Page 1

XFC

Application Note DK9222-0711-0051

XFC technology microincrements

Microincrements | IP67-related solutions

Keywords

microincrements

Distributed Clocks

EtherCAT

EtherCAT Box

XFC

IP 67

EP5101

encoder

This application example describes how an EP5101 EtherCAT Box can be used in a harsh industrial

environment (IP 65/67) to maximize the physical resolution of an incremental encoder. The number of

counted encoder segments can be output in more detail with a data width of just 8 bit, i.e. 256 times.

The resilient IP 67 I/O system from Beckhoff

The Beckhoff EtherCAT Box line delivers EtherCAT I/O technology without requiring a control cabinet. All modules from the IP

67 series have an integrated direct EtherCAT interface, so that the protocol’s high performance is retained right down to each

module. This opens up new options in the IP 67 world: fast process data communication with eXtreme Fast Control (XFC),

high precision measurement technology and drive functions integrated into I/O solutions directly in the field. With dimensions

of only 126 x 30/60 x 26.5 mm (H x W x D) the modules are exceptionally small and are, therefore, particularly suitable for

applications where available space is limited.

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

1

Page 2

XFC

CHA

CHB

2fold

4fold

CH

N

Application Note DK9222-0711-0051

XFC technology microincrements

Technical background

The incremental encoder is the main link between the mechanical system and the control system for monitoring mechanical

movements. Incremental encoders convert linear or rotary movements into signals that can be analyzed electrically. For rotary

movements, a certain number of light/dark segments applied to a pulse disc are scanned with a light beam. A scannable scale

arranged in the direction of motion is used for capturing linear movements. The accuracy of the returned position is limited by

the encoder resolution. For rotary movements, the resolution corresponds to the quotient of revolution (360°) and number of

segments. It indicates the smallest possible measurable difference between two positions. The more segments, the higher the

resolution and the more precise the position information. A standard encoder has 1000 lines, resulting in an accuracy of 360° /

1000 = 0.36°. This means a rotary movement can be monitored with a precision of ±0.36°. In many cases, this is adequate for

simple positioning tasks, although a finer resolution is required in order to monitor axis synchronism in addition to the position.

Fig. 1 Encoder signals with different resolutions

Physical improvement of the resolution through maximization of the encoder segments is only feasible to a certain degree,

since manufacturing tolerances and operating conditions increase the costs of the encoder. A simple and effective way of

maximizing the resolution is to use a second detection point. With two signals that are offset by 90°, three additional edges

are available for detection. They can be used to detect the direction of rotation in addition to the position, and an additional

reference signal for zeroing is output once per revolution. Analysis of these additional edges can refine the resolution by a

factor of 4 (360° / 4 * 1000 = 0.09°), which is why this principle is referred to as quadrature encoder.

Axis synchronism monitoring

Axis synchronism is monitored through cyclic position polling and interpolation of these values within the PLC. The timebase

for the interpolation is provided by the strict cycle-linked processing of the instructions in the PLC. With a cycle time of 1 ms

(which is common for motion applications), the positions are scanned with a timebase of 1 ms. However, the real encoder

scanning intervals are not as rigid as those of the PLC and vary. The reason for the irregularity is inherent to the functional

principle variation of the fieldbus transfer times (jitter) and the encoder inaccuracy with ±½ edge. Since the PLC does not take

this discontinuity of the polling intervals into account and assumes a constant interval duration, the position representation

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

2

Page 3

XFC

0

2

4

6

8

10

12

14

16

n n + 1 n + 2 n + 3 n + 4 n + 5 n + 6 n + 7

Actual course Process image

Cycles

Application Note DK9222-0711-0051

XFC technology microincrements

in the process image of the PLC may be unsteady even if the axis is, in fact, synchronous. This only virtual deviation can have

three different effects:

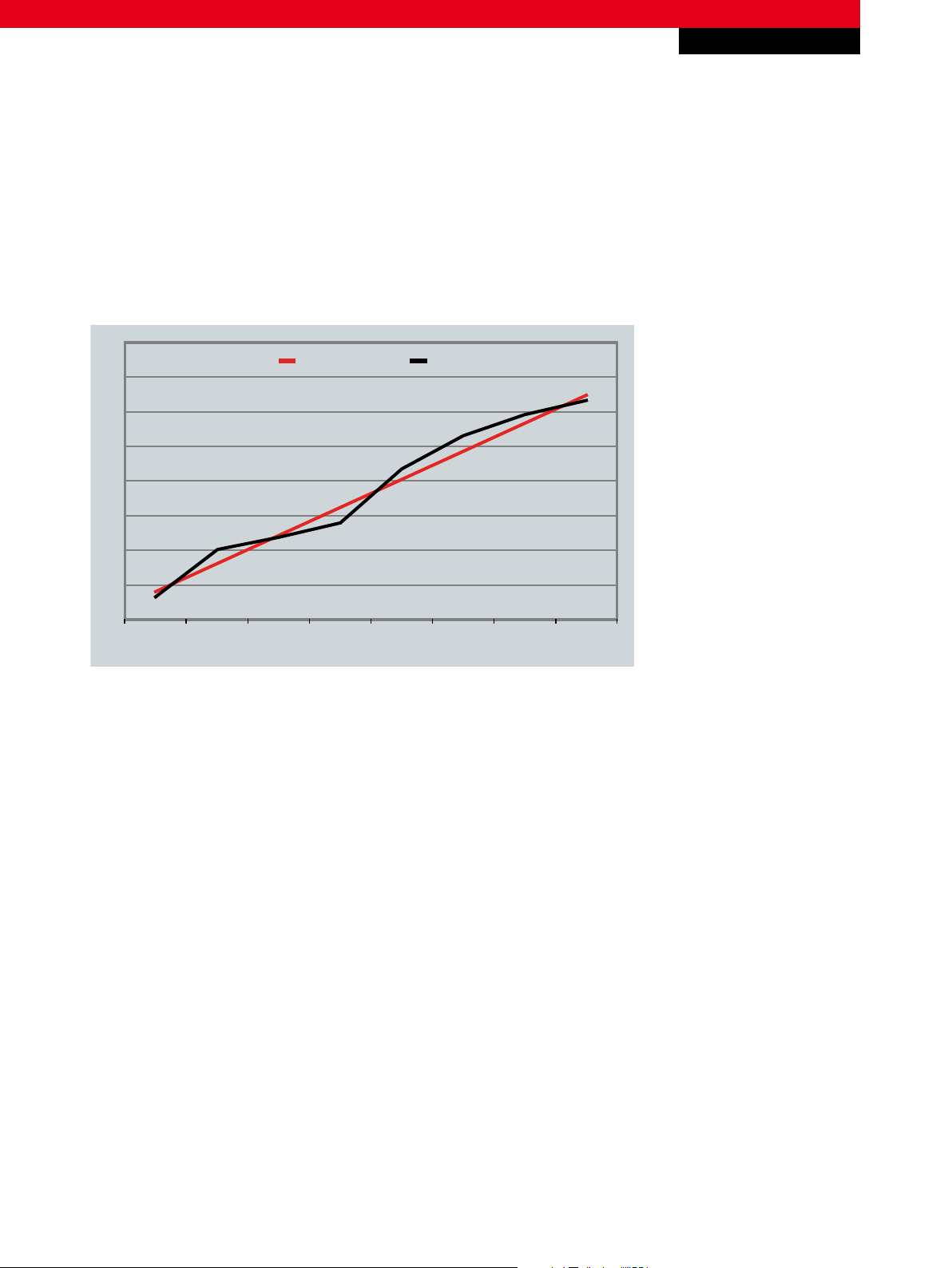

Diagram 1 Asynchronism according to process image

1st case:

Although, in reality, the axis runs absolutely uniformly, the process image shows a non-uniform movement (see Diagram 1)

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

3

Page 4

Application Note DK9222-0711-0051

0

2

4

6

8

10

12

14

16

n n + 1 n + 2 n + 3 n + 4 n + 5 n + 6 n + 7

Actual course Process image

Cycles

0

2

4

6

8

10

12

14

16

n n + 1 n + 2 n + 3 n + 4 n + 5 n + 6 n + 7

Actual course Process image

Cycles

XFC technology microincrements

XFC

Diagram 2 Amplified asynchronism according to process image

2nd case:

While the axis only runs slightly unevenly, the effect is amplified in the process image (see Diagram 2)

Diagram 3 Equalising asynchronism according to the process image

3rd case:

The axis runs unevenly, the process image equalizes the non-uniform movement (see Diagram 3)

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

4

Page 5

XFC

Application Note DK9222-0711-0051

XFC technology microincrements

Synchronization of the strictly cyclical polling through the distributed clock function

High uniformity of the polling intervals can be achieved by using a local clock generator in the EtherCAT slaves, for example,

the distributed clock function within EtherCAT (see Fig. 2). This principle is based on measuring the protocol run times within

the bus and adjustment of the clock generator clocks in the individual fieldbus slaves. With DC, any run-time difference is

known exactly and can be compensated. The polling intervals of the EtherCAT slaves are thus adapted to the strictly cyclic

operation mode of the PLC. For distributed clock function, see the distributed clocks system description which is available from

the download area under www.beckhoff.com/english/download/ethercat.htm.

Fig. 2 Local clock generators in the field

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

5

Page 6

XFC

Submitted

values

per cycle

Encodersignal

Submitted

values

by using

microincrements

4

5

6

7

3

3.05 4.6 5.8 6.5 7.48

Application Note DK9222-0711-0051

XFC technology microincrements

Practical example | Virtual maximization of the physical encoder resolution through

microincrements

The semi-edge inaccuracy of the encoder is eliminated by using the microincrement mode of the Beckhoff EP5101 EtherCAT

Box with encoder interface. In this mode, the EtherCAT Box automatically interpolates the position scans to be transferred

over a width of 8 bits. Therefore, this mode offers a 256 times higher resolution than the encoder is able to provide physically.

The microincrement mode is only suitable for motion analyses, because for interpolation within the EtherCAT Box, the position

is sampled with a significantly higher resolution than is passed on to the fieldbus in interpolated form. The principle of

interpolation in the EtherCAT Box requires a minimum speed, i.e. microincrements cannot be analyzed at (or near) standstill.

Fig. 3 Different encoder signals resolutions (with and without microincrements)

The EP5101 EtherCAT Box is an interface for the direct connection of incremental encoders with differential inputs (RS485).

Due to the optional interpolating microincrement function, the EP5101 can supply even more precise axis positions for dynamic

axes. In addition, it supports the synchronous reading of the encoder value together with other input data in the EtherCAT

system via high-precision EtherCAT distributed clocks (DC). The encoder is connected via an 8-pin M12 socket (EP5101-0002)

or via a 15-pin D-sub socket (EP5101-0011).

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

6

Page 7

Application Note DK9222-0711-0051

XFC technology microincrements

Connector assignment

EP5101-0002

4

4

321

321

1 | GND

2 | VCC

3 | A

4 | /A

5 | B

6 | /B

7 | C

8 | /C

2 412

4

3

3 1

IN OUT

|

EP5101-0002

4

4

321

321

2 412

4

3

3 1

IN OUT

1 | A

2 | GND

3 | B

4 | VCC

5 | n.c.

6 | n.c.

7 | /C

8 | Latch

9 | /A

10 | GND

11 | /B

12 | VCC

13 | /ERR

14 | C

15 | Gate

Fig. 4 Connector assignment of the EP5101 EtherCAT Box

XFC

– Incremental encoder interface for IP 67 www.beckhoff.com/EP5101

– Control architecture for highest performance www.beckhoff.com/XFC

– EtherCAT Extends its Reach into the IP 67 World www.beckhoff.com/EtherCAT-Box

– EtherCAT www.beckhoff.com/EtherCAT

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, July 2011

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

New Automation TechnologyBeckhoff

7

Loading...

Loading...