Page 1

Documentation

KM3701, KM3702 and KM3712

Pressure Measuring Module

Version:

Date:

2.0.0

2017-11-20

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation........................................................................................................... 5

1.2 Safety instructions .......................................................................................................................... 6

1.3 Documentation issue status............................................................................................................ 7

2 Product overview.......................................................................................................................................8

2.1 KM3701 - Introduction .................................................................................................................... 8

2.2 KM3702 - Introduction .................................................................................................................... 9

2.3 KM3712 - Introduction .................................................................................................................. 10

2.4 Technical data .............................................................................................................................. 11

2.5 Basic function principles ............................................................................................................... 12

2.6 LED displays................................................................................................................................. 15

3 Mounting and wiring ...............................................................................................................................16

3.1 Recommended mounting rails ...................................................................................................... 16

3.2 Mounting and demounting - terminals with front unlocking........................................................... 16

3.3 Connection.................................................................................................................................... 18

4 Application examples..............................................................................................................................19

4.1 KM3701 - Application examples ................................................................................................... 19

4.2 KM3702 - Application example ..................................................................................................... 20

4.3 KM3712 - Application example ..................................................................................................... 21

5 KS2000 Configuration software .............................................................................................................22

5.1 KS2000 - Introduction ................................................................................................................... 22

5.2 Parameterization with KS2000 ..................................................................................................... 23

5.3 Register ........................................................................................................................................ 25

5.4 Process Data ................................................................................................................................ 26

6 Access from the user programm ...........................................................................................................27

6.1 KM3701 - Process image ............................................................................................................. 27

6.2 KM3702, KM3712 - Process image .............................................................................................. 27

6.3 Control and Status Byte................................................................................................................ 28

6.4 Register overview ......................................................................................................................... 30

6.5 Register description ...................................................................................................................... 32

6.6 Examples of Register Communication.......................................................................................... 35

6.6.1 Example 1: reading the firmware version from Register 9 ...............................................35

6.6.2 Example 2: Writing to an user register.............................................................................35

7 Appendix ..................................................................................................................................................38

7.1 Support and Service ..................................................................................................................... 38

KM3701, KM3702 and KM3712 3Version: 2.0.0

Page 4

Table of contents

KM3701, KM3702 and KM37124 Version: 2.0.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

KM3701, KM3702 and KM3712 5Version: 2.0.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

WARNING

CAUTION

Attention

Note

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

KM3701, KM3702 and KM37126 Version: 2.0.0

Page 7

1.3 Documentation issue status

Version Comment

2.0.0 • Corrections

• First public issue as PDF

1.2.0 • Technical data updated

• Installation and wiring extended

• Process data corrected

• KM3701-0340 added

1.1.1 Application examples update

1.1.0 Technical data updated

1.0.0 First release

Firmware and hardware versions

Foreword

Documentation

Version

2.0.0 1G 09 1D 07 1E 09

1.2.0 1C 01 1B 01 1B 01

1.1.1 1C 00 1B 00 1B 00

1.1.0 1B 00 1A 00 1A 00

1.0.0 1B 00 1A 00 1A 00

The firmware and hardware versions (delivery state) can be taken from the serial number printed on the side

of the terminal module.

Syntax of the serial number

Structure of the serial number: WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with ser. no.: 35 05 00 01:

35 - week of production 35

05 - year of production 2005

00 - firmware version 00

01 - hardware version 01

KM3701-0000, KM3701-0340 KM3702-0000 KM3712-0000

Firmware Hardware Firmware Hardware Firmware Hardware

KM3701, KM3702 and KM3712 7Version: 2.0.0

Page 8

Product overview

2 Product overview

2.1 KM3701 - Introduction

Fig.1: KM3701

Single-channel differential pressure measuring module

The KM3701 differential pressure measuring module enables direct measurement of pressure differences

between two hose connections. The pressure difference is available in the fieldbus with 16-bit resolution.

The measuring range is between -100hPa and +100hPa (-100mbar to +100mbar). The status LEDs

indicate proper function or errors such as range exceedance.

Two variants are available:

• KM3701-0000: Measuring range -100 to +100hPa (-100 to +100mbar)

• KM3701-0340: Measuring range -340 to +340hPa (-340 to +340mbar)

Quick links

• Mounting and wiring [}16]

• Access from the user program [}27]

• Application examples [}19]

KM3701, KM3702 and KM37128 Version: 2.0.0

Page 9

2.2 KM3702 - Introduction

Product overview

Fig.2: KM3702

Two-channel relative pressure measuring module for 0 to 7500hPa (0 to 7.5bar)

The relative pressure measuring module KM3702 enables direct measurement of two pressure values at the

hose connections. The pressure is determined as the difference to the environment of the KM3702 and is

available in the fieldbus with 16bit resolution. The status LEDs indicate proper function or errors such as

range exceedance.

KM3701, KM3702 and KM3712 9Version: 2.0.0

Page 10

Product overview

2.3 KM3712 - Introduction

Fig.3: KM3712

Dual channel relative pressure measuring module for -1,000hPa to +1,000hPa (-1bar to +1bar)

The relative pressure measuring module KM3712 allows the direct measurement of two negative pressure

values on the hose connections. The pressure is determined as the difference to the environment of the

KM3712 and is available in the fieldbus with 16bit resolution. The status LEDs indicate proper function or

errors such as range exceedance.

KM3701, KM3702 and KM371210 Version: 2.0.0

Page 11

Product overview

2.4 Technical data

Technical Data KM3701-0000 KM3701-0340 KM3702-0000 KM3712-0000

Number of inputs 1 (differential pressure) 2 2

Measuring range -100 to +100hPa

(-100 to +100mbar)

Permissible overpressure max. ±500hPa differential

max. +5000hPa relative to ambient

permissible media non-aggressive gases

Resolution 0.1hPa (0.1mbar) per digit 1hPa (1mbar)

Measuring accuracy 3% (of the full scale value)

Measuring speed typically 5ms

Pressure connectors

Power supply for the

electronics

Current consumption from

the K-bus

Width of a bus terminal

block

Electrical isolation 500V (K-bus/signal voltage)

Bit width in the input

process image

Bit width in the output

process image

Dimensions without tubes

(wxhxd)

Weight approx. 100g

Permissible ambient

temperature range during

operation

Permissible ambient

temperature range during

storage

Permissible relative air

humidity

Mounting [}16] on a 35mm mounting rail [}16] (e.g.DIN rail TH 35-7.5 conforming to EN

Vibration / shock

resistance

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval CE, cULus

screwing plug [}18], M12 x 1

via the K-bus

typically 15mA

Maximum 64 standard Bus Terminals or 80cm

(a KM37xx is equivalent to 2 standard Bus Terminals)

3byte 3byte 6byte 6byte

3byte 3byte 6byte 6byte

approx. 26.5mmx100mmx69mm (width aligned: 24mm)

0°C ... + 55°C

-25°C ... + 85°C

95%, no condensation

60715)

conforms to EN 60068-2-6 / EN 60068-2-27

-340 to +340hPa

(-340 to

+340mbar)

0 to 7500hPa

(0 to 7.5bar)

+10000hPa +5000hPa

per digit

-1000 to +1000hPa

(-1 to +1bar)

1hPa (1mbar) per

digit

KM3701, KM3702 and KM3712 11Version: 2.0.0

Page 12

Product overview

2.5 Basic function principles

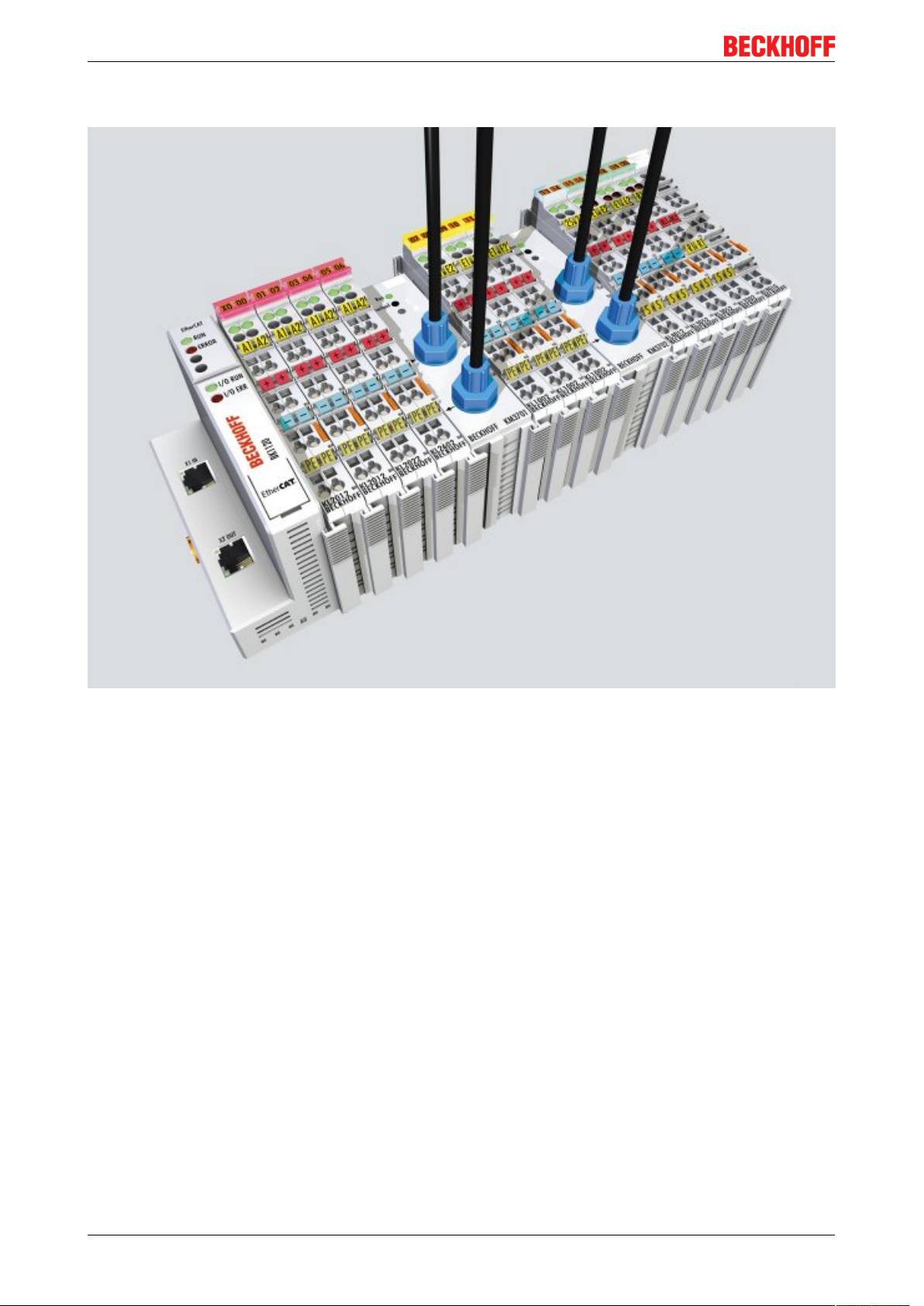

Fig.4: Bus Terminal block with pressure measuring modules

The pressure measuring modules KM3701 and KM3712 directly record differential and relative pressures in

non-aggressive gases. As in electronic signal acquisition the pressure measurement takes place via a

terminal module. The pressure measuring modules convert the measured pressure into an electrical signal

and make it available to the higher-level controller with a resolution of 16bits. The measuring principle is

based on the most up-to-date on-chip sensor technology. In addition to just measuring, the semiconductor

also executes other functions, such as temperature compensation and avoidance of long-term drift. The

status LEDs indicate proper function or errors such as range exceedance.

KM3701, KM3702 and KM371212 Version: 2.0.0

Page 13

Product overview

KM3701 single-channel differential pressure measuring module

Fig.5: KM3701 - Single-channel differential pressure measurement

The KM3701 terminal module can measure pressure differences between 0 and 100hPa (0 and 100mbar)

between two hose connections. The differential pressure can be measured up to an ambient pressure of

7500hPa (7bar) between any points.

KM3702 - Two-channel relative pressure measuring module (0hPa to 7500hPa)

Fig.6: KM3702 - Two-channel relative pressure measurement

The KM3702 terminal module can measure pressure values between 0 and 7000hPa (0 and 7bar) at each

hose connection. Pressure measurement takes place relative to the actual current ambient pressure.

KM3701, KM3702 and KM3712 13Version: 2.0.0

Page 14

Product overview

KM3712 - Two-channel relative pressure measuring module (-1000hPa to +1000hPa)

Fig.7: KM3712 - Two-channel relative pressure measurement

The KM3712 terminal module can measure pressure values between -1000hPa and +1000hPa (-1bar and

+1bar) at each hose connection. Pressure measurement takes place relative to the actual current ambient

pressure.

Installation and connection technique

The pressure measuring terminal samples the pressure values directly. Additional measuring devices are

unnecessary. This avoids connection systems and saves available space compared with the use of

conventional measuring devices. The installation of the pressure measuring terminals is simple and fast and

can be carried out without any additional mounting tools. The measuring hoses are connected directly to the

quick couplings of the pressure measuring terminal. Standard commercial plastic hoses can be used as

measuring hoses. In terms of connections and installation space the pressure measuring terminals are

designed like a "normal" 24 mm Bus Terminal and can be installed with minimum space requirement directly

in the Bus Terminal system.

KM3701, KM3702 and KM371214 Version: 2.0.0

Page 15

2.6 LED displays

KM3701

Fig.8: KM3701 - LEDs

LED Display

Run (green) off Data transmission on the K-bus is not active

on Data transmission on the K-bus is active

Over-range (red) on

Under-range (red) on

The differential pressure is above the permitted measuring range [}11]

The differential pressure is below the permitted measuring range [}11]

Product overview

KM3702, KM3712

Fig.9: KM3702, KM3712 - LEDs

LED Display

Run (green) off Data transmission on the K-bus is not active

on Data transmission on the K-bus is active

Error X1 (red) on The pressure at connection X1 is below (under-range) or above (over-range) the

permitted measuring range [}11]

Error X2 (red) on The pressure at connection X2 is below (under-range) or above (over-range) the

permitted measuring range [}11]

KM3701, KM3702 and KM3712 15Version: 2.0.0

Page 16

Mounting and wiring

3 Mounting and wiring

3.1 Recommended mounting rails

Terminal Modules and EtherCAT Modules of KMxxxx and EMxxxx series, same as the terminals of the

EL66xx and EL67xx series can be snapped onto the following recommended mounting rails:

• DIN Rail TH 35-7.5 with 1 mm material thickness (according to EN 60715)

• DIN Rail TH 35-15 with 1,5 mm material thickness

Pay attention to the material thickness of the DIN Rail

Terminal Modules und EtherCAT Modules of KMxxxx and EMxxxx series, same as the ter-

Note

3.2 Mounting and demounting - terminals with front

minals of the EL66xx and EL67xx series does not fit to the DIN Rail TH 35-15 with 2,2 to

2,5 mm material thickness (according to EN 60715)!

unlocking

The terminal modules are fastened to the assembly surface with the aid of a 35 mm mounting rail (e.g.

mounting rail TH 35-15).

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting

Note

rail. At the installation, the locking mechanism of the components must not come into conflict with the fixing bolts of the mounting rail. To mount the recommended mounting rails under the terminals and couplers, you should use flat mounting connections (e.g. countersunk

screws or blind rivets).

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

WARNING

Mounting

• Fit the mounting rail to the planned assembly location.

disassembly or wiring of the Bus Terminals!

KM3701, KM3702 and KM371216 Version: 2.0.0

Page 17

and press (1) the terminal module against the mounting rail until it latches in place on the mounting

rail (2).

• Attach the cables.

Mounting and wiring

Demounting

• Remove all the cables.

• Lever the unlatching hook back with thumb and forefinger (3). An internal mechanism pulls the two

latching lugs (3a) from the top hat rail back into the terminal module.

• Pull (4) the terminal module away from the mounting surface.

Avoid canting of the module; you should stabilize the module with the other hand, if required.

KM3701, KM3702 and KM3712 17Version: 2.0.0

Page 18

Mounting and wiring

3.3 Connection

The air hoses are connected to push-in fittings.

Technical Data Threaded push-in fitting

Type QSS-4-F

Outer hose diameter 4mm

Nominal diameter 2.6mm

Thread M12 x 1

Width across flats 14mm

KM3701, KM3702 and KM371218 Version: 2.0.0

Page 19

Application examples

4 Application examples

The pressure measuring modules can be used in any applications requiring logging and monitoring of

differential and dynamic pressures in non-aggressive gases, e.g. pressure vessels, pressure cabins or

pneumatic, filter, suction, packaging and positioning systems.

They measure operating pressures, monitor filters and sieves, check the seal tightness of tanks and assist in

position testing of construction elements or monitoring the level of liquids. If flow rates are calculated from

the measured pressures, then the pressure measuring terminals can also be used for flow measurement.

They can therefore be applied in areas such as process engineering, systems engineering, building services

and heating, ventilating and air conditioning.

• Application examples for KM3701 [}19]

• Application example for KM3702 [}20]

• Application example for KM3712 [}21]

4.1 KM3701 - Application examples

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

WARNING

disassembly or wiring of the Bus Terminals!

Tank systems

Fig.10: KM3701 - Application example for the fill level of tanks

• Monitors tank filling levels and activates topping up when the level falls below a defined filling value

• The pressure difference is an indicator for the filling level

• No additional pressure gauges, switches and associated connection equipment are required

KM3701, KM3702 and KM3712 19Version: 2.0.0

Page 20

Application examples

Filter systems, pipe constrictions

Fig.11: KM3701 - Application example for filter systems, pipe restrictions

• Monitors the operating state of filters and screens

• The pressure difference indicates the level of contamination

4.2 KM3702 - Application example

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

WARNING

Pneumatic systems

disassembly or wiring of the Bus Terminals!

Fig.12: KM3702 - Application example for pneumatic systems

• Checking the filling level of stores

• Monitoring the operating pressure of equipment

KM3701, KM3702 and KM371220 Version: 2.0.0

Page 21

• enables monitoring and avoidance of overpressure

4.3 KM3712 - Application example

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

disassembly or wiring of the Bus Terminals!

WARNING

Packaging plant for eggs

Application examples

Fig.13: EM3712 - Application example Packging plant for eggs

• controls suction

• Pressure deviations indicate leakages or positioning inaccuracies

KM3701, KM3702 and KM3712 21Version: 2.0.0

Page 22

KS2000 Configuration software

5 KS2000 Configuration software

5.1 KS2000 - Introduction

The KS2000 configuration software permits configuration, commissioning and parameterization of bus

couplers, of the affiliated bus terminals and of Fieldbus Box Modules. The connection between bus coupler/

Fieldbus Box Module and the PC is established by means of the serial configuration cable or the fieldbus.

Fig.14: KS2000 configuration software

Configuration

You can configure the Fieldbus stations with the Configuration Software KS2000 offline. That means, setting

up a terminal station with all settings on the couplers and terminals resp. the Fieldbus Box Modules can be

prepared before the commissioning phase. Later on, this configuration can be transferred to the terminal

station in the commissioning phase by means of a download. For documentation purposes, you are provided

with the breakdown of the terminal station, a parts list of modules used and a list of the parameters you have

modified. After an upload, existing fieldbus stations are at your disposal for further editing.

Parameterization

KS2000 offers simple access to the parameters of a fieldbus station: specific high-level dialogs are available

for all bus couplers, all intelligent bus terminals and Fieldbus Box modules with the aid of which settings can

be modified easily. Alternatively, you have full access to all internal registers of the bus couplers and

intelligent terminals. Refer to the register description for the meanings of the registers.

KM3701, KM3702 and KM371222 Version: 2.0.0

Page 23

KS2000 Configuration software

Commissioning

The KS2000 software facilitates commissioning of machine components or their fieldbus stations: Configured

settings can be transferred to the fieldbus modules by means of a download. After a login to the terminal

station, it is possible to define settings in couplers, terminals and Fieldbus Box modules directly online. The

same high-level dialogs and register access are available for this purpose as in the configuration phase.

The KS2000 offers access to the process images of the bus couplers and Fieldbus Box modules.

• Thus, the coupler's input and output images can be observed by monitoring.

• Process values can be specified in the output image for commissioning of the output modules.

All possibilities in the online mode can be used in parallel with the actual fieldbus mode of the terminal

station. The fieldbus protocol always has the higher priority in this case.

5.2 Parameterization with KS2000

Connect the configuration interface of your Fieldbus Coupler with the serial interface of your PC via the

configuration cable and start the KS2000 Configuration Software.

Click on the Login button. The configuration software will now load the information

for the connected fieldbus station.

In the example shown, this is

• a BK9000 Bus Coupler for Ethernet

• a KL1xx2 Digital Input Terminal

• a KM3701 differential pressure measuring module

• a KL9010 Bus End Terminal

KM3701, KM3702 and KM3712 23Version: 2.0.0

Page 24

KS2000 Configuration software

Fig.15: Display of the fieldbus station in KS2000

The left-hand KS2000 window displays the terminals of the fieldbus station in a tree structure.

The right-hand KS2000 window contains a graphic display of the fieldbus station terminals.

In the tree structure of the left-hand window, click on the plus-sign next to the module whose parameters you

wish to change (pos. 2 in the example).

Fig.16: KS2000 branch for channel 1 of the KM3701

For the KM3701, the branches Register, Settings and ProcData are displayed:

• Register [}25] enables direct access to the KM3701 registers.

• ProcData [}26] shows the process data of the KM3701.

KM3701, KM3702 and KM371224 Version: 2.0.0

Page 25

KS2000 Configuration software

5.3 Register

Under Register you can directly access the registers of the terminal module (KM3701 in this example). The

meaning of the register is explained in the Register Overview [}30].

Fig.17: Register view in KS2000

KM3701, KM3702 and KM3712 25Version: 2.0.0

Page 26

KS2000 Configuration software

5.4 Process Data

The Status byte (Status), the Control byte (Ctrl) and the process data (Data) are displayed in a tree structure

under ProcData.

The spectacles mark the data that are currently graphically displayed in the History field.

Fig.19: History field

The current input value is displayed numerically in the Value field.

Fig.20: Value field

Output values can be modified through direct input or by means of the fader control.

Fig.21: Value field

Danger for persons, the environment or devices!

Note that changing output values (forcing them) can have a direct effect on your automa-

CAUTION

After pressing the Settings button you can set the format of the numerical display to hexadecimal, decimal or

binary.

tion application. Only modify these output values if you are certain that the state of your

equipment permits it, and that there will be no risk to people or to the machine!

Fig.22: Setting the display

KM3701, KM3702 and KM371226 Version: 2.0.0

Page 27

Access from the user programm

6 Access from the user programm

6.1 KM3701 - Process image

The KM3701 terminal module is represented in the process image with a maximum of 3bytes of input data

and 3bytes of output data. These are organized as follows:

Format Input data Output data

Byte

Word DataIN DataOUT

Key

SB: Status byte

CB: Control byte

DataIN: Input data word

DataOUT: Output data word

• The meaning of the control and status bytes is explained in Control and status bytes.

• In process data mode, the analog value is transferred in the input data word DataIN. The output data

word DataOUT is not used.

SB [}28] CB [}28]

Representation of the analog values

The terminal module displays the analog input values as follows:

KM3701-0000

Differential pressure Decimal Hexadecimal

-100 hPa -1000 0xFC18

0 hPa 0 0x0000

+100 hPa +1000 0x03E8

KM3701-0340

Differential pressure Decimal Hexadecimal

-340 hPa -3400 0xF2B8

0 hPa 0 0x0000

+340 hPa +3400 0x0D48

6.2 KM3702, KM3712 - Process image

The KM3702 and KM3712 terminal modules are represented in the process image with a maximum of

6bytes of input data and 6bytes of output data. These are organized as follows:

Format Input data Output data

Byte

Word DataIN1 DataOUT1

Byte

Word DataIN2 DataOUT2

KM3701, KM3702 and KM3712 27Version: 2.0.0

SB1 [}28] CB1 [}28]

SB2 [}29] CB2 [}29]

Page 28

Access from the user programm

Key

SB n: Status byte for channel n

CB n: Control byte for channel n

DataIN n: Input data word channel n

DataOUT n: Output data word channel n

• The meaning of the control and status bytes is explained in Control and status bytes.

• In process data mode the analog values are transferred in output data words DataIN1 and DataIN2.

Input data words DataOUT1 and DataOUT2 are not used.

Representation of the analog values

The analog input values are represented by the terminal modules as follows:

KM3702-0000

Pressure Decimal Hexadecimal

0 hPa 0 0x0000

7500 hPa 7500 0x1D4C

KM3712-0000

Pressure Decimal Hexadecimal

-1000 hPa -1000 0xFC18

0 hPa 0 0x0000

+1000 hPa +1000 0x03E8

6.3 Control and Status Byte

Channel1

Process data mode

Control byte1 (for process data mode)

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal

module.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess - - - - - - -

Bit Name Description

CB1.7 RegAccess 0

CB1.6 to CB1.1 - 0

... ... ... ...

CB1.0 - 0

Register communication off (process data mode)

bin

reserved

bin

reserved

bin

Status byte1 (for process data mode)

Status byte 1 (SB1) is located in the input image and is transmitted from terminal module to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess Error StateThreshold2 StateThreshold1 Overload Underload

KM3701, KM3702 and KM371228 Version: 2.0.0

Page 29

Bit Name Description

SB1.7 RegAccess 0

SB1.6 Error 1

Acknowledgment for process data mode

bin

an internal error has occurred (current process data is no longer

bin

valid)

SB1.5 / SB1.4 StateThreshold2 0

Threshold 2 [}34] is not enabled via bit R32.10 [}33] of the

bin

feature register

01

Process data is greater than threshold 2

bin

10

Process data is less than threshold 2

bin

11

Process data equals threshold 2

bin

SB1.3 / SB1.2 StateThreshold1 0

Threshold 1 [}34] is not enabled via bit R32.9 [}33] of the

bin

feature register

01

Process data is greater than threshold 1

bin

10

Process data is less than threshold 1

bin

11

Process data equals threshold 1

bin

SB1.1 Overload 1

Process data is greater than specified in register R21 [}33]. The

bin

red error LED of this channel is lit.

SB1.0 Underload 1

Process data are less than specified in register R22 [}33]. The

bin

red error LED of this channel is lit. (The calibration is active if

SB1.0 and SB1.1 are set simultaneously).

Access from the user programm

Register communication

Controlbyte1 (in register communication)

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal

module.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess R/W Reg. no.

Bit Name Description

CB1.7 RegAccess 1

CB1.6 R/W 0

Register communication switched on

bin

Read access

bin

1

Write access

bin

CB1.5 to CB1.0 Reg. no. Register number:

Enter the number of the register [}30] that you

- want to read with input data word DataIn or

- want to write with output data word DataOut.

Statusbyte1 (in register communication)

Status byte 1 (SB1) is located in the input image and is transmitted from terminal module to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess R/W Reg. no.

Bit Name Description

SB1.7 RegAccess 1

SB1.6 R 0

Acknowledgment for register access

bin

Read access

bin

SB1.5 to SB1.0 Reg. no. Number of the register that was read or written.

Channel2 (only KM3702 and KM3712)

The control and status bytes of channel 2 (CB2 and SB2) have the same structure as the control and status

bytes of channel 1 [}28].

KM3701, KM3702 and KM3712 29Version: 2.0.0

Page 30

Access from the user programm

6.4 Register overview

The registers are used for the parameterization of the Bus Terminals and are available for each channel.

They can be read or written by means of register communication.

KM3701, KM3702 and KM371230 Version: 2.0.0

Page 31

Access from the user programm

Register no. Comment Default value R/W Memory

R0 [}32]

R1 reserved 0x0000 0

Raw ADC value variable variable R RAM

dec

- -

... ... ... ... ... ...

R5 reserved 0x0000 0

R6 [}32]

R7 [}32]

R8 [}32]

Diagnostic register 0x0000 0

Command register 0x0000 0

Terminal type KM3701: 0x0E75 3701

KM3702: 0x0E76 3702

KM3712: 0x0E80 3712

R9 [}32]

Firmware version e.g.0x3141 e.g.1A

R10 Multiplex shift register 0x0118 280

R11 Signal channels 0x0218 280

R12 [}32]

minimum data length of a channel 0x0098 152

R13 Data structure 0x0000 0

R14 reserved 0x0000 0

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

R15 Alignment register typically 0x7F80 typically

32640

R16 [}33]

R17 [}33]

R18 [}33]

R19 [}33]

R20 [}33]

R21 [}33]

R22 [}33]

R23 internal use 0x0000 0

R24 internal use 0x1004 4100

R25 reserved 0x0000 0

Hardware version number e.g.0x0000 e.g.0

Vendor calibration:

Offset

Vendor calibration: Gain 0x0000 0

Manufacturer scaling: Offset 0x0000 0

Manufacturer scaling:

Gain

KM3701, KM3712: typically 0xF800 typically

63488

KM3702: typically

0xFE66

KM3701, KM3712: 0x00A2 162

KM3702: 0x021B 539

typically

65126

dec

dec

dec

dec

Overrange limit KM3701, KM3712: 0x03E8 1000

KM3702: 0x1D4C 7500

Under range limit KM3701, KM3712: 0xFC18 -1000

KM3702: 0xFF9C -100

dec

dec

dec

dec

dec

dec

dec

dec

ASCII

dec

dec

dec

- -

R RAM

R/W RAM

R ROM

R ROM

R ROM

R ROM

R ROM

R ROM

- -

R/W RAM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

- -

... reserved - - - -

R30 reserved 0x0000 0

R31 [}33]

R32 [}33]

R33 [}34]

R34 [}34]

R35 [}34]

R36 [}34]

Code word register 0x0000 0

Feature register 0x0202 514

User offset 0x0000 0

User gain 0x0100 256

Threshold 1 0x0000 0

Threshold 2 0x0000 0

dec

dec

dec

dec

dec

dec

dec

- -

R/W RAM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R/W EEPROM

R37 reserved - - - -

... reserved - - - -

R63 reserved - - - -

KM3701, KM3702 and KM3712 31Version: 2.0.0

Page 32

Access from the user programm

6.5 Register description

The registers are used for the parameterization of the Bus Terminals and are available for each channel.

They can be read or written by means of register communication.

R0: Raw ADC value

Register R0 contains the raw value of the analog/digital converter. This is the unchanged analog value prior

to any scaling.

R6: Diagnostic register

Status byte SB1 [}28] is placed into register R6.

R7: Command register

User code word

For the following commands to be executed, it is first necessary for the user code word,

Note

Command 0x7000: Restore Factory Settings

0x1235, to be entered into register R31 [}33]!

Entering 0x7000 in register R7 restores the factory settings for the following registers of both channels:

KM3701, KM3712:

R21: 0x03E8 (1000

R22: 0xFC18 (-1000

R32: 0x0202 (514

R33: 0x0000 (0

R34: 0x0100 (256

R35: 0x0000 (0

R36: 0x0000 (0

dec

dec

dec

dec

)

dec

)

)

dec

)

)

dec

)

)

KM3702:

R21: 0x1D4C (7500

R22: 0xFF9C (-100

R32: 0x0202 (514

R33: 0x0000 (0

R34: 0x0100 (256

R35: 0x0000 (0

R36: 0x0000 (0

dec

dec

dec

dec

)

dec

)

)

dec

dec

)

)

)

)

Delivery state for all channels

The command Restore Factory Settings simultaneously resets all module channels to the

Note

R8: Module ID

Register R8 contains the ID for the terminal module.

KM3701: 0x0C64 (3701

KM3702: 0x0C6E (3702

KM3712: 0xC3C (3712

R9: Firmware version

delivery state, irrespective of which register set it is called from!

)

dec

)

dec

)

dec

Register R9 contains the ASCII coding of the terminal's firmware version, e.g.0x3141 = '1A'. The '0x31'

corresponds here to the ASCII character '1', while the '0x41' represents the ASCII character 'A'.

This value cannot be changed.

R12: Minimum data length of a channel

Bits 0 to 6 of the high-order byte specify the minimum number of output data in bits: 000.0000

bin

= 0

, hence

dec

0bytes.

Bits 0 to 6 of the low-order byte specify the minimum number of input data in bits: 001.1000

bin

= 24

, hence

dec

3 bytes.

The fact that bit 7 is set indicates that the control and status byte are not mandatory for the terminal function

and are not transferred in compact mode.

KM3701, KM3702 and KM371232 Version: 2.0.0

Page 33

Access from the user programm

R16: Hardware version number

Register R16 contains the hardware version of the terminal.

R17: Vendor calibration - offset

This register contains the vendor calibration offset (16bit signed integer).

R18: Vendor calibration - gain

This register contains the vendor calibration gain (16bit unsigned integer x 2

-16

+ 1). Samples:

0x0000 means factor 1

0xFFFF means factor 2

R19: Manufacturer scaling - offset

This register contains the offset of the manufacturer scaling. Can be activated via R32.1 [}33] in the feature

register (16bit signed integer).

R20: Manufacturer scaling - gain

This register contains the gain of the manufacturer scaling. Can be activated via R32.1 [}33] in the feature

register (16bit unsigned integer x 2-8 + 1). Samples:

0x0100 means factor 1.

0x0080 means factor 0.5

R21: Upper measuring range limit

This register contains the upper measuring range limit. It can be activated by R32.8 [}33] in the feature

register.

R22: Lower measuring range limit

This register contains the lower measuring range limit. It can be activated by R32.8 [}33] in the feature

register.

R31: Code word register

• If you write values into the user registers without first entering the user code word (0x1235) into the

code word register, the terminal will not accept the supplied data.

• If you write values into the user registers and have previously entered the user code word (0x1235) in

the code word register, these values are stored in the RAM registers and in the SEEPROM registers

and are therefore retained if the terminal is restarted.

The code word is reset if the terminal is restarted.

R32: Feature register

The feature register defines the module configuration.

Bit R32.15 R32.14 R32.13 R32.12 R32.11 R32.10 R32.9 R32.8

Name - - - - enTh2 enTh1 enOverProt -

Bit R32.7 R32.6 R32.5 R32.4 R32.3 R32.2 R32.1 R32.0

Name - - - enSiemens

Format

enAverage

Format

disWdTimer enManScal enUsrScal

KM3701, KM3702 and KM3712 33Version: 2.0.0

Page 34

Access from the user programm

Bit Name Description default

R32.15 - reserved 0

bin

... ... ... ...

R32.12 - reserved 0

R32.11 enTh2 0

R32.10 enTh1 0

R32.9 enOverProt 0

Threshold 2 not active 0

bin

1

Threshold 2 active

bin

Threshold 1 not active 0

bin

1

Threshold 1 active

bin

Measuring range limitation not active 1

bin

1

Overrange protection active

bin

R32.8 - reserved 0

bin

bin

bin

bin

bin

... ... ... ...

R32.5 - reserved 0

R32.4 enSiemensFormat 0

R32.3 enAverageFormat 0

R32.2 disWdTimer 0

Siemens output format not active 0

bin

1

Siemens output format active

bin

Signed amount representation not active 0

bin

1

Signed amount representation active

bin

Watchdog timer is active (the watchdog is triggered if no

bin

bin

bin

bin

0

bin

process data are received for 100ms)

1

Watchdog timer is not active

bin

R32.1 enManScal 0

R32.0 enUsrScal 0

Manufacturer scaling is not active 1

bin

1

Manufacturer scaling is active

bin

User scaling is not active 0

bin

1

User scaling is active

bin

bin

bin

R33: User scaling - offset

This register contains the offset of the user scaling. The user scaling can be activated in the feature register

through bit R32.0 [}33] (16bit signed integer).

R34: User scaling - gain

This register contains the gain of the user scaling. The user scaling can be activated in the feature register

through bit R32.0 [}33] (16bit unsigned integer x 2-8 + 1, 1

corresponds to 0x0100).

dec

R35: Threshold 1

Threshold 1 is entered in register R35. The threshold can be activated in the feature register through bit

R32.10 [}33].

R36: Threshold 2

Threshold 2 is entered in register R36. The threshold can be activated in the feature register through bit R32

[}33].11.

KM3701, KM3702 and KM371234 Version: 2.0.0

Page 35

Access from the user programm

6.6 Examples of Register Communication

The numbering of the bytes in the examples corresponds to the display without word alignment.

6.6.1 Example 1: reading the firmware version from Register 9

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0x89 (1000 1001

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 specify the register number 9 with 00 1001

• The output data word (byte 1 and byte 2) has no meaning during read access. To change a register,

write the required value into the output word.

Input Data (answer of the bus terminal)

) 0xXX 0xXX

bin

.

bin

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x89 0x33 0x41

Explanation:

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the firmware version 0x3341 in the input data word (byte 1 and byte 2). This is to

be interpreted as an ASCII code:

◦ ASCII code 0x33 represents the digit 3

◦ ASCII code 0x41 represents the letter A

The firmware version is thus 3A.

6.6.2 Example 2: Writing to an user register

Code word

In normal mode all user registers are read-only with the exception of Register 31. In order

Note

I. Write the code word (0x1235) into Register 31.

to deactivate this write protection you must write the code word (0x1235) into Register 31. If

a value other than 0x1235 is written into Register 31, write protection is reactivated. Please

note that changes to a register only become effective after restarting the terminal (poweroff/power-on).

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xDF (1101 1111

) 0x12 0x35

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

.

bin

• The output data word (byte 1 and byte 2) contains the code word (0x1235) for deactivating write

protection.

KM3701, KM3702 and KM3712 35Version: 2.0.0

Page 36

Access from the user programm

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

II. Read Register 31 (check the set code word)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

.

bin

• The output data word (byte 1 and byte 2) has no meaning during read access.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0x12 0x35

bin

Explanation:

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the current value of the code word register in the input data word (byte 1 and byte

2).

III. Write to Register 32 (change contents of the feature register)

Output data

Byte 0: Control byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xE0 (1110 0000

) 0x00 0x02

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 indicate register number 32 with 10 0000

.

bin

• The output data word (byte 1 and byte 2) contains the new value for the feature register.

CAUTION

Observe the register description!

The value of 0x0002 given here is just an example!

The bits of the feature register change the properties of the terminal and have a different

meaning, depending on the type of terminal. Refer to the description of the feature register

of your terminal (chapter Register description) regarding the meaning of the individual bits

before changing the values.

KM3701, KM3702 and KM371236 Version: 2.0.0

Page 37

Access from the user programm

Input data (response from the Bus Terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xA0 (1010 0000

) 0xXX 0xXX

bin

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

IV. Read Register 32 (check changed feature register)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xA0 (1010 0000

) 0xXX 0xXX

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 not set means: reading the register.

• Bits 0.5 to 0.0 indicate register number 32 with 10 0000

.

bin

• The output data word (byte 1 and byte 2) has no meaning during read access.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0xA0 (1010 0000

) 0x00 0x02

bin

Explanation:

• The terminal returns the value of the control byte as a receipt in the status byte.

• The terminal returns the current value of the feature register in the input data word (byte 1 and byte 2).

V. Write Register 31 (reset code word)

Output Data

Byte 0: Control byte Byte 1: DataOUT1, high byte Byte 2: DataOUT1, low byte

0xDF (1101 1111

) 0x00 0x00

bin

Explanation:

• Bit 0.7 set means: Register communication switched on.

• Bit 0.6 set means: writing to the register.

• Bits 0.5 to 0.0 specify the register number 31 with 01 1111

.

bin

• The output data word (byte 1 and byte 2) contains 0x0000 for reactivating write protection.

Input Data (answer of the bus terminal)

Byte 0: Status byte Byte 1: DataIN1, high byte Byte 2: DataIN1, low byte

0x9F (1001 1111

) 0xXX 0xXX

bin

Explanation:

• The terminal returns a value as a receipt in the status byte that differs only in bit 0.6 from the value of

the control byte.

• The input data word (byte 1 and byte 2) is of no importance after the write access. Any values still

displayed are invalid!

KM3701, KM3702 and KM3712 37Version: 2.0.0

Page 38

Appendix

7 Appendix

7.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

KM3701, KM3702 and KM371238 Version: 2.0.0

Page 39

List of illustrations

List of illustrations

Fig. 1 KM3701 ....................................................................................................................................... 8

Fig. 2 KM3702 ....................................................................................................................................... 9

Fig. 3 KM3712 ....................................................................................................................................... 10

Fig. 4 Bus Terminal block with pressure measuring modules ............................................................... 12

Fig. 5 KM3701 - Single-channel differential pressure measurement..................................................... 13

Fig. 6 KM3702 - Two-channel relative pressure measurement ............................................................. 13

Fig. 7 KM3712 - Two-channel relative pressure measurement ............................................................. 14

Fig. 8 KM3701 - LEDs ........................................................................................................................... 15

Fig. 9 KM3702, KM3712 - LEDs ............................................................................................................ 15

Fig. 10 KM3701 - Application example for the fill level of tanks .............................................................. 19

Fig. 11 KM3701 - Application example for filter systems, pipe restrictions.............................................. 20

Fig. 12 KM3702 - Application example for pneumatic systems............................................................... 20

Fig. 13 EM3712 - Application example Packging plant for eggs ............................................................. 21

Fig. 14 KS2000 configuration software.................................................................................................... 22

Fig. 15 Display of the fieldbus station in KS2000 .................................................................................... 24

Fig. 16 KS2000 branch for channel 1 of the KM3701.............................................................................. 24

Fig. 17 Register view in KS2000.............................................................................................................. 25

Fig. 18 Process Data field ....................................................................................................................... 000

Fig. 19 History field.................................................................................................................................. 26

Fig. 20 Value field.................................................................................................................................... 26

Fig. 21 Value field.................................................................................................................................... 26

Fig. 22 Setting the display ....................................................................................................................... 26

KM3701, KM3702 and KM3712 39Version: 2.0.0

Loading...

Loading...