Page 1

BECKETT CLEANCUT

INSTALLATION INFORMATION

2-2-STAGE

FUEL UNIT

Part No. 21941

SINGLE STAGE

FUEL UNIT

Part No. 21844

!

BECKETT CLEANCUT

SINGLE STAGE

Part No. 21844

FUEL UNIT

INSTALLATION INFORMATION

GENERATION INFORMATION - ALL SYSTEMS

IMPORTANT INFORMATION Long or oversized inlet lines may

require the pump to operate dry during initial bleeding period. In

such cases, the priming may be assisted by injecting fuel oil in

the pump gearset. Under lift conditions, lines and fi ttings must be

air tight. To assure this, oil-resistant pipe joint compound may be

applied to both the used and unused inlet and both return fi ttings.

WARNING

!

Incorrect installation, adjustment, or mis-

use of this burner could result in severe

personal injury, death, or substantial property damage from fi re, carbon monoxide

poisoning, soot or explosion.

Please read and understand the manual supplied with this equip-

ment. This equipment must be installed, adjusted and put into

operation only by a qualifi ed individual or service agency that is:

y

Licensed or certifi ed to install and provide technical service

to oil heating systems.

y

Experienced with all applicable codes, standards and ordinances.

y

Responsible for the correct installation and commission of

this equipment.

y

Skilled in the adjustment of oil burners using combustion

test instruments.

The installation must strictly comply with all applicable codes,

authorities having jurisdiction and the latest revision of the National Fire Protection Association Standard for the installation of

Oil-burning Equipment, NFPA 31 (or CSA-B139 and CSA-B140

in Canada).

Regulation by these authorities take precedence over the general

instructions provided in this installation manual.

Professional Service Re-

quired

!

CAUTION

STAGE

This pump must be used with

a controlling device that pro-

FUEL UNIT

Part No. 21941

vides a valve on delay (pre-purge).

Beckett

INLET

USE ONLY WITH

VALVE ON DELAY

A2EA-6520

4 GPH 100-150 PSI 3450 RPM

NO. 2 & LIGHTER FUEL

3 GPH 150-200 PSI 3450 RPM

NO. 2 FUEL

BY-PASS

INLET

Made by Suntec

Exclusively for Beckett

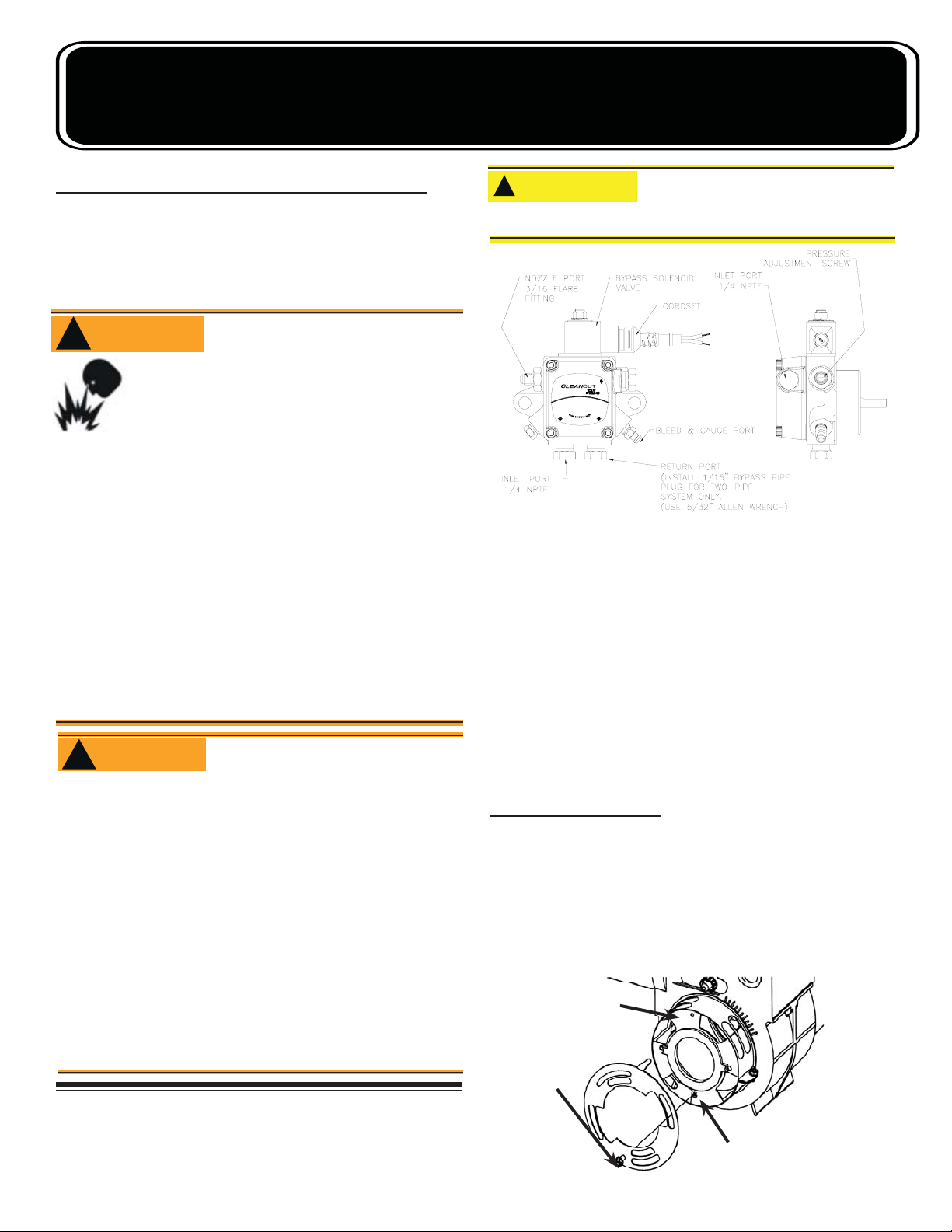

Figure 1

FIGURE 1

MOUNTING POSITION Beckett CleanCut fuel unit may be

mounted in any position (except upside-down during single pipe

installation).

VACUUM CHECK A Vacuum Gauge may be installed in either

of the 1/4” NPT inlet ports. The Beckett CleanCut pump should

be used where the vacuum does not exceed 6” hg. single pipe

and 12” hg. two pipe. The Beckett CleanCut XL pump should be

used where the vacuum is less than 17” hg. Remember, running

vacuum is the total of all pressure drops (eP) in the system from

tank to inlet of pump.

PRESSURE CHECK When a pressure check is made use either

the BLEED PORT OR NOZZLE PORT.

WARNING

!

y

The inlet and return line pressures must not exceed 3 psig,

or pump seal damage and oil leaks could result! See NFP A

31-25, 8.6.3.

y

Do not use a check valve in the inlet line of a 1-pipe system

(with or w/o a boost pump), or in the return line of a 2-pipe

system.

y

NFPA 31-25, 8.5 states that ‘A return line from a burner or

pump to a supply line shall have no valves or obstructions

and shall enter the top of the same tank.’

y

Check valve fl ow restriction in a return line can elevate

pressures and damage the fuel unit seals.

y

Dangerous thermal expansion of oil trapped by an inlet

line check valve can create extreme pressures that damage

fuel unit seals, line fi ttings, inlet fi lters, gauges and other

components. A properly installed vacuum safety valve, such

as Suntec PRV-38, having accumulator ef fect and pressure

relief to tank is acceptable in the inlet line.

Do not use tefl on tape or compression fi ttings.

y

Oil Leak & Fire Hazard

R.W. BECKETT CORPORATION

U.S.A.: P.O. Box 1289 · Elyria, Ohio 44036

Canada: R.W. Beckett Canada, Ltd. · Unit #3, 430 Laird Road · Guelph,

Ontario N1G 3X7

Form Number 61583 R07 © 2007 R.W. Beckett Corporation 10/07

CUTOFF CHECK To check cutoff pressure, dead head a pressure gauge in nozzle port. Run burner for short period of time.

Shut burner off. The pressure will drop and hold above zero.

MOUNTING PUMP (If the shutter screw interferes

with the solenoid on the fuel unit)

To install a CleanCut fuel unit on chassis with existing shutter tab

see Figure 2 and follow these steps:

Remove existing fuel unit and solenoid valves, if applicable, and

appropriately dispose of them.

Note the air setting of the shutter, then remove the air shutter, set

the shutter aside to be reinstalled.

DO NOT INSTALL

THE TOP SHUTTER

SCREW IF IT INTER-

FERES WITH THE

SOLENOID ON THE

FUEL UNIT.

LOWER SHUT-

TER SCREW

O

O

SHUTTER TAB

(REMOVE)

Figure 2

Page 2

Remove the shutter tab by using a pair of side cutter pliers and

fi le sharp edges fl ush with burner surface. This will permit the

shutter to be locked securely.

Install the air shutter using the screw located below the pump.

Adjust the shutter to the original air setting and tighten screw

securely.

NOTICE

screw, it will interfere with the solenoid on the fuel unit.

To install a CleanCut fuel unit on a housing that has two top shut-

ter mounting screw holes, make sure the screw is installed in the

hole on the left that is closest to the front of the burner (air tube

side).

Other Mounting Installations: The CleanCut Pump with a

standard cord set or a PD Timer can be installed on the following

burners: Carlin EZ-1, Wayne ’M’, Wayne ’E’, Wayne ’HS’, Ducane

’DM’, or Aero.

Ducane ’DR’: 5/16” diameter hole will have to be drilled into the

housing through the wire cavity.

Weil ’QB’: The valve coil blocks the air shutter screw. Allow

enough slack in the cord set in order to pivot the valve coil away

from the housing.

On older burners, do not install the top shutter

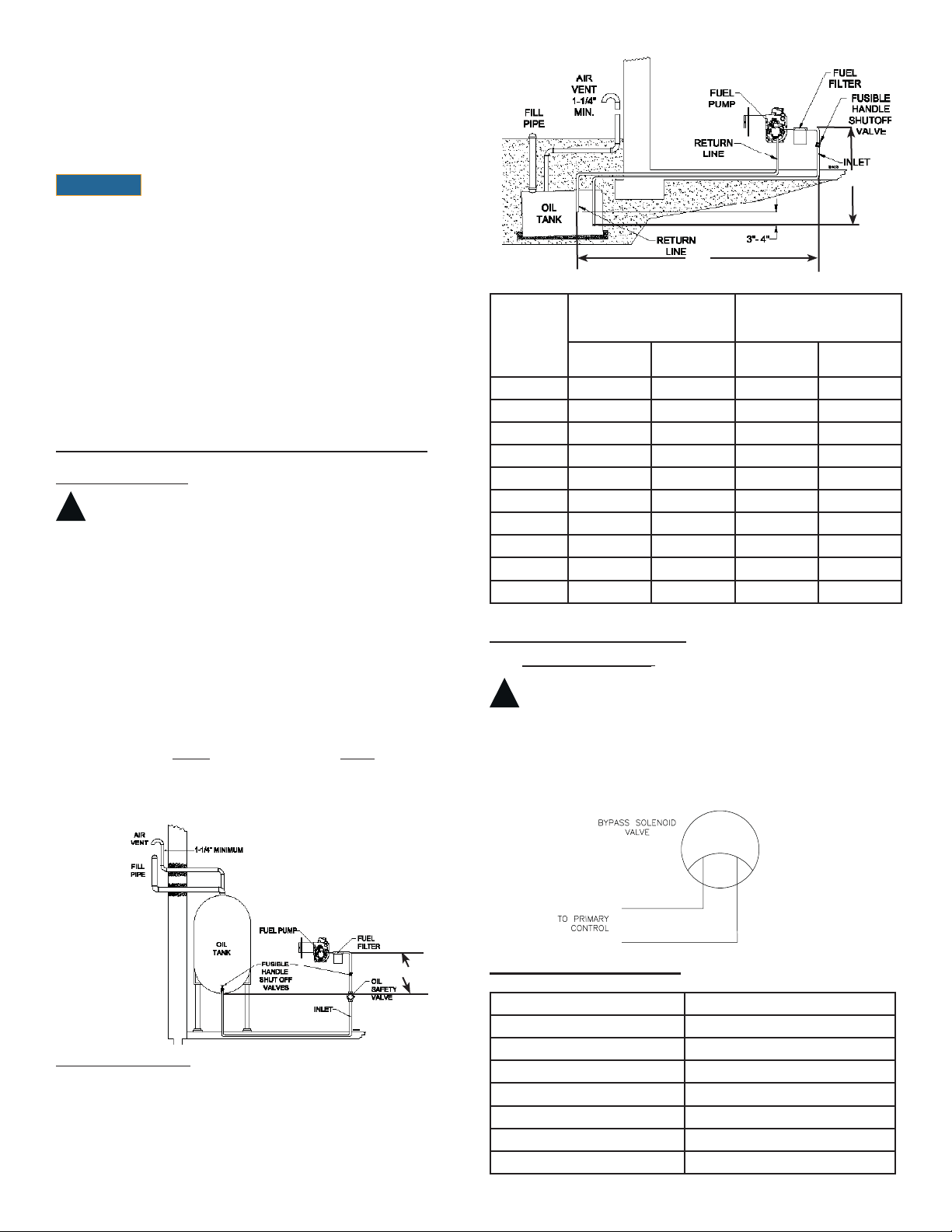

SYSTEM INSTALLATION REQUIREMENTS

ONE-PIPE SYSTEM

!

DO NOT Install bypass plug - the shaft seal will rupture!

Connect inlet line to pump inlet. Start burner. Arrange primary

burner control for continuous operation during purging. Open

bleed valve 1 turn CCW. Bleed unit until all air bubbles disappear. Notice: Hurried bleeding will impair effi cient operation of

unit. Tighten bleed valve securely.

The Clean Cut fuel unit may be installed with a Gravity or Lift Oil

Supply System. The maximum allowable lift is 8 ft.

IMPORTANT: One pipe installations must be absolutely air tight

or leaks or loss of prime may result. Bleed line and fuel unit

completely. Bleed for 15 seconds after last air is seen from bleed

/ gauge port to be certain lines are air free.

L = line Length in Feet H = Head in Feet Q = Firing rate in GPH

3/8” Line L = *6-.75H 1/2” Line L = *6-.75H

.0086Q .00218 Q

* If tank is above pump, change – to +. Fittings, valves and fi lters

will reduce total length allowed.

‘H’

Figure 4

Lift - ‘H’ in

Figure 4

(ft)

0 84’ 100’ 93’ 100’

2 73’ 100’ 85’ 100’

4 63’ 100’ 77’ 100’

6 52’ 100’ 69’ 100’

8 42’ 100’ 60’ 100’

10 31’ 100’ 52’ 100’

12 21’ 83’ 44’ 100’

14 - 41’ 36’ 100’

16 - - 27’ 100’

18 - - - 76’

Run - ‘R’ in Figure 4

Single Stage Pump

(4GPH)

3/8” OD

tubing

‘R’

1/2” OD

tubing

Run - ‘R’ in Figure 4

Two-Stage XL Pump

(4GPH)

3/8” OD

tubing

SK9859

1/2” OD

tubing

WIRING INSTRUCTIONS

SOLENOID WIRING

Disconnect power supply before wiring to prevent elec-

!

trical shock or equipment damage.

Lead wires on these devices are long enough to reach the junction box on most burner installations. Note: check the burner

manufacturer’s installation sheets for correct solenoid wiring.

(See Figure 5). All electrical work must be done according to local and national codes. (Solenoid 115V, 0.1 amp, 60 HZ)

MAXIMUM 1 PIPE (H)

LIFT: 8FT

Figure 3

SK9858

TWO-PIPE SYSTEM

Remove 1/16” pipe bypass plug from plastic bag attached to unit.

Remove 1/4” plug from return port. Insert by-pass plug. Attach

return and inlet lines. Start burner – Air bleeding is automatic.

Opening air bleed valve will allow a faster bleed if desired. Return line must terminate 3-4” above supply line inlet. Failure to

do this may introduce air into the system and could result in the

loss of prime.

VIOLET

WHITE

REPLACEMENT PARTS

Item Beckett Part Number

Strainer/Gasket 51974U

Valve stem 21877U

Valve Coil (115vAC) 21755U

Valve Coil (220/240vAC) 21756U

Valve Coil (12vDC/24vAC) 21754U

PD Timer 21887U

Valve Cord Set 21807

Figure 5

Loading...

Loading...