Page 1

I/O

Application Note DK9222-0909-0012

Bus Terminal

Pulse Train Output Terminal KL2521

Keywords

Encoder simulation

Pulse Train

Stepper motor

Pulse direction signal

Fieldbus substitute

Servo controller

Servo drive

Frequency converter

KL2521

This Application Example describes the control and positioning of drives through pulse patterns (pulse

train), which is common practice in Asia and the USA. In servo or stepper motors this technique is used for

realising simple positioning tasks. The pulses can be generated in the PLC or an associated I/O module, e.g.

Bus Terminal KL2521. It modulates a binary signal with a specified frequency that can be used directly for

control purposes.

The idea is that with the new KL2521 Pulse Train output terminal, Beckhoff are using simple pulses sent to stepper motors

and servo drives to implement digital technology for precise positioning tasks. To do this, the electronic Bus Terminal converts

a binary signal to a frequency, feeding this, electrically isolated from the terminal bus, to the positioning drive. The frequency

is preset by a 24 bit value from the automation unit. The advantage over conventional technology, such as an analog ± 10 V

interface, is that the Bus Terminal‘s high output frequency of 500 kHz allows the operation of the fastest servo drives currently

available. In contrast to analog technology, the set value signal is communicated without any offset drift. The 24 bit resolution

guarantees a high precision, in steps of 10 mHz. This means that set values can be specified in fine, almost continuous, steps.

In practice, the desired maximum output frequency is entered into a register, and then the frequency output can be used much

like a ± 10 V output by using 16 bits of the process image.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

1

Page 2

Application Note DK9222-0909-0012

Bus Terminal KL2521

Set value outputs by

variable frequency

+A

-A

+B

-B

24 V DC

Target/

following error

i. e.

Servoamplifiers,

frequency converters

Servomotors

Set value outputs

Target output

Bus Terminal

I/O

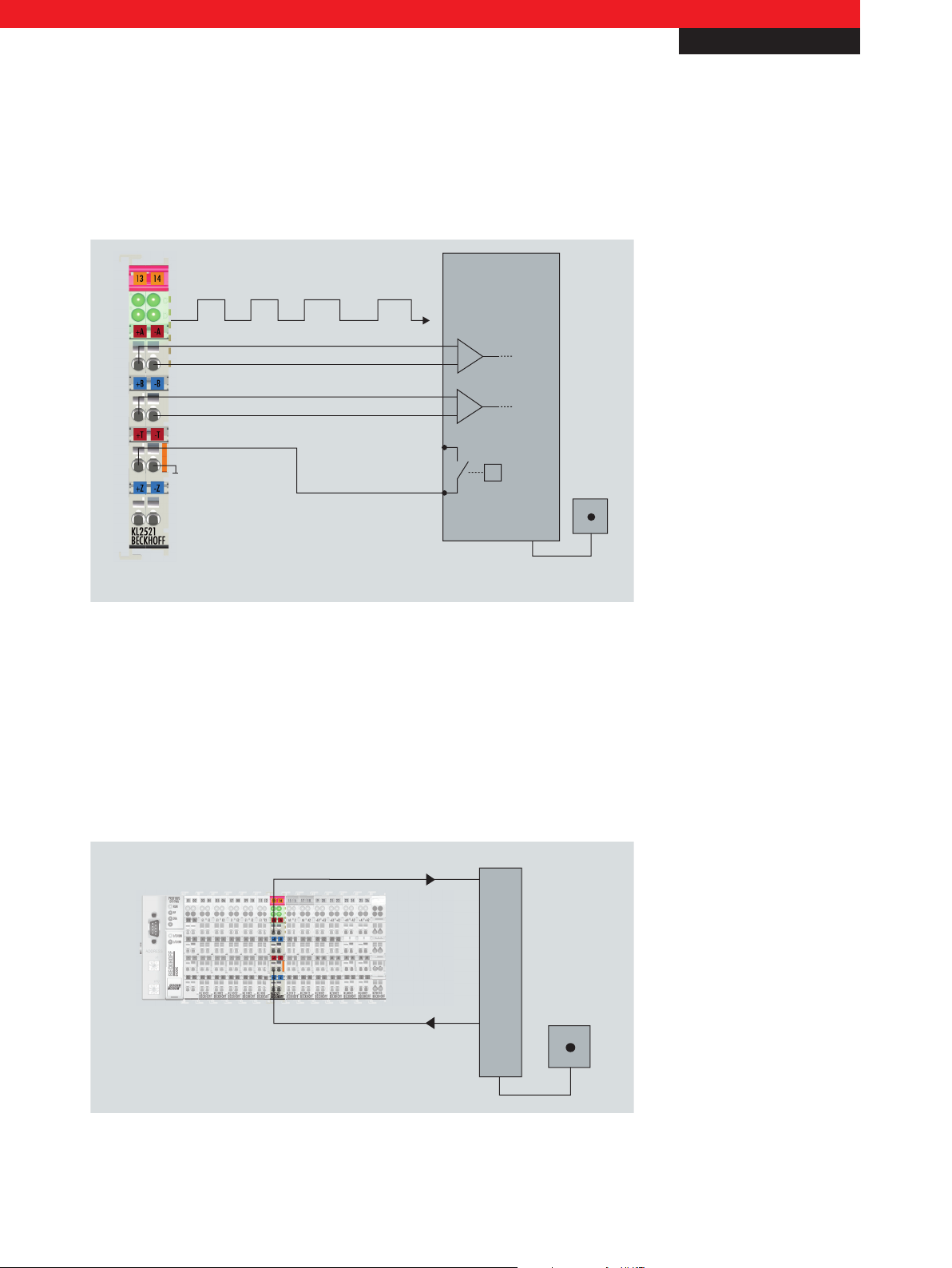

Fig. 1 Connections of the KL2521 pulse train terminal

Set value outputs and the acquisition of actual positions with just one Bus Terminal

The use of the Pulse Train technology to position drives is primarily used in Asia and in the USA. Its origins lie in the

methods for driving stepper motors. The wide acceptance and easy use of the technology resulted in its application to higher

power sectors of drive technology. The interface using Pulse Train technology is nowadays also applied to servoamplifiers

and frequency converters. The user can employ a consistent software and hardware interface, from micro-steppers up to

highpowered servo-drives.

Fig. 2 Set value outputs and the acquisition of actual positions with just one Bus Terminal

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

2

Page 3

I/O

A

B

A

B

A

B

Frequency modulation

Pulse/direction signals

Incremental encoder simulation

Application Note DK9222-0909-0012

Bus Terminal

In the Pulse Train technology, the provision of the set value and the validation of the actual position is implemented with

the aid of just one digital Bus Terminal. The actual position, which is otherwise acquired with the aid of incremental encoder

techniques, is calculated, depending on the specified set value frequency using, for instance, the TwinCAT software PLC/NC

(Figure 2). A difference between the set and actual value is indicated to the Bus Terminal using the target or following error

digital output which is present in all common servoamplifiers.

The KL2521 Pulse Train Bus Terminal supports three different frequency pulse patterns (Figure 3). These may be selected in

using the KS2000 configuration software, or by the higherlevel controller.

Fig. 3 frequency pulse patterns

The pulse patterns are output through the two channels, A and B. They correspond to all usual input circuits::

– Frequency modulation: rotation to the right is associated with output of the frequency signal on channel A, while rotation

to the left is associated with output on channel B. The inactive channel remains at a logical „low“ state.

– Pulse/direction signals: the frequency pattern is always output on channel A, the direction of rotation being indicated by the

„high“ or „low“ level on channel B.

– Incremental encoder simulation: channels A and B output a signal with a 90° phase shift. The shift from A to B is positive

or negative, thus encoding the direction of rotation. The output signal is thus exactly the same as that of an incremental

transducer. The advantage here is the possibility of directly driving frequency converters through the „synchronous axes“

signal input (Figure 4). Ontop of the simple positioning, this arrangement permits a master/slave structure. Users can

therefore couple this system to fieldbusses through existing interfaces - i.e. without additional costs.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

3

Page 4

Application Note DK9222-0909-0012

FU

FU FU

Set value outputs

Signal output „synchronous axes“

Bus Terminal

These 3 different pulse patterns can also be inverted, thus permitting ideal adaptation to the input circuit.

I/O

Fig. 4 Synchronisation of several frequency converters via incremental encoder simulation

The new Bus Terminal does more than simply make a large number of analog interfaces superfluous. The possibility of using the

automatic step counting to implement closed control loops is of even greater significance. The digital technology offers more

functions in comparison to the expensive evaluation involved in analog technology, and at lower cost.

Supplementary functions integrated into the new Bus Terminal support operation and reduce the controller‘s power

requirement. Optimal operation of a stepper motor is easily possible through the specification of a ramp. Just two parameters,

the ramp start frequency and the ramp run-up time, are necessary to initialise the Bus Terminal. The controller now only needs

to specify the frequency. The Bus Terminal performs acceleration and braking tasks. The frequency change is calculated directly

in the Bus Terminal, and takes place, bumplessly at time intervals of 2 ms. The controller‘s computing load is thus reduced,

which permits a number of axis controllers to be implemented using just one intelligent Bus Terminal Controller.

The output terminal can be configured using the associated Bus Coupler or the controller. The output stage is compatible with

RS422. It can, however, also be operated with 24 V DC signals. Either operating mode can be used without the need for a

configuration switch or for parameterisation. The signal state is indicated by light emitting diodes. The LEDs are driven in time

with the outputs and each displays an active output.

– Pulse train output terminal RS422/24 V DC www.beckhoff.com/KL2521

– The modular fieldbus system for automation www.beckhoff.com/Busklemmen

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

4

Page 5

Application Note DK9222-0909-0012

Bus Terminal

I/O

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, September 2009

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Beckhoff

New Automation Technology

5

Loading...

Loading...