Page 1

Documentation | EN

KM6551

Terminal module for wireless data exchange

2021-03-03 | Version: 2.0.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 Product overview.......................................................................................................................................8

2.1 Introduction........................................................................................................................................8

2.2 Technical data ...................................................................................................................................9

2.3 Basic Function Principles ................................................................................................................10

2.4 LED displays....................................................................................................................................12

2.5 DIP switch........................................................................................................................................13

3 IEEE802.15.4 ............................................................................................................................................14

3.1 Introduction......................................................................................................................................14

3.2 Interference caused by other radio systems....................................................................................15

4 Mounting and wiring................................................................................................................................17

4.1 Recommended mounting rails.........................................................................................................17

4.2 Mounting and demounting - terminals with traction lever unlocking ................................................17

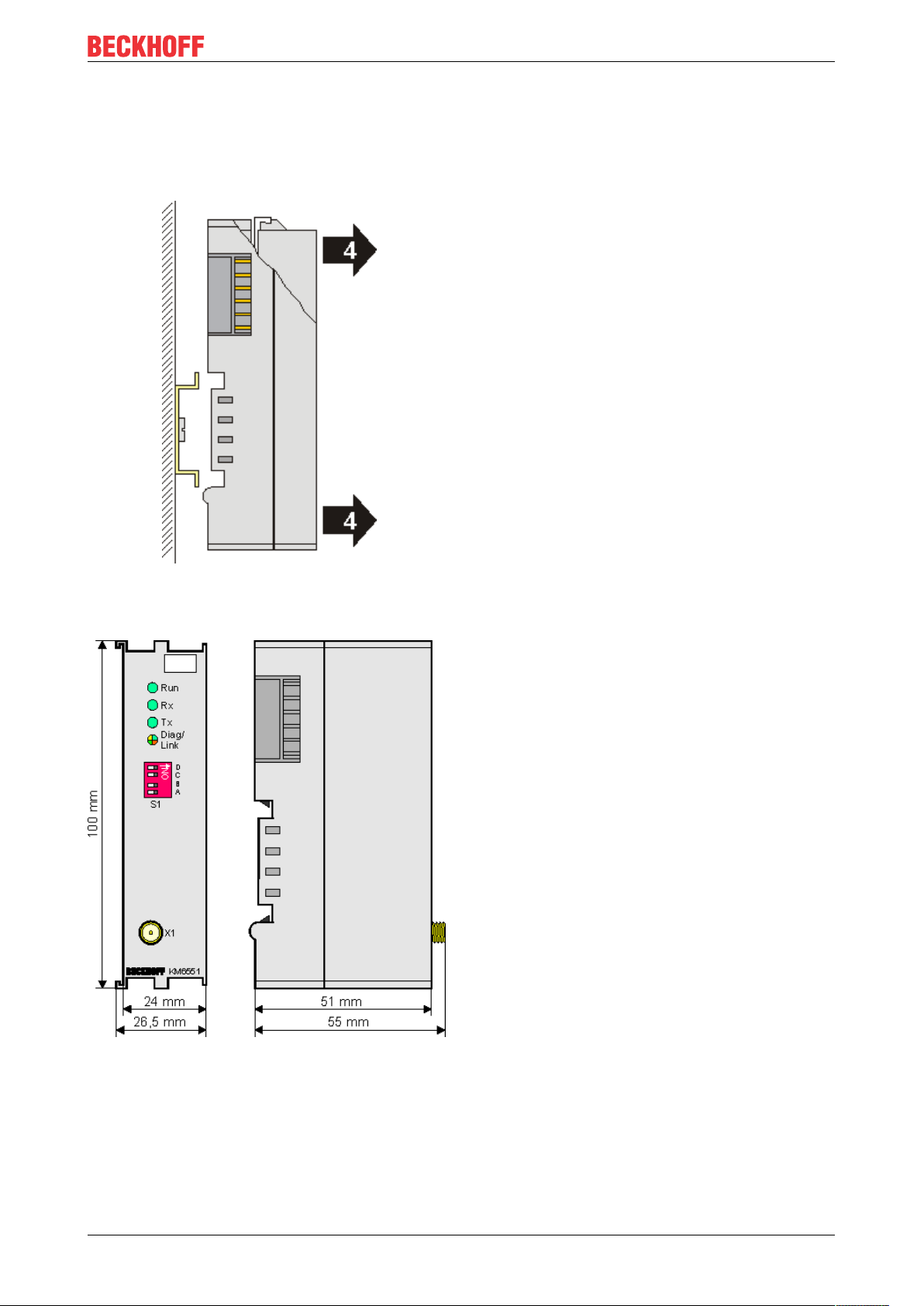

4.3 Dimensions......................................................................................................................................19

4.4 Connection ......................................................................................................................................19

4.5 Antenna alignment...........................................................................................................................21

4.5.1 Directional characteristic.................................................................................................. 21

4.5.2 Alignment examples ........................................................................................................ 23

4.5.3 Polarization ...................................................................................................................... 23

4.5.4 Placement of the antennas .............................................................................................. 24

4.6 Attenuation and range .....................................................................................................................25

4.6.1 Fresnel zone .................................................................................................................... 25

4.6.2 Attenuation in practice ..................................................................................................... 26

4.6.3 Range of different antenna combinations ........................................................................ 26

4.7 Antennas .........................................................................................................................................27

4.7.1 ZS6100-0900 ................................................................................................................... 28

4.7.2 ZS6100-1800 ................................................................................................................... 30

4.7.3 ZS6200-0400 ................................................................................................................... 32

4.7.4 ZS6201-0410 ................................................................................................................... 34

4.7.5 ZS6201-0500 ................................................................................................................... 36

5 Application examples - overview ...........................................................................................................38

5.1 Peer to peer mode...........................................................................................................................38

5.2 Master-Slave mode .........................................................................................................................38

5.3 Broadcast mode ..............................................................................................................................39

5.4 Energy scan.....................................................................................................................................40

6 TwinCAT ...................................................................................................................................................42

6.1 TwinCAT libraries ............................................................................................................................44

6.2 TwinCAT examples .........................................................................................................................44

6.3 Function blocks................................................................................................................................45

6.3.1 Function block FB_KM6551_MAIN.................................................................................. 45

KM6551 3Version: 2.0.0

Page 4

Table of contents

6.3.2 Energy scan..................................................................................................................... 46

6.3.3 Master/Slave mode.......................................................................................................... 47

6.3.4 Broadcast mode............................................................................................................... 49

7 KS2000 Configuration Software.............................................................................................................52

7.1 KS2000 - Introduction......................................................................................................................52

7.2 Parameterization with KS2000 ........................................................................................................53

7.3 Settings............................................................................................................................................55

7.4 Register ...........................................................................................................................................56

7.5 Process data....................................................................................................................................57

8 Access from the user program ..............................................................................................................59

8.1 Process image.................................................................................................................................59

8.2 Control and Status Bytes.................................................................................................................59

8.2.1 Process data mode.......................................................................................................... 59

8.2.2 Register communication .................................................................................................. 61

8.3 Register overview ............................................................................................................................62

8.4 Register description.........................................................................................................................63

8.5 Examples of Register Communication ............................................................................................65

8.5.1 Example 1: reading the firmware version from Register 9............................................... 65

8.5.2 Example 2: Writing to an user register............................................................................. 66

9 Appendix ..................................................................................................................................................69

9.1 General operating conditions...........................................................................................................69

9.2 EC declaration of conformity ...........................................................................................................71

9.3 Calculating with decibels .................................................................................................................72

9.4 Support and Service ........................................................................................................................72

KM65514 Version: 2.0.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATG®, EtherCATG10®, EtherCATP®, SafetyoverEtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH. Other designations used in this publication may be trademarks whose use by third parties for their

own purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702 with corresponding

applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

KM6551 5Version: 2.0.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

KM65516 Version: 2.0.0

Page 7

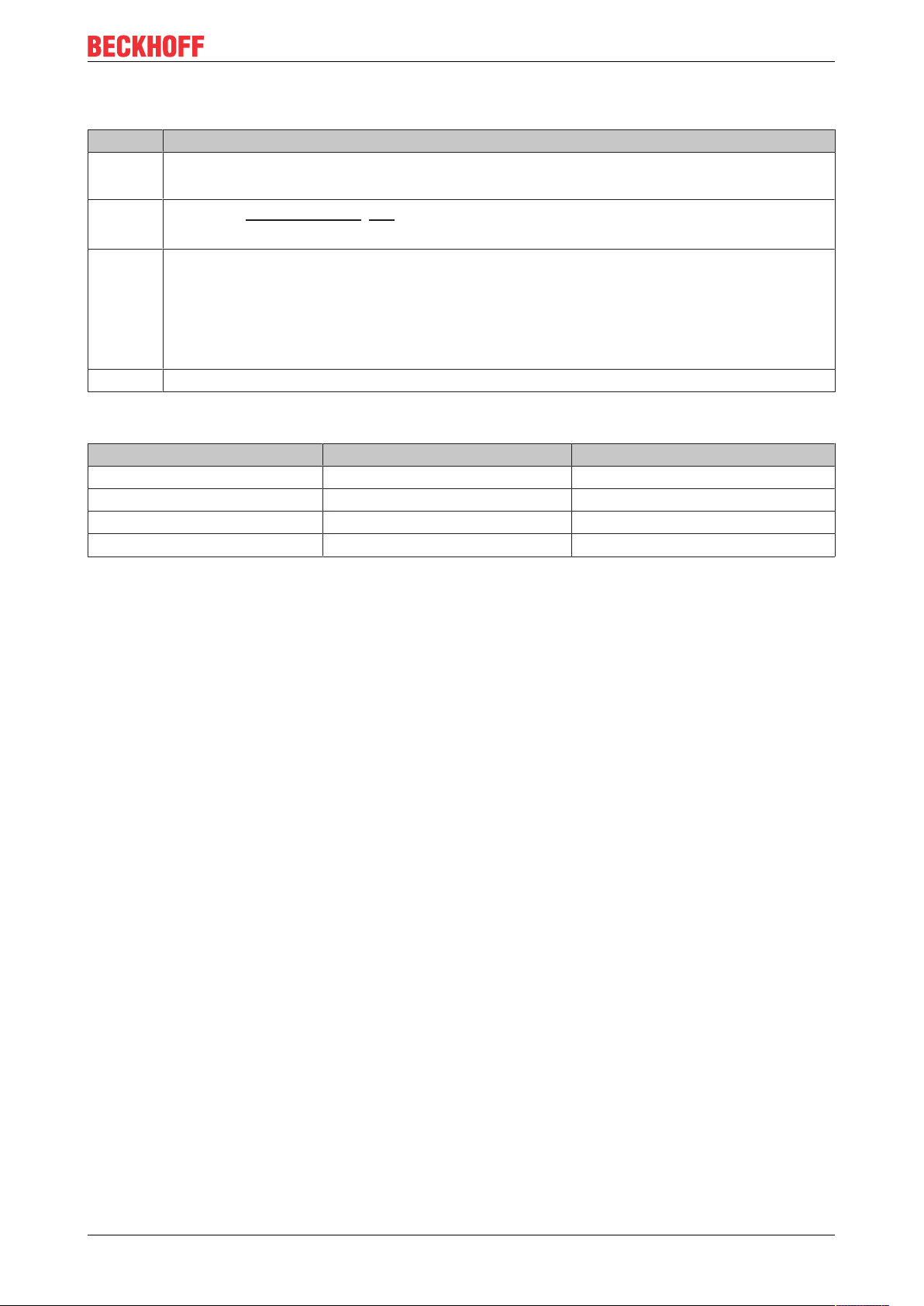

1.3 Documentation issue status

Version Comment

2.0.0 • Migration

• Structure update

1.2.0

1.1.0 • Register description extended

1.0.0 First release

Firmware and hardware versions

Documentation, version Firmware version Hardware version

2.0.0 1F 02

1.2.0 1E 01

1.1.0 1E 00

1.0.0 1B 00

• Included TwinCAT library [}44] updated to version 1.7.0

• Description of the KS2000 configuration software updated

• Notes on interference caused by other radio systems expanded

• Notes on mounting expanded

• Antenna ZS6201-0500 added

• Antenna descriptions updated

Foreword

The firmware and hardware versions (delivery state) can be taken from the serial number printed on the side

of the terminal module.

Syntax of the serial number

Structure of the serial number: WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with serial number 35 05 00 01:

35 - week of production 35

05 - year of production 2005

00 - firmware version 00

01 - hardware version 01

KM6551 7Version: 2.0.0

Page 8

Product overview

2 Product overview

2.1 Introduction

Fig.1: KM6551-0000 - Terminal module for radio transmission

The KM6551-0000 terminal module is a data exchange unit based on radio technology. It uses the

IEEE802.15.4 standard. Data is exchanged or transmitted between two independent controllers via radio,

independent of the higher-level fieldbus. The free-field distance between two KM6551-0000 units can be up

to 300m.

The KM6551-0000 terminal module has a reverse SMA plug (Straight Medium Adapter), to which various

radio antennas [}27] can be connected, which are to be procured from Beckhoff. The directional

characteristic can be adapted to the surroundings by means of specifically selecting the antenna. Status and

data exchange are displayed via LEDs, thereby offering fast and simple diagnostics. A TwinCAT library

[}44] is available for the use of the KM6551-0000 terminal module with TwinCAT.

KM65518 Version: 2.0.0

Page 9

Product overview

2.2 Technical data

Technical data KM6551-0000

Frequency band 2.4GHz

Data transfer rates 250kbit

Output power 0dBm (1mW)

Reception sensitivity -87dBm

Protocol IEEE802.15.4

Antenna connection reverse SMA plug (RP_SMA)

Power supply for the electronics via the K-bus

Current consumption via K-bus typically 135mA

Width of a bus terminal block Maximum 64 standard Bus Terminals or 80cm

(one KM6551-0000 corresponds to 2 standard Bus Terminals

here)

Data width in the input process image 12bytes

Data width in the output process image 12bytes

Dimensions without antenna (W x H x D) approx. 26.5mm x100mm x 55mm (width aligned: 24mm)

Weight app.100g

Permissible ambient temperature range

during operation

Permissible ambient temperature range

during storage

Permissible relative air humidity 95%, no condensation

Mounting [}17] on a 35mm mounting rail [}17] (e.g. DIN rail TH35-7.5

Vibration/shock resistance conforms to EN60068-2-6/ EN60068-2-27, EN60068-2-29

EMC immunity/emission conforms to EN61000-6-2/ EN61000-6-4

Protection class IP20

Installation position variable

Approval CE

0°C ... + 55°C

-25°C ... + 85°C

conforming to EN60715)

KM6551 9Version: 2.0.0

Page 10

Product overview

2.3 Basic Function Principles

Fig.2: Basic Function Principles

The KM6551-0000 data exchange module enables the wireless exchange of data between two or more

controllers. It uses the IEEE802.15.4 standard as its basis with a Beckhoff-specific protocol. 10bytes of user

data are transmitted per data packet. The DIP switch is used to set the operating mode of the KM6551-0000,

i.e. whether the module functions as a master or slave and which communication mode is to be used.

The data is exchanged in the peer to peer and master-slave modes using the polling method. In broadcast

mode, one module is the broadcast master that sends the data and all other modules are broadcast slaves

that receive the data but cannot send data to the broadcast master themselves. Hence, they listen only to

data from the broadcast master.

In master-slave mode you can decide via the software with which slave data should be exchanged. Up to

7slaves can be addressed.

The data exchange module KM6551-0000 supports 16channels, which are freely selectable and can be

used, for example, to establish several radio networks or for placement outside WLANs or other radio

systems that also use 2.4GHz.

The KM6551-0000 can scan the possible 16 channels. The energy in the frequency range is measured to

ascertain in advance whether other systems are active and on which frequencies. Furthermore, the so-called

LQI (LinkofQualityIndex) is transmitted with each data telegram. This makes it possible to determine the

quality of the signal. A high LQI value indicates a good connection, a low value a poor connection. In order to

improve the LQI value, a larger antenna or an antenna with a correspondingly larger transmission factor can

be used.

Communication mode

The KM6551-0000 data exchange module supports three different communication modes.

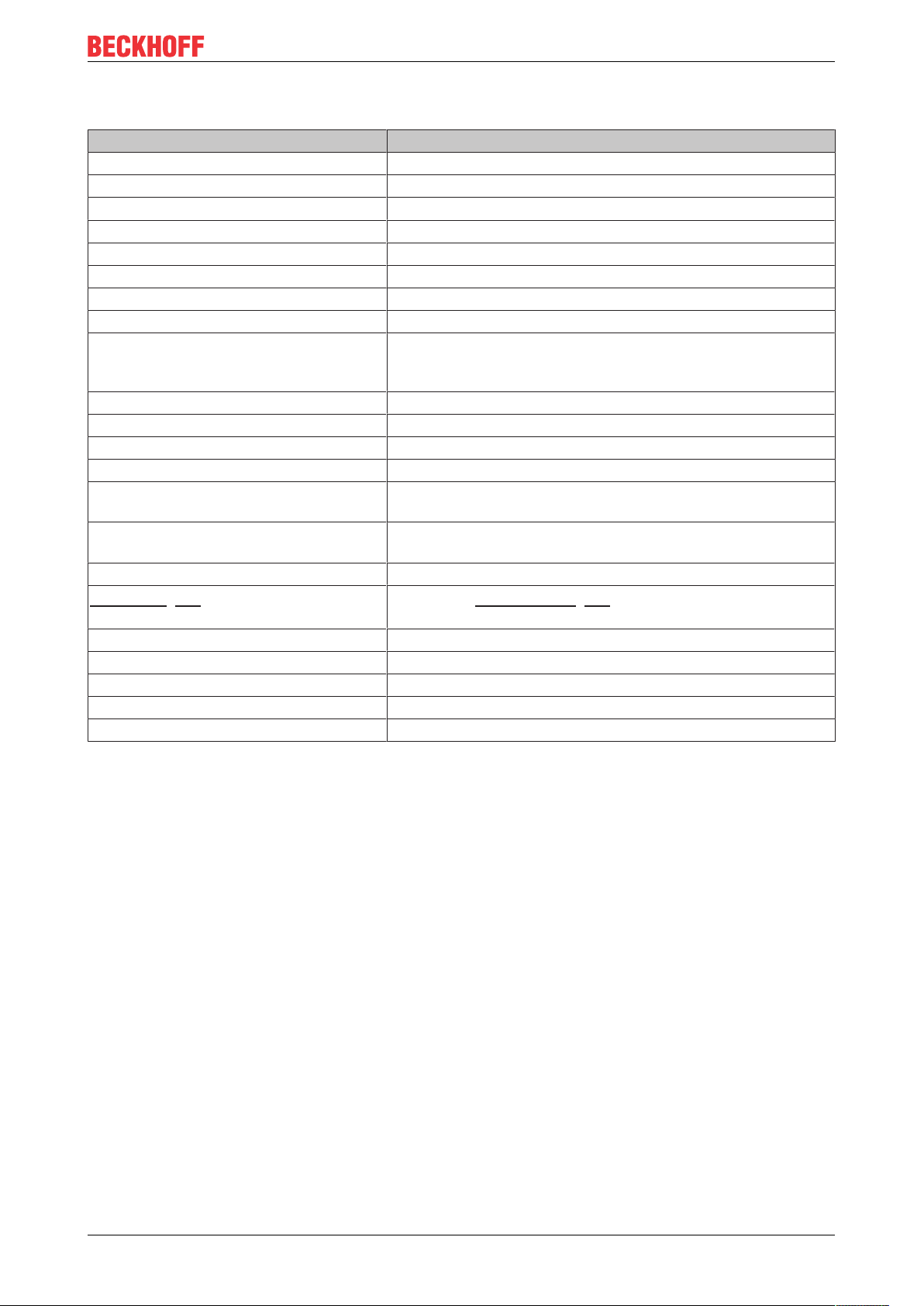

Mode 1: Peer to peer – data exchange between two modules

Enables the exchange of data between two KM6551-0000. A maximum of 10bytes of data can be

transmitted per cycle. In one cycle (typically < 20ms), module1 sends data to module2 and module2 sends

data back to module1.

KM655110 Version: 2.0.0

Page 11

Fig.3: Peer to Peer

Product overview

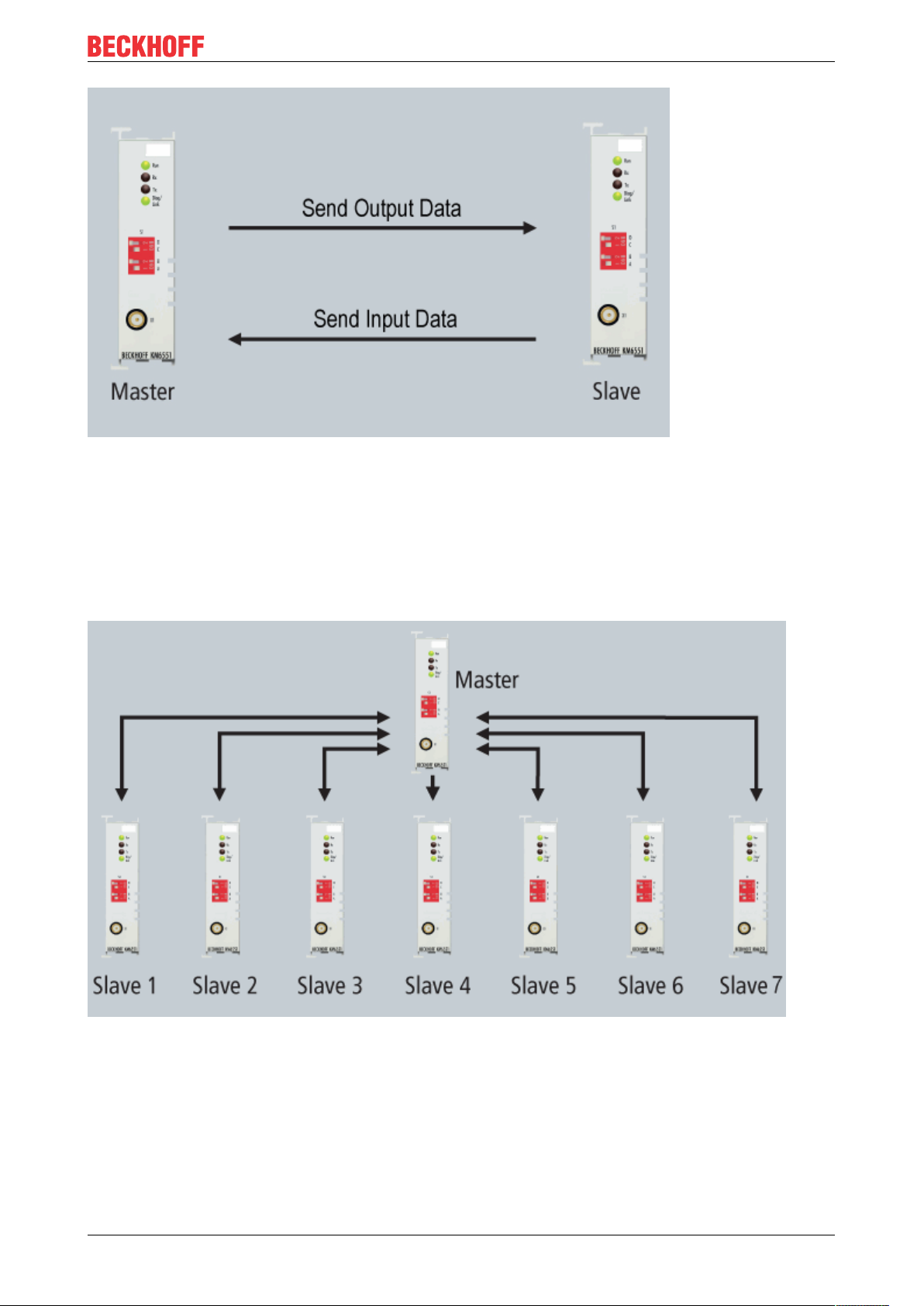

Mode 2: Master-slave – data exchange between a master and up to 7slaves

In master-slave mode the master can communicate with up to seven KM6551-0000 using the polling

method. To do this, set the corresponding slave addresses using the DIP switch. From the PLC you can

inform the master which slave it should communicate with, how often and for how long. Approx. 20ms are

required per slave. For seven slaves this results in a minimum cycle time of 140ms which the master

requires in order to address all 7 slaves once each.

Fig.4: Master-Slave mode

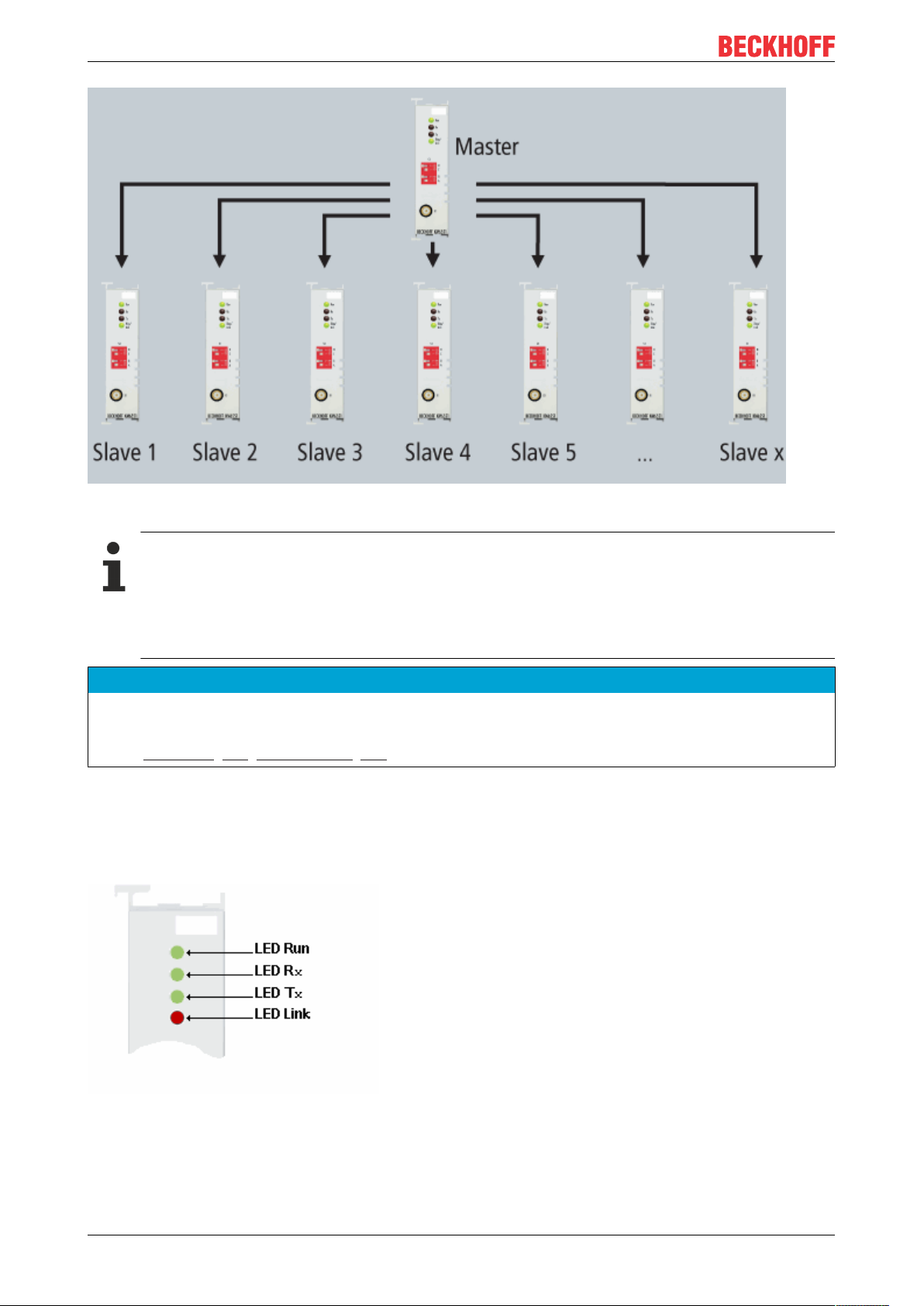

Mode 3: Broadcast to any number of slaves

In broadcast mode, only the broadcast master transmits. All other modules (broadcast slaves) can only

receive data but cannot send data themselves. Any number (x) of broadcast slaves can listen in.

KM6551 11Version: 2.0.0

Page 12

Product overview

Fig.5: Broadcast mode

Support of the KM6551-0000 using Bus Couplers, Bus Terminal Controllers and

TwinCAT

The KM6551-0000 is supported from TwinCAT 2.10 Build 1326 onwards. The following Bus Couplers are supported: BK1120, BK1250, BK2020, BK3120, BK3150, BK9000, BK9050. (Further Bus

Couplers on request). All Bus Terminal Controllers from the BCxxxx, BXxxxx and BXxxxx series are

supported.

NOTE

CE conformity

The CE conformity of the KM6551-0000 is only guaranteed if it is operated with original Beckhoff accessories (antennas [}27], coaxial cable [}19])!

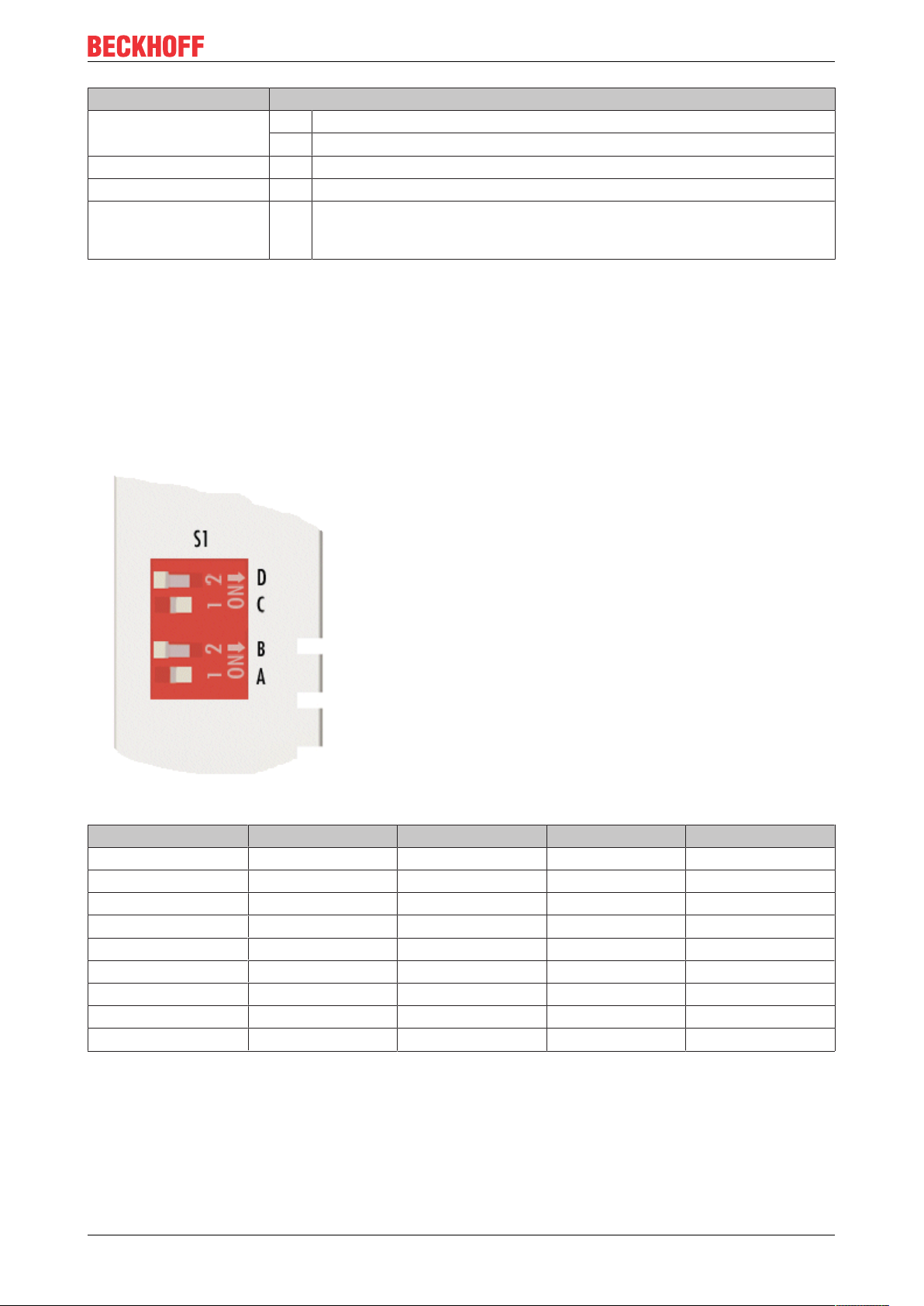

2.4 LED displays

KM6551-0000

Fig.6: KM6551 - LED displays

KM655112 Version: 2.0.0

Page 13

Product overview

LED Display

Run (green) off Data transmission on the K-bus is not active

on Data transmission on the K-bus is active

Rx (green) on Data being received via radio

Tx (green) on Data being sent via radio

Link (green, orange, red) on Green - good signal quality

Orange - moderate signal quality

Red - poor signal quality or watchdog has triggered

2.5 DIP switch

You can activate the different modes of the KM6551-0000 using the DIP switch. This enables the simple

exchange of the modules without additional configuration software.

• DIP switch in right position: ON

• DIP switch in left position: OFF

The picture illustrates the setting for Slave 5.

Fig.7: DIP switch

DIP switch A B C D

Master mode OFF OFF OFF OFF

Slave 1 ON OFF OFF OFF

Slave 2 OFF ON OFF OFF

Slave 3 ON ON OFF OFF

Slave 4 OFF OFF ON OFF

Slave 5 ON OFF ON OFF

Slave 6 OFF ON ON OFF

Slave 7 ON ON ON OFF

Broadcast slave OFF OFF OFF ON

KM6551 13Version: 2.0.0

Page 14

IEEE802.15.4

3 IEEE802.15.4

3.1 Introduction

The terms IEEE802.15.4 and ZigBee are used in many places as synonyms, although there is a clear

demarcation between them, which will be briefly explained at this point.

The 802.15.4 standard, which was elaborated by the Institute of Electrical and Electronics Engineers (IEEE),

specifies the Physical Layer (PHY) and the Medium Access Control (MAC), which correspond to the two

lowest levels of the OSI layer model. The IEEE802.15.4 standard was ratified at the beginning of May 2004

[1]. Therefore, apart from a few expected amendments and clarifications, work on it is deemed to be

complete.

The ZigBee Alliance [2] was founded by several large firms from the semiconductor industry with the aim of

developing a complete protocol suite on the basis of IEEE802.15.4 for wireless communication extending up

to the application interface. However, it is worth mentioning in this respect that the IEEE802.15.4 standard is

in no way linked to the ZigBee Alliance.

No ZigBee!

The KM6551-0000 data transmission module is based on IEEE802.15.4, but it is not a ZigBee

product and is also not ZigBee-compatible!

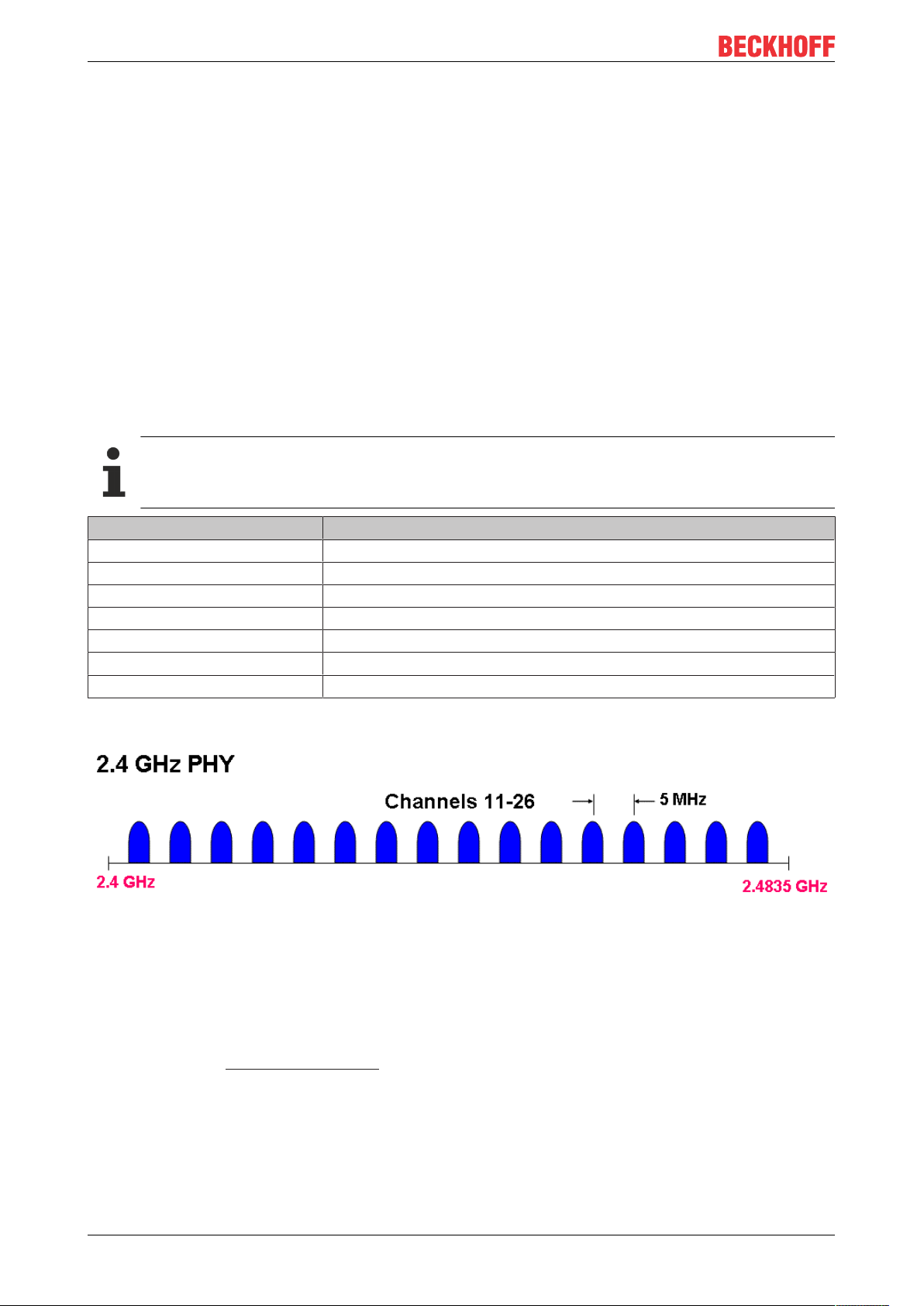

Technical data KM6551

Data transmission band 2.4GHz

Channels 16

Channel separation 5MHz

Channel width 2MHz

Available Worldwide

Data transfer rate 250kbit

Protocol IEEE802.15.4

16 channels, each with a gross data rate of 250kB/s, are available in the worldwide available 2.4GHz band.

Fig.8: Channels 11 to 26

[1] Institute of Electrical and Electronics Engineers (Ed.): IEEE Standard for Information technology -Telecommunication and information exchange between systems -- Local and metropolitan area networks -Specific requirements. Part 15.4: Wireless Medium Access Control (MAC) and Physical Layer (PHY)

Specifications for Low-Rate Wireless Personal Area Networks (LR-WPANs).IEEE Computer Society, New

York, NY, USA, October 2003

[2] ZigBee Alliance, http://www.zigbee.org

KM655114 Version: 2.0.0

Page 15

IEEE802.15.4

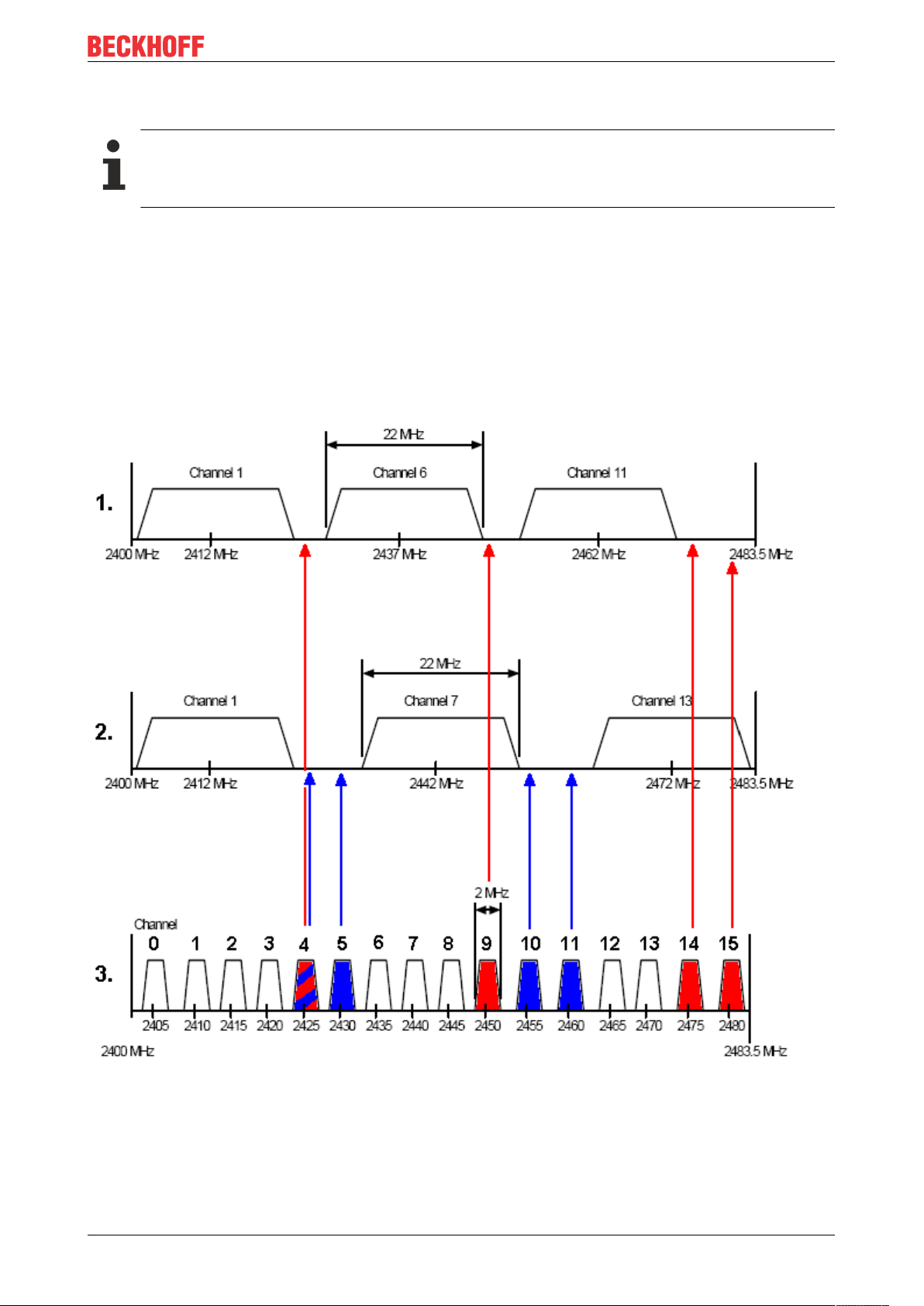

3.2 Interference caused by other radio systems

Check frequency ranges

• WLAN networks on adjacent or the same channels

• Microwave ovens

WLAN

If the IEEE802.15.4 channel used by the KM6551-0000 and the frequency range of a neighboring WLAN

network overlap, this can lead to disruptions in the KM6551-0000 communication.

Select an IEEE802.15.4 channel for the KM6551-0000 that uses the gaps between neighboring WLAN

networks as shown in the figure below.

Even if the maximum possible three non-overlapping WLAN channels are used adjacently, four

IEEE802.15.4 channels remain that the KM6551-0000 can use without interference.

Fig.9: Utilizing gaps between adjacent WLAN networks

1. Three non-overlapping WLAN networks in the WLAN channels permitted in North America (IEEE

802.11b)

2. Three non-overlapping WLAN networks in the WLAN channels permitted in Europe (IEEE 802.11b)

3. Placement of EEE802.15.4 channels (2400MHz PHY) in the gaps between WLAN networks

KM6551 15Version: 2.0.0

Page 16

IEEE802.15.4

Microwave ovens

Since microwave ovens typically operate at a frequency of 2.455GHz, neighboring poorly screened ovens

can interfere with the transmission between the KM6551-0000.

In this case, remove the interfering devices or use only well-screened microwave ovens in the direct vicinity

of the KM6551-0000.

KM655116 Version: 2.0.0

Page 17

Mounting and wiring

4 Mounting and wiring

4.1 Recommended mounting rails

Terminal Modules und EtherCAT Modules of KMxxxx and EMxxxx series, same as the terminals of the

EL66xx and EL67xx series can be snapped onto the following recommended mounting rails:

• DIN Rail TH35-7.5 with 1mm material thickness (according to EN60715)

• DIN Rail TH35-15 with 1,5mm material thickness

Pay attention to the material thickness of the DIN Rail

Terminal Modules und EtherCAT Modules of KMxxxx and EMxxxx series, same as the terminals of

the EL66xx and EL67xx seriesdoes not fit to the DIN Rail TH35-15 with 2,2 to 2,5mm material

thickness (according to EN60715)!

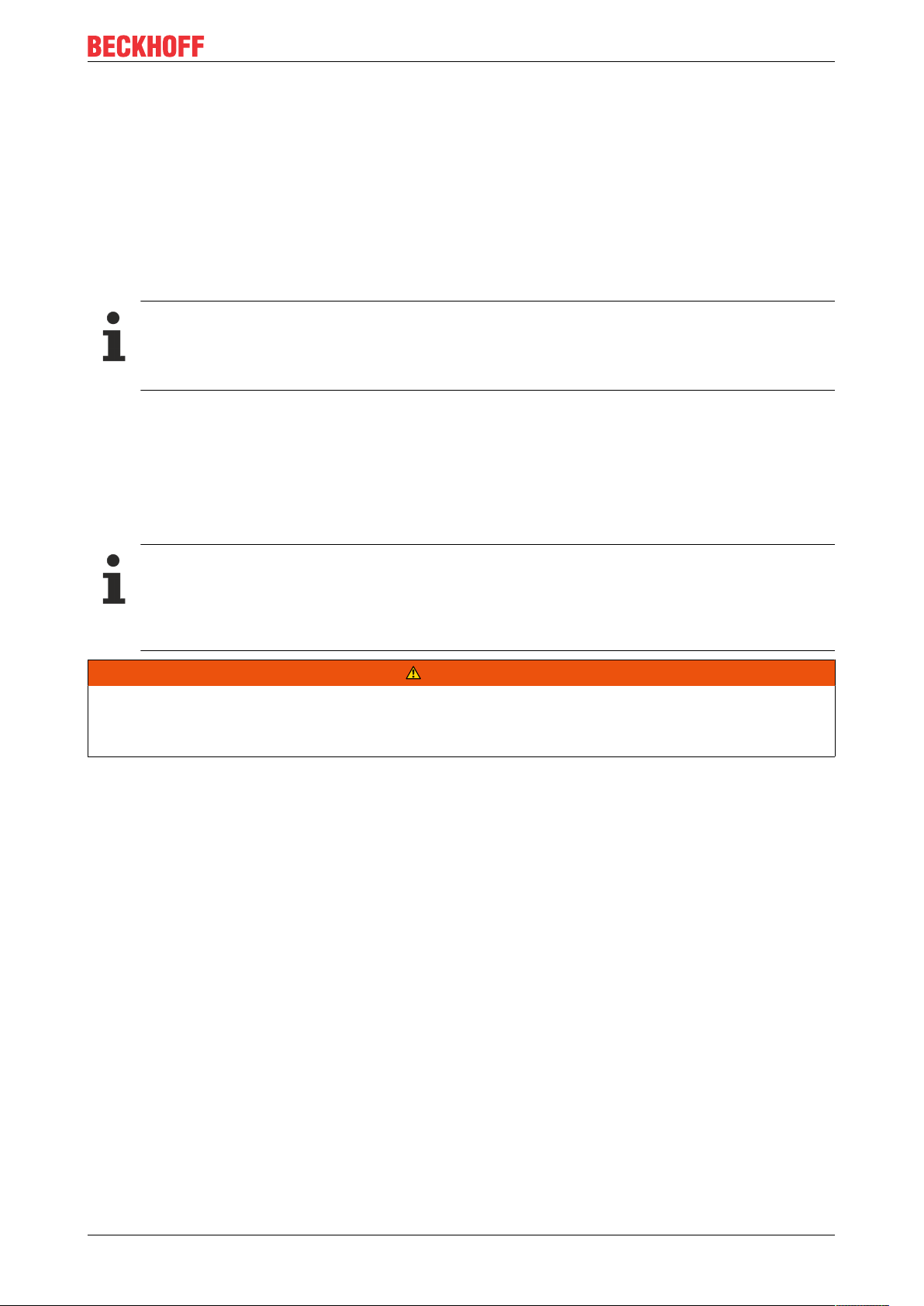

4.2 Mounting and demounting - terminals with traction lever unlocking

The terminal modules are fastened to the assembly surface with the aid of a 35 mm mounting rail (e.g.

mounting rail TH 35-15).

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting rail. At

the installation, the locking mechanism of the components must not come into conflict with the fixing

bolts of the mounting rail. To mount the recommended mounting rails under the terminals and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets).

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or

wiring of the Bus Terminals!

Mounting

• Fit the mounting rail to the planned assembly location.

KM6551 17Version: 2.0.0

Page 18

Mounting and wiring

and press (1) the terminal module against the mounting rail until it latches in place on the mounting

rail (2).

• Attach the cables.

Demounting

• Remove all the cables. Thanks to the KM/EM connector, it is not necessary to remove all the cables

separately for this, but for each KM/EM connector simply undo 2 screws so that you can pull them off

(fixed wiring)!

• Lever the unlatching hook on the left-hand side of the terminal module upwards with a screwdriver (3).

As you do this

◦ an internal mechanism pulls the two latching lugs (3a) from the top hat rail back into the terminal

module,

◦ the unlatching hook moves forwards (3b) and engages

KM655118 Version: 2.0.0

Page 19

Mounting and wiring

• In the case 32 and 64 channel terminal modules (KMxxx4 and KMxxx8 or EMxxx4 and EMxxx8) you

now lever the second unlatching hook on the right-hand side of the terminal module upwards in the

same way.

• Pull (4) the terminal module away from the mounting surface.

4.3 Dimensions

Fig.10: KM6551 dimensions

4.4 Connection

The antennas are connected via a reverse SMA screw plug. Please screw the cable, the coaxial cable or the

antenna hand tight to this screw plug.

KM6551 19Version: 2.0.0

Page 20

Mounting and wiring

Coaxial cable

Name Description

ZK6000-0102-0020 Coaxial cable, characteristic impedance 50Ω, preassembled plug connectors (SMA

plug and reverse SMA socket), black, 2m

ZK6000-0102-0040 Coaxial cable, characteristic impedance 50Ω, preassembled plug connectors (SMA

plug and reverse SMA socket), black, 4m

KM655120 Version: 2.0.0

Page 21

Mounting and wiring

4.5 Antenna alignment

4.5.1 Directional characteristic

Please pay attention to the directional characteristics and polarization of the antennas in order to mount and

align them to each another optimally!

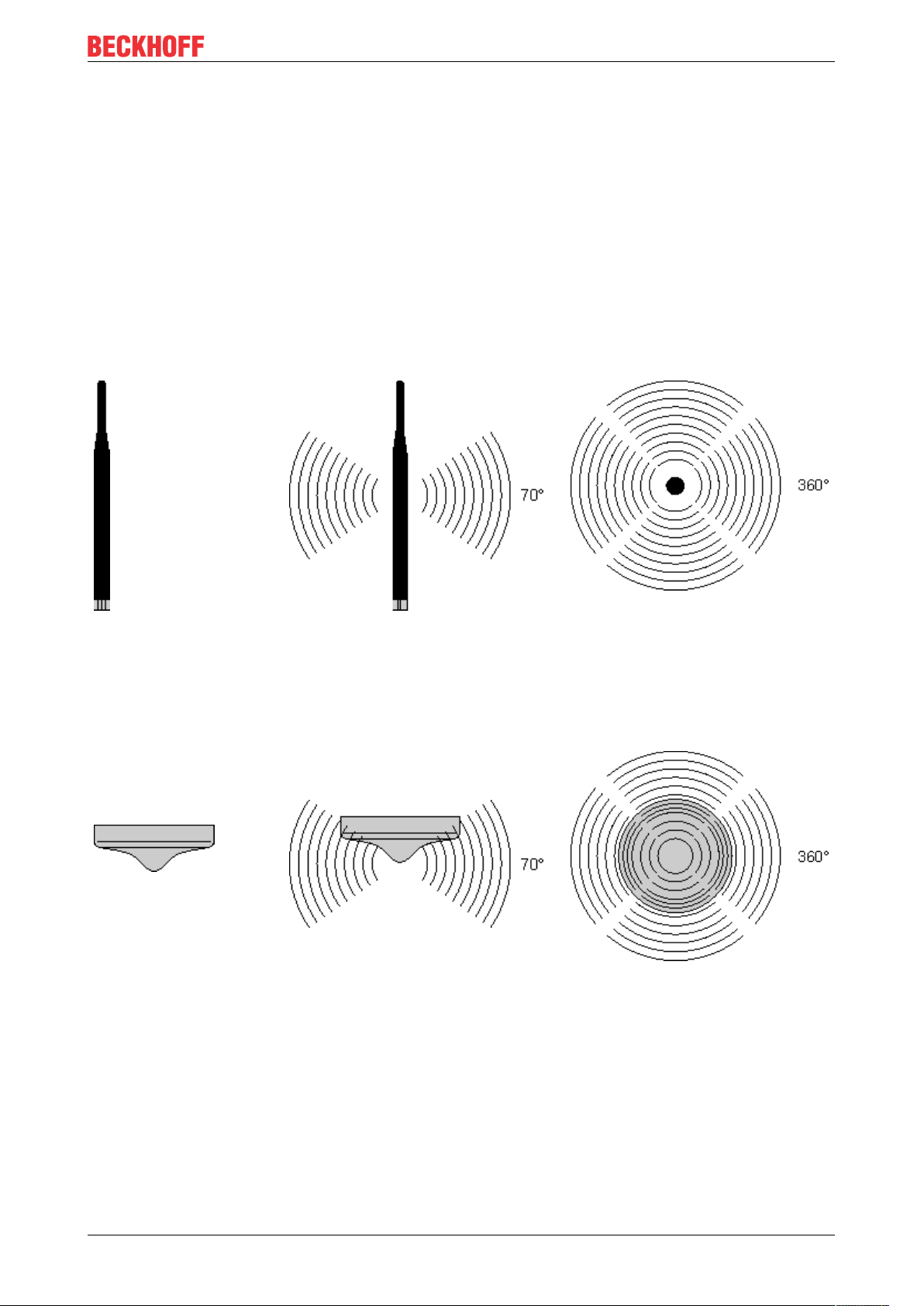

Omnidirectional antennas

ZS6201-0410, ZS6201-0500

Design Side view

(vertical directional characteristic)

ZS6200-0400

Predestined for mounting below the ceiling.

Design Side view

(vertical directional characteristic)

Top view

(horizontal directional characteristic)

Top view

(horizontal directional characteristic)

KM6551 21Version: 2.0.0

Page 22

Mounting and wiring

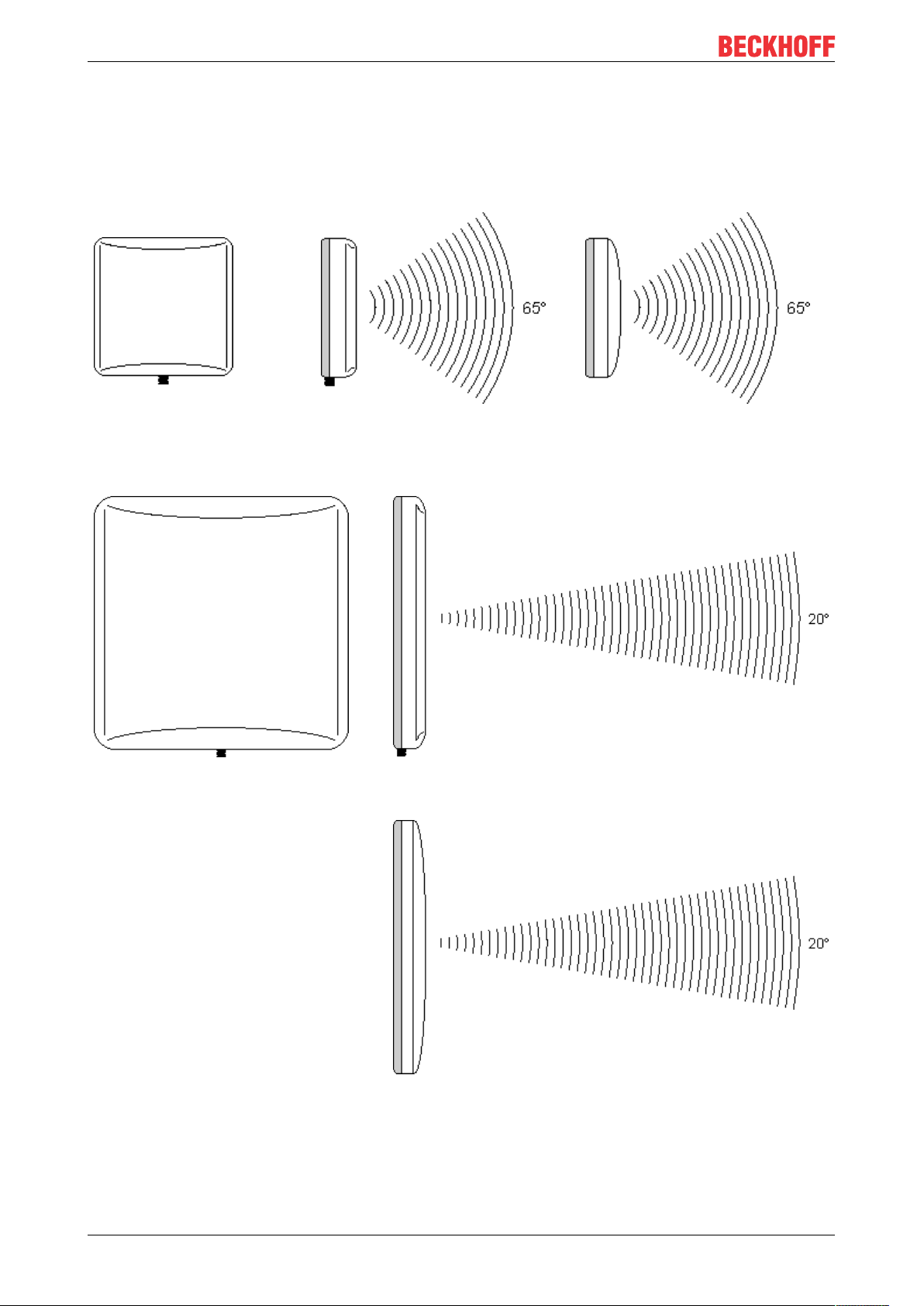

Directional antennas

ZS6100-0900

Design Side view

(vertical directional characteristic)

ZS6100-1800

Design Side view (vertical directional characteristic)

Top view

(horizontal directional characteristic)

Top view (horizontal directional characteristic)

KM655122 Version: 2.0.0

Page 23

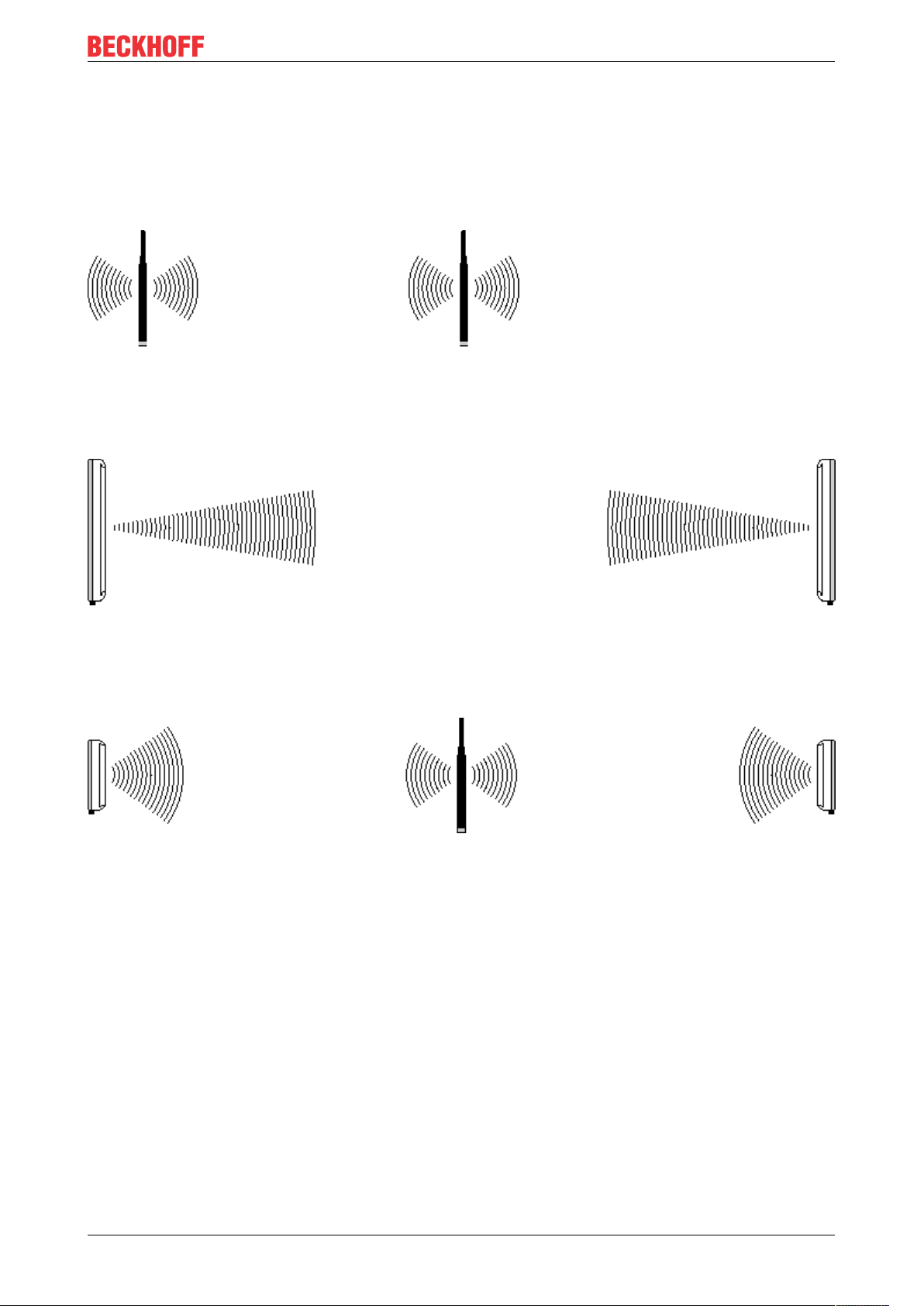

4.5.2 Alignment examples

Align the antennas so that each lies within the radiation cone of the opposite antenna.

Omnidirectional antennas

Two ZS6201-0410 or ZS6201-0500

Fig.11: Omnidirectional antennas

Directional antennas

Two ZS6100-0900 or ZS6100-1800

Mounting and wiring

Fig.12: Directional antennas

Mixed operation

e.g. one ZS6201-0410 and two ZS6100-1800

Fig.13: Mixed operation

4.5.3 Polarization

For optimum transmission, the antennas of all of the KM6551-0000 used must have the same polarization.

Omnidirectional antennas

Care must also be taken when using omnidirectional antennas that the antennas of all of the KM6551-0000

used have the same polarization.

Omnidirectional antennas such as the ZS6201-0410, ZS6201-0500 or ZS6200-0400 are mostly mounted for

vertical polarization.

Directional antennas

Arrows marked with the letters H and V are located on the rear side of the housing of the ZS6100-0900

directional antenna in order to identify the polarization (ZS6100-1800 in preparation).

KM6551 23Version: 2.0.0

Page 24

Mounting and wiring

Mount the directional antennas such that the marked arrows of all the antennas used correspond to one

another.

4.5.4 Placement of the antennas

Mount the antennas such that they can radiate freely!

There must be no obstructions in the direct vicinity of the antenna that could hinder the development of the

Fresnel zone [}25]. Metal obstacles such as control cabinets, machine parts, pipelines, iron beams etc.

particularly hinder the development of the Fresnel zone!

The connection of the antennas [}27] to the KM6551-0000 via the RSMA plug and coaxial cable [}19]

enables the antenna to be mounted remotely, so that you can position the antenna optimally.

KM655124 Version: 2.0.0

Page 25

Mounting and wiring

4.6 Attenuation and range

4.6.1 Fresnel zone

In radio transmission, the space between the transmitting and receiving antennas is known as the Fresnel

zone. The Fresnel zone is a notional spheroid between the antennas.

Fig.14: Fresnel zone

The main portion of the energy is transmitted in the area of the Fresnel zone.

This zone should be free of obstructions (e.g. objects, houses, trees etc.). Metal obstacles such as control

cabinets, machine parts, pipelines, iron beams etc. particularly hinder the development of the Fresnel zone!

Each hindrance of the Fresnel zone attenuates the transmission. If the Fresnel zone is half obscured, for

example, the additional attenuation is 6dB, i.e. the field strength is reduced to half of the free field value.

Reception may then be disturbed or completely interrupted under certain circumstances.

If the Fresnel zone is free from obstructions, the propagating wave is only attenuated by the free space

attenuation.

Fig.15: Radius r of the Fresnel zone in relationship to the distance s

KM6551 25Version: 2.0.0

Page 26

Mounting and wiring

4.6.2 Attenuation in practice

With an attenuation of 6dB the range is shortened to half of the value for an unobstructed connection, with

12dB it is shortened to a quarter.

Material Attenuation Range approx. Example for an un-

obstructed range of

280m

Thin wall 2 … 5dB (free field range)/1.5 - (free field range)/2 180m … 140m

Wooden wall 5dB (free field range)/2 140m

Masonry wall 6 … 12dB (free field range)/2 - (free field range)/4 140m … 70m

Concrete wall 10 … 20dB (free field range)/4 - (free field range)/8 70m … 5m

Concrete

ceiling

20dB (free field range)/8 <35m

4.6.3 Range of different antenna combinations

The given ranges are based on an unobstructed view and adherence to the Fresnel zone.

Two omnidirectional antennas

Fig.16: Two omnidirectional antennas

Omnidirectional antenna combined with a directional antenna

Fig.17: Omnidirectional antenna combined with a directional antenna

KM655126 Version: 2.0.0

Page 27

Two directional antennas

Fig.18: Two directional antennas

Mounting and wiring

4.7 Antennas

Overview

Name Description

ZS6100-0900 [}28]

ZS6100-1800 [}30]

ZS6200-0400 [}32]

ZS6201-0410 [}34]

ZS6201-0500 [}36]

CE conformity

The CE conformity of the KM6551-0000 is only guaranteed if it is operated with original Beckhoff accessories (antennas, coaxial cable [}19])!

Directional antenna (gain 9dBi), without cable

Directional antenna (gain 18dBi), without cable

Omnidirectional antenna (gain 4dBi), without cable

Rod antenna (gain 4dBi), with cable (1m)

Rod antenna (gain 5dBi), without cable

NOTE

KM6551 27Version: 2.0.0

Page 28

Mounting and wiring

4.7.1 ZS6100-0900

Fig.19: ZS6100-0900 - Directional antenna

Fig.20: ZS6100-0900 - Azimuth and Elevation for 2400MHz

KM655128 Version: 2.0.0

Page 29

Mounting and wiring

Technical data

Technical data ZS6100-0900

Frequency range 2400...2485MHz

Transmission factor 9dBi

3dB bandwidth, horizontal 65°

3dB bandwidth, vertical 65°

Connection SMA socket

Dimensions (WxHxD) 93mmx93mmx25mm

Weight (incl. accessories and packaging) approx.190g

Permissible ambient temperature range during

operation

Permissible relative air humidity 95%, no condensation

Protection class IP20

Installation position variable

Approval CE

Mounting Bracket mounting, included in scope of supply

Suitable coaxial cable ZS6000-0102-0020, ZS6000-0102-0040

-40°C ... + 80°C

KM6551 29Version: 2.0.0

Page 30

Mounting and wiring

4.7.2 ZS6100-1800

Fig.21: ZS6100-1800 - Directional antenna with large gain

Fig.22: ZS6100-1800 - Azimuth and Elevation for 2400MHz

KM655130 Version: 2.0.0

Page 31

Mounting and wiring

Technical data

Technical data ZS6100-1800

Frequency range 2400...2485MHz

Transmission factor 18dBi

3dB bandwidth, horizontal 20°

3dB bandwidth, vertical 20°

Connection SMA socket

Dimensions (WxHxD) 360mmx360mmx30mm

Weight (incl. accessories and packaging) approx.3640g

Permissible ambient temperature range during

operation

Permissible relative air humidity 95%, no condensation

Protection class IP20

Installation position variable

Approval CE

Mounting Bracket mounting, included in scope of supply

Suitable coaxial cable ZS6000-0102-0020, ZS6000-0102-0040

-40°C ... + 80°C

KM6551 31Version: 2.0.0

Page 32

Mounting and wiring

4.7.3 ZS6200-0400

Fig.23: ZS6200-0400 - Omnidirectional antenna

Fig.24: ZS6200-0400 - Azimuth and Elevation for 2400MHz

KM655132 Version: 2.0.0

Page 33

Mounting and wiring

Technical data

Technical data ZS6200-0400

Frequency range 2400...2485MHz

Transmission factor 4dBi

3dB bandwidth, horizontal 360°

3dB bandwidth, vertical 70°

Connection SMA socket

Dimensions Height: 110mm, diameter: 45mm

Weight (incl. accessories and packaging) approx.210g

Permissible ambient temperature range during

operation

Permissible relative air humidity 95%, no condensation

Protection class IP20

Installation position variable, predestined for mounting below the ceiling.

Approval CE

Suitable coaxial cable ZS6000-0102-0020, ZS6000-0102-0040

-40°C ... + 80°C

KM6551 33Version: 2.0.0

Page 34

Mounting and wiring

4.7.4 ZS6201-0410

Fig.25: ZS6201-0410 - Rod antenna with cable

Fig.26: ZS6201-0410 - Azimuth and Elevation for 2400MHz

KM655134 Version: 2.0.0

Page 35

Mounting and wiring

Technical data

Technical data ZS6201-0410

Frequency range 2400...2485MHz

Transmission factor 4dBi

3dB bandwidth, horizontal 360°

3dB bandwidth, vertical 70°

Connection Reverse SMA socket (with 1 m cable, permanently

connected to antenna)

Dimensions Height 202mm, foot diameter 35mm

Weight (incl. cable, accessories and packaging) approx.220g

Permissible ambient temperature range during

operation

Permissible relative air humidity 95%, no condensation

Mounting Cap nut M14

Protection class IP20

Installation position variable

Approval CE

Coaxial cable 1m, included in scope of supply

-40°C ... + 80°C

KM6551 35Version: 2.0.0

Page 36

Mounting and wiring

4.7.5 ZS6201-0500

Fig.27: ZS6201-0500 - Rod antenna

Fig.28: ZS6201-0500 - Azimuth and Elevation for 2400MHz

KM655136 Version: 2.0.0

Page 37

Mounting and wiring

Technical data

Technical data ZS6201-0500

Frequency range 2400...2485MHz

Transmission factor 5dBi

3dB bandwidth, horizontal 360°

3dB bandwidth, vertical 70°

Connection Reverse SMA socket

Dimensions Height 195mm, foot diameter 12mm

Weight (incl. packaging) approx.40g

Permissible ambient temperature range during

operation

Permissible relative air humidity 95%, no condensation

Mounting Direct connection with hinged joint

Protection class IP20

Installation position variable

Approval CE

Suitable coaxial cable Not required, direct connection

-40°C ... + 80°C

KM6551 37Version: 2.0.0

Page 38

Application examples - overview

5 Application examples - overview

• Peer to peer mode [}38]

• Master-Slave mode [}38]

• Broadcast mode [}39]

• Energy scan [}40]

5.1 Peer to peer mode

Application

The simplest type of communication between two KM6551-0000 is the peer to peer mode. To do this, set the

DIP switches [}13]

• of the master module to master mode and

• that of the second module to slave address 1.

Now you have to set bit 0 (start bit) in the control byte CB1 [}59] of both modules to TRUE. The modules

acknowledge this bit by setting bit0 of their status bytes SB1 [}59]. The establishment of communication

and the communication itself then begin automatically.

Now 10bytes are always exchanged between the modules. This continues until a start bit is reset to FALSE.

It does not matter which side resets the start bit.

If the connection is disturbed or if the start bit is not set on the opposite side, the module reports an error with

bit 6 in the status byte SB1 [}59]. The error code is output at the same time in status byte SB2 [}59] (see

ErrorID).

5.2 Master-Slave mode

Application

A further possibility is the exchange of data between a master and up to 7 slaves. The address of the slave

is set accordingly with the DIP switch [}13]. The address may only be used once for each channel. Here too

the control byte1 CB1 [}59] must be set to TRUE as bit 0 "Start BIT". Bits 3...5 are used to set the slave

address of the target device. The terminal then sends telegrams to the corresponding slave. If the terminal

receives a response, this is displayed in the status.

Example: Task – you want to speak to slave 2.

Set bit0 to TRUE in order to start data exchange. Bit3 must then be set in order to speak to slave 2. As

soon as the reply from slave 2 is received (after approx. 20ms), the master terminal confirms this in the

status byte by setting bit 4. The address is always counted +1 in the status byte (see table).

CB1 [}59]

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess reserve Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 1 0 0 1

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 1 0 0 0 1

KM655138 Version: 2.0.0

Page 39

Application examples - overview

Address Control byte bit 3...5 Status byte bit 3...5

Slave 1 0

Slave 2 1

Slave 3 2

Slave 4 3

Slave 5 4

Slave 6 5

Slave 7 6

dec

dec

dec

dec

dec

dec

dec

000

001

010

011

100

101

110

bin

bin

bin

bin

bin

bin

bin

1

dec

2

dec

3

dec

4

dec

5

dec

6

dec

7

dec

001

010

011

100

101

110

111

bin

bin

bin

bin

bin

bin

bin

Hence, you can now poll the terminals at any desired speed and in any desired rhythm. If you only send data

very rarely to a slave, remember that the watchdog in the slave terminal can trigger. The watchdog time in

the slave is approx. 400ms and can be set in register R38 [}64]. The default value is 20 and must be

multiplied by 20ms.

If a slave does not answer, then either the radio connection is disturbed or bit 0 of the control byte on the

slave side is not set; the master terminal sets the error bit 6. The error code is contained in the high nibble in

SB2.

If you want to address a new slave, make sure that the data bytes 0...9 are updated on the new slave at the

same time. When the slave replies, you should only accept the data from the new slave if the new slave

address appears in the status and the error bit is not set.

5.3 Broadcast mode

Application

Broadcast mode enables data to be sent from a master to any number of slaves. Data is thereby sent to the

slaves. The slaves receive the data, but the master does not receive any reply from the slaves.

For broadcast mode, the master must be set to master operation with the aid of the DIP switch [}13] and

register 39 [}64] must be set to broadcast mode before setting data communication. It is sufficient for the

slave to be set to broadcast-slave mode via the DIP switch.

The sequence for setting the master module to broadcast-master mode is as follows:

1. Remove the write protection R31 [}63]

2. Write broadcast master mode to R39 [}64]

3. Read out R39 [}64]to check that master mode has really been set

4. Set the start bit in CB1 [}59]

Example: Task – start the data exchange (same for master and slave)

Set bit 0 to TRUE in order to start data exchange.

CB1 [}59]

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess reserve Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 0 1

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 0 1

KM6551 39Version: 2.0.0

Page 40

Application examples - overview

5.4 Energy scan

Application

The energy scan enables the 16 IEEE802.15.4 channels to be monitored in order to detect other radio

systems. The energy in a frequency band is determined and displayed. Each channel is measured for

approx. 5seconds before moving to the next channel. Care must be taken that a channel does not

communicate during these 5seconds. It therefore makes sense to repeat the scanning of the channels a

couple of times in order to obtain a more accurate statement as to whether or not a channel is occupied. The

energy level is displayed through 0...0xF; "0" means no energy, "0xF" or 16dec stands for high energy level.

Set bit 1 in CB1 to TRUE. The KM6551-0000 confirms this in the status with bit1, which is then also set to

TRUE. The scan is finished when bit 1 of SB1 goes to FALSE. The result is then available in the input data

byte 0 to 7. Each channel then corresponds to a nibble, i.e. half of a byte.

Example

Byte number Description Value

(hex)

1 SB1 - Status byte 1

2 SB2 - Status byte 2

3 Data IN[0] 0x3F 3 - channel 1 low energy, F - channel 2 very high energy

4 Data IN[1] 0x01 0 - channel 3 no energy, 1 - channel 4 very low energy

5 Data IN[2] 0x7F 7 - channel 5 moderate energy, F - channel 5 very high energy

6...9 ... ... ... (not considered in this example for reasons of simplicity)

10 Data IN[8] 0x10 1 - channel 15 low energy, 0 - channel 16 no energy

11...12 Data IN[8...9] - not required

The result is to be interpreted as follows. Channels 2 and 5 are to be avoided at all costs, but channels 3 and

16 look very good. No energy was measured here. Please note that these are instantaneous values. You

can exclude channels with a high energy from further searches for free channels, but channels with no or

only moderate energy may lead under certain circumstances to entirely different results.

Example: activation of the energy scan

Set bit 1 to TRUE in order to start data exchange.

CB1 [}59]

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess reserve Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 1 0

Meaning

The terminal sets bit 1 of the status byte SB1 to TRUE as long as the scan is active.

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 1 0

The terminal resets bit 1 of the status byte SB1 to FALSE once the scan is finished. You can now evaluate

the input data bytes 0...7 (bytes 8-9 have no meaning and should not be evaluated).

The scan takes approx. 80 seconds.

KM655140 Version: 2.0.0

Page 41

Application examples - overview

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 0 0

KM6551 41Version: 2.0.0

Page 42

TwinCAT

6 TwinCAT

PLC and Motion Control on the PC

TwinCAT - The Windows Control and Automation Technology

The TwinCAT automation software converts any compatible PC into a real-time controller with multi-PLC, NC

axis control, programming environment and operating station. TwinCAT replaces conventional PLC and NC

controllers as well as operating devices:

• open, compatible PC hardware

• Embedding of IEC 61131-3 software PLC, software NC and software CNC in Windows NT/2000/XP,

NT/XP Embedded, CE

• Programming and runtime systems optionally together on one PC or separated

• Connection to all common fieldbus systems

• PC interfaces are supported

• Data communication with user interfaces and other programs by means of open Microsoft standards

(OPC, OCX, DLL, etc.)

TwinCAT architecture

TwinCAT consists of runtime systems for real-time execution of control programs and development

environments for programming, diagnosis and configuration. Any Windows programs, for instance

visualization programs or Office programs, can access TwinCAT data via Microsoft interfaces, or can

execute commands.

A practically oriented software solution

TwinCAT offers a precise time-base in which programs are executed with the highest deterministic features,

independently of other processor tasks. The real-time load on a PC is set with TwinCAT: This achieves a

defined operating behavior. TwinCAT displays the system load for running programs. A loading threshold

can be set, in order to assure a defined computing capacity for the operating programs and for Windows

NT/2000/XP. If this threshold is exceeded, a system message is generated.

TwinCAT supports system diagnosis

The general use of hardware and software from the open PC world requires some checking: Unsuitable

components can upset the PC system. Beckhoff integrates a handy display of the real-time jitter in order to

provide administrators with a simple means of evaluating hardware and software. A system message during

operation can draw attention to error states.

KM655142 Version: 2.0.0

Page 43

TwinCAT

Start/stop behavior

Depending on the setting, TwinCAT is started and stopped manually or automatically. Since TwinCAT is

integrated into Windows NT/2000/XP as a service, an operator is not needed to start the system: switching

on is enough.

Restarting and data backup

When a program is started or restarted, TwinCAT loads programs and remanent data. To backup data, and

to shut down Windows NT/2000/XP correctly, a UPS (uninterruptible power supply) is of great value.

TwinCAT and "Blue Screen"

The TwinCAT system can be configured such that real-time capability is maintained in the event of a BSOD

(Blue-Screen-of-Death) operating system crash. Real-time tasks such as PLC and NC can thus continue to

run and place the controlled process in a safe state. Ultimately, it is the decision of the programmer whether

or not to utilize this feature, bearing in mind that data or programs may already have been destroyed by the

BSOD.

World-wide connection through message routing - "remote" connection is inherent to the system

According to the requirement for operating resources, the TwinCAT software devices can be distributed:

TwinCAT PLC programs can be executed on PCs and on Beckhoff Bus Terminal controllers. A "message

router" manages and distributes all the messages, both in the system and via TCP/IP connections. PC

systems can be connected to one another by TCP/IP; Bus Terminal controllers are connected via serial

interfaces and fieldbus systems (EtherCAT, Lightbus, PROFIBUS DP, PROFINET, Interbus, CANopen,

DeviceNet, RS232, RS485, Ethernet TCP/IP, Ethernet/IP).

World-wide access

Since standard TCP/IP services from Windows NT/2000/XP are used, this data exchange can take place

worldwide. The system offers scalable communication capacity and timeout periods for the monitoring of

communications. OPC provides a standardized means for accessing many different SCADA packets. The

SOAP (Simple Object Access Protocol) enables a connection between two computers to be established by

means of an internet connection via standard HTTP. A TwinCAT component is available for this purpose.

Beckhoff Information System

Further information on the TwinCAT automation software can be found in the Beckhoff Information System.

The setup for installing the Beckhoff Information System is available to you on the Beckhoff

Products&Solutions DVD and on our website for download.

In addition, the online version of the Beckhoff Information System can be found at https://

infosys.beckhoff.com.

KM6551 43Version: 2.0.0

Page 44

TwinCAT

6.1 TwinCAT libraries

A TwinCAT library is available for all Beckhoff controller families (BC, BX, CX and IPC) for the operation of

the KM6551-0000 under TwinCAT. This library takes care of communication with the terminal. It sets

parameters in or reads parameters from the terminal. The use of the library simplifies communication with

the terminal for the user.

ZIP file TC_KM6551.zip: https://infosys.beckhoff.com/content/1033/km6551/Resources/

zip/9305592971.zip

Copy the libraries into the TwinCAT\PLC\Lib directory.

Other required libraries:

For Bus Terminal Controllers from the BCxx00 series

• Standard.lb6

• PlcHelper.lb6

For Bus Terminal Controllers from the BCxx20 and BCxx50 series

• Standard.lbx

• TcBaseBCxx50.lbx

• TcSystemBCxx50.lbx

For Bus Terminal Controllers from the BXxxxx series

• Standard.lbx

• TcBaseBX.lbx

• TcSystemBX.lbx

For 386-based systems such as Industrial PCs, Embedded PCs (CX)

• Standard.lib

• TcBase.lib

• TcSystem.lib

The user can write his own function blocks for the operation of the KM6551-0000 under other controllers.

6.2 TwinCAT examples

For the examples you need one CX9000 with K-bus, one BC9050, two KM6551-0000, two KL9010 end

terminals and one KL2xx4 (optional).

Example for master/slave communication (https://infosys.beckhoff.com/content/1033/km6551/Resources/

zip/9305595147.zip)

A KM6551-0000 is plugged into the CX9000 as a master module and optionally the KL2xx4 Bus Terminal. A

KM6551-0000 is plugged into the BC9050 as a slave module.

Example for broadcast communication (https://infosys.beckhoff.com/content/1033/km6551/Resources/

zip/9305597323.zip)

A KM6551-0000 is plugged into the CX9000 as a master module and optionally the KL2xx4 Bus Terminal. A

KM6551-0000 is plugged into the BC9050 as a broadcast slave module.

Example for energy scan (https://infosys.beckhoff.com/content/1033/km6551/Resources/

prx/9305599499.prx)

One BX9000, one KL6551-0000 and one KL9010 are required.

KM655144 Version: 2.0.0

Page 45

TwinCAT

6.3 Function blocks

6.3.1 Function block FB_KM6551_MAIN

This function block takes care of communication to the KM6651-0000 and takes care of and makes settings

in the module by means of register communication. Only one FB_KM6551_MAIN function block is permitted

per KM6551-0000.

Fig.29: Function block FB_KM6551_MAIN

VAR_INPUT

bActivate

:BOOL;

bBroadcast

:BOOL;

iChannel_Set

:INT;

uiSlaveTM

:UINT;

KM6551_IN

:ARRAY[1..12]ofBYTE;

KM6551_OUT

:ARRAY[1..12]ofBYTE;

Key

bActivate: Positive edge activates the function block and writes parameters to the KM6551-0000.

bBroadcast: Can only be activated in master mode. TRUE – sets the KM6651-0000 to broadcast master

mode (see register 39 [}64]).

iChannel_Set: The IEEE802.15.4 channel is set here. Permitted values 0..15 (see register 32/33 [}63]).

uiSlaveTM: Only usable in slave mode; setting of the watchdog for the slave mode (see register 38 [}64]).

KM6551_IN: Is connected to the INPUT data of the KM6551-0000.

KM6551_OUT: Is connected to the OUTPUT data of the KM6551-0000.

VAR_OUTPUT

bActive

:BOOL;

bError

:BOOL;

iErrorID

:E_KM6551_ERRORID;

bBusy

:BOOL;

strLinkData:KM6551_Data;

Key

b Active: The function block has successfully transmitted the parameters to KM6551-0000 and can now

commence data communication with the other KM6551-0000 function blocks.

bError: The function block has an error.

iErrorID: Contains the error code.

bBusy: The function block is still working as long as bBusy is set, i.e. is TRUE; wait until bBusy changes to

KM6551 45Version: 2.0.0

Page 46

TwinCAT

FALSE.

strLinkData: Data required by the higher-level function blocks. Connect this data to the additional function

blocks that they call.

6.3.2 Energy scan

Application

The energy scan enables the 16 IEEE802.15.4 channels to be monitored in order to detect other radio

systems. The energy in a frequency band is determined and displayed. Each channel is measured for

approx. 5seconds before moving to the next channel. Care must be taken that a channel does not

communicate during these 5seconds. It therefore makes sense to repeat the scanning of the channels a

couple of times in order to obtain a more accurate statement as to whether or not a channel is occupied. The

energy level is displayed through 0...0xF; "0" means no energy, "0xF" or 16dec stands for high energy level.

Set bit 1 in CB1 to TRUE. The KM6551-0000 confirms this in the status with bit 1, which is then also set to

TRUE. The scan is finished when bit 1 of SB1 goes to FALSE. The result is then available in the input data

byte 0 to 7. Each channel then corresponds to a nibble, i.e. half of a byte.

Example

Byte number Description Value

(hex)

1 SB1 - Status byte 1

2 SB2 - Status byte 2

3 Data IN[0] 0x3F 3 - channel 1 low energy, F - channel 2 very high energy

4 Data IN[1] 0x01 0 - channel 3 no energy, 1 - channel 4 very low energy

5 Data IN[2] 0x7F 7 - channel 5 moderate energy, F - channel 5 very high

6...9 ... ... ... (not considered in this example for reasons of simplicity)

10 Data IN[8] 0x10 1 - channel 15 low energy, 0 - channel 16 no energy

11...12 Data IN[8...9] - not required

The result is to be interpreted as follows. Channels 2 and 5 are to be avoided at all costs, but channels 3 and

16 look very good. No energy was measured here. Please note that these are instantaneous values. You

can exclude channels with a high energy from further searches for free channels, but channels with no or

only moderate energy may lead under certain circumstances to entirely different results.

Example: activation of the energy scan

Set bit 1 to TRUE in order to start data exchange.

CB1 [}59]

Meaning

energy

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess reserve Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 1 0

The terminal sets bit 1 of the status byte SB1 to TRUE as long as the scan is active.

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 1 0

KM655146 Version: 2.0.0

Page 47

TwinCAT

The terminal resets bit 1 of the status byte SB1 to FALSE once the scan is finished. You can now evaluate

the input data bytes 0...7 (bytes 8-9 have no meaning and should not be evaluated).

The scan takes approx. 80seconds.

SB1 [}59]

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error Add3 Add2 Add1 Scan EnergyScan Start

Value 0 0 0 0 0 0 0 0

6.3.3 Master/Slave mode

6.3.3.1 Function block FB_KM6551_MASTER_10BYTE

This function block takes care of communication to the individual slaves. Only one function block can be

called per slave. A maximum of 7 slaves are allowed, for which reason a maximum of 7 function blocks of

this type may be called per master terminal. A positive edge on bStart activates communication to the slave

that is stored in the variable iSlaveAddr. bBusy goes to TRUE as long as the function block is active. If

bBusy changes to FALSE, the function block has finished. If bError is FALSE, then communication was

successful and the input data is valid. If the bError bit is TRUE, an error has occurred. A precise error cause

can be read out in iErrorID. ptData_IN is a pointer address for the input data (ADR command to determine

the pointer address) and iLenData_IN is the length of the data. The length can be determined with SIZEOF

and must not be larger than 10 bytes. The same applies to the output data. The strLinkData variable is

linked to the FB_KM6551_MAIN function block (the variable has exactly the same name). The

FB_KM6551_MAIN function block should be finished before the FB_KM6551_MASTER_10BYTE function

block is called, (see bActive in this function block).

Fig.30: Function block FB_KM6551_Master_10Byte

VAR_INPUT

bStart

:BOOL;

iSlaveAddr

:INT;

strLinkData

:KM6551_Data;

ptData_IN

:DWORD;

iLenData_IN:INT;

ptData_OUT

:DWORD;

iLenData_OUT:INT;

Key

bStart: A positive edge activates the function block.

iSlaveAddr: The address of the slave is entered here (see DIP switch on your slave module)

strLinkData: Is linked with strLinkData from FB_KM6551_MAIN.

ptData_IN: Pointer to the variable into which the device data should be copied (pointer address is

KM6551 47Version: 2.0.0

Page 48

TwinCAT

determined with ADR(Variable_name)).

iLenData_IN: Length of the variable (the length can be determined with SIZEOF (variable_name))

ptData_OUT: Pointer to the variable into which the master terminal should transmit to the slave (pointer

address is determined with ADR(Variable_name)).

iLenData_OUT: Length of the variable (the length can be determined with SIZEOF (variable_name))

VAR_OUTPUT

bError

:BOOL;

bBusy

:BOOL;

iErrorID

:E_KM6551_ERRORID;

iSignalQuality:INT;

E_Addr

:E_KM6551_DIP;

Key

b Error: The function block has an error.

bBusy: The function block is still working as long as bBusy is set, i.e. is TRUE; wait until bBusy changes to

FALSE.

iErrorID: Contains the error code.

iSignalQuality: LQI value, quality of the signal received; 100 very good transmission, 0 very poor

transmission - the LQI value should be as high as possible and should have a minimum value of 10-20. You

can improve the LQI value by the use of better antennas or shorter cables or better alignment of the

antennas.

E_Addr: Reads out the DIP switch setting of the KM6551-0000 module and displays it.

6.3.3.2 Function block FB_KM6551_SLAVE_10BYTE

This function block takes care of communication to the slave module. Only one function block can be called

per slave. A positive edge on bStart activates communication to the slave. If bError is FALSE, then

communication was successful and the input data is valid. If the bError bit is TRUE, an error has occurred. A

precise error cause can be read out in iErrorID. ptData_IN is a pointer address for the input data (ADR

command to determine the pointer address) and iLenData_IN is the length of the data. The length can be

determined with SIZEOF and must not be larger than 10bytes. The same applies to the output data. The

strLinkData variable is linked to the FB_KM6551_MAIN function block (the variable has exactly the same

name). The FB_KM6551_MAIN function block should be finished before the FB_KM6551_SLAVE_10BYTE

function block is called, (see bActive in this function block).

Fig.31: Function block FB_KM6551_Slave_10Byte

VAR_INPUT

bStart

:BOOL;

strLinkData

:KM6551_Data;

ptData_IN

:DWORD;

iLenData_IN:INT;

KM655148 Version: 2.0.0

Page 49

TwinCAT

ptData_OT

:DWORD;

iLenData_OUT:INT;

Key

bStart: A positive edge activates the function block.

strLinkData: Is linked with strLinkData from FB_KM6551_MAIN.

ptData_IN: Pointer to the variable into which the device data should be copied (pointer address is

determined with ADR(Variable_name)).

iLenData_IN: Length of the variable (the length can be determined with SIZEOF (variable_name))

ptData_OUT: Pointer to the variable into which the master terminal should transmit to the slave (pointer

address is determined with ADR(Variable_name)).

iLenData_OUT: Length of the variable (the length can be determined with SIZEOF (variable_name))

VAR_OUTPUT

bError

:BOOL;

bBusy

:BOOL;

iErrorID

:E_KM6551_ERRORID;

iSignalQuality:INT;

E_Addr

:E_KM6551_DIP;

Key

b Error: The function block has an error.

bBusy: The function block is still working as long as bBusy is set, i.e. is TRUE; wait until bBusy changes to

FALSE.

iErrorID: Contains the error code.

iSignalQuality: LQI value, quality of the signal received; 100 very good transmission, 0 very poor

transmission - the LQI value should be as high as possible and should have a minimum value of 10-20. You

can improve the LQI value by the use of better antennas or shorter cables or better alignment of the

antennas.

E_Addr: Reads out the DIP switch setting of the KM6651-0000 module and displays it.

6.3.4 Broadcast mode

6.3.4.1 Function block FB_KM6551_MASTERBROADCAST_10BYTE

This function block takes care of communication to the individual slaves in broadcast mode. The number of

data telegrams can be reduced with the time tPolling. Data will then only be sent within the time tPolling. If

the tPolling time is high for the broadcast slaves, make sure that you also enter a higher watchdog time, as

otherwise the slave will display a watchdog error. A positive edge on bStart activates communication. If the

bError bit is TRUE, an error has occurred. A precise error cause can be read out in iErrorID. ptData_OUT is

a pointer address for the input data (ADR command to determine the pointer address) and iLenData_OUT is

the length of the data. The length can be determined with SIZEOF and must not be larger than 10 bytes. The

strLinkData variable is linked to the FB_KM6551_MAIN function block (the variable has exactly the same

name). The FB_KM6551_MAIN function block should be finished before the

FB_KM6551_MASTER_10BYTE function block is called, (see bActive in this function block).

KM6551 49Version: 2.0.0

Page 50

TwinCAT

Fig.32: Function block FB_KM6551_Masterbroadcast_10Byte

VAR_INPUT

bStart

:BOOL;

iSlaveAddr

:INT;

strLinkData

:KM6551_Data;

ptData_OUT

:DWORD;

iLenData_OUT:INT;

tPolling

:TIME;

Key

bStart: A positive edge activates the function block.

iSlaveAddr: The address of the slave is entered here (see DIP switch on your slave module)

strLinkData: Is linked with strLinkData from FB_KM6551_MAIN.

ptData_OUT: Pointer to the variable into which the master terminal should transmit to the slave (pointer

address is determined with ADR(Variable_name)).

iLenData_OUT: Length of the variable (the length can be determined with SIZEOF (variable_name))

tPolling: Time cycle in which the data should be sent to the slaves.

VAR_OUTPUT

bError

:BOOL;

bActive

:BOOL;

iErrorID

:E_KM6551_ERRORID;

E_Addr

:E_KM6551_DIP;

Key

b Error: The function block has an error.

bActive: Indicates whether or not the function block is working.

iErrorID: Contains the error code.

E_Addr: Reads out the DIP switch setting of the KM6551-0000 and displays it.

6.3.4.2 Function block FB_KM6551_SLAVEBROADCAST_10BYTE

This function block takes care of communication to the broadcast slave module. Only one function block can

be called per slave. A positive edge on bStart activates communication to the slave. If bError is FALSE, then

communication was successful and the input data is valid. If the bError bit is TRUE, an error has occurred. A

precise error cause can be read out in iErrorID. ptData_IN is a pointer address for the input data (ADR

command to determine the pointer address) and iLenData_IN is the length of the data. The length can be

determined with SIZEOF and must not be larger than 10 bytes. The same applies to the output data. The

strLinkData variable is linked to the FB_KM6551_MAIN function block (the variable has exactly the same

name). The FB_KM6551_MAIN function block should be finished before the

FB_KM6551_MASTER_10BYTE function block is called, (see bActive in this function block).

KM655150 Version: 2.0.0

Page 51

Fig.33: Function block FB_KM6551_Slavebroadcast_10Byte

VAR_INPUT

bStart

:BOOL;

strLinkData

:KM6551_Data;

ptData_IN

:DWORD;

iLenData_IN:INT;

Key

bStart: A positive edge activates the function block.

strLinkData: Is linked with strLinkData from FB_KM6551_MAIN.

ptData_IN: Pointer to the variable into which the device data should be copied (pointer address is

determined with ADR(Variable_name)).

iLenData_IN: Length of the variable (the length can be determined with SIZEOF (variable_name))

TwinCAT

VAR_OUTPUT

bError

:BOOL;

bActive

:BOOL;

iErrorID

:E_KM6551_ERRORID;

iSignalQuality:INT;

E_Addr

:E_KM6551_DIP;

Key

b Error: The function block has an error.

bActive: Indicates whether or not the function block is working.

iErrorID: Contains the error code.

iSignalQuality: LQI value, quality of the signal received; 100 very good transmission, 0 very poor

transmission - the LQI value should be as high as possible and should have a minimum value of 10-20. You

can improve the LQI value by the use of better antennas or shorter cables or better alignment of the

antennas.

E_Addr: Reads out the DIP switch setting of the KM6651-0000 module and displays it.

KM6551 51Version: 2.0.0

Page 52

KS2000 Configuration Software

7 KS2000 Configuration Software

7.1 KS2000 - Introduction

The KS2000 configuration software permits configuration, commissioning and parameterization of bus

couplers, of the affiliated bus terminals and of Fieldbus Box Modules. The connection between bus coupler/

Fieldbus Box Module and the PC is established by means of the serial configuration cable or the fieldbus.

Fig.34: KS2000 configuration software

Configuration

You can configure the Fieldbus stations with the Configuration Software KS2000 offline. That means, setting

up a terminal station with all settings on the couplers and terminals resp. the Fieldbus Box Modules can be

prepared before the commissioning phase. Later on, this configuration can be transferred to the terminal

station in the commissioning phase by means of a download. For documentation purposes, you are provided

with the breakdown of the terminal station, a parts list of modules used and a list of the parameters you have

modified. After an upload, existing fieldbus stations are at your disposal for further editing.

Parameterization

KS2000 offers simple access to the parameters of a fieldbus station: specific high-level dialogs are available

for all bus couplers, all intelligent bus terminals and Fieldbus Box modules with the aid of which settings can

be modified easily. Alternatively, you have full access to all internal registers of the bus couplers and

intelligent terminals. Refer to the register description for the meanings of the registers.

KM655152 Version: 2.0.0

Page 53

KS2000 Configuration Software

Commissioning

The KS2000 software facilitates commissioning of machine components or their fieldbus stations: Configured

settings can be transferred to the fieldbus modules by means of a download. After a login to the terminal

station, it is possible to define settings in couplers, terminals and Fieldbus Box modules directly online. The

same high-level dialogs and register access are available for this purpose as in the configuration phase.

The KS2000 offers access to the process images of the bus couplers and Fieldbus Box modules.

• Thus, the coupler's input and output images can be observed by monitoring.

• Process values can be specified in the output image for commissioning of the output modules.

All possibilities in the online mode can be used in parallel with the actual fieldbus mode of the terminal

station. The fieldbus protocol always has the higher priority in this case.

7.2 Parameterization with KS2000

Connect the configuration interface of your Fieldbus Coupler with the serial interface of your PC via the

configuration cable and start the KS2000 Configuration Software.

Click on the Login button. The configuration software will now load the information

for the connected fieldbus station.

In the example shown, this is

• a BK9000 Bus Coupler for Ethernet

• a KL1002 input terminal

• a KM6551-0000 data exchange terminal

• a KL9010 Bus End Terminal

KM6551 53Version: 2.0.0

Page 54

KS2000 Configuration Software

Fig.35: Display of the fieldbus station in KS2000

The left-hand KS2000 window displays the terminals of the fieldbus station in a tree structure.

The right-hand KS2000window contains a graphic display of the fieldbus station terminals.

In the tree structure of the left-hand window, click on the plus-sign next to the module whose parameters you

wish to change (pos. 2 in the example).

Fig.36: KS2000 branch for channel 1 of the KM6551

The tree branches Register, Settings and ProcData are displayed for the KM6551-0000:

• Register [}56] allows direct access to the registers of the KM6551-0000.

• Under settings [}55] you will find dialog masks for parameterizing the KM6551-0000.

• Process data [}57] shows the process data of the KM6551-0000.

KM655154 Version: 2.0.0

Page 55

7.3 Settings

Dialog screen for parameterizing the KM6551.

Fig.37: Dialog screen for parameterizing the KM6551

KS2000 Configuration Software

Settings

Radio channel for KM6551 (R33)

R33 [}64]

Here you can set the radio channel. (Default: 5, permissible values: 0 to 15).

Scan settings

Found slaves

Displays the number of slaves found (R40 [}64]).

Slaves (R40)

R40 [}64]

Displays the slave numbers of the found slaves.

KM6551 55Version: 2.0.0

Page 56

KS2000 Configuration Software

7.4 Register

Under Register you can directly access the registers of the KM6551-0000 terminal module. The meaning of

the register is explained in the Register overview [}62].

Fig.38: Register view in KS2000

KM655156 Version: 2.0.0

Page 57

KS2000 Configuration Software

7.5 Process data

The Status byte (Status), the Control byte (Ctrl) and the process data (Data) are displayed in a tree structure

under ProcData.

Fig.39: Process Data field

The spectacles mark the data that are currently graphically displayed in the History field.

Fig.40: History field

The current input value is displayed numerically in the Value field.

Fig.41: Value field

Output values can be modified through direct input or by means of the fader control.

KM6551 57Version: 2.0.0

Page 58

KS2000 Configuration Software

Fig.42: Value field

CAUTION

Danger for persons, the environment or devices!

Note that changing output values (forcing) can have a direct effect on your automation application. Only

modify these output values if you are certain that the state of your equipment permits it, and that there will

be no risk to people or to the machine!

After pressing the Settings button you can set the format of the numerical display to hexadecimal, decimal or

binary.

Fig.43: Setting the display

KM655158 Version: 2.0.0

Page 59

Access from the user program

8 Access from the user program

8.1 Process image

The KM6551-0000 terminal module represents itself in the process image with a maximum of 12bytes of

input data and 12bytes of output data. These are organized as follows:

Format Input data Output data

Byte

Byte SB2 CB2

Array of bytes (0...9) DataIN DataOUT

Key

SBn: status byte n

CBn: control byte n

DataIN: Array of 10 input bytes (0...9)