BEA BODYGUARD III GT 400, BODYGUARD III GT 300 User Manual

1 PWR

2 PWR

3 COM

4 NO

5 NC

6 IN 7 IN +

RED

BLACK

WHITE

GREEEN

BROWN

BLUE

10 PIN

PCB

BODYGUARD III

QUICK SETUP GUIDE

PRESENCE SENSOR FOR PEDESTRIAN DOORS

1 Description

The Bodyguard III Quick Setup Guide is for the installation and setup of the Bodyguard III. This document is provided for experienced installers,

service personnel & AAADM Certied Inspectors that are familiar with the Bodyguard III. For those who are not completely familiar with the

installation and setup of the Bodyguard III, BEA recommends following the detailed installation and setup instructions found in the Bodyguard III

User’s Guide (75.5134). Bodyguard performance shall be adjusted and in compliance with all applicable current safety standards (ANSI A156.10).

2 Installation

1. The Bodyguard shall be mounted near ush with the bottom of the automatic door header on the swing side. This is absolutely necessary to allow

the Bodyguard detection pattern to reach back through the threshold area when the door is in the open position. If any portion of the door face or

related hardware on the swing side project beyond the Bodyguard face, a Bodymount must be installed in conjunction with the Bodyguard.

2. The Bodyguard should be mounted at a height range of 6’ 6” to 8’ (Max. of 9’).

3. The Bodyguard should be center mounted up above on the header and ush with the bottom of the automatic door header. This is absolutely

necessary to allow the detection pattern to reach back through the threshold area with the Bodyguard is in the open door position.

SINGLE DOOR APPLICATIONS - The Bodyguard should be mounted overhead at the center of the door opening. However, if this is not possible, the

DOUBLE-EGRESS APPLICATIONS - One Bodyguard shall be mounted overhead on the header over each swing-path. There should be at least 40”

unit may be installed off-center. In such cases, pattern location will have to be altered for proper placement of the

eld of detection. Try to avoid mounting locations that may pose potential problems such as directly over a door arm.

of separation between the 2 Bodyguards when measured between the centerline of each sensor. Most double

egress applications are knowing act. Ensure compliance with current ANSI 156.10-2005 Section 9.2. Most

double egress installations will require IR frequency and/or open door pattern depth adjustments. Change IR

frequency of one Bodyguard to 3 and the other to 4 (See Tech Bulletin #32 or Bodyguard User Guide 75.5134

for more explicit information regarding double egress applications with respect to location and setting up the

Bodyguard.

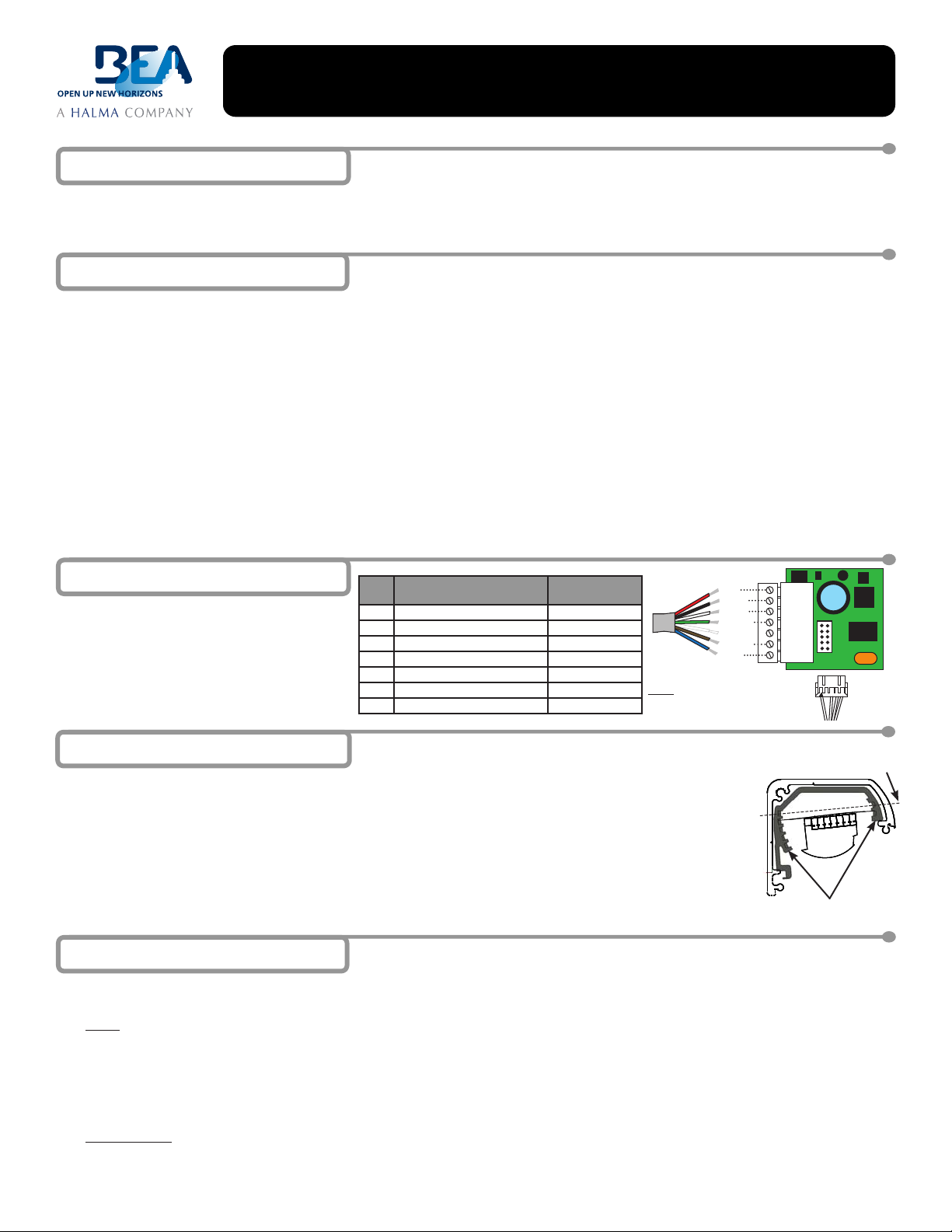

3 Wiring

Use the cable that is provided for use with the

10-pin connector as shown or wire the 7-pin

terminal block. If wiring the Bodyguard to a

BEA module (i.e. LO LINX or a version of the

LO-21), refer to the wiring diagrams for the

respective module. For ease of installation,

wire the terminal before attaching it to the

Bodyguard.

POS CONNECTION (7-Pin)

1 12 to 24 VAC/VDC +/- 10% Red

2 12 to 24 VAC/VDC +/- 10% Black

3 COM White

4 NO Green

5 NC

6 Data - Brown

7 Data + Blue

WIRE COLOR

(10-Pin Cable)

NOTE: Never short the data wires

when power is applied as this

will destroy the lockout.

4 Mechanical Adjustment

1. Aside from placement on the header, the only mechanical adjustment that may be made to the sensor is the angle

adjustment. The Bodyguard is factory pre-set to the +5° position, but may be reduced to a 0° position or increased to

a 10° position. The greater the angle, the farther from the door the pattern will be. The 0° angle should only be used

when the Bodyguard is mounted to a Bodymount block or to a soft above the door that extends out from the face of the

swing side of the door (in this case, the 0° setting would improve the location of the detection eld across the threshold

area of the doorway). It is recommended that for most applications, the unit be powered and walk tested at the pre-set

5° angle. After walk testing, if the detection eld needs to be changed, then proceed with changes as explained next.

2. To change the angle setting the end caps, lenses, center eye shield and terminal block if it has been wired must be

removed. Once removed, release the white clips and rotate outward to remove the PCB. Once the PCB is completely

removed from the housing, the angle position may be changed. There are two clips per Bodyguard and the angle must

match for each clip on the PCB.

5° Default Angle

ANGLE ADJUSTMENT

CLIP (WHITE)

5 Setup

1. Upon completion of mechanical and electrical installation, apply 12 to 24 VAC/VDC +/- 10% to the Bodyguard with the door in the closed position.

The Bodyguard will ash a green LED at a rate of 2 Hz, then it will expire upon a successful set-up in the door closed position.

NOTE: If applying the Bodyguard to a door control that requires a learn cycle upon powering, it is recommended to allow the doors to complete a

learn cycle before applying power to the Bodyguard.

2. Activate the door to the full open position. When using BEA’s lockout relay, the Bodyguard will once again ash the green LED and will

execute a door-open set-up. Upon completion of the set-up for the door-open position, the doors will begin closing. Normal operation should

resume thereafter. Proceed with ne-tuning to insure compliance with all current applicable safety standards (i.e. ANSI A 156.10). If set-up is

unsuccessful, refer to the Troubleshooting Guide at the end of the Bodyguard User’s Guide (75.5134) and also to the guide located at the end of

the respective lockout User’s Guide.

HELPFUL HINT: After set-up and to conrm the correct motor polarity to the lockout, the correct data and data polarity and to ensure the lockout is

75.5362.01 20090210 Page 1 of 2

communicating properly to the Bodyguard. Activate the door open and perform a door open set-up with the remote by pressing

Unlock, Magic Wand, #2. If the Bodyguard ashes green continue with nal tune in. If not, refer to Bodyguard User Guide

(75.5134). The most likely cause is the motor lead polarity is reversed at the lockout or data polarity is reversed at Bodyguard.

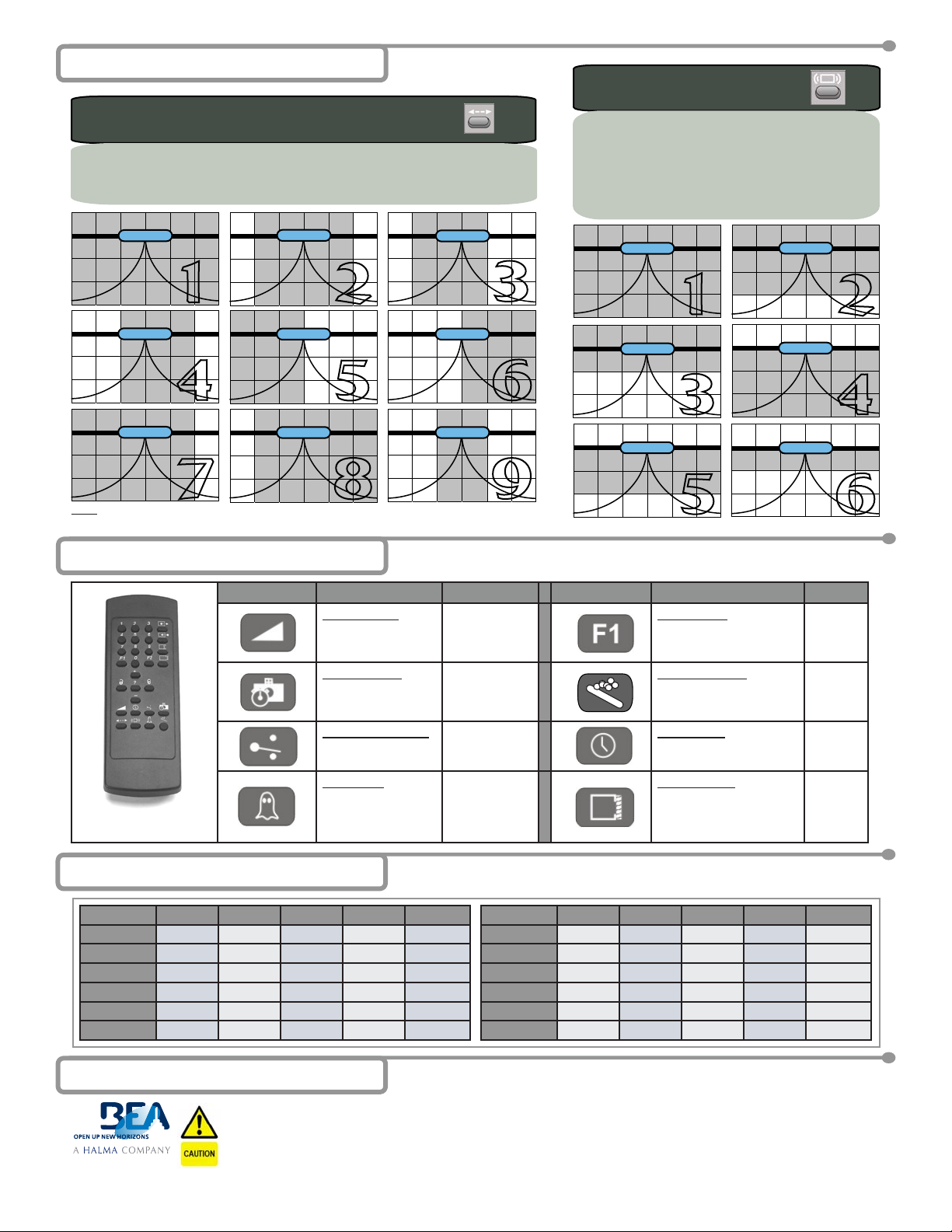

6 Sensing Zone Adjustment

1

4

3

5

6

2

1ST ROW OF IR

THRESHOLD

2ND ROW OF IR

3RD ROW OF IR

4TH ROW OF IR

Pattern Depth

1: Deep (Threshold ON)

2: Medium (Threshold ON - OPEN)

3: Limited (Threshold ON)

4: Deep (Threshold OFF)

5: Medium (Threshold OFF - CLOSED)

6: Limited (Threshold OFF)

1

4

3

5 6

2

1ST ROW OF IR

THRESHOLD

2ND ROW OF IR

3RD ROW OF IR

4TH ROW OF IR

7 8 9

Pattern Width (Open / Closed)

1: Wide (CLOSED DOOR) 4: Asymmetric Right Narrow 7: Asymmetric Left Wide

2: Middle (OPEN DOOR) 5: Narrow Left 8: Asymmetric Right Wide

3: Asymmetric Left Narrow 6: Narrow Right 9: Center Narrow

NOTE: When pattern width or depth is changed, a setup of the new pattern size will automatically be triggered

once a value key has been pressed.

Pattern Width, Depth & Sensitivity all

have independent door closed and

door open values.

7 Congurations

BUTTON PARAMETER VALUE BUTTON PARAMETER VALUE

SENSITIVITY

Door Closed = 6

Door Open = 7

AUTO LEARN

0 = 30 sec

9 = Innite

OUTPUT CONFIG.

NO

NC

IMMUNITY

8 Door Control Connections

SWING ACT COM SAF STALL STALL COM SWING ACT COM SAF STILL STALL COM

Besam 300 13 12 11 15, 17 16, 18 HUNTER ACT RTN SAF 1 SAF 2 RTN

Besam M/P 3 4 9 5 13 KM K Green White Red Yellow White

DOM Yellow Grey Blue Purple Grey STANLEY L Orange Yellow Red Blue Yellow

GT 300/400 Black Red White White Red STANLEY M/P 2 1, 8 7 7 1, 8

GT MAG 6 Black 5 Red 4 White 3 Violet 5 Red STANLEY 521 TB4-5 TB4-4 TB4-8 TB4-10 TB4-9

HORTON 4190 2 3, 6, 8 4 10 3, 6, 8 TORMAX TDA 2 1, 3, 6, 8 8 & 9 7 1, 3, 6, 8

Low (Normal)

Medium (Rain)

High (Snow) *

* - BGIII-C

ENSURE COMPLIANCE WITH ALL APPLICABLE CURRENT SAFETY STANDARDS (I.E. ANSI A156.10).

0 (min)

9 (max)

0 (min)

9 (max)

1

2

1

2

3 *

INTERFACE

New Style

Old Style (LO21, B, K,

P, S, U, LO-LINX, MC15)

SETUP / WAND

Door Closed = 1

Door Open = 2

Restore to Default

HOLD TIME

0 = 0.5 sec

9 = 9 sec

FREQUENCY

Normal Mode; Low

Normal Mode; High

Quiet Mode; Low

Quiet Mode; High

1

2

1

2

9

0 (min)

9 (max)

1

2

3

4

9 Company Contact

Do not leave problems unresolved. If a satisfactory solution cannot be achieved after troubleshooting a problem, please call BEA, Inc. If you must wait for the

Page 2 of 2 75.5362.01 20090210

following workday to call BEA., leave the door inoperable until satisfactory repairs can be made. Never sacrice the safe operation of the automatic door or

gate for an incomplete solution. The following numbers can be called 24 hours a day, 7 days a week. For more information, visit www.beasensors.com.

US and Canada:

Canada:

Northeast:

1-866-249-7937

1-866-836-1863

1-866-836-1863

Southeast:

Midwest:

West:

1-800-407-4545

1-888-308-8843

1-888-419-2564

Loading...

Loading...