Baxi Platinum Combi 24 HE, Platinum Combi 28 HE, Platinum Combi 33 HE User's Operating Instructions & Important Warranty Information

Page 1

Please keep these instructions safe.

Should you move house, please hand

them over to the next occupier.

Baxi Platinum Combi HE Range

Gas Fired Wall Mounted Condensing

Combination Boiler

User’s Operating Instructions &

Important Warranty Information

Page 2

2

Natural Gas

Baxi Platinum Combi 24 HE

G.C.No47 075 20

Baxi Platinum Combi 28 HE

G.C.No47 075 21

Baxi Platinum Combi 33 HE

G.C.No47 075 22

Warranty

heateam the service division of Baxi Heating UK Limited provide

a 5 year free warranty for your peace of mind. Once your boiler

is registered with us and in the unlikely event your boiler develops

a fault and your installer is unable to assist, heateam will provide a

free service to you provided the boiler is under 5 years old.

Otherwise heateam will offer a competitive fixed price repair rate

including parts, labour and VAT. To arrange an engineer visit

either in warranty or out, please call heateam on 08700 60 30 60.

It would help if you had your boiler serial number when you call,

the serial number is shown on the back cover of this guide.

Annual Service

To ensure you receive the maximum efficiency from your boiler

we recommend your boiler has an annual service so you and

your family can continue to enjoy heating and hot water comfort.

To arrange an annual service from one of our Baxi Heating UK

Limited heating experts, please call heateam on 08700 60 30 60

to arrange a visit convenient to you.

Benchmark Commissioning Check List

Please ensure that your installer hands you the boiler Installation

& Service Instructions with the “Benchmark” Commissioning

Checklist sections completed. The details in the Checklist will be

required in the event of any warranty work. Keep the instructions

in a safe place and ensure that the Service Interval Record at the

back is completed at each service visit.

5 Years Free Warranty - register today

To receive your 5 years free warranty please complete the form

supplied with the boiler or simply call heateam, the service

division of Baxi Heating UK Limited on 08700 60 30 60.

Baxi is one of the leading manufacturers of domestic

heating products in the UK.

Our first priority is to give a high quality service to our

customers. Quality is designed into every Baxi product -

products which fulfil the demands and needs of customers,

offering choice, efficiency and reliability.

To keep ahead of changing trends, we have made a

commitment to develop new ideas using the

latest technology - with the aim of continuing to

make the products that customers want to buy.

Everyone who works at Baxi has a commitment to quality

because we know that satisfied customers mean continued

success.

We hope you get a satisfactory service from Baxi. If not,

please let us know.

Baxi is a BS-EN ISO 9001

Accredited Company

Page 3

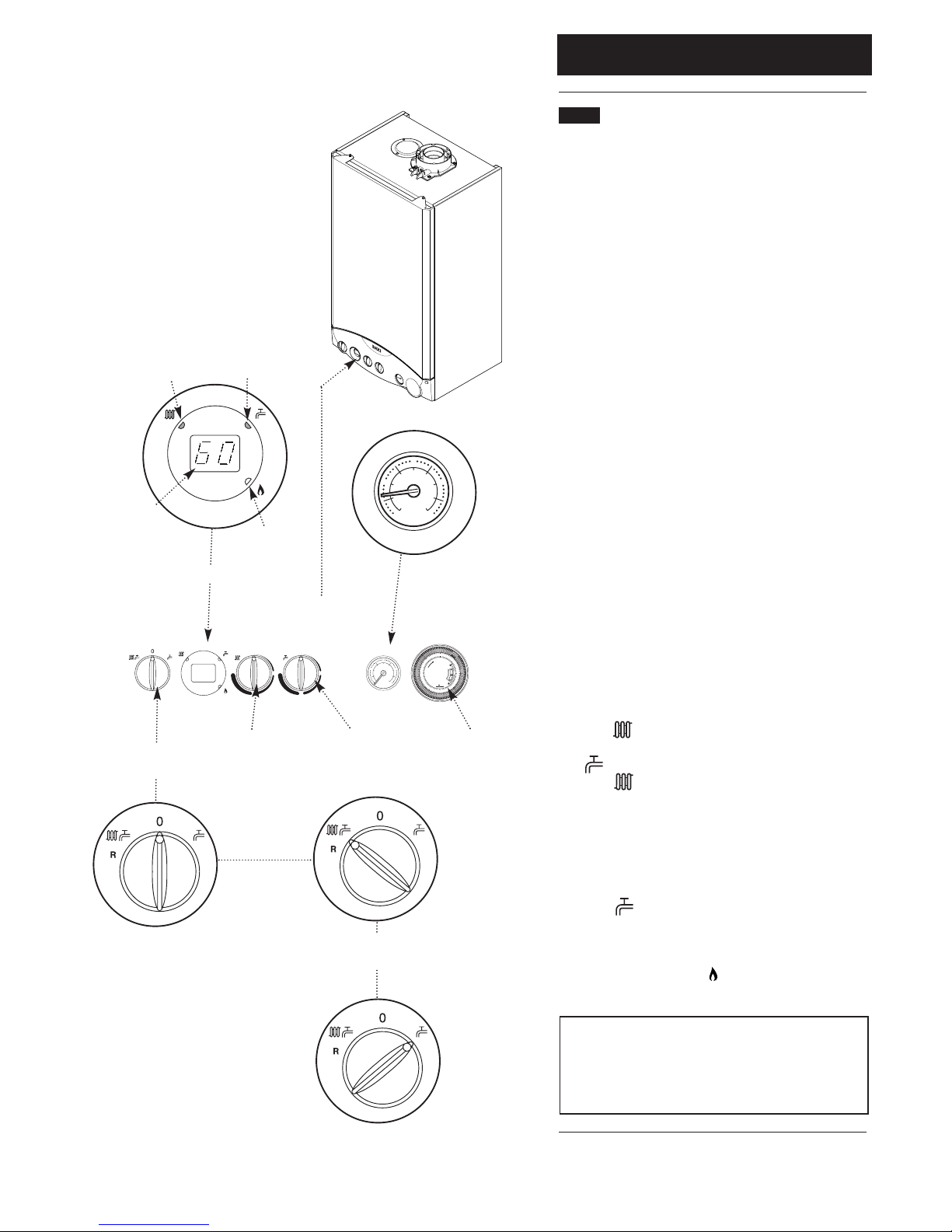

1.0 Operating the Boiler

3

1.1 Operating the Boiler

The Central Heating and Hot Water you need will be

available when the gas and electricity supplies to the boiler

are turned on with the timer and other heating controls in

your system set correctly.

Other heating controls are items such as room

thermostats, cylinder thermostats and thermostatic

radiator valves. To give the most energy efficient

performance these controls can switch your boiler

on and off even when your timer is on. Instructions

on how to use your programmer and other

heating controls should have been supplied with

the items. Baxi Heating UK Limited also produce a

guide ‘How to get the best out of your NEW

Central Heating System’. Telephone our Literature

Hotline on 08706 060 623 to request your free

copy.

1. Ensure that the electricity and gas supplies are turned on.

Check that the central heating pressure is at least 0.5 bar

(Fig. 1).

2. Turn the On/Off/Reset selector switch either anticlockwise from the OFF position (Fig. 3) to both central

heating and domestic hot water or clockwise to domestic

hot water only.

3. In either position the display will illuminate showing the

current boiler temperature in degrees centigrade (Fig. 2).

4. Position (i) Heating and Hot Water (Fig. 4) In this

position the central heating will operate on demand from

the integral timer, room thermostat etc or domestic hot

water will be provided when a tap or shower is turned on.

Priority is given to domestic hot water. The central heating

indicator ( ) will illuminate when the boiler is supplying

central heating. If there is a demand for domestic hot water

the ( ) indicator will illuminate and the central heating

indicator ( ) will extinguish (Fig. 2). As the temperature

rises the display will change, showing the current boiler

output temperature.

5. Position (ii) Hot Water Only (Fig. 5) In this position only

hot water will be provided when a tap or shower is turned

on - Central Heating will not operate. The hot water

indicator ( ) will illuminate (Fig. 2).

6. The boiler will light automatically on demand.

7. The burner on indicator ( ) will illuminate when the

boiler is operating and the main burner has lit (Fig. 2).

IMPORTANT: When the selector switch is in the ‘0’

(Off) position the electrical supply to the boiler is

isolated. The boiler will not operate and the integral

timer will require resetting once the selector switch is

set to either Position (i) or Position (ii).

2

1

0

4

3

bar

R

1

2

3

4

5

P

M

7

8

9

10

11

12

1

2

3

4

5

AM

7

8

9

10

11

12

GRASSLIN

0

Position (ii)

(Hot Water)

Fig. 4

Fig. 5

OFF Position

Fig. 3

Fig. 1

2

1

0

4

3

bar

Central Heating System

Pressure Gauge

Position (i)

(Central Heating or Hot Water)

On/Off/Reset

Selector Switch

Fig. 2

Central Heating

Temperature Control

Domestic Hot Water

Temperature Control

Central Heating

Indicator

Domestic Hot

Water Indicator

Burner On

Indicator

Current Boiler

Output

Temperature

Display

Timer

Page 4

1.0 Operating the Boiler

4

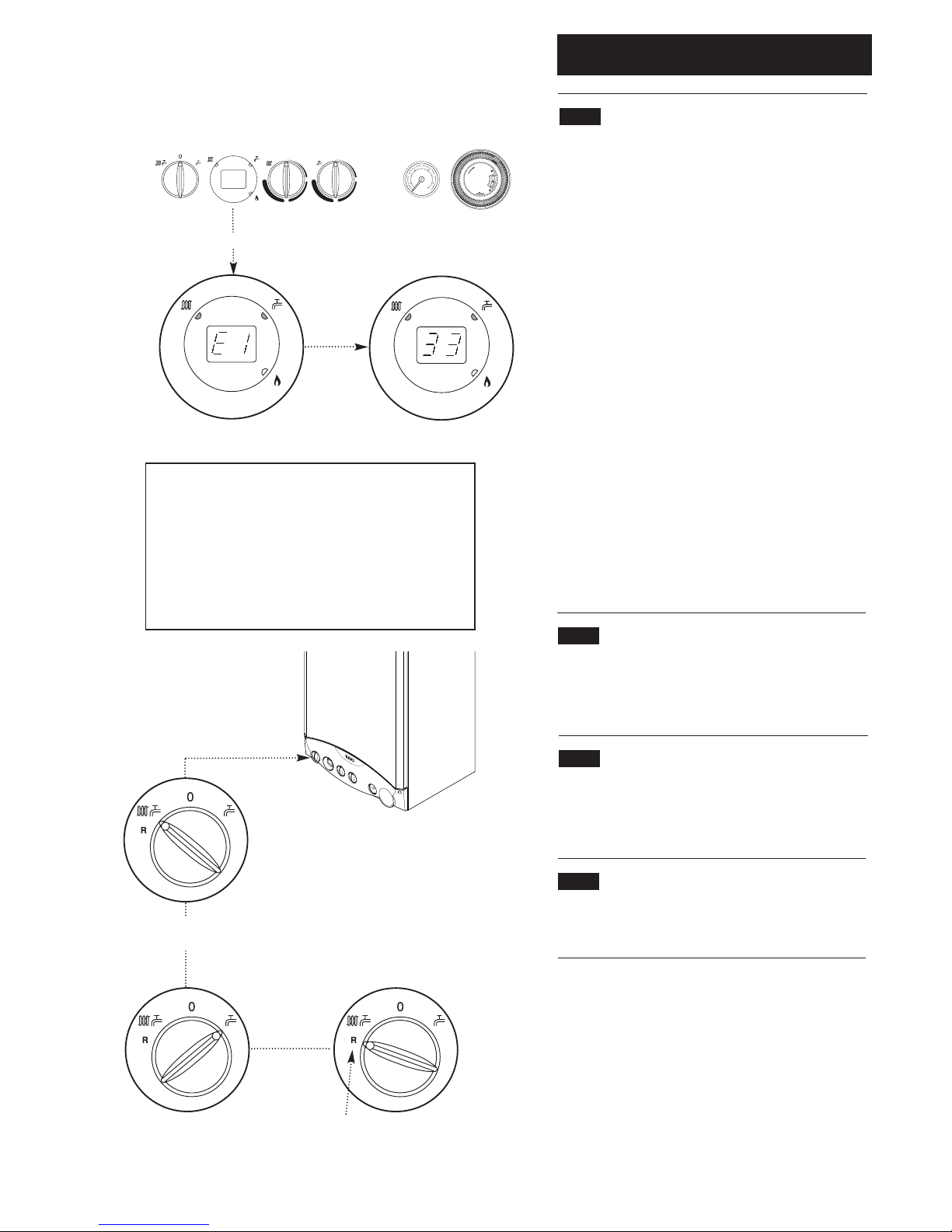

1.2 Fault Indication

1. If a fault occurs on the boiler an error code may be

shown on the facia display.

2. The codes are either two or three digit, preceded by the

letter 'E'. For example, code E133 will be displayed by 'E1'

alternating with '33'. E50 is shown as 'E' then '50'.

3. E20, E28, E50, E125 & E160 indicate faulty components.

You should make a note of the displayed error code and

contact your installer or service engineer.

4. If E110 or E130 is displayed overheat of the primary

water or flue system has occurred. Turn the selector switch

to the reset position and hold for at least 5 seconds. If the

boiler does not relight, or the code is displayed regularly

contact your installer or service engineer.

5. E119 is displayed when the primary water pressure is less

than 0.5 bar. After repressurising the system the boiler

should operate. Your installer will be able to advise you

about the method of repressurising. See page 6 for further

details.

6. E133 indicates that the gas supply has been interrupted,

ignition has failed or the flame has not been detected.

Ensure that the gas supply has not been turned off, and turn

the selector switch to the reset position and hold for at

least 5 seconds. If the boiler does not relight, or the code is

displayed regularly contact your installer or service engineer.

1.3 Resetting (Fig. 8)

1. To reset the boiler turn the selector switch fully

anticlockwise against the spring pressure for approximately

5 seconds and release.

1.4 Pump Protection

1. With the selector switch in either Position (i) or Position

(ii) (Figs. 7 & 9) the pump will automatically operate for 1

minute in every 24 hours to prevent sticking.

1.5 3-Way Valve - Anti-sticking

1. If there is no demand for heat in a 24 hour period, the 3way valve will be operated once to help prevent sticking.

Central Heating NTC Fault

Flue NTC Fault

Hot Water NTC Fault

Safety Thermostat Operated

Water Pressure Switch Not Operated

Pump Fault

Flue NTC Operated

Interruption Of Gas Supply or Flame Failure

Fan or Fan Wiring Fault

E20

E28

E50

E110

E119

E125

E130

E133

E160

Table of Error Codes

2

1

0

4

3

bar

R

1

2

3

4

5

P

M

7

8

9

10

11

12

1

2

3

4

5

AM

7

8

9

10

11

12

GRASSLIN

0

Display

Then

Fig. 6

Fig. 7

Fig. 9

Reset Position

Fig. 8

Position (ii)

(Hot Water)

Position (i)

(Central Heating or Hot Water)

Page 5

1.0 Operating the Boiler

5

1.6 Temperature Control

1. Central Heating: The central heating hot water flow

temperature can be adjusted between 25° C minimum

and 80° C maximum.

2. Turn the control knob clockwise to increase the

temperature (Fig. 10). As the control knob is turned the

selected temperature is displayed for approximately 4

seconds. The display then reverts to the current boiler

output temperature.

3. In normal winter usage we recommend that the central

heating temperature be set at maximum.

4. Domestic Hot Water: The temperature of the domestic

hot water can be adjusted by turning the control knob

clockwise to increase up to a maximum of 60° C (Fig. 11).

As the control knob is turned the selected temperature is

displayed for approximately 4 seconds. The display then

reverts to the current boiler output temperature.

5. The temperature of the water is also dependent on the

water flow rate and the temperature of the mains coming

into the house.

6. By slightly reducing the flow from the tap the

temperature will increase up to the maximum if required.

7. The flow rate can be reduced down to as low as 2 litres

per minute. The boiler will still recognise the need to heat

the water.

Domestic Hot Water

Temperature Control

Fig. 10

Central Heating

Temperature Control

Fig. 11

Page 6

1.0 Operating the Boiler

6

2

1

0

4

3

bar

2

1

0

4

3

bar

2

1

0

4

3

bar

2

1

0

4

3

bar

ON/OFF

Selector Switch

OFF Position

Fig. 16

Normal Pressure (when cold)

Normal Pressure (operating)

Fig. 12

Fault

Fig. 13

Below Minimum

Fig. 14

Fig. 15

Pressure Gauge

1.7 Central Heating System Pressure

1. The water pressure in the central heating system is

indicated by the pressure gauge.

2. With the system cold and the boiler not operating the

pressure should be at least 0.5 bar. During operation the

pressure should not exceed 2.5 bar, and will normally be

between 1.0 and 2.0 (Figs. 12 & 13).

3. A pressure of 3 or greater indicates a fault. The safety

pressure relief valve will operate, at a pressure of 3 (Fig.

14). It is important that your Installer or Service Engineer

is contacted as soon as possible.

4. The MINIMUM pressure for correct operation is 0.5. If

the pressure falls below 0.5, this may indicate a leak on the

central heating system (Fig. 15). Error Code E119 will be

shown on the display.

1.8 To Shut Off the Boiler

1. For short periods: Turn the selector switch to the OFF

position (Fig. 16).

2. For long periods: Turn off the selector switch (Fig.16),

electricity and gas supplies.

If your home is to be left unoccupied for long periods

during cold weather the boiler and whole system should

be drained unless there is additional frost protection.

3. Your installer will advise you about frost protection and

draining the system.

IMPORTANT: When the selector switch is in the ‘0’

(Off) position the electrical supply to the boiler is

isolated. The boiler will not operate and the integral

timer will require resetting once the selector switch is

set to either Position (i) or Position (ii).

1.9 Boiler Frost Protection Mode

1. The frost protection feature will operate when the

selector switch is in the central heating and domestic hot

water mode.

The gas and electrical supplies to the boiler must be on and

the system pressure must be within the range described

above.

2. If the system temperature falls below 5°C, then the

boiler will operate until the water temperature has been

raised.

Page 7

2.0 Care of the Boiler

7

2.1 Servicing and Repair of your Boiler

heateam can service and repair your boiler if your installer

is not able to.

Our Baxi Heating UK Limited trained heating experts will

quickly get your heating and hot water working again. If

your boiler is out of its free 3 year period, heateam can

provide a competitive fixed price repair rate including parts,

labour and VAT.

To find out more call heateam on 08700 60 30 60, open

Monday to Friday 8am - 6pm, weekends and bank holidays

8.30am - 2pm, closed on Christmas and New Years Day.

An appointment convenient for you can be arranged. It

would help if you had your boiler serial number when you

call, the serial number is shown on the back cover of this

guide.

2.2 Cleaning the Outer case

The painted panels should be wiped with a damp cloth and

then dried completely.

Page 8

3.0 Timer

8

3.1 Setting the Timer

The Electro-Mechanical Timer allows the central heating

system to be set every 15 minutes.

Using the three position switch the timer will allow either

constant operation, timed operation or central heating off.

Move the switch button by sliding to the desired position.

Three position switch (Fig. 17)

Constant (Top position): The heating will

be on constantly irrespective of the position

of the tappets.The heating will be controlled

by the main thermostat on the appliance

and/or any external controls.

Timed (Central position): The heating will

operate according to the position of the

tappets and be controlled as above.

0 Off (Bottom position): No central heating.

Domestic hot water will operate on demand.

To set the time of day

Turn the timer outer bezel clockwise, to align the pointer

with the correct time to the nearest 15 minutes

ensuring that A.M./P.M. is considered.

Do not at any time attempt to turn the bezel anticlockwise.

To set the timed heating program

Decide which times of the day the central heating is

required.

The heating will operate when the white tappets are set to

the outer edge of the bezel.

To ensure the heating stays OFF set the required tappets

inwards towards the centre of the bezel.

Each tappet represents 15 minutes.

For example: If the heating is not required between

10 A.M. and 11 A.M. the four tappets anticlockwise from

the 10 A.M. will be set inwards (Fig. 18).

2

3

4

5

AM

7

8

9

10

N

0

9

10

11

12

1

2

3

4

5

PM

7

8

9

10

11

12

1

2

3

4

5

AM

7

8

9

10

11

12

GRASSLIN

0

4

Constant

Time Pointer

Timed

Off

Rotate to adjust time

Off Position

On Position

Time Pointer

Fig. 17

Fig. 18

Page 9

4.0 Clearances

9

Fig. 19

Fig. 20

2

1

0

4

3

bar

R

1

2

3

4

5

P

M

7

8

9

10

11

12

1

2

3

4

5

AM

7

8

9

1

0

1

1

1

2

GRASSLIN

0

200mm Min

780mm

450mm

200mm Min

5mm Min

5mm Min

450mm Min

For Servicing

Purposes

In Operation

5mm Min

4.1 For your Safety

1. This appliance must have been installed in accordance

with the manufacturer’s instructions and the regulations

in force.

2. Any modification that may interfere with the normal

operation of the appliance without express written

permission from the manufacturer or his agent could

invalidate the appliance warranty. In GB this could also

infringe the Gas Safety (Installation and Use) Regulations.

3. Your boiler must not be operated without the casing

correctly fitted.

4. Do not interfere with any sealed components on this

boiler.

5. Take note of any warning labels on your boiler.

6. Your boiler should have the following minimum

clearances for Safety and Maintenance

(Figs.19 & 20):-

Top - 200mm

Bottom - 200mm

Left side - 5mm

Right Side - 5mm

Front - 5mm (In Operation)

- 450mm (For Servicing)

7. If your boiler is installed in a compartment, do not use

it for storage purposes. Do not obstruct any purpose

provided ventilation openings.

8. Flammable materials must not be stored in close

proximity to your boiler.

9. Avoid skin contact when your boiler is in operation, as

some surfaces may get hot e.g. pipework.

10. Ensure that the flue terminal, outside the house,

does not become damaged or obstructed, particularly

by foliage.

11. It is important that the condensate drain system is

not blocked, modified or damaged in any way as this

would affect the operation of your boiler. Your installer

should have insulated any exposed pipework.

GB - Heating Industry definition meaning England, Scotland,

Wales, Northern Ireland, Isle of Man and the Channel Isles

Page 10

5.0 Fault Finding/Emergency

10

No Heating/Hot Water

User to check

fault diagnosis

Contact your installer

Installer unable

to rectify fault

Contact heateam

Important information

you need to arrange

an appointment:

- Product serial number

- Make and model

- Installer details

- Proof of purchase

Contact

heateam

08706 60 30 60

Installer contacts

Help-line

In the unlikely event you have a problem with your boiler

please check the following.

1. Is the electricity supply to your boiler switched on

and the selector switch set to Central Heating and Hot

Water?

If so the Green ‘Power On’ neon will be on.

2. Is a fault suggested by the neon indicators?

Yes - Identify as described on Page 4.

No - Continue below

3. Is the gas supply turned on?

4. Is the mains water supply turned on?

5. Is the system pressure correct?

6. Is the programmer or timer switch set to On?

Refer to the instruction booklet supplied with these

items for correct setting and operation.

7. Are the temperature controls on the boiler turned

on and set high enough?

8. Are all system controls such as room and cylinder

thermostats set high enough?

9. Are the thermostatic radiator valves set high enough?

Contact your Installer

If you have followed the steps in this simple checklist but

your boiler still does not fire contact your installer.

Any repairs to the boiler will usually be the responsibility of

the Installer during the warranty period.

Installer Help-line

Should your installer need assistance he/she can contact our

trade support help-line for diagnostic and remedy advice.

Page 11

11

If you smell gas

Turn off the gas supply at the meter and call your gas

supplier immediately. It is possible to isolate the boiler and

at the isolating valve (Fig. 19).

In GB, Transco operate a 24 hour emergency service and

the telephone number will be listed in your telephone

directory.

Faulty boiler

If it is known or suspected that a fault exists

on the boiler, it must not be used until the fault

has been corrected by a competent person.

Warning !

Gas Tap

Heating Flow, Heating

Return and Mains Water

Inlet Isolating Valves

Fig. 19

Fig. 20

In an Emergency

If a water or gas leak occurs or is suspected, the boiler can

be isolated at the inlet valves as follows;

1. Turn off the electrical supply and turn the selector

switch on the facia to the OFF position.

2. Using a suitable open ended spanner or screwdriver

turn the square on the gas tap to the left to isolate the gas

supply at the boiler (Fig. 19).

3. The isolating valves are positioned under the boiler and

can be closed by turning their taps to the right towards

the wall (Fig. 20).

4. Call your Installer or Service Engineer as soon as

possible.

Page 12

Serial Number

Date of Installation

Installer Details (name, address and contact number(s)

Please complete the boxes below

heateam

heateam is the national customer service division of Baxi

Heating UK Limited providing a free warranty service within 5

years of installation of your boiler. If your installer is unable to

rectify your boiler fault, by contacting one of our friendly

advisors we can arrange an engineer if required.

When calling heateam it would be helpful if you could have the

following information to hand:

1 Boiler serial number.

2 Boiler make and model number.

3 Your installer name and address details.

4 Proof of purchase (if you do not have the

boiler serial number).

heateam will verify the boiler age via the serial number and

offer a free warranty service within 5 years of installation of the

boiler. If you are unable to provide this information or the

boiler has been installed for over 5 years, heateam will charge a

competitive rate for the repair. The engineer when visiting will

verify if the boiler is under the free 5 years warranty service, in

this case heateam will provide a full refund.

If you have contacted your installer and they are unable to

assist you at this time, please contact heateam.

heateam is open Monday to Friday 8am - 6pm, weekends and

bank holidays 8.30am - 2pm, closed on Christmas and New

Years Day.

Telephone 08700 60 30 60*

* To aid in continuous improvement and staff training, calls

to this line may be monitored or recorded.

Baxi Heating UK Limited

Brownedge Road Bamber Bridge Preston Lancashire PR5 6UP

After Sales Service 08700 60 30 60 Technical Enquiries 08706 049 049

Website www.baxi.co.uk

company

Comp No5116281 - Iss 2 - 11/05

924.354.1

Information Label

(on inside of panel)

Loading...

Loading...