Page 1

Operating instructions

AL225x Connector-Box

Accessory for servo drives of the series AX5000 and AX2000

Version:

Date:

1.9

2019-05-15

Page 2

Page 3

Contents

Contents

1 Foreword ...................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Documentation Issue Status..............................................................................................................6

1.3 Intended use .....................................................................................................................................6

2 Guidelines and Standards .......................................................................................................................7

3 For your safety...........................................................................................................................................8

3.1 Staff qualification ...............................................................................................................................8

3.2 Description of symbols ......................................................................................................................9

3.3 Special safety instructions for the connector box ...........................................................................10

4 Product identification .............................................................................................................................11

4.1 Scope of delivery ............................................................................................................................11

4.2 Name plate ......................................................................................................................................11

4.3 Type key ..........................................................................................................................................11

5 Technical description .............................................................................................................................12

5.1 Configuration of the connector boxes..............................................................................................12

5.2 Connection technology AL225x-0001 at AX5000............................................................................13

5.3 Connection technology AL225x-0000 at AX2000............................................................................14

5.4 Selection criteria ..............................................................................................................................15

5.4.1 Connection examples ...................................................................................................... 15

6 Mechanical installation ..........................................................................................................................17

6.1 Mounting the connector box on the slide.........................................................................................17

7 Electrical installation ..............................................................................................................................18

7.1 Important notes ...............................................................................................................................18

8 Technical data .........................................................................................................................................19

8.1 Dimensional drawing of connector box AL2250 ..............................................................................19

8.2 Dimensional drawing of connector box AL2255/AL2256.................................................................19

9 Appendix .................................................................................................................................................20

9.1 Support and Service ........................................................................................................................20

AL225x Connector-Box 3Version: 1.9

Page 4

Contents

AL225x Connector-Box4 Version: 1.9

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

AL225x Connector-Box 5Version: 1.9

Page 6

Foreword

1.2 Documentation Issue Status

Origin of the document

This documentation was originally written in German. All other languages are derived from the German

original.

Product features

Only the product features specified in the current user documentation are valid. Further information given on

the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative.

Issue Notice

1.9 Chapter update:

Mechanical installation 6.1; Technical data 8.1 and 8.2

1.8 Chapter update:

Selection criteria 5.3; Technical data 8

1.7 Chapter update:

Connection technology AL225x-0001 at AX5000 5.2; Selection criteria 5.3; Mounting the

connector box on the slide 6.1; Technical data 8

New Chapter:

Connection technology AL225x-0000 at AX2000 5.3

1.6 Chapter update:

Name plate 4.2; Type key 4.3; Dimensional drawing Connector-Box 8.1 – 8.3

1.5 Chapter update:

1.0 Foreword; 3.0 Safety

1.4 Chapter update:

5.2; 5.3

1.3 Chapter update:

5.2

1.2 Chapter update:

5.2; 8.2; 8.3

1.0 First issue

1.3 Intended use

Connector boxes of the AL225x series are exclusively used for connecting linear motors of the AL2000

series to servo drives of the AX5000, AX2500 and AX2000 series. The connector boxes of the AL225x

series are exclusively installed or mounted as components in electrical installations. Accordingly, they may

only be commissioned as integrated system components.

DANGER

Serious risk of injury through high electrical voltage!

• Connector boxes are installed at open line ends. All system components and assemblies MUST be deenergized when installing and working on the connector boxes.

This documentation must be followed during wiring and commissioning of the connector boxes.

AL225x Connector-Box6 Version: 1.9

Page 7

Guidelines and Standards

2 Guidelines and Standards

In addition to the safety instructions mentioned in this manual, the general statutory and other rules and

regulations for the prevention of accidents (e.g. personal protective equipment) and for environmental

protection must be followed.

AL225x Connector-Box 7Version: 1.9

Page 8

For your safety

3 For your safety

Read the section on safety and heed the notices to protect yourself against personal injury and material

damages.

Liability limitations

All the components of the AL225x connector box are supplied in certain hardware and software

configurations appropriate for the conditions of the application. Unauthorized modifications to the hardware

and/or software configurations other than those described in the documentation are not permitted, and nullify

the liability of Beckhoff Automation GmbH & Co. KG.

In addition, the following actions are excluded from the liability of Beckhoff Automation GmbH & Co.

KG:

• Failure to comply with this documentation

• Untrained personnel

• Use of unauthorized spare parts

3.1 Staff qualification

Only technical personnel with knowledge of control and automation technology may carry out any of the

illustrated work steps on the Beckhoff software and hardware, in particular on the connector box AL225x.

The technical personnel must have knowledge of drive technology and electrical systems and must also

know how to work safely on electrical equipment and machines.

This also includes:

• work preparation and

• securing of the working environment (e.g. securing the control cabinet against being switched on

again).

The technical personnel must be familiar with the current and necessary standards and directives for the

automation and drive environment.

AL225x Connector-Box8 Version: 1.9

Page 9

For your safety

3.2 Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

Symbols that warn of personal injury:

DANGER

Serious risk of injury!

This is an extremely dangerous situation. Disregarding the safety notice will lead to serious permanent injuries or even death.

WARNING

Risk of injury!

This is a dangerous situation. Disregarding the safety notice may lead to serious injuries.

CAUTION

Personal injuries!

This is a dangerous situation. Disregarding the safety notice may lead to minor injuries.

Symbols that warn of damage to property or equipment:

NOTE

Warning of damage to property or the environment!

This notice indicates disturbances in the operational procedure that could damage the product or the environment.

Symbols indicating further information or tips:

Tip or pointer!

This notice provides important information that will be of assistance in dealing with the product or

software. There is no immediate danger to product, people or environment.

UL note!

This symbol indicates important information regarding UL certification.

AL225x Connector-Box 9Version: 1.9

Page 10

For your safety

3.3 Special safety instructions for the connector box

The safety instructions are designed to avert danger and must be followed during installation,

commissioning, production, troubleshooting, maintenance and trial or test assemblies. The connector boxes

of the AL225x series are not designed for stand-alone operation and are always installed in a machine or

system. After installation, the documentation the documentation and the safety instructions provided by the

machine manufacturer must be read and applied.

WARNING

Serious risk of injury through high electrical voltage!

• Negligent, improper handling of the connector boxes and bypassing of the safety facilities of the system

or machine may result in personal injury or death through electric shock.

• When installing and working on the connector boxes, all machine components and assemblies MUST be

de-energized and secured against unintentional restoration of electrical power.

• The machine manufacturer must prepare a hazard analysis for the machine, and must take appropriate

measures to ensure that unexpected movements cannot lead to injury to persons or to objects.

• Power connections may be live, even if machine components don't move. Never undo the electrical connections to the motor when it is live. Under unfavorable conditions arcing may occur, resulting in injury

and damage to contacts.

• Disconnect the linear motor from the servo drive and secure it against reconnection before working on

electrical parts with a voltage > 50 V.

• Due to the DC link capacitors, the DC link contacts "ZK+ and ZK- (DC+ and DC-)" and "RB+ and RB-"

may be subject to dangerous voltages exceeding 890VDC, even after the servo drive was disconnected

from the mains supply. Wait 5 minutes for the AX5101 - AX5125 and AX520x; 15 minutes for the

AX5140/AX5160/AX5172; 30 minutes for the AX5190/AX5191; 45 minutes for the AX5192/AX5193 after

disconnecting, and measure the voltage at the DC links "ZK+ and ZK- (DC+ and DC-)". The device is

safe once the voltage has fallen below 50 V.

WARNING

Risk of injury through failure of the drive system!

Electronic equipment is not fail-safe. The machine manufacturer is responsible for ensuring that the connected motors and the machine are brought into a safe state in the event of a fault in the drive system.

WARNING

Caution – Risk of injury through electric shock!

Remove the motor and feedback lines from the connector box to the servo drive when you open the connector box.

Selection of motor and feedback cables!

For connecting linear drives, we recommend drag chain-capable, highly dynamic motor and feedback cables.

NOTE

Danger for persons, the environment or equipment

• Please read this manual carefully before using the connector boxes. Follow all safety instructions.

Should anything be unclear, please contact the sales office for your area and refrain from any further

work on the system.

• Only well trained, qualified electricians with sound knowledge of drive equipment may work on the device.

AL225x Connector-Box10 Version: 1.9

Page 11

Product identification

4 Product identification

4.1 Scope of delivery

The scope of delivery consists of the connector box accordingly the product type of the AL225x series and

the housing seal.

Before commissioning the products, check the delivery for completeness.

Should delivered components be damaged, notify the logistics company and Beckhoff Automation GmbH &

Co. KG immediately.

• Connector box of the AL225x series

• Housing seal

4.2 Name plate

The type key for the AL225x connector box contains information about the selected type. For further

information, please refer to the chapter: "Type key [}11]".

4.3 Type key

AL225x Connector-Box 11Version: 1.9

Page 12

Technical description

5 Technical description

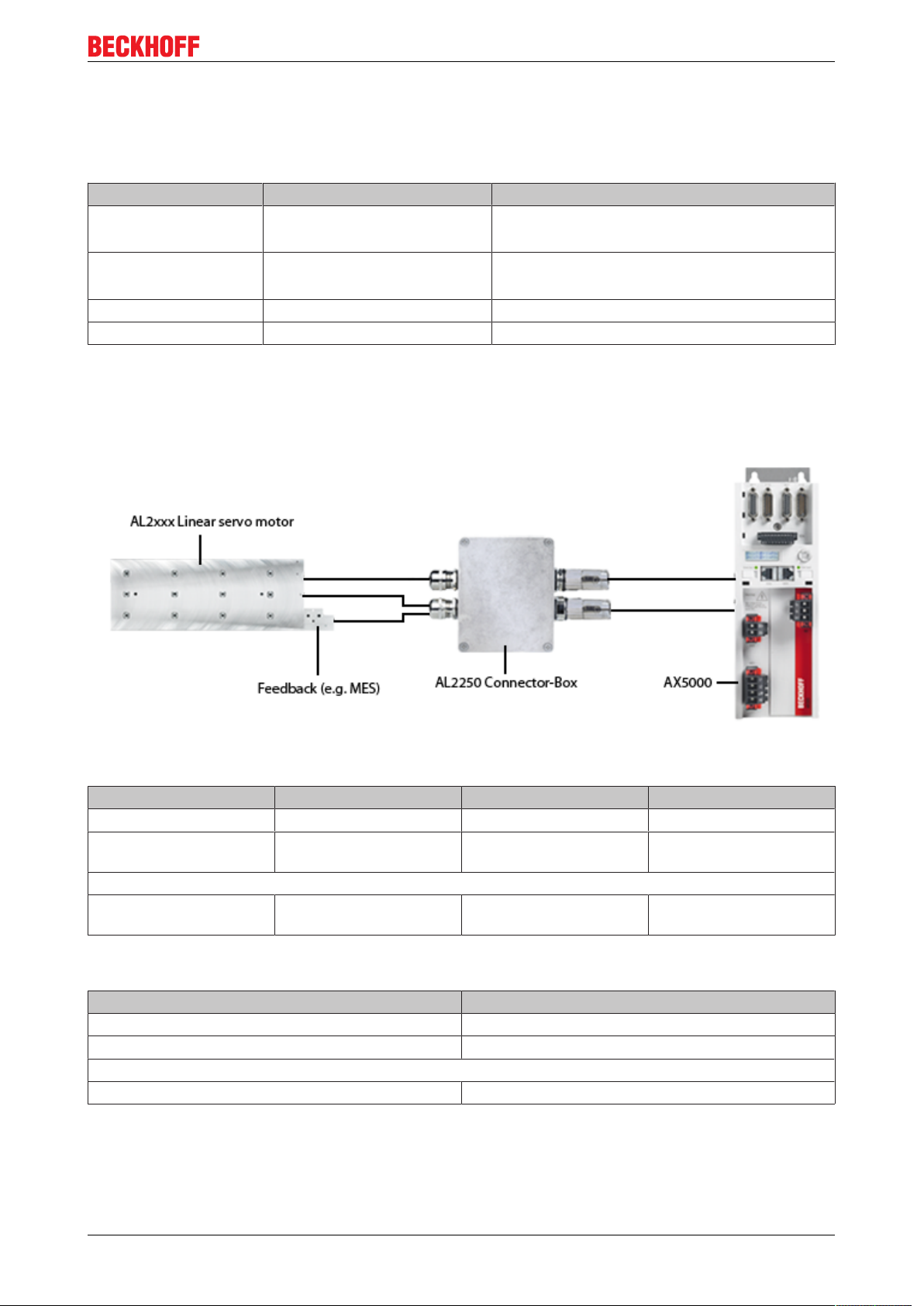

5.1 Configuration of the connector boxes

The AL225x connector boxes are aluminium boxes with ports for cables to the motor and the amplifier.

With the Beckhoff AL225x connector box you can simply connect the motor, encoder and thermal protection

contact cables of the AL2xxx and AL38xx linear motor with the drag chain-capable motor and encoder

cables of the AX5000, AX2500 and AX2000 servo drives series.

To this end, each connector box has ports for Beckhoff motor and feedback cables on the input side. The

output side features screw connections, through which non-assembled motor and feedback system cables

can be introduced.

By using the connector box, the wires of the temperature sensor are connected to the motor cable. No

separate cable is required. This means that only two outgoing cables from the connector box are required.

The terminal strip in the connector box is designed for the signals of several feedback protocols, so that

feedback systems from different manufacturers can be used.

The direct connection of individual wires in the connector box avoids the problem of assembling the

feedback connector.

AL225x Connector-Box12 Version: 1.9

Page 13

Technical description

5.2 Connection technology AL225x-0001 at AX5000

Connection Signal descrip-

X1 – PE PE / GND shield shield shield white / green schield

X2 – 1 SIN + green yellow red green blue

X2 – 2 GND white black black white white

X2 – 3 COS + blue green yellow blue orange

X2 – 4 + 5 V

X2 – 5 DATA + --- white blue grey pink

X2 – 6 US 9 V --- --- --- --- ---

X2 – 7 REF Z - --- --- --- --- ---

X2 – 8 Clock + --- --- --- --- ---

X2 – 9 SIN - yellow blue orange yellow yellow

X2 – 10 GND sense grey --- --- --- ---

X2 – 11 COS - red orange green red grey

X2 – 12 + 5 V sense pink --- --- --- ---

X2 – 13 DATA - --- --- pink pink green

X2 – 14 REF Z + --- --- --- --- ---

X2 – 15 Clock - --- --- --- --- ---

tion

DC

MES AL2200 LIKA SMS-V1 SIKO LE100 N J* LIA1Vss SONY PL101

brown red brown brown red

Jumper

Using the jumpers, the wiring of the temperature contact can be determined.

Connector-Box Connection of the thermo contact Jumper position

Standard AL225x-0001 Thermo contact (T) connected with motor

cable (X3)

Jumper upstairs

AL225x Connector-Box 13Version: 1.9

Page 14

Technical description

5.3 Connection technology AL225x-0000 at AX2000

Connection Signal descrip-

X1 – PE PE / GND shield shield shield white / green shield

X2 – 1 COS - red orange green red grey

X2 – 2 GND white black black white white

X2 – 3 SIN - yellow blue orange yellow yellow

X2 – 4 + 5 V

X2 – 5 DATA + / Z + --- white blue grey pink

X2 – 6 n.c. --- --- --- --- ---

X2 – 7 PTC --- --- --- --- ---

X2 – 8 Clock + --- --- --- --- ---

X2 – 9 COS + blue green yellow blue orange

X2 – 10 GND sense grey --- --- --- ---

X2 – 11 SIN + green yellow red green blue

X2 – 12 + 5 V sense pink --- --- --- ---

X2 – 13 DATA - / Z - --- --- pink pink green

X2 – 14 PTC --- --- --- --- ---

X2 – 15 Clock - --- --- --- --- ---

tion

DC

MES AL2200 LIKA SMS-V1 SIKO LE100 N J* LIA1Vss SONY PL101

brown red brown brown red

Jumper

Using the jumpers, the wiring of the temperature contact can be determined.

Connector-Box Connection of the thermo contact Jumper position

Standard AL225x-0000 Thermo contact (T) connected with encoder ca-

ble (X2)

Jumper downstairs

AL225x Connector-Box14 Version: 1.9

Page 15

Technical description

5.4 Selection criteria

The connector boxes are designed for operation with Beckhoff linear motors and Beckhoff servo drives. The

choice of connector box depends on the motor and servo drive combination. Please refer to the table below.

Order details for servo drive applicable motor types

AL2250-0000 AX2xxx AL2003 – AL2830-0001 and AL2830-1000

AL3803 – AL3818-0000

AL2250-0001 AX5xxx AL2003 – AL2830-0001 and AL2830-1000

AL3803 – AL3818-0000

AL2255-0001 AX5xxx AL2830-1001-0000 and AL2845-1000-0000

AL2256-0001 AX5xxx AL2845-1001-0000

5.4.1 Connection examples

Linear motors with Beckhoff encoder (MES) and connector box AL225x

AL2250-000x

Cable AX2000 AX2500 AX5000

Motor cable* ZK4000-2111 ZK4000-2711 ZK4500-0023

Encoder cable for MES or

absolute encoder

or

Encoder cable for encoder

with zero pulse

AL2255-0001

Cable AX5000

Motor cable* ZK4500-0023

Encoder cable for MES or absolute encoder ZK4510-0020

or

Encoder cable for encoder with zero pulse ZK4520-0020

ZK4000-2610 ZK4000-2610 ZK4510-0020

ZK4000-2610 ZK4000-2610 ZK4520-0020

AL225x Connector-Box 15Version: 1.9

Page 16

Technical description

AL2256-0001

Cable AX5000

Motor cable* ZK4500-0017

Encoder cable for MES or absolute encoder ZK4510-0020

or

Encoder cable for encoder with zero pulse ZK4520-0020

Linear motors with Beckhoff encoder (MES) without connector box

Cable AX2000 AX2500 AX5000

Motor cable* ZK4000-2111 ZK4000-2711 ZK4500-0023

Thermal protection contact

cable

Encoder cable for MES or

absolute encoder

*wire cross-section depends on motor/applications current

ZK4000-2510 ZK4000-2510 ZK4540-0020

ZK4000-2610 ZK4000-2610 ZK4510-0020

AL225x Connector-Box16 Version: 1.9

Page 17

Mechanical installation

6 Mechanical installation

6.1 Mounting the connector box on the slide

Mounting the connector box on the slide!

The motor cables of the linear motors are generally not drag chain-capable. The connector box

must therefore be mounted on the moving part of the linear axis.

Connector boxes AL2250-0000 and AL2250-0001

The connector boxes are mounted with 2 screws (e.g. M4 / DIN13).

Remove the cover (2) of the connector box and insert the screws through the appropriate slot (1).

Connector boxes AL2255-0001 and AL2256-0001

The connector boxes are mounted with 4 screws (e.g. M5 / DIN13).

Insert the screws through the mounting straps (1) of the boxes.

AL225x Connector-Box 17Version: 1.9

Page 18

Electrical installation

7 Electrical installation

7.1 Important notes

Assembling the motor cable (at the linear motor)

Strip the wires of the motor cable and fit wire end sleeves.

Twist the shielding of the motor cable and solder a cable with a minimum diameter of 1.5 mm² to it.

Guide the wires through socket "A" in the box and fasten the nut on the socket "A". Fit the shielded

and PE cables with a "PE" connection and the power wires on connection "X1".

Assembling the encoder cable (at the encoder)!

Strip the wires of the encoder cable and fit wire end sleeves!

Twist the shielding of the encoder cable and solder a cable with a minimum diameter of 0.75 mm² to

it. Fit wire end sleeves or a cable lug to the free end. Place the nut of socket "B" over the encoder

cable and feed the wires through the socket "B" in the box and screw the nut onto socket "B". Fit a

"PE" connection to the shielded cable. Wire the signal wires to the "X2" connection as per the table.

DANGER

Serious risk of injury through high electrical voltage!

The connector box must be opened for assembling the cables as described above.

• Make sure all system and machine components and assemblies are de-energized and secured against

unintentional restoration of electrical power.

• Check the earthing of the system or machine and all relevant components and assemblies.

• Remove the motor and feedback cables from the connector box and the servo drive. When removing the

cables from the servo drive, please note that there are residual charges at the DC link contacts of the

servo drive, even after the power has been switched off. Wait 5 minutes for the AX5101 - AX5125 and

AX520x; 15 minutes for the AX5140/AX5160/AX5172; 30 minutes for the AX5190/AX5191; 45 minutes

for the AX5192/AX5193 after disconnecting, and measure the voltage at the DC links "ZK+ and ZK- (DC

+ and DC-)". The device is safe once the voltage has fallen below 50 V.

AL225x Connector-Box18 Version: 1.9

Page 19

8 Technical data

8.1 Dimensional drawing of connector box AL2250

All dimensions in mm

Technical data

1*) The holes with the diameter Ø 4.2 are provided for mounting the connector box. The holes are provided

for M4 flat head screws DIN 7984.

8.2 Dimensional drawing of connector box AL2255/AL2256

All dimensions in mm

2*) The holes on the mounting lugs are provided for M5 flat head screws.

3*) The holes with M4 x 20 threads on the connector box (for mounting the cover) are provided for

countersunk head screws.

Connection plugs and cables:

For further information about connection technology and cables, please take a look at the chapter:

“Technical description [}12]”.

AL225x Connector-Box 19Version: 1.9

Page 20

Appendix

9 Appendix

9.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

AL225x Connector-Box20 Version: 1.9

Loading...

Loading...