Page 1

I/O

Application Note DK9222-1209-0007

Measurement technology

Keywords

Energy measurement

Power factor

Energy analysis

EtherCAT Terminal

Bus Terminal

KL3403

EL3403

Consideration of the energy efficiency of a plant by

means of energy measurement

The measurement of energy consumption variables in the connected circuit is possible using the KL3403 Bus

Terminal and the EL3403 EtherCAT Terminal: the terminals directly output the effective values for voltage,

current and active power and total up the energy consumption internally; further parameters can be

calculated on the basis of the values determined.

Approach

Energy costs belong to the operating costs of a plant and are accounted for as overheads in lump sum shares to all cost

centres, since they cannot be attributed to any particular originator. In order to increase profits by reducing energy costs, the

costs must primarily be attributed to a particular consumer. This could similarly be entire plants or buildings or also individual

segments. If the consumption can be attributed, the optimisation of operating conditions is easier to implement and, in case of

doubt, their benefit also proven. By means of a transparent supply network, savings potentials can be specifically implemented

and the success of individual measures can also be observed in the long term. Furthermore, the financial expenditure for the

production of a certain lot size can be adopted into the cost calculation, since the energy throughput per production lot can be

determined as a result.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

1

Page 2

Application Note DK9222-1209-0007

Active power

P

Apparent power

S

Reactive power

Q

Active power factor

cos φ

Reactive power factor

sin φ

Electric work

W

~ Energy consumption

= U * I * cos φ

= U

eff

* I

eff

= P2+Q2

= U * I * sin φ

=

=

= U * I * t

P

S

Q

S

Q

S

P

φ

Measurement technology

As a rule, the following are starting points that need to be addressed in order to reduce energy costs:

– reduction in electricity costs: total active energy obtained, reactive power costs and also costs for peak loads

– stabilisation of manufacturing processes and avoidance of production losses

– identification of ‘energy hogs’

– lowering of maintenance costs

– extension of the service lives of electronic and electrical equipment

– cost centre allocation

Both the EL3403 EtherCAT Terminal and the KL3403 Bus Terminal provide the hardware for the analysis and localisation of

I/O

energy consumption. In addition to the important data from a three-phase supply network, they also record any energy peaks

occurring over a selectable time period and total up the energy consumption internally, so that different modes of operation or

shifted peak usage times can be judged even after just one production cycle. In addition to a general consideration of energy

efficiency, the quantity of energy used for the production of a particular lot size can be determined in order to adapt the price

per unit accordingly or to optimise manufacturing costs.

Function of the KL3403 Bus Terminal

The KL3403 Bus Terminal enables analysis via the fieldbus of the energy consumption of the connected plant or building

segment or, quite specifically, the key energy data of individual consumers. The voltages of the three phases and neutral can be

measured by directly wiring the individual cables to the terminal. In order to measure current, the current of the three phases

L1, L2 and L3 is fed in via simple current transformers. The measured current and voltage values are output as effective values.

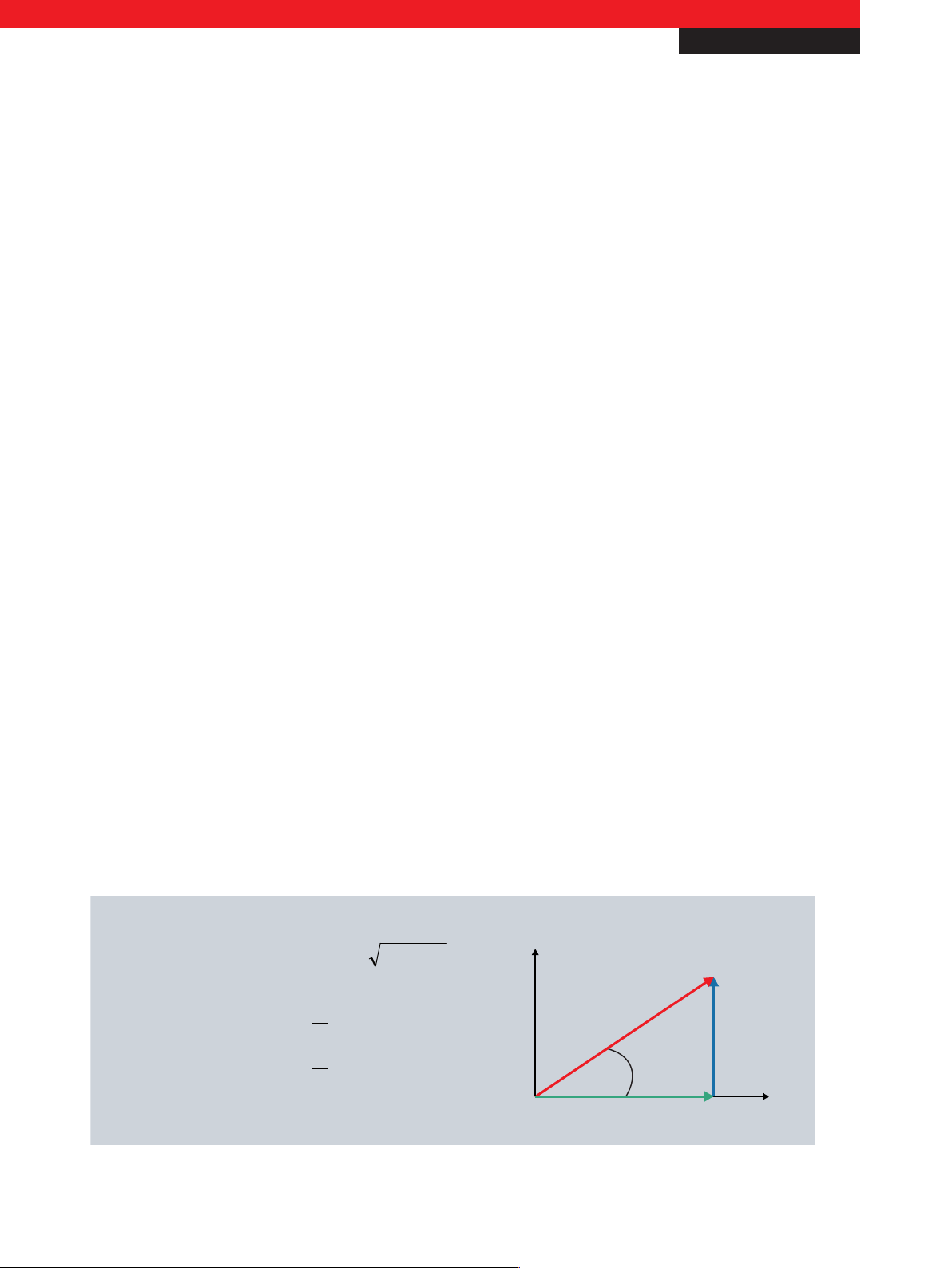

From the effective values for voltage (U) and current (I), the KL3403 calculates the effective power (P), the energy consumption

(W) and the power factor (cos φ) for each phase. The apparent power (S) and the phase shift angle (φ) can be derived from

these values.

For application notes see disclaimer on the last page

Fig. 1: Calculation of the important energy consumption variables

Beckhoff

New Automation Technology

2

Page 3

Application Note DK9222-1209-0007

u i

t

a)

u

1

t

b)

t

c)

u

1

u

1

Measurement

interval 2T

i

i

i

u

t

ϕ

i

t

P

S

P

Measurement technology

I/O

Fig. 2: Left: typical current-voltage curve, right: types of current that can be measured

The following types of current can be measured with the KL3403: current and voltage curve for phase control (a), pulse

duration control (b) and burst firing control (c); the measurement interval is set analogous to the control interval.

Integration of the KL3403 Bus Terminal

Internal pre-processing of the KL3403 provides rms values in the process image, without requiring high computing capacity

on the controller. The terminal outputs the measurement data in a 3 x 3-byte block, i.e. three bytes for each phase. Two bytes

per phase are pure process data, while one byte transmits the different status bits. The measured total energy performance is

written to the terminal’s internal non-volatile memory in a 15-minute cycle, so that these data are also available after a loss of

power. The recorded measurement values are transmitted to the controller via an arbitrary fieldbus (integration of the terminal

via bus coupler) and are available to the higher-level control system (BDE, ERP or the like) for continuous energy monitoring. In

order to achieve fast, cost-optimised and reliable communication of the energy data, the terminal can be integrated in existing

network architectures via different bus couplers.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

3

Page 4

Application Note DK9222-1209-0007

M

3~

230 V AC, 50 Hz

L1

L2

L3

N

PE

Etherne t TCP/IP

Fipio

Drive

Y-axis

Measurement technology

I/O

Fig. 3: Integration in any fieldbus environment as Bus Terminal or EtherCAT Terminal

Differences between EL3403 and KL3403

In principle, the EL3403 EtherCAT Terminal has the same range of functions as the KL3403 Bus Terminal, but is optimised for

measurements in the 50/60 Hz mains network. Significant differences are briefly listed here; further information and specific

details on the respective terminals can be taken from the documentation at www.beckhoff.com. EtherCAT Terminals are

integrated via EtherCAT Couplers, Bus Terminals via Bus Couplers.

Unlike the KL3403, the value for reactive power is also calculated internally in the EL3403. The energy consumption is totalled

up per sign, since different tariffs often apply to drawing out and feeding in.

As opposed to the KL3403, the EL3403 offers a considerably higher measurement value resolution. The standard version of the

KL3403 achieves a measurement value resolution of 1 mA, whereas the EL3403 enables a resolution of down to 1 µA. Both

values have a tolerance of 0.5 % FS (see documentation for details and further terminal variants). The EL3403 uses EtherCAT

as the transmission medium with a high data transmission rate, with which it is possible to read out all essential measurement

values in parallel if need be.

The EL3403’s measurement range for frequency measurements is narrower, but considerably more accurate. However, the

KL3403 can also be used for DC measurements. The measurement cycle is also optimised to the 50/60 Hz mains network in the

case of the EL3403: the measurement range automatically snaps to one period of the mains frequency. A multiple of the period

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

4

Page 5

I/O

– 3-phase power measurement terminal www.beckhoff.com/KL3403

– 3-phase power measurement EtherCAT Terminal www.beckhoff.com/EL3403

– Bus Terminal www.beckhoff.com/BusTerminal

– EtherCAT Terminal www.beckhoff.com/EtherCAT-Terminal

– Documentations www.beckhoff.com/documentations

Application Note DK9222-1209-0007

Measurement technology

can also be selected.

Further details on technology and configuration can be taken from the documentation. Program examples for the use of the

KL3403 in combination with other controllers are available on request.

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, December 2009

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Beckhoff

New Automation Technology

5

Loading...

Loading...