Page 1

MW-3000529-01

en

Installation and Service Manual

Reversible air/water "Split Inverter" heat pump

Platinum BC iPlus

iMPI/H 4-8

iMPI/E 4-8

iMPI/H 11-16

iMPI/E 11-16

iMPI/H 4–8 insulated

iMPI/E 4-8 insulated

iMPI/H 11–16 insulated

iMPI/E 11-16 insulated

Page 2

Contents

1 Safety instructions and recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Refrigerant safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Domestic water safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.6 Hydraulic safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.7 Recommendations for the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.8 Specific instructions for service, maintenance and breakdowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.9 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Symbols used on the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.1.2 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2.1 Heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 Heat pump weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.3 Combination heaters with medium-temperature heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.4 Sensor specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.2.5 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.1 AWHP 4.5 MR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.2 AWHP 6 MR-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.3 AWHP 8 MR-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3.4 AWHP 11 MR-2 – AWHP 16 MR-2 – AWHP 11 TR-2 – AWHP 16 TR-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.3.5 iMPI with hydraulic back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.6 iMPI with electrical back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.2.1 Treatment of the heating water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.2 Special precautions for the connection of the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.3 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3.2 Overall space needed by the indoor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3.3 Distance between modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3.4 Installing the outdoor unit on the ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Fitting the outdoor sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4.1 Recommended positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.4.2 Positions to be avoided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Connecting diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.1 Connection for the iMPI heat pump with electrical back-up with a domestic hot water tank and an underfloor heating

circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.1.1 Connect and configure the iMPI heat pump with electrical back-up with a domestic hot water tank and a

direct circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.2 Connection for the iMPI heat pump with electrical back-up with 2 circuits and a buffer tank . . . . . . . . . . . . . . . . . . . . 38

6.2.1 Connect and configure the iMPI heat pump with electrical back-up with 2 circuits and a buffer tank . . . . . . 39

6.3 Connection for the iMPI heat pump with electrical back-up with 2 circuits with a low-loss header . . . . . . . . . . . . . . . .40

Contents

2 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 3

6.3.1 Connect and configure the iMPI heat pump with electrical back-up with a direct circuit, a circuit with mixing

valve, a low-loss header and two TXM connected thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4 Connection for the iMPI heat pump with hydraulic back-up with a direct circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4.1 Connect and configure the iMPI heat pump with hydraulic back-up with a direct circuit . . . . . . . . . . . . . . . . 42

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.1 Mounting the indoor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.3.1 Connecting the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.2 Connecting the safety valve drain pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4 Refrigeration connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4.1 Installing the refrigeration link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4.2 Connecting the refrigeration link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.4.3 Test the tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.4.4 Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.4.5 Opening the valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.5.2 Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

7.5.3 Description of the connection terminal blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5.4 Recommended cable cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

7.5.5 Accessing the PCBs and connection terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.5.6 Electrically connecting the outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5.7 Connecting the outdoor unit bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5.8 Connecting the outside sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5.9 Connecting the hydraulic back-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5.10 Connecting the power supply for the electrical back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5.11 Connecting a swimming pool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

7.6 Connecting the options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.6.1 Connecting an on/off or modulating thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

7.6.2 Connecting a thermostat with heating/cooling connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.7 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

7.7.1 Filling the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2.1 Checking the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

8.2.2 Checking the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2.3 Checking the refrigeration circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.3 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.3.1 CNF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.3.2 Start-up cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

8.4 Using the installation wizard on the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.5 Checking the minimum flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.6 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9.1 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.1.1 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9.1.2 Browsing in the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.3 Description of the PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.3.1 Switching off the heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.3.2 Shutting down the cooling function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9.4 Frost Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

10 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.1 Modifying the installer parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2 Installer menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2.1 Installer \CIRCA and CIRCB menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

10.2.2 Installer \CIRCA and CIRCB\ADV menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Contents

7685645 - v04 - 07032018 AWHP-2 iMPI 3

Page 4

10.2.3 Installer \DHW menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

10.2.4 Installer \DHW\ADV menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.2.5 Installer \EHC–04 and SCB-04 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.2.6 Installer \EHC–04 and SCB-04\ADV menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

10.3 COUNTERS /TIME PROG / CLOCK menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.3.1 COUNTERS, TIME PROG, CLOCK \CNT menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.3.2 COUNTERS, TIME PROG, CLOCK \CIRCA, CIRCB and DHW menus . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.3.3 COUNTERS, TIME PROG, CLOCK \CLK menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.4 Description of the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

10.4.1 Running the back-up in heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.4.2 Setting the switch between heating and production of domestic hot water . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.4.3 Running the back-up in domestic hot water mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

10.5 Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10.5.1 Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10.5.2 Selecting the type of outdoor unit and the type of back-up (CN1 et CN2) . . . . . . . . . . . . . . . . . . . . . . . . . . .90

10.5.3 Setting the heating curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.5.4 Configuring the estimated electrical energy consumption function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.5.5 Configuring a hydraulic back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.5.6 Configuring the hybrid operating mode of a hydraulic back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.5.7 Configuring a convection fan or underfloor cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.5.8 Screed drying with the aid of the heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.5.9 Drying screed without the heat pump outdoor unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.5.10 Supplying the heat pump with photovoltaic energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.5.11 Connecting the installation to a Smart Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.5.12 Reducing the noise level of the outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.5.13 Detecting an additional or replacement PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

10.6 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.6.1 Control system sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

11 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.2 Checking operation of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

11.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.3.1 Checking the safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.3.2 Check the hydraulic pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.3.3 Cleaning the casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.3.4 Draining the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.4 Specific maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.4.1 Cleaning the 500 µm filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.4.2 Replacing the battery in the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

12.1 Resetting the safety thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

12.2.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12.2.2 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

12.2.3 Alarm codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

12.3 Accessing the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13 Decommissioning and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

13.1 Decommissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

13.2 Disposal and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Contents

4 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 5

1 Safety instructions and recommendations

1.1 Safety

Operation

Danger

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the haz

ards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

Electrical

The appliance is intended to be permanently connected to the domestic water

mains network.

Before any work on the appliance, carefully read all documents that accompa

ny the product. These documents are also available on our website. See the

last page.

Install the appliance in accordance with national rules on electrical installation.

A disconnection device must be fitted to the permanent pipes in accordance

with installation rules.

If a power supply cable comes with the appliance and it turns out to be dam

aged, it must be replaced by the manufacturer, its after sales service or per

sons with similar qualifications in order to obviate any danger.

If the appliance is not wired in the factory, carry out the wiring according to the

wiring diagram described in the chapter Electrical Connections. See the Instal

lation and Service Manual.

This appliance must be connected to the protective earth.

Earthing must comply with the prevailing installation standards.

Earth the appliance before making any electrical connections.

Type and calibre of the protective equipment: refer to the chapter Recommen

ded cable cross-sections. See the Installation and Service Manual.

To connect the appliance to the electricity mains, refer to the chapter Electrical

Connections. See the Installation and Service Manual.

In order to prevent any danger owing to the unexpected reset of the thermal

circuit breaker, this appliance must not be powered through an external switch,

such as a timer, or be connected to a circuit which is regularly switched on and

off by the electricity provider.

1 Safety instructions and recommendations

7685645 - v04 - 07032018 AWHP-2 iMPI 5

Page 6

Domestic wa

ter

Draining the appliance:

1. Shut off the domestic cold water inlet.

2. Open a hot water tap in the installation.

3. Open a valve on the safety unit.

4. When the water stops flowing, the appliance has been drained.

The pressure limiter device (safety valve or safety unit) must be regularly oper

ated in order to remove limescale deposits and ensure that it is not blocked.

A pressure limiter device must be fitted to a discharge pipe.

As water may flow out of the discharge pipe, the pipe must be kept open to the

open air, in a frost-free environment, and at a continuous downward gradient.

To ascertain the type or specifications of the pressure limiter and to find out

how to connect it, refer to the chapter Connecting the domestic hot water tank

to the drinking water mains. See the Installation and Service Manual.

Hydraulics

Caution

Respect the minimum and maximum water pressure and tem

perature to ensure the appliance operates correctly. See

chapter on Technical Specifications.

Installation

Important

Allow the space required to install the appliance correctly, re

ferring to the chapter Dimensions of the Appliance. See the

Installation and Service Manual.

1.2

General instructions

The system must satisfy each point in the rules in force in the country that

govern works and interventions in individual homes, blocks of flats or other

buildings.

Only qualified professionals are authorised to work on the appliance and

the heating installation. They must respect prevailing local and national

regulations during fitting, installation and maintenance of the installation.

Commissioning must be performed by a qualified professional.

1.3 Electrical safety

Before making any electrical connections, earth the appliance in accord

ance with prevailing standards.

Danger

Danger of electric shock: the length of the conductors between the

traction arrester device and the terminal blocks must be such that

the active conductors are put under tension before the earth con

ductor.

Only qualified professionals may carry out electrical connections, always

with the power off.

Separate the very low voltage cables from the 230/400 V circuit cables.

1 Safety instructions and recommendations

6 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 7

1.4 Refrigerant safety

Warning

Refrigerant fluid and pipes:

Use only R410A refrigerant fluid to fill the installation.

Use tools and pipe components especially designed for use with

R410A refrigerant fluid.

Use copper pipes deoxidised with phosphorus to carry the re

frigerant fluid.

Store the refrigerant connection pipes away from dust and hu

midity (risk of damage to the compressor).

Do not use a load cylinder.

Protect the heat pump components, including the insulation and

structural elements. Do not overheat the pipes as brazed com

ponents may cause damage.

Contact between the refrigerant fluid and a flame may result in

emissions of toxic gases.

France: Pursuant to Article L. 113-3 of the French Consumer Code, the in

stallation of equipment must be done by a certified operator whenever the

refrigerant load is in excess of two kilograms or when a refrigerant connec

tion is necessary (the case with split systems, even when fitted with a

quick coupling device).

All work on the refrigeration circuit must be done by a qualified professio

nal, according to prevailing codes of practice and safety in the profession

(recovery of the refrigerant, brazing under nitrogen). All brazing work must

be done by qualified welders.

Do not touch the refrigeration connection pipes with your bare hands while

the heat pump is running. Danger of burn or frost injury.

In the event of a refrigerant leakage:

1. Switch off the appliance.

2. Open the windows.

3. Do not use a naked flame, do not smoke, do not operate electrical

contacts.

4. Avoid contact with the refrigerant. Danger of frost injuries.

Locate the probable leak and seal it immediately. Use only original parts to

replace a defective refrigeration component.

Use only dehydrated nitrogen for detecting leaks or for pressurised tests.

Do not allow the refrigerant fluid to escape into the atmosphere.

1.5 Domestic water safety

In accordance with safety rules, a safety valve calibrated to 0.7 MPa (7

bar) is mounted on the tank's domestic cold water inlet.

A pressure reducer (not provided) is required when the supply pressure

exceeds 80% of the safety valve or safety unit calibration and must be lo

cated upstream of the appliance.

There must be no cut-off devices between the safety valve or unit and the

domestic hot water tank.

The hydraulic installation must be capable of handling a minimum flow rate

at all times.

Heating water and domestic water must not come into contact with each

other. Domestic water must not circulate through the exchanger.

Limit temperature at the draw-off point: the maximum domestic hot water

temperature at the draw-off point is subject to special regulations in the

various countries in which the appliance is sold in order to protect the

user. These special regulations be observed when installing the appliance.

Take precautions with the domestic hot water. Depending on the heat

pump settings, the domestic hot water temperature may exceed 65°C.

1 Safety instructions and recommendations

7685645 - v04 - 07032018 AWHP-2 iMPI 7

Page 8

In order to limit the risk of being scalded, a thermostatic mixing valve must

be installed on the domestic hot water flow pipes.

1.6 Hydraulic safety

When making the hydraulic connection, it is imperative that the standards

and corresponding local directives be respected.

If radiators are connected directly to the heating circuit: install a differential

valve between the indoor module and the heating circuit.

Keep a heating circuit without thermostatic valve and or without solenoid

valve in order to avoid having all valves closed at the same time.

Fit drainage valves between the indoor module and the heating circuit.

Do not add any chemical products to the heating water without first con

sulting a water treatment specialist. For example: antifreeze, water soften

ers, products to increase or reduce the pH value, chemical additives

and/or inhibitors. These may cause faults in the heat pump and damage

the heat exchanger.

1.7

Recommendations for the installation

Install the heat pump's indoor module in a frost-free location.

Insulate the pipes to reduce heat losses to a minimum.

Apply refrigerant oil to the beaded parts to facilitate tightening and improve

the seal.

Keep this document close to the place where the appliance is installed.

Do not make any modifications to the heat pump without the written con

sent of the manufacturer.

To benefit from extended warranty cover, no modifications should be

made to the appliance.

Install the heat pump indoor module and outdoor unit on a solid, stable

structure able to bear its weight.

Do not install the heat pump in a place that has an atmosphere with a high

salt content.

Do not install the heat pump in a place exposed to steam and combustion

gases.

Do not install the heat pump in a place that may be covered in snow.

1.8 Specific instructions for service, maintenance and breakdowns

Maintenance work must be carried out by a qualified professional.

Only a qualified professional is authorised to set, correct or replace the

safety devices.

Before any work, switch off the mains electricity to the heat pump, the in

door unit and the hydraulic or electrical back-up if connected.

Wait for approx. 20-30 seconds for the outdoor unit capacitors to be dis

charged, and check that the lights on the outdoor unit PCBs have gone

out.

Before working on the refrigeration circuit, switch off the appliance and

wait a few minutes. Certain items of equipment such as the compressor

and the pipes can reach temperatures in excess of 100 °C and high pres

sures, which may cause serious injuries.

Locate and correct the cause of power cut before resetting the safety ther

mostat.

Only genuine spare parts may be used.

Removal and disposal of the heat pump must be carried out by a qualified

professional in accordance with prevailing local and national regulations.

Do not allow the refrigerant fluid to escape into the atmosphere.

1 Safety instructions and recommendations

8 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 9

After maintenance or repair work, check the entire heating system to en

sure that there are no leaks.

Remove the casing only to perform maintenance and repair work. Put the

casing back in place after maintenance and repair work.

1.9

Liabilities

Manufacturer's liability Our products are manufactured in compliance with the requirements of the various Directives appli

cable. They are therefore delivered with the marking and any documents necessary. In the inter

ests of the quality of our products, we strive constantly to improve them. We therefore reserve the

right to modify the specifications given in this document.

Our liability as manufacturer may not be invoked in the following cases:

Failure to abide by the instructions on installing the appliance.

Failure to abide by the instructions on using the appliance.

Faulty or insufficient maintenance of the appliance.

Installer's liability The installer is responsible for the installation and initial commissioning of the appliance. The instal

ler must observe the following instructions:

Read and follow the instructions given in the manuals provided with the appliance.

Install the appliance in compliance with prevailing legislation and standards.

Carry out initial commissioning and any checks necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the obligation to check the appliance and keep it in

good working order.

Give all the instruction manuals to the user.

1 Safety instructions and recommendations

7685645 - v04 - 07032018 AWHP-2 iMPI 9

Page 10

2 About this manual

2.1 Additional documentation

This manual contains information on the heat pump's indoor module, in

cluding the domestic hot water tank, as well as various items of informa

tion on the outdoor unit.

For additional information on the outdoor unit, refer to the manual provided

with that unit.

2.2

Symbols used

2.2.1

Symbols used in the manual

This manual uses various danger levels to draw attention to special in

structions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal in

jury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

2.2.2 Symbols used on the appliance

1 Alternating current

2 Protective earthing

3 Before installing and commissioning the appliance, carefully read

the instruction manuals provided.

4 Dispose of used products through an appropriate recovery and re

cycling structure.

5 Caution: danger of electric shock, live parts. Disconnect the mains

power prior to carrying out any work.

Fig.1 Symbols used on the appliance

1 2

MW-2000068-1

1

2

3

4

5

2 About this manual

10 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 11

1 Information concerning the heat pump: refrigerant type, maximum

allowable operating pressure

2 The symbol indicates compatibility with the TXM connected ther

mostat.

3 Information on the electrical back-up: power supply and maximum

output (only for versions with electrical back-up)

4 Before installing and commissioning the appliance, carefully read

the instruction manuals provided

5 Dispose of used products in an appropriate recovery and recycling

structure

Fig.2 Symbols used on the data plate

MW-5000752-1

1

4

2

5

3

2 About this manual

7685645 - v04 - 07032018 AWHP-2 iMPI 11

Page 12

3 Technical specifications

3.1 Homologations

3.1.1 Directives

This product complies with the requirements of the following European Di

rectives and Standards:

Pressure Equipment Directive 2014/68/EU

Low Voltage Directive 2014/35/EU

Generic standard: EN 60335-1

Relevant standards: EN 60335-2-21, EN 60335-2-40

Electromagnetic Compatibility Directive 2014/30/EU

Generic standards: EN 61000-6-3, EN 61000-6-1

Relevant Standard: EN 55014

This product conforms to the requirements of European Directive

2009/125/EC on the ecodesign of energy-related products.

In addition to the legal requirements and guidelines, the supplementary

guidelines in this manual must also be followed.

Supplements or subsequent regulations and guidelines that are valid at

the time of installation shall apply to all regulations and guidelines speci

fied in this manual.

EC Declaration of Conformity

The unit complies with the standard type described in the EC declaration

of conformity. It has been manufactured and commissioned in accordance

with European directives.

The original declaration of conformity is available from the manufacturer.

3.1.2 Factory test

Before leaving the factory, each indoor module is tested on the following

items:

Tightness of the heating circuit

Electrical safety

Tightness of the refrigerant circuit

Tightness of the domestic hot water circuit

3.2 Technical data

3.2.1 Heat pump

Maximum operating pressure: 0.3 MPa (3 bar)

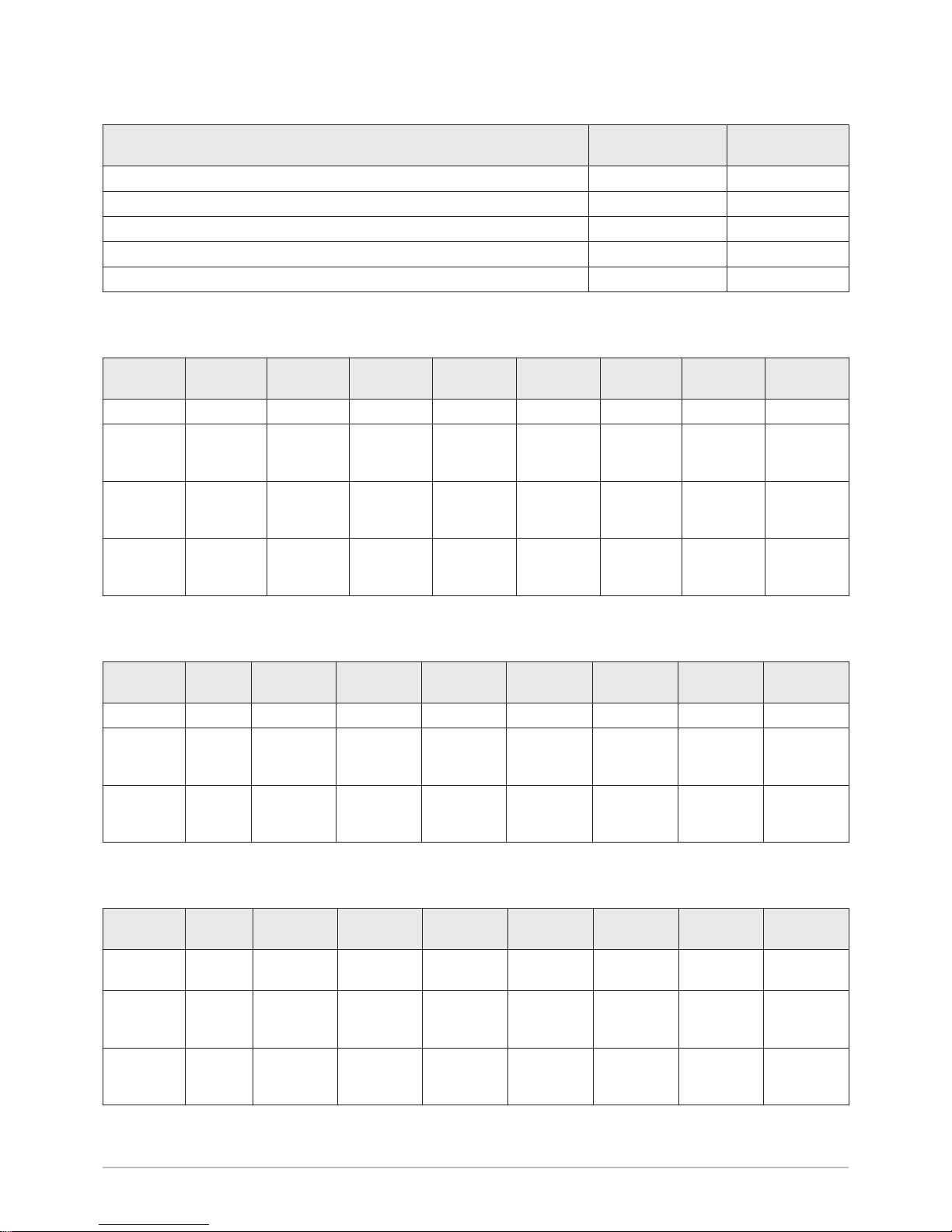

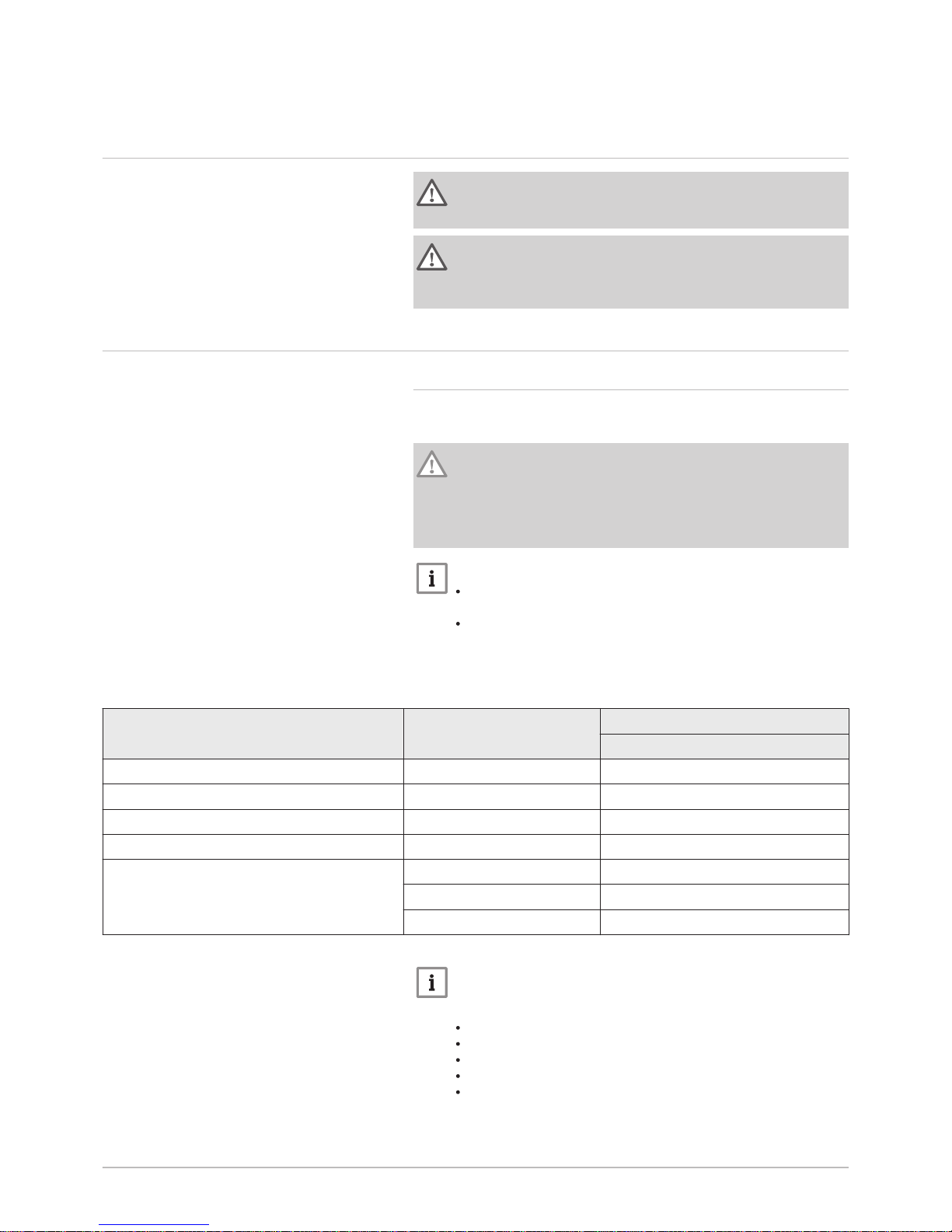

Tab.1 Conditions of use

AWHP 4.5 MR AWHP 6 MR-3 AWHP 8 MR-2

Limit water operating temperatures in heating mode +18 °C/+55 °C +18 °C/+60 °C +18 °C/+60 °C

Limit outdoor air operating temperatures in heating mode -15 °C/+35 °C -15 °C/+35 °C -20 °C/+35 °C

Limit water operating temperatures in cooling mode for

uninsulated models

+18 °C/+25 °C +18 °C/+25 °C +18 °C/+25 °C

Limit water operating temperatures in cooling mode for in

sulated models

+7°C / +25°C +7°C / +25°C +7°C / +25°C

Limit outdoor air operating temperatures in cooling mode +7 °C/+40 °C +7 °C/+40 °C +7 °C/+40 °C

3 Technical specifications

12 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 13

Tab.2 Conditions of use

AWHP 11 MR-2

AWHP 11 TR-2

AWHP 16 MR-2

AWHP 16 TR-2

Limit water operating temperatures in heating mode +18 °C/+60 °C +18 °C/+60 °C

Limit outdoor air operating temperatures in heating mode -20 °C/+35 °C -20 °C/+35 °C

Limit water operating temperatures in cooling mode for uninsulated models +18 °C/+25 °C +18 °C/+25 °C

Limit water operating temperatures in cooling mode for insulated models +7°C / +25°C +7°C / +25°C

Limit outdoor air operating temperatures in cooling mode +7 °C/+40 °C +7 °C/+40 °C

Tab.3 Heating mode: outside air temperature +7°C, water temperature at the outlet +35°C. Performances in accordance with

EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Heat output kW 4.60 5.79 8.26 11.39 11.39 14.65 14.65

Coefficient

of Perform

ance (COP)

5.11 4.05 4.27 4.65 4.65 4.22 4.22

Absorbed

electrical

power

kWe 0.90 1.43 1.93 2.45 2.45 3.47 3.47

Nominal wa

ter flow rate

(ΔT = 5K)

m3/hour

0.88 1.13 1.53 1.96 1.96 2.53 2.53

Tab.4 Heating mode: outside air temperature +2°C, water temperature at the outlet +35°C. Performances in accordance with

EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Heat output kW 3.47 3.65 5.3 10.19 10.19 12.90 12.90

Coefficient

of Perform

ance (COP)

3.97 3.23 3.46 3.20 3.20 3.27 3.27

Absorbed

electrical

power

kWe 0.88 1.13 1.53 3.19 3.19 3.94 3.94

Tab.5 Cooling mode: outside air temperature +35°C, water temperature at the outlet +18°C. Performances in accordance

with EN 14511-2.

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Cooling out

put

kW 3.80 4.69 7.90 11.16 11.16 14.46 14.46

Energy effi

ciency ratio

(EER)

4.28 4.09 3.99 4.75 4.75 3.96 3.96

Absorbed

electrical

power

kWe 0.89 1.15 2.00 2.35 2.35 3.65 3.65

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 13

Page 14

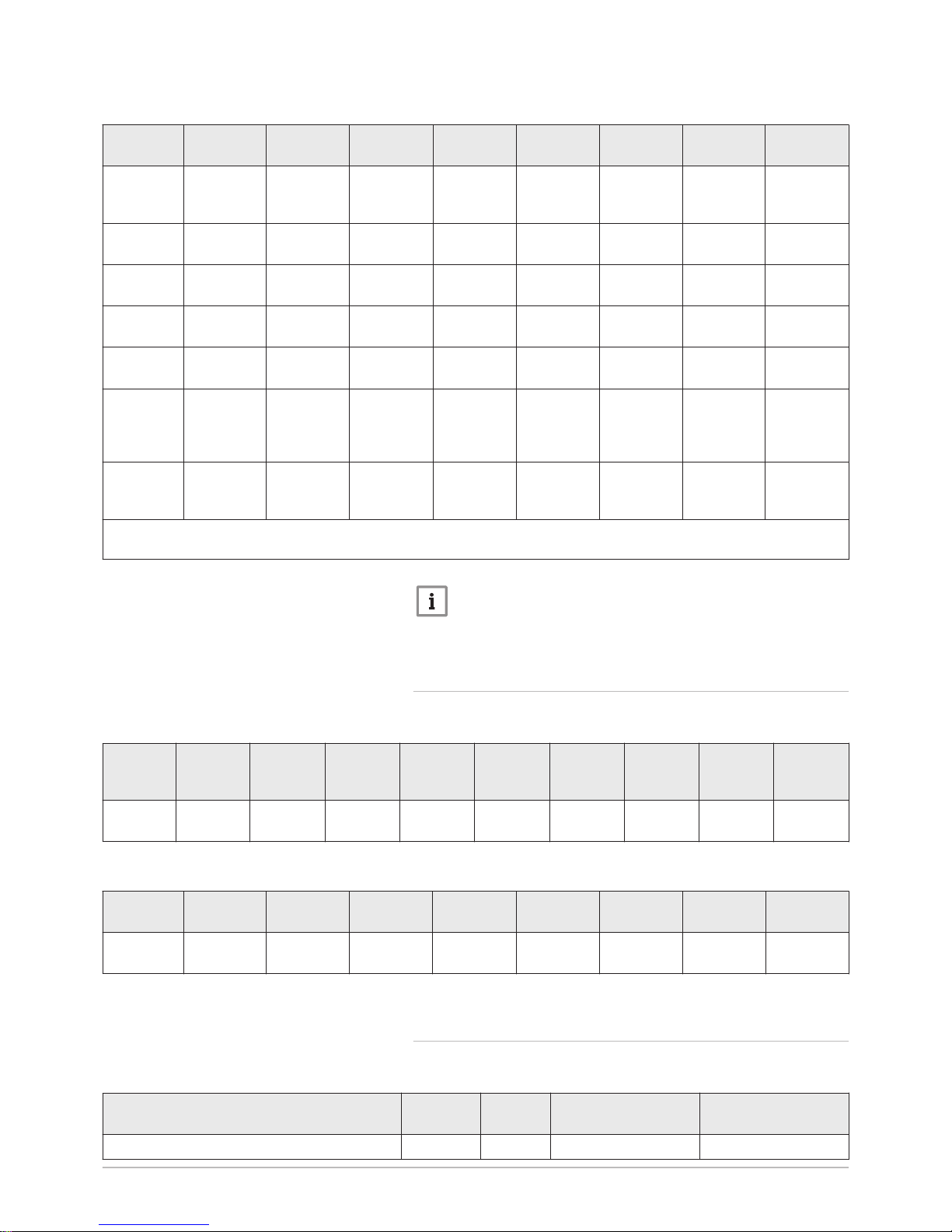

Tab.6 Common specifications

Measure

ment type

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Power volt

age of the

outdoor unit

V 230 230 230 230 400 230 400

Start-up

amperage

A 5 5 5 5 3 6 3

Maximal

amperage

A 12 13 19 29.5 13 29.5 13

Refrigerant

fluid R410A

kg 1.3 1.4 3.2 4.6 4.6 4.6 4.6

R410A re

frigerant

(1)

tCO2e 2.714 2.923 6.680 9.603 9.603 9.603 9.603

Refrigerant

connection

(Liquid Gas)

inch 1/4 - 1/2 1/4 - 1/2 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8 3/8 - 5/8

Max. precharged

length

m 7 10 10 10 10 10 10

(1) The quantity of refrigerant in CO2 equivalent is calculated using the following formula: quantity (in kg) of refrigerant x GWP / 1000. The

Global-Warming Potential (GWP) of R410A gas is 2088.

Important

The Global-Warming Potential (GWP) of R410A gas is 2088.

The values in tonnes of CO2 equivalent are calculated using the

following formula: quantity (in kg) of refrigerant x GWP / 1000.

3.2.2 Heat pump weight

Tab.7 Indoor module

Indoor

module

Unit iMPI/H 4-8 iMPI/E 4-8 iMPI/H

11-16

iMPI/E 11–16iMPI/H 4–8

insulated

iMPI/E 4-8

insulated

iMPI/H 11–

16

insulated

iMPI/E 11–

16

insulated

Weight

(empty)

kg 36.1 35.5 36.1 35.5 38.2 36.7 38.2 36.7

Tab.8 Outdoor unit

Outdoor

unit

Unit AWHP 4.5 MRAWHP 6

MR-3

AWHP 8

MR-2

AWHP 11

MR-2

AWHP 11

TR-2

AWHP 16

MR-2

AWHP 16

TR-2

Weight

(empty)

kg 54 42 75 118 130 118 130

3.2.3 Combination heaters with medium-temperature heat

pump

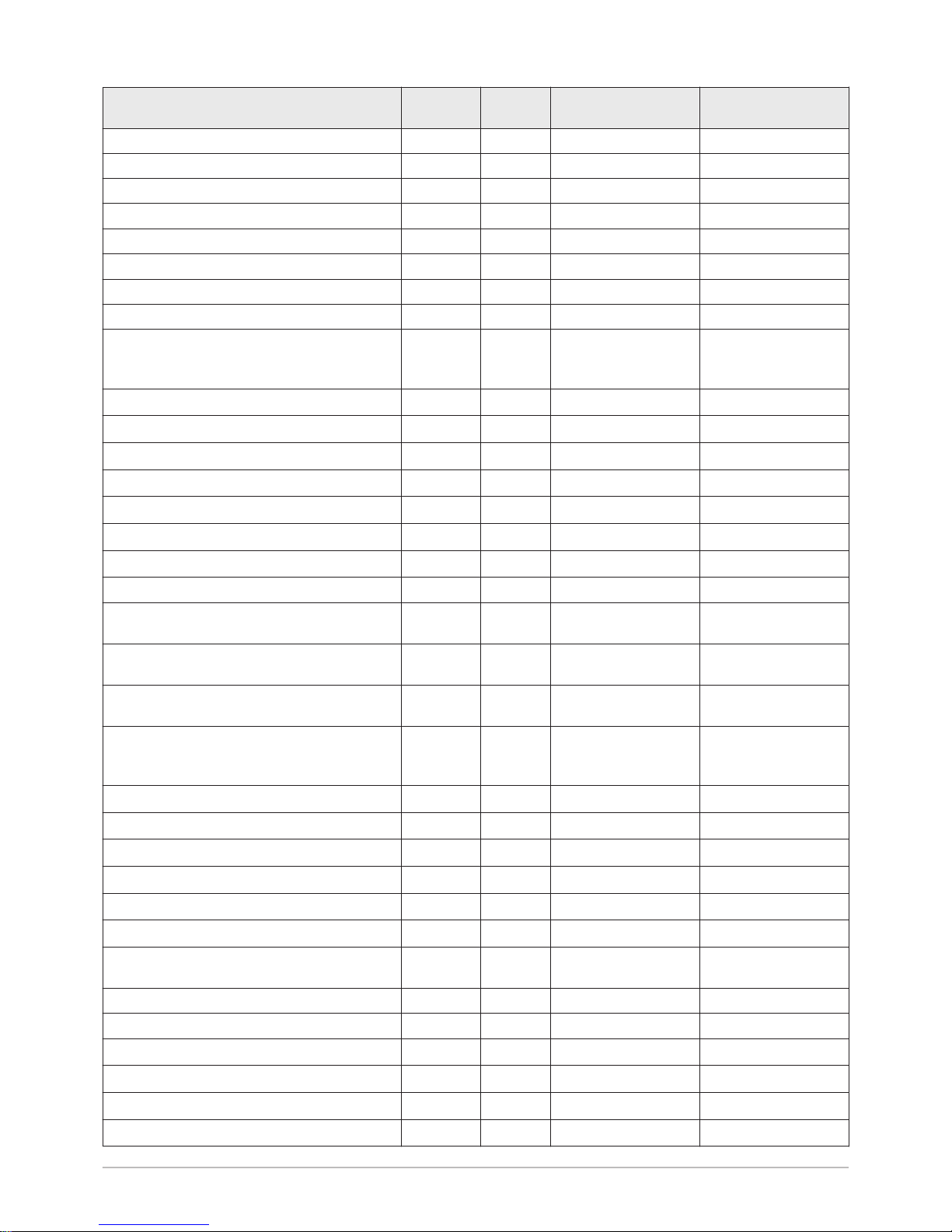

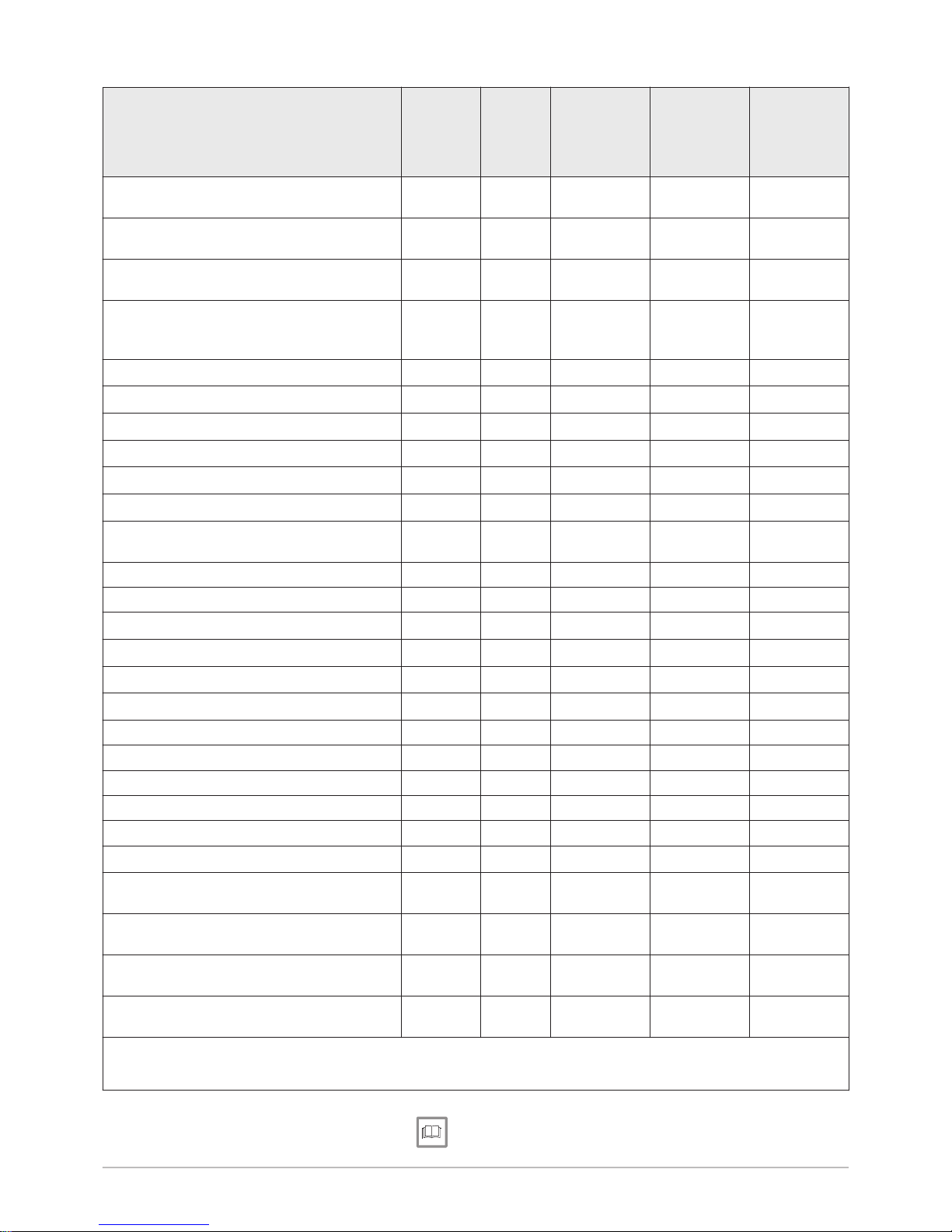

Tab.9 Technical parameters for heat pump combination heaters (parameters declared for medium-temperature application)

Product name AWHP-2 iMPI

AWHP 4.5 MR

AWHP-2 iMPI

AWHP 6 MR-3

Air-to-water heat pump Yes Yes

3 Technical specifications

14 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 15

Product name AWHP-2 iMPI

AWHP 4.5 MR

AWHP-2 iMPI

AWHP 6 MR-3

Water-to-water heat pump No No

Brine-to-water heat pump No No

Low-temperature heat pump No No

Equipped with a supplementary heater Yes Yes

Heat pump combination heater No No

Rated heat output under average conditions

(1)

Prated

kW 4 4

Rated heat output under colder conditions

Prated

kW 5 4

Rated heat output under warmer conditions

Prated

kW 4 5

Declared capacity for heating for part load at an

indoor temperature of 20°C and outdoor tempera

ture

T

j

T

j

= -7°C

Pdh

kW 3.8 3.5

T

j

= +2°C

Pdh

kW 4.3 4.5

T

j

= +7°C

Pdh

kW 4.5 4.8

T

j

= +12°C

Pdh

kW 5.5 5.2

T

j

= bivalent temperature

Pdh

kW 3.9 3.6

T

j

= operation limit temperature

Pdh

kW 3.9 3.6

Bivalent temperature

T

biv

°C -10 -10

Degradation coefficient

(2)

Cdh

— 1.0 1.0

Seasonal space heating energy efficiency under

average conditions

ƞ

s

% 134 137

Seasonal space heating energy efficiency under

colder conditions

ƞ

s

% 109 116

Seasonal space heating energy efficiency under

warmer conditions

ƞ

s

% 179 172

Declared coefficient of performance or primary

energy ratio for part load at an indoor tempera

ture of 20°C and outdoor temperature

T

j

T

j

= -7°C

COPd

- 1.64 1.89

T

j

= +2°C

COPd

- 3.46 3.53

T

j

= +7°C

COPd

- 4.96 4.74

T

j

= +12°C

COPd

- 7.90 7.08

T

j

= bivalent temperature

COPd

- 1.20 1.52

T

j

= operation limit temperature

COPd

- 1.20 1.52

Operation limit temperature for air-to-water

heat pumps

TOL

°C -10 -10

Heating water operating limit temperature

WTOL

°C 55 60

Electrical power consumption

Off mode

P

OFF

kW 0.009 0.009

Thermostat-off mode

P

TO

kW 0.049 0.049

Stand-by

P

SB

kW 0.009 0.015

Crankcase heater mode

P

CK

kW 0.000 0.055

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 15

Page 16

Product name AWHP-2 iMPI

AWHP 4.5 MR

AWHP-2 iMPI

AWHP 6 MR-3

Supplementary heater

Rated heat output

Psup

kW 0.0 0.0

Type of energy input Electricity Electricity

Other specifications

Capacity control Variable Variable

Sound power level, indoors - outdoors

L

WA

dB 49 – 61 49 – 62

Annual energy consumption under average

conditions

Q

HE

kWh 2353 2124

Annual energy consumption under colder con

ditions

Q

HE

kWh 4483 3721

Annual energy consumption under warmer

conditions

Q

HE

kWh 1249 1492

Rated air flow rate, outdoors for air-to-water

heat pumps

—

m3/h

2100 2100

(1) The rated heat output

Prated

is equal to the design load for heating

Pdesignh

, and the rated heat output of a supplementary heater

Psup

is equal to the supplementary capacity for heating

sup(Tj)

.

(2) If

Cdh

is not determined by measurement, the default degradation coefficient is

Cdh

= 0.9.

Tab.10 Technical parameters for heat pump combination heaters (parameters declared for medium-temperature application)

Product name AWHP-2 iMPI

AWHP 8 MR-2

AWHP-2 iMPI

AWHP 11

MR-2

AWHP 11

TR-2

AWHP-2 iMPI

AWHP 16

MR-2

AWHP 16

TR-2

Air-to-water heat pump Yes Yes Yes

Water-to-water heat pump No No No

Brine-to-water heat pump No No No

Low-temperature heat pump No No No

Equipped with a supplementary heater Yes Yes Yes

Heat pump combination heater No No No

Rated heat output under average conditions

(1)

Prated

kW 6 6 9

Rated heat output under colder conditions

Prated

kW 6 4 7

Rated heat output under warmer conditions

Prated

kW 6 8 13

Declared capacity for heating for part load at an

indoor temperature of 20°C and outdoor tempera

ture

T

j

T

j

= -7°C

Pdh

kW 5.6 5.9 9.0

T

j

= +2°C

Pdh

kW 2.9 5.3 6.5

T

j

= +7°C

Pdh

kW 6.4 9.0 12.9

T

j

= +12°C

Pdh

kW 4.3 7.7 10.0

T

j

= bivalent temperature

Pdh

kW 5.2 6.3 8.8

T

j

= operation limit temperature

Pdh

kW 5.2 6.3 8.8

Bivalent temperature

T

biv

°C -10 -10 -10

Degradation coefficient

(2)

Cdh

— 1.0 1.0 1.0

3 Technical specifications

16 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 17

Product name AWHP-2 iMPI

AWHP 8 MR-2

AWHP-2 iMPI

AWHP 11

MR-2

AWHP 11

TR-2

AWHP-2 iMPI

AWHP 16

MR-2

AWHP 16

TR-2

Seasonal space heating energy efficiency under

average conditions

ƞ

s

% 129 125 121

Seasonal space heating energy efficiency under

colder conditions

ƞ

s

% 119 113 113

Seasonal space heating energy efficiency under

warmer conditions

ƞ

s

% 169 167 161

Declared coefficient of performance or primary

energy ratio for part load at an indoor tempera

ture of 20°C and outdoor temperature

T

j

T

j

= -7°C

COPd

- 1.95 1.87 1.85

T

j

= +2°C

COPd

- 3.22 3.17 3.02

T

j

= +7°C

COPd

- 4.57 4.54 4.34

T

j

= +12°C

COPd

- 6.55 6.19 5.75

T

j

= bivalent temperature

COPd

- 1.70 1.20 1.35

T

j

= operation limit temperature

COPd

- 1.70 1.20 1.35

Operation limit temperature for air-to-water

heat pumps

TOL

°C -10 -10 -10

Heating water operating limit temperature

WTOL

°C 60 60 60

Electrical power consumption

Off mode

P

OFF

kW 0.009 0.009 0.009

Thermostat-off mode

P

TO

kW 0.049 0.023 0.035

Stand-by

P

SB

kW 0.014 0.023 0.023

Crankcase heater mode

P

CK

kW 0.055 0.055 0.055

Supplementary heater

Rated heat output

Psup

kW 0.0 0.0 0.0

Type of energy input Electricity Electricity Electricity

Other specifications

Capacity control Variable Variable Variable

Sound power level, indoors - outdoors

L

WA

dB 49 – 67 48 – 69 48 – 70

Annual energy consumption under average

conditions

Q

HE

kWh 3499 3999 5861

Annual energy consumption under colder con

ditions

Q

HE

kWh 4621 3804 5684

Annual energy consumption under warmer

conditions

Q

HE

kWh 1904 2580 4120

Rated air flow rate, outdoors for air-to-water

heat pumps

—

m3/h

3300 6000 6000

(1) The rated heat output

Prated

is equal to the design load for heating

Pdesignh

, and the rated heat output of a supplementary heater

Psup

is equal to the supplementary capacity for heating

sup(Tj)

.

(2) If

Cdh

is not determined by measurement, the default degradation coefficient is

Cdh

= 0.9.

See

The back cover for contact details.

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 17

Page 18

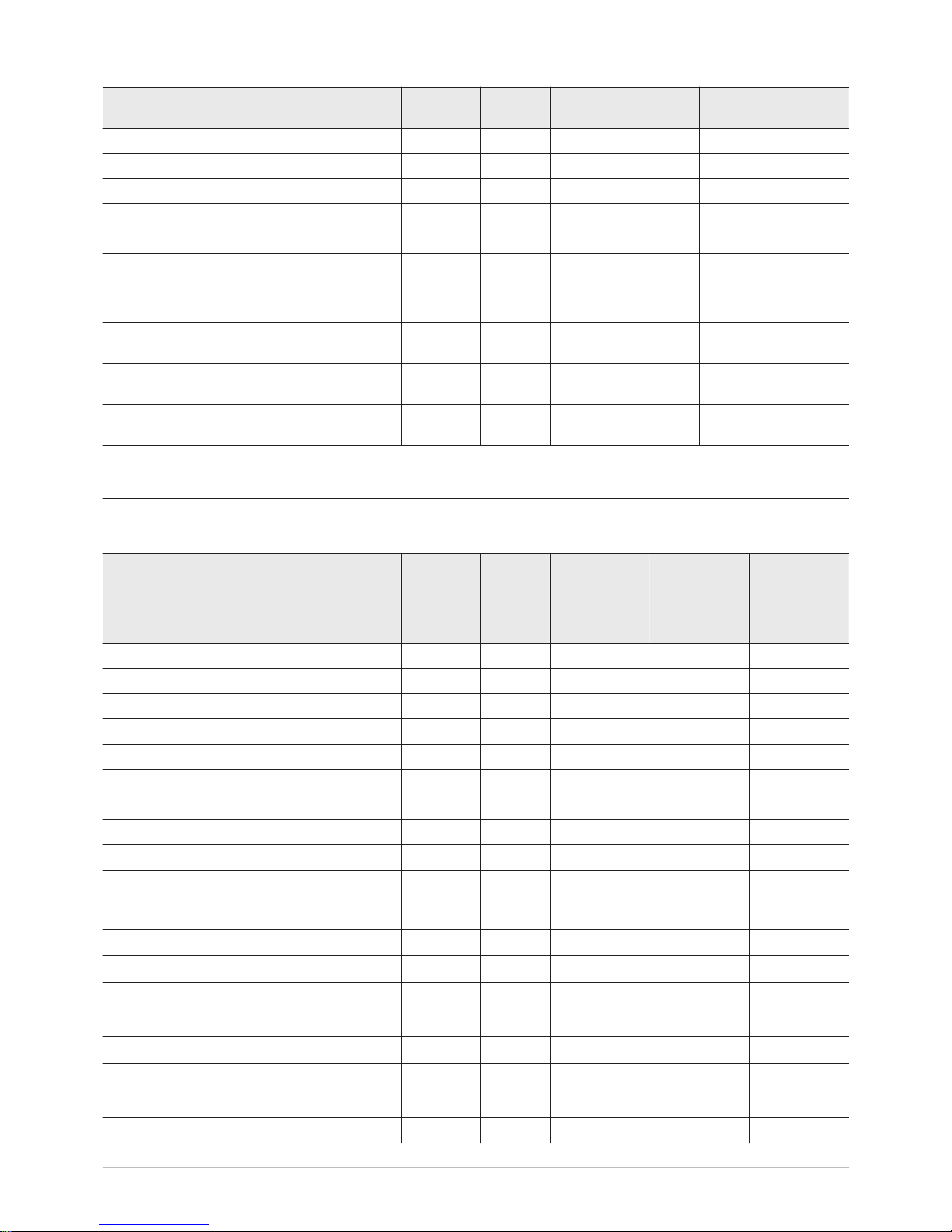

3.2.4 Sensor specifications

Outside sensor specifications

Tab.11 Outside sensor

Temperature °C -20 -16 -12 -8 -4 0 4 8 12 16 20 24

Resistance Ohm 2392 2088 1811 1562 1342 1149 984 842 720 616 528 454

Flow sensor specifications

Tab.12 Flow sensor

Temperature in °C0 10 20 25 30 40 50 60 70 80 90

Resistance in Ω 32014 19691 12474 10000 8080 5372 3661 2535 1794 1290 941

PT1000 sensor specifications

Tab.13 PT1000 condenser flow and return sensors

Temperature °C -10 0 10 20 30 40 50 60 70 80 90 100

Resistance Ohm 961 1000 1039 1077 1117 1155 1194 1232 1271 1309 1347 1385

3.2.5 Circulating pump

Important

The benchmark for the most efficient circulating pumps is EEI ≤

0.20.

The circulating pump in the indoor module is a variable speed pump. It

adapts its speed to the distribution network.

The speed of the circulating pump is controlled to reach a set point flow

rate. This set point depends on the HP069 parameter. This value is auto

matically configured according to the power of the outdoor unit when the

codes CN1 and CN2 are configured when the device is first started.

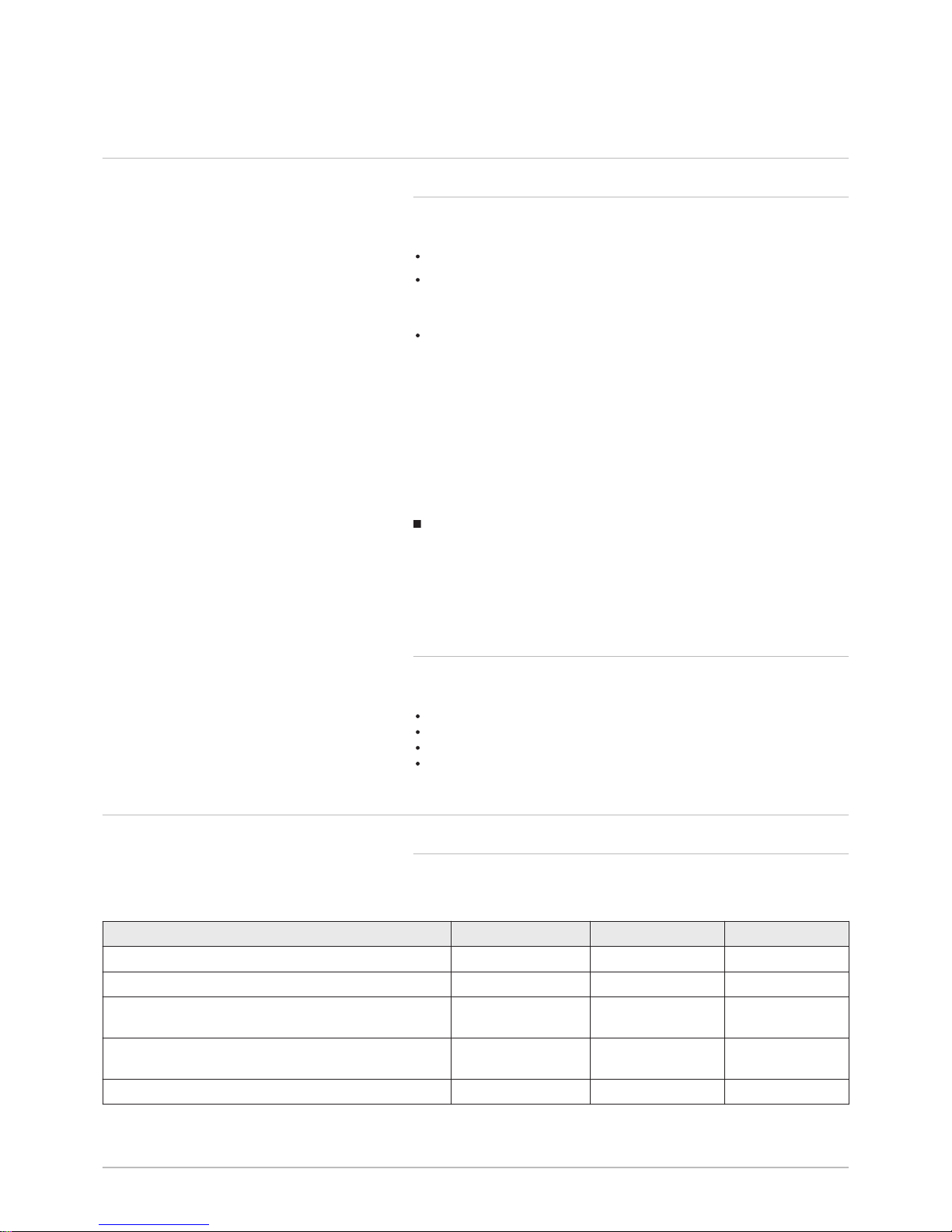

1 Available pressure in metres of water column (mWc)

2

Water flow rate in cubic metres per hour (m3/h)

3 Available pressure for 4.5 to 8 kW outdoor units

4 Available pressure for the 11 and 16 kW outdoor units

Fig.3 Pressure available

MW-1001170-1

0

1

2

3

4

5

6

7

8

9

0 0.2 0.4 0 .6 0 .8 1 1.2 1 .4 1 .6 1.8 2 2.2

1

2

4

3

3 Technical specifications

18 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 19

3.3 Dimensions and connections

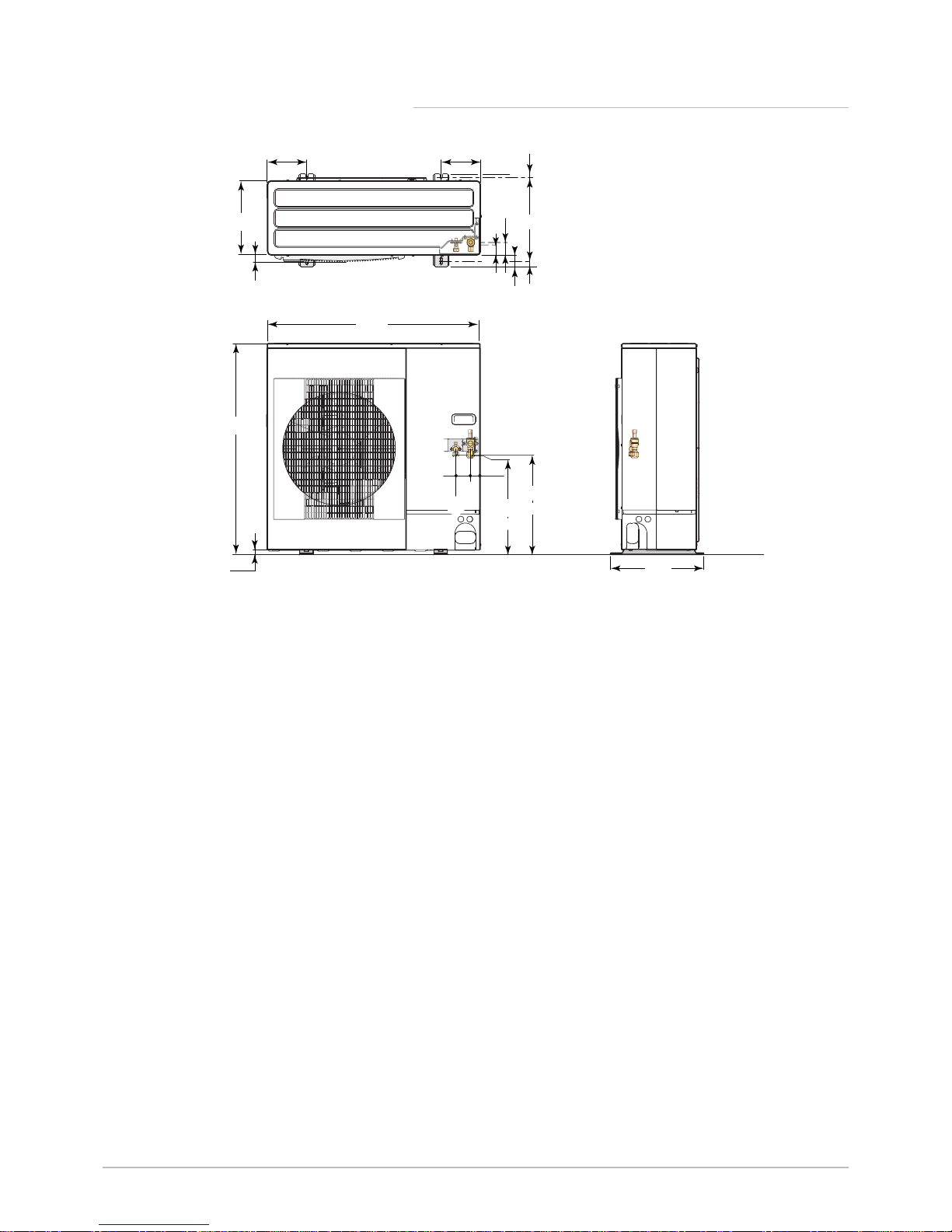

3.3.1 AWHP 4.5 MR

Fig.4

MW-1000430-1

155

69

90

1

2

840

109

81

880

452

(417.5)

417.5

40

42

10 X 21

360

175

500

330

50

1 1/4" refrigerant fluid connection 2 1/2" refrigerant gas connection

3.3.2 AWHP 6 MR-3

Fig.5

23.2

1

2

99.5

164.5

492

193.5

35°

43°

360

330

32.5

300

40

404.5

48

22.3

630

320

8.5

809

500

310

154.5

62

MW-1000919-1

1 1/4" refrigerant fluid connection 2 1/2" refrigerant gas connection

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 19

Page 20

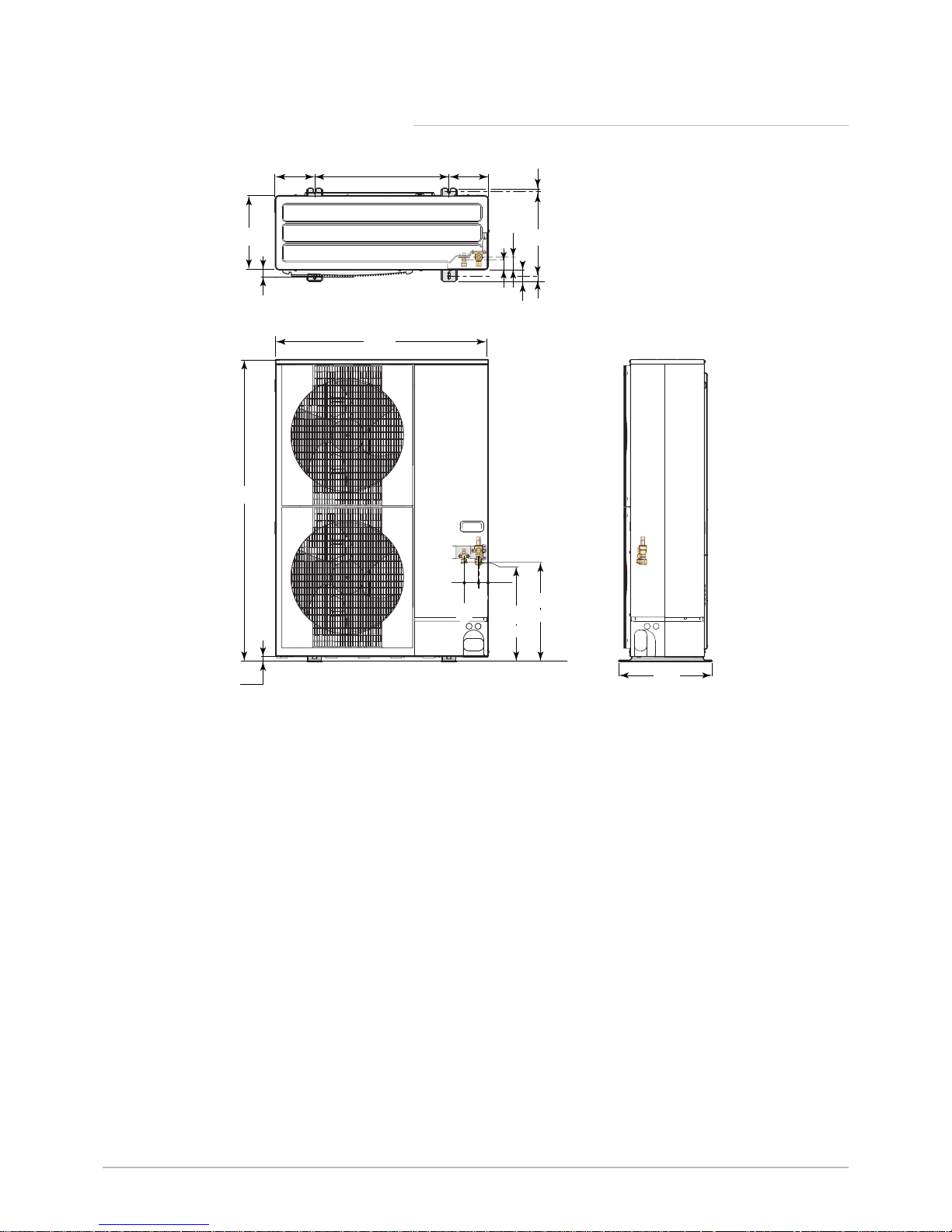

3.3.3 AWHP 8 MR-2

Fig.6

943

950

45

56

53 28

19

23

417

175

330

370

30

443

447

175

65 42

2

(A)

(B)

MW-M001442-2

1

1

3/8" refrigerant fluid connection

2

5/8" refrigerant gas connection

3 Technical specifications

20 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 21

3.3.4 AWHP 11 MR-2 – AWHP 16 MR-2 – AWHP 11 TR-2 –

AWHP 16 TR-2

Fig.7

1350

950

45

56

53 28

19

23

417

175 600

330

370

30

443

447

175

65 42

2

(A)

(B)

1

MW-M001443-2

1

3/8" refrigerant fluid connection

2

5/8" refrigerant gas connection

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 21

Page 22

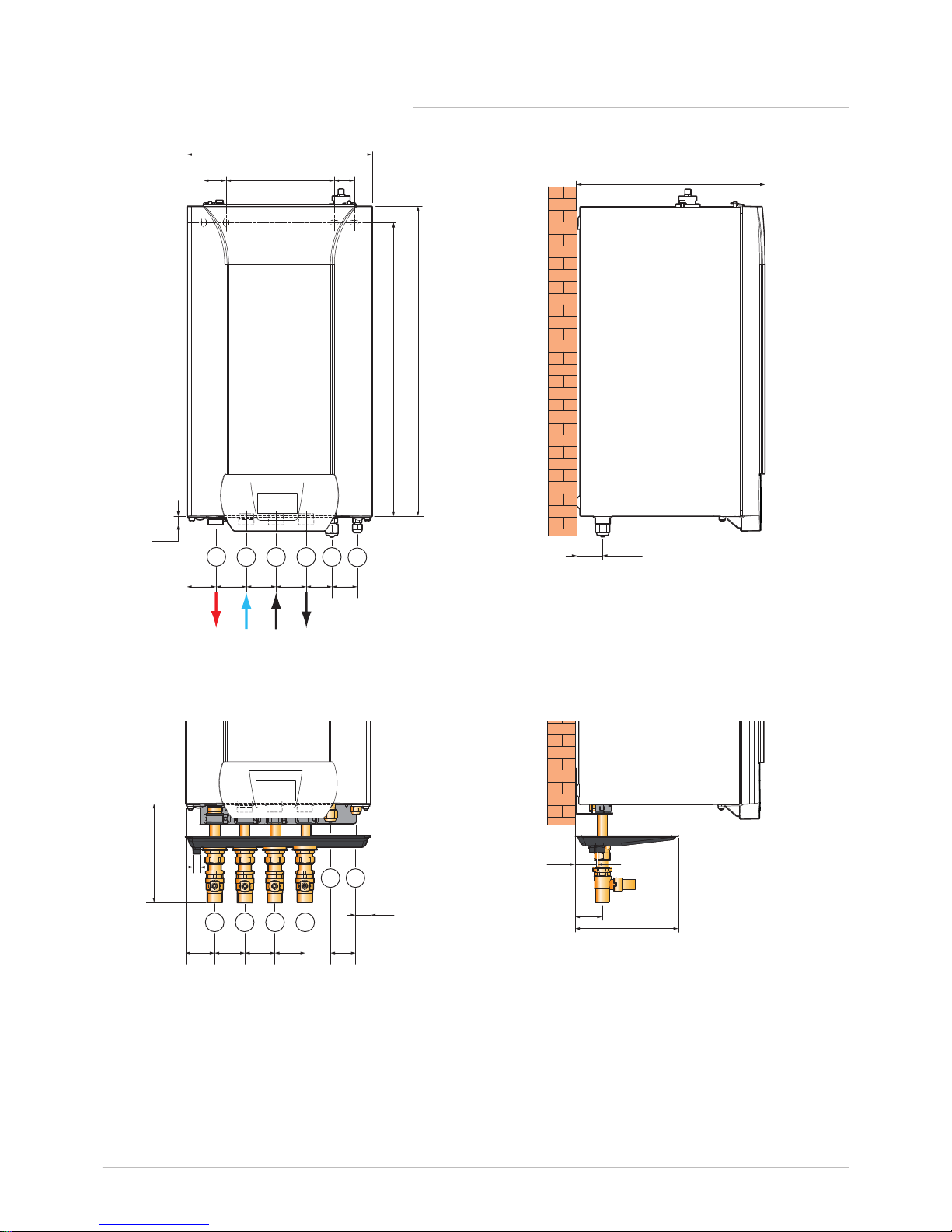

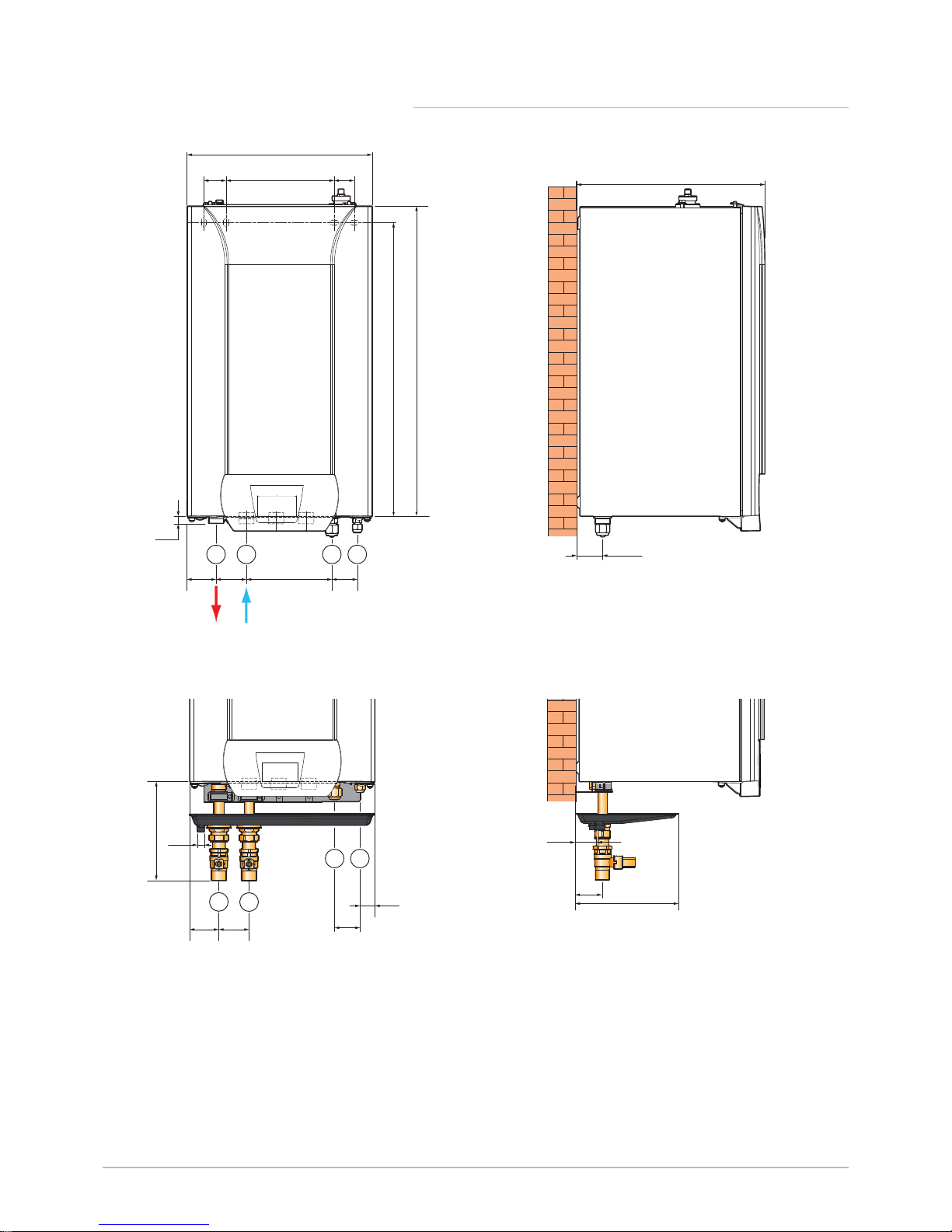

3.3.5 iMPI with hydraulic back-up

Fig.8 iMPI/H

MW-3000532-01

679

621

63

65

65

65

55

55

16

400

218

45

40

1

2

3 4 5

6

402

56,5

1 Heating circuit flow G 1"

2 Heating circuit return G 1"

3 Back-up boiler flow G 1"

4 Back-up boiler return G 1"

5 5/8" refrigerant gas connection

6 3/8" refrigerant fluid connection

Fig.9 iMPI/HI

MW-3000533-01

55

32

22

213

63 65 63 65

4321

5 6

57

211

48

1 Heating circuit flow G 1"

2 Heating circuit return G 1"

3 Back-up boiler flow G 1"

4 Back-up boiler return G 1"

5 5/8" refrigerant gas connection

6 3/8" refrigerant fluid connection

3 Technical specifications

22 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 23

3.3.6 iMPI with electrical back-up

Fig.10 iMPI/EM, iMPI/ET

MW-3000530-01

400

218

45

40

679

621

63

65

185

55

16

21 3 4

56,5

402

1 Heating circuit flow G 1"

2 Heating circuit return G 1"

3 5/8" refrigerant gas connection

4 3/8" refrigerant fluid connection

Fig.11 iMPI/EMI, iMPI/ETI

MW-3000531-01

57

211

48

63

65

55

32

22

213

3

1 2

4

1 Heating circuit flow G 1"

2 Heating circuit return G 1"

3 5/8" refrigerant gas connection

4 3/8" refrigerant fluid connection

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 23

Page 24

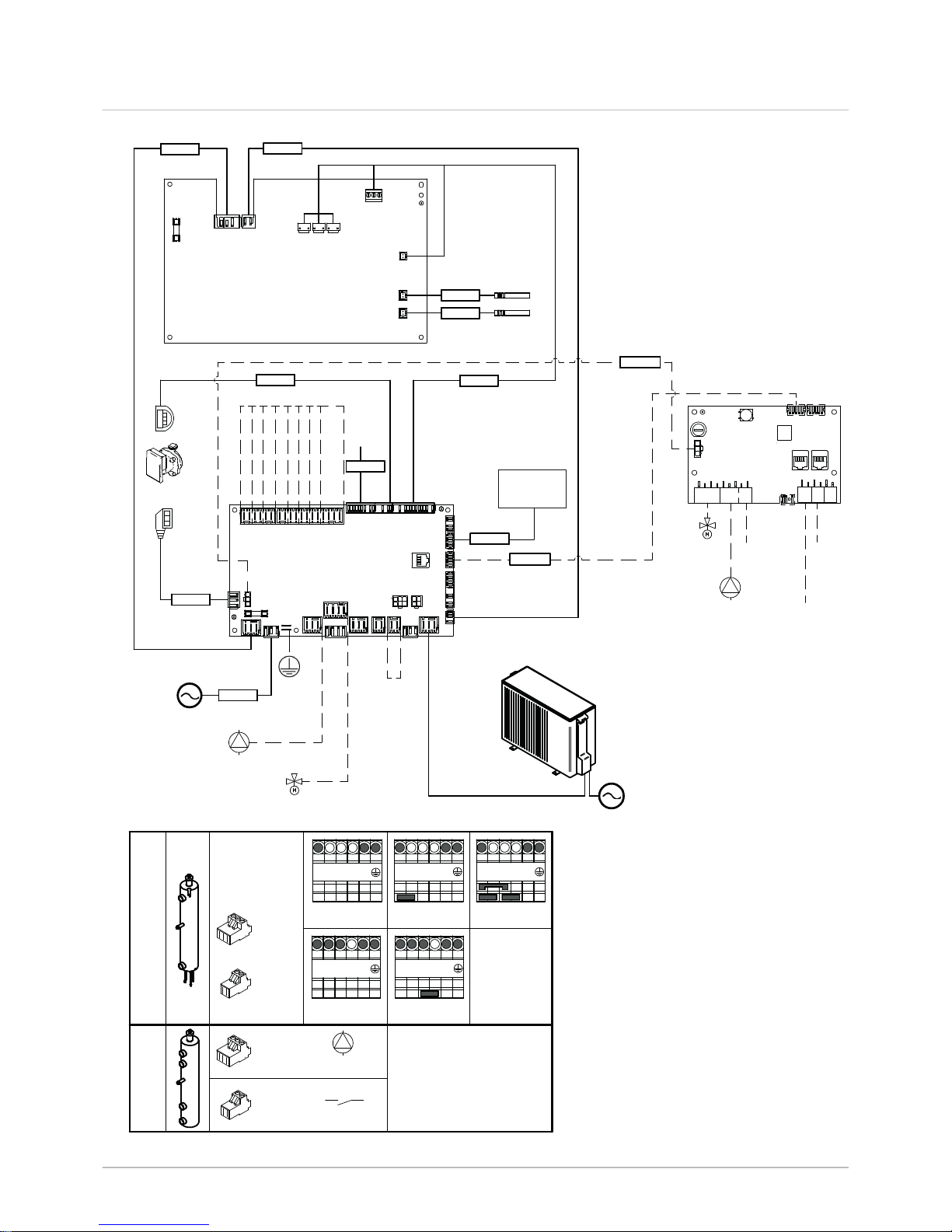

3.4 Electrical diagram

Fig.12

HPC-01

Sensor Liquid

Sensor Target

7679484

7622566

7685744

7679483

7619601

7679482

7679481

Low noise

Pump

3 Way Valve

DHW

Water

Sensors

7679489

2kW 230V~

6kW 400V 3N~

X7

X6

X5

X1

X2

X3

X4

X12

X11

FUSE

EHC-04

X8

X7

X6

X22

X27

X15

X26

X23

X30

X1

X4

X5

X19

X24

X25

X10

X9

X18

FUSE

X17

X16

X13

X21

X2

SCB-04B

X6

X8

X9

X1

X2

X3

SW2

FUSE

L1 L2 L3 D3 N

Hydraulic

Backup

Electric

Backup

7621758

ON/OFF

X4

EHC-04

X5

EHC-04

7622059

Pump

3 Way

Valve

Room Unit

T°C

Flow

Safety

Thermostat

Outdoor Unit

7681340

Pump

Harness

N° 7679488

Domestic Hot Water t° High

Domestic Hot Water t° Low

230V~

Outside temperature sensor

Room Unit

BL1 Multifunction

BL2 Multifunction

So+/So- Energy counter

Condensate sensor ON/OFF

9kW 400V 3N~

4kW 230V~

6kW 230V~

X4

EHC-04

X5

EHC-04

Pump

L1 L2 L3 D3 N

L1 L2 L3 D3 N

L1 L2 L3 D3 N

L1 L2 L3 D3 N

S2 / S3

7691321

MW-5000747-1

HMI

X28

X12

3 Technical specifications

24 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 25

Tab.14 Wiring diagram legend

230 V ~ Power supply

3 WAY VALVE Three-way valve

3-WAY DHW VALVE 3-way domestic hot water valve

BL1 MULTIFUNCTION BL1 multifunction

BL2 MULTIFUNCTION BL2 multifunction

CONDENSATE SENSOR ON/OFF Underfloor heating

DOMESTIC HOT WATER T° HIGH Temperature at the top of the tank

DOMESTIC HOT WATER T° LOW Temperature at the bottom of the tank

EHC-04 Hybrid heat pump control system central unit PCB

ELECTRICAL BACKUP Electrical back-up

FUSE Fuse

HMI Control panel

HPC-01 HPC PCB (interface for the outdoor unit)

HYDRAULIC BACKUP Hydraulic back-up

LOW NOISE Silent option

OUTDOOR UNIT Outdoor unit

OUTDOOR TEMPERATURE SENSOR Outdoor temperature sensor

PUMP Circulating pump

ROOM UNIT Room thermostat

SAFETY THERMOSTAT Safety thermostat

SCB-04 PCB for controlling a second circuit (optional)

SENSOR LIQUID Exchanger refrigerant temperature sensor

SENSOR TARGET Water temperature sensor on the exchanger outlet

SO+/SO- ENERGY COUNTER SO+/SO- energy meter

T°C FLOW Second circuit heating flow temperature

WATER SENSORS Water sensors

3 Technical specifications

7685645 - v04 - 07032018 AWHP-2 iMPI 25

Page 26

4 Description of the product

4.1 Operating principle

The outdoor unit produces heat or cold and transfers it to the indoor mod

ule via the refrigerant in the plate exchanger. The indoor module is equip

ped with a specific control system which is used to adjust the temperature

of the heating water to the needs of the home.

4.2 Main components

1 Safety valve

2 Exchanger

3 Air vent

4 PCB box

5 Low-loss header

6 Pressure gauge

7 Display

8 Control panel

9 Circulating pump

10 Flow meter

11 8-litre expansion vessel

1 Safety valve

2 Exchanger

3 Air vent

4 Low-loss header with electrical back-up

5 PCB box

6 Pressure gauge

7 Display

8 Control panel

9 Circulating pump

10 Flow meter

11 8-litre expansion vessel

1 HPC–01 PCB: PCB for interface with the outdoor unit

2 EHC–04 central unit PCB: Control system for the heat pump and

the first heating circuit

Fig.13 iMPI/H

MW-3000535-01

9

2

3

5

4

7

6

8

11

1

10

Fig.14 iMPI/ET, iMPI/EM

MW-3000534-01

9

2

3

4

5

7

6

8

11

1

10

Fig.15 Position of the PCBs

MW-3000587-01

1

2

4 Description of the product

26 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 27

4.3 Standard delivery

Delivery includes several packages:

One indoor module package

One outdoor unit package

Contents of the indoor module package:

An indoor module

An outside sensor

An installation and service manual

A user guide

4 Description of the product

7685645 - v04 - 07032018 AWHP-2 iMPI 27

Page 28

5 Before installation

5.1 Regulations governing installation

Warning

The heat pump must be installed by a qualified installer in accord

ance with local and national regulations.

Warning

The components used for the connection to the cold water supply

must comply with the prevailing standards and regulations in the

country concerned.

5.2

Installation requirements

5.2.1

Treatment of the heating water

In many cases, the heat pump and the heating system can be filled with

mains water, without treating the water.

Caution

Do not add any chemical products to the heating water without

first consulting a water treatment specialist. For example: anti

freeze, water softeners, products to increase or reduce the pH val

ue, chemical additives and/or inhibitors. These may cause faults in

the heat pump and damage the heat exchanger.

Important

Flush the installation with at least 3 times the volume of water

contained in the heating system.

Flush the DHW circuit with at least 20 times its volume of water.

The water in the installation must comply with following characteristics:

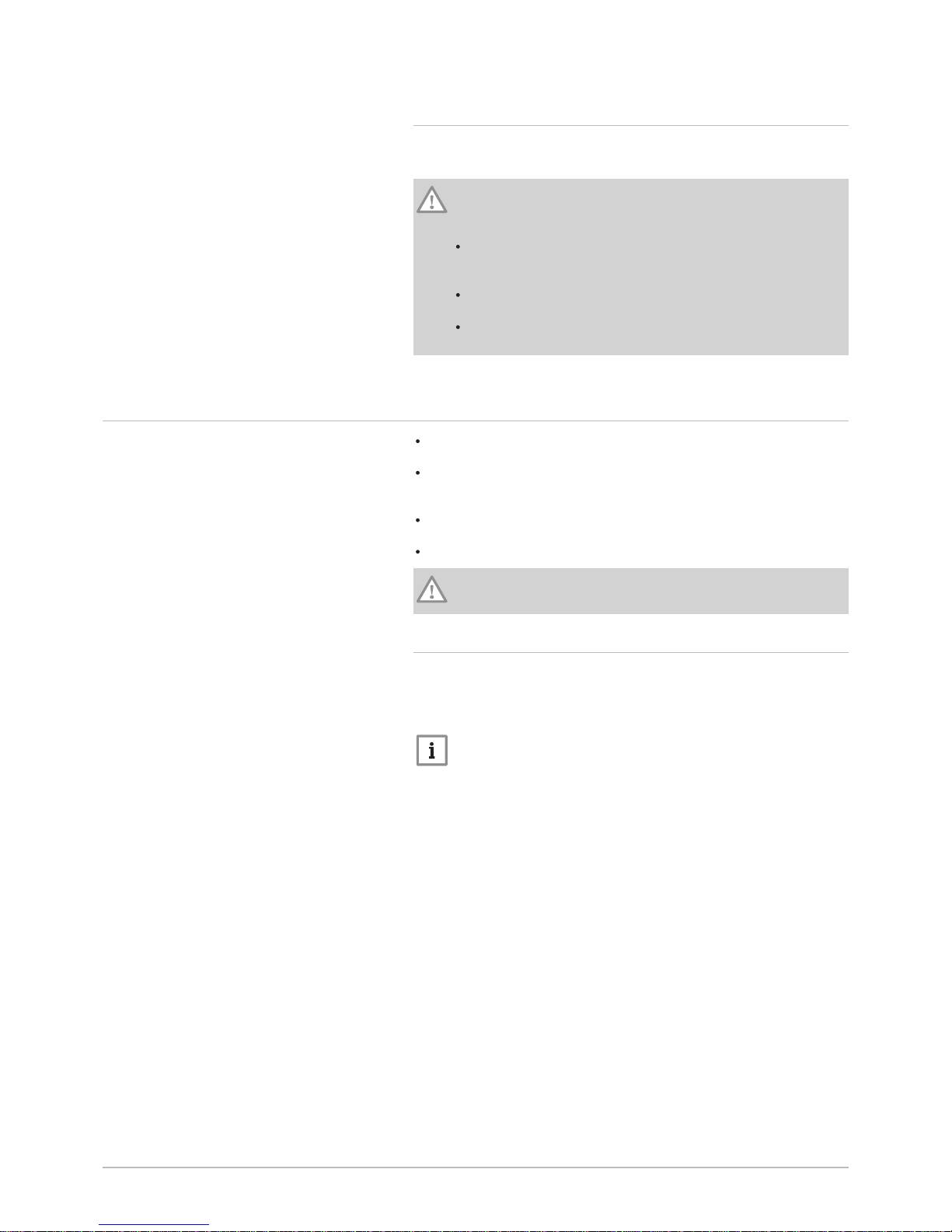

Tab.15 Heating water specifications

Specifications Unit

Total system output

≤ 70 kW

Hydrogen potential (pH) 7.5 - 9

Conductivity at 25°C μS/cm 10 to 500

Chlorides mg/litre ≤ 50

Other components mg/litre < 1

Total water hardness

°f 7 - 15

°dH 4 - 8.5

mmol/l 0.7 - 1.5

Important

If water treatment proves necessary, Baxi recommends the follow

ing manufacturers:

Cillit

Climalife

Fernox

Permo

Sentinel

5 Before installation

28 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 29

5.2.2 Special precautions for the connection of the heating cir

cuit

When making the connection, it is imperative that the standards and corre

sponding local directives be respected.

Caution

The hydraulic installation must be capable of handling a minimum

flow rate at all times:

If radiators are connected directly to the heating circuit: install a

differential valve between the indoor module and the heating cir

cuit.

Leave one heating circuit without a thermostatic valve and/or

without a solenoid valve.

Fit drainage valves between the indoor module and the heating

circuit.

Install a filter on the heating return circuit.

5.3

Choice of the location

Decide on the ideal location, bearing in mind the space required by the

heat pump and any legal directives.

Install the heat pump's indoor module on a solid, stable structure capa

ble of bearing the weight of the heat pump when full of water and fitted

with its various accessories.

Install the indoor module as close as possible to the draw-off points in

order to minimise energy losses through the pipes.

Install the heat pump's outdoor module on a solid, stable structure.

Caution

The indoor module must be installed on frost-free premises.

5.3.1 Data plate

The data plates identify the product and provide the following important in

formation.

The data plates must be accessible at all times.

Important

Never remove or cover labels and data plates affixed to the appli

ances. Labels and data plates must be legible throughout the en

tire lifetime of the appliance.

Damaged or illegible instructions and warning stickers must be re

placed immediately.

5 Before installation

7685645 - v04 - 07032018 AWHP-2 iMPI 29

Page 30

Data plate on the indoor module

Data plate on the outdoor unit

5.3.2

Overall space needed by the indoor module

Allow sufficient space around the heat pump's indoor module to ensure

adequate access and facilitate maintenance.

Fig.16

MW-3000537-01

Fig.17

MW-M001832-1

Fig.18

MW-3000536-01

393

10

00

1200

400

500

500

670

100

5 Before installation

30 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 31

5.3.3 Distance between modules

1 Outdoor unit

2 Indoor module

Allow a refrigeration connection of at least 2 m by making one or two

horizontal loops in order to lessen these disruptions. If the refrigeration

connection between the outdoor unit and the indoor module is less than

2 m, the following disruptions may occur:

Functional disruptions caused by a fluid overload

Noise pollution caused by the circulation of the refrigerant

Respect the minimum curve radii of 100 to 150 mm.

To ensure that the heat pump functions correctly, respect the minimum

and maximum connection lengths between the indoor module and the

outdoor unit.

Tab.16

Outdoor unit AWHP 4.5 MR AWHP 6 MR-3

AWHP 8 MR-2

AWHP 11 MR-2 AWHP 11 TR-2 AWHP 16 MR-2 AWHP 16 TR-2

A:

Maximum/mini

mum length

2 to 30 m 2 to 40 m 2 to 75 m 2 to 75 m 2 to 75 m 2 to 75 m

B:

Maximum height

difference

30 m 30 m 30 m 30 m 30 m 30 m

C:

Maximum num

ber of elbows

10 15 15 15 15 15

5.3.4 Installing the outdoor unit on the ground

When mounting on the ground, a concrete base must be installed, with no

rigid connection to the building served to avoid the transmission of vibra

tions.

The data plate must be accessible at all times.

1. Dig a run-off channel with a pebble bed.

2. Install a concrete base frame with a minimum height of 200 mm ca

pable of bearing the weight of the outdoor unit.

3. Install the outdoor unit on the concrete base frame.

Installation in cold and snowy regions

Wind and snow may significantly impair the performance of the heat

pump. Ensure that the following information is respected to install the out

door unit correctly.

Always install the outdoor unit sufficiently high off the ground to allow

correct condensates discharge.

The width of the base must not exceed the width of the outdoor unit.

Icing may lead to it breaking (refrigerant fluid leak).

The height of the base frame must be higher than the height of the

heaviest snowfalls. This measure helps to protect the exchanger from

snow and prevent the formation of ice during the defrosting operation.

For regions where heavy snowfalls occur, raise the above-ground pro

tection by at least 200 mm compared with the average depth of the cov

ering of snow.

Fig.19 Diagram of distances between mod

ules

MW-M00 1439-2

A

B

2

1

C

Fig.20

MW-M001452-3

200

2

1

3

5 Before installation

7685645 - v04 - 07032018 AWHP-2 iMPI 31

Page 32

Caution

If the outside temperatures become negative, take the necessa

ry precautions to prevent the risk of freezing in the evacuation

pipes.

Prevent any risk of the condensates freezing in a passing-by

zone.

Fig.21 Installation of a single outdoor unit or several outdoor units

MW-6000252-2

1 2 3/

4

1. Always install the outdoor unit as far as possible from the thorough

fare as the condensates discharge may freeze, causing a potential

hazard (sheet of black ice).

2. Place the outdoor units beside each other and not on top of each oth

er to prevent the condensates from the lower unit to freeze.

Installing a noise abatement screen

In some cases, additional precautions are necessary owing to the fact, for

example, of too short a distance between you and your neighbours.

Fig.22 Noise abatement screen

MW-C000373-1

Brrrrr....

Brrrrr....

Brrrrr....

Brrrrr....

Locate the noise abatement screen as close as possible to the noise

source whilst allowing for the free circulation of air in the exchanger on the

outdoor unit and maintenance work.

5 Before installation

32 AWHP-2 iMPI 7685645 - v04 - 07032018

Page 33

Fig.23 Distances of the appliance from the wall

MW-M001450-1

G

F

F

G

A

C

B

B

C

E

A

1000

D

M

ax. 500

M

ax. 500

Tab.17 Minimum dimensions in mm

AWHP 4.5 MR

AWHP 6 MR-3

AWHP 8 MR-2

AWHP 11 MR-2

AWHP 16 MR-2

AWHP 11 TR-2

AWHP 16 TR-2

A 100 150

B 500 1000

C 200 300

D 1000 1500

E 300 500

F 150 250

G 100 200

Position of the outdoor unit