Beckett SDC 24 VDC User Manual

24 Vdc Oil Burner Manual

CORPORATION

Potential for Fire, Smoke and Asphyxiation Hazards

Incorrect installation, adjustment, or misuse of this burner could result in death, severe

personal injury, or substantial property damage.

To the Homeowner or Equipment Owner:

Please read and carefully follow all instructions

y

provided in this manual regarding your responsibilities

in caring for your heating equipment.

Contact a professional, qualifi ed service agency for

y

installation, start-up or service work.

READ THESE INSTRUCTIONS AND SAVE FOR

y

REFERENCE.

To the Professional, Qualifi ed Installer or Service

Agency:

Please read and carefully follow all manual instructions

y

and any supplements provided, before installing,

starting, or servicing this burner or heating system.

The Installation must be made in accordance with all

y

state and local codes having jurisdiction.

Contents

Burner Application Scope and Intended Use ...........2

Prepare Before Installing ............................................ 3

Notice Special Requirements.............................................3

Specifi cations .....................................................................3

Hazard Defi nitions

Indicates a hazardous situation,

which, if not avoided, will result

in death or serious injury.

General Information ....................................................4

A. Equipment Located in Confi ned Space ......................... 4

Exhaust Fans and Other Air-Using Devices. ...................... 4

B.

C. Clearances to Burner and Equipment ...........................4

D. Exhausting Hazardous Fumes ......................................4

Nozzle Assembly Maintenance .................................. 4

A. Replace the Burner Nozzle............................................4

B. Check/Adjust Electrodes ...............................................5

C. Igniter Maintenance .......................................................6

D. Servicing Nozzle Line Assembly ...................................6

E. Check/Adjust “Z” Dimension ..........................................6

Fuel Supply ..................................................................7

A. Connect Fuel Lines........................................................7

B. Fuel Supply Level with or Above Burner........................7

C. Fuel Supply Below Level of Burner ...............................7

D. Fuel Line Replacement (Remote Tank Only) ................7

E. Fuel Line Valve and Filter ............................................. 7

Burner Wiring ...............................................................8

A. Burner installed on equipment .......................................8

B. Burner Replacement......................................................8

Drive Component Maintenance .................................. 9

A. Motor, Blower Wheel, & Coupling Replacement............9

B. Pump Maintenance........................................................9

C. Solenoid Valve Testing ................................................10

Indicates a hazardous situation,

which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation,

which, if not avoided, could

result in minor or moderate injury.

Within the boundaries of the hazard warning, there will

be information presented describing consequences if the

warning is not heeded and instructions on how to avoid

the hazard.

Intended to bring special attention

to information, but not related to

personal injury or property damage.

Start Up Burner & Set Combustion ..........................10

A. Basic Burner Operation ...............................................10

B. Combustion Set-up ......................................................10

C. Set Combustion with Instruments................................10

Maintain & Service Burner ........................................ 11

A. Owner’s Information ....................................................11

B. Owner Service and Maintenance ...............................11

C. Extended Down Time .................................................. 11

D. Regular Service/Maintenance ..................................... 11

Troubleshooting ........................................................12

Replacement Parts ....................................................14

Limited Warranty Information ..................................16

Burner Application Scope

and Intended Use

The SDC burner is designed for use in road

maintenance equipment applications that

have DC voltage charging systems capable of

sustaining the specifi ed voltage requirements.

For other equipment applications, please contact

Beckett Technical Services at 1-800-645-2876.

2

Section: Prepare Before Installing

Prepare Before Installing

Owner’s Responsibility

Incorrect installation, adjustment, and

use of this burner could result in severe

personal injury, death, or substantial

property damage from fi re, carbon

monoxide poisoning, soot or explosion.

Contact a professional, qualifi ed service agency for the

installation, adjustment and service of your oil heating

system. This work requires technical training, trade

experience, licensing or certifi cation in some states and

the proper use of special combustion test instruments.

Please carefully read and comply with the following

instructions:

Never store or use gasoline or other fl ammable liquids

y

or vapors near this burner or appliance.

Never attempt to burn garbage or refuse in this

y

appliance.

Never attempt to light the burner/appliance by throwing

y

burning material into the appliance.

Never attempt to burn any fuel not specifi ed and

y

approved for use in this burner.

y

Never restrict the air inlet openings to the burner or

the combustion air ventilation openings in the room.

Impaired Burner Performance

and Fire Hazard.

Specifi cations

See ‘Adequate Voltage Required’ warning on page 4

Rated Voltage: 27 Vdc (Nominal Charging System Voltage)

Reference Voltage: 24 Vdc (Battery Discharge Voltage)

Capacity Firing Rate (27V): 1.75 – 5.50 GPH

Input: 245,000 - 770,000 Btu/h

Firing Rate (24V)*: 1.75 - 5.00 GPH

Input: 245,000 - 700,000 Btu/h

Fuels USA: No. 1 or No. 2 diesel fuel or kerosene;

No.1 or No. 2 heating oil (ASTM D396)

DO NOT USE

GASOLINE, CRANKCASE OIL, OR

ANY OIL CONTAINING GASOLINE.

Electrical Burner Voltage (nominal): 27 Vdc

Voltage Range: 21.6V - 28V

Operating Load

w/ igniter on: 14 Amps

w/ igniter off: 10 - 12 Amps

Motor Voltage (nominal): 27 Vdc

Voltage Range: 21.6V - 30V

Full Load Amps: 10 Amps

Starting Amps: 50 Amps Max.

1/4 HP, 3400 RPM, NEMA “N” Flange

Igniter Voltage (nominal): 24 Vdc

Voltage range: 21.6V - 32V

Current: 1.2 Amps

Ignition Secondary: 19kVpk 35mA

Interrupted OR intermittent duty

Valve Coil Voltage: 24 Vdc

Current: < 0.5A

Do NOT operate the burner beyond specifi cations

outlined in the table to the right.

For applications beyond these limits, consult Beckett

y

Technical Service at 1-800-645-2876.

y

NOTE: Some packaged appliances with burners

may be agency listed as a unit to operate beyond

these limits. Consult the appliance manufacturer’s

specifi cations and agency approvals for verifi cation.

Notice Special Requirements

If you discover damage to the burner

or controls during unpacking, notify

the carrier at once and fi le the appropriate claim.

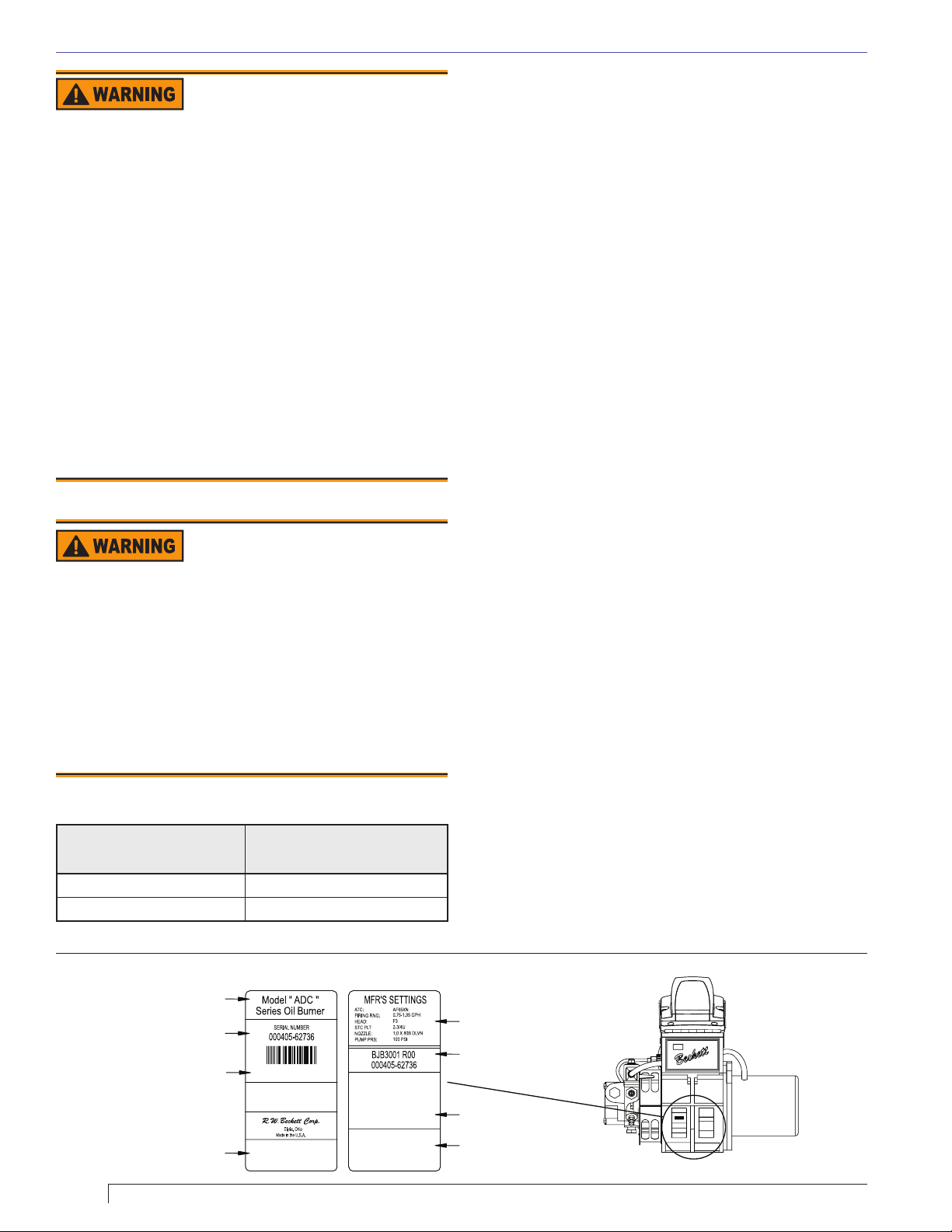

When contacting Beckett for service

information — Please record the

burner serial number (and have available when calling or

writing). You will fi nd the serial number on the silver label

located on the left rear of the burner. See Figure 1.

24 Vdc SDC Burner Manual

Pump Outlet pressure: Note 1

Dimensions Height (maximum): 11 ½ inches

Width (maximum): 14 3/8 inches

Depth (chassis only): 6 9/16 inches

Air tube diameter: 4 inches

Ambient

Operating

Temperature

*Firing rate capacity is based on airfl ow volume. In the SDC burner, airfl ow

volume and motor speed are proportional to the DC voltage. This results in a

lower maximum fi ring rate at 24V.

Note 1. See equipment manufacturer’s burner specifi cations for recommended

outlet pressure. Pressure is 100 psig unless otherwise noted.

+32° F. (0° C.) Minimum

+115° F. (+46° C.) Maximum

(See Warning on Impaired Burner

Performance and Fire Hazard.)

High altitude installations – Accepted

industry practice requires no derate

of burner capacity up to 2,000 feet above sea level. For

altitudes higher than 2,000 feet, derate the burner capacity

2% for each 1,000 feet above the 2,000 feet.

3

Section: General Information & Nozzle Assembly Maintenance

Adequate Voltage Required

A low or erratic power supply could result in impaired

burner operation, severe delayed ignition or an

explosion inside the heat exchanger resulting in a

burn and/or asphyxiation hazard.

The Model SDC requires a continuous supply of 21.8 to

y

28 volts DC measured at the burner during operation with

a minimum supply & circuit capacity of 15A. See page 3

for maximum capacity and voltage specifi cations.

An automotive or small engine charging system that is

y

capable of supplying the required continuous voltage/

amperage is recommended with certain road equipment,

such as asphalt hot patchers and similar applications.

This is especially true while maintaining nominal load

y

temperatures during idle periods.

Once the burner is set-up at a specifi c voltage, a voltage

y

regulator shall be used to maintain that voltage within

+/- 1 Vdc during burner operation.

Adequate Combustion

and Ventilation Air Supply

Required

Failure to provide adequate air supply could seriously

affect the burner performance and result in damage to

the equipment, asphyxiation, explosion or fi re hazards.

The burner cannot properly burn the fuel if it is not

y

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the NFPA

y

31 and CSA-B139 regarding providing adequate air

for combustion and ventilation.

General Information

Refer to the Troubleshooting section of this manual when

experiencing a possible fault condition.

A. Equipment Located in Confi ned Space

The confi ned space should have two permanent openings:

one near the top of the enclosure and one near the

bottom of the enclosure. Each opening shall have a free

area of not less then one square inch per 1,000 BTU’s

per hour of the total input rating of all equipment within

the enclosure. The openings shall have free access to the

building interior, which should have adequate infi ltration

from the outside.

B.

Exhaust Fans and Other Air-Using Devices.

Size air openings large enough to allow for all air using

devices in addition to the minimum area required for

combustion air. If there is any possibility of the equipment

room developing negative pressure (because of exhaust

fans, for example), either pipe combustion directly to the

burner or provide a sealed enclosure for the burner and

provide it with its own combustion air supply.

C. Clearances to Burner and Equipment

Provide space around burner and equipment for easy

service and maintenance. Check minimum clearances

against those shown by the equipment manufacturer and

by applicable codes.

D. Exhausting Hazardous Fumes

See warning on this page. Also be conscious of any fumes

produced by the materials that are being heated. Always

ensure adequate ventilation to exhaust all fumes.

Nozzle Assembly

Maintenance

Table 1. Combustion Head Firing Rates

Firing Rate GPH

(min - max)

Head

1.75 - 3.25 F22/F220

2.50 - 5.50 F310

Figure 1. Typical Burner Nameplate

General Model Information

Serial Number

Including Date Code

Rating Information

Primary Group

and Fuel Oil

4

A. Replace the Burner Nozzle.

If applicable, remove the plastic plug protecting the

1.

nozzle adapter threads.

Place a 3/4” open-end wrench on the nozzle adapter.

2.

Insert the nozzle into the adapter and fi nger tighten.

Finish tightening with a 5/8” open-end wrench.

R.W. Beckett

Manufacturer’s Settings

R.W. Beckett Specification

Number and Revision

Can Be Customized by

Individual Specification

State & Local Approvals

RWB

Model " AFG "

Series Oil Burner

000405-62736

R.W.Beckett Corp.

ELYRIA

OHIO U.S.A.

MFR'S SETTINGS

ATC:

AF65XN

FIRING RNG:

0.75-1.35 GPH

F3HEAD:

SERIAL NUMBER

STC PLT:

2-3/4U

NOZZLE:

1.0 X 80B DLVN

PUMP PRS: 100 PSI

BJB3001 R00

000405-62736

Elyria, Ohio

Made in the U.S.A.

SK10090

Section: Nozzle Assembly Maintenance

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates could

result in impaired combustion, underfi ring, over-fi ring, sooting, puff-back of

hot gases, smoke and potential fi re or

asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph),

spray angle and pattern specifi ed by the appliance

manufacturer.

Follow the appliance manufacturer’s specifi cations for the

required pump outlet pressure for the nozzle, since this

affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates at

y

100 psig.

When pump pressures are higher than 100 psig, the

y

actual nozzle fl ow rate will be greater than the gph

stamped on the nozzle body. (Example: A 1.00 gph

nozzle at 140 psig = 1.18 gph)

Securely tighten the nozzle (90 torque inch pounds). For typical

nozzle fl ow rates at various pressures refer to Table 2.

If the nozzle is already installed, remove the nozzle

3.

line assembly to verify that the nozzle size and spray

pattern are correct for the application (per equipment

manufacturer’s information). Verify that the electrode

tip settings comply with Figure 3.

Use care when removing or

installing an oil nozzle

A damaged nozzle could cause impaired combustion,

sooting, puffback of hot gases, oil leakage and

potential fi re or asphyxiation hazards.

Inspect the nozzle adapter to insure that the sealing

y

surface is not grooved or scratched.

To insure that the nozzle functions properly, check the

y

orifi ce and strainer for dirt, scratches or other damage

before installation.

Do NOT attempt to install or remove a nozzle without

y

securing the adapter to prevent seriously damaging

the alignment.

Use care when handling the nozzle line assembly

y

to prevent changing the electrode tip settings or

damaging the ceramic electrode insulators.

Ensure the electrode settings match the values shown

y

in Figure 3.

B. Check/Adjust Electrodes

Check the electrode tip settings. Adjust if necessary

to comply with the dimensions shown in Figure 3. To

adjust, loosen the electrode clamp screw and slide/rotate

electrodes as necessary. Securely tighten the clamp

screw when fi nished.

Figure 2. Nozzle, Line & Electrode Assembly

Contacts to be parallel with

Electrode gap to be centered

with nozzle center.

horizontal center line within 2°.

Figure 3. Electrode Tip Setting

5/32” GAP

1/4” ABOVE

CENTER

1/8” NOZZLE-TO-TIP

SPACING

6

8

1

11

10

9

4

Item # Description

1 Electrode Contact (3” ATC or extension over 3”)

2 Nozzle Line

3 Spider spacer assembly

4 Static Plate

5 Electrode clamp

6 Electrode clamp retaining screws

7 Nozzle line setscrew

8 Electrode Insulator

9 Nozzle adapter

10 Nozzle tip

11 Electrode tip

2

7

Air Tube Length Dimension ‘S’

2-5/8” to 3” 1-3/8”

3-5/8” to 4-1/2” 1-5/8”

over 4-7/8” 2-13/32”

90°

3

5

4

24 Vdc SDC Burner Manual

5

Loading...

Loading...