To the Installer:

Please attach these instructions

next to the water heater.

To the Consumer:

Please read these and all component

instructions and keep for future reference.

OIL-FIRED BCS

Instruction Manual

Warranty, Registration Card and Parts List are included.

Homeowner: Please remember to r

eturn the Registration Card!

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause serious injury or property damage. Refer to this manual.

For assistance or additional information, consult a qualified installer or service agency.

WARNING

If the information in these instructions is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or

death.

WARNING

Do not install on combustible flooring. Install

in accordance with all local codes. In the

absence of local codes, refer to NFPA 31 or

ANSI Z21.10.1.

CAUTION

The recommended temperature for normal

residential use is 120°F. The dial on the aquastat

does not always reflect the out-coming water

temperature and it could occasionally exceed

120°F. Variation in out-coming temperature

could be based on factors including but not

limited to usage patterns and type of installation. T

heater. (See page 8 for measuring the outcoming water temperature.)

est water at the tap near

est to the water

WARNING

.

Hotter water increases the risk of scald injur

Befor

e adjusting the water temperature setting,

read this instruction manual. Temperatures at

which injury occurs vary with the person’s age

and the length of exposure. The slower reaction time of children, elderly or physically or

mentally challenged persons increases the

scalding hazard to them. It is recommended

that lower water temperatures be used where

these exposur

small children or invalids may require a temperature setting less than 120°F to prevent accidental contact with hot water. To produce

less than 120°F, use point-of-use temperature limiting devices.

e hazar

ds exist. Households with

y

If higher water temperature is needed in part

of the water system, automatic temperature

limiting devices must be used on all lines to

water taps.

WARNING

Flammable vapors may be drawn to this water

heater from other areas of the structure by air

currents. Do not store or use any flammable

liquids in the vicinity of this heater.

WARNING

Water heater blankets may restrict air flow to

the water heater and cause fire, asphyxiation,

personal injury or death.

THIS MANUAL HAS BEEN PREPARED

TO ACQUAINT YOU WITH THE INSTALLATION,

OPERATION, AND MAINTENANCE OF YOUR

WATER HEATER AND TO PROVIDE

IMPORTANT SAFETY INFORMATION.

Read all instructions thoroughly before attempting installation or operation of your

water heater. Keep these instructions for future

reference.

Local plumbing and electrical codes must be

followed in the installation of this water

heater. In the absence of a local code use the

UNIFORM PLUMBING CODE and the NFPA

Code. Local codes may supersede instr

in this installation manual.

These instructions are a guide for the corr

installation of the water heater. The manufacturer will not be liable for damages caused by

e to comply with the installation and

failur

operating instructions outlined on the

following pages.

If you lack the necessary skills required or have

difficulty following the directions, seek help

om a qualified person for that par

fr

installation you do not understand.

AILURE TO FOLLOW THESE INSTRUCTIONS

F

OR ALL APPLICABLE BUILDING CODES

AND REGULATIONS VOIDS THE WARRANTY

ON THIS WATER HEATER.

uctions

ect

t of the

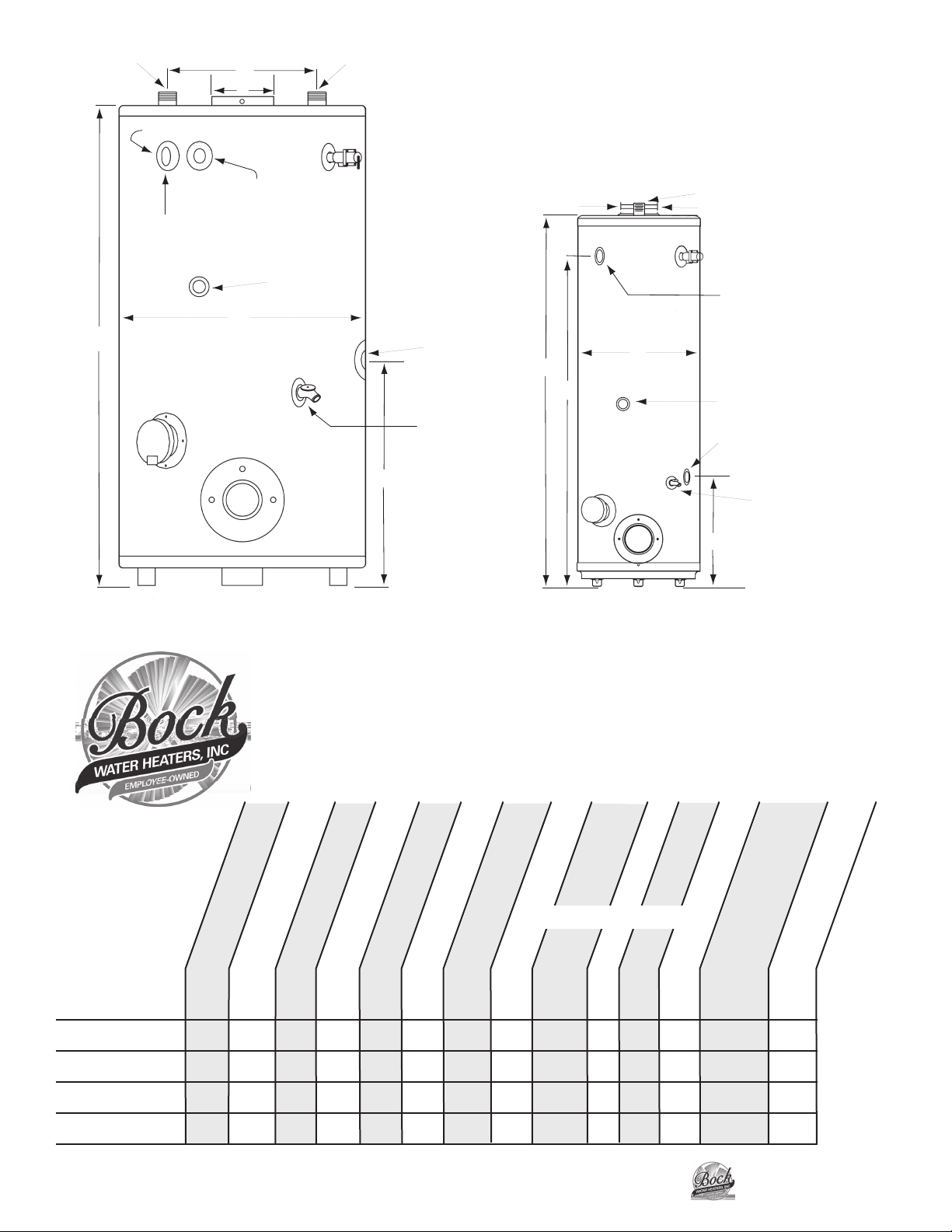

HOT OUTLET

C

D

B

AUXILIARY OUTLET

(COMBINED APPLIANCE)

COLD INLET

AQUASTAT

RETURN

A

E

HOT OUTLET

AQUASTAT

B

AUXILIARY OUTLET

(COMBINED APPLIANCE)

32, 51

AVERAGER (190 ONLY)

HIGH LIMIT 120, 190

COLD INLET

RETURN

120, 190

RETURN

32, 51

E

A

C

D

E

XPANSION TANK

(

OPTIONAL)

IF ANY OF THESE DEVICES ARE USED,

A PROPERLY SIZED EXPANSION TANK

MUST BE INSTALLED.

32E-BCS 32 104 .753⁄4''3⁄4'' 1'' 90° 114 51'' 20'' 6'' 11'' 17'' 120/60 312

40E-BCS

51E-BCS 50 152 1.1 1'' 1'' 1'' 90° 161 59'' 24'' 6'' 11'' 18'' 120/60 370

32, 51, 120, 190E-BCS

(gal.)

Storage Capacity

40

126

(GPH)

(Thousands)

Cold Inlet

Firing Rate

BTUH

.9

3

⁄4''3⁄4''

40E-BCS

OIL-FIRED BCS

Instruction Manual

e Rise (F)

Hot Outlet

1''

Return

90

Temperatur

°

136

(GPH)

y

Dimensions

Recover

A

B

E

D

C

61'' 20'' 6'' 54'' 18'' 120/60 344

oltage

V

(V/Hz)

eight

W

(lbs.)

(inc. burner & controls)

120E-BCS 113 155 1.1 1'' 2'' 2'' 90° 163 67'' 311⁄2'' 6'' 19'' 22'' 120/60 751

190E-BCS 113 190 1.35 1'' 2'' 2'' 90° 199 67'' 311⁄2'' 6'' 19'' 22'' 120/60 751

WHEN YOU RECEIVE YOUR NEW WATER HEATER

Check the new equipment to see if all components are in good condition and were not

amaged in shipment. The water heater and burner may be shipped as separate units. The

d

aquastat and immersion well are packed with the burner. If damage is observed or parts

ppear to be missing, contact your wholesaler.

a

WHEN THE WATER HEATER IS USED IN A COMBINED APPLIANCE APPLICATION, PLEASE CONTACT

OUR LOCAL DISTRIBUTOR OR THE FACTORY FOR INSTALLATION INSTRUCTIONS ON “SYSTEM PLUS”.

Y

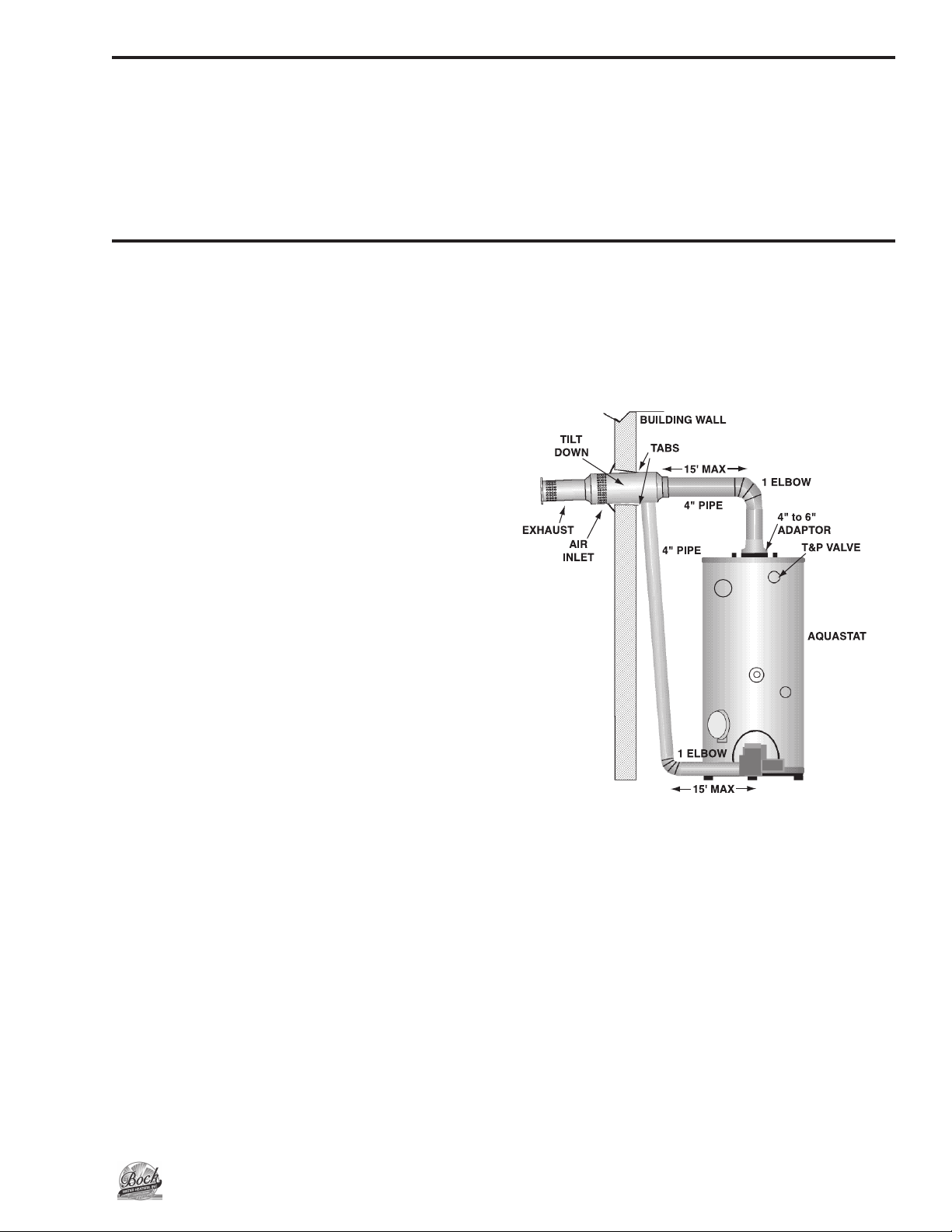

FLUE OUTLET PLACEMENT AND INSTALLATION

Flue outlet placement is of utmost importance for maximizing the performance of your Bock

Balanced Combustion System (BCS). Please see page 13 for unit dimensions. The following

instructions are recommended and may be code mandated for BCS installation:

n The wall opposite to prevailing winds

(east or south wall, if prevailing winter

winds are typically out of the west or

north) is the preferred wall for installation. This reduces the likelihood that

the Balanced Flue

operating against high winds and

severe cold when it is cycling the

most often.

n The flue outlet must be placed at least

one (1) foot above the highest anticipated snow load to prevent flue

blockage.

™

application will be

n Use a flat wall for the flue outlet and

stay a minimum of three feet from corners or any structure to reduce eddy

currents.

n The flue outlet should be located even

with or above the top of the water

heater and in a location requiring the

fewest inlet and outlet elbows possible.

n To reduce frosting effects, place the out-

let as far as possible from windows,

doors and other structural openings

such as eave vents—four feet is the recommended minimum.

n A minimum distance of three feet from

the outlet to plants and shr

gested; a greater distance is preferred, as

moisture and frost effects can result in

damage or loss.

n The Balanced Flue should be located

away from high traffic areas to prevent

damage to wall outlet and human contact with the hot exhaust sur

ubs is sug

faces.

-

Oil-Fired BCS Page 3Page 14 Oil-Fired BCS

1. Cut a 7" O.D. opening in the preferred wall and provide a minimum of 1⁄2" clearance

2 Mounting Tabs:

Attach to vent with

4 metal screws

supplied.

A

ttach vent to

b

uilding structure

w

ith 4 appropriate screws.

(

customer supplied)

of non-combustible space around the Balanced Flue. The opening should allow for a

1

downward pitch to the outside for drainage of any condensate in the Balanced Flue.

⁄2"

2. Insert the Balanced Flue from the

nside through the wall. Check the

i

outside extension to be sure air inlet

oles are exposed and will not be

h

covered by the flashing ring. Fasten

the assembly to the inside wall with

the tabs provided (see installation

detail drawing). On the outside

wall, install the flashing ring provided. Caulk around the outer and

inner rim of the flashing ring to

prevent moisture from entering

through the wall.

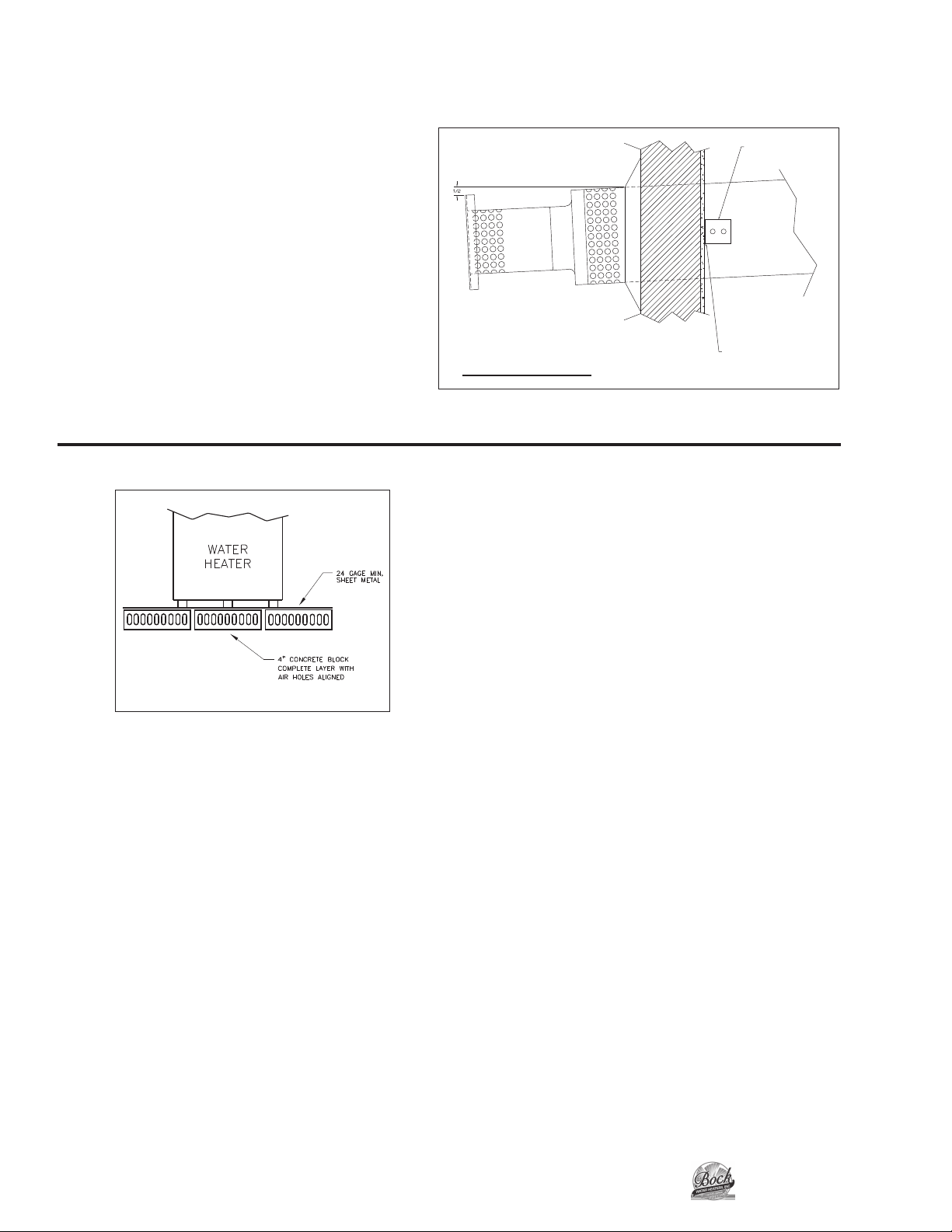

Installation Detail

WATER HEATER PLACEMENT

NOTE: Locate the heater so it is not subject to physical

damage from moving vehicles or flooding.

DO NOT INSTALL THE WATER HEATER ON COMBUSTIBLE FLOORING. Place on noncombustible

flooring and maintain clearances prescribed by this

manufacturer and per code NFPA 31. If the water heater

must be located on combustible flooring it should be

raised off the floor with a layer of 4" concrete block laid

so the air holes are aligned as shown in the drawing at

left. Please contact Bock Water Heaters or consult NFPA

31 with questions concerning proper flooring materials.

Leave adequate room for periodic maintenance of

heater and burner. The heater should be placed as near to the Balanced Flue as convenient in

order to keep vent connector length to a minimum, with a maximum horizontal run length of

15 feet.

Minimum clearance to combustible construction is: SIDES 6"; BACK 6"; FRONT 24". The installation

of this water heater must conform with local codes and ordinances. In the absence of local

codes, the installation must comply with the National Fir

otection Association (NFP

e Pr

A 31) Code.

Page 4 Oil-Fired BCS

CONNECT WATER PIPING

Be careful not to apply any heat to the water heater nipples. Install dielectric unions and shut

ff valves on both hot and cold water lines.

o

An approved pressure and temperature relief valve is factory installed in the opening provided

in the upper right-hand side of the water heater. Pipe the T&P to within 6" of the floor or to a

floor drain with a free flowing drain pipe.

CAUTION: Scalding injury and/or water damage can occur from either the manual

lifting of the lever or the normal operation of the T&P valve if it is not piped to a proper

drain. If the valve fails to flow water or reseat, call your plumber.

Check incoming water line for backflow preventers or water pressure reducing valves, as these

may cause pressure to build up in the water heater and result in tank failure. If this water

heater is installed in a closed system or if backflow preventers and pressure regulators are

installed, a properly sized expansion tank must be installed.

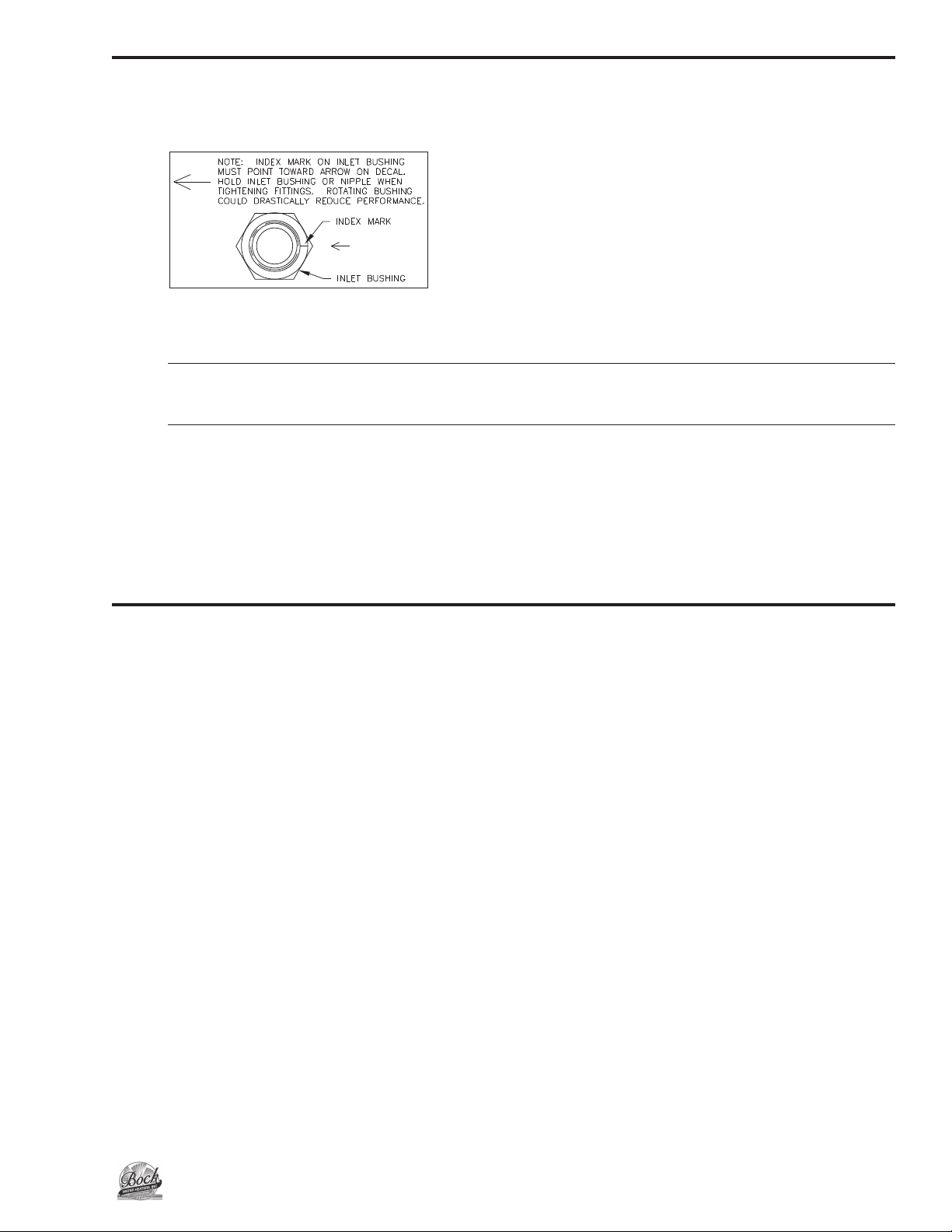

40 BCS models are equipped with a brass inlet bushing installed in the tank. Heaters equipped with this bushing are

marked next to the inlet by the decal shown on the left.

he purpose of this bushing is to help keep the tank bot-

T

tom free of sediment by aiding tank flushing. This bushing must be located as shown on the decal to function

properly. Do not allow the bushing to rotate out of position when tightening the inlet fittings.

Note: Do not try to heat hard water as this will drastically reduce heater life. Install a water

softener if the water heater is being installed in a hard water area (water hardness higher than

seven grains).

EXHAUST VENT

Where clearances to combustibles are a concern use double wall venting. Venting approved for Category III applicances is ideal but not required, single wall venting may be used

if allowed by local code. Caution: Do not use B-vent. The vent connector from the heater to

the rear of the Balanced Flue should be made using galvanized or stainless (preferred) vent material with a 4'' minimum diameter. A 6" × 4" reducer is placed on top of the heater flue. Note:

For 190E-BCS, a 6" vent pipe is preferred. Use one elbow to connect the heater to the venting.

An additional elbow may be used if the maximum horizontal distance from the BCS outlet to

the heater is reduced three feet. Maximum horizontal distance is 15 feet.

Venting from the heater to the Balanced Flue should be sealed but does not have to be pressure

tight. High temperature stainless sealing tape (2" wide) or high temperature (+500°F) RTV silicon sealants are recommended. Make certain the flue connector is removable for servicing.

Oil-Fired BCS Page 5

Loading...

Loading...