Page 1

I/O

Application Note DK9222-0610-0027

Motion

Keywords

Buffer capacitor

Brake chopper

Fieldbus

Drive

Stepper

DC motor

Output stage

DC link

Overload

Recovery

EtherCAT

K-Bus

Bus Terminal

PLC

Overvoltage protection and voltage stabilization for

Motion Control terminals

This application example describes how Motion Control applications with the output stages for servo, DC

and stepper motors by Beckhoff are optimized by the utilization of buffer capacitors. The buffer capacitor

terminals EL9570 for EtherCAT and KL9570 for K-Bus stabilize the voltage supply by absorbing the fed back

energy and dumping the energy that the buffer capacitor cannot protect against into an external braking

resistor. The buffer capacitor terminal protects the DC power supply and other motor terminals that may

be sharing the same DC power source. The buffer capacitor terminal extends the area of application for

Beckhoff Motion Control terminals to also include applications with short start/stop ramp times and large

inertia. Additional installation space in control cabinets is saved due to the solution’s compact design as a

double-sized standard terminal block.

Electrical drives

Variable-speed electrical drives are used in practically all industrial sectors. They are preferred for the following reasons:

– Good system efficiency

– Good or very good static and dynamic control characteristics

– Communication with higher-level controllers is possible

– Market prices are in line with user expectations.

Electrical drives are also influenced by the control electronics. New servo drives make complete solutions that are compact

and energy-saving possible. These exhibit dynamic control behavior, good torque stability, and control capability down to zero

speed.

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

1

Page 2

I/O

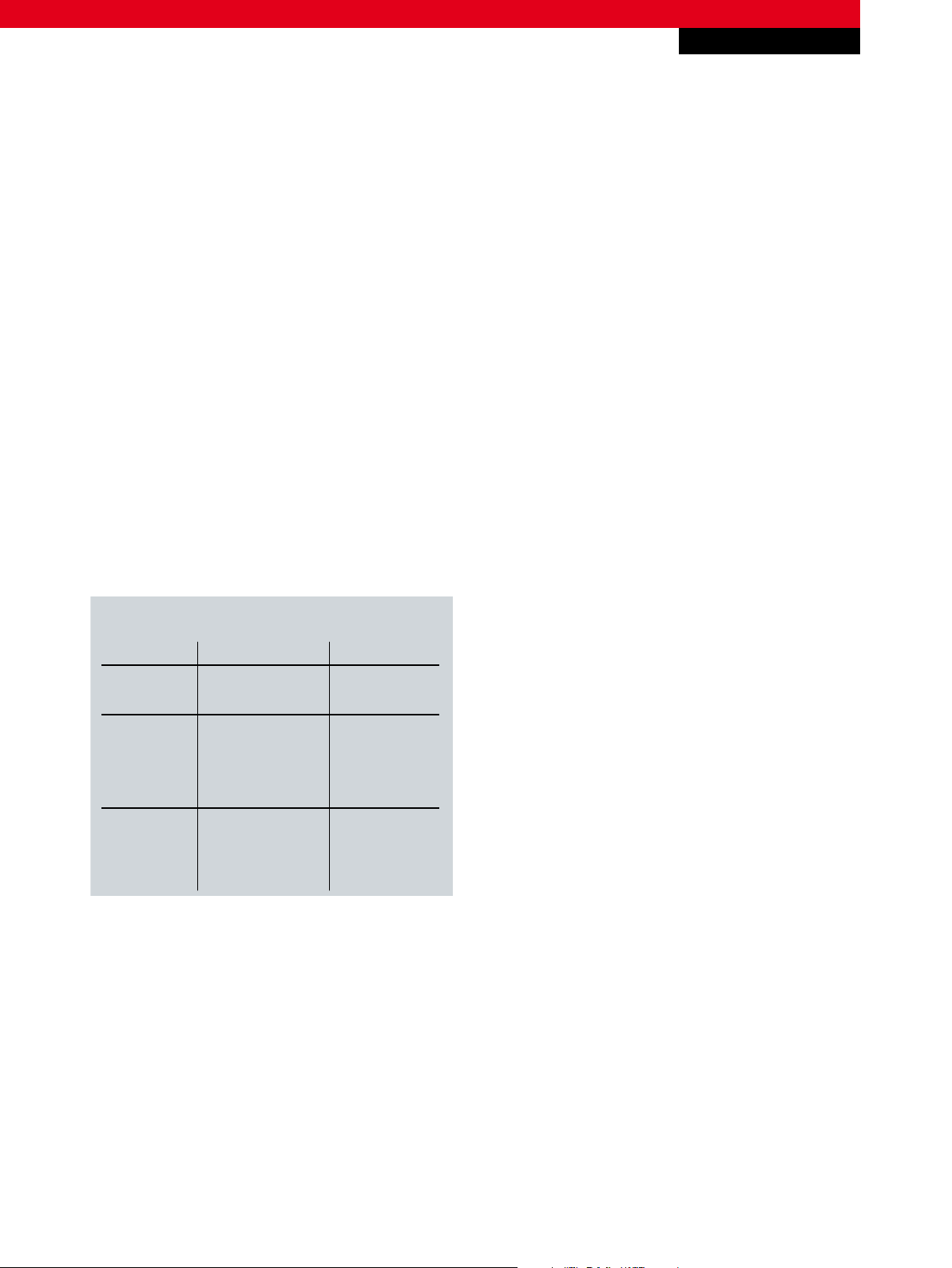

Overview of Motion Control terminals

EtherCAT Terminals Bus Terminals

Servomotors

EL7201

50 V DC, 4 A

–

DC motors

Stepper motors

EL7332

24 V DC, 1 A

EL7342

50 V DC, 3.5 A

EL7031

24 V DC, 1.5 A

EL7041

50 V DC, 5 A

KL2532

24 V DC, 1 A

KL2552

50 V DC, 5 A

KL2531

24 V DC, 1.5 A

KL2541

50 V DC, 5 A

Application Note DK9222-0610-0027

Motion

Servo motors are suitable drives for position control applications. They combine motor, speed and angular position measuring

systems. For cost-sensitive applications with low dynamics, stepper motors may be used as an alternative. In the lower capacity

range, DC motors offer good control ability with low costs. The suitability of a drive is judged on the basis of the torque

produced and the dynamics.

Motion Control in a very compact form factor

The modular I/O system from Beckhoff also encompasses Motion Control in an exceptionally compact form factor. Motors are

driven directly from the PLC with output stages for servo, stepper and DC motors. To have an output stage means that the

motor amplifier is built right into the motor terminal. Whether using an EtherCAT or a Bus Terminal, these I/O devices with

a built in drive can be integrated into any control environment using Beckhoff Bus Couplers. The TwinCAT System Manager

reduces familiarization efforts to a minimum, since TwinCAT enables equal treatment of all motors on the software side. The

interfaces are almost identical, and parameterization is quite straightforward.

Fig. 1 Overview of the Motion Control terminals

DC, servo and stepper motors (principle of operation)

The principles of operation for DC motors and stepper motors are fundamentally different. DC motors generate a torque and a

rotary motion when a voltage is applied. Stepper motors only generate a torque. A prerequisite for the rotary motor motion is

For application notes see disclaimer on the last page

commutation of the current, i.e. inversion of the direction of current flow in the electromagnetic coil during a motor rotation.

DC motors with brushes are self-commutating. Stepper motors cannot commutate independently. Servo motors do not differ

from the aforementioned types of motors in their physical operating principle, but rather in the way they are controlled: they

are operated in conjunction with position feedback in a closed control loop.

Beckhoff

New Automation Technology

2

Page 3

I/O

V DC

max.

t

U

I

t

Application Note DK9222-0610-0027

Motion

Power supply of electrical drives – problems from real applications

A Voltage peaks at the power supply unit

In highly dynamic applications, fast decelerations cause the feedback of energy, which will lead to voltage spikes at the power

supply unit. The overvoltage spikes can destroy the power supply unit. ’Intelligent’ power supplies with overvoltage protection

switch themselves off briefly, but this results in the drive losing control. These are all factors that will significantly impair

system reliability.

Fig. 2 Voltage spikes at the power supply unit

B Ripple currents

Fig. 3 Occurrence of ripple currents

Ripple currents occur during fast acceleration. The power supply unit can no longer compensate, resulting in voltage drops.

Ripple currents additionally occur with the commutation of DC machines, which have a negative influence on synchronization,

particularly in the case of short start/stop ramp times of the motors, and appear as torque ripple (rough mechanical operation).

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

3

Page 4

I/O

55 V DC

t

U

Application Note DK9222-0610-0027

Motion

C Braking energy/energy recovery

The faster the deceleration time of the motors, the more negative energy is generated, which appears as a voltage peak at the

power supply unit.

See A Voltage peaks

Optimization potential with the Beckhoff buffer capacitor terminals

The EL9570 and KL9570 buffer capacitor terminals are intended for use with the output stages of stepper motors and DC

motors. With a capacitance of 500 µF they stabilize the power supply, feed energy back and protect highly dynamic drives

against overvoltage. The 12 mm wide EL9570 and KL9570 buffer capacitor terminals supplement the extensive I/O system kit

for Motion Control in miniature format and can be integrated in any control environment via Bus Couplers.

Overvoltage protection

Fig. 5 Prevention of overvoltage

The KL9570 and EL9570 buffer capacitor terminals can absorb the energy generated by highly dynamic drives due to their

500 µF capacitors, which are particularly resistant to ripple current. If the fed-back energy exceeds the capacity of the

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

4

Page 5

I/O

KL9570 in combination with:

KL2531 | Stepper motor terminal

24 V DC, 1.5 A

KL2541 | Stepper motor terminal

50 V DC, 5 A, with incremental encoder

KL2532 | 2-channel DC motor output stage

24 V DC, 1 A

KL2552 | 2-channel DC motor output stage

50 V DC, 5 A

EL9570 in combination with:

EL7031 | Stepper motor terminal

24 V DC, 1.5 A

EL7041 | Stepper motor terminal

50 V DC, 5 A, with incremental encoder

EL7201 | Servomotor terminal

50 V DC, 4 A, with resolver, motor brake

EL7332 | 2-channel DC motor output stage

24 V DC, 1 A

EL7342 | 2-channel DC motor output stage

50 V DC, 3.5 A

Application Note DK9222-0610-0027

Motion

ccapacitors, an external braking resistor prevents overvoltage. The low internal resistance and the high pulse current capability

of up to 10 A enables good buffering parallel to the power supply.

Fig. 6 Possible combinations of Beckhoff Motion Control and buffer capacitor terminals

– Buffer capacitor terminal www.beckhoff.com/KL9570

– Buffer capacitor terminal EtherCAT www.beckhoff.com/EL9570

Bus Terminals

– Stepper motor terminal 24 V DC, 1.5 A www.beckhoff.com/KL2531

– Stepper motor terminal 50 V DC, 5 A, with incremental encoder www.beckhoff.com/KL2541

– 2-channel DC motor output stage 24 V DC, 1 A www.beckhoff.com/KL2532

– 2-channel DC motor output stage 50 V DC, 5 A www.beckhoff.com/KL2552

EtherCAT Terminals

– Servomotor terminal 50 V DC, 4 A EtherCAT www.beckhoff.com/EL7201

– Stepper motor terminal 24 V DC, 1.5 A EtherCAT www.beckhoff.com/EL7031

– Stepper motor terminal 50 V DC, 5 A, with incremental encoder EtherCAT www.beckhoff.com/EL7041

– 2-channel DC motor output stage 24 V DC, 1 A EtherCAT www.beckhoff.com/EL7332

– 2-channel DC motor output stage 50 V DC, 3.5 A EtherCAT www.beckhoff.com/EL7342

For application notes see disclaimer on the last page

Beckhoff

New Automation Technology

5

Page 6

Application Note DK9222-0610-0027

Motion

I/O

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, June 2010

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Beckhoff

New Automation Technology

6

Loading...

Loading...