Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

0602-20

0612-20

To extend battery pack life:

Follow the "BATTERY PACK CARE AND USE" section of

this manual.

Charge battery packs before use.

Follow the charging instructions in your charger manual.

Pour étendre la durée de vie de la batterie:

Suivre les instructions de la section «UTILISATION ET

ENTRETIEN DE LA BATTERIE» de ce manuel.

Charger les batteries avant de les utiliser.

Suivre les instructions de charge du manuel du chargeur.

Para extender la duración de la batería:

Seguir la sección USO Y CUIDADO DE LA BATERÍA en

este manual.

Cargar las baterías antes de usarlas.

Seguir las instrucciones de carga en el manual del cargador.

12 AND 14.4 V DRIVER DRILLS

PERCEUSE ÉLECTRIQUE DE 12 ET 14,4 V

TALADRO DE 12 Y 14,4 V

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET

BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

Page 2

GENERAL SAFETY RULES-FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fire

and/or serious injury. The term "power tool" in all of the warnings listed

below refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

SAVE THESE INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the

dust or fumes.

3. Keep children and bystanders

away while operating a power

tool. Distractions can cause you to

lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

5. Avoid body contact with earthed

or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is

earthed or grounded.

6. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

7. Do not abuse the cord. Never use

the cord for carrying, pulling, or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges, or moving parts. Damaged

or entangled cords increase the risk

of electric shock.

8. When operating a power tool out-

doors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the

risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence

of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious personal injury.

10. Use safety equipment. Always

wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

11. Avoid accidental starting. Ensure

the switch is in the off-position

before plugging in. Carrying tools

with your finger on the switch or plugging in power tools that have the

switch on invites accidents.

12. Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

13. Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

32

Page 3

14. Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away

from moving parts. Loose clothes,

jewellery, or long hair can be caught in

moving parts.

15. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dustrelated hazards.

POWER TOOL USE AND CARE

16. Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

17. Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

18. Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting

the tool accidentally.

19. Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tools or these instructions

to operate power tools. Power

tools are dangerous in the hands of

untrained users.

20. Maintain power tools. Check for

misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool's operation. If

damaged, have the power tool

repaired before use. Many acci-

dents are caused by poorly maintained

power tools.

21. Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

likely to bind and are easier to control.

22. Use the power tool, accessories

and tool bits etc., in accordance

with these instructions and in the

manner intended for the particular type of power tool, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

23. Ensure the switch is in the off

position before inserting battery

pack. Inserting the battery pack into

power tools that have the switch on

invites accidents.

24. Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type of

battery pack may create a risk of fire

when used with another battery pack.

25. Use power tools only with spe-

cifically designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

26. When battery pack is not in use,

keep it away from other metal

objects like paper clips, coins,

keys, nails, screws, or other

small metal objects that can make

a connection from one terminal

to another. Shorting the battery ter-

minals together may cause burns or a

fire.

27. Under abusive conditions, liquid

may be ejected from the battery,

avoid contact. If contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally

seek medical help. Liquid ejected

from the battery may cause irritation

or burns.

SERVICE

28. Have your power tool serviced by

a qualified repair person using

only identical replacement parts.

This will ensure that the safety of the

power tool is maintained.

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates. These carry important information. If unreadable

or missing, contact a MILWAUKEE service facility for a free replacement.

2. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry products, and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

3. Use auxiliary handles supplied with the tool. Loss of control can cause per-

sonal injury.

4. Wear ear protectors with impact drills. Exposure to noise can cause hearing

loss.

5. Hold power tools by insulated gripping surfaces when performing an op-

eration where the cutting tool may contact hidden wiring or its own cord.

Contact with a live wire will make exposed metal parts of the tool live and shock

the operator.

6. Keep hands away from all cutting edges and moving parts.

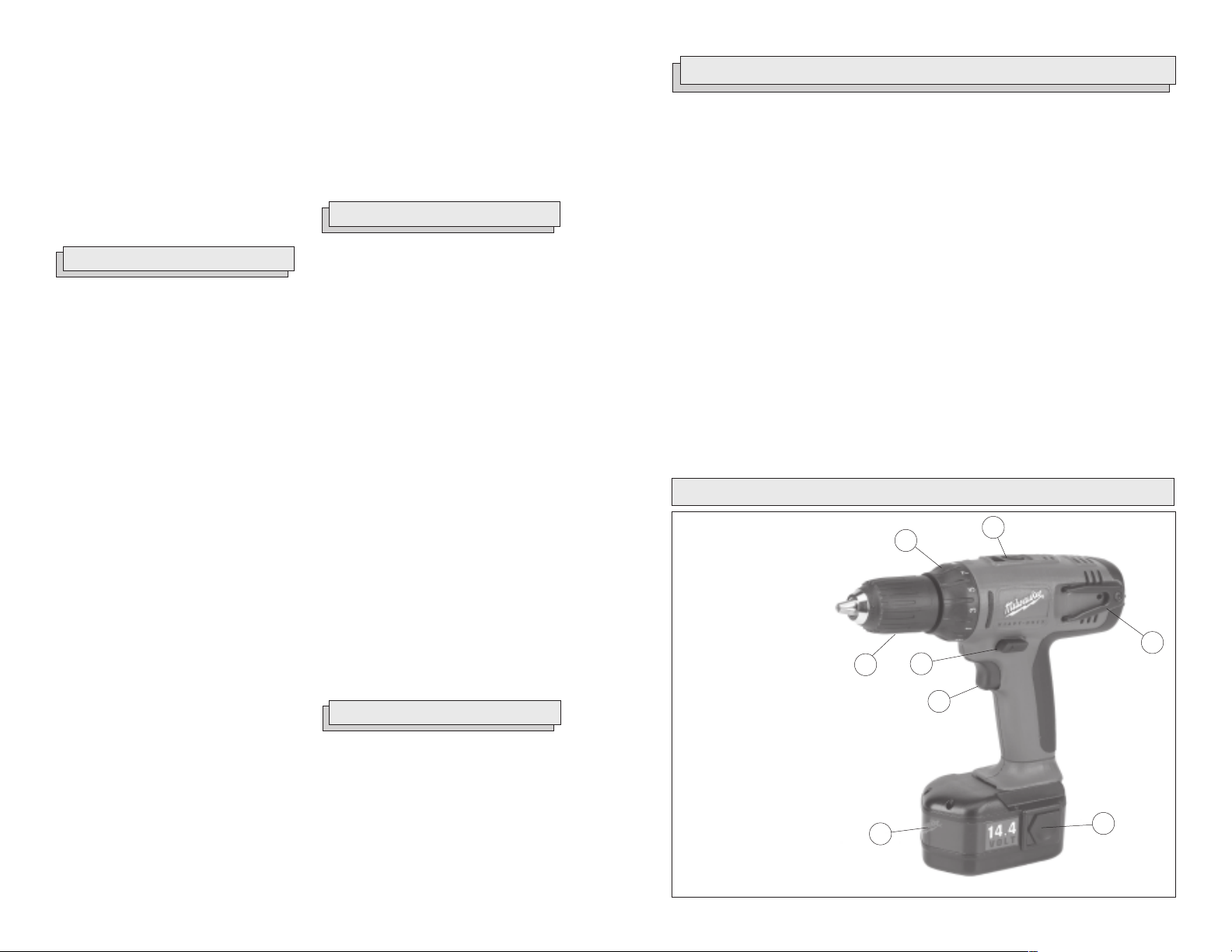

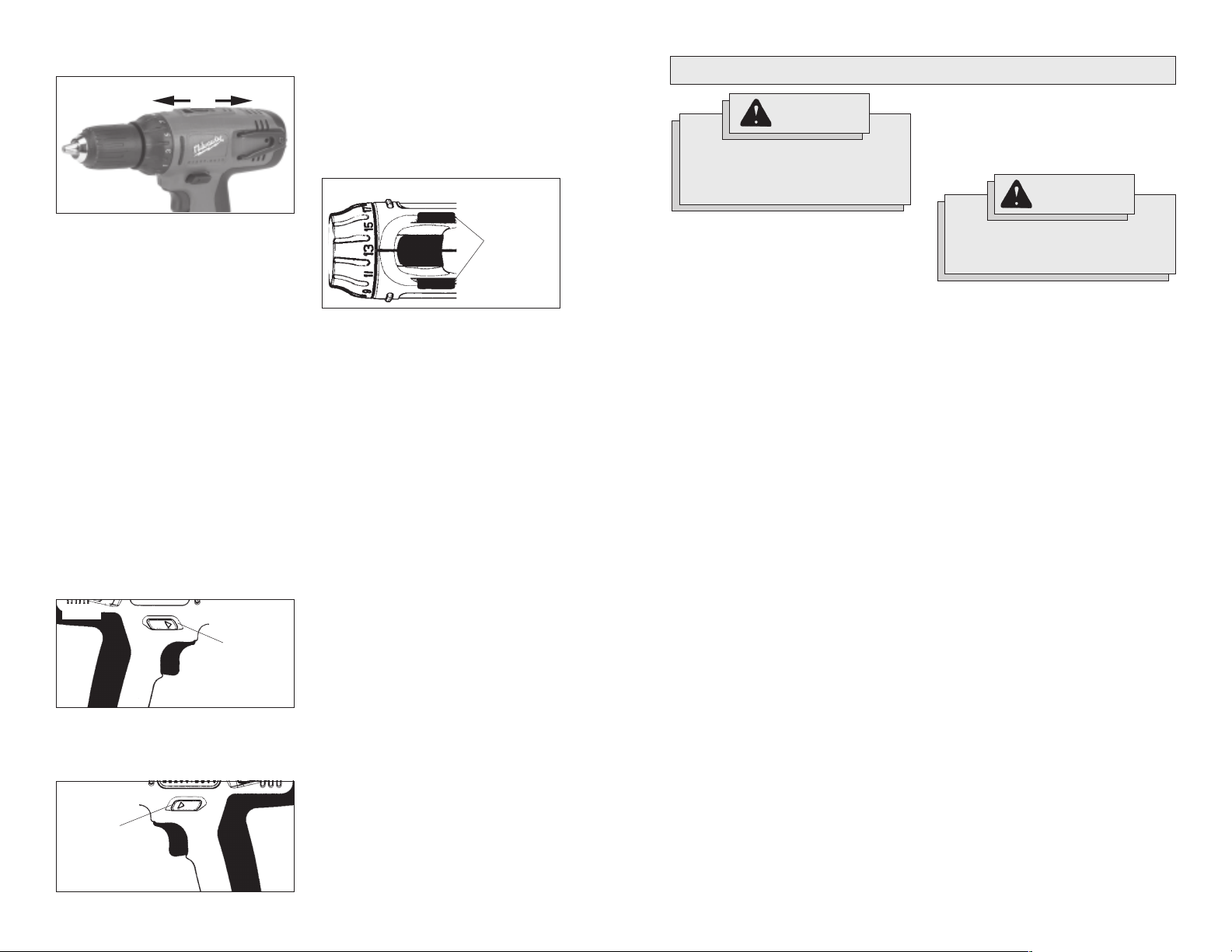

FUNCTIONAL DESCRIPTION

1

2

3

1. Speed selector

2. Tool holder

3. Battery latch

4. Battery pack

5. Trigger

6. Control switch

7. Keyless chuck

8. Torque selector collar

8

7

6

5

4

54

Page 4

Symbology

Properly Recycle

Nickel Cadmium

Batteries

Direct Current

Underwriters

Laboratories, Inc.

No Load Revolutions

per Minute (RPM)

Cat. No.

0602-20

0612-20

Specifications

Volts DC

12

14.4

No Load RPM

Low 0 - 400

High 0 - 1400

Low 0 - 400

High 0 - 1400

Capacities

Cat. No.

0602-20

0612-20

Steel

3/8"

1/2"

High Speed

Flat Bit in

Wood

7/8"

1"

Hole Saw

in Wood

1-1/4"

1-3/4"

Pathfinder

Bit

7/8"

1-1/4"

Steel

3/8"

1/2"

Low Speed

Auger Bit

in Wood

1"

1-1/8"

Screws (dia.)

in Wood

1/4"

1/4"

BATTERY PACK CARE AND USE

EXTENDING AND MAINTAINING

BATTERY PACK LIFE

MILWAUKEE battery packs will operate for many years and/or hundreds of cycles when

they are used, charged, and stored according to these instructions. Properly using,

charging, and storing your battery pack can greatly extend its life.

Charge the new battery pack

overnight before use to allow

the cells to become fully

charged. New battery packs are not fully

charged. Two to ten normal charging/

discharging cycles may be required before the pack can take its maximum charge.

Never completely discharge

the battery pack. MILWAUKEE

battery packs do not develop a

"memory" when charged after only a partial discharge. Taping-on triggers or leaving work lights on for extended periods

to completely discharge the battery pack

will reduce its life by upsetting the electrochemical balance and can result in shortcircuiting of the battery.

Do not charge batteries in hot

or cold places (below 40°F (5°C)

or above 105°F (40°C)). Temperature

extremes reduce the ability for battery pack

cells to hold a charge. Do not store batter-

ies where the temperature may exceed

120°F (50°C), such as in a vehicle or metal

building during the summer.

To avoid overheating to a battery pack,

allow cordless tools cool down between high torque drilling/cutting

applications. The increased energy dis-

charge rate will heat the battery pack cells

faster than the cells can release the heat.

This could damage the cells.

After use, allow a hot battery pack to

cool to room temperature before inserting

it into the charger. If a hot battery is put on

a charger, charging will not begin until the

battery has cooled to a safe temperature.

See your charger manual for more information on charging temperatures. Charging a hot battery will damage the cells.

Never forcibly heat up or cool down

batteries. This will damage some cells in

the pack, causing them to not be able to hold

a charge.

Remove the battery pack from the tool

for charging when the tool can no

longer perform its intended function

(i.e., drilling, cutting, etc.).

Leave the battery pack on the

charger after it has reached a full

charge; the pack will continue to re-

ceive a trickle charge to ensure capacity

is maintained.

Occasionally (once a week) leave the

batteries on the charger overnight to

help maintain cell balance.

Do not store the battery on the

charger (for more than 24 hours); this

could reduce battery life.

Never leave batteries on chargers

where power interruptions are common. Damage to the battery cells could

occur.

Store batteries at room temperature away from moisture.

Do not store in damp locations

where corrosion of terminals may occur.

Do not submerge your battery or cordless tools in water. This will damage the

battery and tool.

Charge unused batteries overnight

at least every six months to maximize

battery life. Unused batteries discharge

at a rate of about 1% per day and will be

fully discharged after six months. For batteries stored for a long time, two to ten

normal charging cycles may be required

before the pack is fully charged.

Do not use oil or solvents to clean or

lubricate your battery pack. The plastic

casing will become brittle and crack, causing a risk of injury.

WARNING!

Charge only MILWAUKEE 12, 14.4

and 18 Volt battery packs in

MILWAUKEE chargers. Other

brands of batteries may explode

causing personal injury and

damage.

For specific charging instructions, please read the operator's

manual supplied with your

charger.

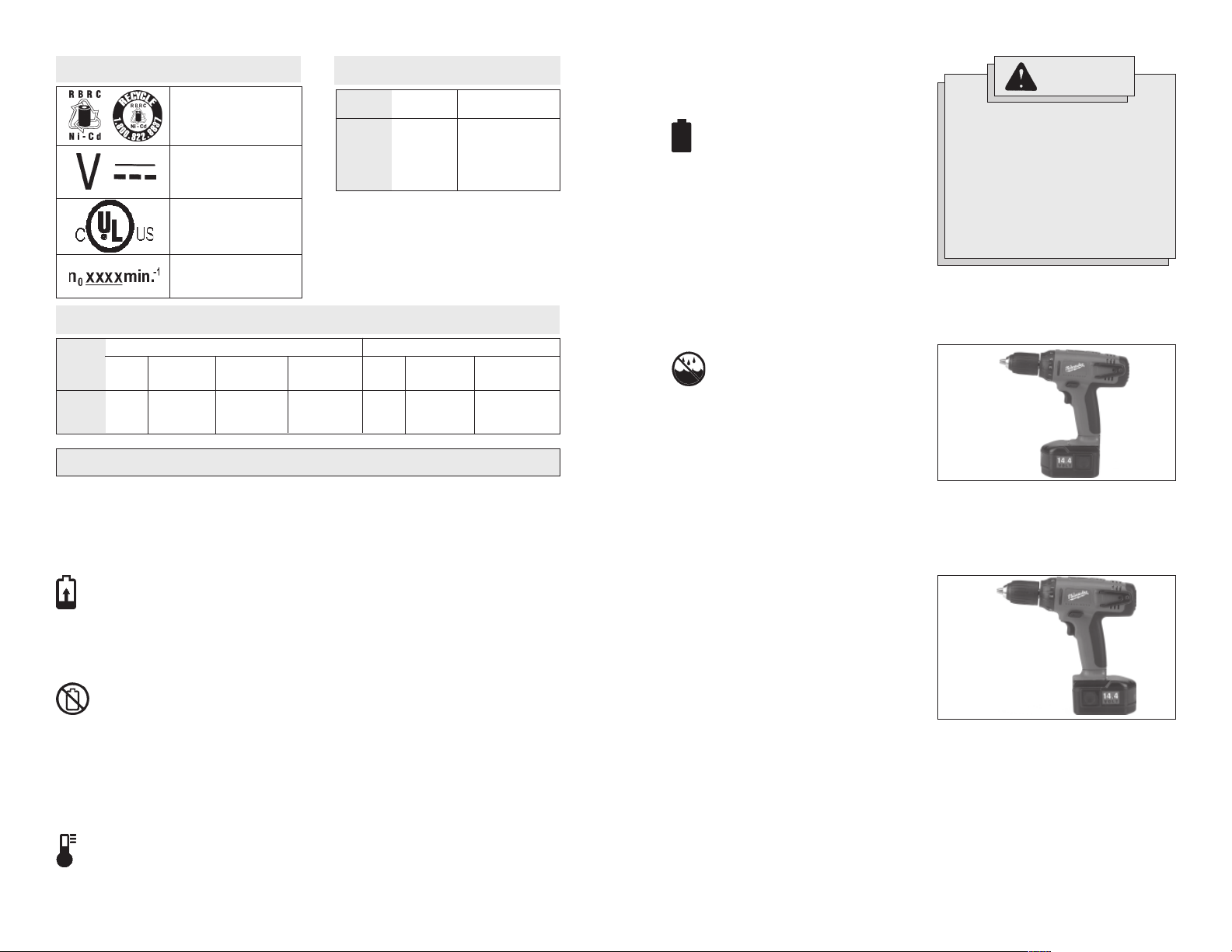

Inserting Battery Pack onto Tool

(Fig. 1 & 2)

Battery pack can be inserted onto the tool

in two ways.

Fig. 1

1. For working in restricted spaces.

Insert the battery pack from the front

by sliding battery pack onto the body

of the tool. Insert the battery pack until

the battery latches lock.

Fig. 2

2. For optimum weight distribution and

balance.

Insert the battery pack from the back

by sliding the battery pack onto the

body of the tool. Insert the battery pack

until the battery latches lock.

3. To remove the battery pack, press in

both battery latches and slide the battery pack off of the tool.

76

Page 5

ASSEMBLY

OPERATION

WARNING!

Always remove battery pack

before changing or removing accessories. Only use accessories

specifically recommended for this

tool. Others may be hazardous.

Clip-Lok

The Clip-Lok system consists of three

pieces; the belt clip, the tool holder, and the

bit holder.

The system is shipped assembled for righthanded use. To change the assembly for

left-handed use:

1. Remove battery pack.

2. Remove screws holding the tool holder

3. Lift the holders at the narrow end and

4. Replace the pieces onto the desired

TM

System (Fig. 3 & 4)

Fig. 3

and the bit holder.

pull the front tangs out of their slots.

side by sliding the tangs into the slots.

Tighten the screws securely.

Belt clip

Tool holder

Front tangs

Bit holder

Attaching the Belt Clip (Fig. 4)

Fig. 4

Stud

Pin

Tool

release lever

The belt clip can be mounted to tool belts,

bags, buckets, etc. To mount the belt clip:

1. Push and hold the clamp release lever.

2. Pull out the clamp at the back of the

belt clip and release the clamp release

lever.

3. Slide the clamp over the desired tool

belt, bag, bucket, etc.

4. Press in the clamp to achieve the desired tightness.

Using the Clip-Lok Tool Holder

1. To attach the tool to the belt clip, slide

the tool holder over the stud on the

belt clip until it is held in place by the

protruding pin.

2. To release the tool from the belt clip,

grasp the tool handle, push down on

the tool release lever with your thumb,

and pull up on the tool.

Using the Clip-Lok Bit Holder

The bit holder holds two standard 1/4" hex

shank bits up to two inches long.

1. Insert the bit by pressing it into the

clip.

2. Remove the bit by lifting the tip of the

bit and pulling it out of the clip.

Clamp release

lever

Clamp

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields.

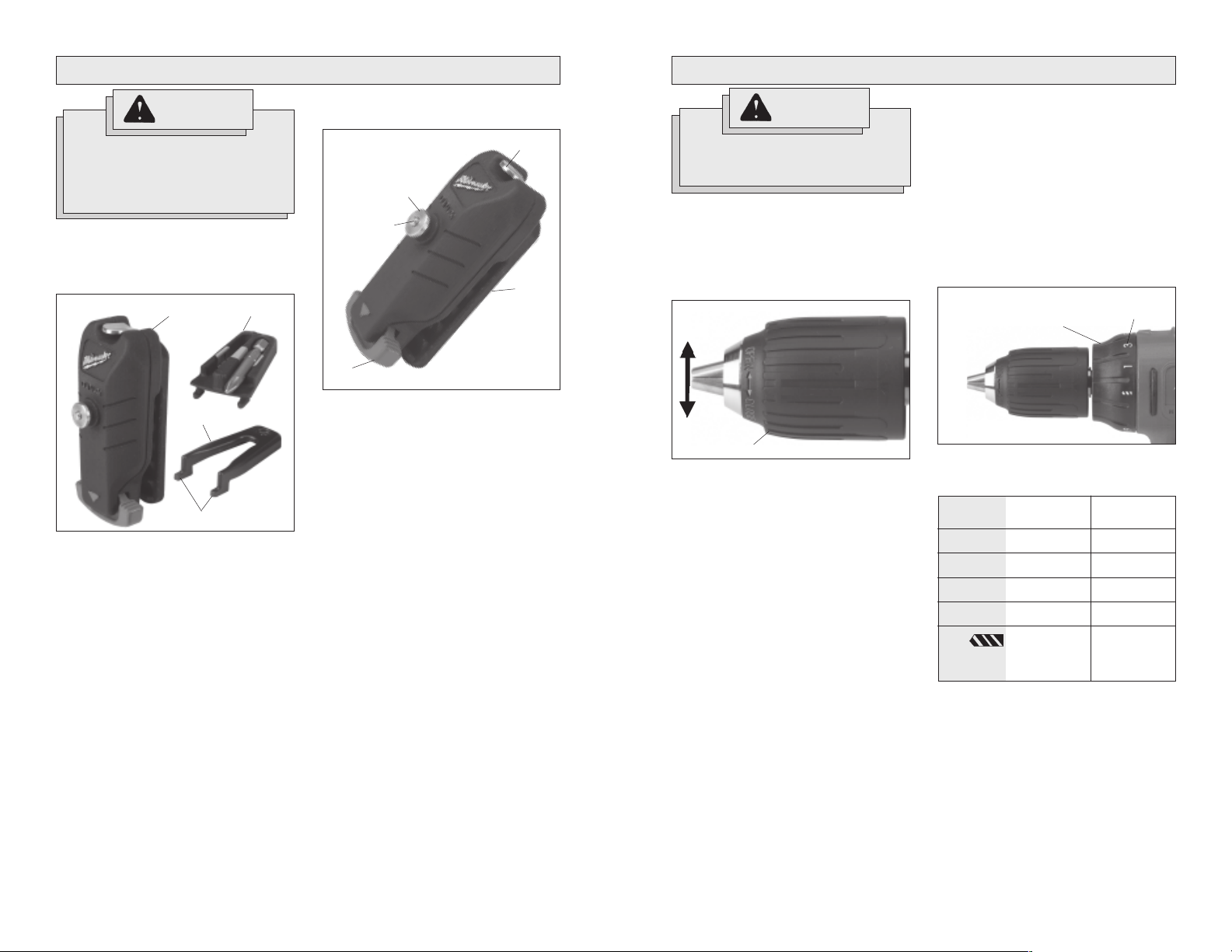

Using Keyless Chucks (Fig. 5)

Your cordless tool is equipped with a spindle

lock that allows the chuck to be tightened

with one hand.

Always remove the battery pack or lock

the trigger before inserting or removing bits.

Fig. 5

Open

Close

Sleeve

1. To open the chuck jaws, turn the sleeve

in the "OPEN" direction indicated on

the chuck.

When using drill bits, allow the bit to

strike the bottom of the chuck. Center

the bit in the chuck jaws and lift it about

1/16" off of the bottom.

When using screwdriver bits, insert

the bit far enough for the chuck jaws

to grip the hex of the bit.

2. To close the chuck jaws, turn the

sleeve in the "CLOSE" direction indicated on the chuck. The bit is secure

when the chuck makes a ratcheting

sound and the sleeve can not be rotated any further.

NOTE: A ratcheting sound may be heard

when the chuck is opened or closed. This

noise is part of the locking feature, and

does not indicate a problem with the chuck's

operation.

Using Clutch (Fig. 6)

This tool has an adjustable clutch for driving different types of screws into different materials. When properly adjusted, the

clutch will slip at a preset torque to prevent driving the screw too deep and to

prevent damage to the screw or tool.

To adjust the clutch, turn the torque selector collar to one of the twenty positions

shown on the collar. The number must line

up with the arrow on top of the tool.

Fig. 6

The torque specifications shown here are

approximate values obtained with a fully

charged battery pack.

Positions

1 - 5

6 - 10

11 - 15

16 - 20

Drill

Low

High

NOTE: Because the above settings are only

a guide, use a piece of scrap material to

test the different clutch positions before

driving screws into the workpiece.

Torque

selector

collar

0602-20

Torque

0 - 10 in. lbs.

12 - 21 in. lbs.

24 - 32 in. lbs.

35 - 44 in. lbs.

280 in. lbs.

80 in. lbs.

Position

numbers

0612-20

Torque

0 - 10 in. lbs.

12 - 21 in. lbs.

24 - 32 in. lbs.

35 - 44 in. lbs.

390 in. lbs

100 in. lbs.

98

Page 6

Selecting Speed (Fig. 7)

Fig. 7

High

Low

To lock the trigger, push the control switch

to the center position (Fig. 10). The trigger

will not work while the control switch is in

the center locked position. Always lock the

trigger or remove the battery pack before

performing maintenance, changing accessories, storing the tool and any time the

tool is not in use.

Fig. 10

APPLICATIONS

WARNING!

To reduce the risk of electric

shock, check work area for hidden

pipes and wires before drilling or

driving screws.

Overloading

Continuous overloading may cause permanent damage to tool or battery pack.

WARNING!

The speed selector is on top of the motor

housing. Allow the tool to come to a complete stop before changing speeds. See

Applications for recommended speeds

under various conditions.

1. For Low speed (up to 400 RPM), push

the speed selector back, displaying the

"1" for low.

2. For High speed (up to 1400 RPM), push

the speed selector forward, displaying the "2" for high.

Using Control Switch (Fig. 8, 9 and 10)

The control switch may be set to three

positions: forward, reverse and lock. Due

to a lockout mechanism, the control switch

can only be adjusted when the ON/OFF

switch is not depressed. Always allow the

motor to come to a complete stop before

using the control switch.

For forward (clockwise) rotation, push in

the control switch from the right side of the

tool (Fig. 8). Check the direction of rota-

tion before use.

Fig. 8

Push in

for forward

For reverse (counterclockwise) rotation,

push in the control switch from the left

side of the tool (Fig. 9). Check direction

of rotation before use.

Fig. 9

Push to

center

position to

lock trigger

Starting, Stopping & Controlling

Speed

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger

and an electric brake stops the tool

instantly.

All models feature variable speed control.

To vary the speed, increase or decrease

pressure on the trigger. The further the

trigger is pulled, the greater the speed.

Drilling

Set the torque selector collar to the drill

position

Place the bit on the work surface and apply firm pressure before starting. Too much

pressure will slow the bit and reduce drilling efficiency. Too little pressure will cause

the bit to slide over the work area and dull

the point of the bit.

If the tool begins to stall, reduce pressure

slightly to allow the bit to regain speed. If

the bit binds, reverse the motor to free the

bit from the workpiece.

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill slowly, gradually increasing speed as you drill. When

drilling into wood, use wood augers or

twist drill bits. Always use sharp bits.

When using twist drill bits, pull the bit out of

the hole frequently to clear chips from the

bit flutes. To reduce the chance of splintering, back work with a piece of scrap

wood. Select low speeds for plastics with

a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel

twist drills or hole saws. Use a center

punch to start the hole. Lubricate drill bits

with cutting oil when drilling in iron or steel.

Use a coolant when drilling in nonferrous

metals such as copper, brass or aluminum.

Back the material to prevent binding and

distortion on breakthrough.

Driving Screws and Nut Running

Drill a pilot hole when driving screws into

thick or hard materials. Set the torque selector collar to the proper position and set

the speed to low. Use the proper style and

size screwdriver bit for the type of screw

you are using.

With the screwdriver bit in the screw, place

the tip of the screw on the workpiece and

apply firm pressure before pulling the trigger. Screws can be removed by reversing

the motor.

High rotational force. To reduce

the risk of injury, always hold or

brace securely.

Bit Binding

A high rotational force occurs when a bit

binds. If the bit binds, the tool will be forced

in the opposite direction of the bit rotation.

Bits may bind if they are misaligned or when

they are breaking through a hole. Wood

boring bits can also bind if they run into

nails or knots. Be prepared for bit binding

situations.

To reduce the chance of bit binding:

Use sharp bits. Sharp bits are less

likely to bind when drilling.

Use the proper bit for the job. There

are bits that are designed for specific

purposes.

Use caution when drilling pitchy,

knotty, wet or warped material or

when drilling in material that may contain nails, screws, staples, etc.

Push in

for reverse

1110

Page 7

MAINTENANCE

WARNING!

To reduce the risk of personal

injury, always unplug the charger

and remove the battery pack from

the charger or tool before performing any maintenance. Never

disassemble the tool, battery

pack or charger. Contact a

MILWAUKEE service facility for

ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger

in good repair by adopting a regular maintenance program. After six months to one

year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE

service facility for:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

Electrical inspection (battery pack,

charger, motor)

Testing to assure proper mechanical

and electrical operation

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack to a

MILWAUKEE service facility for repairs.

Maintaining Battery Pack

MILWAUKEE battery packs will operate

for many years and/or hundreds of cycles

when they are maintained and used according to these instructions.

A battery pack that is stored for six months

without being used will discharge itself.

Batteries discharge at a rate of about 1%

per day. Charge the battery every six

months even if it is unused to maximize

battery life. Do not tape the trigger in the

ON position and leave the tool unattended

as this may discharge the battery to a point

where it will no longer be able to recharge.

Use a MILWAUKEE battery pack only until

it no longer performs with the power and

torque needed for your application.

Store your battery pack in a cool, dry place.

Do not store it where the temperature may

exceed 120°F (50°C) such as in a vehicle

or metal building during the summer. High

temperatures will overheat the battery pack,

reducing battery life. If it is stored for several months, the battery pack will gradually lose its charge. One to three cycles of

charging and discharging through normal

use will restore the capacity of the battery

pack. During the life of the battery pack,

the operating time between charges becomes shorter. If the operating time becomes extremely short after a proper

charge, the usable life of the battery pack

has been reached and it should be replaced.

WARNING!

To reduce the risk of personal

injury and damage, never

immerse your tool, battery pack

or charger in liquid or allow a liquid

to flow inside them.

Cleaning

Clean dust and debris from charger and

tool vents. Keep tool handles clean, dry and

free of oil or grease. Use only mild soap and

a damp cloth to clean the tool, battery pack

and charger since certain cleaning agents

and solvents are harmful to plastics and

other insulated parts. Some of these include gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

WARNING!

To reduce the risk of explosion,

never burn a battery pack even if

it is damaged, dead or completely

discharged.

RBRC Battery Recycling Seals

The RBRC Battery Recycling Seals (see

"Symbology") on your tool battery packs indicate that MILWAUKEE has arranged for

the recycling of that battery pack with the

Rechargeable Battery Recycling Corporation

(RBRC). At the end of your battery pack's

useful life, return the battery pack to a

MILWAUKEE Branch Office/Service Center

or the participating retailer nearest you. For

more information, visit the RBRC web site at

www.rbrc.org.

Disposing of Nickel-Cadmium Battery

Packs

Nickel-Cadmium battery packs are recyclable. Under various state and local laws,

it may be illegal to dispose of this battery

into the municipal waste stream. Dispose

of your battery pack according to federal,

state and local regulations.

Repairs

For repairs, return the tool, battery pack

and charger to the nearest service center

listed on the back cover of this operator's

manual.

Battery Pack Warranty

Battery packs for cordless tools are warranted

for one year from the date of purchase.

ACCESSORIES

WARNING!

Always remove battery pack before changing or removing accessories. Only use accessories specifically recommended for this

tool. Others may be hazardous.

For a complete listing of accessories refer

to your MILWAUKEE Electric Tool catalog

or go on-line to www.milwaukeetool.com.

To obtain a catalog, contact your local distributor or a service center.

1/2" Keyless Chucks

Cat. No. 48-66-1270

3/8" Keyless Chucks

Cat. No. 48-66-1250

Plastic Carrying Case

Cat. No. 48-55-0670

Plastic Carrying Case

Cat. No. 48-55-0675

Belt Clip

Cat. No. 48-67-0150

FIVE YEAR TOOL

LIMITED WARRANTY

Every MILWAUKEE tool is tested before

leaving the factory and is warranted to be

free from defects in material and workmanship. MILWAUKEE will repair or

replace (at MILWAUKEEs discretion),

without charge, any tool (including battery

chargers) which examination proves to be

defective in material or workmanship from

five (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE Factory Service/Sales

Support Branch location or MILWAUKEE

Authorized Service Station, freight prepaid

and insured. This warranty does not cover

damage from repairs made or attempted

by other than MILWAUKEE authorized

personnel, abuse, normal wear and tear,

lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL MILWAUKEE BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, OR

CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL,

EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal

rights. You may also have other rights that

vary from state to state and province to

province. In those states that do not allow

the exclusion of implied warranties or

limitation of incidental or consequential

damages, the above limitations or

exclusions may not apply to you. This

warranty applies to the United States,

Canada, and Mexico only.

1312

Page 8

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS

ALIMENTÉS PAR BATTERIE

AVERTISSEMENT!

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs

électriques, des incendies et/ou des blessures graves. Le terme «outil

électrique» figurant dans les avertissements ci-dessous renvoie à loutil

électrique à alimentation par le réseau (à cordon) ou par batterie (sans fil).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU

DE TRAVAIL

1. Maintenir la zone de travail propre

et bien éclairée. Les zones

encombrées ou mal éclairées sont

favorables aux accidents.

2. Ne pas utiliser doutil électrique

dans une atmosphère explosive,

telle quen en présence de

liquides, de gaz ou de

poussières inflammables. Les

outils électriques génèrent des

étincelles qui peuvent enflammer les

poussières ou les fumées.

3. Tenir les enfants et les

personnes non autorisées à

lécart pendant le fonctionnement

dun outil électrique. Un manque

dattention de lopérateur risque de lui

faire perdre le contrôle de loutil.

SÉCURITÉ ÉLECTRIQUE

4. La fiche de loutil électrique doit

correspondre à la prise

dalimentation. Ne jamais modifier

la fiche dune manière

quelconque. Ne pas utiliser

dadaptateur avec les outils

électriques mis à la terre (à la

masse). Des fiches non modifiées et

des prises dalimentation assorties

réduisent le risque de choc électrique.

5. Éviter tout contact corporel avec

des surfaces reliées à la masse

ou à la terre telles que tuyaux,

radiateurs, cuisinières et

réfrigérateurs. Un risque de choc

électrique plus élevé existe si le corps

est relié à la masse ou à la terre.

6. Ne pas exposer les outils

électriques à la pluie ou à

lhumidité. Le risque de choc

électrique augmente si de leau sinfiltre

dans un outil électrique.

7. Prendre soin du cordon. Ne

jamais utiliser le cordon pour

transporter, tirer ou débrancher

loutil électrique. Tenir le cordon

à lécart de la chaleur, des huiles,

des arêtes coupantes ou des

pièces en mouvement. Un cordon

endommagé ou emmêlé présente un

risque accru de choc électrique.

8. Se procurer un cordon

dalimentation approprié en cas

dutilisation dun outil électrique

à lextérieur. Lutilisation dun cordon

dalimentation pour usage extérieur

réduit le risque de choc électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif

et faire preuve de bon sens en

utilisant un outil électrique. Ne pas

utiliser un outil électrique en cas

de fatigue ou sous linfluence de

drogues, dalcool ou de

médicaments. Un instant dinattention

lors de lutilisation dun outil électrique

peut entraîner des blessures graves.

10. Utiliser un équipement de

sécurité. Toujours porter des lunettes de protection. Un

équipement de sécurité comprenant

masque anti-poussière, chaussures

de sécurité anti-dérapantes, casque

ou dispositif de protection anti-bruit

peut, dans les circonstances

appropriées, réduire le risque de

blessure.

11. Éviter tout démarrage accidentel

de loutil. Sassurer que le

commutateur est en position OFF

(Arrêt) avant de brancher loutil.

Le port de loutil avec un doigt sur le

commutateur ou son branchement

avec le commutateur en position ON

(Marche) sont favorables aux accidents.

12. Retirer toute clé de réglage avant

de mettre loutil sous tension.

Une clé laissée attachée sur une pièce

mobile de loutil électrique peut

entraîner des blessures.

13. Ne pas travailler à bout de bras.

Bien garder un bon équilibre à tout

instant. Ceci permet de mieux

préserver la maîtrise de loutil

électrique dans des situations

imprévues.

14. Porter des vêtements adéquats.

Ne pas porter de vêtements

amples ni de bijoux. Ne pas

approcher les cheveux,

vêtements et gants des pièces

en mouvement. Les vêtements

amples, les bijoux ou les cheveux

longs risquent dêtre happés par les

pièces en mouvement.

15. Si des dispositifs sont prévus

pour lextraction et la

récupération des poussières,

vérifier quils sont connectés et

utilisés correctement. Lutilisation

de ces dispositifs peut réduire les

risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE LOUTIL ÉLECTRIQUE

16. Ne pas forcer loutil électrique.

Utiliser loutil électrique

approprié à lapplication

considérée. Loutil électrique adapté

au projet considéré produira de

meilleurs résultats, dans des conditions de sécurité meilleures, à la

vitesse pour laquelle il a été conçu.

17. Ne pas utiliser loutil électrique si

le commutateur ne le met pas

sous ou hors tension. Tout outil

électrique dont le commutateur de

marche-arrêt est inopérant est

dangereux et doit être réparé.

18. Débrancher la fiche de la prise

dalimentation et/ou la batterie de

loutil électrique avant deffectuer

des réglages, de changer

daccessoires ou de ranger

loutil. De telles mesures de sécurité

préventive réduisent le risque de mettre

loutil en marche accidentellement.

19. Ranger les outils électriques

inutilisés hors de la portée des

enfants et ne pas laisser des

personnes qui connaissent mal

les outils électriques ou ces instructions utiliser ces outils. Les

outils électriques sont dangereux dans

les mains dutilisateurs non formés à

leur usage.

20. Entretien des outils électriques.

Sassurer de labsence de tout

désalignement ou de grippage

des pièces mobiles, de toute rupture de pièce ou de toute autre

condition qui pourrait affecter le

bon fonctionnement de loutil

électrique. En cas de dommages,

faire réparer loutil avant de

lutiliser de nouveau. Les outils

électriques mal entretenus sont à la

source de nombreux accidents.

21. Garder les outils de coupe affûtés

et propres. Les outils de coupe

correctement entretenus et bien

affûtés risquent moins de se gripper

et sont plus faciles à manier.

22. Utiliser cet outil électrique, les

accessoires, les mèches, etc.

conformément à ces instructions

et de la façon prévue pour ce type

particulier doutil électrique, tout

en prenant en compte les conditions de travail et le type de projet

considérés. Lutilisation de cet outil

électrique pour un usage autre que

lusage prévu peut créer des situations dangereuses.

UTILISATION ET ENTRETIEN

DE LA BATTERIE

23. Sassurer que le commutateur

est en position OFF (Arrêt) avant

dinsérer la batterie. Linsertion de

la batterie dans un outil électrique dont

le commutateur est en position ON

(Marche) est favorable aux accidents.

1514

Page 9

24. Ne recharger la batterie quavec

le chargeur spécifié par le

fabricant. Un chargeur qui convient à

un type de batterie peut créer un risque dincendie sil est utilisé avec un

autre type de batterie.

25. Nutiliser les outils électriques

quavec les batteries

spécialement conçues pour eux.

Lutilisation de batteries dautres

marques peut créer un risque de

blessure et dincendie.

26. Lorsque la batterie est hors ser-

vice, la ranger à lécart dautres

objets métalliques tels que trombones, pièces de monnaie, clés,

clous, vis et autres petits objets

métalliques qui peuvent établir

une connexion dune borne à

lautre. Un court-circuit aux bornes

de la batterie peut provoquer des

brûlures ou un incendie.

27. Du liquide peut être éjecté de la

batterie en cas de manutention

abusive ; éviter tout contact. En

cas de contact accidentel avec les

projections, rincer à leau. En cas

de contact avec les yeux, consulter un médecin. Le liquide

séchappant de la batterie peut

provoquer des irritations ou des

brûlures.

ENTRETIEN

28. Faire effectuer lentretien de

loutil électrique par un technicien

qualifié qui nutilisera que des

pièces de rechange identiques.

La sécurité dutilisation de loutil en sera

préservée.

RÈGLES DE SÉCURITÉ

SPÉCIFIQUES

1. Entretenez les étiquettes et

marques du fabricant. Les indica-

tions qu'elles contiennent sont

précieuses. Si elles deviennent illisibles

ou se détachent, faites-les remplacer

gratuitement à un centre de service

MILWAUKEE accrédité.

2. AVERTISSEMENT! La poussière

dégagée par perçage, sciage et autres

travaux de construction contient des

substances chimiques reconnues

comme pouvant causer le cancer, des

malformations congénitales ou

dautres troubles de reproduction. Voici

quelques exemples de telles substances :

Le plomb contenu dans la

peinture au plomb.

Le silice cristallin contenu dans

la brique, le béton et divers produits

de maçonnerie.

Larsenic et le chrome servant

au traitement chimique du bois.

Les risques associés à lexposition à

ces substances varient, dépendant de

la fréquence des travaux. Afin de

minimiser lexposition à ces substances chimiques, assurez-vous de

travailler dans un endroit bien aéré et

dutiliser de lequipement de sécurité

tel un masque antipoussière

spécifiquement conçu pour la filtration

de particules microscopiques.

3. Utiliser les poignées auxiliaires

fournies avec loutil. Une perte de

contrôle peut provoquer des

blessures.

4. Porter des protège-oreilles avec

un marteau perforateur. Une exposition au bruit peut provoquer une

perte auditive.

5. Tenir loutil par les surfaces de

prise isolées si, au cours des

travaux, loutil de coupe risque

dentrer en contact avec des fils

cachés ou avec son propre cordon. Le contact avec un fil sous ten-

sion met les parties métalliques

exposées de loutil sous tension, ce

qui infligera un choc électrique à

lopérateur.

6. Tenez les mains à l'écart des

arêtes tranchantes et des pièces

en mouvement.

Disposez correctement des batteries au

nickel-cadmium

Tension Courant Direct

Underwriters Laboratories, Inc.

Tours-minute á vide (RPM)

No. de

Cat.

0602-20

0612-20

DESCRIPTION FONCTIONNELLE

7

1. Sélecteur de vitesses

2. Porte-outils

3. Verrou de la batterie

4. Batterie

5. Détente

6. Commutateur

7. Mandrin sans clé

8. Collier de sélection de couple

Pictographie

Spécifications

Volts CD

12

14,4

8

6

Bas 0 - 400

Haut 0 - 1 400

Bas 0 - 400

Haut 0 - 1 400

5

Tr/min.

à vide

1

2

3

4

1716

Page 10

Capacités

0602-20

0612-20

Acier

10 mm

(3/8 po.)

13 mm

(1/2 po.)

Grande vitesse

Mèche

plate

dans du

bois

22 mm

(7/8 po.)

25 mm

(1 po.)

Scie-

cloche

dans du

bois

32 mm

(1-1/4 po.)

45 mm

(1-3/4 po.)

Mèche

Pathfinder

22 mm

(7/8 po.)

32 mm

(1-1/4 po.)

(3/8 po.)

(1/2 po.)

Acier

10 mm

13 mm

Vitesse lente

Mèche de

tarière

dans du

bois

25 mm

(1 po.)

29 mm

(1-1/8 po.)

(diamètre)

Vis

dans

du bois

6 mm

(1/4 po.)

6 mm

(1/4 po.)

UTILISATION ET ENTRETIEN DE LA BATTERIE

ENTRETIEN ET DURÉE DE VIE DE LA BATTERIE

Les batteries MILWAUKEE fonctionneront pendant de nombreuses années et/ou pour

des centaines de cycles si elles sont utilisées, chargées et remisées conformément à ces

instructions. Lutilisation, la charge et le remisage corrects de la batterie peuvent prolonger

grandement sa durée de vie.

Charger la batterie neuve durant

toute une nuit avant lutilisation

afin de permettre aux éléments

de batterie dêtre complètement

chargés. Les batteries neuves ne sont

pas complètement chargées. De deux à

dix cycles de charge/décharge normaux

peuvent être requis avant que la batterie

acquière sa charge maximum.

Ne jamais complètement

décharger la batterie. Les

batteries MILWAUKEE ne

développent pas de «mémoire» lorsquelles

sont chargées uniquement après une

décharge partielle. Le fait de maintenir les

gâchettes enclenchées avec du ruban

adhésif ou de laisser léclairage de travail

allumé pendant de longues périodes pour

décharger complètement la batterie réduit

sa durée de vie en altérant son équilibre

électrochimique et peut entraîner un courtcircuit de la batterie.

Ne pas charger les batteries

dans des endroits froids ou

chauds (en dessous de 5 °C [40 °F]

ou au-dessus de 40 °C [105 °F]). Les

températures extrêmes réduisent la

capacité des éléments de batterie à

maintenir la charge. Ne pas les remiser

dans des endroits où la température peut

dépasser 50 °C (120 °F), tels que dans un

véhicule ou un bâtiment en métal durant

lété.

Pour éviter de surchauffer une

batterie, laisser les outils sans fil

refroidir entre les applications de

coupe et de perçage à couple élevé.

Le taux supérieur dénergie libérée chauffe

plus rapidement les éléments de batterie

que la capacité des éléments à dissiper la

chaleur. Ceci peut endommager les

éléments.

Après utilisation, laisser la batterie

chaude refroidir à la température

ambiante avant de linsérer dans le

chargeur. Si une batterie chaude est mise

dans le chargeur, la charge ne commence

que lorsque la batterie a atteint une

température adéquate. Voir le manuel du

chargeur pour plus dinformations sur les

températures de charge. Le fait de charger

une batterie chaude endommage les

éléments.

Ne jamais chauffer ou refroidir les

batteries de force. Ceci endommage

certains éléments de la batterie, les rendant

incapables de maintenir la charge.

Retirer la batterie de loutil pour la

charger lorsque loutil ne peut plus

effectuer la tâche pour laquelle il est

conçu (cest-à-dire percer, couper, etc.).

Laisser la batterie sur le chargeur

une fois quelle est

complètement chargée. La batterie

continue à recevoir une charge dentretien

garantissant que la capacité est maintenue.

Occasionnellement(une fois par

semaine), laisser les batteries sur le

chargeur toute une nuit pour

permettre de maintenir léquilibre

des éléments.

Ne pas remiser la batterie sur le

chargeur pendant plus de 24 heures;

ceci peut réduire sa durée de vie.

Ne jamais laisser les batteries sur les

chargeurs lorsque des coupures de

courant sont fréquentes. Ceci pourrait

endommager les éléments de la batterie.

Remiser les batteries à

température ambiante et à labri

de lhumidité. Ne pas les remiser

dans des endroits humides où une corrosion des bornes peut avoir lieu.

Ne pas immerger la batterie et les

outils sans fil dans de leau. Ceci

endommage la batterie et loutil.

Charger les batteries inutilisées

durant toute une nuit au moins tous

les six mois pour allonger leur durée

de vie. Des batteries non utilisées se

déchargent à un taux d1% par jour et sont

complètement déchargées au bout de six

mois. Deux à dix cycles de charge normaux

peuvent être nécessaires pour charger

complètement la batterie lorsquelle a été

remisée pendant une longue durée.

Ne pas utiliser dhuile ou de solvant

pour nettoyer ou graisser la batterie.

Le boîtier en plastique peut se fendre ou

se casser et créer un risque de blessures.

AVERTISSEMENT!

Charger uniquement des

batteries MILWAUKEE de 12, 14,4

et 18 V dans les chargeurs

MILWAUKEE. Des batteries de

marques différentes peuvent

exploser et causer des blessures

et des dommages.

Pour les instructions de charge

spécifiques, lire le manuel de

lopérateur fourni avec le

chargeur.

Insertion du bloc de piles dans loutil

(Fig. 1 & 2)

Le bloc de pile peut être inséré de deux

façons.

Fig. 1

1. Pour un travail dans des espaces

restreints.

Insérez le bloc de piles à partir de

lavant en le faisant glisser dans le

corps de loutil. Insérez le bloc de piles

jusquà ce que son loquet se verrouille.

Fig. 2

2. Pour obtenir le meilleur équilibre et la

meilleure répartition de poids

possibles.

Insérez le bloc de piles à partir de

larrière en le faisant glisser dans le

corps de loutil. Insérez le bloc de piles

jusquà ce que son loquet se verrouille.

3. Pour retirer le bloc de piles, enfoncez

les deux loquets de la pile et faites

glisser le bloc hors de loutil.

1918

Page 11

MONTAGE DE L'OUTIL

MANIEMENT

AVERTISSEMENT!

Il faut toujours retirer la batterie et

verrouiller la détente de loutil

avant de changer ou denlever les

accessoires. Lemploi daccessoires

autres que ceux qui sont

expressément recommandés

pour cet outil peut comporter des

risques.

Système Clip-LokTM (Fig. 3 et 4)

Le système Clip-Lok consiste en trois

éléments : lattache de ceinture, le porteoutils et le porte-mèches.

Fig. 3

Le système est expédié assemblé pour un

utilisateur droitier. Pour modifier le montage

pour un utilisateur gaucher :

1. Déposer la batterie.

2. Déposer les vis retenant le porte-outils

3. Relever le porte-outils et le porte-

4. Remettre les éléments sur le côté

Attache de ceinture

Porte outils

Tenons avant

et le porte-mèches.

mèches à lextrémité la plus étroite et

tirer les tenons avant hors de leurs

encoches.

désiré en glissant les tenons dans les

encoches. Serrer les vis fermement.

Portemèches

Fixation de lattache de ceinture (Fig. 4)

Fig. 4

Levier de libération de loutil

Lattache de ceinture peut être montée sur

des ceintures à outils, des sacs, des seaux

etc. Pour monter lattache de ceinture :

1. Pousser et maintenir le levier de

2. Extraire la bride à larrière de lattache

3. Faire glisser la bride sur la ceinture à

4. Appuyer sur la bride pour atteindre le

Utilisation du porte-outils Clip-Lok

1. Pour fixer loutil à lattache de ceinture,

2. Pour libérer loutil de lattache de

Utilisation du porte-mèches Clip-Lok

Le porte-mèches porte deux mèches

hexagonales standard de 6 mm (1/4 po.)

de 51 mm (2 po.) de long au maximum.

1. Insérer la mèche en lappuyant dans

2. Retirer la mèche en relevant

Levier de libération de la bride

Goujon

Broche

Bride

libération de la bride.

de ceinture et relâcher le levier de

libération de la bride.

outils, le sac, le seau etc.

serrage désiré.

faire glisser le porte-outil sur le goujon

de lattache de ceinture jusquà ce quil

soit maintenu en place par la broche

protubérante.

ceinture, saisir le manche de loutil,

pousser le levier de libération de loutil

avec le pouce et extraire loutil.

lattache.

lextrémité de la mèche et en la tirant

hors de lattache.

AVERTISSEMENT!

Pour minimiser les risques de

blessures, portez des lunettes à

coques latérales.

Utilisation des mandrins sans clé (Fig. 5)

Cet outil sans fil est équipé dun verrou

daxe qui permet au mandrin dêtre serré

dune main.

Toujours retirer la batterie ou verrouiller la

détente avant dinsérer ou de retirer des

mèches.

Fig. 5

Ouvert

Fermé

Manchon

1. Pour ouvrir les mâchoires du mandrin,

tourner le manchon dans la direction

«OPEN» (ouvert) indiquée sur le mandrin.

Lors de lutilisation de mèches de

perceuse, permettre à la mèche

datteindre le fond du mandrin. Centrer

la mèche dans les mâchoires du mandrin et la relever denviron 2 mm

(1/16 po.) du fond.

Lors de lutilisation de mèches de

tournevis, insérer la mèche

suffisamment loin pour que les

mâchoires du mandrin prennent

lextrémité hexagonale de la mèche.

2. Pour fermer les mâchoires du mandrin, tourner le manchon dans la direction «CLOSE» (fermé) indiquée sur

le mandrin. La mèche est fixée quand

le mandrin émet un cliquetis et que le

manchon ne peut plus être tourné.

N.B. : Un bruit de cliquetis est normal lors

de louverture ou de la fermeture du mandrin. Ce bruit fait partie de la fonction de

verrouillage et nindique aucun problème

de fonctionnement du mandrin.

Utilisation de lembrayage (Fig. 6)

Loutil est muni dun embrayage réglable

permettant denfoncer différents types de

vis dans plusieurs types de matériaux. Une

fois réglé correctement, lembrayage

sengage dans un couple préréglé afin

déviter denfoncer la vis trop profondément

et dendommager la vis ou loutil.

Pour régler lembrayage, tournez le collier

sélecteur de couple à une des vingt position illustrées sur le collier. Le numéro doit

être aligné avec la flèche située sur le dessus

de loutil.

Fig. 6

Les spécifications de couples indiquées

ici sont approximatives et sont obtenues

avec un bloc de piles à pleine charge.

Positions

1 à 5

6 à 10

11 à 15

16 à 20

Perceuse

Bas

Haut

N.B. : Les réglages ci-dessus ne sont

quune approximation, vérifiez les positions

dembrayage en utilisant un morceau de

rebut avant denfoncer des vis dans la

pièce à travailler.

2120

Collier

sélecteur

de couple

0602-20

Couple

0 à 1,1 Nm

1,4 à 2,4 Nm

2,7 à 3,6 Nm

4 à 5 Nm

31,6 Nm

9 Nm

Numéros de

position

0612-20

Couple

0 à 1,1 Nm

1,4 à 2,4 Nm

2,7 à 3,6 Nm

4 à 5 Nm

44 Nm

11,3 Nm

Page 12

Sélection de la vitesse (Fig. 7)

Fig. 7

Le sélecteur de vitesse est situé à

lextrémité du boîtier du moteur. Laissez

loutil arrêter complètement avant de

changer la vitesse. Voir la section «Applications» pour connaître les vitesses

adaptées à différentes conditions.

1. Pour la vitesse Bas (jusquà

400 tr/mn), pousser le sélecteur de

vitesse en arrière, en faisant apparaître

le «1» pour bas.

2. Pour la vitesse Haut (jusquà

1 400 tr/mn), pousser le sélecteur de

vitesse en avant, en faisant apparaître

le «2» pour haut.

Utilisation du commutateur (Fig. 8, 9,

et 10)

Le commutateur peut être réglé sur trois

positions: marche avant, marche arrière et

verrouillée. En raison dun mécanisme de

verrouillage, le commutateur ne peut être

réglé que lorsque la commande MARCHE/

ARRÊT nest pas enfoncée. Toujours

laisser le moteur sarrêter complètement

avant dutiliser le commutateur.

Pour une rotation en marche avant (dans

le sens horaire), pousser le commutateur

sur le côté droit de loutil (Fig. 8). Vérifier la

direction de rotation avant utilisation.

Fig. 8

Pour une rotation en marche arrière

(dans le sens anti-horaire), pousser le

commutateur sur le côté gauche de loutil

(Fig. 9). Vérifier la direction de rota-

tion avant utilisation.

Fig. 9

Pousser pour

la marche

arrière

Haut

Bas

Pousser pour

la marche

avant

Pour verrouiller la détente, pousser le

commutateur vers la position centrale

(Fig. 10). La détente ne fonctionne pas tant

que le commutateur est sur la position

verrouillée centrale. Toujours verrouiller la

détente ou déposer la batterie avant

deffectuer un entretien, de changer

daccessoire, de remiser loutil et toutes

les fois que loutil est inutilisé.

Fig. 10

Pousser

en position

centrale

pour

verrouiller

la détente

Démarrage, arrêt et contrôle de la

vitesse

1. Pour mettre loutil en marche, appuyez

sur la gâchette.

2. Pour arrêter loutil, relâchez la gâchette

et le frein électrique arrête loutil

instantanément.

Tous les modèles sont équipés dune

commande de vitesse variable. Pour faire

varier la vitesse, il sagit simplement

daugmenter ou de diminuer la pression sur

la gâchette. Plus la gâchette est enfoncée,

plus la vitesse est grande.

Perçage

Réglez le collier sélecteur de couple à la

position de perçage.

Placez lextrémité du foret ou de la mèche

contre la surface de la pièce et appuyez

fermement avant de démarrer. Une

pression trop grande ralentit le foret et

diminue lefficacité du perçage. Une

pression trop faible fait glisser le foret sur

la surface de la pièce et émèche la pointe

du foret.

Si loutil commence à bloquer, réduisez

légèrement la vitesse pour permettre au

foret de reprendre de la vitesse. Si le foret

se bloque, inversez le sens de rotation du

moteur pour le libérer de la pièce.

APPLICATIONS

AVERTISSEMENT!

Pour réduire le risque de

décharge électrique, vérifier avant

de percer ou de visser si laire de

travail nest pas traversée par des

tuyaux dissimulés.

Perçage du bois, des matériaux

synthétiques et du plastique

Lorsque vous percez du bois, des

matériaux synthétiques et du plastique,

démarrez lentement la perceuse et

augmentez graduellement la vitesse à

mesure que vous percez. Lors du perçage

dans le bois, utilisez des mèches ou des

forets hélicoïdaux. Utilisez toujours des

forets ou des mèches bien affûtés.

Lorsque vous utilisez des forets

hélicoïdaux, retirez-les fréquemment du

trou pour enlever les copeaux des

goujures. Afin de réduire les risques

déclatement, appuyez la pièce sur un

morceau de bois de rebut. Sélectionnez

des vitesses lentes pour le perçage de

matières plastiques qui ont un point de fusion assez bas.

Perçage dans du métal

Lors du perçage dans du métal, utilisez

des forets hélicoïdaux à haute vitesse en

acier ou des scies-cloches. Utilisez un

centrage au pointeau dans le trou de

départ. Lubrifiez les forets avec de lhuile

de coupe lors du perçage dans le fer ou

lacier. Utilisez un fluide de refroidissement

lors du perçage de métaux non-ferreux

comme le cuivre, le laiton ou laluminium.

Calez le matériau pour éviter un coincement

ou une distorsion lors du débouchage de

la coupe.

Enfonçage de vis et vissage décrou

Percez un trou pilote lorsque vous

enfoncez des vis dans des matériaux épais

ou durs. Réglez le collier sélecteur de

couple à la position correcte et à une

vitesse lente. Utilisez le bon type et la bonne

taille dembout de tournevis pour le type de

vis utilisé.

Placez un foret pour tournevis dans la vis

et le bout de lavis sur la pièce à travaillez;

appuyez fermement avant dappuyer sur

la gâchette. Vous pouvez enlever les vis

en inversant le sens de rotation du moteur.

Surcharge

Une surcharge continue peut endommager

loutil ou le bloc de piles en permanence.

AVERTISSEMENT!

Haute puissance rotatoire. Afin de

réduire les risques de blessures,

tenez toujours loutil solidement

et étayez-le fermement.

Coincement de mèches

Une grande force rotatoire se dégage

lorsquune mèche reste coincée dans le

matériau. Loutil est alors projeté dans la

direction opposée à la rotation de la mèche.

Les mèches peuvent rester coincées

lorsquelles sont mal alignées ou lorsquelles

passent au travers du matériau. Les

mèches à bois peuvent aussi rester

coincées si elles viennent en contact avec

des clous ou des noeuds. Prévenez les

mouvements de recul dûs au coincement

de la mèche.

Pour minimiser los risques do coincement :

Employez des mèches bien affûtées.

Les mèches bien affûtées sont moins

sujettes au coincement en cours de

perçage.

Utilisez une mèche appropriée à la

tâche. Il y a des mèches pour chaque

tâche spécifique.

Faire preuve de prudence en perçant

du matériau poisseux, noueux, mouillé

ou gauchi ou en perçant du matériau

qui peut contenir des pointes, des vis,

des agrafes etc.

2322

Page 13

MAINTENANCE

AVERTISSEMENT!

Pour minimiser les risques de

blessures corporelles, débranchez

le chargeur et retirez la batterie du

chargeur ou de loutil avant dy

effectuer des travaux dentretien. Ne

démontez jamais loutil, la batterie ou

le chargeur. Pour toute réparation,

consultez un centre de service

MILWAUKEE accrédité.

Gardez loutil, la batterie et le chargeur en

bon état en adoptant un programme

dentretien ponctuel. Après une période de

six mois à un an, selon lutilisation, renvoyez

loutil, la batterie et le chargeur à un centre

de service MILWAUKEE accrédité pour les

services suivants:

Lubrification

Inspection et nettoyage de la

mécanique (engrenages, pivots,

coussinets, boîtier etc.)

Inspection électrique (batterie,

chargeur, moteur)

Vérification du fonctionnement

électromécanique

Entretien de loutil

Si loutil ne démarre pas ou ne fonctionne

pas à pleine puissance alors quil est

branché sur une batterie complètement

chargée, nettoyez les points de contact

entre la batterie et loutil. Si loutil ne

fonctionne toujours pas correctement,

renvoyez loutil, le chargeur et la batterie à

un centre de service MILWAUKEE

accrédité, afinquon en effectue la

réparation (voir Réparations).

Entretien de la batterie

Les batteries MILWAUKEE sont conçues

pour durer plusieurs années et/ou des

milliers de cycles lorsquelles sont bien

entretenues et utilisées selon les instructions de ce manuel.

Une batterie qui est rangée durant six mois

perdra sa charge si elle nest pas utilisée.

Les batteries se déchargent selon un taux

denviron 1% par jour. Rechargez la

batterie tous les six mois, même si elle nest

pas utilisée, cela prolongera sa durée.

Nemaintenez pas la détente dinterrupteur

à la positon ON à laide dun ruban adhésif

et ne laissez pas loutil sans surveillance

car cela pourrait décharger la batterie0 à

un point tel quil deviendra impossible de la

recharger. Employez une batterie

MILWAUKEE aussi longtemps quelle

fournira la puissance requise.

Rangez la batterie dans un endroit frais et

sec. Ne la rangez pas dans un endroit où

la température pourrait excéder 50°C

(120°F),dans un véhicule ou une structure

dacier, lété par exemple. Les températures

élevées provoquent la surchauffe de la

batterie et en réduisent la durée. Si la

batterie est rangée pour une période de

plusieurs mois, elle perdra graduellement

sa charge. Cependant, après plusieurs

cycles de recharge et de décharge en

période dutilisation normale, elle retrouvera

sa charge initiale. Avec le temps, les

intervalles entre les recharges de la batterie

deviendront de plus en plus courts.

Lorsque ces intervalles, devenus trop

courts, rendront loutil inutilisable, il faudra

remplacer la batterie.

AVERTISSEMENT!

Pour minimiser les risques de

blessures ou de dommages à

l'outil, n'immergez jamais l'outil, la

batterie ou le chargeur et ne laissez

pas de liquide s'y infiltrer.

Nettoyage

Débarrassez les évents du chargeur et de

loutil des débris et de la poussière. Gardez

les poignées de loutil propres, à sec et

exemptes dhuile ou de graisse. Le nettoyage

de loutil, du chargeur et de la batterie doit se

faire avec un linge humide et un savon doux.

Certains nettoyants tels lessence, la

térébenthine, lesdiluants à laque ou à

peinture, les solvants chlorés, lammoniaque

et les détergents dusage domestique qui en

contiennent pourraient détériorer le plastique

et lisolation des pièces. Ne laissez jamais de

solvants inflammables ou combustibles

auprès de loutil.

AVERTISSEMENT!

Pour minimiser les risques

dexplosion ne faites jamais brûler

une batterie, même si elle est avariée,

âgée ou complètement épuisée.

Sceaux de recyclage pour pile RBRC

Les sceaux de recyclage pour piles

RBRC (voir la «Pictographie») sur la pile

de votre outil, indiquent que MILWAUKEE a

pris des dispositions avec Rechargeable

Battery Recycling Corporation (RBRC) pour

le recyclage de ce bloc de piles. Lorsque la

vie utile de ce bloc de pile est épuisée,

retournez-le à une succursale ou à un centre de service MILWAUKEE, ou au détaillant

participant le plus près de chez vous. Pour

obtenir plus dinformations, visitez le site

Web RBRC au www.rbrc.org.

Disposition des batteries au nickelcadmium

Les batteries au nickel-cadmium sont

recyclables. En vertu des différents

règlements provinciaux et locaux, il peut être

illégal de disposer d'une batterie par le service d'enfouissement des déchets. Disposez

de votre batterie en conformité de la

réglementation fédérale, provinciale et locale.

Réparations

Pour les réparations, retournez outil, batterie

et chargeur en entier au centre-service le

plus près, selon la liste apparaissant à la

derniè page de ce manuel.

Garantie des batteries

Les batteries pour outils sans cordon sont

garanties pour un an à compter de la date

dachat.

GARANTIE LIMITÉE DE

LOUTIL DE CINQ ANS

Tous les outils MILWAUKEE sont testés

avant de quitter lusine et sont garantis

exempts de vice de matériau ou de

fabrication. MILWAUKEE réparera ou

remplacera (à la discrétion de

MILWAUKEE), sans frais, tout outil (y

compris les chargeurs de batterie) dont

lexamen démontre le caractère défectueux

du matériau ou de la fabrication dans les

cinq (5) ans suivant la date dachat.

Retourner loutil et une copie de la facture

ou de toute autre preuve dachat à une

branche Entretien usine/Assistance des

ventes de létablissement MILWAUKEE ou

à un centre dentretien agréé par

MILWAUKEE, en port payé et assuré. Cette

garantie ne couvre pas les dommages

causés par les réparations ou les tentatives

de réparation par quiconque autre que le

personnel agréé par MILWAUKEE, les

utilisations abusives, lusure normale, les

carences dentretien ou les accidents.

Les batteries, les lampes de poche et les

radios sont garanties pour un (1) an à partir

de la date dachat.

LES SOLUTIONS DE RÉPARATION ET DE

REMPLACEMENT DÉCRITES PAR LES

PRÉSENTES SONT EXCLUSIVES.

MILWAUKEE NE SAURAIT ÊTRE

RESPONSABLE, EN AUCUNE

CIRCONSTANCE, DES DOMMAGES

ACCESSOIRES, SPÉCIAUX OU INDIRECTS,

Y COMPRIS LES MANQUES À GAGNER.

CETTE GARANTIE EST EXCLUSIVE ET

REMPLACE TOUTES LES AUTRES

GARANTIES OU CONDITIONS, ÉCRITES OU

ORALES, EXPRESSES OU TACITES DE

QUALITÉ MARCHANDE OU DADAPTATION

À UNE UTILISATION OU UNE FIN

PARTICULIÈRE.

Cette garantie vous donne des droits

particuliers. Vous pouvez aussi bénéficier

dautres droits variant dun état à un autre

et dune province à une autre. Dans les

états qui nautorisent pas les exclusions

de garantie tacite ou la limitation des

dommages accessoires ou indirects, les

limitations ou exclusions ci-dessus peuvent

ne pas sappliquer. Cette garantie sapplique

aux États-Unis, au Canada et au Mexique

uniquement.

2524

Page 14

ACCESSOIRES

AVERTISSEMENT!

Il faut toujours retirer la batterie et verrouiller la détente de

loutil avant de changer ou denlever les accessoires. Lemploi

daccessoires autres que ceux qui sont expressément

recommandés pour cet outil peut comporter des risques.

Pour une liste complète des accessoires, prière de se reporter au catalogue MILWAUKEE

Electric Tool ou visiter le site internet www.milwaukeetool.com. Pour obtenir un catalogue,

il suffit de contacter votre distributeur local ou l'un des centres-service.

Mandrins sans clé de 13 mm (1/2 po)

No de cat. 48-66-1270

Mandrins sans clé de 10 mm (3/8 po)

No de cat. 48-66-1250

Mallette de transport en plastique

No de cat. 48-55-0670

Mallette de transport en plastique

No de cat. 48-55-0675

Agrafe de ceinture

No de cat. 48-67-0150

REGLAS DE SEGURIDAD GENERALES PARA HERRAMIENTAS

OPERADAS POR BATERÍA

¡ADVERTENCIA!

LEA TODAS LAS INSTRUCCIONES

Si no se siguen todas las siguientes instrucciones se puede provocar una

descarga eléctrica, un incendio y/o lesiones graves. El término herramienta

eléctrica en todas las advertencias incluidas más abajo se refiere a su

herramienta operada por conexión (cable) a la red eléctrica o por medio de

una batería (inalámbrica).

GUA0RDE ESTAS INSTRUCCIONES

SEGURIDAD EN EL ÁREA

DE TRABAJO

1. Mantenga limpia y bien iluminada

el área de trabajo. Las áreas

desordenadas u oscuras contribuyen

a que se produzcan accidentes.

2. No utilice herramientas eléctricas

en atmósferas explosivas, como

en la presencia de líquidos, gases

o polvo inflamables. Las

herramientas eléctricas crean chispas

que pueden incendiar el polvo o las

emanaciones.

3. Mantenga a los niños y otras per-

sonas alejadas mientras utiliza

una herramienta eléctrica. Las

distracciones pueden hacerle perder

el control.

SEGURIDAD ELÉCTRICA

4. Los enchufes de las herramientas

eléctricas deben ser del mismo

tipo que el tomacorrientes. Nunca

realice ningún tipo de

modificación en el enchufe. No

use enchufes adaptadores con

herramientas eléctricas con

conexión a tierra. Se reducirá el

riesgo de descarga eléctrica si no se

modifican los enchufes y los

tomacorrientes son del mismo tipo.

5. Evite el contacto corporal con su-

perficies con conexión a tierra,

como tuberías, radiadores,

estufas y refrigeradores. El riesgo

de descarga eléctrica aumenta si su

cuerpo está conectado a tierra.

6. No exponga la herramientas

eléctricas a la lluvia o a

condiciones de humedad. El agua

que entra en una herramienta eléctrica

aumenta el riesgo de descarga

eléctrica.

7. No abuse del cable. Nunca use el

cable para transportar la

herramienta eléctrica, tirar de ella

o desenchufarla. Mantenga el

cable alejado del calor, los bordes

afilados o las piezas en

movimiento. Los cables dañados o

enmarañados aumentan el riesgo de

descarga eléctrica.

8. Cuando se utiliza una herramienta

eléctrica en el exterior, use una

extensión que sea apropiada para

uso en el exterior. El uso de un cable

apropiado para el exterior reduce el

riesgo de descarga eléctrica.

SEGURIDAD PERSONAL

9. Manténgase alerta, ponga cuidado

a lo que está haciendo y use el

sentido común cuando utilice una

herramienta eléctrica. No use una

herramienta eléctrica cuando está

cansado o bajo la influencia de

drogas, alcohol o medicinas.

Despistarse un minuto cuando se utiliza

una herramienta eléctrica puede tener

como resultado lesiones personales

graves.

10. Use equipo de seguridad. Lleve

siempre protección ocular. Llevar

equipo de seguridad apropiado para

la situación, como una máscara

antipolvo, zapatos de seguridad

2726

Page 15

antideslizantes casco o protección

auditiva, reducirá las lesiones

personales.

11. Evite los arranques accidentales.

Asegúrese de que el interruptor

esté en la posición de apagado

antes de enchufar la herramienta.

Mover herramientas con el dedo en el

interruptor o enchufar herramientas

con el interruptor en la posición de

encendido contribuye a que se

produzcan accidentes.

12. Quite todas las llaves de ajuste

antes de encender la herramienta.

Una llave que esté acoplada a una

pieza giratoria de la herramienta puede

provocar lesiones personales.

13. No se estire demasiado. Mantenga

los pies bien asentados y el

equilibrio en todo momento. Esto

permite tener mejor control de la

herramienta eléctrica en situaciones

inesperadas.

14. Vístase de manera apropiada. No

lleve ropa suelta ni joyas. Mantenga

el cabello, la ropa y los guantes

lejos de la piezas en movimiento.

La ropa floja, las joyas o el cabello

largo pueden quedar atrapados en las

piezas en movimiento.

15. Si se proporcionan dispositivos

para la conexión de sistemas de

recolección y extracción de polvo,

asegúrese de que estén

conectados y se usen

apropiadamente. El uso de estos

dispositivos puede reducir los peligros

relacionados con el polvo.

USO Y CUIDADO DE LAS

HERRAMIENTAS ELÉCTRICAS

16. No fuerce la herramienta eléctrica.

Use la herramienta eléctrica

correcta para la aplicación. La

herramienta eléctrica correcta

funcionará mejor y de manera más

segura a la velocidad para la que se

diseñó.

17. No use la herramienta eléctrica si

el interruptor no la enciende ni la

apaga. Cualquier herramienta eléctrica

que no se pueda controlar con el

interruptor es peligrosa y se debe

reparar.

18. Desconecte el enchufe de la toma

de alimentación y/o la batería de

la herramienta eléctrica antes de

realizar cualquier ajuste, cambiar

accesorios o almacenar las

herramientas eléctricas. Dichas

medidas preventivas de seguridad

reducen el riesgo de que la herramienta

se prenda accidentalmente.

19. Almacene las herramientas

eléctricas fuera del alcance de los

niños y no permita que personas

no familiarizadas con ellas o estas

instrucciones las utilicen. Las

herramientas eléctricas son peligrosas

en las manos de usuarios no

capacitados.

20. Mantenimiento de las

herramientas eléctricas. Revise

que no haya piezas móviles que

estén desalineadas o que se

atasquen, piezas rotas ni ninguna

otra condición que pueda afectar

el funcionamiento de la

herramienta eléctrica. Si se

encuentran daños, haga que le

reparen la herramienta antes de

usarla. Las herramientas mal

mantenidas son la causa de muchos

accidentes.

21. Mantenga las herramientas de

corte limpias y afiladas. Es menos

probable que se atasquen las

herramientas de corte con filos

afilados que se mantienen de manera

apropiada y también son más fáciles

de controlar.

22. Use la herramienta eléctrica, los

accesorios y las brocas, etc.

siguiendo estas instrucciones y

de la manera para la que dicha

herramienta eléctrica en particular fue diseñada, teniendo en

cuenta las condiciones de trabajo

y la tarea que se va a realizar. El

uso de la herramienta eléctrica para

operaciones diferentes de aquellas

para las que se diseño podría resultar

en una situación peligrosa.

USO Y CUIDADO DE LAS

HERRAMIENTAS CON BATERÍA

23. Asegurarse de que el interruptor

esté en la posición apagada antes de colocar la batería. Colocar la

batería en las herramientas eléctricas