Page 1

POWER UNITS

& Gardening Attachments

OWNERS

USE & CARE

MANUAL

CODE NUMBER 90103079 EDITION 11.17

M O D E L S

710

722

732

718

HARVESTER

PROFESSIONAL

948

852

853

PROFESSIONAL

PROFESSIONAL

NEW HANDLEBARS

GARDENER

HARVESTER

PROFESSIONAL

Page 2

Dear Customer,

A

Thank you for your purchase. Get set to enjoy the benefits your wise

selection of a BCS unit has earned for you. We believe that no other

make machine that can handle so many lawn and garden tasks with

such fine results – and with so little effort on your part.

Your BCS unit has precision gearing for lasting, trouble-free service.

There are no drive belts to stretch and break.

Our network of BCS distributors and servicing dealers stands ready to

supply tour needs for attachments, accessories, parts and service.

With a yearly check-up, your dealer can help you keep your BCS

equipment to shape. Meanwhile, be sure to follow the operating and

maintenance tips in this owner’s manual for satisfied performance of

your machine.

BCS America

MODELS IN THIS EDITION

BCS America maintains a dynamic updating policy. If notifies the field of the serial number of the

first unit off the line after a change.

This edition covers the models and model options

listed in the specifications on page 16.

ccordingly, be sure to record the BCS unit serial

number printed between two stars on the transmission, and the engine model and serial numbers from the engine name plate.

GRAPHIC SYMBOL

IT FLAGS YOUR ATTENTION TO DANGER WARNINGS IN THE MANUAL.

WHEN PLACED OVER A PICTURE OR AN ITEM IN THE PICTURE, THIS SYMBOL SAYS

“NO !” DO NOT DO, OR USE OR PERMIT WHATEVER IS SHOWN.

THIS SYMBOL IS LIKE A FLAG.

READ ALL SAFETY RULES AND OPERATING AND MAINTENANCE

INSTRUCTIONS IN THIS MANUAL BEFORE USING ANY POWER UNIT,

ATTACHMENT, OR ACCESSORY.

WARNING

2

Page 3

CONTENTS

SECTION ONE

RULES FOR SAFE OPERATION

OF UNIT AND ATTACHMENTS

SECTION TWO

SCHEME CONFIGURATIONS

SECTION THREE

USE AND CARE OF ATTACHMENTS

GENERAL PRECAUTIONS AND INSTRUCTIONS

REAR-TINE TILLER PRECAUTIONS

ROTARY MOWER PRECAUTIONS

CUTTER BAR MOWER PRECAUTIONS

SNOW THROWER PRECAUTIONS

POWER SPRAYER PRECAUTIONS

CHIPPER/SHREDDER PRECAUTIONS

POWER SWEPPER PRECAUTIONS

MODELS DESIGNED FOR FRONT-MOUNTED ATTACHMENTS

MODELS DESIGNED FOR REAR-MOUNTED ATTACHMENTS

SPECIFICATIONS

MODEL 852, 853

MODELS 710

MODELS 718, 722, 732

MODEL 948

UNPACKING

ASSEMBLING THE UNIT

LUBRICATION FILTER AND FUEL

ENGINE CRANKCASE LUBRICATION

GEARBOX LUBRICATION

ENGINE AIR CLEANER

GASOLINE ENGINE FUEL

STARTING AND STOPPING

SETTING CONTROLS FOR COLD STARTING

CRANKING TO START

STOPPING

DIFFERENTIAL AND TWO-WHEEL DRIVE

WHEEL BRAKES

SHUT-DOWN (STORAGE)

TAKING CONTROL OF THE MACHINE

GEAR AND P.T.O. ENGAGEMENT

MAKING A CONVERSION FRONT-TO-REAR, OR REAR-TO-FRONT

OPERATING IN CONVERTED MODE

MAINTENANCE PROGRAM

LUBRICATION OF ATTACHMENTS

COUPLING ATTACHMENT TO P.T.O.

USE AND CARE OF REAR-TINE TILLER

PREPARING NEW TILLER

WIDTH OF TILTH

TILLING DEPTH ADJUSTMENT

GARDENING SUGGESTIONS

TRANSPORT SULKY FOR REAR-TINE TILLER

USE AND CARE OF CUTTER BAR MOWER ATTACHMENT

GENERAL CUTTER BAR MOWER INFORMATION

RECOMMENDED OPERATION

MOWER BAR MAINTENANCE

USE AND CARE OF 2-BLADE ROTARY MOWER

THE UNITS CONVERTED FOR MOWER USE

ASSEMBLY, CONNECTION AND LEVELING OF THE 2-BLADE MOWER

LUBRICATION

ROTARY MOWER OPERATION

INSPECTION AND MAINTENANCE

USE AND CARE OF SNOW THROWERS

GENERAL INFORMATION

SNOW THROWER OPERATION

USE AND CARE OF CHIPPER / SHREDDER

CHIPPER / SHREDDER MAINTENANCE

USE AND CARE OF POWER SWEEPER

OPERATION

MAINTENANCE AND STORAGE

USE AND CARE OF DOZER BLADE

Page 5

“ 8

“ 9

“ 10

“ 10

“ 11

“ 12

“ 13

“ 15

“ 15

“ 16

“ 17

“ 18

“ 19

“ 20

“ 21

“ 21

“ 25

“ 25

“ 25

“ 26

“ 27

“ 28

“ 29

“ 30

“ 30

“ 30

“ 30

“ 31

“ 31

“ 31

“ 32

“ 33

“ 35

“ 36

“ 36

“ 37

“ 37

“ 37

“ 37

“ 38

“ 38

“ 39

“ 39

“ 39

“ 39

“ 41

“ 41

“ 41

“ 42

“ 42

“ 43

“ 44

“ 44

“ 44

“ 45

“ 45

“ 46

“ 46

“ 46

“ 47

3

Page 4

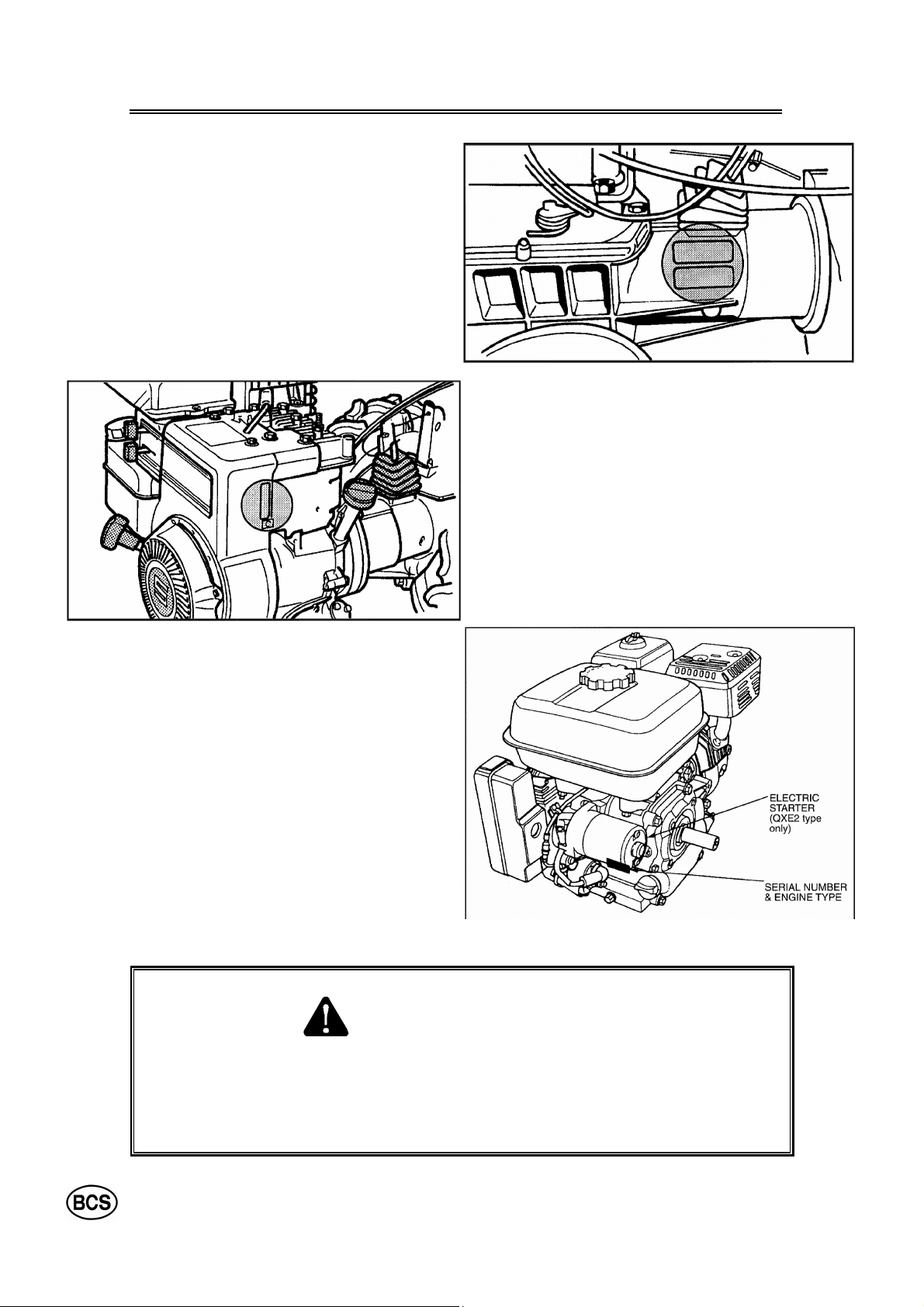

RECORD OF SERIAL NUMBERS .

BCS UNIT SERIAL NUMBER * __________ *

(Located between stars on transmission)

BRIGGS & STRATTON

ENGINE SERIAL NUMBER __________

(Stamped on crankcase about two inches from

name plate on side of engine)

HONDA ENGINE SERIAL NUMBER:

TYPE _____________

SERIAL NO. ____________

KOHLER ENGINE SERIAL NUMBER ____________________ (Located on engine crankcase)

READ ALL SAFETY RULES AND OPERATING AND MAINTENANCE

INSTRUCTIONS IN THIS MANUAL BEFORE USING ANY POWER UNIT,

ATTACHMENT, OR ACCESSORY.

WARNING

4

Page 5

SECTION

INSTRUCTIONS FOR SAFE OPERATION OF

BCS POWER UNITS AND ATTACHMENTS

General precautions and instructions are followed by specific precautions

for each combination of attachment and power unit in the owner’s manual.

GENERAL PRECAUTIONS AND

INSTRUCTIONS .

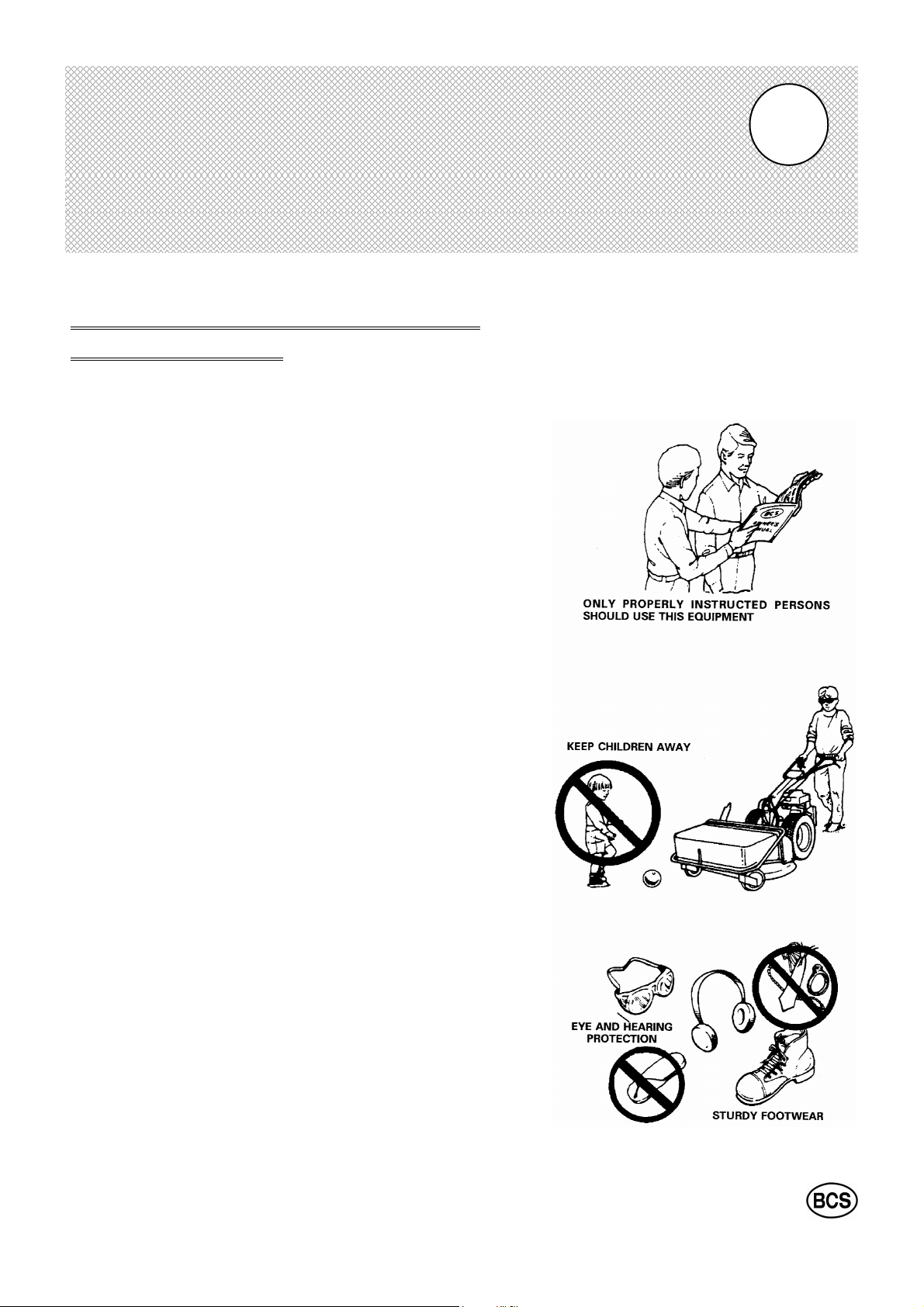

TRAINING

READ THIS OWNER'S MANUAL PRIOR TO OPERATING THE

POWER UNITS AND ATTACHMENTS.

BCS power units and attachments are designed for operation by properly instructed adults only. Make certain that any person operating

this equipment has read this manual.

DO NOT LET CHILDREN OPERATE THE POWER UNIT.

KEEP THE OPERATING AREA CLEAR OF PEOPLE AND ANIMALS. BE CAREFUL THAT CHILDREN DO NOT COME NEAR.

During storage, and whenever the power unit is unattended, disengage the PTO (power take-off) and render the engine unstartable by

disconnecting the spark plug wire from spark plug.

1

PREPARATION

Wear appropriately protective clothing and safety protection articles

for the climate and type of attachment you are to operate.

1. For all walk-behind applications, wear sturdy non-slip boots or safety toe shoes. See recommendations listed for use of a particular

attachment. Do not wear open-toed sandals or go barefoot when

operating these machines.

2. Wear snug-fitting protective clothing which allows freedom of mo-

vement without being loose-fitting. Ties, scarf and jewels which

could be caught in the machinery should not be worn.

3. Wear hearing protection.

4. Wear eye protection when operating a snow-thrower, power spra-

yer, chipper / shredder or mower attachment.

Overexposure to sunlight can be damaging to your eyes and skin.

5.

When working in strong sunlight, protect your eyes with sun glasses and either keep your body covered or apply a sun screen

lotion.

Do not operate on terrain where you cannot maintain good footing or

where the machine could overturn or slide into you. When walking

behind the unit, walk slowly. DO NOT RUN!

5

Page 6

2 1

Thoroughly inspect the area where you are going to mow or

thatch the lawn, sweep walks or drives or throw snow. Remove toys, stones, bones, wires, glass, newspapers and other

objects which could be caught up and thrown by the machine.

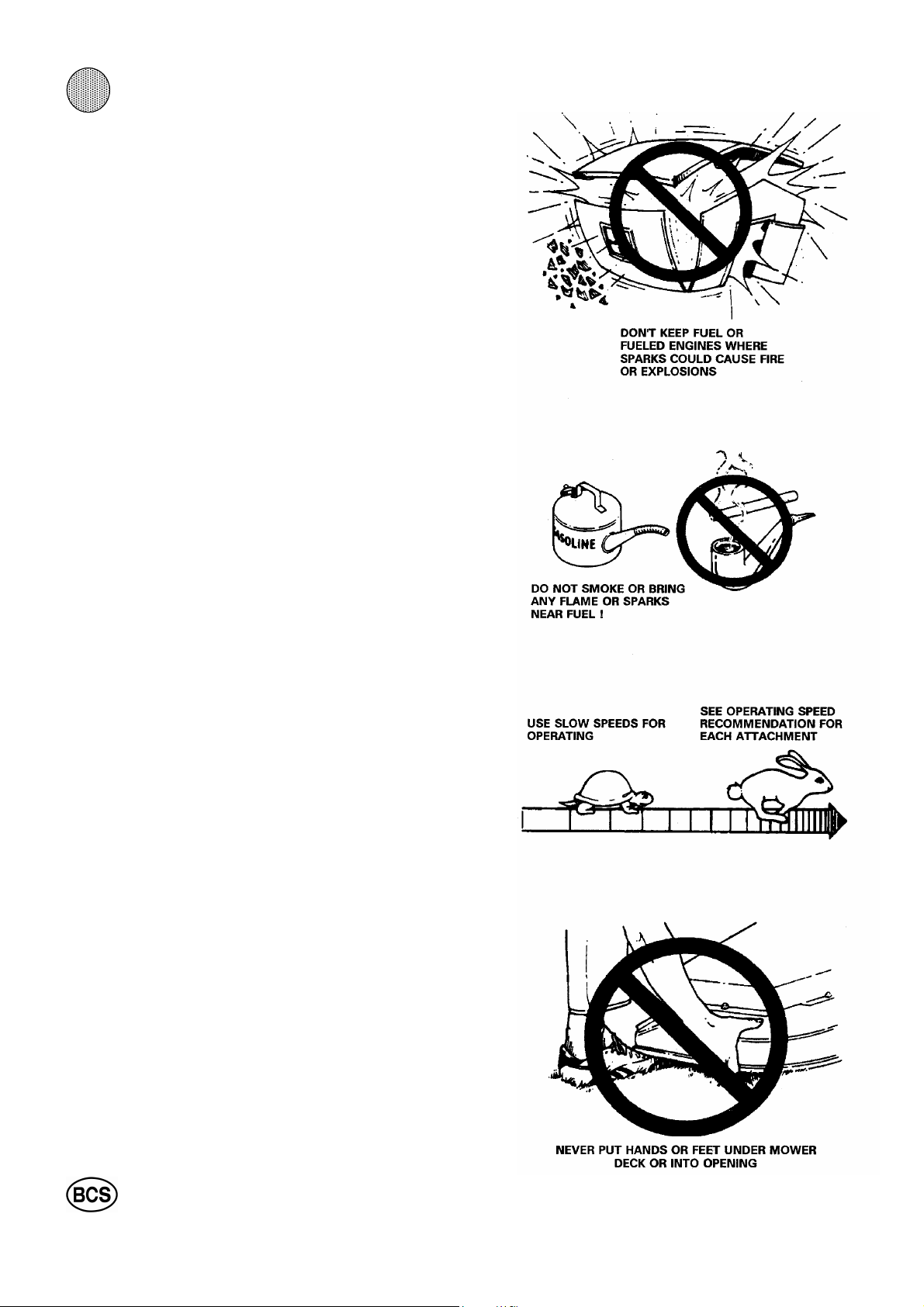

Take the following precautions for the safe handling and storage of fuel:

1.

Keep fuel supplies in approved type, properly labelled fuel

containers.

2.

Do not store fuels or fuelled units in closed (unventilated)

areas or in garages or shops connected to human living quarters. Do not store units or fuel where there are flames or sources of sparks such as electrical appliances and switches.

3. Obey all local regulations for the storage and handling of

fuel.

4. Do not smoke when fuelling, or fuel where the fumes could

be ignited by fire or sparks.

5. Do all fuelling outdoors over non-flammable surfaces. If fuel

is spilled on the unit, wipe the unit dry and properly dispose of

the wiping rag. ALWAYS MOVE THE UNIT AT LEAST 10

FEET (3 m.) AWAY from the fuelling spot and fuel supplies before starting the engine.

6. Always remove the engine fuel cap very slowly to equalize

tank pressure and avoid spurting of fuel. Keep your face and

eyes away from the tank while loosening the fuel cap.

7. Do not fuel a running or hot engine. Do not loosen the fuel

cap until the engine has stopped.

Then wait several minutes for the engine to cool before pouring fuel. Before starting the engine, put all control levers in

neutral (N) position. All "N" positions on the gear selector are

neutral. Also be sure to disengage the PTO (power take-off) to

the attachment. Never make blade height or any other adjustment to the power unit or any attachment while the engine is

running.

OPERATION

Operate only when there is good visibility. Do not operate at

dusk or at night. Do not operate when it is foggy or hazy.

Never change the engine governor setting or overspeed the

engine. Use the throttle and gear settings recommended for

particular attachments and applications in this owner's manual.

Do not put hands and feet under the mower deck or into the

discharge openings of a rotary mower.

Do not put fingers or any other part of the body into the intake

or discharge openings of any mower, snow-thrower or chipper/

shredder unless you have disconnected the spark plug wire so

engine cannot be started accidentally.

Keep the machine clean-out holes closed. Stay out of the discharge stream of a mower, chipper/shredder, power sweeper

or power sprayer.

Always stop operation of a rotary mower, a cutter bar mower,

snow thrower or a tiller before crossing paved or gravel roadways.

6

Page 7

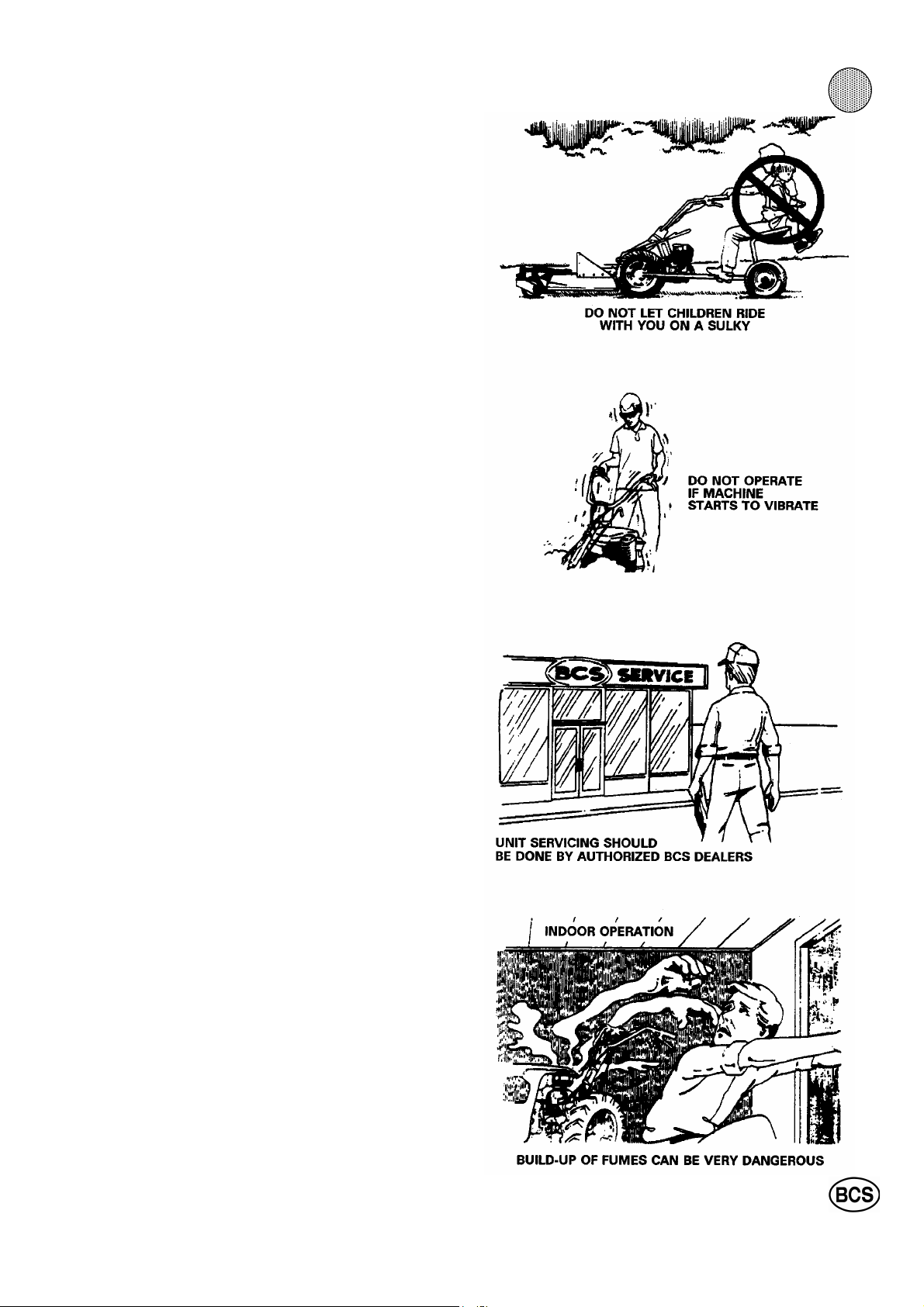

Never ride the tractor or an attachment. Ride only on riding accessories designed for the purpose. Do not take

children on a sulky with you.

1. Use transport sulkies only for transport to and from

the operating area and never for operation.

2. Use utility wagons only for hauling and limit the pay-

load to the rated capacity of the wagon.

3. A mowing sulky is exclusively for operation of a rota-

ry mower and must not be used with any other attachment.

4. Never use ride-on attachments on the highway or

any city street.

Do not disconnect or otherwise defeat the purpose of

the lockout devices.

The high-speed lockout prevents using too fast a gear

for backing up a front-mounted attachment.

The PTO/REVERSE lockout permits backing up a rearmounted attachment only when the PTO is disengaged.

Read Section Two for explanation of the lockout devices.

Do not use the highest numbered gear on the gear selector when walking behind the machine.

On all units in this manual, the highest gear produces

much faster than walking speed and is only to be used

for transport in conjunction with a transport sulky.

Don't make adjustments or repairs to the machine when

the engine is running.

Put all controls in neutral, wait until reciprocating or rotating parts of the attachment have stopped and disconnect the spark plug wire:

1. Before leaving the unit where unauthorized persons

may start it accidentally.

2. When a foreign object has been struck or taken into

the attachment. Proper operation should be restored before further use.

3. Before cleaning out a clogged attachment such as a

rotary mower, cutter bar mower, snow-thrower, chipper/

shredder or power sweeper.

4. If the machine suddenly starts to vibrate or run erra-

tically. The entire machine should be inspected by an

authorized BCS servicing dealer before further use.

All safety guards, plates, lockouts, deflectors and shields

must be in proper position.

Do not operate if any safety devices or fastening parts

are missing from the unit.

Do not run the engine indoors where deadly poisonous

carbon monoxide fumes can collect.

If the engine is to be started inside a garage or barn,

open the doors and windows wide so the fumes can

escape.

7

21

Page 8

2 1

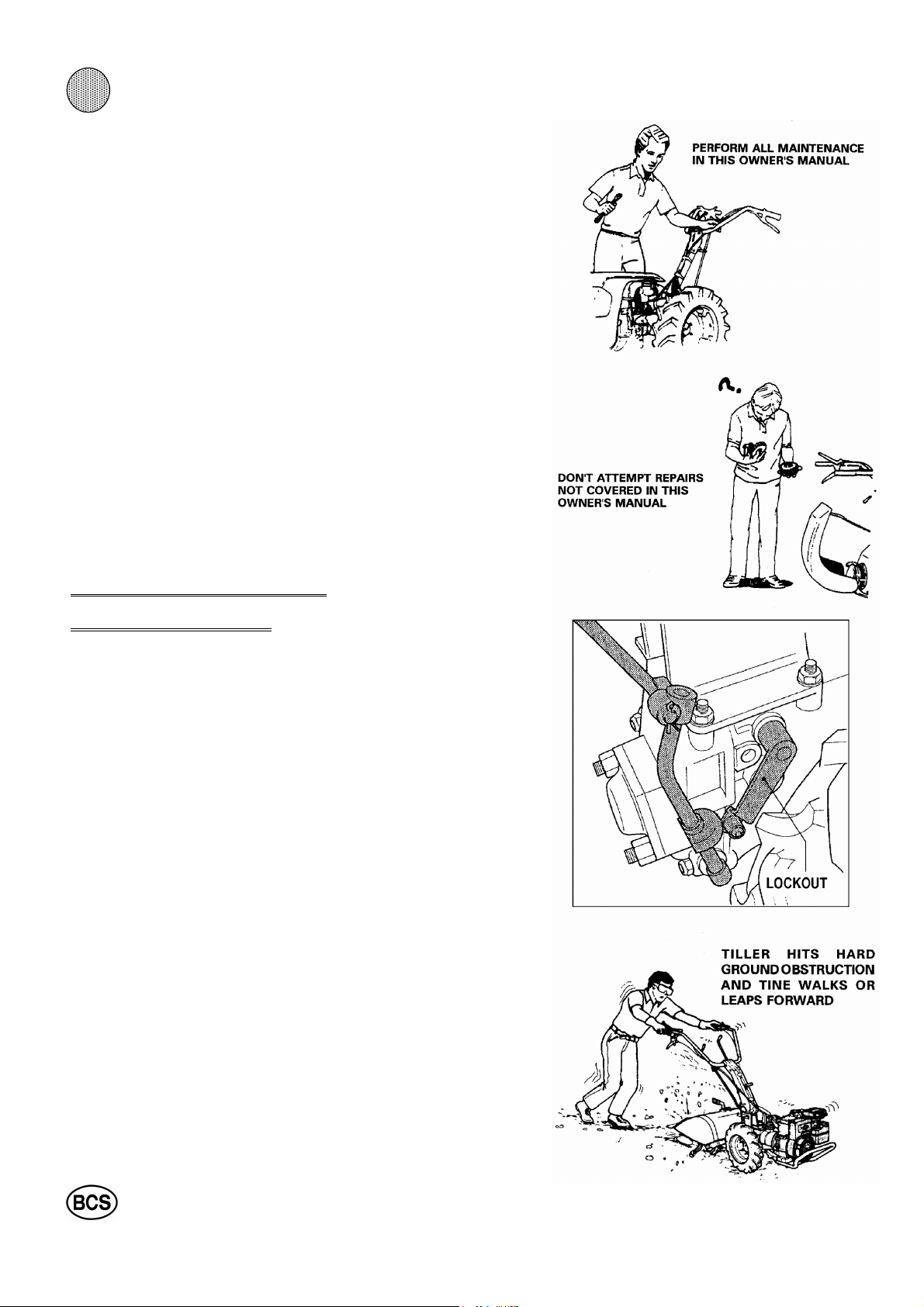

MAINTENANCE AND STORAGE

Keep engine, tractor and all attachments in safe working condition. Clean the unit and accessories at regular intervals, also

check for damaged or missing parts.

Check the tightness of all fasteners. Perform the items of maintenance recommended in this owner’s manual. Do not attempt any

disassembly and repairs for which instructions have not been

furnished.

Certain engine adjustments, and interval servicing of the engine,

tractor, clutch and transmission, and gearboxes of attachments

should be done only by a BCS-trained service-man at an authorized BCS servicing dealer or distributor.

Do not store the machine with fuel in the system. Disconnect the

fuel line at the carburettor inlet, and drain the fuel into a fuel

container. Then reconnect the fuel line. Start and run the engine

until it stops from lack of fuel.

When storing the machine, use the spring latch (illustrated on page 29) to latch the clutch lever in the depressed

(disengaged) position. This prevents the clutch cone from

sticking to the lining during storage.

Store the machine in a well-ventilated place, protected from

dampness and the weather.

REAR-TINE TILLER

PRECAUTIONS .

All the models have PTO / reverse lockout devices to prevent

tine rotation while the Tiller is being backed up. These devices

are shown and their operation described on page 28. Before

operating the Tiller, always check that the lockout device is

properly assembled on the machine. Do not remove the high

speed lockout or render it inoperable.

Don’t put hands or feet near or under the tiller housing. Keep

away from the rotating tines. The tines of the BCS tiller rotate

at high speeds independent of the tractor gear speed settings.

Inspect the area to be tilled. Pick up rocks and other objects of

a size which may jam or otherwise interfere with tiller operation. Till only when there is good light.

Use caution to avoid slipping and falling. Wear footwear which

will improve footing on slippery surfaces. Do not over-load the

machine by attempting to till too deeply or in fast forward. See

tiller operation instructions in Section 3.

On new (previously untilled) or hard, rocky ground, use lowest

gear and throttle settings, and set the tiller tines for minimum

soil penetration. Be alert for the possibility the machine may

leap forward if the tines contact an underground obstruction. If

this occurs, let go of the tiller handles to stop the engine.

Do not use makeshift accessories in conjunction with the tractor and the tiller. Use only wheels, counterweights, shaft extensions, connectors, and tine combinations recommended for

each tractor and tiller attachment by BCS.

The highest number gear selection is only for transport of

the unit and tiller attachment in conjunction with a transport sulky.

8

Page 9

Don't operate the tiller in high gear. Don't use high transport

speeds on slippery surfaces. When using a transport sulky, look

behind and use care when backing.

DO NOT MOW WITH

GRASS DEFLECTORS OPEN

21

ROTARY MOWER PRECAUTIONS

IMPORTANT NOTICE

Do not deactivate the PTO Reverse Lockout on any of the

convertible models. The new design lock-outs on thee models automatically disengage during a conversion for frontmount attachments.

Clear the area to be mowed of all objects (wires, rocks, toys,

etc.) which might be picked up and thrown by the mower.

Disengage the PTO and put the transmission into neutral (gear

selector position "N") before cranking to start the engine and also

whenever leaving the operator zone behind the handlebar or dismounting from a sulky. Stay alert for holes, rocks, roots in the terrain and other hidden hazards. Keep away from drop-offs. Use

wheel extensions for added stability of a walk-behind mower.

When walking behind, be especially cautions when changing direction on slopes.

When operating from a riding sulky, reduce speed and use extreme caution on slopes and in sharp turns to prevent tipping and

loss of control.

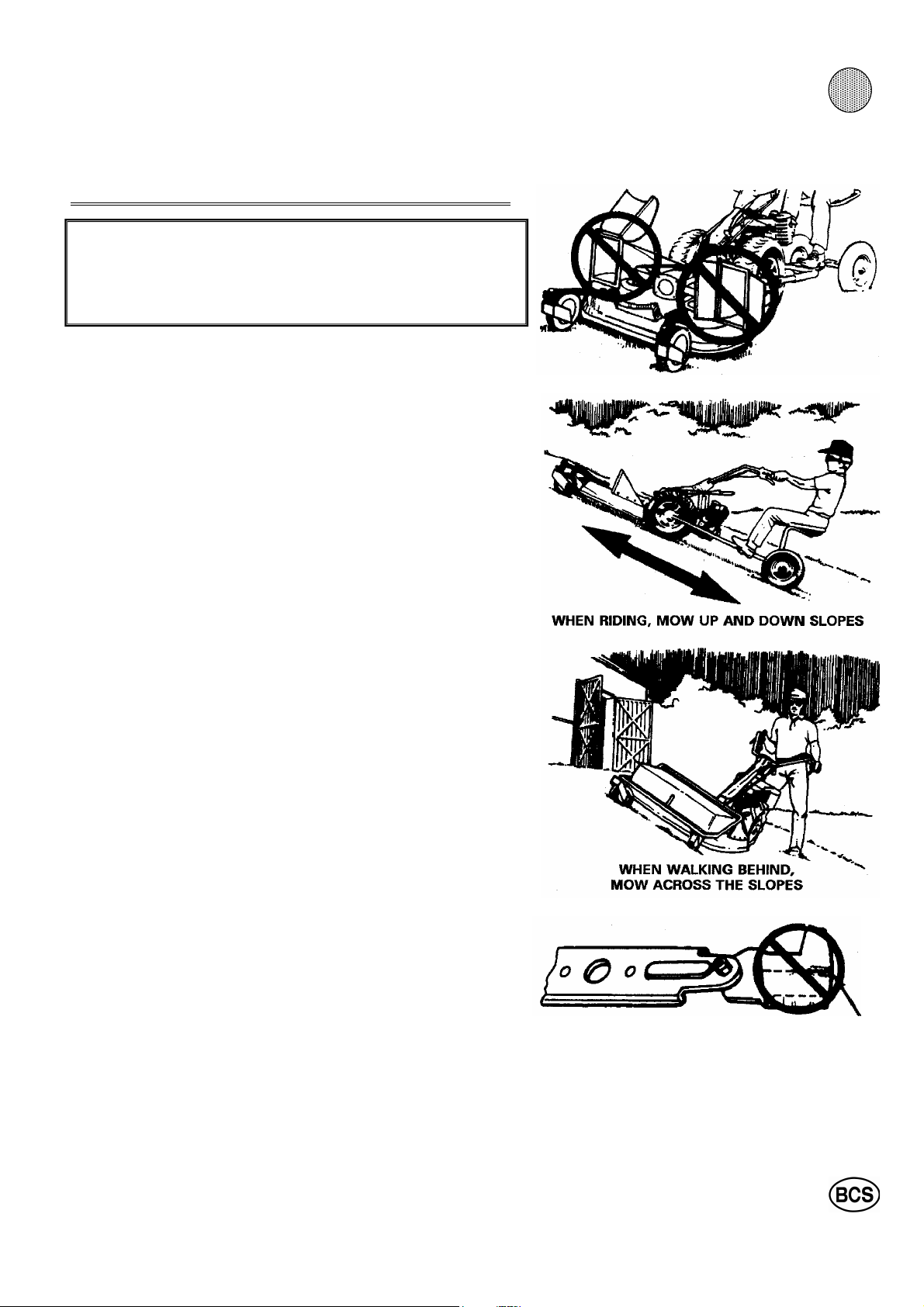

MOW SLOPES AS FOLLOWS:

1. When riding, mow up and down, never across the slopes.

2. When walking behind, mow across the slopes, never up and

down.

3. Do not mow excessively steep slopes.

Be careful not to discharge grass in direction of roadways, houses, vehicles and people. Inspect grass bags frequently for wear

and deterioration. Replace grass bags which are not in good condition.

When the 2-blade mower is used without the grass bag, the

grass deflector must be in the down position covering one discharge chute, and the door on the other chute must be closed to

prevent open discharge from the chutes.

When mounting the grass bag on the deck to collect the cuttings,

open the door and raise the deflector for discharge from the volutes into the bag.

Before removing the grass bag for emptying, disengage the PTO,

shut off the engine and wait until the mower blades have stopped.

Never put hands in any openings of the mower or grass bag

when the engine is running. If necessary to clear out the discharge chute with your hands, always first disconnect the spark

plug wire.

Keep the mower blades in good condition. Inspect, sharpen and

maintain blades as recommended for mower attachments in Section 3. Replace bent, badly worn blades, because pieces breaking off can become projectiles. After sharpening, blades should

be balanced.

CRACKS

9

Page 10

2 1

IMPORTANT NOTICE

Do not deactivate the PTO Reverse Lockout on any of

the convertible models. The new design lockouts on

these models automatically disengage during a conversion for front-mount attachments.

CUTTER BAR MOWER

PRECAUTIONS

Cutter Bar Mower attachments are intended for walk behind operation only. Do not use a riding sulky.

Mow only at a slow rate of speed. See page 39 for recommended throttle and gear combinations for cutter

bar mowing. Do not use (transport) gear # 4 on 852 for

any purpose other than using a transport sulky for transport. Transport speed of these models far exceeds the

walking speed of an operator.

The models 718, 722, 732 and 948 converted for cutter

bar operation have high gear position blocked by a high

speed lockout.

Do not remove or otherwise defeat the purpose of

the high speed lockout device.

Disengage the PTO when backing the machine.

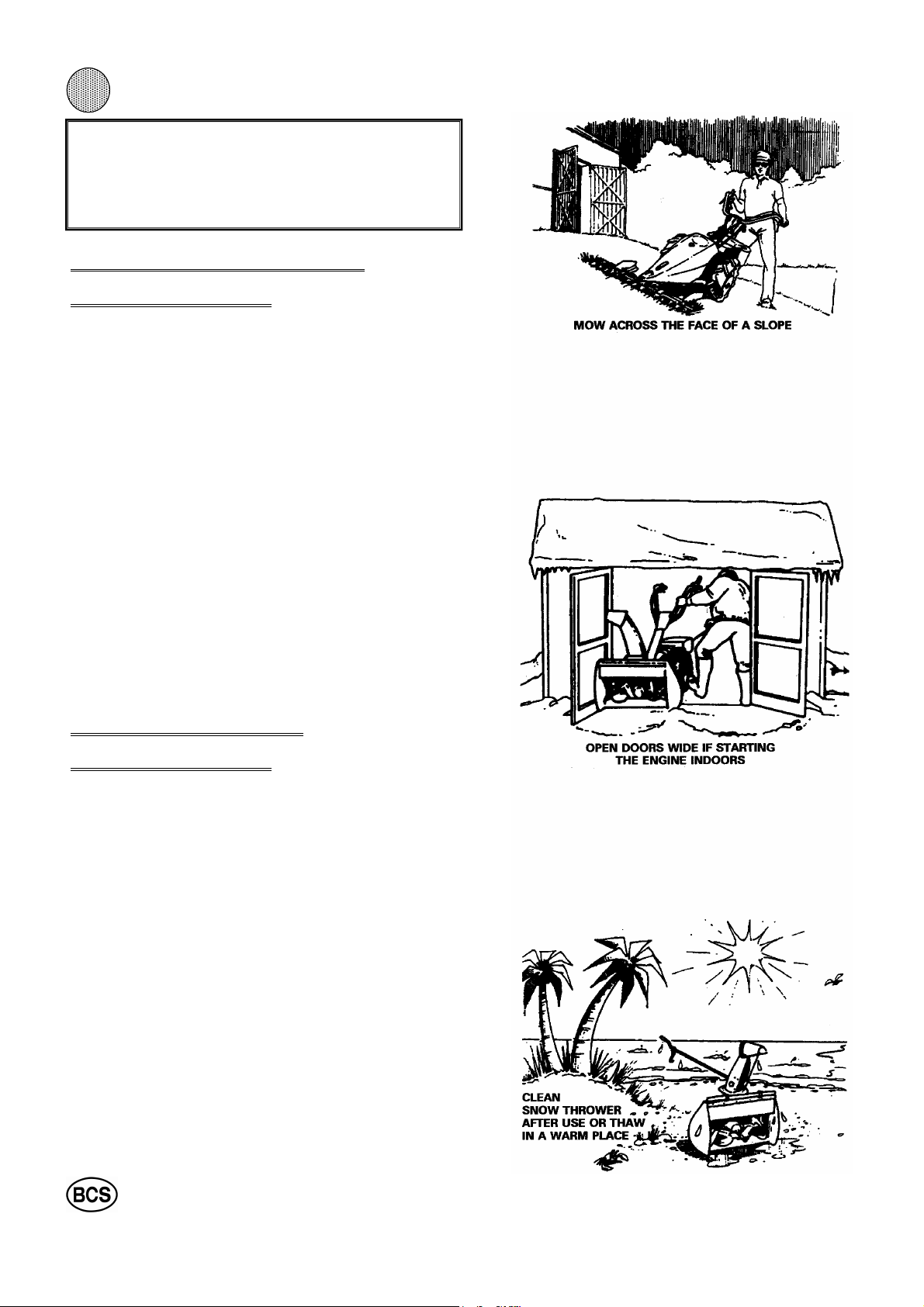

Cutter bar mowers are designed for mowing over terrain

which is too rugged or steep for use of rotary mowers.

Use care when mowing hilly terrain. Always mow across

the face of a slope, never up and down. Use wheel

extenders for added stability. Do not mow excessively

steep slopes. Go slowly and carefully on all turns.

SNOW THROWER

PRECAUTIONS

Wear protective trim fitting winter clothing with no scarf

or draw strings which could be caught in the machinery.

Wear boots or shoes designed to improve tour footing

on slippery surfaces. Wear proper eye protection. When

necessary to start the engine indoors and drive the machine out of the building, keep the doors and windows

wide open. Exhaust fumes can be dangerous.

Never put your hands into the discharge opening or impeller/collector when the engine is running. Always disengage the PTO, shut off the engine and wait until all

moving parts have stopped before doing the following:

1. Cleaning or deicing the impeller/collector and discharge chute (if possible, detach snow-thrower and

thaw in a warm, dry place).

2. After striking a foreign object, thoroughly inspect for

damage. Make repairs before further operation.

Never use the snow-thrower near glass enclosures,

automobiles, window wells, drop-offs, etc., without adjusting the discharge angle away from them.

Keep children, pets and observers away.

10

Page 11

21

POWER SPRAYER

PRECAUTIONS

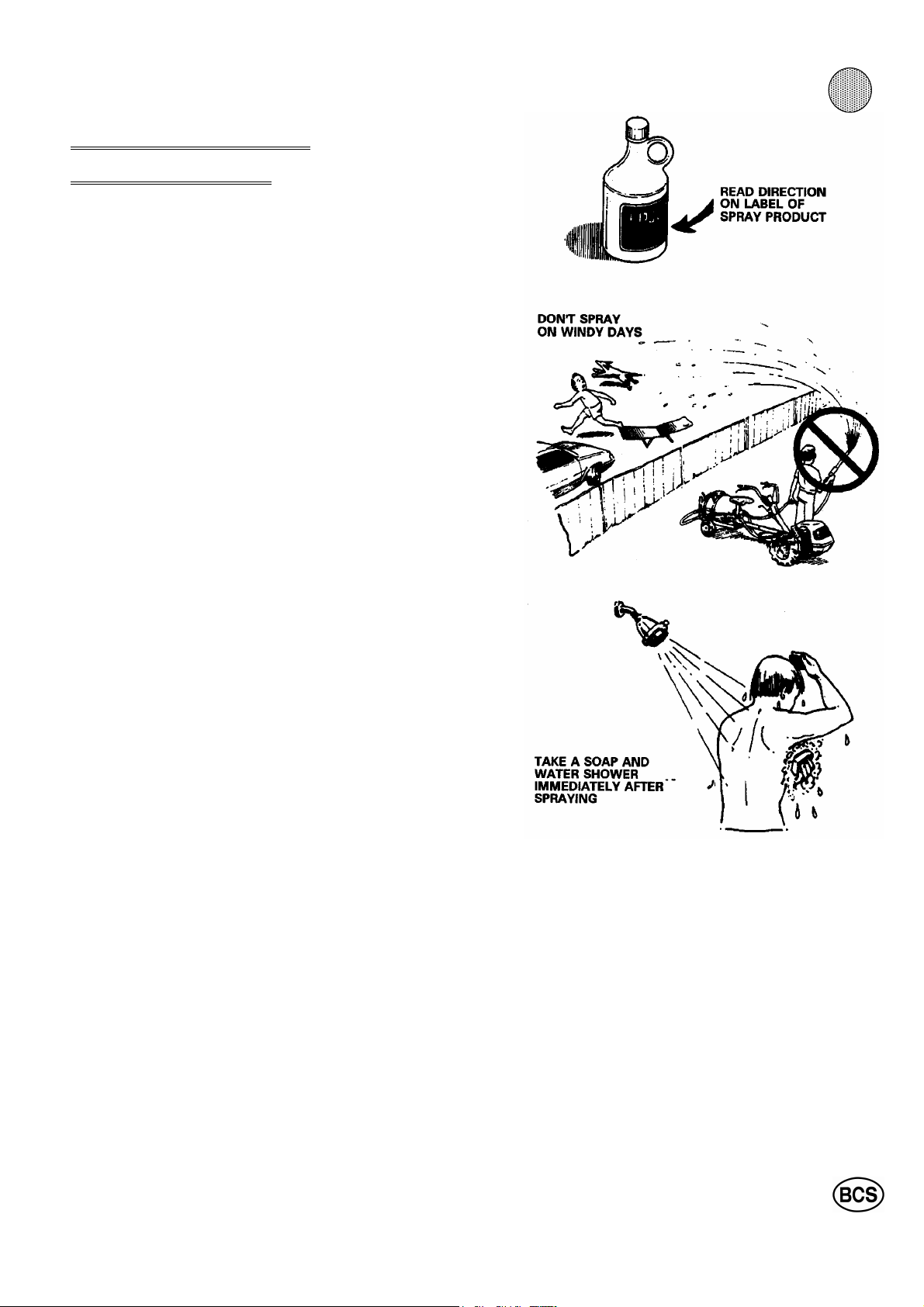

Always read and follow the information and instructions for

the application of herbicides, fungicides, insecticides and

fertilizer obtained from the labels of such products or from

the manufacturer.

In addition, advice on chemicals approved for use in your

area can be obtained from your local county agent. Be

sure you know the proper application rate for any chemical

you wish to spray.

Inspect the sprayer before each use. The sprayer develops high pressure so be sure all pressure lines and connections are in good condition.

Choose windless days for the spraying of any chemical

considered hazardous. Do not spray where drift could contaminate people, animals or property.

When applying any substance dangerous if breathed in or

absorbed through skin, wear adequate protection. This

should include rubber gloves and boots, goggles, respirator masks, caps and clothing to cover as much as possible of the body. Cotton articles are suggested for their

washable as well as high absorbency. After the spraying of

any hazardous substance, remove clothing articles for

laundering and immediately take a thorough soap-andwater shower before residues have time to enter your body.

Before spraying, always prepare for proper wash-down of

equipment.

Never allow passengers to ride the sprayer.

The pressure at the discharge nozzle is as high as 300 psi.

The spray can penetrate the skin and cause severe blood

poisoning. Do not put hands into the discharge stream. Do

not direct spray at people or animals.

Unless the manufacturer of the chemicals claims that certain products can be combined for application, spray only

one chemical at a time. Flush the sprayer tank before

changing sprays.

Always hose down the equipment and flush the sprayer

tank after each use. Select an area where the run-off will

not contaminate ground water. Do not dump into ditches

and storm sewers.

11

Page 12

A

2 1

CHIPPER/SHREDDER

PRECAUTIONS

Read all instructions in this owner's manual, plus detailed instructions in the Chipper/Shredder owner's manual.

Material may be thrown out of the intake or discharge

openings at high velocity. Wear safety eye protection

goggles stamped "Z87" (for ANSI Standard Z87). Also

wear a hat.

Wear trim-fitting articles of clothing with no dangling ties

laces, chains, etc. Remove rings, bracelets and wrist

watches before operating the Chipper/Shredder. Gloves

may be worn when feeding the Chipper but remove

gloves before feeding material into the Shredder hopper.

Set up the machine on soft, firm ground which provides

support and acts as a shock absorber. But, do not set

up on hard paved or gravel surfaces which provide no

cushion.

Before starting the engine, always look to be sure the

Chipper/Shredder is empty.

Do not go on the discharge side when the Chipper/

Shredder is running. Do not look into the Shredder hopper or place your head over it when feeding material. Do

not feed the chipper chute from directly in front but always stand to the side.

Do not reach into the chipper chute to push through

short pieces. Push short ends through with another long

branch.

Put only materials which can be shredded into the hopper.Be careful not to include cloth, string plastics, grass,

rubber, rocks or paving, bricks, large wood chunks, metal or long branches or vines. These things cannot be

shredded and can cause violet ejection of materials

from the Chipper/Shredder.

Do not allow processed material to pile up in the discharge area. A blockage of the discharge can result in

kickback of material through the feed opening.

lways disengage the PTO before transporting the unit

and attachment. Never leave the machine unattended

without putting the controls in neutral and disconnecting

the spark plug wire to prevent unauthorized operations.

12

Page 13

A

21

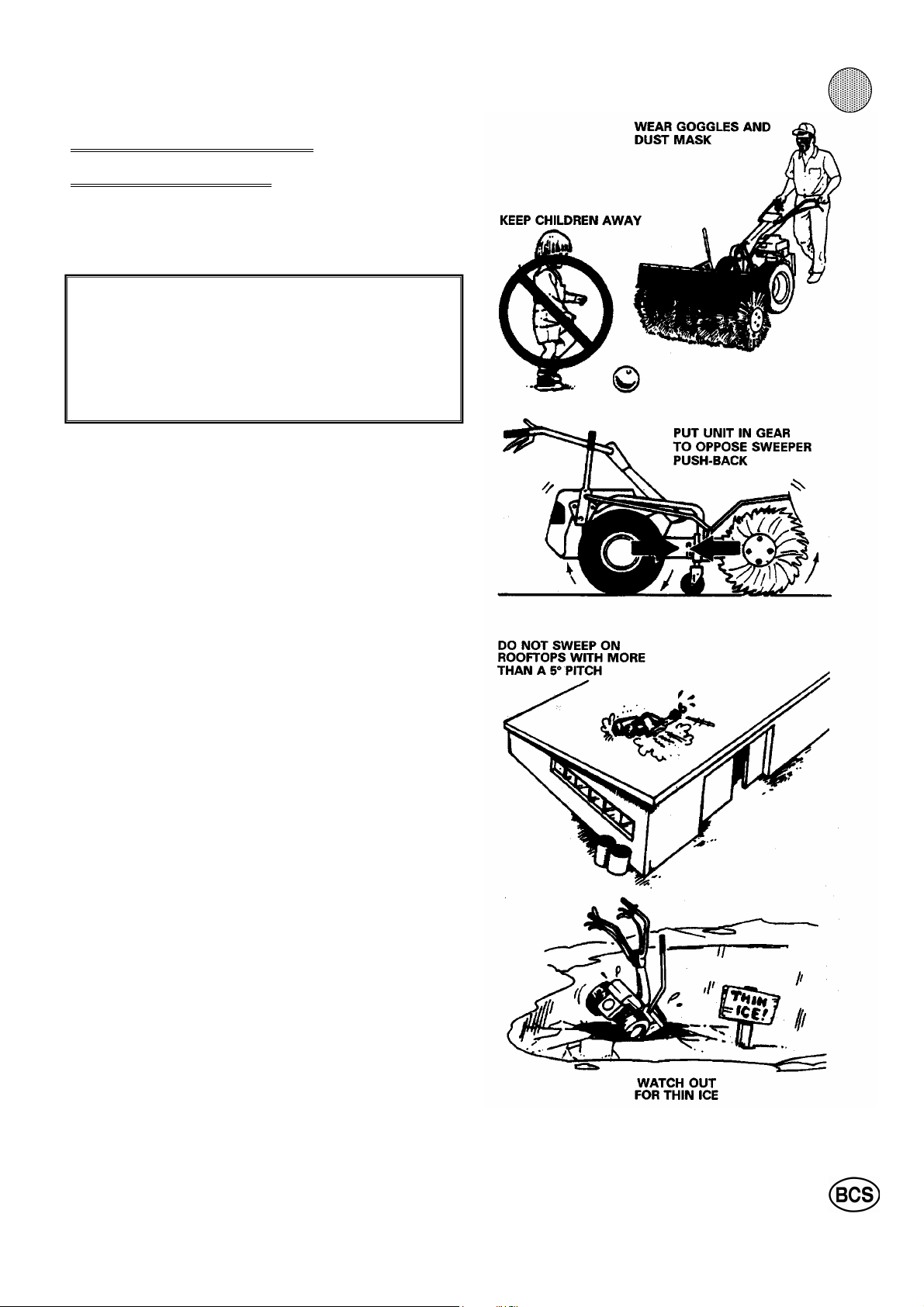

POWER SWEEPER

PRECAUTIONS

Follow "General Precautions and Instructions" in Section One of this manual, and all instructions in the Power Sweeper Attachment owner's manual (part number

101.00915) for the safe use of the Power Sweeper.

IMPORTANT NOTICE

Deactivation of the PTO Reverse Lockout (see WARNING in Sweeper owner's manual) is not to be done

on the tractor models in this updated owner's manual.

New design lockouts automatically disengage during

the conversion of these models for the Sweeper or any

other front-mounted attachment.

Do not put hands, feet or any other part of your body

near the sweeper brush or any other rotating part.

Keep the work area clear of people and pets. Do not let

children come near. Be extremely careful on gravel or

paved surfaces to direct the discharge away from people and passing vehicles.

Wear a dust mask or respirator for protection when

sweeping dusty surfaces.

Wear eye protection goggles stamped "Z87" (for ANSI

Standard Z87).

Before transport or storage of the unit adjust the casters

of the sweeper so the bristles do not touch the ground.

Thoroughly inspect the surface to be swept and remove

objects which could be thrown by the sweeper or cause

it to run off course. Remove wires, glass objects, doormats, boards, toys and other obstructions.

lways put the unit in gear before engaging the PTO to

power the sweeper. If the sweeper bristles engage the

ground when the unit is in neutral, the sweeper will drive

back the unit.

On irregular terrain with hillocks, prepare to let go of the

controls to stop all motion if the brush suddenly drives

the unit backward.

Do not use the sweeper on any surface where you

cannot keep tour footing or the unit could overturn. Walk

behind the unit. Disengage the PTO when going up or

down a slope. Work across the slope when sweeping or

thatching.

If using the sweeper on rooftops, set up barricades so

you will not come too close to the edges. Be sure the

surface is dry and does not pitch more than 5 degrees

(1/2" per foot).

Do not drive the sweeper onto frozen lakes or ponds

unless the ice is thick and strong enough to support the

combined weight of you, the sweeper and the unit.

13

Page 14

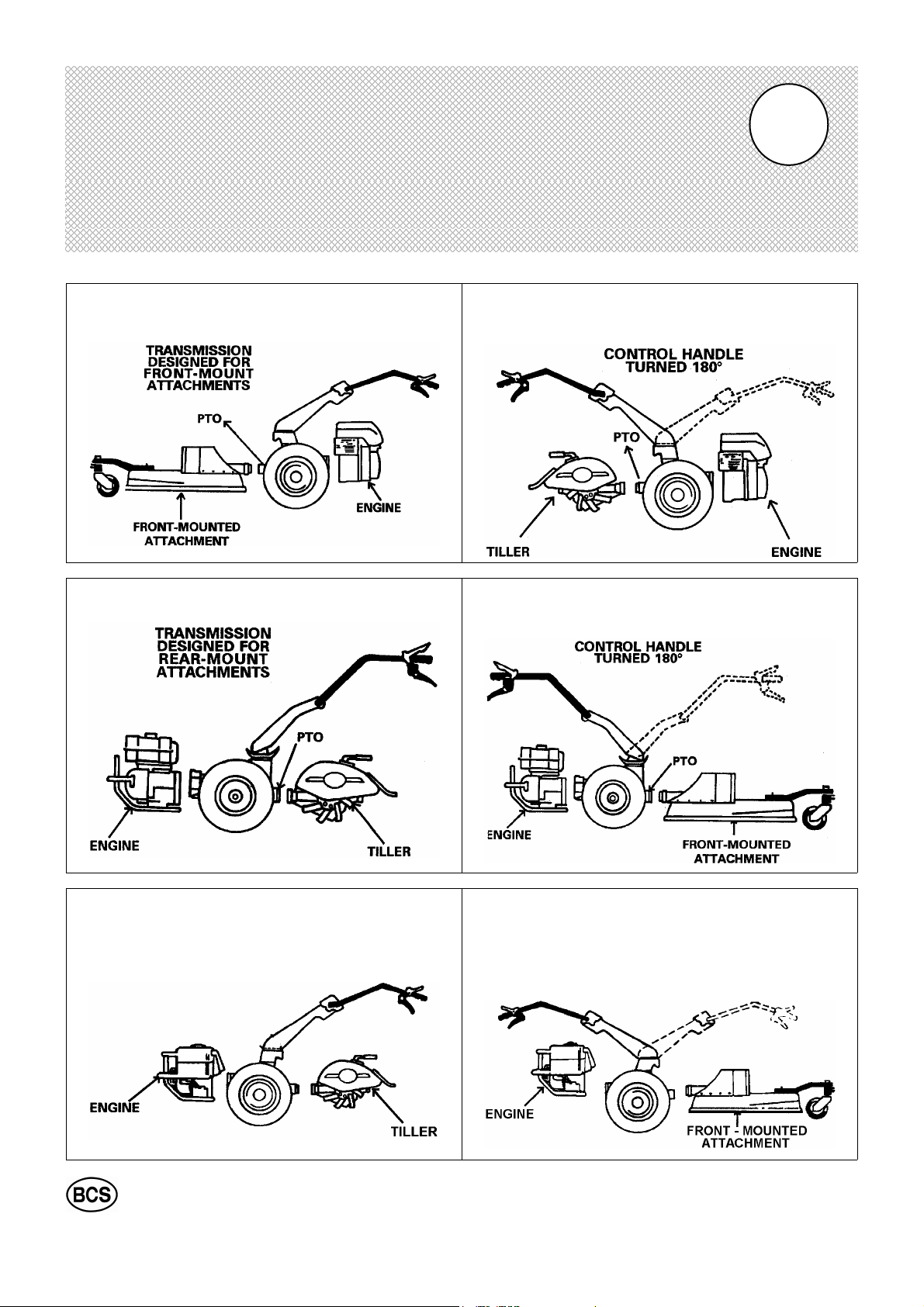

SECTION

SCHEME CONFIGURATIONS

2

MODEL 852 / 853

FRONT-MOUNT MODE

MODELS 710/718/722/732

REAR-MOUNT MODE

NATURAL CONFIGURATION CONVERSE-MODE CONFIGURATION

MODEL 852 / 853

CONVERSION FOR REAR-MOUNT ATTACHMENT

MODELS 710/718/722/732

CONVERSION FOR FRONT-MOUNT ATTACHMENT

MODEL 948

REAR-MOUNT MODE

TRASMISSION DESIGNED FOR

REAR-MOUNT ATTACHMENTS

MODEL 948

CONVERSION FOR FRONT-MOUNT ATTACHMENT

CONTROL HANDLE

TURNED 180°

14

Page 15

MODELS DESIGNED FOR

FRONT-MOUNTED ATTACHMENTS

Models of the 800 series are convertible model designed primarily as pusher for front-mount attachments,

they have the PTO (power take-off) coupling up front,

and the engine and control column at the rear.

852 has 4 speeds forward and 3 speeds reverse as pusher, 3 speeds forward and 3 speeds reverse as tractor.

853 has 3 speeds forward and 3 speeds reverse as

pusher, but in rear-mount attachments (tractor) has 4

speeds forward and 3 speeds reverse.

Swinging the handlebars around to place them over the

PTO coupling at the rear of the unit converts them for

rear-mount attachments (tractor).

The transmission changes drive wheel rotation to drive

the unit forward in either front-mount or rear-mount

mode.

Selecting one of three available gear positions on the

gear selector, and engaging the red reverser lever on

the right handlebar backs up the unit in either frontmount or rear-mount mode.

The high speed lockout blocks selection of gear position #4 for backing up the units.

MODELS DESIGNED FOR

REAR-MOUNTED ATTACHMENTS

All models of the 700 series and 948 are designed for

rear-mount tillers, and all models are convertible for

front-mount attachments.

In the rear-mount mode, the PTO (power take-off) flange and the control column are at the rear and the engine is up front.

Models 710, 718, 722 and 732 have three speeds

forward, two reverse.

Model 948 has four speeds forward, three reverse.

Swinging the control column around from the PTO end

of the unit to the engine end converts it for front-mount

attachments.

A safety high speed/reverse lockout device on the control column blocks the high forward speeds on 710,

718, 722, 732 and 948 which are too fast for use in

backing the unit.

All models have a new type transmission that drives the

unit forward when placed in gear-even when converted

for front-mount attachments. In either front-drive or reardrive mode, selecting any gear except the high speed

(that the lockout blocks) and moving the red reverser

lever on the right handlebar backs up the unit. Gear #3

(#4 for 948) is too fast for backing up the unit.

2

15

Page 16

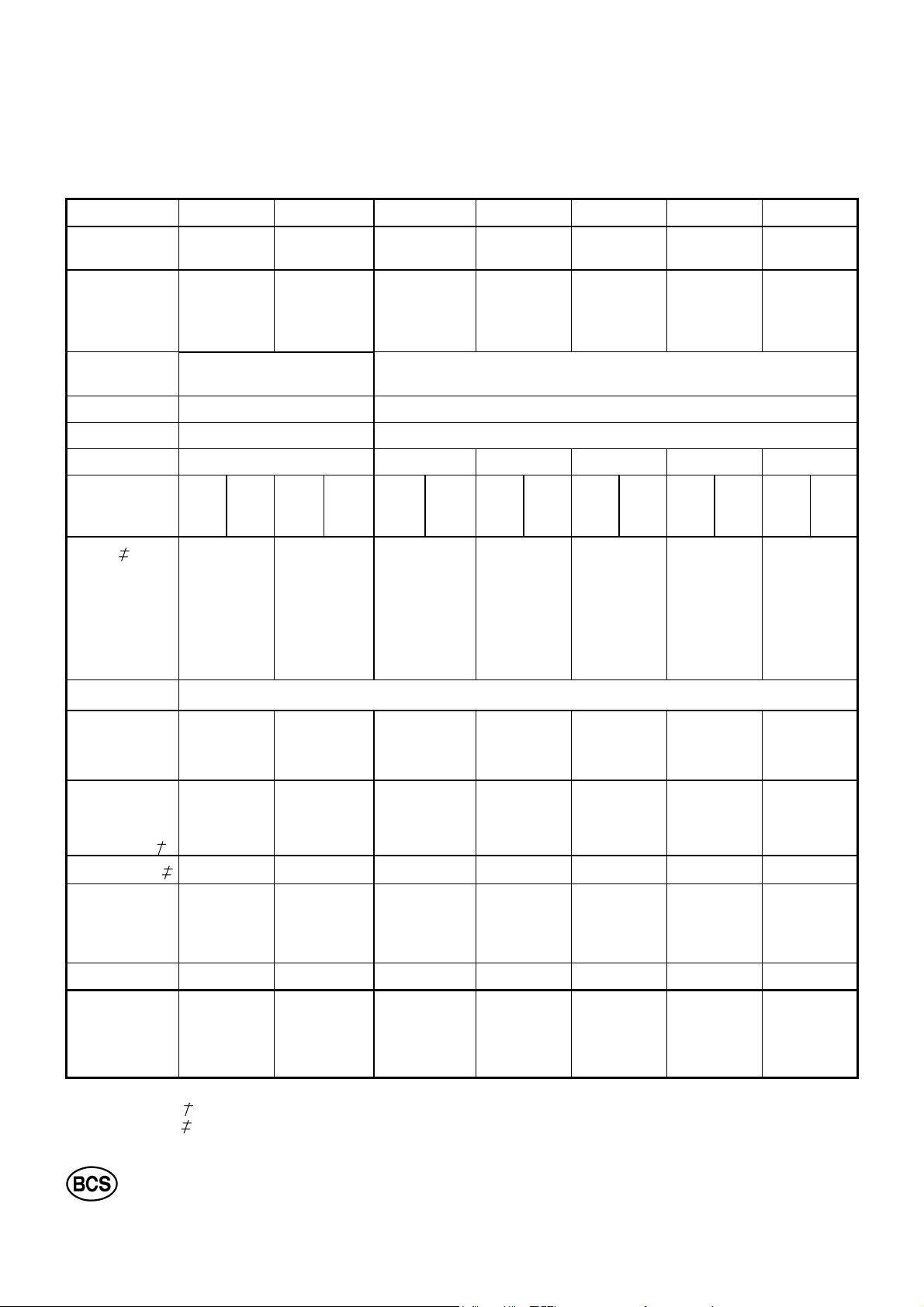

SPECIFICATIONS

ENGINE AND POWER UNIT

MODEL 852 853 710 718 722 732 948

Design Type

Convertible

Engine

Make

Type

Pusher

To Tractor

HONDA

GX390 carb.

or KOHLER

KD440

Pusher

To Tractor

HONDA

GX390 carb.

or KOHLER

KD440

Tractor

To pusher

Subaru SP170

Subaru EX27

Kohler CH270

Tractor

To pusher

HONDA

GX200 carb.

Tractor

To pusher

HONDA

GX240 carb.

Tractor

To pusher

HONDA

GX340 carb.

Subaru EX27

Kohler CH395

Tractor

To pusher

HONDA

GX390 carb.

Type of air filter

HONDA dry cartridge

KOHLER oil bath

Dry cartridge

Prefilter Standard Standard

Transmission

Precision steel gears Precision steel gears

Differential Yes No No No Yes Yes

Gears:

Forward

Reverse

Speed (mph)

1st

nd

2

rd

3

th

4

1st Reverse

nd

Reverse

2

rd

Reverse

3

Power take-off

PTO rpm/

Engine rpm

Attaching

Method

Wheels & Tires

Size

Tread

Track width

4

3*

Tract.

3

3*

Push.

0.8

1.6

2.7

8.3

0.8

1.7

2.8

990 / 3600

2 threaded

studs w / nuts

5.0 x 10”

Tractor

20”

Push.

3

3*

0.8

1.6

2.7

8.3

0.8

1.7

2.8

Tract.

4

3*

Push.

2

2*

0.7

1.6

7.0

-

0.7

1.6

-

Tract.

3

2*

Push.

2

2*

0.7

1.6

7.0

-

0.7

1.6

-

Tract.

3

2*

Push.

2

2*

Tract.

3

2*

0.7

1.6

7.0

-

0.7

1.6

-

(independent – PTO rpm controlled by throttle setting on all models)

990 / 3600

2 threaded

studs w / nuts

5.0 x 10”

Tractor

20”

990 / 3600

2 threaded

studs w / nuts

4.00 x 8”

Tractor

17”

990 / 3600

2 threaded

studs w / nuts

4.00 x 8”

Tractor

17”

990 / 3600

2 threaded

studs w / nuts

4.00 x 8”

Tractor

17”

Push.

Tract.

2

2*

0.7

1.6

7.5

-

0.7

1.7

-

990 / 3600

2 threaded

studs w / nuts

4.0 x 10”

Tractor

19”

3

2*

Push.

3

3*

0.6

1.4

2.1

6.5

0.6

1.5

2.2

990 / 3600

3 threaded

studs w / nuts

6.5 / 80 x 12”

Tractor

26”

Weight (lbs.) 230 230 130 130 140 160 330

Dimensions (in.)

Height

Width

Lenght

47”

27”

47”

47”

27”

47”

40”

25”

63”

40”

25”

63”

40”

25”

63”

40”

25”

63”

34” - 43”

27”

78”

Tract.

4

3*

Extra tires 5.00-12 5.00-12 - - - - -

Capacities (L)

Transmission

Crankcase

Running time

2.00

1.10

2 Hrs.

2.00

1.10

2 Hrs.

1.90

0.60

2 1/2 Hrs.

1.90

0.60

2 1/2 Hrs.

1.90

1.10

2 1/2 Hrs.

1.90

1.10

2 1/2 Hrs.

2.20

1.10

2 Hrs.

@3000 rpm**

NOTE: * Has “Reverser” control to change direction of travel.

May be adapted by mode of mounting wheels, or with optional accessories.

Power unit with standard wheels and tires.

** at ¾ load.

16

Page 17

MODELS 852 / 853

RIGHT BRAKE

LEVER

RED

REVERSER

LEVER

GEAR ROD

THROTTLE

LEVER

P.T.O.

CONTROL

ROD

DIFFERENTIAL

LEVER

TRANSPORT SULKY /

UTILITY TRAILER HITCH

P.T.O.

CONTROL COLUMN INDEXING LEVER

ENGINE

HANDLEBAR

HEIGHT

ADJUSTMENT

LEVER

RED

ENGINE

STOP

LEVER

These “pusher” models, designed and geared to drive mowers and

other front-mounted attachments, may be converted into a tractor by

swinging the control handles around as illustrated on page 32.

Of the very latest design, they have both high speed and PTO / reverse

safety lockout devices that function when needed, and require no disassembly or deactivation.

A differential lever on the right handlebar has two-wheel drive and differential drive settings.

In differential drive, applying just one wheel brake aids in turning to that

side.

Whether in the front-drive or rear-drive mode, the unit will drive forward

when placed in any gear on the gear selector.

With the reverser lever pulled and left against the handlebar, and gear

position #1, #2 or #3 selected, the unit will back up.

Too fast to use when backing the unit, gear position #4 is blocked by

the high speed lockout. 852 model has the fourth speed in pusher

mode; 853 has the fourth speed in tractor mode.

CLUTCH LEVER

LEFT

BRAKE

LEVER

LEVER

LATCH

17

Page 18

2

MODEL 710

THROTTLE LEVER

P.T.O. CONTROL ROD

CONTROL COLUMN

INDEXING LEVER

RED ENGINE STOP

LEVER

CLUTCH LEVER

ENGINE

The model 710 is the smallest tractor of the BCS product line. It has 3 forward speeds and 2 reverse, without

differential.

The drive is controlled using only one control rod located on the left side of the handlebar.

On these models there is also a PTO / reverse lockout

device that prevents shifting into reverse with the tiller

engaged.

The lockout disengages automatically when a front attachment is installed on the unit.

When a front attachment is installed on the unit, what

was the reverse gear in the tilling mode is now the forward gear.

When a front mount attachment is on the unit, the

third gear (transport gear) is blocked out.

LEVER LATCH

GEAR SHIFT ROD

CABLE GUIDES

18

Page 19

CONTROL COLUMN

INDEXING LEVER

2

MODELS 718

MC 732

FORWARD / REVERSE

PTO CONTROL ROD

ENGINE

THROTTLE LEVER

DIFFERENTIAL

722

732

RED ENGINE

STOP LEVER

BLACK CLUTCH

LEVER

GEAR SHIFT ROD

The models 718 / 722 / 732 have three forward speeds

and two reverse.

The drive gears are available through a rod on the left

side of the handlebar.

Forward and reverse are controlled with the red lever

on the right top of the handlebar.

On each of these models, a PTO/ reverse lockout device prevents shifting into reverse with the tiller engaged.

But the lockout disengages automatically during operation with a front mount attachment on the unit.

When a front mount attachment is on the unit, the third

gear (transport gear) is blocked out.

NOTE:

The differential is only on model 732.

19

Page 20

2

RIGHT BRAKE

LEVER

THROTTLE

LEVER

MODEL 948

GEAR ROD

RED

REVERSER

LEVER

DIFFERENTIAL

LEVER

This is the largest tractor in the BCS product line.

It has a differential drive transmission and two wheel brakes,

four forward gears and three reverse gears. The drive is controlled using only one control rod located on the left side of the

handlebar.

The PTO is controlled using one control rod located on the

right side of the handlebar.

With the tiller attachment on this model there is also a PTO/

reverse lockout device that prevent shifting into reverse with

the tiller tines engaged. This lockout automatically disengages

when a front-mount attachment is in-stalled.

This allows you to drive in forward or reverse with the PTO engaged.

When a front mount attachments installed, what was the reverse gears in the tilling mode are now the forward gears in the

front attachment mode.

In the front attachment mode there is a high speed lock-out

that blocks out the high speed gears that were used in the

tilling mode.

CONTROL COLUMN INDEXING LEVER

P.T.O.

CONTROL

ROD

HANDLEBAR

HEIGHT

ADJUSTMENT

LEVER

RED

ENGINE

STOP

LEVER

CLUTCH LEVER

LEFT

BRAKE

LEVER

LEVER

LATCH

20

Page 21

G

21

UNPACKIN

IMPORTANT

Use extreme care to avoid crimping or severely bending

the control cables while unpacking and assembling the

unit.

WARNING

Take care to avoid being cut by the staples or nails

when opening the carton.

Open the top and lay out the sides of the carton. Remove the parts and tools to be used in assembling the unit.

The fasteners required for assembly have been placed

at locations where they are to be used.

ASSEMBLING THE

UNIT

1. INSTALL THE WHEELS:

a) Except for one or two special sizes, most wheel and

tire combinations can be mounted for either a wide

or narrow track.

For all applications except tilling and plowing, the recommended mounting is wide track for stability.

The "Vees" of tractor tread tires should point in the

direction of forwards rotation.

On convertible models, which can be used with both

front-mount and rear-mount attachments, mount the

wheels for the attachment that will be used the most.

It is not necessary to remount the wheels when changing attachments.

b) For wide track, mount the wheels with the tire valves

towards the outside.

For a narrower track, mount the wheels with the valves toward the inside.

2. ADJUST THE PRESSURE TO 15 POUNDS.

21

Page 22

3. MODELS 852, 853 AND 948

These models come with the control column and handlebar preassembled, but mounted in a compact position on

the unit.

22

Page 23

2

NOTE

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................................

23

Page 24

2 2

4. TRANSMISSION

For shipping purposes, the transmission (gear case)

filler hole is sealed with a plastic plug and the dipstick

is in the owner's kit.

Remove the plug. Before installing the dipstick, it is

important to oil the O-ring with a light engine oil.

Then install the dipstick on the hole (see drawing).

Check the level of gear oil at this time (see "Gearbox

Lubrication" on page 25).

5. ENGINE PRE-SERVICE

BRIGGS AND STRATTON ENGINES

Remove and discard the thimble-shaped, clear plastic

cover from the oil breather tube located to the left of

the carburettor.

Remove the crankcase oil filler plug (or dipstick) and

check that the oil is at proper level (see "Engine

crankcase lubrication" on page 25 and its specific use

and care manual).

HONDA AND KOHLER ENGINES

Check the oil fill cap/dipstick at the left of engine. If oil

level is below full mark, see "Engine crankcase lubrication" on page 25.

No other pre-service is required. For Honda engine

operating and service instructions see "Honda engine

owner's manual 31ZH7622".

ELECTRIC SYSTEM BATTERY

The battery is a 12 Volt 14 : 16 AH

(dimensions: mm 160x90x161 - ref. YB16;

or mm 190x127x160 ref. UR1).

Push the unit to an open ventilated spot.

Wear safety goggles and gloves when filling the cells

with the electrolyte solution.

Follow instructions supplied with the battery for filling

with electrolyte, maintaining fluid level in the cells and

charging and recharging.

DANGER

The battery electrolyte is a strong acid.

The acid or the fumes from it can cause severe burns.

The battery constantly emits hydrogen gas which can

be exploded by flame or sparks. Avoid contact with the

battery acid.

Always fill the battery in a well ventilated place and do

not bring flame or sparks of any kind near the battery.

If acid contacts your body, flood the area immediately

with soap and water.

24

Page 25

LUBRICATION,

FILTERS AND FUEL

NOTE

Engine manufacturers recommend the types and

weights of oil for seasonal use in their engine. Always consult the engine instruction manual for their

recommendations.

22

BRIGGS & STRATTON ENGINE

ENGINE CRANKCASE

LUBRICATION

The oils selected for use should be high quality, high

detergent products of API service classification "SF".

The oil usually recommended for warm weather use a

straight SAE 30 weight.

A multi-viscosity type oil such as SAE 10W-40 can also

be used in warm weather.

When the air temperature falls below 32 degrees F (0°

C) switch to 10W-40 or 10W-30 weight oil. For extremely cold (sub-zero Celsius) temperatures, it may be necessary to use SAE 5W-30 or 5W-20 weight oils.

Always check the oil level every day of use.

Change the oil after the first five hours of engine operation and at least once a season thereafter.

Put the unit on a level surface when checking oil level. If

the engine has a dipstick, maintain the oil level between

the high and low marks on the stick. If no dipstick, keep

the oil level no lower than half an inch (12.7 mm) below

the top thread of the filler hole.

For all the engines check the oil level such as indicated on the owner's manual. Add oil if the oil level

is at the half of the dipstick.

KOHLER AND HONDA ENGINE

When changing oil, always run the engine to get the oil

warm. Then shut down, remove the drain plug and drain

the dirty oil into a container for proper disposal. Do not

pollute the environment with waste oil.

GEARBOX LUBRICATION

The gearbox requires maintenance of the oil level with

SAE 80/90 or SAE 90 EP (extreme pressure) gear oil.

The gearbox filler cap (see drawing on page 24) has a

dipstick with marker rings denoting full and low levels.

NOTE

When checked on a brand new machine, the oil level will be at the full mark on the dipstick. When it

drops near the low mark add oil, but do not fill above the full mark. Do not operate if level is not up to

the low mark.

1. Twist and pull up the filler cap to check the dipstick.

Checking every 50 operating hours is recommended.

2. Put the dipstick back into the filler hole and twist the

stick around so the flat side is toward the centre of

the transmission gearbox.

25

Page 26

2 2

ENGINE AIR CLEANER

The dry element filters used on B&S, Honda and Kohler

engines are shown in different drawings. Optional

commercial type pre-cleaner elements are available to

fit these air cleaners.

Pre-cleaners are recommended particularly when using

a Power Sweeper, Dozer Blade or Tiller, in dry and dusty conditions.

Open the air cleaner and check the air filter at regular

intervals. Under very dusty conditions, check often and

change filters when necessary. A clogged filter raises

the engine temperature.

Dry element filters can be cleaned by tapping gently

against a flat surface but it is far better to replace a dirty

filter than try to clean it. The pre-cleaners, however, can

be cleaned with soap and water or mineral spirits, but

must be dried thoroughly, then oiled before use.

Soak the cleaned and dried pre-cleaner in clean engine

oil. Then squeeze out the oil before installing the precleaner.

KOHLER CH270

KOHLER CH395

26

Page 27

GASOLINE ENGINE FUEL

The 4-cycle will run on either leaded or unleaded gasoline.

Gasoline of 87 to 93 octane is recommended.

1. Remove the fuel cap, fill fuel tank, and re-install the

cap securely.

2. Push the tractor at least 10 feet from fuelling area

and wipe off any spillage before starting the engine.

3. Open the fuel line valve at the tank outlet, so fuel can

flow by gravity to the carburettor.

DANGER

Gasoline is explosive ! Read page 5 of safety “Rules”,

before filling the fuel tank and starting the engine.

Use approved type, properly labelled fuel containers.

Do not smoke or bring fuel near any sparks or open

flame.

Do all fuelling outdoors, never in a garage or shop

connected to living quarters. Do not refuel when the

engine is running or still hot.

22

27

Page 28

STARTING AND STOPPING

Including PTO Engagement and Control Unit

710

Backing with the PTO engaged is dangerous. So all

convertible units have a PTO / REVERSE LOCKOUT to prevent simultaneous engagement of PTO

and REVERSE.

You must be sure that the PTO lockout bar is aligned with the donut-shaped stop on the PTO lever

when the unit is in the rear-mount mode (see drawing).

DO NOT REMOVE OR MOVE THIS LOCK-OUT

BAR ASIDE FOR PTO ENGAGEMENT DURING

BACKING OF THE TILLER.

WARNING

WARNING

Be sure to shift into NEUTRAL (N) position on the

gear selector, and disengage the PTO before starting the engine.

If started in gear, the unit will move along.

If started with the PTO engaged, a Tiller, or a Power Sweeper may run out of control.

Inadvertent operation of any attachment can be

dangerous.

28

Page 29

SETTING CONTROLS FOR

22

COLD STARTING

1. DISENGAGE THE PTO

IMPORTANT

MODELS IN REAR-MOUNT MODE:

Pull back on the PTO shift rod to disengage the

PTO.

MODELS IN FRONT-MOUNT MODE:

Push down the PTO shift rod to disengage the PTO.

2. SHIFT INTO NEUTRAL

On the gear speed selector, all positions marked "N" are

neutral.

3. OPEN THE THROTTLE

Advance the throttle lever on the right handlebar to between half and full throttle position.

4. OPEN THE FUEL VALVE

If valve has a handle, open position is handle in line with

the fuel line. If valve has a round control knob, turn the

knob counter-clockwise (to the left).

5. CLOSE THE CHOKE

Closed choke position on the carburettor is the upward

or lateral position of the choke lever. Downward is "open

choke", the position used after engine is running and

warm.

6. LATCH BOTH CLUTCH AND STOP SWITCH LE-

VERS FOR ENGINE STARTING

The clutch is the black lever and the stop switch is the

red lever on the left handlebar. The red lever has to be

held depressed during operation or it will shut off the

engine. For starting, squeeze both levers against the

handlebar with one hand and prop them in this position

by setting the wire spring latch (see drawing).

WARNING

The RED engine stop switch lever is designed to stop

the engine in the event the operator loses control of

the moving machine. It is necessary to latch the stop

lever during starting, and to lock it in the run position

when it is necessary for the operator to attend a

stationary attachment such as the Chipper/Shredder.

Pin holes are provided in the lever and handlebar for

this purpose.

For use of a moving attachment, DO NOT LOCK,

TAPE DOWN, or otherwise defeat the purpose of the

stop switch lever.

NOTE

Squeezing the clutch lever dislodges the wire spring

latch, letting you take over control of the clutch. If you let

go of the handlebar, the engine will be switched to a

stop.

29

Page 30

2

CRANKING TO START

RECOIL START ONLY: Read warning about starter rope. Grasp the starter grip with one hand only.

Place your foot against the side of the tire tread to

steady the machine. Pull the grip gently until the starter

engages THEN PULL RAPIDLY to crank engine. Open

the choke when the engine starts.

WARNING

NEVER WRAP THE STARTER ROPE AROUND

YOUR HAND OR WRIST, OR USE TWO HANDS TO

PULL THE STARTER GRIP. You want the grip to

slim from your grasp if the engine kicks during

cranking.

ELECTRIC START ONLY: Turn the ignition key to

START to crank the engine. Key will return to the RUN

position when you let go. When engine starts, open the

choke.

ENGINE WARM-UP PERIOD: let the engine warm up

for a few moments without any load (in neutral N and

PTO disengaged) to give the oil time to reach the parts

of the engine in need of lubrication.

RESTARTING WARM ENGINE: When the engine has

run and is still warm,it requires no choking to start. In

fact, cranking a warm engine at closed choke may flood

it.

DIFFERENTIAL AND TWO-WHEEL DRIVE

A feature of models 948,852,853, 732 the differential

drive directs the driving to one wheel, allowing the other

to free-wheel. Differential drive facilitates making tight

turns with the unit.

When two-wheel drive is needed for traction, lock in the

differential lever on the right handlebar.

When placed in differential drive, models 948, 852 and

853 can be turned by squeezing the left or right brake lever.

WHEEL BRAKES

Models 852,853 and 948 have two-wheel brakes, with

brake levers on handlebar.

For parking pull completely both levers. However, the

machine may also be placed in gear to keep it from rolling when the engine is shut off.

A brake kit is available for other models.

STOPPING

Any time you let go of the left handlebar, the red stop

lever on top will activate the ignition stop switch to stop

the engine. On an electric start, turn off the switch to

prevent current drain when the unit is not in use. In case

the stop switch becomes open (disconnected) you can

make an emergency stop on the engine either by closing the carburetor choke or by doing the instructions

obtained from the engine owner’s manual.

30

Page 31

IMPORTANT

Directions such as right and left are always called

out as you would see them when operating with the

unit in the mode for which it was designed.

However when the handlebars of a convertible unit

are swung 180 degrees from designated position,

the right lever on the right handlebar will still brake

the right wheel.

But the right wheel will be on the left side.

SHUT-DOWN (STORAGE)

(See instructions on page 8)

TAKING CONTROL OF THE

MACHINE

1. When the engine is running, grasp the left handle-

bar. Hold the stop switch depressed and squeeze

the clutch lever to dislodge the spring latch. Now

both clutch and stop levers will be under your control.

2. Do not let up the stop switch lever or it will stop the

engine. When ready for action, shift into the desired

gear and release the clutch lever. Instructions for

operation of unconverted units are given immediately below, and those for converted units are on page

33.

NOTE

Transmission to the axle and wheels is independent

of transmission through the PTO to an attachment.

The advantage of this BCS design is that the most

efficient operating rpm of the attachment can be selected by the throttle setting, and the desired machine movement chosen independently through a combination of throttle setting and gear selection.

GEAR AND PTO

ENGAGEMENT

(For converted units, skip to page 33)

1. Start the engine and take over control of the unit.

Keep the throttle at moderate speed setting.

Hold the clutch lever (left handlebar) depressed

2.

while shifting, and engaging the PTO lever, and until

you are ready to drive.

3. Shift into the lowest forward speed position on the

gear speed selector. If the gears will not engage, release (slip) the clutch just a bit unit the gears mesh.

4. Smoothly release the clutch lever and the machine

will move forward. If you wish to stop momentarily

without killing the engine or shifting into neutral, depress the clutch lever fully.

5.

USING RED REVERSER FOR BACKING.

Disengage the clutch

Position 1, 2 and 3 (852 / 853 / 948) on the gear selector will be available for backing and 4 will be locked

out. On the models 710, 718, 722 and 732 are available position 1 and 2; position 3 is locked out.

Select speed, and depress the red reverser lever

on right handlebar before engaging the clutch

when going back to forward drive disengage the

clutch.

31

Page 32

MAKING A CONVERSION

FRONT-TO-REAR,

OR REAR-TO-FRONT

Mod. 852 – 853

PUSHER TO TRACTOR

Mod. 710

TRACTOR TO PUSHER

LOCATING OF CONTROL COLUMN INDEXING LEVERS

Mod. 718 – 722 – 732 – 948

TRACTOR TO PUSHER

NOTE

Put on the new attachment (or leave the other in

place) to keep unit from rotating during positioning of the control column.

1. Shift into the lowest forward gear position. This

will provide clearance for turning the handlebars

to the other end of the unit.

2. Detach the PTO and gear selector shift rods from

their supports and let them hang down.

3. Locate the control column indexing rod or lever

(according to model; see drawings.) Use it to free

the column from the support in preparation to

swing it around.

Mod. 710

Mod. 718 - 722 - 732 - 852 - 853 - 948

32

Page 33

4. Be careful not to stress or sharply bend the control cables while indexing the control column.

Turn column 180 degrees as follows:

a) models 710,718,722,732 and 948: convert from

tractor to pusher by pulling rod or lever and turning

the control column 180 degrees counter-clockwise

(to go back to tractor mode, turn clockwise).

b) models 852 and 853: convert from pusher to trac-

tor by pulling the lever on right handlebar and turning column 180 degrees clockwise (to go back to

pusher mode, turn counterclockwise).

5. Put the shift rods back in their brackets on the control

column. Check the position of the control cables and

see that they are neither bunched up nor pulled taut.

2

OPERATING IN CONVERTED

MODE, ALL MODELS

1. TRACTOR MODE:

Push the PTO shift rod forward to engage the PTO,

pull it back for the disengagement.

2. PUSHER MODE:

Pull the PTO shift rod back to engage the PTO, push

it forward for the disengagement.

3. SHIFTING THE GEARS:

Shift into desired gear according to model.

33

Page 34

a) Models 852 and 948: in the converted mode, three of

the four gear positions on the gear selector can be

used for travel in either forward or reverse direction.

The fourth gear is blocked because it is too fast to

use for backing the unit: select desired gear and engage clutch to move forward. To back up, disengage

clutch, engage the red reverser lever on the right

handlebar and engage clutch.

Models 853 and 948 have the fourth gear in tractor

mode.

b) Models 710, 718,722 and 732: two of the three gear

positions can be used, in the converted mode, in

either direction. The third is blocked because it is too

fast to use in backing the unit.

3. Engage the PTO and the clutch to put the unit to

work.

710 / 718 / 722 / 732

710

34

Page 35

SEASONALLY:

MAINTENANCE PROGRAM

1. Refer to the maintenance instructions and illustra-

tions in the "Use and Maintenance" manual furnished

for your model engine.

Change oil, filters, etc., and clean the cylinder fins

and crankcase breather as instructed in the engine

manual.

2. DAILY CLEAN-UP:

When the machine is very dirty you may hose down

everything except the engine immediately after use.

But to avoid cracking the engine, you must let it cool

before hosing it down. You may, however, idle the

engine until it is warm enough to evaporate the wash

water from around the spark plug.

3. AFTER FIRST 10 OPERATING HOURS

(and afterwards as recommended):

a) tighten nuts and bolts:

b) check tire pressure;

c) originally, the position of A lever is normal.

As clutch wears out the same lever could have a

wider opening being so uneasy to use, this means

that it is necessary to adjust the cable, setting lever A on its original position acting on adjustment

device B and on counter-nut C;

d) check the gear oil level of each attachment.

Re-check rotary mowers every 50 hours and the

other attachments every 100 hours.

4. OCCASIONALLY AS NEEDED

Clean any dirt and old grease from the PTO connections of all equipment and pack with clean bearing

grease.

5.

a) lubricate the control cables with a light oil;

b) models with engine hood: lubricate the hinge with

a light oil. Do not use mineral oil.

c) clean parts thoroughly and apply grease to the

control column indexing rod or lever, column fork,

column support or pivot post (according to model).

22

35

Page 36

SECTION

USE AND CARE OF ATTACHMENTS

3

LUBRICATION OF

ATTACHMENTS

1. TILLERS, ROTARY MOWERS, SNOW THROWERS

AND POWER SWEEPERS:

Remove the pipe plug on top of the attachment gear

housing. If the oil level is more than 2 inches (50

mm) below the filler hole, fill to the top with SAE 80/

90 or SAE 90EP (extreme pressure) gear oil. Maintain at the nearly full level.

2. MOWER BARS:

These require no gear oil but need frequent greasing

with a lithium based (general purpose) grease pumped through two "zerk" type fittings on the housing.

3. ALL ATTACHMENTS:

Remove dirty grease and lubricate the PTO coupling

of the attachment with bearing grease whenever

greasing the unit PTO. For other points of lubrication,

see the particular attachment.

COUPLING ATTACHMENT

TO PTO

A. DIRECT COUPLING:

1. Remove the lock nuts and washers from the

tractor PTO studs.

2. Align the tractor PTO with the connecting flange

of the attachment. Always bring the tractor to the

attachment. If necessary use props to level the

attachment.

3. Slide the PTO studs into the attachment flange

and secure with the washers and lock nuts.

When the PTO flange of the attachment is coupled to

the unit PTO flange and the PTO is engaged, the splined shaft slides out to engage the splined (grooved)

shaft of the attachment.

Then the shafts rotate as a single member until the PTO

shift lever is used to retract the drive shaft.

Although the attachment may be coupled directly to the

unit PTO, there is a quick hitch that can shorten the time

for coupling and uncoupling attachments. There are also PTO extensions in lengths of 3" and 6" which can be

coupled between the PTO and attachment for better balance with certain attachment and engine combinations.

B. QUICK HITCH:

1. The hitch consists of two parts held together by

a captive T-handled pin. Pull and turn pin sideways to separate the parts.

2. Remove the two nuts from the tractor PTO studs

and the two bolts and nuts from the quick hitch.

3. Attach the female part, pin-side-up, to the tractor

PTO. Attach the male part, hole-side-up, to the

attachment connecting flange. Install and tighten

the four nuts.

4. Fit the attachment part into the PTO part. Twist

the pin so it drops down into locking position, securing the two parts together.

5. To uncouple, pull the pin.

36

Page 37

3

USE AND CARE OF REAR-TINE TILLER ATTACHMENT

PREPARING NEW TILLER

SINGLE ROW ATTACHMENT FOR 710, 718, 722, 732

(or converted 852):

Available sizes are 18", 20", 26" and 30".

1. Open the carton and stand the tiller on end so you can

see the underside. Fasteners required for assembly are

included. The bolts in the assembly drawing are labelled (M8 or M10) for the metric diameters and length is

given in millimetres.

If a sulky or utility cart is to be hitched to the tractor, assemble the depth gauge bar in a position 180 degrees

from that in the drawing.

2. Use the self-locking nut to fasten the depth gauge to

the gear housing. Install the flange nut at the stabilizer

bar bottom connection.

3. The depth gauge and stabilizer bar protrude through

the top of the tiller housing. The bar is bolted to the brackets. The gauge is pinned with the clevis pin and "hairpin". Tighten all nuts.

WIDTH OF TILTH

IMPORTANT

When changing sets of tines, it is important to keep

the tines in place on one side for use as a model while

changing tines on the other.

Do not mount the tines backwards on the flange.

SINGLE ROW ATTACHMENT FOR MODEL 948:

This comes preassembled for a 32" tilling width. The

width can be increased to 40" or decreased to 27" by

adding or removing flanges of tines, and by changing

the tines to bend inward or outward (see drawing).

TILLING DEPTH ADJUSTMENT

The procedure is the opposite of what many people first

would believe. For the deepest soil penetration, you raise the depth controlling "knife" by pinning the bar in the

bottom hole (see drawing).

37

Page 38

A

2 3

GARDENING SUGGESTIONS

1. When breaking new ground or preparing hard, rocky

soil, till at a maximum depth at the lowest gear setting

and at a fast throttle setting.

In soft soil you can probably start right off tilling at

1. Remove the hairpin and the clevis pin from the bracket and bar.

Raise or lower the bar handle to align the holes in

2.

the bar and brackets. Pin the bar at desired setting,

or as recommended in step 3.

3. In hard ground, as when tilling a patch of ground for

the first time, pin the depth adjustment rod through

the top hole for a shallow cut.

fter a pass or two to break up the hard top crust,

stop the engine and pin the depth adjustment bar

through the lower position hole.

Pinning the bar through the bottom holes raises the

depth-gauging "knife" for maximum tilling depth.

maximum depth and finest tilth are achieved in the lowest gear speeds.

2. You can avoid trampling over and tamping the freshtilled rows by walking to one side of the tiller.

Swing the handlebar to the side and adjust it to a comfortable height. After a bit of practice with the tiller, you

can work out a pattern where your footprints will be erased with each new pass.

TRANSPORT SULKY FOR REARTINE TILLER

The Transport Sulky is exclusively for riding the machine to and from the working site. As warned in Section

One, you must never operate the Tiller from a sulky or

wagon of any type. A curved coupling is needed to attach the Transport Sulky to most models.

38

Page 39

USE AND CARE OF CUTTER BAR

3

MOWER ATTACHMENTS

SICKLE BAR DESIGNED FOR CUTTING FIELD AND CEREAL GRASSES-HASLONG, POINTED TOOTH COMB.

DOES NOT RECUT (MULCH).

.

GENERAL CUTTER BAR MOWER

INFORMATION

1. ALL THE TRACTORS must be converted to the front-

mount mode.

2. The SICKLE BAR and MULCHER BAR are the two original types of BCS mower bars.

The COMBINATION BAR combines features and abilities of both. Although construction of the bars is very similar, there are differences to be encountered in adjustment and maintenance.

RECOMMENDED OPERATION

WARNING

Never operate the mower bar from a mowing sulky.

1. It is unnecessary to run the engine at wide open throttle

for satisfactory performance.

Cutter bar mowers give excellent results when operated

at medium throttle settings and there is less wear and

tear on the reciprocating parts.

If necessary to increase ground speed, select a higher

gear rather than advance the throttle.

2. The short teeth of the Mulching Bar can cut wet grass

without clogging.

COMBINATION BAR COMBINES SOME OF THE ABILITIES OF THE SICKLE BAR AND MULCHING BAR

IN ONE ATTACHMENT.

Both the Mulching and Combination Bars are designed

for re-cutting (mulching) mown grass. For brush cutting

and also when operating in extremely rugged terrain,

go slowly and deliberately with either type attachment.