Page 1

KL6051

Data transfer terminal with serial RS422 terminal

Configuration Instructions

Version 2.1

2006-10-24

Page 2

Contents

Contents

1. Foreword 3

Notes on the documentation 3

Safety Instructions 4

2. Technical data 5

3. Description of functions 6

4. Terminal configuration 6

5. Register description 8

General register description 8

Terminal-specific register description 10

Register communication KL6051 10

6. Data transfer, function 13

7. Annex 14

Mapping in the bus coupler 14

Table of the register 16

Support and Service 17

Beckhoff Headquarters 17

2 KL6051

Page 3

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

KL6051 3

Page 4

Foreword

i

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the environ-

Attention

Note

ment.

This symbol indicates information that contributes to better understanding.

4 KL6051

Page 5

Technical data

Technical data

Technical data KL6051

Data transfer channels

Data transfer rate

Bit transfer

Line impedance

Data transfer link

Power supply

Current consumption from K-Bus

Electrical isolation

Bit width in the process image

Configuration

Weight approx..

Operating temperature

Storage temperature

Relative humidity

Vibration/shock resistance

EMC resistance Burst / ESD

Installation position

Type of protection

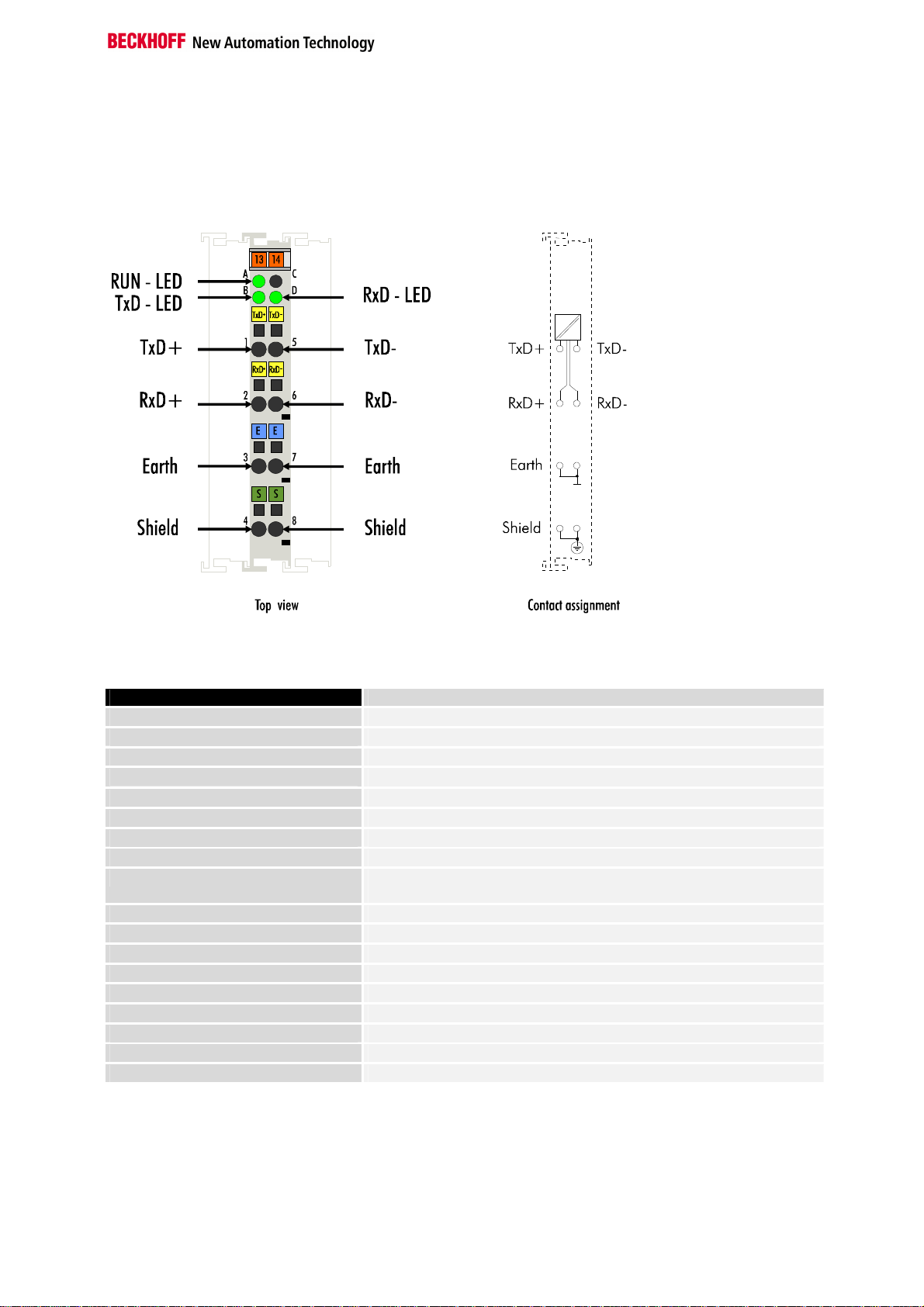

TxD and RxD, full duplex

62500 Baud (8N1)

with differential signal

120 Ω

approx. 1000 m twisted pair

via the K-Bus

65 mA typ.

500 Vrms (K-Bus / signal voltage)

I/O: 4 x 8 bits user data, 1 x 8 bits control/status (up to 5 x 8 bits user

data possible)

no address setting or configuration settings

60 g

0°C ... +55°C

-25°C ... +85°C

95%, no condensation

conforms to IEC 68-2-6 / IEC 68-2-27

conforms to EN 50082 (ESD, Burst) / EN 50081

any

IP20

KL6051 5

Page 6

Description of functions

Offset Terminal1 = 0

Offset Terminal2 Channel1 = 1

Offset Terminal2 Channel2 = 2

Offset Terminal3 Channel1 = 1

User information data allocation

To the bus terminal

Features

Beckhoff Lightbus

coupler BK2000

Description of functions

The KL6051 serial interface terminal enables an exchange of data between

different field bus systems. Regardless of the higher-level field bus system,

data can be exchanged in full duplex mode. Up to 40 inputs and 40 outputs

are transmitted between the field bus systems and, in addition, the status

byte contains information about the quality and the status of data transfer.

The terminal is supplied with a 200 ms RCV timeout, i.e. the inputs of the

higher-level controller are set to zero if the terminal does not receive any

valid data via the serial interface from the second station within 200 ms. In

the default setting, 32 bits are bidirectionally available for data exchange.

Coupling of two field bus systems

Exchange of up to 40 bits bidirectionally

Status byte for data channel status message

Safeguarded data transfer by longitudinal parity, vertical parity, log

Transmission medium: RS422 full duplex

Maximum transmission distance: 1000 m

Simple software interface for control by the emulation of up to 40 bits

Parallel I/O

Data transfer time exchange time < 5 ms

Terminal configuration

The terminal can be configured and parametrized via the internal register

structure.

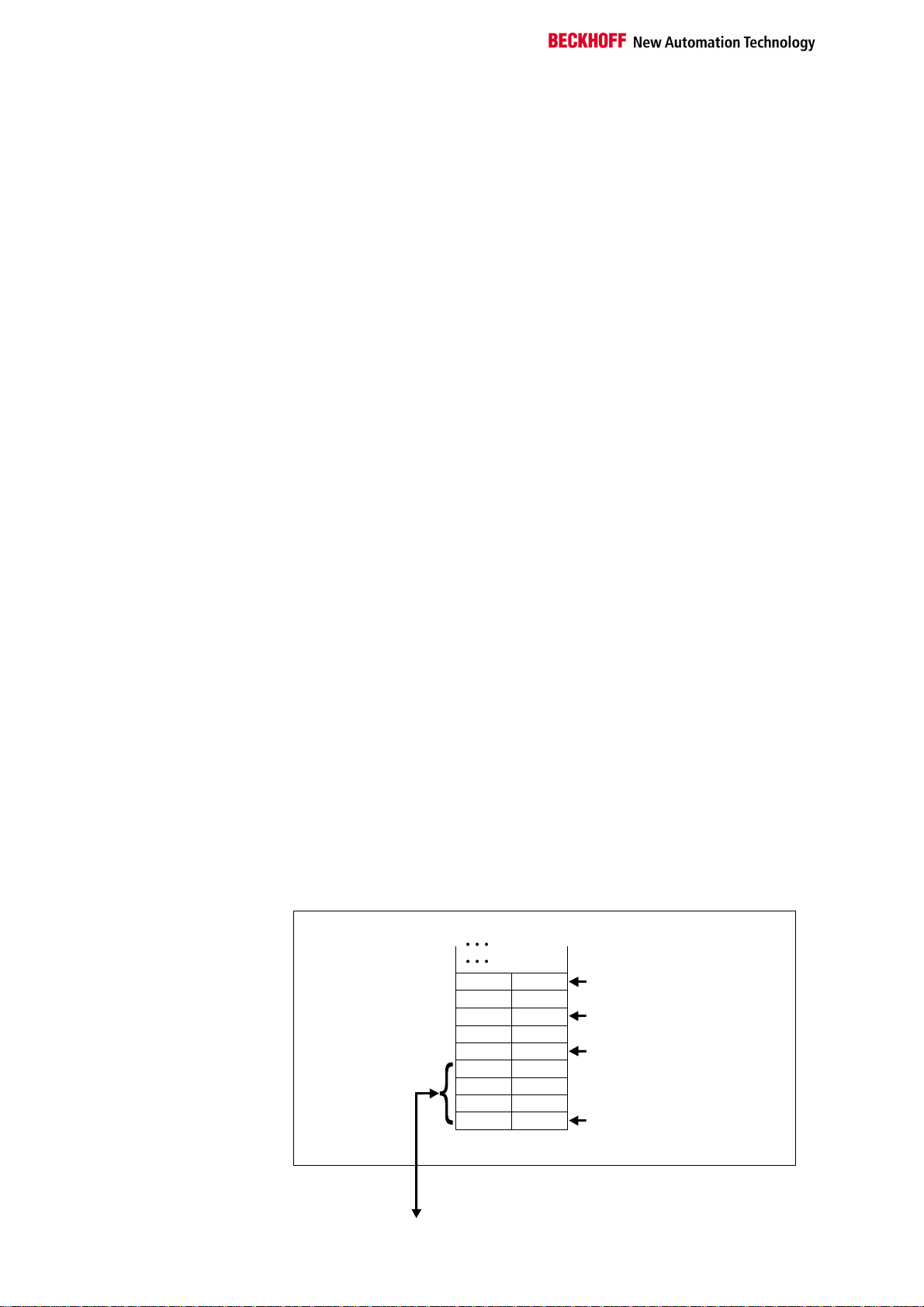

Each terminal channel is mapped in the bus coupler. The data of the terminal is mapped differently in the memory of the bus coupler depending on

the type of the bus coupler and on the set mapping configuration (eg Motorola / Intel format, word alignment.

For parametrization of a terminal, the control / status byte must also be

mapped.

When using the Beckhoff Lightbus coupler BK2000, the control / status

byte is always mapped in additon to the data bytes. It is always in the low

byte at the offset address of the terminal channel. In the case of the

KL6051 there will be 6 bytes data (5 bytes user data and 1 byte control/status) exchanged with the control system.

6 KL6051

Beckhoff Lightbus

bus coupler

BK2000

The terminal is

mapped in the

bus coupler

0

K-Bus

Data H

D4

D1

C/S

Data LData H

C/S

Data L

C/S

D3

D2

D0

C/S

LH

depending on mapping

KL6051

Page 7

To the bus terminal

Offset Terminal1 = 0

Offset Terminal2 Channel1 = 1

Offset Terminal2 Channel2 = 1

Offset Terminal3 Channel1 = 1

The control/status byte must be

To the bus terminal

i

Terminal configuration

Profibus coupler BK3000

Interbus coupler BK4000

When using the Profibus coupler BK3000, how the KL6051 is to map itself

in the bus coupler is set in the master configuration software. The figure

shows the mapping for 6 bytes of input data and 6 bytes of output data.

Profibus bus coupler

The control/status byte must be

inserted for parametrization

BK3000

The terminal is

mapped in the

bus coupler

Data L

Data H

C/S

D3

D4

D2

D0

D1

0

C/S

Offset Terminal2 Channel1 = 1

The conrol/staus byte and D2

can be inserted (KL6051)

Offset Terminal1 = 0

K-Bus

By default, the Interbus coupler BK4000 maps the KL6051 with 4 bytes of

input data and 4 bytes of output data. Parametrization via the field bus is

not possible. The KS2000 software is needed to redefine the terminal’s

parameters.

Other bus couplers and

further information

Note

Parametrization with the

KS2000 software

Interbus bus coupler

BK4000

The terminal is

mapped in the

bus coupler

Data H

Data L

Data H

Data L

Data H

D2

D3

D0

0

D1

inserted for parametrization

(KS2000)

KL6051

K-Bus

You will find further information of the mapping configuration of bus couplers in the annex of the respective bus coupler manual under the heading

of "Configuration of Masters".

The annex contains an overview of possible mapping configurations depending on the parameters that can be set.

Parametrization operations can be carried out independently of the field

bus system using the Beckhoff KS2000 configuration software via the serial configuration interface in the bus coupler.

KL6051 7

Page 8

Register description

Register description

Process variables R0 - R7: Registers in the terminal’s internal RAM:

The complex terminals can be adjusted to different operating modes or

functionalities. The " general description of register " describes the contents of the registers, which are identical for all complex terminals.

The terminal-specific registers are explained in the section following to it.

The access to the internal registers of the terminal is described in the sec-

tion " register communication ".

General register description

Complex terminals that possess a processor are capable of bidirectionally

ex-changing data with the higher-level control system. Below, these terminals are referred to as intelligent bus terminals. They include the analog

inputs (0-10V, -10-10V, 0-20mA, 4-20mA), the analog outputs (0-10V, -1010V, 0-20mA, 4-20mA), serial interface terminals (RS485, RS232, TTY,

data transfer terminals), counter terminals, encoder interfaces, SSI interfaces, PWM terminals and all other parametrizable terminals.

Internally, all intelligent terminals possess a data structure that is identical

in terms of it's essential characteristics. This data area is organized in

words and embraces 64 memory locations. The essential data and parameters of the terminal can be read and adjusted by way of the structure.

Function calls with corresponding parameters are also possible. Each logical channel of an intelligent terminal has such a structure (therefore, 4channel analog terminals have 4 register sets.

This structure is broken down into the following areas:

(You will find a list of all registers at the end of this documentation).

Area Address

Process variables

Type registers

Manufacturer parameters

User parameters

Extended user area

The process variables can be used in additional to the actual process

image and their functions are specific to the terminal.

R0 - R5: These registers have a function that depends on the terminal

type.

R6: Diagnostic register

The diagnostic register may contain additional diagnostic information. In

the case of serial interface terminals, for example, parity errors that have

occurred during data transfer are indicated.

R7: Command register

High-Byte_Write = function parameter

Low-Byte _Write = function number

High-Byte _Read = function result

Low-Byte_ Read = function number

0-7

8-15

16-30

31-47

48-63

8 KL6051

Page 9

Register description

Type registers R8 - R15 Registers in the terminal’s internal ROM der Klemme

The type and system parameters are programmed permanently by the

manufacturer and can only be read by the user but cannot be modified.

R8: Terminal type:

The terminal type in register R8 is needed to identify the terminal.

R9: Software version X.y

The software version can be read as an ASCII character string.

R10: Data length

R10 contains the number of multiplexed shift registers and their length in

bits.

The bus coupler sees this structure.

R11: Signal channels

In comparison with R10, the number of logically existing channels is located here. For example, one physically existing shift register may consist of

several signal channels.

R12: Minimum data length

The respective byte contains the minimum data length of a channel to be

transferred. If the MSB is set, then the control/status byte is not necessarily

needed for the function of the terminal and, with appropriate configuration

of the coupler, is not transferred to the control system.

R13: Data type register

Data type register

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x11

0x12

0x13

0x14

0x15

0x16

Terminal without valid data type

Byte array

1 byte n bytes structure

Word array

1 byte n words structure

Double word array

1 byte n double words structure

1 byte 1 double word structure

1 byte 1 double word structure

Byte-array with a variable logical channel length

1 byte n bytes structure with a variable logical channel

length (eg 60xx)

Word-array with a variable logical channel length

1 byte n words structure with a variable logical channel

length

Double word array with a variable logical channel length

1 byte n double words structure with a variable logical

channel length

R14: not used

R15: Alignment bits (RAM)

The analog terminal is set to a byte limit in the terminal bus with the alignment bits.

Manufacturer parameters R16 - R30 is the area of the "Manufacturer parameters" (SEEROM)

The manufacturer parameters are specific to each terminal type. They are

programmed by the manufacturer but can also be modified from the control

system. The manufacturer parameters are stored permanently in a serial

EEPROM and are therefore not destroyed by power failures.

These registers can only be modified after setting a code word in R31.

KL6051 9

Page 10

Register description

i

User parameters

Note

Extended application area R47 - R63

Process variables R1-R5: no function

Type registers R8: terminal type [0x17A3] [R]

10 KL6051

R31 - R47 "Application parameters" area (SEEROM)

The application parameters are specific to each terminal type. They can be

modified by the programmer. The application parameters are stored permanently in a serial EEPROM in the terminal and cannot be destroyed by

power failures. The user area is write protected over a Codeword.

R31: Code word-register in the RAM

The code word 0x1235 must be entered here to enable modification of

parameters in the user area. Write-protection is set if a different value is

entered in this register. When write protection is inactive, the code word is

returned during reading of the register. The register contains the value zero

when write protection is active.

R32: Feature-register

This register defines the operating modes of the terminal. For example, a

user-specific scaling can be activated for the analog I/O’s.

R33 - R47

Registers that depend on the terminal type

These registers have not yet been implemented.

Terminal-specific register description

R6: diagnostic register [R/W]

HB HB Status of station 2 (partner terminal)

LB LB Status of station 1

R7: no function

The terminal type in register R8 is identical with the general terminal designation.

HB,LB = 6051

HB = 0x17

LB = 0xA3

R9: software version X.y [R]

HB = main number X of X.y

LB = sub-number y of X.y

R10: data length [R]

R10 contains the number of multiplexed shift registers in the terminal bus

and their length in bits. The bus coupler sees this structure.

HB = 2 - multiplexed channels

LB = 24-bit shift registers

R11: signal channels [R]

In comparison with R10, this register contains the number of logically existing channels. Thus, for example, one physically existing shift register

may consist of several signal channels or vice versa.

HB = 1

LB = 48

R12: minimum data length (auto configuration) [R]

The respective byte contains the minimum data length to be transferred of

a signal channel. The status byte is omitted if the MSB is set.

HB = 48 ; HB is the number of outputs in the case of auto configuration

LB = 48 ; LB is the number of inputs in the case of auto configuration

Page 11

R15: alignment bits (RAM)

With the alignment bits, the analog terminal is set to a byte limit in the terminal bus.

HB = LB converted (contains zero in the event of input)

LB = number of bit doublets 0,1,2,3

Manufacturer parameter R16: hardware version [R/W]

HB = main number X of X.y

LB = sub-number y of X.y

User parameters R32 Feature register

[0x0007]

Feature bit nr.

bit 0

bit 1

bit 2

bit 3

bit 15-4

R33: Baud rate

[0x0003] (62.5kHz)

HB = DC

LB = Baud rate = 4MHz / (16 * (LB + 1))

R34: RCV timeout

[0x00014] (200ms)

HB, LB = unsigned integer, 1 digit corresponds to 10ms

When the RCV timeout enable bit is set in R32, this value is valid. If the

terminal does not receive any valid data via the serial interface for X-ms,

the controller's inputs are set to the value ZERO.

R35: TRS timeout

[0x0014] (200ms)

HB, LB = unsigned integer,1 digit corresponds to 10ms

When the TRS timeout enable bit is set in R32, this value is valid. If the

terminal does not receive any valid data via the serial interface for X-ms,

no data is sent via the serial interface. Accordingly, the RCV timeout of the

2rd terminal would take effect.

Register communication KL6051

Register access via

process data transfer

Bit 7=1: register mode

When bit 7 of the control byte is set, the first two bytes of the user data are

not used for process data transfer, but are written into or read out of the

terminal’s register.

Bit 6=0: read

Bit 6=1: write

In bit 6 of the control byte, you define whether a register is to be read or

written. When bit 6 is not set, a register is read without modification. The

value can be taken from the input process image.

When bit 6 is set, the user data is written into a register. The operation is

concluded as soon as the status byte in the input process image has supplied an acknowledgement (see examples).

Bits 0 to 5: address

The address of the register to be addressed is entered in bits 0 to 5 of the

control byte.

1 RCV-timeout enable (R334) [1]

1 TRS-timeout enable (R35) [1]

0/1 0: terminal bus communiction via interrupt

0/1 0: data is transferred word-consistently

- not used

Register description

1: terminal bus: poll state [1]

1: data is transferred completely consistently

KL6051 11

Page 12

Register description

0

63

Terminal´s

Control-/

HHL

L

Control byte in the

register mode

MSB

REG=1 W/R

A5

A4

A3

A2

A1

REG = 0 : Process data transfer

REG = 1 : Access to register structure

W/R = 0 : Read register

W/R = 1 : Write register

A5..A0 = Register address

A total of 64 registers can be addressed with the addresses A5....A0.

To the bus coupler

K-Bus

User data

status byte

C/S-bit 7

2 or mors bytes

If control bit 7=0: input/output

If control bit 7=1:

registerconfiguration

A0

Example

If control bit 7=1:

adress in the control bit 0-5

If control bit 6=0: read

If control bit 6=1: write

register set

64 words

Complex bus terminal

The control or status byte occupies the lowest address of a logical channel.

The corresponding register values are located in the following 2 data bytes

(the BK2000 is an exception to the rule: here, an unused data byte is inserted after the control or status byte, thus setting the register value to a word

limit).

Reading register 8 in the BK2000 with a Kl3022 and the end terminal.

If the following bytes are transferred from the controller to the terminal,

Byte0

Control

0x88 0xXX 0xXX 0xXX

the terminal returns the following type designation (0x0BCE corresponds to

the unsigned integer 3022).

Byte0

Status

0x88 0x00 0x0B 0xCE

Byte1

Not used

Byte1

Not used

Byte2

Data OUT, high byte

Byte2

Data IN, high byte

Byte3

Data OUT, low byte

Byte3

Data IN, low byte

12 KL6051

Page 13

A further example

Writing register 31 in the BK2000 with an intelligent terminal and the end

terminal.

If the following bytes (user code word) are transferred from the controller to

the terminal,

Byte0

Control

0xDF 0xXX 0x12 0x35

the user code word is set and the terminal returns the register address with

the bit 7 for register access and the acknowledgement.

Byte0

Status

0x9F 0x00 0x00 0x00

Data transfer, function

Status byte in

the process data mode

8 data bits, 1 start bit, 1 stop bit, even parity

Data containing errors is not transferred to the controller. The processed

data is still valid when the CHK, OVR or PAR date is set. These bits merely

represent the quality of data transfer.

MSB

REG=0

PAR: parity error or invalid data frame

OVR: buffer overflow

CHK: invalid checksum

RCVT2: the partner terminal has an RCD timeout

RCVT1: the terminal is not receiving any data from the partner. The termi-

nal has set the controller inputs to zero.

For use without status information, the data transfer link can be monitored

from the other respective side of the link by means of a bit set by the controller. Data transfer of the KL6051 is checked by a watchdog. Thus, failures of the field buses or of data transfer between the KLK6051 units are

easily recognizable.

Data transfer, function

Byte1

Not used

Byte1

Not used

RCVT1 RCVT2 CHK OVR PAR

Byte2

Data OUT, high byte

Byte2

Data IN, high byte

Byte3

Data OUT, low byte

Byte3

Data IN, low byte

KL6051 13

Page 14

Annex

Mapping in the bus coupler

Default: CANCAL,

CANopen, RS232,

RS485, ControlNet,

DeviceNet

Default: Interbus,

Profibus

Default: Lightbus,

Bus Terminal Controller

(BCxxxx)

Annex

As already described in the chapter terminal configuration, each bus terminal is mapped in the bus coupler. In the standard case, this mapping is

done with the default setting in the bus coupler / bus terminal. This default

setting can be modified with the Beckhoff KS2000 configuration software or

using master configuration software (e.g. ComProfibus or TwinCAT System

Manager). The following tables provide information on how the KL6051

maps itself in the bus coupler depending on the set parameters.

Mapping in the bus coupler

The KL is mapped in the bus coupler depending on the set parameters.

The terminal occupies memory space in the process image of the inputs

and outputs.

I/O Offset High Byte Low Byte

Complete evaluation = 0 3

MOTOROLA format = 0 2

Word alignment = X 1 D3 D2

0 D1 D0

I/O Offset High Byte Low Byte

Complete evaluation = 0 3

MOTOROLA format = 1 2

Word alignment = X 1 D2 D3

0 D0 D1

I/O Offset High Byte Low Byte

Complete evaluation = 1 3

MOTOROLA format = 0 2 D4 D3

Word alignment = 0 1 D2 D1

0 D0 CT/ST

I/O Offset High Byte Low Byte

Complete evaluation = 1 3

MOTOROLA format = 1 2 D3 D4

Word alignment = 0 1 D2 D0

0 D1 CT/ST

I/O Offset High Byte Low Byte

Complete evaluation = 1 3 D4 D3

MOTOROLA format = 0 2 D2

Word alignment = 1 1 D1 D0

0 CT/ST

I/O Offset High Byte Low Byte

Complete evaluation = 1 3 D3 D4

MOTOROLA format = 1 2 D2

Word alignment = 1 1 D0 D1

0 CT/ST

14 KL6051

Page 15

Legend

Complete evaluation: the terminal is mapped with control / status byte.

Motorola format: the Motorola or Intel format can be set.

Word alignment: the terminal is at a word limit in the bus coupler.

CT: Control- Byte (appears in the PI of the outputs).

ST: Status- Byte (appears in the PI of the inputs).

D0 – D4: Data bytes 0 - 4

Annex

KL6051 15

Page 16

Annex

Table of the register

Register set

Address Designation Default R/W Storage medium

R0

Not used 0x0000 R

R1

Not used 0x0000 R

R2

Not used 0x0000 R

R3

Not used 0x0000 R

R4

Not used 0x0000 R

R5

Not used 0x0000 R

R6

Diagnostic register 0x0000 R RAM

R7

Command register not used 0x0000 R

R8

Terminal type 6051 R ROM

R9

Software version number 0x???? R ROM

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R34

R35

R36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

Multiplexed shift register 0x0218 R ROM

Signal channels 0x0130 R ROM

Minimum data length 0x3030 R ROM

Data structure 0x0000 R ROM

Not used 0x0000 R

Alignment register variable R/W RAM

Hardware version number specific R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Code word register variable R/W RAM

Feature register 0x0007 R/W SEEROM

Baud rate 0x0003 R/W SEEROM

RCV timeout 0x0014 R/W SEEROM

TRS timeout 0x0014 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

Not used 0x0000 R/W SEEROM

16 KL6051

Page 17

Annex

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

•

spare parts servive

• hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

KL6051 17

Loading...

Loading...