© Baxi Heating UK Ltd 2014

Megaflo 2 System Compact GA

Range

Gas Fired Wall Mounted Condensing

System Boiler

Installation & Servicing Instructions

These instructions include the Benchmark Commissioning Checklist

and should be left with the user for safe keeping.

2

© Baxi Heating UK Ltd 2014

Model Range

Baxi Megaflo 2 System 12 Compact GA

G.C.No 41-075-70

Baxi Megaflo 2 System 15 Compact GA

G.C.No 41-075-71

Baxi Megaflo 2 System 18 Compact GA

G.C.No41-075-72

Baxi Megaflo 2 System 24 Compact GA

G.C.No41-075-73

Baxi Megaflo 2 System 28 Compact GA

G.C.No41-075-74

Baxi Megaflo 2 System 32 Compact GA

G.C.No41-075-75

© Baxi Heating UK Ltd 2014 All rights reserved. No part of this publication may

be reproduced or transmitted in any form or by any means, or stored in any

retrieval system of any nature (including in any database), in each case whether

electronic, mechanical, recording or otherwise, without the prior written

permission of the copyright owner, except for permitted fair dealing under

Copyrights, Designs and Patents Act 1988.

Applications for the copyright owner’s permission to reproduce or make other

use of any part of this publication should be made, giving details of the proposed

use, to the following address:

The Company Secretary, Baxi Heating UK Limited,

Brooks House, Coventry Road, Warwick. CV34 4LL

Full acknowledgement of author and source must be given.

WARNING: Any person who does any unauthorised act in relation to a

copyright work may be liable to criminal prosecution and civil claims for damages.

The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment for

their needs, that it is installed, commissioned and serviced in accordance with the

manufacturer’s instructions by competent persons and that it meets the

requirements of the appropriate Building Regulations. The Benchmark Checklist

can be used to demonstrate compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work

in accordance with the Benchmark Code of Practice which is available from the

Heating and Howitzer Industry Council who manage and promote the Scheme.

Visit www.centralisation.co.UK for more information.

0086

ISO 9001

FLEM 00866

Building Regulations and the Benchmark Commissioning

Checklist

Building Regulations (England & Wales) require notification of

the installation of a heating appliance to the relevant Local

Authority Building Control Department. From 1 April 2005 this

can be achieved via a Competent Persons Self Certification

Scheme as an option to notifying the Local Authority directly.

The Health & Safety Executive operates the ‘Gas Safe Register’,

a self-certification scheme for gas heating appliances.

These arrangements represent a change from the situation

whereby compliance with Building Regulations was accepted as

being demonstrated by completion of the Benchmark Logbook

(which was then left on site with the customer).

With the introduction of Self Certification Schemes, the

Benchmark Logbook is being withdrawn. However, a similar

document in the form of a commissioning checklist and service

interval record is incorporated at the back of these instructions.

This company is a member of the Benchmark initiative and fully

supports the aims of the programme. Its aim is to improve the

standards of installation and commissioning of central heating

systems in the UK and to encourage the regular servicing of all

central heating systems to ensure safety and efficiency.

Building Regulations require that installations should comply

with manufacturer's instructions. It is therefore important that

the commissioning checklist is completed by the installer. The

relevant section of Building Regulations only relates to

dwellings. Therefore the checklist only applies if the appliance is

being installed in a dwelling or some related structure.

The flowchart opposite gives guidance for installers on the

process necessary to ensure compliance with Building

Regulations.

3

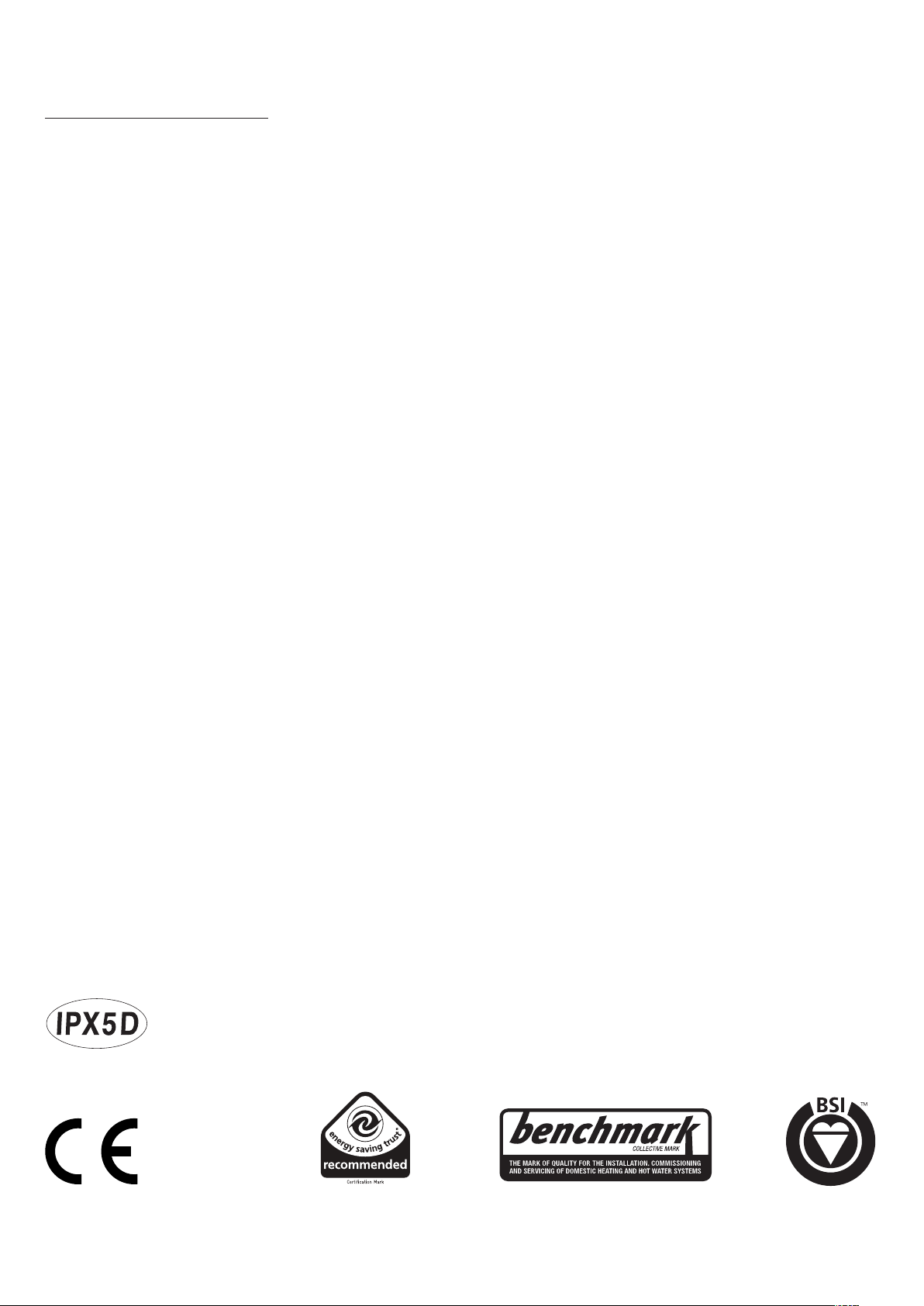

Installer Notification Guidelines

© Baxi Heating UK Ltd 2014

Choose Building

Regulations Notification

Route

Competent Person's

Self Certification Scheme

Install and Commission this

appliance to manufacturer's

instructions

Complete the

Benchmark Checklist

If you notify via the ‘Gas Safe

Register’, the register will issue

the Building Regulations

certificate on members’ behalf

Building Control

Contact your relevant Local

Authority Building Control

(LABC) who will arrange

an inspection or contact

a government approved

inspector

Install and Commission this

appliance to manufacturer's

instructions

Scheme Members only

Call ‘Gas Safe Register’ on:

0800 408 5577

or log onto:

www.gassaferegister.co.uk

within 10 days

You must ensure that the

certificate number issued by

the ‘Gas Safe Register’ is written

onto the Benchmark Checklist

‘Gas Safe Register’ will issue a

Building Regulations Compliance

Certificate to the property owner

and inform the relevant LABC

Complete the

Benchmark Checklist

LABC will record the data

and will issue a

certificate of compliance

4

Legislation

© Baxi Heating UK Ltd 2014

Codes of Practice - refer to the most recent version

IMPORTANT - Installation, Commissioning, Service & Repair

This appliance must be installed in accordance with the manufacturer’s instructions and

the regulations in force. Read the instructions fully before installing or using the

appliance.

In GB, this must be carried out by a competent person as stated in the Gas Safety

(Installation & Use) Regulations.

Definition of competence: A person who works for a Gas Safe registered company

and holding current certificates in the relevant ACS modules, is deemed competent.

In IE, this must be carried out by a competent person as stated in I.S. 813 “Domestic

Gas Installations”.

The addition of anything that may interfere with the normal operation of the appliance

without express written permission from the manufacturer or his agent could invalidate

the appliance warranty. In GB this could also infringe the Gas Safety (Installation and

Use) Regulations.

Warning - Check the information on the data plate is compatible with local supply

conditions.

This company declares that no substances harmful to

health are contained in the appliance or used during

appliance manufacture.

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force, and

only used in a suitably ventilated location.

In GB, the installation must be carried out by a Gas Safe

Registered Installer. It must be carried out in accordance with

the relevant requirements of the:

• Gas Safety (Installation & Use) Regulations.

• The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

• The Water Fittings Regulations or Water Byelaws in

Scotland.

• The Current I.E.E. Wiring Regulations.

Where no specific instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent

Person and installed in accordance with the current edition of

I.S. 813 ‘Domestic Gas Installations’, the current Building

Regulations and reference should be made to the current ETCI

rules for electrical installation.

All systems must be thoroughly flushed and treated with

inhibitor (see section 6.2).

In GB the following Codes of Practice apply:

Standard Scope

BS 6891 Gas Installation.

BS 5546 Installation of hot water supplies for domestic

purposes.

BS 6798 Installation of gas fired hot water boilers.

BS 5440 Part 1 Flues.

BS 5440 Part 2 Ventilation.

BS 7074 Expansion vessels and ancillary equipment for

sealed water systems.

BS 7593 Treatment of water in domestic hot water

central heating systems.

BS EN 12828 Heating systems in buildings - Design for

water-based heating systems

BS EN 12831 Heating systems in buildings - Method for

calculation of the design heat load

BS EN 14336 Heating systems in buildings - Installation and

commissioning of water-based heating systems

In IE the following Codes of Practice apply:

Standard Scope

I.S. 813 Domestic Gas Installations.

The following standards give valuable additional information;

BS 5546 Installation of hot water supplies for domestic

purposes.

BS 7074 Expansion vessels and ancillary equipment for

sealed water systems.

BS 7593 Treatment of water in domestic hot water

central heating systems.

BS EN 12828 Heating systems in buildings - Design for

water-based heating systems

BS EN 12831 Heating systems in buildings - Method for

calculation of the design heat load

BS EN 14336 Heating systems in buildings - Installation and

commissioning of water-based heating systems

The boiler meets the requirements of Statutory Instrument “ The Boiler (Efficiency)

Regulations 1993 N

o

3083” and is deemed to meet the requirements of Directive

92/42/EEC on the energy efficiency requirements for new hot water boilers fired with

liquid or gaseous fuels:-

Type test for purpose of Regulation 5 certified by:

Notified Body 0085.

Product/Production certified by:

Notified Bodies 0085 & 0086.

For GB/IE only.

All Gas Safe registered engineers carry an ID card with their licence number and a

photograph. You can check your engineer is registered by telephoning

0800 408 5500 or online at www.gasgaferegister.co.uk

5

Safe Manual Handling

© Baxi Heating UK Ltd 2014

General

The following advice should be adhered to, from when first handling the boiler to the final stages of installation, and also during maintenance.

Most injuries as a result of inappropriate handling and lifting are to the back, but all other parts of the body are vulnerable, particularly shoulders, arms and hands.

Health & Safety is the responsibility of EVERYONE.

There is no ‘safe’ limit for one man - each person has different capabilities. The boiler should be handled and lifted by TWO PEOPLE.

Do not handle or lift unless you feel physically able.

Wear appropriate Personal Protection Equipment e.g. protective gloves, safety footwear etc.

Preparation

Co-ordinate movements - know where, and when, you are both going.

Minimise the number of times needed to move the boiler - plan ahead.

Always ensure when handling or lifting the route is clear and unobstructed. If possible avoid steps, wet or slippery surfaces, unlit areas etc. and take special care

on ladders/into lofts.

Technique

When handling or lifting always use safe techniques - keep your back straight, bend your knees. Don’t twist - move your feet, avoid bending forwards and

sideways and keep the load as close to your body as possible.

Where possible transport the boiler using a sack truck or other suitable trolley.

Always grip the boiler firmly, and before lifting feel where the weight is concentrated to establish the centre of gravity, repositioning yourself as necessary. See the

‘Installation’ section of these instructions for recommended lift points.

Remember

The circumstances of each installation are different. Always asses the risks associated with handling and lifting according to the individual conditions.

If at any time when installing the boiler you feel that you may have injured yourself STOP !!

DO NOT ‘work through’ the pain - you may cause further injury.

IF IN ANY DOUBT DO NOT HANDLE OR LIFT THE BOILER - OBTAIN ADVICE OR ASSISTANCE BEFORE PROCEEDING !!

6

© Baxi Heating UK Ltd 2014

CONTENTS

1.0 Introduction 7

2.0 General Layout 8

3.0 Appliance Operation 9

4.0 Technical Data 10

5.0 Dimensions and Fixings 11

6.0 System Details 12

7.0 Site Requirements 14

8.0 Flue 19

9.0 Installation 21

10.0 Commissioning 26

11.0 Completion & System Draining 30

12.0 Servicing 31

13.0 Changing Components 33

14.0 Combustion & Calibration 40

15.0 Electrical 41

16.0 Short Parts List 42

17.0 Fault Finding 43

18.0 32 kW Model Supplement 47

Benchmark Checklist 50

Section Page

7

1.0 Introduction

© Baxi Heating UK Ltd 2014

1.1 Description

1. The Baxi Megaflo 2 System Compact GA Range are fully

automatic gas fired wall mounted condensing system boilers.

They are room sealed and fan assisted.

2. The boiler is set to give a maximum output of :-

12 models - 12 kW

12.7 kW (Condensing)

15 models - 15 kW

15.9 kW (Condensing)

18 models - 18 kW

19 kW (Condensing)

24 models - 24 kW

25.4 kW (Condensing)

28 models - 28 kW

29.6 kW (Condensing)

32 models - 32 kW

33.8 kW (Condensing)

3. The boiler is factory set for use on Natural Gas (G20). It can

be adapted to operate on Propane (G31) - see Section 10.1

‘Gas Type Check’.

4. The boiler incorporates a circulating pump and expansion

vessel. It is suitable for use only on fully pumped sealed

systems.

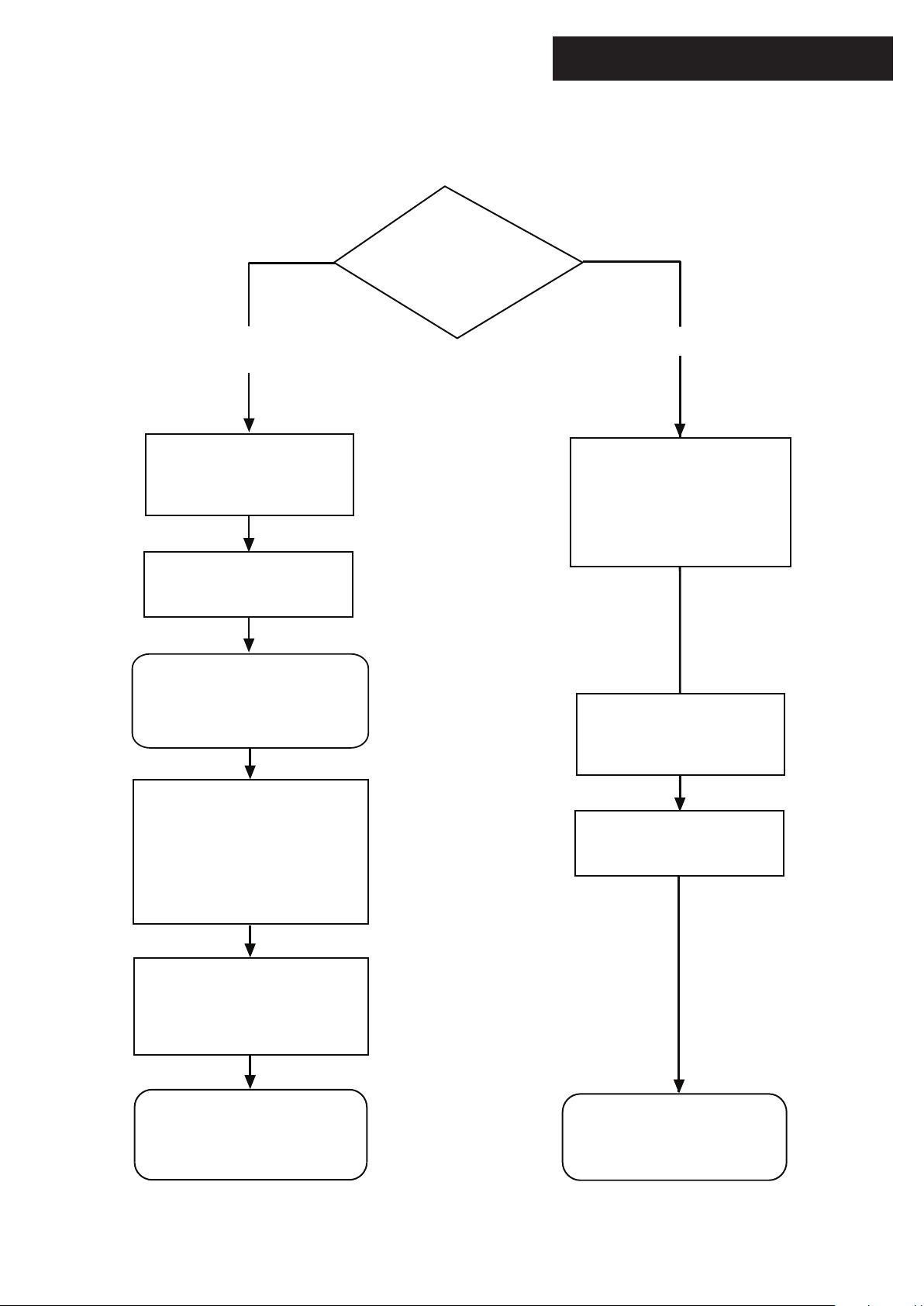

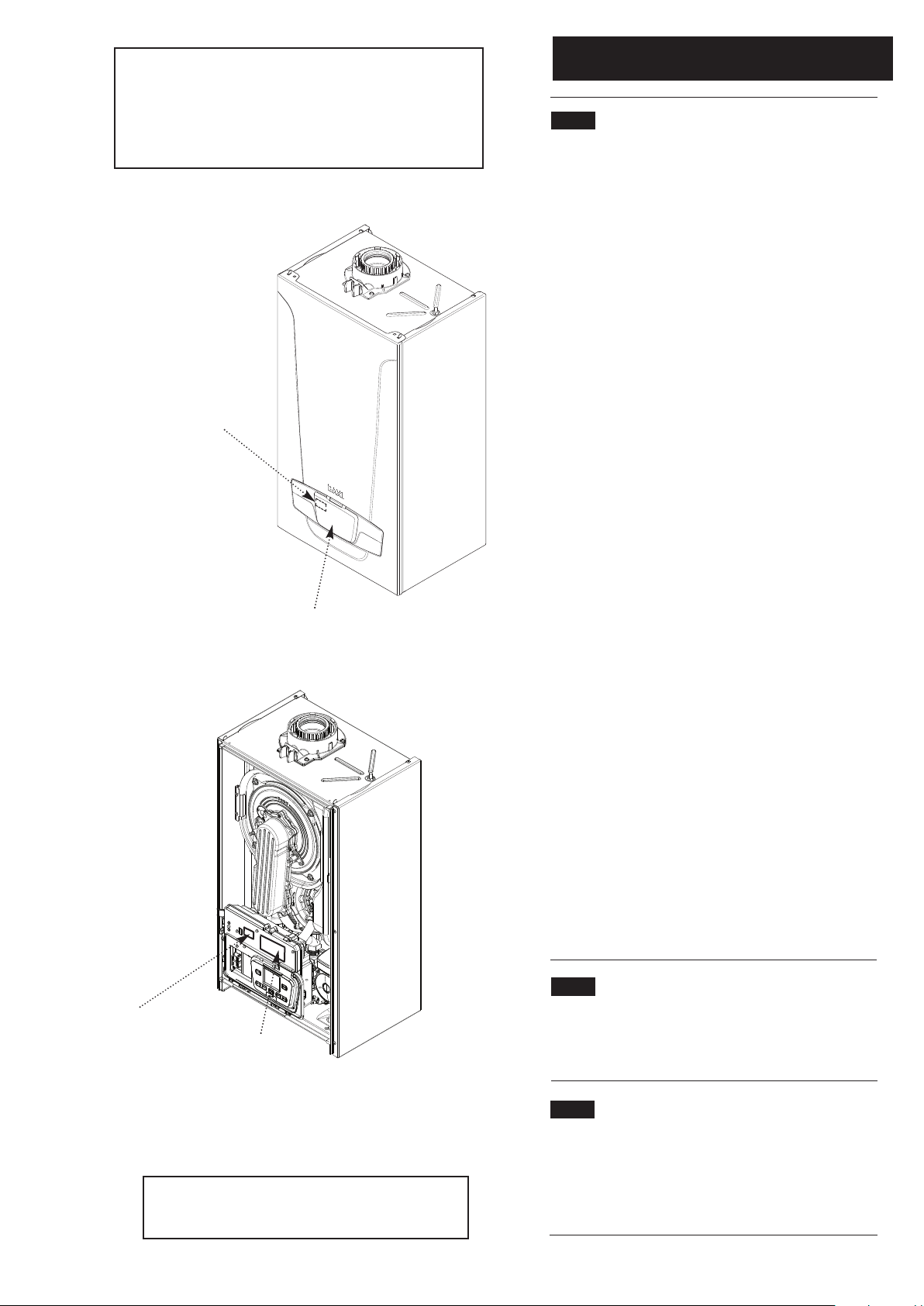

5. The boiler data badge gives details of the model, serial

number and Gas Council number and is situated on the

control box. It is visible when the case front panel is removed

(Fig. 2).

6. The boiler model name and serial number are also shown

on the information label behind the boiler control flap (Fig. 1).

This is for user reference.

7. The boiler is intended to be installed in residential /

domestic environments on a governed meter supply only.

8. The boiler must be installed with one of the purpose

designed flues such as one of the standard horizontal

telescopic flue kits detailed in the Flue Installation Guide .

9. All systems must be thoroughly flushed and treated with

inhibitor (see section 6.1).

1.2 Optional Extras

Various timers, external controls, etc. are available as optional

extras. Full details are contained in the relevant sales

literature.

1.3 Contents of Pack

The pack contains:-

• Boiler

• Wall Plate (including taps)

• Template

• Literature Pack

Fig. 1

Data Badge

Fig. 2

NOTE: These Installation & Servicing Instructions MUST be

read in conjunction with the Flue Installation Guide

supplied in the Literature Pack.

Control Flap

Information Label

Gas Type Label

The 12 to 28 kW models in the Baxi Megaflo 2

System Compact GA Range are of the same

dimensions and layout. The 32 kW model differs

in several respects - these are detailed in

Section 18.0 ‘32 kW Model Supplement’

8

2.0 General Layout

© Baxi Heating UK Ltd 2014

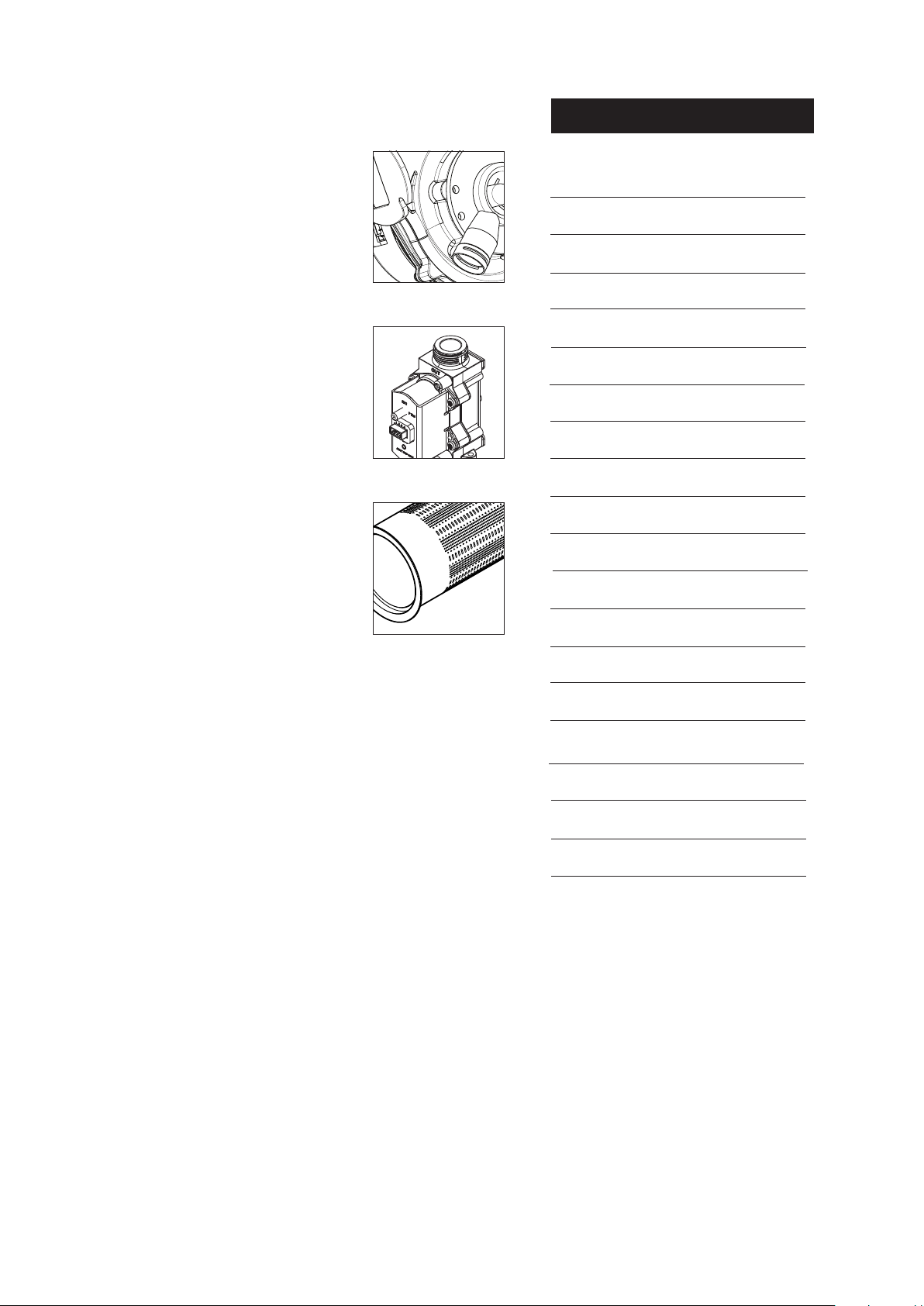

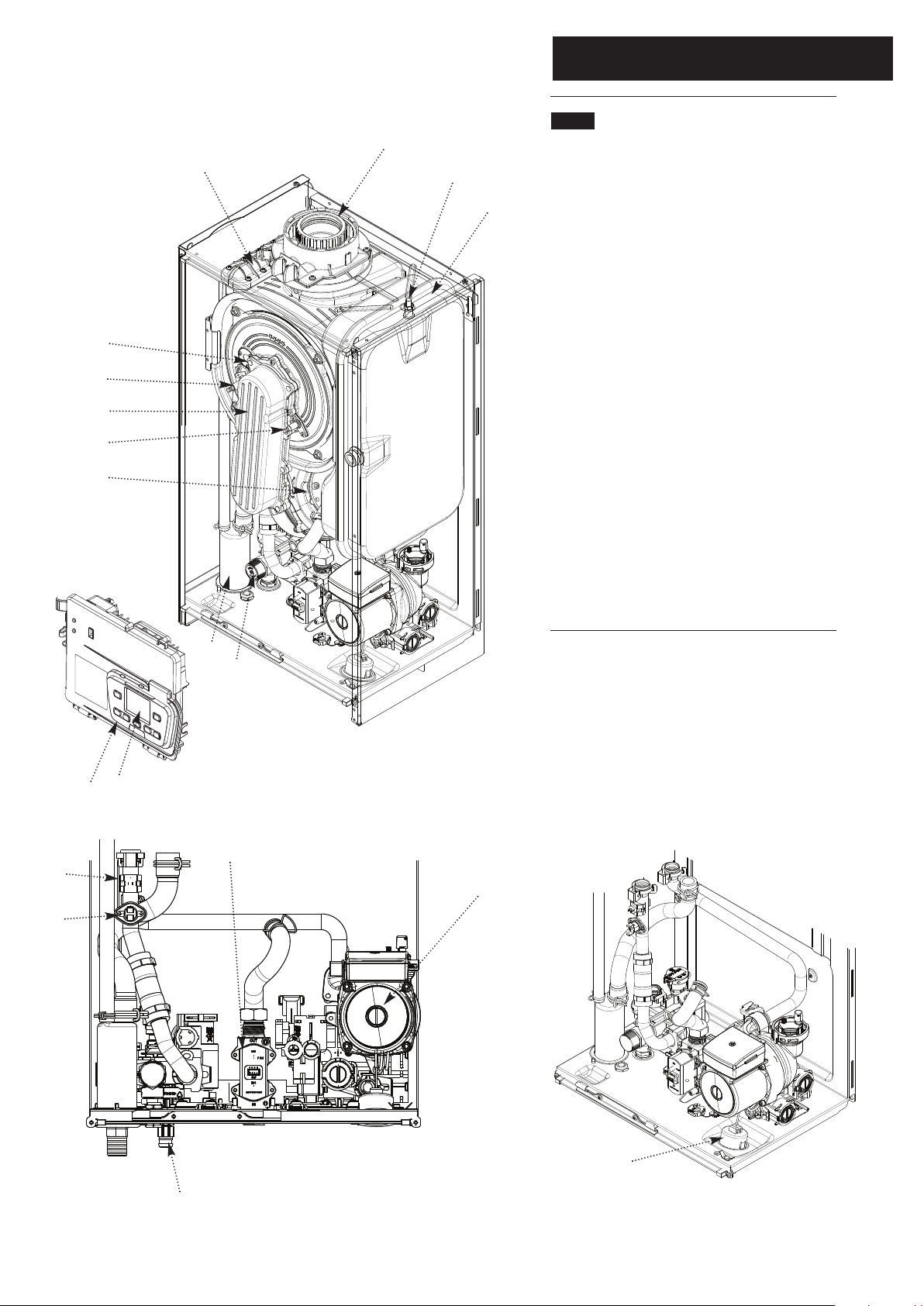

2.1 Layout 12 - 28 Models

1. Expansion Vessel

2. Expansion Vessel Locating Stud

3. Boiler Adaptor

4. Primary Heat Exchanger

5. Pump with Automatic Air Vent

6. Central Heating System Pressure Gauge

7. Fan Assembly

8. Flame Sensing Electrode

9. Air/Gas Collector

10. Spark Ignition Electrode

11. Combustion Box Cover & Burner

12. Condensate Trap

13. Safety Pressure Relief Valve

14. Boiler Control

15. Gas Valve

16. Boiler Drain Tap

17. Control Box Display

18. Heating Flow Sensor

19. Safety Thermostat

2

3

4

5

7

10

8

11

12

13

15

14

6

9

16

17

18

19

1

Loading...

Loading...