0x752 1874 0x9811 0752 ADSERR_CLIENT_REMOVEHASH Key not found in the table.

0x753 1875 0x9811 0753 ADSERR_CLIENT_NOMORESYM No symbols in the cache.

0x754 1876 0x9811 0754 ADSERR_CLIENT_SYNCRESINVALID Invalid response received.

0x755 1877 0x9811 0755 ADSERR_CLIENT_SYNCPORTLOCKED Sync Port is locked.

responding in the specified ADS timeout. The route

setting of the remote terminal may be configured incorrectly.

RTime error codes

Hex Dec HRESULT Name Description

0x1000 4096 0x9811 1000 RTERR_INTERNAL Internal error in the real-time system.

0x1001 4097 0x9811 1001 RTERR_BADTIMERPERIODS Timer value is not valid.

0x1002 4098 0x9811 1002 RTERR_INVALIDTASKPTR Task pointer has the invalid value 0 (zero).

0x1003 4099 0x9811 1003 RTERR_INVALIDSTACKPTR Stack pointer has the invalid value 0 (zero).

0x1004 4100 0x9811 1004 RTERR_PRIOEXISTS The request task priority is already assigned.

0x1005 4101 0x9811 1005 RTERR_NOMORETCB No free TCB (Task Control Block) available. The

0x1006 4102 0x9811 1006 RTERR_NOMORESEMAS No free semaphores available. The maximum num-

0x1007 4103 0x9811 1007 RTERR_NOMOREQUEUES No free space available in the queue. The maximum

0x100D 4109 0x9811 100D RTERR_EXTIRQALREADYDEF An external synchronization interrupt is already ap-

0x100E 4110 0x9811 100E RTERR_EXTIRQNOTDEF No external sync interrupt applied.

0x100F 4111 0x9811 100F RTERR_EXTIRQINSTALLFAILED Application of the external synchronization interrupt

0x1010 4112 0x9811 1010 RTERR_IRQLNOTLESSOREQUAL Call of a service function in the wrong context

0x1017 4119 0x9811 1017 RTERR_VMXNOTSUPPORTED Intel VT-x extension is not supported.

0x1018 4120 0x9811 1018 RTERR_VMXDISABLED Intel VT-x extension is not enabled in the BIOS.

0x1019 4121 0x9811 1019 RTERR_VMXCONTROLSMISSING Missing function in Intel VT-x extension.

0x101A 4122 0x9811 101A RTERR_VMXENABLEFAILS Activation of Intel VT-x fails.

maximum number of TCBs is 64.

ber of semaphores is 64.

number of positions in the queue is 64.

plied.

has failed.

TCP Winsock error codes

Hex Dec Name Description

0x274C 10060 WSAETIMEDOUT A connection timeout has occurred - error while establishing the connection, because

0x274D 10061 WSAECONNREFUSED Connection refused - no connection could be established because the target computer

0x2751 10065 WSAEHOSTUNREACH No route to host - a socket operation referred to an unavailable host.

the remote terminal did not respond properly after a certain period of time, or the established connection could not be maintained because the connected host did not respond.

has explicitly rejected it. This error usually results from an attempt to connect to a service that is inactive on the external host, that is, a service for which no server application is running.

More Winsock error codes: Win32 error codes [}40]

TF6610 39Version: 1.1

Page 40

Appendix

8.4 Win32 Error Codes

The following table provides a list of Win32 error codes.

0 [}41], 100 [}43], 200 [}45], 1001 [}47], 1100 [}49], 1200 [}51], 1400 [}56], 1600 [}58], 1800

[}62], 2000 [}64], 3000 [}65], 5000 [}68], 6000 [}71], 8000 [}73], 8500 [}82], 9001 [}86],

10004 [}88], 12000 [}91],

TF661040 Version: 1.1

Page 41

Appendix

Error Description

decimal Hexadecimal Name

0 0x00000000 ERROR_SUCCESS The operation completed successfully.

1 0x00000001 ERROR_INVALID_FUNCTION Incorrect function.

2 0x00000002 ERROR_FILE_NOT_FOUND The system cannot find the file specified.

3 0x00000003 ERROR_PATH_NOT_FOUND The system cannot find the path specified.

4 0x00000004 ERROR_TOO_MANY_OPEN_FILES The system cannot open the file.

5 0x00000005 ERROR_ACCESS_DENIED Access is denied.

6 0x00000006 ERROR_INVALID_HANDLE The handle is invalid.

7 0x00000007 ERROR_ARENA_TRASHED The storage control blocks were destroyed.

8 0x00000008 ERROR_NOT_ENOUGH_MEMORY Not enough storage is available to process this

9 0x00000009 ERROR_INVALID_BLOCK The storage control block address is invalid.

10 0x0000000A ERROR_BAD_ENVIRONMENT The environment is incorrect.

11 0x0000000B ERROR_BAD_FORMAT An attempt was made to load a program with an

12 0x0000000C ERROR_INVALID_ACCESS The access code is invalid.

13 0x0000000D ERROR_INVALID_DATA The data is invalid.

14 0x0000000E ERROR_OUTOFMEMORY Not enough storage is available to complete this

15 0x0000000F ERROR_INVALID_DRIVE The system cannot find the drive specified.

16 0x00000010 ERROR_CURRENT_DIRECTORY The directory cannot be removed.

17 0x00000011 ERROR_NOT_SAME_DEVICE The system cannot move the file to a different

18 0x00000012 ERROR_NO_MORE_FILES There are no more files.

19 0x00000013 ERROR_WRITE_PROTECT The media is write protected.

20 0x00000014 ERROR_BAD_UNIT The system cannot find the device specified.

21 0x00000015 ERROR_NOT_READY The device is not ready.

22 0x00000016 ERROR_BAD_COMMAND The device does not recognize the command.

23 0x00000017 ERROR_CRC Data error (cyclic redundancy check).

24 0x00000018 ERROR_BAD_LENGTH The program issued a command but the com-

25 0x00000019 ERROR_SEEK The drive cannot locate a specific area or track on

26 0x0000001A ERROR_NOT_DOS_DISK The specified disk or diskette cannot be ac-

27 0x0000001B ERROR_SECTOR_NOT_FOUND The drive cannot find the sector requested.

28 0x0000001C ERROR_OUT_OF_PAPER The printer is out of paper.

29 0x0000001D ERROR_WRITE_FAULT The system cannot write to the specified device.

30 0x0000001E ERROR_READ_FAULT The system cannot read from the specified de-

31 0x0000001F ERROR_GEN_FAILURE A device attached to the system is not function-

32 0x00000020 ERROR_SHARING_VIOLATION The process cannot access the file because it is

33 0x00000021 ERROR_LOCK_VIOLATION The process cannot access the file because an-

34 0x00000022 ERROR_WRONG_DISK The wrong diskette is in the drive. Insert %2 (Vol-

36 0x00000024 ERROR_SHARING_BUFFER_EXCEEDED Too many files opened for sharing.

38 0x00000026 ERROR_HANDLE_EOF Reached the end of the file.

39 0x00000027 ERROR_HANDLE_DISK_FULL The disk is full.

50 0x00000032 ERROR_NOT_SUPPORTED The request is not supported.

51 0x00000033 ERROR_REM_NOT_LIST The remote computer is not available.

52 0x00000034 ERROR_DUP_NAME A duplicate name exists on the network.

53 0x00000035 ERROR_BAD_NETPATH The network path was not found.

54 0x00000036 ERROR_NETWORK_BUSY The network is busy.

55 0x00000037 ERROR_DEV_NOT_EXIST The specified network resource or device is no

56 0x00000038 ERROR_TOO_MANY_CMDS The network BIOS command limit has been

57 0x00000039 ERROR_ADAP_HDW_ERR A network adapter hardware error occurred.

command.

incorrect format.

operation.

disk drive.

mand length is incorrect.

the disk.

cessed.

vice.

ing.

being used by another process.

other process has locked a portion of the file.

ume Serial Number: %3) into drive %1.

longer available.

reached.

TF6610 41Version: 1.1

Page 42

Appendix

Error Description

decimal Hexadecimal Name

58 0x0000003A ERROR_BAD_NET_RESP The specified server cannot perform the re-

59 0x0000003B ERROR_UNEXP_NET_ERR An unexpected network error occurred.

60 0x0000003C ERROR_BAD_REM_ADAP The remote adapter is not compatible.

61 0x0000003D ERROR_PRINTQ_FULL The printer queue is full.

62 0x0000003E ERROR_NO_SPOOL_SPACE Space to store the file waiting to be printed is not

63 0x0000003F ERROR_PRINT_CANCELLED Your file waiting to be printed was deleted.

64 0x00000040 ERROR_NETNAME_DELETED The specified network name is no longer avail-

65 0x00000041 ERROR_NETWORK_ACCESS_DENIED Network access is denied.

66 0x00000042 ERROR_BAD_DEV_TYPE The network resource type is not correct.

67 0x00000043 ERROR_BAD_NET_NAME The network name cannot be found.

68 0x00000044 ERROR_TOO_MANY_NAMES The name limit for the local computer network

69 0x00000045 ERROR_TOO_MANY_SESS The network BIOS session limit was exceeded.

70 0x00000046 ERROR_SHARING_PAUSED The remote server has been paused or is in the

71 0x00000047 ERROR_REQ_NOT_ACCEP No more connections can be made to this remote

72 0x00000048 ERROR_REDIR_PAUSED The specified printer or disk device has been

80 0x00000050 ERROR_FILE_EXISTS The file exists.

82 0x00000052 ERROR_CANNOT_MAKE The directory or file cannot be created.

83 0x00000053 ERROR_FAIL_I24 Fail on INT 24.

84 0x00000054 ERROR_OUT_OF_STRUCTURES Storage to process this request is not available.

85 0x00000055 ERROR_ALREADY_ASSIGNED The local device name is already in use.

86 0x00000056 ERROR_INVALID_PASSWORD The specified network password is not correct.

87 0x00000057 ERROR_INVALID_PARAMETER The parameter is incorrect.

88 0x00000058 ERROR_NET_WRITE_FAULT A write fault occurred on the network.

89 0x00000059 ERROR_NO_PROC_SLOTS The system cannot start another process at this

quested operation.

available on the server.

able.

adapter card was exceeded.

process of being started.

computer at this time because there are already

as many connections as the computer can accept.

paused.

time.

TF661042 Version: 1.1

Page 43

Appendix

Error Description

decimal Hexadecimal Name

100 0x00000064 ERROR_TOO_MANY_SEMAPHORES Cannot create another system semaphore.

101 0x00000065 ERROR_EXCL_SEM_ALREADY_OWNED The exclusive semaphore is owned by another

102 0x00000066 ERROR_SEM_IS_SET The semaphore is set and cannot be closed.

103 0x00000067 ERROR_TOO_MANY_SEM_REQUESTS The semaphore cannot be set again.

104 0x00000068 ERROR_INVALID_AT_INTERRUPT_TIME Cannot request exclusive semaphores at interrupt

105 0x00000069 ERROR_SEM_OWNER_DIED The previous ownership of this semaphore has

106 0x0000006A ERROR_SEM_USER_LIMIT Insert the diskette for drive %1.

107 0x0000006B ERROR_DISK_CHANGE The program stopped because an alternate

108 0x0000006C ERROR_DRIVE_LOCKED The disk is in use or locked by another process.

109 0x0000006D ERROR_BROKEN_PIPE The pipe has been ended.

110 0x0000006E ERROR_OPEN_FAILED The system cannot open the device or file speci-

111 0x0000006F ERROR_BUFFER_OVERFLOW The file name is too long.

112 0x00000070 ERROR_DISK_FULL There is not enough space on the disk.

113 0x00000071 ERROR_NO_MORE_SEARCH_HANDLES No more internal file identifiers available.

114 0x00000072 ERROR_INVALID_TARGET_HANDLE The target internal file identifier is incorrect.

117 0x00000075 ERROR_INVALID_CATEGORY The IOCTL call made by the application program

118 0x00000076 ERROR_INVALID_VERIFY_SWITCH The verify-on-write switch parameter value is not

119 0x00000077 ERROR_BAD_DRIVER_LEVEL The system does not support the command re-

120 0x00000078 ERROR_CALL_NOT_IMPLEMENTED This function is not supported on this system.

121 0x00000079 ERROR_SEM_TIMEOUT The semaphore timeout period has expired.

122 0x0000007A ERROR_INSUFFICIENT_BUFFER The data area passed to a system call is too

123 0x0000007B ERROR_INVALID_NAME The filename, directory name, or volume label

124 0x0000007C ERROR_INVALID_LEVEL The system call level is not correct.

125 0x0000007D ERROR_NO_VOLUME_LABEL The disk has no volume label.

126 0x0000007E ERROR_MOD_NOT_FOUND The specified module could not be found.

127 0x0000007F ERROR_PROC_NOT_FOUND The specified procedure could not be found.

128 0x00000080 ERROR_WAIT_NO_CHILDREN There are no child processes to wait for.

129 0x00000081 ERROR_CHILD_NOT_COMPLETE The %1 application cannot be run in Win32 mode.

130 0x00000082 ERROR_DIRECT_ACCESS_HANDLE Attempt to use a file handle to an open disk parti-

131 0x00000083 ERROR_NEGATIVE_SEEK An attempt was made to move the file pointer be-

132 0x00000084 ERROR_SEEK_ON_DEVICE The file pointer cannot be set on the specified de-

133 0x00000085 ERROR_IS_JOIN_TARGET A JOIN or SUBST command cannot be used for a

134 0x00000086 ERROR_IS_JOINED An attempt was made to use a JOIN or SUBST

135 0x00000087 ERROR_IS_SUBSTED An attempt was made to use a JOIN or SUBST

136 0x00000088 ERROR_NOT_JOINED The system tried to delete the JOIN of a drive that

137 0x00000089 ERROR_NOT_SUBSTED The system tried to delete the substitution of a

138 0x0000008A ERROR_JOIN_TO_JOIN The system tried to join a drive to a directory on a

139 0x0000008B ERROR_SUBST_TO_SUBST The system tried to substitute a drive to a direc-

140 0x0000008C ERROR_JOIN_TO_SUBST The system tried to join a drive to a directory on a

141 0x0000008D ERROR_SUBST_TO_JOIN The system tried to SUBST a drive to a directory

process.

time.

ended.

diskette was not inserted.

fied.

is not correct.

correct.

quested.

small.

syntax is incorrect.

tion for an operation other than raw disk I/O.

fore the beginning of the file.

vice or file.

drive that contains previously joined drives.

command on a drive that has already been joined.

command on a drive that has already been substituted.

is not joined.

drive that is not substituted.

joined drive.

tory on a substituted drive.

substituted drive.

on a joined drive.

TF6610 43Version: 1.1

Page 44

Appendix

Error Description

decimal Hexadecimal Name

142 0x0000008E ERROR_BUSY_DRIVE The system cannot perform a JOIN or SUBST at

143 0x0000008F ERROR_SAME_DRIVE The system cannot join or substitute a drive to or

144 0x00000090 ERROR_DIR_NOT_ROOT The directory is not a subdirectory of the root di-

145 0x00000091 ERROR_DIR_NOT_EMPTY The directory is not empty.

146 0x00000092 ERROR_IS_SUBST_PATH The path specified is being used in a substitute.

147 0x00000093 ERROR_IS_JOIN_PATH Not enough resources are available to process

148 0x00000094 ERROR_PATH_BUSY The path specified cannot be used at this time.

149 0x00000095 ERROR_IS_SUBST_TARGET An attempt was made to join or substitute a drive

150 0x00000096 ERROR_SYSTEM_TRACE System trace information was not specified in

151 0x00000097 ERROR_INVALID_EVENT_COUNT The number of specified semaphore events for

152 0x00000098 ERROR_TOO_MANY_MUXWAITERS DosMuxSemWait did not execute; too many sem-

153 0x00000099 ERROR_INVALID_LIST_FORMAT The DosMuxSemWait list is not correct.

154 0x0000009A ERROR_LABEL_TOO_LONG The volume label you entered exceeds the label

155 0x0000009B ERROR_TOO_MANY_TCBS Cannot create another thread.

156 0x0000009C ERROR_SIGNAL_REFUSED The recipient process has refused the signal.

157 0x0000009D ERROR_DISCARDED The segment is already discarded and cannot be

158 0x0000009E ERROR_NOT_LOCKED The segment is already unlocked.

159 0x0000009F ERROR_BAD_THREADID_ADDR The address for the thread ID is not correct.

160 0x000000A0 ERROR_BAD_ARGUMENTS The argument string passed to DosExecPgm is

161 0x000000A1 ERROR_BAD_PATHNAME The specified path is invalid.

162 0x000000A2 ERROR_SIGNAL_PENDING A signal is already pending.

164 0x000000A4 ERROR_MAX_THRDS_REACHED No more threads can be created in the system.

167 0x000000A7 ERROR_LOCK_FAILED Unable to lock a region of a file.

170 0x000000AA ERROR_BUSY The requested resource is in use.

173 0x000000AD ERROR_CANCEL_VIOLATION A lock request was not outstanding for the sup-

174 0x000000AE ERROR_ATOMIC_LOCKS_NOT_SUPPORTED The file system does not support atomic changes

180 0x000000B4 ERROR_INVALID_SEGMENT_NUMBER The system detected a segment number that was

182 0x000000B6 ERROR_INVALID_ORDINAL The operating system cannot run %1.

183 0x000000B7 ERROR_ALREADY_EXISTS Cannot create a file when that file already exists.

186 0x000000BA ERROR_INVALID_FLAG_NUMBER The flag passed is not correct.

187 0x000000BB ERROR_SEM_NOT_FOUND The specified system semaphore name was not

188 0x000000BC ERROR_INVALID_STARTING_CODESEG The operating system cannot run %1.

189 0x000000BD ERROR_INVALID_STACKSEG The operating system cannot run %1.

190 0x000000BE ERROR_INVALID_MODULETYPE The operating system cannot run %1.

191 0x000000BF ERROR_INVALID_EXE_SIGNATURE Cannot run %1 in Win32 mode.

192 0x000000C0 ERROR_EXE_MARKED_INVALID The operating system cannot run %1.

193 0x000000C1 ERROR_BAD_EXE_FORMAT %1 is not a valid Win32 application.

194 0x000000C2 ERROR_ITERATED_DATA_EXCEEDS_64k The operating system cannot run %1.

195 0x000000C3 ERROR_INVALID_MINALLOCSIZE The operating system cannot run %1.

196 0x000000C4 ERROR_DYNLINK_FROM_INVALID_RING The operating system cannot run this application

197 0x000000C5 ERROR_IOPL_NOT_ENABLED The operating system is not presently configured

198 0x000000C6 ERROR_INVALID_SEGDPL The operating system cannot run %1.

199 0x000000C7 ERROR_AUTODATASEG_EXCEEDS_64k The operating system cannot run this application

this time.

for a directory on the same drive.

rectory.

this command.

for which a directory on the drive is the target of a

previous substitute.

your CONFIG.SYS file, or tracing is disallowed.

DosMuxSemWait is not correct.

aphores are already set.

character limit of the target file system.

locked.

not correct.

plied cancel region.

to the lock type.

not correct.

found.

program.

to run this application.

program.

TF661044 Version: 1.1

Page 45

Appendix

Error Description

decimal Hexadecimal Name

200 0x000000C8 ERROR_RING2SEG_MUST_BE_MOVABLE The code segment cannot be greater than or