Page 1

I/O

Application Note DK9222-0112-0059

Measuring analog signals

Keywords

Loop-powered

2-wire transmitter

True Zero

4-20 mA

KL3458

Analog

Single-ended

Current loop

Loop power

Live Zero

KL3454

KL3054

Difference

Input

Analog signal transmission: Current interface 4…20 mA

(Live Zero principle)

This application example describes the facets of analog signal recording and their forms of transmission in

general. In particular, this document covers the recording of measured values using the KL3054, KL3454 and

KL3458 analog input Bus Terminals from Beckhoff. When used in conjunction with 2 or 3-wire sensors, these

terminals enable the detection of cable breakage and sensor failures internally in the circuit according to

the Live Zero principle.

Analog signal recording

Analog measured variables such as pressure, temperature, flow, speed, etc. are converted by sensors into analog values and,

depending on the sensor, are also linearized inside the sensor. Sensors for analog measured variables usually consist of two

functional elements – the measuring sensor and the transducer – and determine the change in the measured variable by

means of a physical principle. The digitized analog signal transmitted to the controller normally corresponds to a standardized

level and is always composed of the type (voltage, current, resistance, etc.) and the value (0 – 10 V, ± 1 V, 0 – 20 mA, 500 mΩ,

etc.)

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

1

Page 2

Application Note DK9222-0112-0059

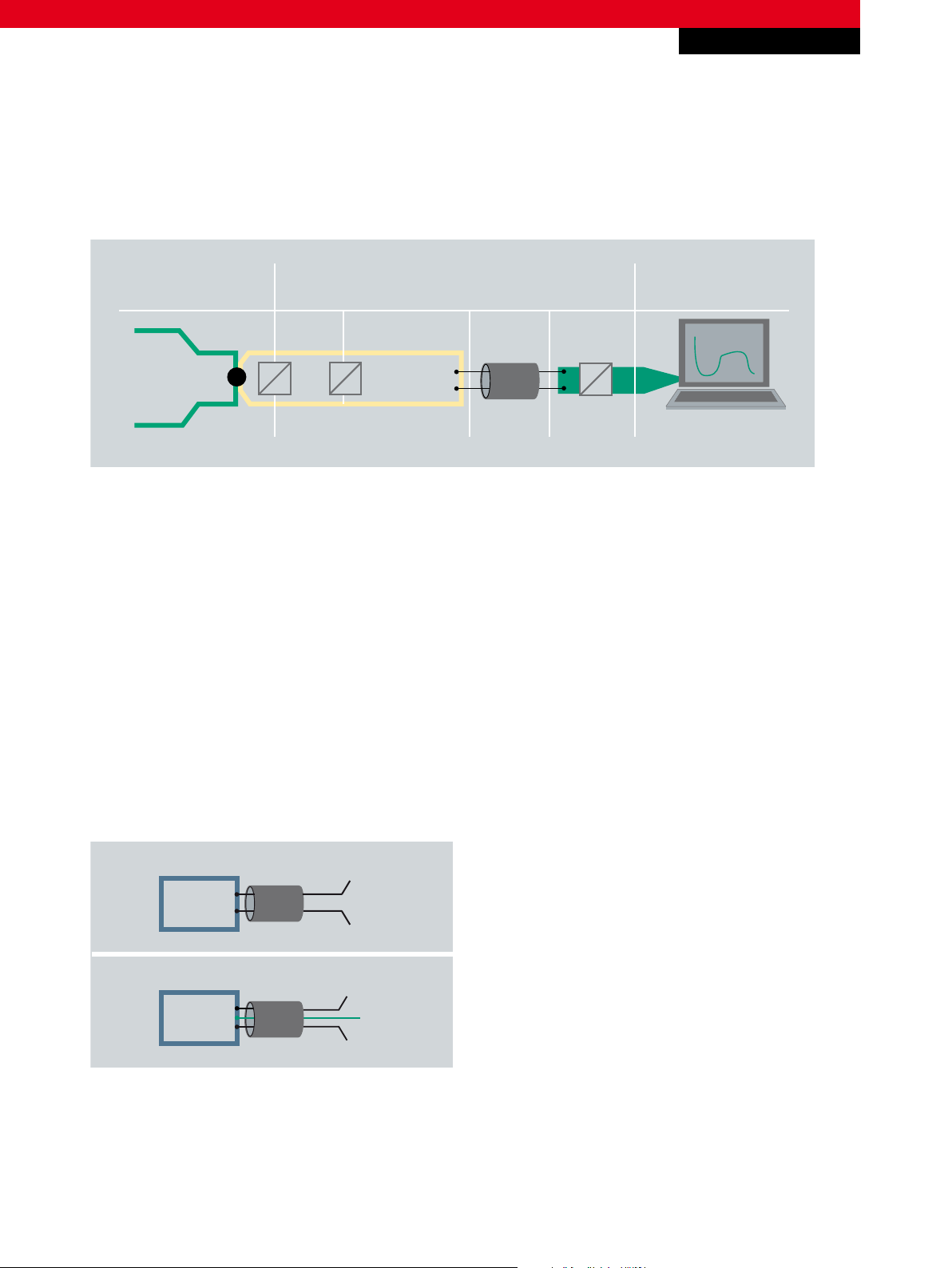

Process

Sensor

Physical quantity

Digital variable

Process data format

Measured

value

Analog

value

Analog

standard signal

Signal

transmission

Analog

input

Control

2-wire sensor

3-wire sensor

sensor

signal

GND

U

B

sensor

signal -

signal +

Measuring analog signals

Fig. 1 The path of an analog process value: from the field into the controller

I/O

In control technology, a sensor can also contain further functional elements (bus connection, integrated scaling of the

measured value, pattern recognition, etc.). It is then usually called a “smart” sensor.

Types of analog sensor connections

Sensors that directly connect to the analog inputs of the controller (‘classic analog sensors’) can be manufactured with a 4-, 3-

or 2-wire configuration, depending on the power supply concept and signal transmission method.

4-wire sensors conduct signal and power each via two wires. The wiring expenditure is high with this type of connection.

3-wire sensors use two wires for the power supply and output the signal via a separate wire. The reference potential is the

GND wire.

2-wire sensors conduct the signal and power supply via one (common) supply wire. The 2-wire technique requires little wiring

expenditure and represents the state of the art in measuring transducers for field and sensor head mounting.

For application notes see disclaimer on the last page

Fig. 2 2-wire sensor with power and signal on one wire, 3-wire sensor with separate wires for power and signal

Methods of transmission of analog process values

In control technology the signal levels for the transmission of the sensor signals are standardized in order to ensure the

most extensive compatibility of sensors and evaluation units possible, without restricting the level of freedom in product

New Automation TechnologyBeckhoff

2

Page 3

I/O

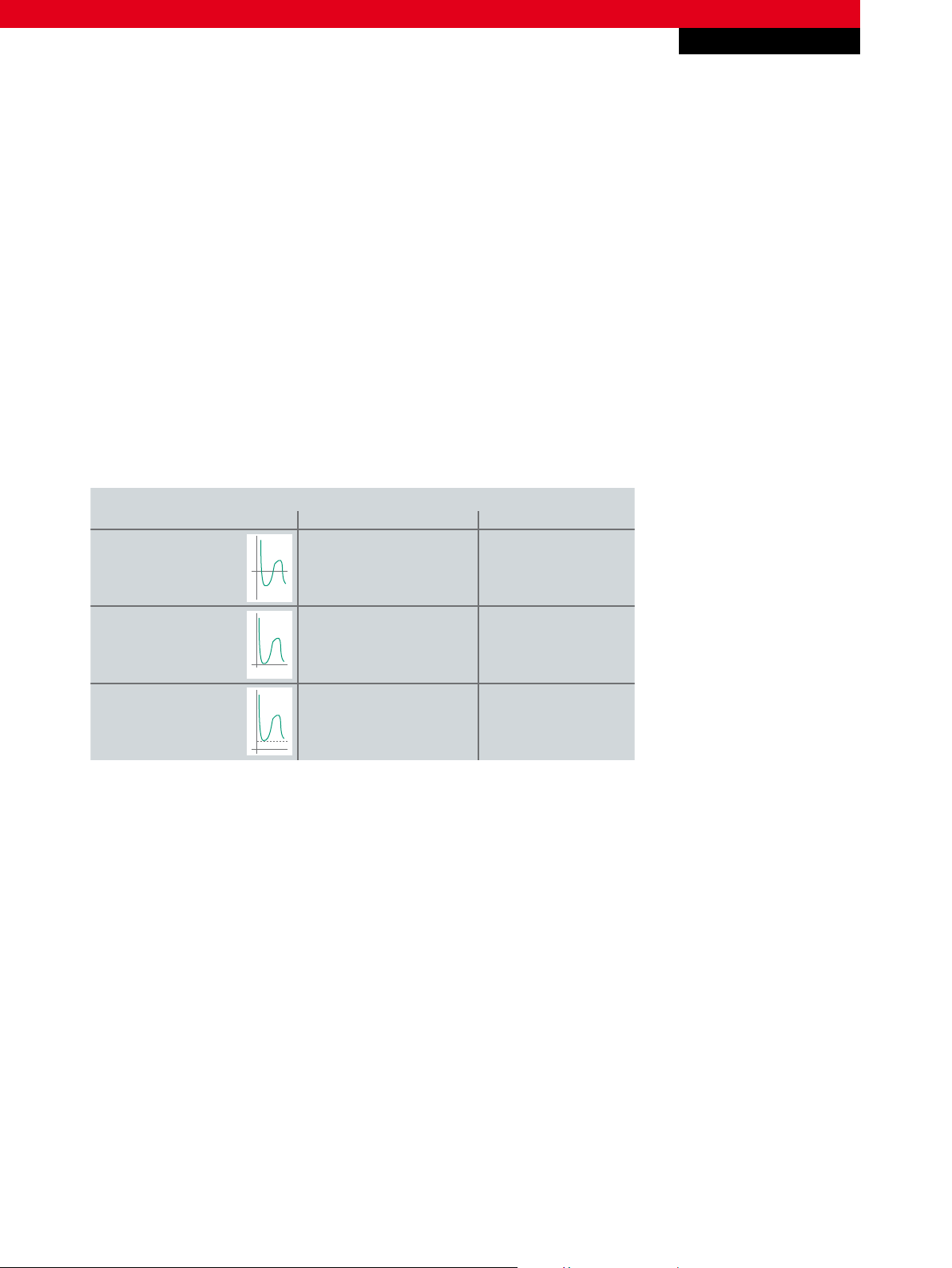

Voltage Current

Types of analog signals

±2 V, ±10 V –bipolar

0…20 mA

0…2 V, 0…10 Vtrue zero

1…10 V 4…20 mA

live zero

+

–

0

+

0

+

0

Application Note DK9222-0112-0059

Measuring analog signals

development. Voltage or current-based methods of transmission are mainly used (table 1). In the transmission of analog

process values, one must also keep in mind that the digitalized signal has a tendency to dither as the resolution increases

(the more finely it represents the process value). If a high-resolution signal is demanded, the transmission must be free from

superimposed interference. Current-based transmission via so-called “current interfaces” is particularly recommended for such

applications. In comparison with voltage signals they are significantly less sensitive to electromagnetic interference. In general

it can be concluded that, in the case of current interfaces, power-related voltage drops (resulting from the internal resistance

of the supply line) hardly affect the quality of the signal transmission if at all: The length of the cable is limited only by the

maximum available supply voltage of the power source.

Tab. 1 Types of analog signals

Bipolar signals

Bipolar signals alternate around a voltage or current level that is usually 0 (“zero”). Depending on the application and the

specification of the sensor, an offset can be applied to the level. With this type of signal it must be ensured that the sensor

and the evaluation electronics are also suitable for AC voltages. The current-based transmission of bipolar signals is not very

common.

True Zero (0…2/10 V | 0…20 mA)

This type of signal is only conditionally suitable for transmission via 2-wire connections, since signals with the classification

“True Zero” always require external auxiliary power at the start of the measuring range so that the sensor remains “viable.” In

addition, a wire breakage or sensor failure can be detected reliably only with external monitoring.

The adequate detection of a wire breakage or a sensor defect is problematic because the value “0” can be interpreted both as

the end value of the measuring range and as an error. In practice, therefore, an additional external sensor monitor is frequently

used.

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

3

Page 4

I/O

Bus Terminals for the evaluation of current-based analog signals (KL3xxx | KS3xxx)

8-channel

True Zero

Live Zero

KL3448 | KS3448

8 x 1-wireconnection, 12 bit

KL3458 | KS3458

8 x 1-wireconnection, 12 bit

1-channel

KL3011 | KS3011

Differential input,

12 bit

KL3041 | KS3041

loop-powered,

12 bit

KL3021 | KS3021

Differential input,

12 bit

KL3051 | KS3051

loop-powered,

12 bit

4-channel

KL3444 | KS3444

4 x 2-wireconnection, 12 bit

KL3044 | KS3044

12 bit

KL3454 | KS3454

4 x 2-wireconnection, 12 bit

KL3054 | KS3054

12 bit

2-channel

KL3012 | KS3012

Differential input,

12 bit

KL3042 | KS3042

loop-powered,

12 bit

KL3112 | KS3112

Differential input,

16 bit

KL3142 | KS3142

16 bit, 0,05%

KL3022 | KS3022

Differential input,

12 bit

KL3052 | KS3052

loop-powered,

12 bit

KL3122 | KS3122

Differential input,

16 bit

0 ... 20 mA

4 ... 20 mA

+

0

+

0

Application Note DK9222-0112-0059

Measuring analog signals

Live Zero (1/2…10 V | 4…20 mA)

Since a finite value (value > 0) of the lower measuring range (1/2 V, 4 mA) enables the permanent supply of power to the

sensor or the internal circuit without an external supply, internal monitoring (sensor defect/wire breakage) can also be realized

in this way. Signals with the classification “Live Zero” are typical for 2-wire sensors with high availability checking. The

Live Zero circuit is also advantageous for fault-finding: The signal curve can be measured with a multimeter over the entire

transmission link.

Note:

The Beckhoff products described below are not to be assigned to the HART classification. They are neither “HART-compatible”

nor are they suitable for use as intrinsically safe equipment in explosive zones.

The Beckhoff analog Bus Terminals | Evaluation units for analog signals

For the evaluation of analog sensor signals, Beckhoff offers an extensive range of Bus Terminals from the KL3xxx series, which

cover a broad range of applications in analog signal processing. The input circuit of the Bus Terminals differs between single-

ended and differential inputs. A single-ended input expects a signal with a fixed reference to ground.

Tab. 2 Bus Terminals for the evaluation of current-based analog signals

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

4

Page 5

Application Note DK9222-0112-0059

Bus Terminals for Live Zero signals 4…20 mA

Integrated

voltage supply

Number of channels

Resolution

Reference ground

Connection example

Sensor supply

Optional power

feed terminal

KL3454

yes/24 V DC

4

12 bit

0 V power contact

2-wire sensor

loop-powered

–

KL3454

sensor

KL3054

no

4

12 bit

common reference

ground of all 4 inputs

2/3-wire sensor

external; terminal

as galvanic island

–

KL3054

sensor

+U

B

KL3458

no

8

12 bit

0 V power contact

3-wire sensor 2-wire sensor

KL9184 KL9186

8 x 24 V DC

8 x ground

8 x 24 V DC

KL3058

sensor

+U

B

U

B

KL3058

sensor

+U

B

Measuring analog signals

I/O

Tab. 3 The measuring error of all 4 – 20 mA Bus Terminals is < ± 0.3% (in relation to the full scale value).

KL3454 | Loop-powered 2-wire sensors (“loop powered”, Live Zero)

The KL3454 4-channel analog input Bus Terminal supports the direct connection of 2-wire sensors without an external power

supply. The sensors are supplied with power directly via the evaluation unit – they are “loop-powered.” An external voltage

supply can be omitted, since the 24 V power contact is fed to the terminal points. The KL3454 digitizes current signals within

the range of 4 to 20 mA with a maximum resolution of 12 bits. The internal wiring of the KL3454 has such a low impedance

that even if the sensor reaches full scale (signal level 20 mA) the low voltage drop inside the terminal can still provide the

sensor with sufficient power. The resistance of the internal wiring (80 Ω) and the length-dependent wire resistance add up

to a total that lies significantly below the otherwise usual 500 Ω. Therefore, it is usually not necessary to impose a maximum

permissible cable length.

KL3054 4-channel analog input Bus Terminal

The KL3054 also supports the connection of sensors for 4 – 20 mA signals using the 2-wire configuration. Exclusively

externally-powered sensors may be connected, i.e. they must be supplied externally with power, since the Bus Terminal

functions as a galvanic island. Using the KL3054, analog values can be determined with different sensor supply voltages or

between components that have no common ground connection. Like the KL3454, the KL3054 digitizes the sensor signals with

12 bits.

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

5

Page 6

I/O

1-wire connection of externally-powered sensors via KL3458:

common reference potential

Necessary coupling between GND and 0 V power contact

K-Bus power supply

0 V power contact

KL3458

arbitrary

fieldbus connection

+ 24 V

GND

sensor A sensor B

Application Note DK9222-0112-0059

Measuring analog signals

KL3458 8-channel analog input Bus Terminal

The KL3458 unites eight inputs in a single housing, offering the possibility to connect multi-channel sensors using single-wire

technology in a minimal amount of space. The KL3458 is suitable for externally-powered 2 and 3-wire sensors, but a connection

must be made in each case between the ground of the sensor power supply and that of the Bus Terminal node (0 V power

contact).

Fig. 4 KL3458 connection example: for the single-wire connection of externally-powered sensors, it is necessary to couple the GND

(sensor power supply) to the 0 V power contact of the terminal node.

Bus Terminals for Live Zero signals – “differential input”

Despite the advantages in signal transmission, the connection of sensors via a current loop also has disadvantages: unlike

with voltage-based signals, consumers cannot be connected in parallel with each other. If a measured value is to be processed

in several places, a series connection of the evaluation units is necessary. Only one evaluation unit with a ground reference

can work in this series connection, all others require a differential input that does not expect a common connection of the

individual grounds.

Such a series connection is created, for example, if a measured value is not to be transmitted exclusively to the controller,

but is to be visualized via a display device (a digital ammeter installed in the control cabinet) without the intervention of

the controller. In such cases measurement via an analog differential input that does not expect a common connection of the

individual ground connections should be used.

For application notes see disclaimer on the last page

New Automation TechnologyBeckhoff

6

Page 7

Application Note DK9222-0112-0059

Correct multiple tapping of a current-based measured value

A

=

KL3022

differential

input

KL3xxx

Single-

ended

4…20 mA

Measuring analog signals

Fig. 5 Series connection of differential and single-ended inputs for the multiple tapping of a current-based measured value

I/O

Worth knowing

HART protocol

The HART communication (Highway Addressable Remote Transducer) also uses analog 4 – 20 mA technology in conjunction

with 2-wire sensors. HART describes remotely addressable transducers and is a function-oriented extension of the analog

current signal by the simultaneous superimposition of digital information. HART is typically used in the process industry where

it is frequently implemented in explosive zones, among other areas.

Systematic measuring error with user-specific scaling

4 mA are always needed for the sensor supply, as a result, the hub of 16 mA represents the process data information that must

be evaluated by the evaluation unit. Typical errors frequently result from an incorrectly adapted user scaling, which does not

map the zero point correctly.

High-energy overvoltage

For applications in which high-energy overvoltages are to be expected on the supply voltage, analog signals can be additionally

screened by the employment of a KL9540-0010 surge filter terminal from Beckhoff.

– Bus Terminals for analoge input signals www.beckhoff.com/KL3xxx

– Surge filter field supply for analog terminals www.beckhoff.com/KL9540-0010

– Potential distribution (0V | 24 V ) for eight 3-wire sensors www.beckhoff.com/KL9184

– Potential distribution (24 V ) for eight 2-wire sensors www.beckhoff

– Modular fieldbus system for automation www.beckhoff.com/Busterminal

For application notes see disclaimer on the last page

.com/KL9186

f

New Automation TechnologyBeckhof

7

Page 8

Application Note DK9222-0112-0059

Measuring analog signals

I/O

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the

customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this

publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described

in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit

our website (www.beckhoff.com).

© Beckhoff Automation GmbH, January 2012

The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be

held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

New Automation TechnologyBeckhoff

8

Loading...

Loading...