Page 1

Version: 1.5

Documentation

Synchronous Servomotor AM3000 and AM3500

Date: 2015-03-10

Page 2

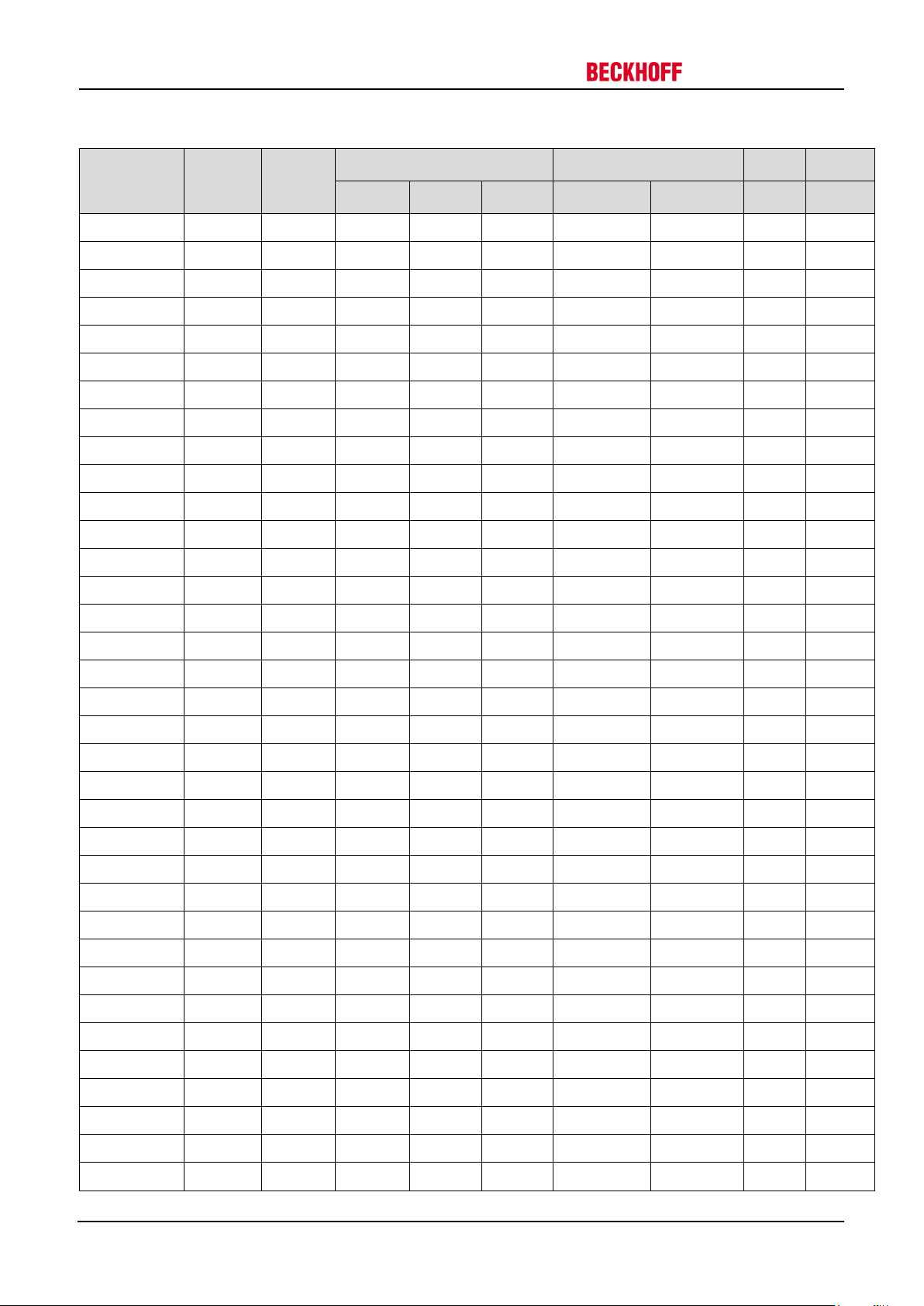

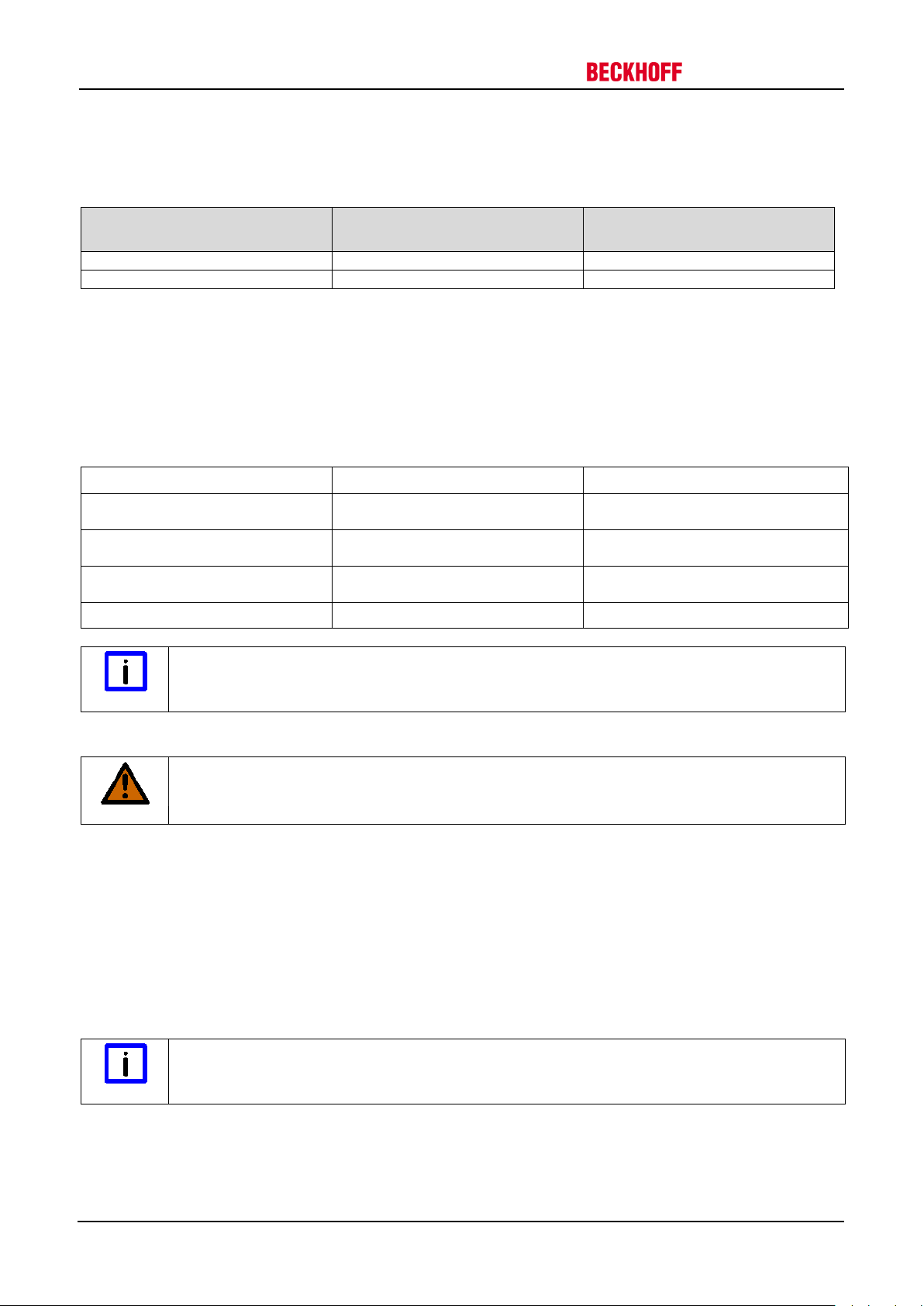

Documented motors

Rated speed at rated supply

voltage

without

brake

with

brake

without

brake

with

brake

Documented motors

Drive Technology

Rotor moment of inertia Weight Weight

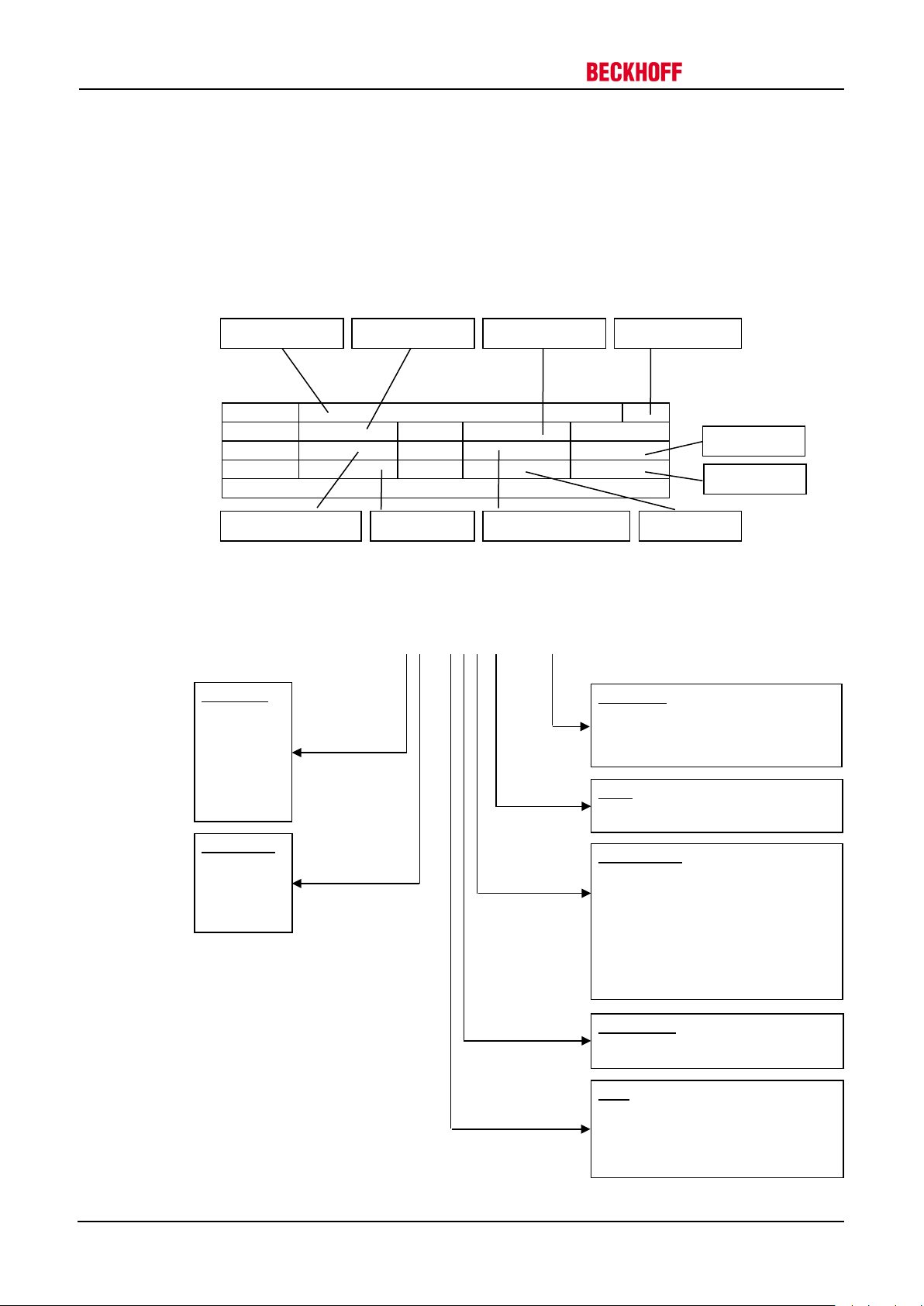

AM3tuv-wxyz

Standstill

torque

Standstill

current

230 V AC 400 V AC 480 V AC

AM3011-wB00 0.18Nm 1.16 A 8000 min

AM3012-wC00 0.31Nm 1.51 A 8000 min

-1

-1

- - 0,017 kg cm² 0,021 kg cm² 0,35 kg 0,55 kg

- - 0,031 kg cm² 0,035 kg cm² 0,49 kg 0,69 kg

AM3013-wC00 0.41Nm 1.48 A 8000 min-1 - - 0,045 kg cm² 0,049 kg cm² 0,63 kg 0,83 kg

AM3021-wCyz 0.48 Nm 1.58 A 8000 min-1 - - 0.107 kg cm² 0.118 kg cm² 0.82 kg 1.09 kg

AM3022-WCyz 0.84 Nm 1.39 A 3500 min-1 8000 min

AM3023-wCyz 1.13Nm 1.41 A 2500 min-1 5500 min

AM3024-wCyz 1.38Nm 1.42 A 2000 min-1 4500 min

AM3024-wDyz 1.41 Nm 2.21 A 4000 min-1 8000 min

AM3031-wCyz 1.15 Nm 1.37 A 2500 min-1 5000 min

-1

8000 min

-1

7000 min

-1

5500 min

-1

8000 min

-1

6000 min

-1

0.161 kg cm² 0.172 kg cm² 1.10 kg 1.37 kg

-1

0.216 kg cm² 0.227 kg cm² 1.38 kg 1.65 kg

-1

0.270 kg cm² 0.281 kg cm² 1.66 kg 1.93 kg

-1

0.270 kg cm² 0.281 kg cm² 1.66 kg 1.93 kg

-1

0.330 kg cm² 0.341 kg cm² 1.55 kg 1.90 kg

AM3031-wEyz 1.20 Nm 2.99 A 6000 min-1 - - 0.330 kg cm² 0.341 kg cm² 1.55 kg 1.90 kg

AM3032-wCyz 2.00 Nm 1.44 A 1500 min-1 3000 min

AM3032-wDyz 2.04 Nm 2.23 A 2500 min-1 5500 min

AM3033-wCyz 2.71 Nm 1.47 A 1000 min-1 2000 min

AM3033.wEyz 2.79 Nm 2.58 A 2000 min-1 4500 min

AM3041-wCyz 1.95 Nm 1.46 A 1200 min-1 3000 min

AM3041-wEyz 2.02 Nm 2.85 A 3000 min-1 6000 min

AM3042-wEyz 3.42 Nm 2.74 A 1800 min-1 3500 min

AM3042-wGyz 3.53 Nm 4.80 A 3500 min-1 6000 min

AM3043-wEyz 4.70 Nm 2.76 A 1500 min-1 2500 min

AM3043-wGyz 4.80 Nm 4.87 A 2500 min-1 5000 min

AM3043-wHyz 4.82 Nm 5.4 A 3000 min-1 6000 min

AM3044-wEyz 5.76 Nm 2.90 A 1200 min-1 2500 min

AM3044-wGyz 5.88 Nm 5.00 A 2000 min-1 4000 min

AM3044-wHyz 5.89 Nm 5.6 A 2500 min-1 5000 min

AM3044-wJyz 6.00 Nm 8.80 A 4000 min-1 6000 min

AM3051-wEyz 4.70 Nm 2.75 A 1200 min-1 2500 min

AM3051-wGyz 4.75 Nm 4.84 A 2500 min-1 5000 min

AM3051-wHyz 4.79 Nm 6.00 A 3000 min-1 6000 min

AM3052-wGyz 8.43 Nm 4.72 A 1500 min-1 2500 min

AM3052-wHyz 8.48 Nm 5.9 A 1800 min-1 3500 min

AM3052-wKyz 8.60 Nm 9.30 A 3000 min-1 5500 min

AM3053-wGyz 11.37Nm 4.77 A 1000 min-1 2000 min

Am3053-wHyz 11.51 Nm 6.60 A - 3000 min

AM3053-wKyz 11.60 Nm 9.40 A 2000 min-1 4000 min

AM3054-wHyz 14.90 Nm 5.50 A 1000 min-1 1800 min

-1

3500 min

-1

6000 min

-1

2500 min

-1

5000 min

-1

3500 min

-1

6000 min

-1

4000 min

-1

6000 min

-1

3000 min

-1

6000 min

-1

-1

2500 min

-1

5000 min

-1

6000 min

-1

6000 min

-1

3000 min

-1

6000 min

-1

6000 min

-1

3000 min

-1

4000 min

-1

6000 min

-1

2400 min

-1

3500 min

-1

4500 min

-1

2000 min

-1

0.590 kg cm² 0.601 kg cm² 2.23 kg 2.58 kg

-1

0.590 kg cm² 0.601 kg cm² 2.23 kg 2.58 kg

-1

0.850 kg cm² 0.861 kg cm² 2.90 kg 3.25 kg

-1

0.850 kg cm² 0.861 kg cm² 2.90 kg 3.25 kg

-1

0.810 kg cm² 0.878 kg cm² 2.44 kg 3.07 kg

-1

0.810 kg cm² 0.878 kg cm² 2.44 kg 3.07 kg

-1

1.450 kg cm² 1.518 kg cm² 3.39 kg 4.02 kg

-1

1.450 kg cm² 1.518 kg cm² 3.39 kg 4.02 kg

-1

2.090 kg cm² 2.158 kg cm² 4.35 kg 4.98 kg

-1

2.090 kg cm² 2.158 kg cm² 4.35 kg 4.98 kg

- 2.090 kg cm² 2.158 kg cm² 4.35 kg 4.98 kg

-1

2.730 kg cm² 2.798 kg cm² 5.30 kg 5.93 kg

-1

2.730 kg cm² 2.798 kg cm² 5.30 kg 5.93 kg

-1

2.730 kg cm² 2.798 kg cm² 5.30 kg 5.93 kg

-1

2.730 kg cm² 2.798 kg cm² 5.30 kg 5.93 kg

-1

3.420 kg cm² 3.593 kg cm² 4.20 kg 5.30 kg

-1

3.420 kg cm² 3.593 kg cm² 4.20 kg 5.30 kg

-1

3.420 kg cm² 3.593 kg cm² 4.20 kg 5.30 kg

-1

6.220 kg cm² 6.393 kg cm² 5.80 kg 6.90 kg

-1

6.220 kg cm² 6.393 kg cm² 5.80 kg 6.90 kg

-1

6.220 kg cm² 6.393 kg cm² 5.80 kg 6.90 kg

-1

9.120 kg cm² 9.293 kg cm² 7.40 kg 8.50 kg

-1

9.120 kg cm² 9.293 kg cm² 7.40 kg 8.50 kg

-1

9.120 kg cm² 9.293 kg cm² 7.40 kg 8.50 kg

-1

12.92 kg cm² 12.093 kg cm² 9.00 kg 10.10 kg

2 Version: 1.5 AM3000 / AM3500

Page 3

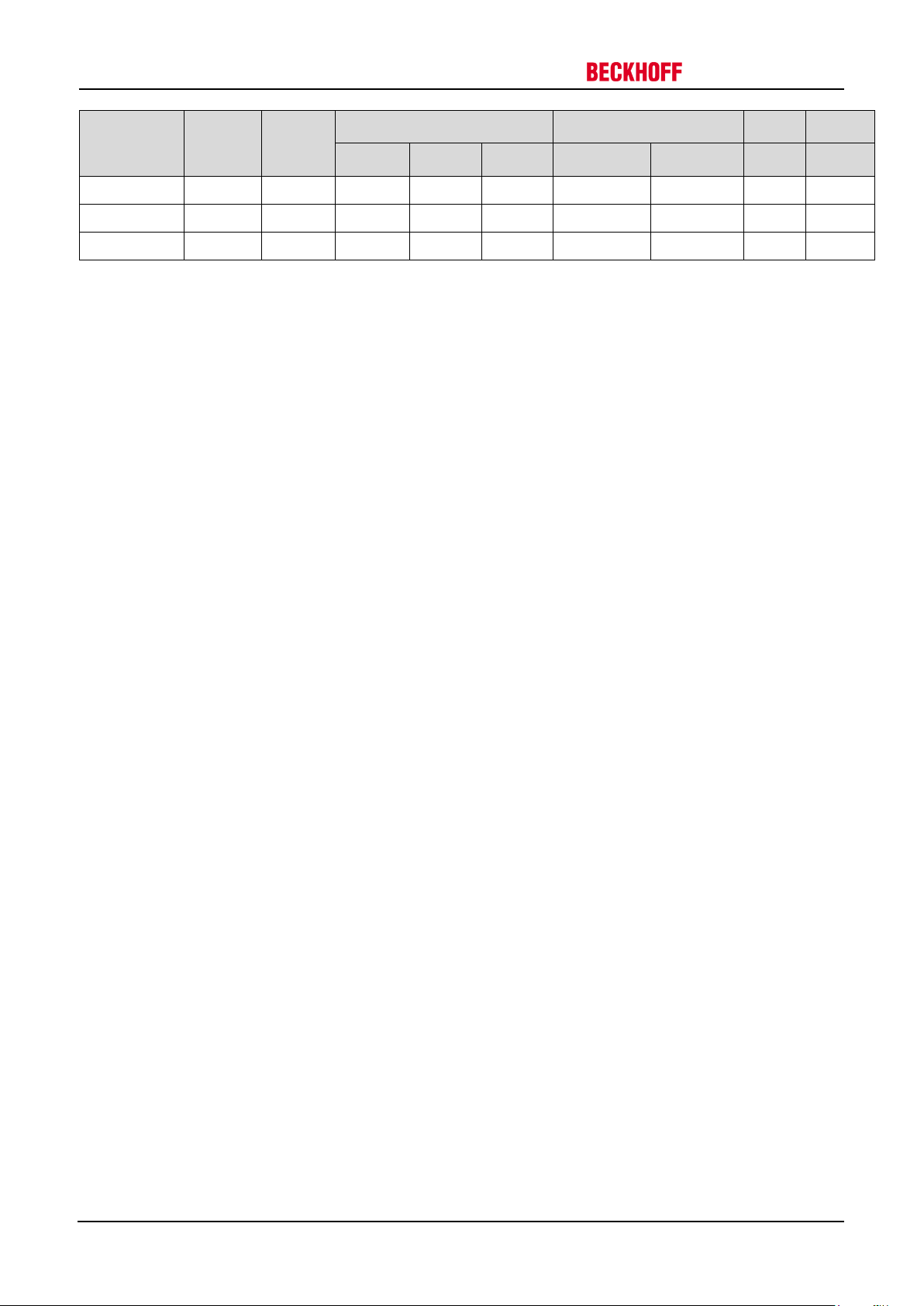

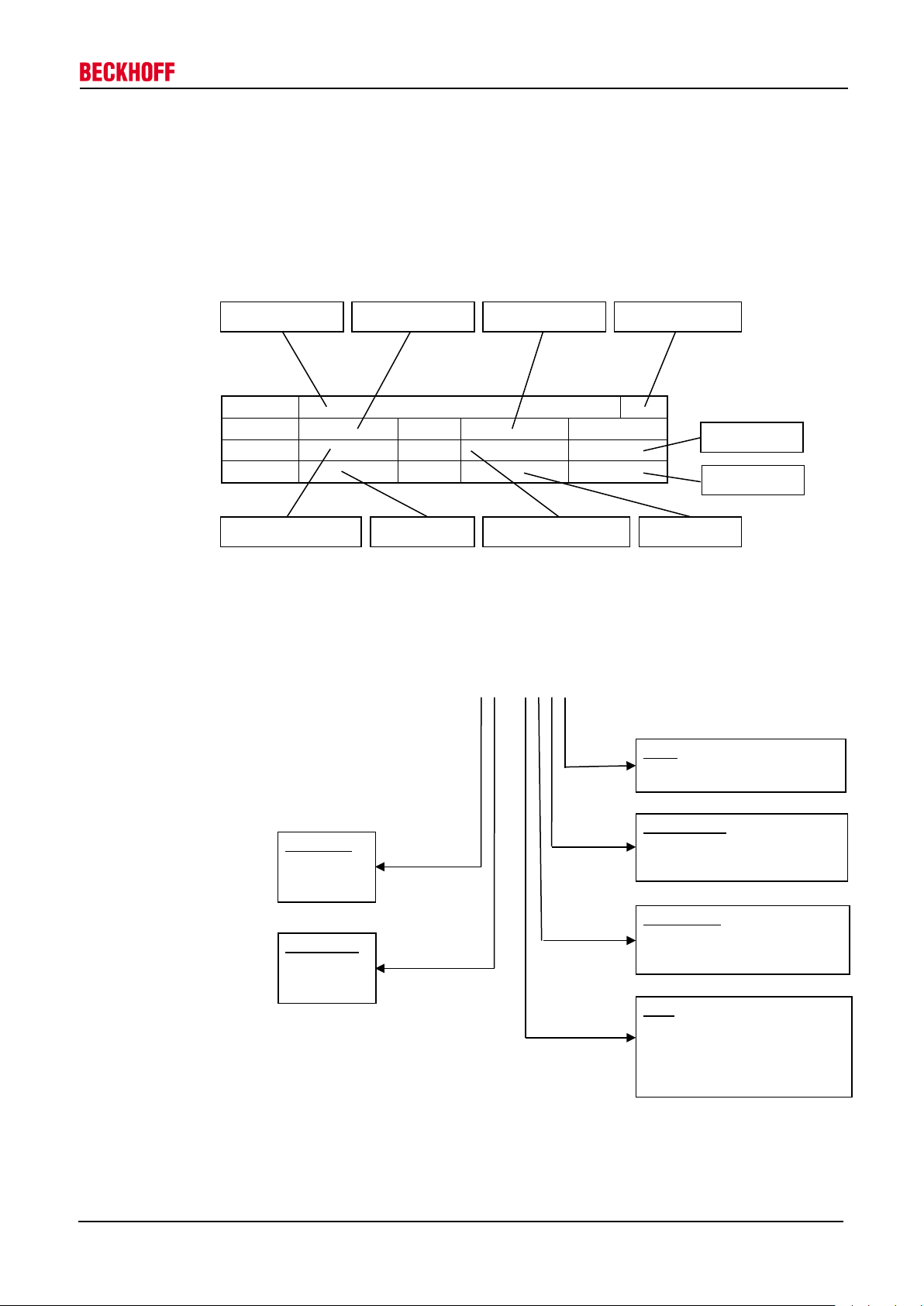

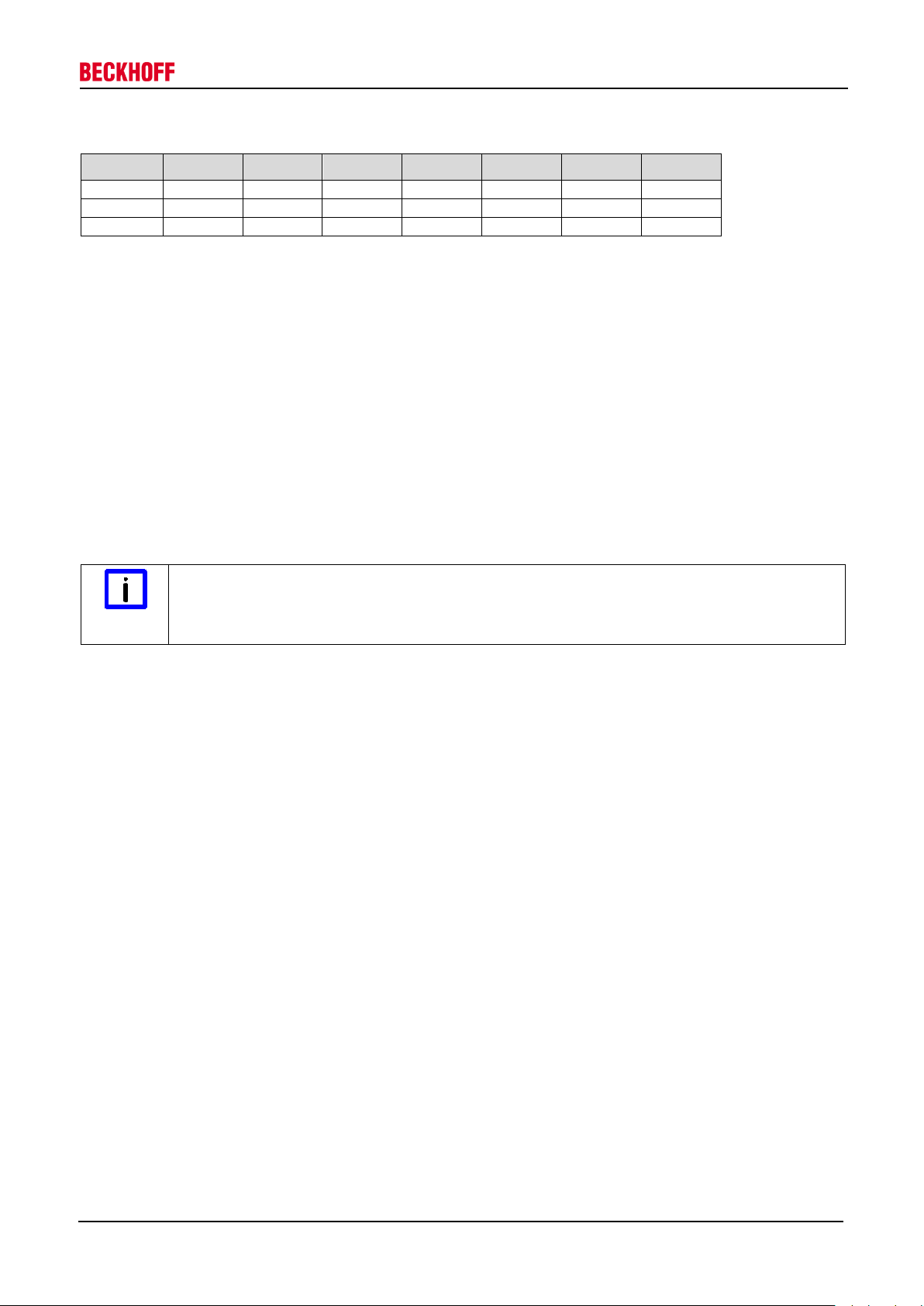

Rated speed at rated supply

voltage

without

brake

with

brake

without

brake

with

brake

Drive Technology Documented motors

AM3tuv-wxyz

Standstill

torque

Standstill

current

230 V AC 400 V AC 480 V AC

AM3054-wKyz 14.40 Nm 9.70 A 1800 min-1 3500 min

AM3062-wHyz 11.90 Nm 5.40 A 1000 min-1 2000 min

AM3062-wKyz 12.20 Nm 9.60 A 2000 min-1 3500 min

AM3062-wMyz 12.20 Nm 13.40 A 3000 min-1 6000 min

AM3063-wKyz 16.80Nm 9.90 A 1500 min-1 3000 min

AM3063-wMyz 17.00 Nm 13.80 A 2000 min-1 4000 min

AM3063-wNyz 17.00 Nm 17.40 A 3000 min-1 5000 min

AM3064-wHyz 16.60 Nm 5.60 A - 1500 min

AM3064-wKyz 20.80 Nm 9.20 A 1200 min-1 2000 min

AM3064-wLyz 21.00 Nm 12.80A 1500 min-1 3000 min

AM3064-wPyz 20.40 Nm 18.60 A 2500 min-1 4500 min

AM3065-wKyz 24.80 Nm 9.80 A 1000 min-1 2000 min

AM3065-wMyz 25.00 Nm 13.60 A 1500 min-1 2500 min

AM3065-wNyz 24.30 Nm 17.80 A 2000 min-1 3500 min

AM3065-wPyz 24.50 Nm 19.80 A 3000 min-1 4000 min

AM3072-wKyz 27.70 Nm 9.30 A - 1500 min

AM3072.wMyz 30.00 Nm 13.00 A - 2000 min

AM3072-wPyz 29.40 Nm 18.70 A 1800 min

-1

3000 min

AM3072-wQyz 29.70 Nm 20.90 A - 3500 min

AM3073-wMyz 42.00 Nm 13.60 A - 1500 min

AM3073-wMyz 41.60 Nm 19.50 A 1300 min

-1

2400 min

AM3073-wQyz 41.60 Nm 24.60 A - 2500 min

AM3074-wLyz 53.00 Nm 12.90 A - 1200 min

AM3074-wPyz 52.50 Nm 18.50 A - 1800 min

AM3074-wQyz 51.90 Nm 26.20 A - 2500 min

AM3082-wTyz 75.00 Nm 48.00 A - 2500 min

AM3083-wTyz

AM3084-wTyz

130.00 Nm

180.00 Nm

62.00 A - 2200 min

67.00 A - 1800 min

AM3541-w0yz 1.9 Nm 1.7 A - 3000 min

AM3541-w1yz 1.9 Nm 2.8 A - 6000 min

AM3542-w0yz 3.3 Nm 2.4 A - 3000 min

AM3542-w1yz 3.3 Nm 4.5 A - 6000 min

AM3543-w0yz 4.2 Nm 3.0 A - 3000 min

AM3543-w1yz 4.2 Nm 5.2 A - 6000 min

AM3551-w0yz 4.1 Nm 3.4 A - 3000 min

AM3551-w1yz 4.1 Nm 6.1 A - 6000 min

AM3552-w0yz 6.3 Nm 4.8 A - 3000 min

Rotor moment of inertia Weight Weight

-1

4000 min

-1

2400 min

-1

4500 min

-1

6000 min

-1

3500 min

-1

4500 min

-1

6000 min

-1

1800 min

-1

2500 min

-1

3500 min

-1

5500 min

-1

2200 min

-1

3000 min

-1

4000 min

-1

5000 min

-1

1800 min

-1

2500 min

-1

3500 min

-1

4000 min

-1

1800 min

-1

2800 min

-1

3000 min

-1

1400 min

-1

2000 min

-1

3000 min

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

11.92 kg cm² 12.093 kg cm² 9.00 kg 10.10 kg

-1

16.90 kg cm² 17.51 kg cm² 8.90 kg 10.90 kg

-1

16.90 kg cm² 17.51 kg cm² 8.90 kg 10.90 kg

-1

16.90 kg cm² 17.51 kg cm² 8.90 kg 10.90 kg

-1

24.20 kg cm² 24.81 kg cm² 11.10 kg 13.10 kg

-1

24.20 kg cm² 24.81 kg cm² 11.10 kg 13.10 kg

-1

24.20 kg cm² 24.81 kg cm² 11.10 kg 13.10 kg

-1

31.60 kg cm² 32.21 kg cm² 13.30 kg 15.30 kg

-1

31.60 kg cm² 32.21 kg cm² 13.30 kg 15.30 kg

-1

31.60 kg cm² 32.21 kg cm² 13.30 kg 15.30 kg

-1

31.60 kg cm² 32.21 kg cm² 13.30 kg 15.30 kg

-1

40.00 kg cm² 40.61 kg cm² 15.40 kg 17.40 kg

-1

40.00 kg cm² 40.61 kg cm² 15.40 kg 17.40 kg

-1

40.00 kg cm² 40.61 kg cm² 15.40 kg 17.40 kg

-1

40.00 kg cm² 40.61 kg cm² 15.40 kg 17.40 kg

-1

64.50 kg cm² 66.14 kg cm² 19.70 kg 21.80 kg

-1

64.50 kg cm² 66.14 kg cm² 19.70 kg 21.80 kg

-1

64.50 kg cm² 66.14 kg cm² 19.70 kg 21.80 kg

-1

64.50 kg cm² 66.14 kg cm² 19.70 kg 21.80 kg

-1

92.10 kg cm² 93.74 kg cm² 26.70 kg 28.80 kg

-1

92.10 kg cm² 93.74 kg cm² 26.70 kg 28.80 kg

-1

92.10 kg cm² 93.74 kg cm² 26.70 kg 28.80 kg

-1

119.70 kg cm² 121.64 kg cm² 33.60 kg 35.70 kg

-1

119.70 kg cm² 121.64 kg cm² 33.60 kg 35.70 kg

-1

119.70 kg cm² 121.64 kg cm² 33.60 kg 35.70 kg

3000 172 kg cm² 177.53 65 kg 73

2500 334 kg cm² 339.53 85 kg 93

2000 495 kg cm² 500.53 105 kg 113

- 2.0 kg cm² 2.2 kg cm² 2.4 kg 3.0 kg

- 2.0 kg cm² 2.2 kg cm² 2.4 kg 3.0 kg

- 4.0 kg cm² 4.2 kg cm² 3.8 kg 4.4 kg

- 4.0 kg cm² 4.2 kg cm² 3.8 kg 4.4 kg

- 8.0 kg cm² 8.2 kg cm² 5.35 kg 5.9 kg

- 8.0 kg cm² 8.2 kg cm² 5.35 kg 5.9 kg

- 15.0 kg cm² 15.6 kg cm² 5.8 kg 6.6 kg

- 15.0 kg cm² 15.6 kg cm² 5.8 kg 6.6 kg

- 19.0 kg cm² 19.6 kg cm² 7.0 kg 7.8 kg

AM3000 / AM3500 Version: 1.5 3

Page 4

Documented motors

Rated speed at rated supply

voltage

without

brake

with

brake

without

brake

with

brake

Drive Technology

AM3tuv-wxyz

AM3553-w0yz 8.6 Nm 6.4 A - 3000 min

AM3562-w0yz 11.6 Nm 10.3 A - 3000 min

AM3563-w0yz 14.9 Nm 12.5 A - 3000 min

Standstill

torque

Standstill

current

230 V AC 400 V AC 480 V AC

Rotor moment of inertia Weight Weight

-1

- 20.0 kg cm² 20.6 kg cm² 8.9 kg 9.7 kg

-1

- 40.0 kg cm² 42.0 kg cm² 10.7 kg 11.8 kg

-1

- 60.0 kg cm² 62.0 kg cm² 13.6 kg 14.7 kg

4 Version: 1.5 AM3000 / AM3500

Page 5

Drive Technology Table of contents – AM3000 and AM3500

Chapter Page

Table of contents – AM3000 and AM3500

Documented motors ............................................................................................................................................. 2

Table of contents – AM3000 and AM3500 .......................................................................................................... 5

1 Foreword ................................................................................................................................................ 7

1.1 Notes on the documentation .......................................................................................................... 7

1.2 Disclaimer ...................................................................................................................................... 7

1.3 Brands ............................................................................................................................................ 7

1.4 Patents ........................................................................................................................................... 7

1.5 Copyright ........................................................................................................................................ 7

1.6 Documentation issue status ........................................................................................................... 7

1.7 Appropriate use .............................................................................................................................. 8

2 Guidelines and Standards ................................................................................................................... 9

2.1 EC declaration of conformity .......................................................................................................... 9

3 Safety .................................................................................................................................................... 10

3.1 General safety instructions .......................................................................................................... 10

3.1.1 Personnel qualification ................................................................................................................. 10

3.1.2 Description of safety symbols ...................................................................................................... 10

3.2 Special safety instructions for AM3000 and AM3500 .................................................................. 11

4 Handling ............................................................................................................................................... 12

4.1 Transport ...................................................................................................................................... 12

4.2 Packaging .................................................................................................................................... 12

4.3 Storage ......................................................................................................................................... 12

4.4 Maintenance / Cleaning ............................................................................................................... 12

4.5 Disposal ....................................................................................................................................... 13

5 Product identification ........................................................................................................................ 14

5.1 AM3000, scope of supply ............................................................................................................. 14

5.2 AM3000 nameplate ...................................................................................................................... 14

5.3 AM3000 type key ......................................................................................................................... 14

5.4 AM3500, scope of supply ............................................................................................................. 15

5.5 AM3500 nameplate ...................................................................................................................... 15

5.6 AM3500 type key ......................................................................................................................... 15

6 Technical description ........................................................................................................................ 16

6.1 Design of the motors .................................................................................................................... 16

6.2 General technical data ................................................................................................................. 16

6.3 Standard features ......................................................................................................................... 17

6.3.1 Style ............................................................................................................................................. 17

6.3.2 Shaft end, A-side .......................................................................................................................... 17

6.3.3 Flange .......................................................................................................................................... 17

6.3.4 Protection class ............................................................................................................................ 17

6.3.5 Overtemperature protection ......................................................................................................... 17

6.3.6 Insulation material class ............................................................................................................... 17

6.3.7 Vibration class .............................................................................................................................. 18

6.3.8 Connection technology................................................................................................................. 18

6.3.9 Feedback unit ............................................................................................................................... 18

6.3.10 Holding brake ............................................................................................................................... 18

6.3.11 Pole numbers ............................................................................................................................... 19

6.4 Options ......................................................................................................................................... 19

6.5 Selection criteria ........................................................................................................................... 19

7 Mechanical installation ....................................................................................................................... 20

7.1 Important notes ............................................................................................................................ 20

8 Electrical installation........................................................................................................................... 21

8.1 Important notes ............................................................................................................................ 21

8.2 Connection of motors with pre-assembled cables ....................................................................... 22

8.2.1 AX5000 ........................................................................................................................................ 22

8.2.2 AX2000 and AX2500.................................................................................................................... 26

8.3 AX5000 connection diagram for motors with EnDAT / BiSS encoder ......................................... 29

AM3000 / AM3500 Version: 1.5 5

Page 6

Table of contents – AM3000 and AM3500

8.4 AX5000 connection diagram for motors with resolver ................................................................. 30

8.5 AX5000 connection diagram for motors with resolver and yTec-Plug ......................................... 31

8.6 AX2000 connection diagram for motors with EnDAT / BiSS encoder ......................................... 32

8.7 AX2000 connection diagram for motors with resolver ................................................................. 33

9 Commissioning .................................................................................................................................... 34

9.1 Important notes ............................................................................................................................ 34

9.2 Guide for commissioning.............................................................................................................. 34

9.3 Troubleshooting ........................................................................................................................... 34

10 Technical data ...................................................................................................................................... 36

10.1 Term definitions ............................................................................................................................ 36

10.2 AM301x ........................................................................................................................................ 37

10.2.1A Dimensional drawing .................................................................................................................... 38

10.2.1B Dimensional drawing .................................................................................................................... 38

10.2.2 Radial / axial forces at the shaft end ............................................................................................ 39

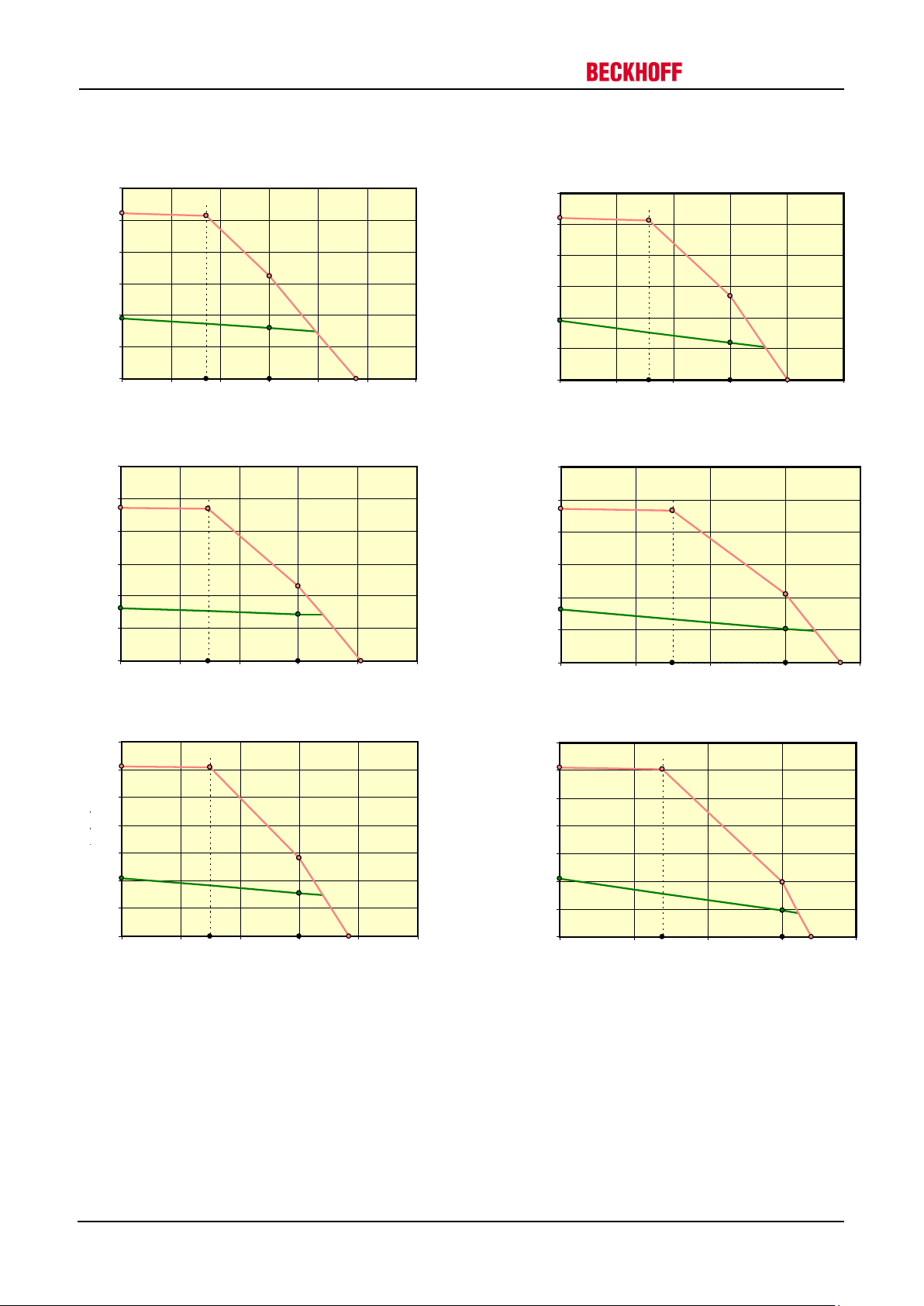

10.2.3 Characteristic torque / speed curves ........................................................................................... 39

10.3 AM302x ........................................................................................................................................ 40

10.3.1 Dimensional drawing .................................................................................................................... 41

10.3.2 Radial / axial forces at the shaft end ............................................................................................ 41

10.3.3 Characteristic torque / speed curves ........................................................................................... 41

10.4 AM303x ........................................................................................................................................ 42

10.4.1 Dimensional drawing .................................................................................................................... 43

10.4.2 Radial / axial forces at the shaft end ............................................................................................ 43

10.4.3 Characteristic torque / speed curves ........................................................................................... 43

10.5 AM304x ........................................................................................................................................ 44

10.5.1 Dimensional drawing .................................................................................................................... 45

10.5.2 Radial / axial forces at the shaft end ............................................................................................ 45

10.5.3 Characteristic torque / speed curves ........................................................................................... 45

10.6A AM305x (AM3051; AM3052) ........................................................................................................ 46

10.6B AM305x(AM3053 and AM3054) ................................................................................................... 47

10.6.1 Dimensional drawing .................................................................................................................... 48

10.6.2 Radial / axial forces at the shaft end ............................................................................................ 48

10.6.3 Characteristic torque / speed curves ........................................................................................... 48

10.7 AM306x ........................................................................................................................................ 49

10.7.1 Dimensional drawing .................................................................................................................... 50

10.7.2 Radial / axial forces at the shaft end ............................................................................................ 50

10.7.3 Characteristic torque / speed curves ........................................................................................... 50

10.8 AM307x ........................................................................................................................................ 51

10.8.1 Dimensional drawing .................................................................................................................... 52

10.8.2 Radial / axial forces at the shaft end ............................................................................................ 52

10.8.3 Characteristic torque / speed curves ........................................................................................... 52

10.9 AM308x ........................................................................................................................................ 53

10.9.1 Dimensional drawing .................................................................................................................... 54

10.9.2 Radial / axial forces at the shaft end ............................................................................................ 55

10.9.3 Characteristic torque / speed curves ........................................................................................... 55

10.10 AM354x ........................................................................................................................................ 56

10.10.1 Dimensional drawing .................................................................................................................... 57

10.10.2 Characteristic torque / speed curves ........................................................................................... 58

10.11 AM355x ........................................................................................................................................ 59

10.11.1 Dimensional drawing .................................................................................................................... 60

10.11.2 Characteristic torque / speed curves ........................................................................................... 61

10.12 AM356x ........................................................................................................................................ 62

10.12.1 Dimensional drawing .................................................................................................................... 63

10.12.2 Characteristic torque / speed curves ........................................................................................... 64

11 Appendix ............................................................................................................................................. 65

11.1 Support and Service ..................................................................................................................... 65

11.1.1 Beckhoff Support .......................................................................................................................... 65

11.1.2 Beckhoff Service .......................................................................................................................... 65

11.2 Beckhoff headquarters ................................................................................................................. 65

Drive Technology

6 Version: 1.5 AM3000 / AM3500

Page 7

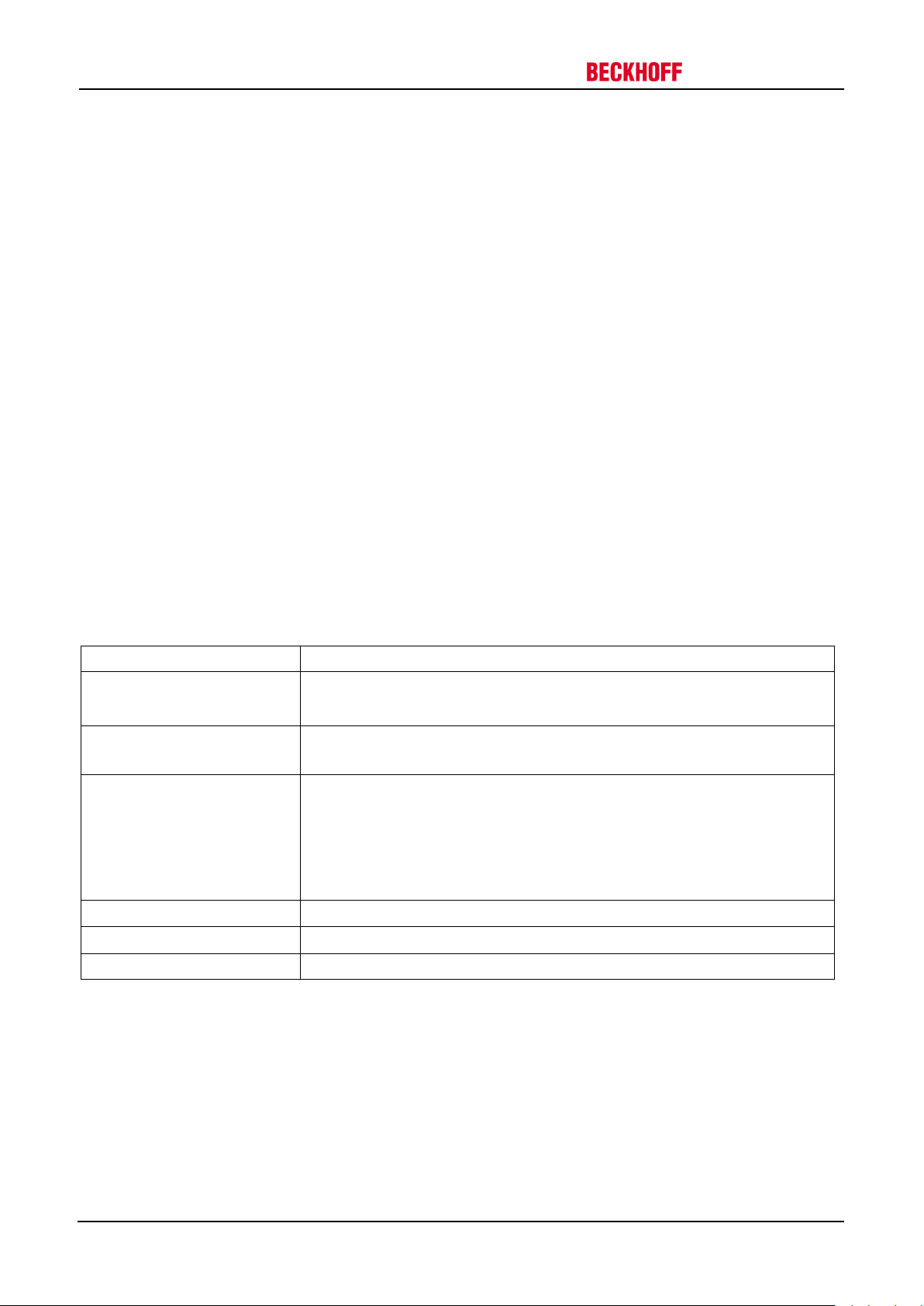

Issue

Comment

1.5

Chapter update:

10.2.1B

1.4

Chapter update:

10.8; 10.9; 10.9.1; 10.10; 10.10.1; 10.11; 10.12; 10.12.1

1.3

Chapter update:

6.3.10

Drive Technology 1 Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components. The "General safety instructions" and "Special

safety instructions for AM3000 and AM3500" sections are also essential.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Danger for persons, the environment or equipment

The motors are operated in the drive system in conjunction with Beckhoff servo drives. Please

CAUTION

1.2 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under

development.

For this reason, the documentation may not always have been fully checked for consistency with the

performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and without

notice.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

observe the entire documentation which consists of:

− AM3000 and AM3500 documentation (this manual)

− Complete documentation (online and paper) for Beckhoff servo drives available at

www.beckhoff.com.

− Complete machine documentation (provided by the machine manufacturer)

1.3 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered and licensed

brand names of Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to an

infringement of the rights of the respective trademark owner.

1.4 Patents

The TwinCAT technology is patent protected, in particular by the following applications and patents:

EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.5 Copyright

© Beckhoff Automation GmbH & Co. KG.

The copying, distribution and utilisation of this document as well as the communication of its contents to others

without express authorisation is prohibited.

Offenders shall be held liable for damages. All rights conferred by patent grant or registration of a utility model

or registered design are reserved.

1.6 Documentation issue status

8.4; 8.5; 8.6; 8.7; 10.2; 10.9.1

New chapter:

Documented motors; 5.3; 6.3.2; 6.3.6; 8.2.1; 8.2.2; 10.2; 10.3; 10.4; 10.5; 10.5.1; 10.6; 10.7;

AM3000 / AM3500 Version: 1.5 7

Page 8

1 Foreword

Issue

Comment

1.2

Chapter update:

Documented motors; 10.2; 10.3; 10.4; 10.5; 10.6; 10.7; 10.8; 10.9

1.1

Chapter update:

8.5

1.0

First issue (description of the AM3000 and AM3500 motors consolidated in one document and

amended)

drive system.

Documented motors; 5.3; 10.2; 10.3; 10.4; 10.5; 10.6; 10.7; 10.8; 10.9; 10.10; 10.11; 10.12

New chapter:

Drive Technology

1.7 Appropriate use

Synchronous servomotors of the AM3000 and AM3500 series are designed as drives for handling equipment,

textile machines, machine tools, packaging machines and similar machines with demanding requirements in

terms of dynamics. The motors of the AM3000 and AM3500 series are exclusively intended for speed- and/or

torque-controlled operation via digital servo drives from Beckhoff.

The thermal protection contact incorporated in the motor windings must be analysed and monitored.

Caution – Risk of injury!

Electronic equipment is not fail-safe. The machine manufacturer is responsible for ensuring that

WARNING

The servomotors from the AM3000 and AM3500 series are exclusively designed for installation as components

in electrical systems or machines and may only be operated as integrated components of the system or

machine.

The motors may only be operated under the ambient conditions defined in this documentation.

the connected motors and the machine are brought into a safe state in the event of a fault in the

8 Version: 1.5 AM3000 / AM3500

Page 9

conformity of the complete machine or system.

Drive Technology 2 Guidelines and Standards

2 Guidelines and Standards

Danger for persons, the environment or equipment

Servomotors of the AM3000 and AM3500 series are not classified as products within the

CAUTION

2.1 EC declaration of conformity

We,

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

hereby declare, under our sole responsibility, that the product range

motor series AM3000

(types AM301x, AM302x, AM303x, AM304x, AM305x, AM306x, AM307x, AM308x)

motor series AM3500

(types AM354x, AM355x, AM 356x)

complies with following relevant regulations:

− EC Directive 2004/108/EC

Electromagnetic compatibility

Applied harmonised standard EN 61800-3

− EC Directive 2006/95/EC

Electrical equipment designed for use within certain voltage limits

Applied harmonised standard EN 61800-5-1

Attachment of the CE marking: 2007

Issued by: Management

H. Beckhoff

Verl, 25.05.2007

meaning of the EC Machinery Directive. Operation of the servomotors in machines or systems is

only permitted once the machine or system manufacturers has provided evidence of CE

AM3000 / AM3500 Version: 1.5 9

Page 10

3 Safety

DANGER

WARNING

CAUTION

Attention

Note

Drive Technology

3 Safety

3.1 General safety instructions

3.1.1 Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

3.1.2 Description of safety symbols

The following safety symbols and associated safety instructions are used in this document. These safety

instructions must be read and followed.

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life

and health of persons.

Caution – Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Damage to the environment or devices!

Failure to follow the safety instructions associated with this symbol can lead to damage to the

environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

UL note

This symbol indicates important information regarding UL certification.

10 Version: 1.5 AM3000 / AM3500

Page 11

Drive Technology 3 Safety

3.2 Special safety instructions for AM3000 and AM3500

The safety instructions are designed to avert danger and must be followed during installation, commissioning,

production, troubleshooting, maintenance and trial or test assemblies.

The servomotors of the AM3000 and AM3500 series are not designed for stand-alone operation and are always

installed in a machine or system. After installation the additional documentation and safety instructions provided

by the machine manufacturer must be read and followed.

Serious risk of injury through high electrical voltage!

• Never open the servomotor when it is live. The measured voltage between terminals U, V

WARNING

and W must have dropped below 50 V. Opening the device would invalidate any warranty

and liability claims against Beckhoff Automation GmbH & Co. KG.

• Negligent, improper handling of the servomotor and bypassing of the safety devices can lead

to personal injury or death through electric shock.

• Ensure that the protective conductor is connected properly.

• The machine manufacturer must prepare a hazard analysis for the machine, and must take

appropriate measures to ensure that unexpected movements can not lead to injury to

persons or to material damage.

• Power leads may be live, even if the motor is not running. Never undo the electrical

connections to the motor when it is live. Under unfavourable conditions arcing may occur,

resulting in injury and damage to contacts.

WARNING

Attention

• Disconnect the servomotor from the servo drive and secure it against reconnection before

working on electrical parts with a voltage > 50 V.

• The DC link voltage of the servo drive may exceed 890 V. Wait until the DC link capacitors

are discharged before touching live terminals. The measured voltage between terminals DC+

and DC- (X02) must have dropped below 50 V.

Serious risk of injury through hot surfaces!

• The surface temperature may exceed 50 °C, resulting in a risk of burns.

• Avoid touching the housing during or shortly after operation.

• Leave the servomotor to cool down for at least 15 minutes after it is switched off.

• Use a thermometer to check whether the surface has cooled down sufficiently.

Danger for persons, the environment or equipment

• Carefully read this manual before using the servomotor thoroughly, paying particular

attention to the safety instructions. In the event of any uncertainties please notify your sales

office immediately and refrain from working on the servomotor.

• Only well trained, qualified electricians with sound knowledge of drive equipment may work

on the device.

• During installation it is essential to ensure that the specified ventilation clearances and

climatic conditions are adhered to. Further information can be found in the "Technical data"

and "Mechanical installation" sections.

• If a servomotor is installed in a machine it must not be commissioned until proof of

compliance of the machine with the latest version of the EC Machinery Directive has been

provided. This includes all relevant harmonised standards and regulations required for

implementation of this Directive in national legislation.

AM3000 / AM3500 Version: 1.5 11

Page 12

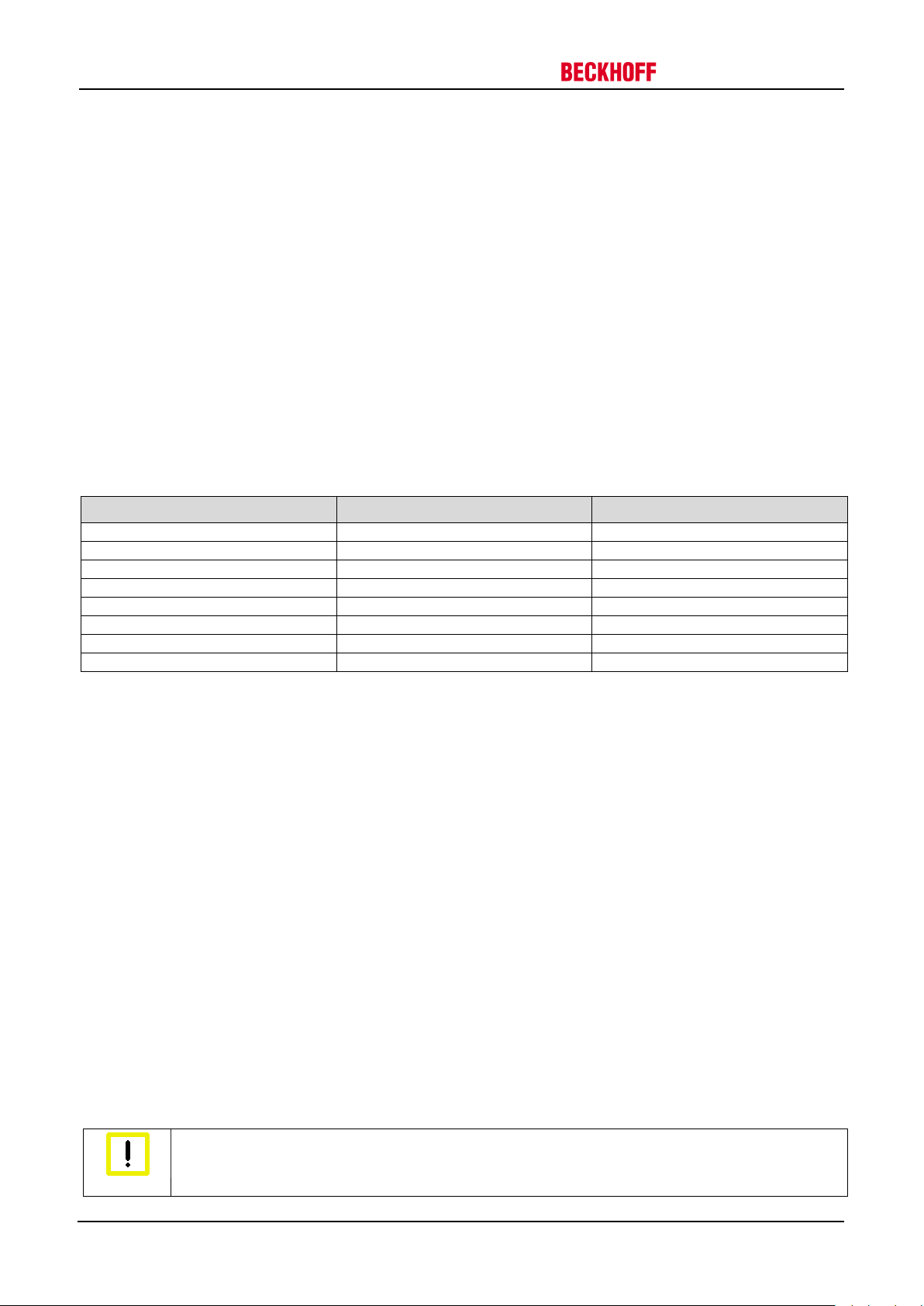

4 Handling

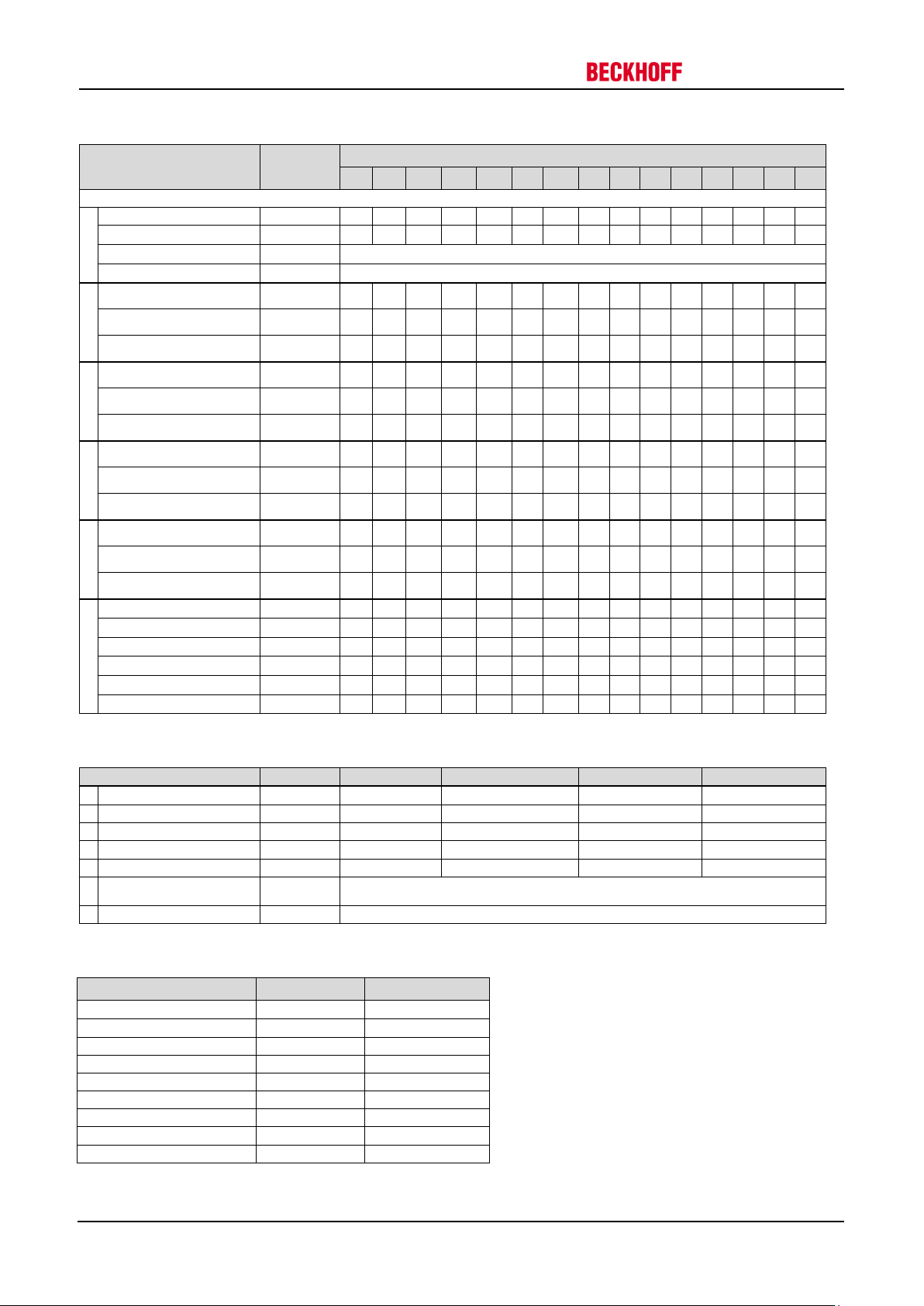

AM301x

X

10

AM302x

X

10

AM303x

X 6 AM304x

X 6 AM305x

X 5 AM306x

X 1 AM307x

X 1 AM308x

X

1

Attention

Drive Technology

4 Handling

4.1 Transport

• Climate category: 2K3 according to EN 50178

• Transport temperature: -25 °C - +70 °C, max. fluctuation 20 K/hour

• Transport humidity: relative humidity 5% - 95%, non-condensing

• The servomotor may only be transported by qualified personnel and in the manufacturer's original recyclable

packaging.

• Avoid hard impacts, particularly at the shaft end.

• If the packaging is damaged, check the motor for visible damage. Inform the transport company and, if

necessary, the manufacturer.

4.2 Packaging

• Cardboard packaging with Instapak

• You can return the plastic portion to the supplier (see Disposal)

Motor type Carton Max. stacking height

®

foam cushion.

4.3 Storage

• Climate category 1K4 according to EN50178

• Storage temperature: -25 °C - +55 °C, max. fluctuation 20 K/hour

• Air humidity: relative humidity 5% - 95%, non-condensing

• Max. stacking height: see table Packaging

• Storage time: without limitation

• Store only in the manufacturer’s original recyclable packaging

4.4 Maintenance / Cleaning

• Maintenance and cleaning only by qualified personnel.

• The ball bearings have a grease filling with a service life of 20,000 hours under normal operating conditions.

The bearings should be replaced after 20,000 hours of operation under rated conditions.

• Check the motor for bearing noise every 2,500 operating hours or once per year. If any noises are heard,

stop the operation of the motor. The bearings must be replaced.

• Opening the motor invalidates the warranty.

• Clean the housing with isopropanol or similar.

Destruction of the servomotor

Never immerse or spray the servomotor.

12 Version: 1.5 AM3000 / AM3500

Page 13

Drive Technology 4 Handling

4.5 Disposal

• In accordance with the WEEE 2002/96/EC Directives we take old devices and accessories back for

professional disposal, provided the transport costs are taken over by the sender. Please send the devices

to:

Beckhoff Automation GmbH & Co. KG

Eiserstrasse 5

33415 Verl

Germany

AM3000 / AM3500 Version: 1.5 13

Page 14

5 Product identification

BECKHOFF

Type

SN Art.No.

Mo

Nm

Udc

V

Iso. cl.

Nn

r/min

In A IP

Made in EU

Flange size

8 = 250 mm

Rotor length

5

Feedback unit

8 SKM multi turn

Winding type

S = special winding

Shaft

5 food industry

AM30 6 2 – 0 P 0 1 – 0000

Servomotor type

Serial number

Item number

Date of manufacture

Standstill torque

Nominal speed

DC link voltage

Rated current

Insulation class

Brake

1 24 V holding brake

Connection

6 terminal box

Protection class

5 Product identification

5.1 AM3000, scope of supply

Please check that the delivery includes the following items:

• Motor from the AM3000 series

• Motor package leaflet (short info)

5.2 AM3000 nameplate

5.3 AM3000 type key

Drive Technology

1 = 40 mm

2 = 58 mm

3 = 70 mm

4 = 84 mm

5 = 108 mm

6 = 138 mm

7 = 188 mm

0 rotatable angular connectors

1 0.5 m cable with connector

5 yTec connector

0 none brake

1

2

3

4

0 resolver, 2-pole

1 EnDAT single turn

2 EnDAT multi turn

3 BISS single turn

4 BISS multi turn

5 EQI single turn

6 EQI multi turn

7 SKS single turn

A…Z

0 smooth shaft

1 feather key groove

2 sealing ring – smooth shaft

3 sealing ring – feather key groove

14 Version: 1.5 AM3000 / AM3500

Page 15

BECKHOFF

Type

SN Art.No.

Mo

Nm

Udc V Iso. cl.

Nn

r/min

In A IP

Made in EU

Flange size

6 138 mm

Rotor length

3

Brake

1 24V holding brake

Feedback unit

4 BISS multi turn

Winding type

9 special winding

Shaft

groove

AM35 4 1 – 0 0 0 1

Servomotor type

Serial number

Item number

Date of manufacture

Standstill torque

Nominal speed

DC link voltage

Rated current

Insulation class

Protection class

Drive Technology 5 Product identification

5.4 AM3500, scope of supply

Please check that the delivery includes the following items:

• Motor from the AM3500 series

• Motor package leaflet (short info)

5.5 AM3500 nameplate

5.6 AM3500 type key

4 84 mm

5 108 mm

1

2

0 without brake

0 Resolver

3 BiSS single turn

0 3000 min-1

1 6000 min

0 smooth shaft

1 feather key groove

2 sealing ring – smooth shaft

3 sealing ring – feather key

-1

AM3000 / AM3500 Version: 1.5 15

Page 16

6 Technical description

3K3 according to EN 50178

+5 - +40 °C for site altitudes up to 1000 m amsl

above 40 °C and encapsulated installation of the motors.

95% relative humidity, non-condensing

For site altitudes above 1000 m amsl and 40 °C

reduction of 10K / 1000m

=20,000 operating hours

→ see Section 10

→ see Section 4

Drive Technology

6 Technical description

6.1 Design of the motors

The synchronous servomotors of the AM3000 and AM3500 series are brushless three-phase motors for

demanding servo-applications. In conjunction with our digital servo drives they are particularly suitable for

positioning tasks in industrial robots, machine tools, transfer lines etc. with demanding requirements in terms of

dynamics and stability.

The servomotors are equipped with permanent magnets in the rotor. This advanced neodymium magnetic

material makes a significant contribution to the motors' exceptional dynamic properties. A three-phase winding

is housed in the stator, and this is powered by the servo drive. The motor has no brushes, the commutation

being implemented electronically in the servo drive.

The temperature of the winding is monitored by temperature sensors in the stator windings and is signalled via

an electrically isolated thermistor (PTC, _550 Ω / _1330 Ω).

The motors normally have an integrated resolver to provide feedback. Beckhoff servo drives analyse the

resolver position of the rotor and supply the motors with sine currents. The optional feedback systems may

require modification of the motor length and cannot be retrofitted.

The motors are available with or without built-in holding brake. The brake cannot be retrofitted.

The motors have a matt black coating (RAL 9005). The finish is not resistant against solvents (e.g.

trichlorethylene, thinners or similar). The “Washdown”-model is white coated and FDA (Food and Drug

Administration) conform.

6.2 General technical data

Climate category

Ambient temperature

(at rated values)

Permissible humidity

(at rated values)

Power derating

(currents and torques)

Ball bearing service life

Technical data

Storage and transport data

It is vital to consult our applications department for ambient temperatures

6% at 2000 m amsl

17% at 3000m amsl

30% at 4000m amsl

55% at 5000m amsl

No derating for site altitudes above 1000 m amsl with temperature

16 Version: 1.5 AM3000 / AM3500

Page 17

Drive Technology 6 Technical description

6.3 Standard features

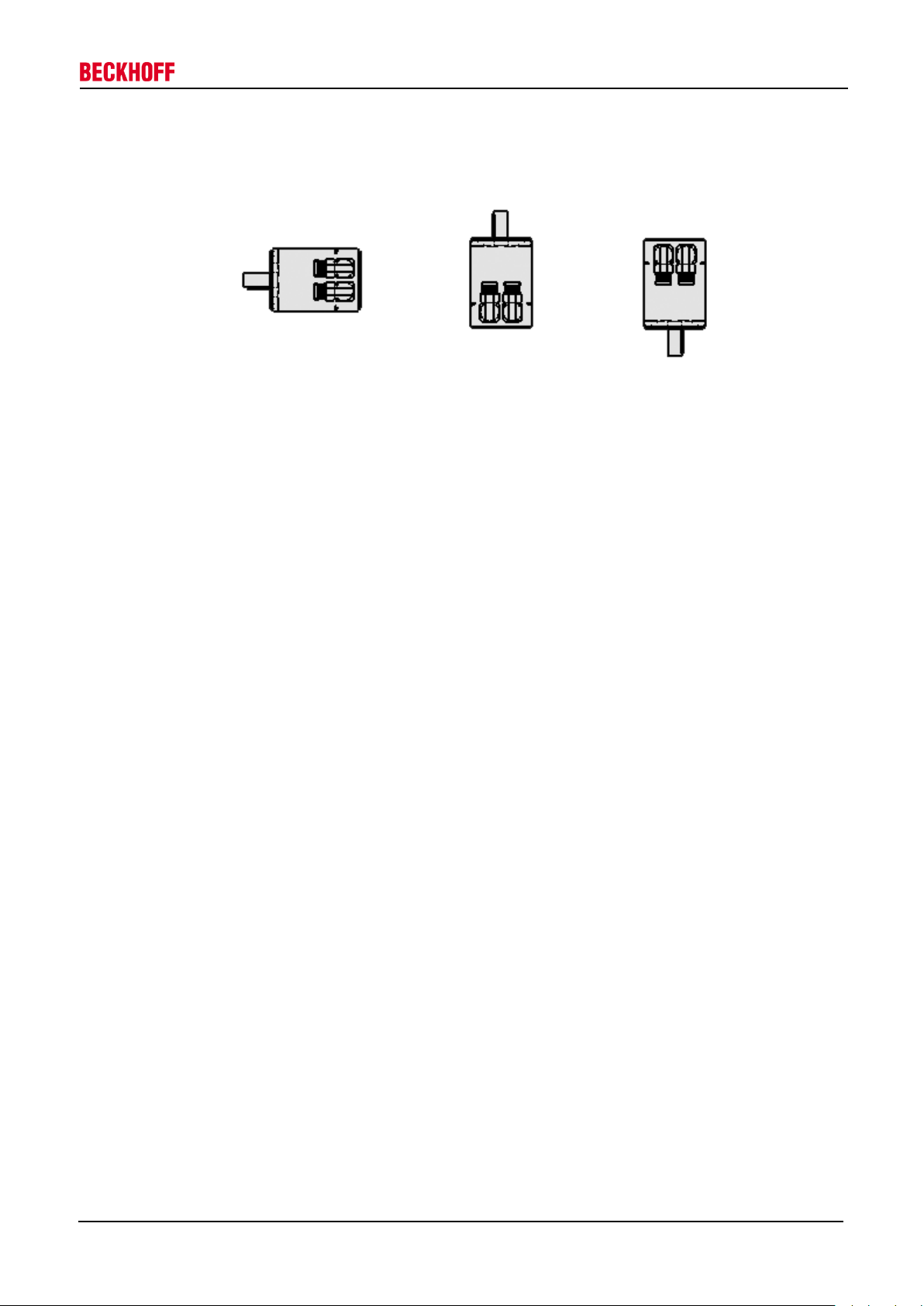

6.3.1 Style

The basic style for the AM3000 and AM3500 synchronous servomotors is IM B5 according to DIN EN 60034-7.

IM B 5 (B5) IM V 3 (V3) IM V 1 (V)

The permitted mounting positions are specified in the technical data.

6.3.2 Shaft end, A-side

Power transmission is made through the cylindrical shaft end A, fit k6 (AKM1: h7) according to EN 50347, with

a locking thread or optionally with a feather key groove. The bearings are designed for a service life of 20,000

hours.

Radial force

If the motors drive via pinions or toothed belts, then high radial forces will occur. The permissible values at the

shaft end, depending on the speed, may be read from the diagrams in the Section 10. The permissible

maximum values can be found in the technical data. Power take-off from the middle of the free end of the shaft

allows a 10% increase in FR.

Axial force

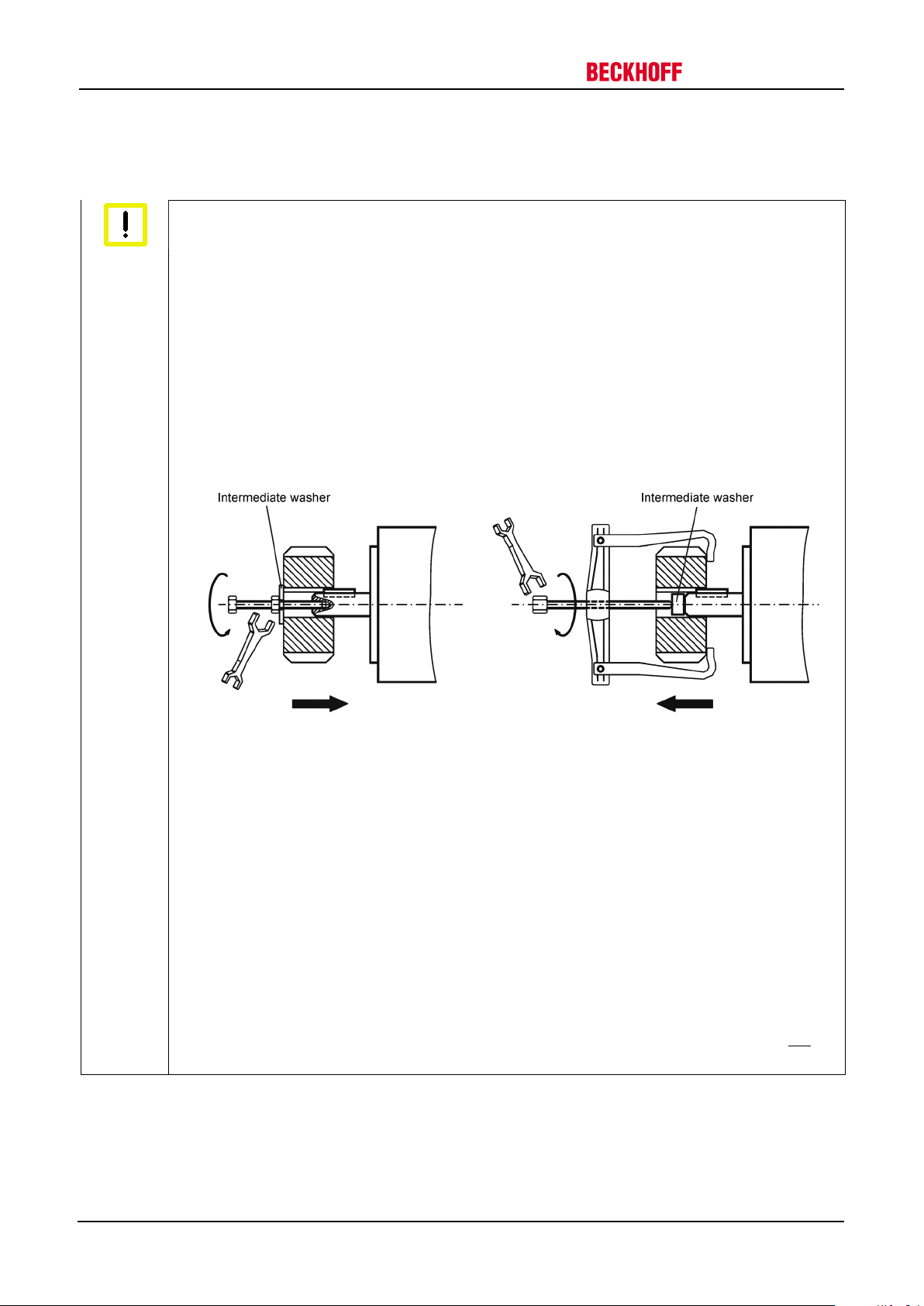

Axial forces arise when assembling pinions or pulleys on the shaft and using angular gearheads, for example.

The permissible maximum values can be found in the technical data.

Coupling

Double-coned collets, possibly in association with metal bellows couplings, have proven themselves as

excellent, zero backlash coupling elements.

6.3.3 Flange

Flange dimensions according to IEC standard, fit j6 (AM301x: h7), accuracy according to DIN 42955

Tolerance class: N

6.3.4 Protection class

Standard version IP65

Standard shaft bushing IP54

Shaft bushing with shaft sealing ring IP67

6.3.5 Overtemperature protection

The standard version of each motor is fitted with an electrically isolated PTC with a rated temperature of 155 °C

± 5%. The PTC does not provide any protection against short, heavy overloading.

Provided that our preassembled cable is used, the PTC is integrated into the monitoring system of the digital

servo drives.

6.3.6 Insulation material class

The motors conform to insulation material class F according to IEC 60085 (UL 1446 class F).

AM3000 / AM3500 Version: 1.5 17

Page 18

6 Technical description

<= 1800

90

23

> 1800

65

16

Resolver

Two-pole, hollow shaft

EnDAT Encoder, Singleturn

AM302x-AM304x: ECN 1113,

AM305x-AM307x: EQN 1325

EnDAT Encoder, Multiturn

AM302x-AM304x: EQN 1125

AM305x-AM307x: EQN 1325

BiSS Encoder, Single- / Multiturn

AM302x-AM304x: AD36

AM305x-AM307x: AD58

BiSS Encoder, Single- / Multiturn

AM35xx: AD34

Note

WARNING

Note

Drive Technology

6.3.7 Vibration class

The motors are made to vibration class A according to DIN EN 60034-14. For a speed range of 600-3600 rpm

and a shaft centre height between 56-132 mm, this means that the actual value of the permitted vibration

severity is 1.6 mm/s.

Speed [rpm] Max. rel. vibration

displacement [µm]

Max. run-out [µm]

6.3.8 Connection technology

The motors are fitted with angular connectors (AM301x: straight connectors at the cable ends) for the power

supply and the feedback signals.

The mating connectors are not included in the scope of supply. We can supply preassembled feedback and

power cables. Information regarding the cable materials can be found in Section 8.2.

6.3.9 Feedback unit

Standard

Option

Option

Option

Option

Motor length

The motor length depends on the built-in feedback unit, among other factors. Retrofitting is not

possible.

6.3.10 Holding brake

Serious risk of injury!

The holding brake is not personal safety. If the brake is released then the rotor can be moved

without a remanent torque!

The AM302x-AM308x and AM35xx motors are optionally available with an in-built holding brake. The AM3000

model features a spring-actuated brake (24 V DC), the AM3500 features a permanent-magnet brake (24 V DC).

When the brake is de-energised it blocks the rotor. The holding brakes are designed as standstill brakes

and are not suited for repeated operational braking.

The holding brakes can be controlled directly by the servo drive (no personal safety!), in which case the brake

winding is suppressed in the servo drive. Additional circuitry is not required.

If the holding brake is not controlled directly by the servo drive, additional circuitry (e.g. varistor) is required.

Consult our applications department beforehand.

Motor length

The motor length depends on the built-in holding brake, among other factors. It is not possible to

fit one at a later date.

18 Version: 1.5 AM3000 / AM3500

Page 19

AM301x

6

AM304x

10

AM307x

10

AM354x

10

AM302x

6

AM305x

10

AM308x

10

AM355x

10

AM303x

8

AM306x

10

AM356x

10

data.

Drive Technology 6 Technical description

6.3.11 Pole numbers

Motor Poles Motor Poles Motor Poles Motor Poles

6.4 Options

Holding brake

The holding brake is integrated in the motor. It increases the motor length.

Radial shaft-sealing ring

Radial shaft-sealing ring (Teflon) for sealing against oil mist and oil spray. This increases the protection class of

the shaft bushing to IP67.

Feather key

The motors are available with feather key groove and fitted feather key according to DIN6885. The rotor is

balanced with half a feather key.

EnDat (only AM30xx), BiSS

This model features a different feedback system in place of the resolver, which may result in an increase of the

motor length.

Installation options and reduction of rated values

With the exception of the sealing ring, the options cannot be retrofitted.

Note

Options such as sealing ring, holding brake, EnDAT or BiSS can lead to a reduction of the rated

6.5 Selection criteria

The three-phase servomotors are designed for operation with servo drives.

Both units together form a speed or torque control loop.

The main selection criteria are:

— Standstill torque M0 [Nm]

— Rated speed at rated supply voltage nn [min-1]

— Moment of inertia of motor and load J [kgcm²]

— Effective torque (calculated) Mrms [Nm]

The static load and the dynamic load (acceleration/braking) must be taken into account in the calculation of the

required motors and servo drives. Formulas and calculation example are available from our applications

department on request.

AM3000 / AM3500 Version: 1.5 19

Page 20

7 Mechanical installation

2

0

min

x

F

M

dR≥

7 Mechanical installation

7.1 Important notes

Destruction of the motors

• Protect the motors from unacceptable stresses. Take care, especially during transport and

Attention

handling, that components are not bent and that insulation clearances are not altered.

• The site must be free of conductive and aggressive material. For V3-mounting (shaft end

upwards), make sure that no liquids can enter the bearings. If an encapsulated assembly is

required, please consult our applications department beforehand.

• Ensure unhindered ventilation of the motors and observe the permissible ambient and flange

temperatures. For ambient temperatures above 40 °C please consult our applications

department beforehand.

• Servomotors are precision devices. The flange and shaft are especially vulnerable during

storage and assembly. It is important to use the locking thread which is provided to tighten

up couplings, gear wheels or pulleys and warm up the drive components, where possible.

Blows or the use of force will lead to damage to the ball bearings and the shaft.

Drive Technology

• Wherever possible, use only backlash-free, frictionally-locking collets or couplings. Ensure

correct alignment of the couplings. A displacement will cause unacceptable vibration and the

destruction of the ball bearings and the coupling.

• For toothed belts, it is vital to observe the permissible radial forces. An excessive radial load

on the shaft will significantly shorten the life of the motor.

• Avoid axial loads on the motor shaft, as far as possible. Axial loading significantly shortens

the life of the motor.

• In any case, avoid creating a mechanically constrained motor shaft mounting by using a rigid

coupling with additional external bearings (e.g. in a gearbox).

• Take note of the no. of motor poles and the no. of resolver poles and ensure that the correct

setting is made in the used servo drives. An incorrect setting can lead to the destruction of

the motor, especially with small motors.

• Check compliance the permitted radial and axial loads F

drive, the minimum permitted diameter of the pinion follows from the equation:

and FA. When using a toothed belt

R

20 Version: 1.5 AM3000 / AM3500

Page 21

Connect the motor holding brake

Drive Technology 8 Electrical installation

8 Electrical installation

8.1 Important notes

Serious risk of injury through electric shock!

• Only staff qualified and trained in electrical engineering are allowed to wire up the motor.

DANGER

Attention

• Check the assignment of the servo drive and the motor. Compare the rated voltage and the

rated current of the devices.

• Always make sure that the motors are de-energised during assembly and wiring, i.e. no

voltage may be switched on for any piece of equipment which is to be connected. Ensure

that the control cabinet remains turned off (barrier, warning signs etc.). The individual

voltages will only be turned on again during commissioning.

• Never undo the electrical connections to the motor when it is live. A dangerous voltage,

resulting from residual charge, can be still present on the capacitors up to 5 minutes after

switch-off of the mains supply.

Measure the DC link voltage and wait until it has fallen below 40 V.

Control and power leads may be live, even if the motor is not running.

Smooth operation

• Ensure that there the servo drive and the motor are earthed properly. See below for further

information regarding EMC shielding and earthing. Earth the mounting plate and motor

housing. Further details of connection types can be found in Section 8.2

Attention

Note

• Route the power and control cables as separately as possible from one another (separation

> 20 cm). This will improve the immunity of the system to electromagnetic interference. If a

motor power cable is used which includes integral brake control leads, then these brake

control leads must be shielded. The shielding must be connected at both ends (see below).

• Install all cables carrying a heavy current with an adequate cross-section, as per EN 60204.

The recommended cross-section can be found in the technical data.

• Wiring:

Connect the resolver or encoder

Connect the motor cables

Connect shields to shield terminals or EMC connectors at both ends

Connect the temperature contact

HF interference

• The ground symbol , which you will find in the wiring diagrams, indicates that you must

provide an electrical connection, with as large a surface area as possible, between the unit

indicated and the mounting plate in the control cabinet. This connection is to suppress HF

interference and must not be confused with the PE (protective earth) symbol (protective

measure according to EN 60204).

Follow the instructions in the circuit diagrams in Sections 8.3 to 8.6

Long motor cables

• In case of long motor cables (>25m) a motor choke must be provided between the motor and

the servo drive.

AX2000 / AX2500: Connect up all shielding via a wide surface-area contact (low impedance)

and metallised connector housings or EMC cable glands. Install the motor choke close to the

servo drive.

AX5000: The motor choke is supplied with a connection cable. Do not alter the configuration

(cable length, cross-section etc.).

AM3000 / AM3500 Version: 1.5 21

Page 22

8 Electrical installation

Specification

4 x 1.5 mm2 + 2 x (2 x 0.75 mm2)

General data

Weight

kg / km

Min. bending radius

203 mm

Overall diameter

11.3 mm +/- 4%

Max. velocity

180 m/min

Max. acceleration

5 m/s2

Max. no. of cycles

50.000

Max. tensile load

20 N/mm2

Operating temperature

-10 to 80 °C

Standards and features

UL AWM listed

80 °C – 1000 V

CSA AWM listed

75 °C – 1000 V

VDE (U0 / U)

0.6/1 kV

Flame resistance

DIN EN 50265-2-1

Oil resistance

UL 1581

Silicone-free

yes

CFC-free

yes

Halogen-free

no

Sheath

Material

PVC according to UL AWM & CSA AWM

Shielding

tinned copper braid, optical cover ≥ 85%

Separator

Polyester strap

Colour

RAL 2003 (orange)

Power leads

4 x 1.5 mm2

Conductor material

blank copper cl.5 (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

TEO Flexene ® polymer compound, compliant

with UL AWM & CSA AWM

Colour code

black (1 -3) + green/yellow

Signal leads

2 x (2 x 0.75 mm2)

Conductor material

blank copper cl. 5 (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

TEO Flexene ® polymer compound, compliant

with UL AWM & CSA AWM

Structure

pair-wise twisted

Shielding per pair

tinned copper sheath, optical cover ≥ 85%

Separator

fleece tape

Colour code for signal pairs

2 pairs

Drive Technology

8.2 Connection of motors with pre-assembled cables

Beckhoff offers preassembled motor and feedback cables for safe, faster and flawless installation of the

motors. Beckhoff cables have been tested with regard to the materials, shielding and connectors used. They

ensure proper functioning and compliance with statutory regulations such as EMC, UL etc. The use of other

cables may lead to unexpected interference and invalidate the warranty.

• Carry out the wiring in accordance with the valid standards and regulations.

• Only use our preassembled shielded cables for the power and feedback connections.

• Connect up the shielding according to the wiring diagrams in sections 8.3 to 8.6. Incorrectly installed

shielding inevitably leads to EMC interference.

All available cable types are listed below. Should you require additional information please contact our support.

8.2.1 AX5000

All cables are UL-listed.

8.2.1.1 Cables for fixed installation

Motor cable with signal line

22 Version: 1.5 AM3000 / AM3500

Page 23

1st pair

black and black (5-6)

2nd pair

black and black (7-8)

Electrical specifications

Test conditions

20 °C

Test voltage for power

Requirement

Operating voltage

≤1000 V

Conductor resistance

IEC 60228 Cl.5

Insulation resistance

≥2500 MOhm x km

Capacitance:

Signals

max. 100 pF / m

Specification

Encoder cable

7x(2x0.14mm2)+1x(2x0.5mm2)

Reserved

General data

Weight

kg / km

Min. bending radius

137 mm

Overall diameter

7.6 mm +/- 0.3 mm

Max. velocity

180 m / min

Max. acceleration

5 m / s2

Max. no. of cycles

50.000

Max. tensile load

20 N / mm2

Operating temperature

-10 to 80 °C

Standards and features

UL AWM listed

80 °C – 30 V

CSA AWM listed

75 °C – 30 V

Flame resistance

DIN EN 50265-2-1

Oil resistance

UL 1581

Silicone-free

yes CFC-free

yes Halogen-free

no

Sheath

Material

PVC according to UL AWM & CSA AWM

Shielding

tinned copper braid, optical cover ≥ 85%

Separator

Polyester strap

Colour

RAL 6018 (green)

Signal leads

7 x (2 x 0.14 mm2)

Conductor material

Conductor resistance

tinned copper 7x0.16 mm

≤140 Ohm / km

Insulation

polypropylene compliant with UL AWM & CSA AWM

Structure

pair-wise twisted

Colour code for signal

pairs

1st pair

brown and white

2nd pair

green and yellow

3rd pair

grey and pink

4th pair

red and blue

5th pair

black and violet

Drive Technology 8 Electrical installation

Encoder cable

leads

(conductor/conductor conductor/shielding)

Test voltage for signal

leads

(conductor/conductor conductor/shielding)

Power

4 kV eff. 5 min.

2 kV eff. 1 min.

undamaged insulation

max. 150 pF / m

AM3000 / AM3500 Version: 1.5 23

8 pairs

Page 24

8 Electrical installation

6th pair

grey/pink and red/blue

7th pair

white/green and brown/green

8th pair

white/yellow and yellow/brown

Electrical specifications

Test conditions

20 °C

Test voltage

Requirement

Operating voltage

≤ 30 V

Conductor material

Conductor resistance

2 x 0.5 mm², tinned copper 19 x 0.18 mm

0.5 mm2 ≤ 40 Ohm / km

Insulation resistance

min. 2500 MOhm x km

Capacitance:

Signals

max. 120 pF / m

Specification

4 x 1.5 mm2 + 2 x (2 x 0.75 mm2)

General data

Weight

kg / km

Min. bending radius

85 mm

Overall diameter

12.2 mm E 4mm

Max. velocity

240 m / min

Max. acceleration

30 m / s2

Max. no. of cycles

10 million

max. horizontal length

20 m

max. vertical length

5 m

Max. tensile load

20 N / mm2

Operating temperature

-10 to 80 °C

Standards and features

UL AWM listed

80 °C – 1000 V

CSA AWM listed

75 °C – 1000 V

VDE (U0 / U)

0.6 / 1 kV

Flame resistance

DIN EN 50265-2-1

Oil resistance

UL 1581

Silicone-free

yes

CFC-free

yes

Halogen-free

yes

Sheath

Material

TMPU, halogen-free, compliant with UL AWM &

CSA AWM

Shielding

tinned copper braid, optical cover ≥ 85%

Separator

Polyester strap

Colour

RAL 2003 (orange)

Power leads

4 x 1.5 mm2

Conductor material

blank copper cl.5 (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

TEO Flexene ® polymer compound, compliant

with UL AWM & CSA AWM

Colour code

black (1 -3) + green/yellow

Signal leads

2 x (2 x 0.75 mm2)

Conductor material

blank copper cl. 5 (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

TEO Flexene ® polymer compound, compliant

with UL AWM & CSA AWM

Drive Technology

(conductor/conductor conductor/shielding)

Power

8.2.1.2 Cables for flexible installation / highly dynamic operation

Motor cable with signal line

1500 VDC

undamaged insulation

max. 100 pF / m

24 Version: 1.5 AM3000 / AM3500

Page 25

Structure

pair-wise twisted

Shielding per pair

tinned copper sheath, optical cover ≥ 85%

Separator

fleece tape

Colour code for signal pairs

2 pairs

1st pair

black and black (5-6)

2nd pair

black and black (7-8)

Electrical specifications

Test conditions

20 °C

Test voltage for power

Requirement

Operating voltage

≤ 1000 V

Conductor resistance

IEC 60228 Cl.5

Insulation resistance

≥ 2500 MOhm x km

Capacitance:

Signals

max. 100 pF / m

Specification

Encoder cable

7x(2x0.14mm2)+1x(2x0.5mm2)

Reserved

General data

Weight

kg / km

Min. bending radius

53 mm

Overall diameter

7.6 mm ± 0.3 mm

Max. velocity

240 m / min

Max. acceleration

30 m / s2

Max. no. of cycles

10 million

max. horizontal length

20 m

max. vertical length

5 m Max. tensile load

20 N/mm2

Operating temperature

-10 to 80 °C

Standards and features

UL AWM listed

80 °C – 30 V

CSA AWM listed

75 °C – 30 V

Flame resistance

DIN EN 50265-2-1

Oil resistance

UL 1581

Silicone-free

yes CFC-free

yes Halogen-free

yes Sheath

Material

TMPU, halogen-free, compliant with UL AWM & CSA

AWM

Shielding

tinned copper braid, optical cover ≥ 85%

Separator

Polyester strap

Colour

RAL 6018 (green)

Signal leads

7 x (2 x 0.14 mm2)

Conductor material

Conductor resistance

tinned copper 7 x 0.16 mm

≤140 Ohm / km

Insulation

polypropylene compliant with UL AWM & CSA AWM

Structure

pair-wise twisted

Drive Technology 8 Electrical installation

Encoder cable

leads

(conductor/conductor conductor/shielding)

Test voltage for signal

leads

(conductor/conductor conductor/shielding)

Power

4 kV eff. 5 min.

2 kV eff. 1 min.

undamaged insulation

max. 150 pF / m

AM3000 / AM3500 Version: 1.5 25

Page 26

8 Electrical installation

Colour code for signal

pairs

1st pair

brown and white

2nd pair

green and yellow

3rd pair

grey and pink

4th pair

red and blue

5th pair

black and violet

6th pair

grey/pink and red/blue

7th pair

white/green and brown/green

8th pair

white/yellow and yellow/brown

Electrical specifications

Test conditions

20 °C

Test voltage

Requirement

Operating voltage

≤ 30 V

Conductor material

Conductor resistance

2 x 0.5 mm², tinned copper 19 x 0.18 mm

≤ 40 Ohm / km

Insulation resistance

min. 2500 MOhm x km

Capacitance:

Signals

max. 120 pF / m

Specification

AX2000

4 x 1.5 mm2 + 2 x 1 mm2

AX2500

4 x 1 mm2 + 2 x 1 mm2

General data

Min. bending radius

118 mm

115 mm

Weight

185 kg / km

155 kg / km

Overall diameter

10.6 mm ± 4 %

10 mm ± 4 %

Max. velocity

120 m / min

Max. acceleration

4 m / s2

Max. no. of cycles

10 million

Max. tensile load

static / dynamic

Operating temperature

0 to 80 °C

Oil resistance

“VDE 0472 Part 803 B”; “VDE 0282 Part 10”;

“UL 1581”

Sheath

Material

PUR according to the UL standard

Shielding

tinned copper braid, optical cover ≥ 85%

Colour

RAL 2003 (orange)

Power leads

4 x 1.5 mm2

4 x 1 mm2

Conductor material

blank copper (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

polyolefin polymer according to the

UL standard

Signal leads

2 x 1 mm2

Conductor material

blank copper (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

polyolefin polymer according to the

UL standard

Shielding

tinned copper sheath, optical cover ≥ 85%

Electrical specifications

8 pairs

Drive Technology

(conductor/conductor conductor/shielding)

Power

1500 VDC

undamaged insulation

max. 100 pF / m

8.2.2 AX2000 and AX2500

All cables are specified for flexible routing. They enable highly dynamic operation and are UL-listed.

Motor cable with signal line

26 Version: 1.5 AM3000 / AM3500

50 / 20 N / mm2

Page 27

Test conditions

20 °C

Test voltage for power leads

Requirement

Operating voltage

≤ 1000 V

Conductor resistance

Signal leads

20.5 Ohm / km

Shielding resistance

Signal leads

50 Ohm / km

Insulation resistance

Signal leads

min. 20 MOhm x km

Capacitance

Signal leads

max. 150 pF / m

Specification

Encoder cable

8 x 2 x 0.14 mm2

Resolver cable

4 x 2 x 0.25 mm2

General data

Weight

69 kg / km

80 kg / km

Min. bending radius

75 mm

Overall diameter

7.5 mm +/- 4%

Max. velocity

120 m / min

Max. acceleration

4 m / s2

Max. no. of cycles

10 million

Max. tensile load

static / dynamic

Operating temperature

0 to 80 °C

Oil resistance

“VDE 0472 Part 803 B”; “VDE 0282 Part 10”; “UL

1581”

Sheath

Material

PUR according to the UL standard

Shielding

tinned copper braid, optical cover ≥ 85%

Colour

RAL 6018 (green)

Signal leads

8 x 2 x 0.14 mm2

4 x 2 x 0.25 mm2

Conductor material

blank copper (DIN EN 60228; VDE 0295; IEC

60228)

Insulation

polyolefin polymer according to the

UL standard

Structure

pair-wise twisted

Colour code for signal pairs

8 pairs

4 pairs

1st pair

brown and white

2nd pair

green and yellow

3rd pair

grey and pink

4th pair

red and blue

5th pair

black and violet

---

6th pair

grey/pink and red/blue

---

7th pair

white/green and

brown/green

8th pair

white/yellow and

yellow/brown

Electrical specifications

Test conditions

20 °C

Drive Technology 8 Electrical installation

(conductor/conductor conductor/shielding)

Test voltage for signal leads

(conductor/conductor conductor/shielding)

Test period

Power leads

Power leads

Encoder and resolver cable

3 kV eff.

1.5 kV

5 min.

undamaged insulation

min. 5000 MOhm x km

max. 120 pF / m

50 / 20 N / mm2

---

---

AM3000 / AM3500 Version: 1.5 27

Page 28

8 Electrical installation

Test voltage for signal

Requirement

Operating voltage

300 V

Insulation resistance

Signal leads min. 5000 MOhm x km

Capacitance

max. 120 pF / m

Drive Technology

leads

(conductor/conductor conductor/shielding)

Test period

1.5 kV eff.

5 min.

undamaged insulation

28 Version: 1.5 AM3000 / AM3500

Page 29

Drive Technology 8 Electrical installation

8.3 AX5000 connection diagram for motors with EnDAT / BiSS encoder

Power connector Motor cable

8-poles, round ZK4500-xxxx-xxxx

Power

Encoder connector Encoder cable

17-poles, round ZK4510-xxxx-xxxx

D-Sub 15 poles

Thermal protection contact and brake

AM3000 / AM3500 Version: 1.5 29

Page 30

8 Electrical installation

Power

Drive Technology

8.4 AX5000 connection diagram for motors with resolver

Thermal protection contact and brake

Power connector Motor cable

8-poles, round ZK4500-xxxx-xxxx

Resolver connector Resolver cable

12-poles, round ZK4530-xxxx-xxxx

D-Sub 15 poles

30 Version: 1.5 AM3000 / AM3500

Page 31

Drive Technology 8 Electrical installation

8.5 AX5000 connection diagram for motors with resolver and yTec-Plug

Brake

Power connector Motor cable

9 pol. - yTec ZK4500-0211-xxxx

Power

Resolver connector Resolver cable

12 pol. - yTec ZK4530-xxxx-xxxx

D-Sub 15 poles

AM3000 / AM3500 Version: 1.5 31

Page 32

8 Electrical installation

Encoder connector Encoder cable

8.6 AX2000 connection diagram for motors with EnDAT / BiSS encoder

17-poles, round ZK4000-xxxx-xxxx

D-Sub 15 poles

Drive Technology

32 Version: 1.5 AM3000 / AM3500

Page 33

Resolver connector Resolver cable

Drive Technology 8 Electrical installation

8.7 AX2000 connection diagram for motors with resolver

12-poles, round ZK4000-xxxx-xxxx

D-Sub 9 poles

AM3000 / AM3500 Version: 1.5 33

Page 34

9 Commissioning

9 Commissioning

9.1 Important notes

Serious risk of injury!

• Only specialist personnel with extensive knowledge in the areas of electrical engineering /

DANGER

9.2 Guide for commissioning

drive technology are allowed to install and commission the equipment.

• Check that all live connection points are protected against accidental contact. Dangerous

voltages can occur, up to 900 V.

• Never undo the electrical connections to the motor when it is live. The residual charge in the

capacitors of the servo drives can produce dangerous voltages up to 5 minutes after the

mains supply has been switched off.

• The surface temperature of the motor can exceed 100 °C in operation. Check (measure) the

temperature of the motor. Wait until the motor has cooled down below 40 °C before touching

it.

• Make sure that, even if the drive starts to move unintentionally, no danger can result for

personnel or machinery.

Drive Technology

The procedure for commissioning is described as an example.

A different method may be appropriate or necessary, depending on the application of the equipment.

• Check the assembly and orientation of the motor.

• Check the drive components (coupling, gear unit, pulley) for the correct seating and setting (observe the

permissible radial and axial forces).

• Check the wiring and connections to the motor and the servo drive. Check that the earthing is correct.

• Test the function of the holding brake, if used. (apply 24 V, the brake must be released).

• Check whether the rotor of the motor revolves freely (release the brake, if necessary). Listen out for grinding

noises.

• Check that all the required measures against accidental contact with live and moving parts have been

carried out.

• Carry out any further tests which are specifically required for your system.

• Now commission the drive according to the commissioning instructions for the servo drive.

• In multi-axis systems, individually commission each drive unit (servo drive/motor(s)).

9.3 Troubleshooting

The following table is to be seen as a “First Aid” box. There can be a large number of different reasons for a

fault, depending on the particular conditions in your system. The fault causes described below are mostly those

which directly influence the motor. Peculiarities which show up in the control behaviour can usually be traced

back to an error in the parameterisation of the servo drive. The documentation for the servo drive and the

commissioning software provides information on these matters.