Baumuller b maXX 3000, BM3000, BM3200, BM3300 Instruction Handbook Manual

Instruction handbook

Language English

Translation

Document No. 5.11018.11

Part No. 441839

Status 05.03.2018

E

5.11018.11

b maXX 3000

BM3000

Mains rectifier

BM3200 / BM3300

Compact servo unit

Read the Instruction handbook before starting any work!

Copyright This Instruction handbook may be copied by the owner in any quantity, but only for internal

use. This Instruction handbook may not be copied or reproduced, in whole or in part, for any

other purposes.

The use and disclosure of information contained in this Instruction handbook are not permitted.

Designations and company marks contained in this Instruction handbook could be trademarks, the use of which by third parties for their own purposes could violate the rights of the

rights holder.

Preliminary information

Warning Insofar as this document is identified as being preliminary information, the following

applies:

this version is regarded as providing advance technical information to users of the described

devices and their functions at an early enough time in order to adapt to any possible changes

or expanded functionality.

This information must be regarded as being preliminary, as it has not yet passed through

Baumüller's internal review process. In particular, this information is still subject to changes,

thus no legal liability can be derived from this preliminary information. Baumüller assumes no

liability for damages that might arise from this possibly faulty or incomplete version.

If you detect or suspect any content errors and/or major form errors in this preliminary information, we request that you notify the Baumüller support specialist responsible for you.

Please provide us, via this employee, with your insights and comments so that we can take

them into account and include them when transitioning from the preliminary information to

the final information (as reviewed by Baumüller).

The conditions stipulated in the following section under "Obligatory" are invalid in case of preliminary information.

Obligatory This Instruction handbook are a part of the equipment/machine. This Instruction handbook

must be available to the operator at all times and must be in legible condition. If the equip

ment/machine is sold or moved another location, this Instruction handbook must be passed

on by the owner together with the equipment/machine.

After any sale of the equipment/machine, this original and all copies must be handed over to

the buyer. After disposal or any other end use, this original and all copies must be destroyed.

When the present Instruction handbook is handed over, corresponding sets of Instruction

handbooks of a previous version are automatically invalidated.

Please note that the specifications/data/information are current values according to the

printing date. These statements are not legally binding with regard to measurements,

computation or calculations.

Baumüller Nürnberg GmbH reserves the right, in developing its products further, to change

the technical specifications and handling of it products concerned without prior notice.

No liability can be accepted concerning the correctness of this Instruction handbook unless

otherwise specified in the General Conditions of Sale and Delivery.

-

Baumüller Nürnberg GmbH

Ostendstr. 80 - 90

90482 Nuremberg

Germany

Tel. +49 9 11 54 32 - 0

Fax: +49 9 11 54 32 - 1 30

Email : mail@baumueller.de

Internet: www.baumueller.de

Table of contents

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Information on this Instruction handbook. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Copyright protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.8 Guarantee provisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.10 Terms used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Contents of the Instruction handbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Changes and modifications to the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Responsibility of the operating company . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Training of the personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 Special hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.9 Fire fighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.10 Safety equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11 Behavior in hazardous situations or at accidents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.12 Signs and labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Dimensions BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.2 Dimensions BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.1 System types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.2 Requirements to the energy supply: power supply . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.3 Requirements to the control voltage / 24 V-supply . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.4 Requirements to the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.5 Required environmental conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.3.6 Correction factors at modified operational conditions . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3.6.1 Installation altitude. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3.6.2 Environmental temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.6.3 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.6.4 DC-link voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.7 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.1 Electrical data BM3002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.2 Electrical data BM3X01-XT/BM3X11-XT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4.3 Electrical data BM3X02-XT, BM3X03-XT, BM3X04-XT, 400 V. . . . . . . . . . . . . . . . . 38

3.4.4 Electrical data BM3X12-XT, BM3X13-XT, 400 V . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.5 Electrical data BM3XXX-XE, 230 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.4.6 Frequency-output-dependent current derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.7 Load cycle according to EN61800-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

3

of 218

Table of contents

4 Design and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.2 Identification of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2.1 Part number BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2.2 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2.3 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3 UL notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.4 Display elements BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.5 Display- and operating elements BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.5.1 Function of the 7-segment display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.5.2 Function of the LEDs H11 to H14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.5.3 Function of the LEDs H31/H32 and H41/H42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.5.4 Settings address switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Transport and Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.1 Safety notes for transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2 What to observe when transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.3 Transport inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.4 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.5 Disposal of the packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Preparing for mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.3 Drilling templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4 Mounting instruction BM3000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.5 Mounting instruction BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.2 Voltage test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.3 Demands on the electrical power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4 Requirements for the connection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.5 Protection of the device and accordingly of the cable . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.6 PE connection and RCD compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.7 Installation requirements with regard to EMC stability . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.8 Shielding plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.8.1 Shielding connection mounting plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.8.2 Shielding connection with shield sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.8.2.1 Mounting shield sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.8.2.2 Connecting the shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.9 Requirements for the motor temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.10 Installation procedure BM3000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.11 Installation procedure BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.12 Connecting diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.12.1 Mains rectifier BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.12.2 BM3XXX-XT as a compact servo unit (3-phase) . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7.12.3 BM3XXX as an axis unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

7.12.4 BM3XXX-XT as a compact servo unit (single-phase) . . . . . . . . . . . . . . . . . . . . . . . 108

7.12.5 BM3XXX-XE as compact servo unit (1-phase, 230 V). . . . . . . . . . . . . . . . . . . . . . . 111

7.12.6 Application: Power supply connection (3-phase) with energy compensation . . . . . 114

7.12.7 Application: DC link connection of further BM3000 or of additional capacities . . . . 116

4

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

Table of contents

7.13 Connections BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.13.1 X100 input bridging relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.13.2 Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.14 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.14.1 BM3200, BM3300 front side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.14.1.1 X1 - Service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.14.1.2 X2 - Digital inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7.14.1.3 X3 / X4 - fieldbus connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7.14.1.4 X6 - analog inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

7.14.1.5 X7 - encoder connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

7.14.2 Connections BM3200, BM3300 on top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.14.2.1 X200 - 24V voltage supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

7.14.2.2 X202, X203, X205 - power supply, DC link, ballast resistor connection . . . . . . . . 138

7.14.2.3 X300 - signal bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

7.14.3 Connections BM3200, BM3300 at the bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

7.14.3.1 X101 - motor temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

7.14.3.2 X102 - safe torque off - option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

7.14.3.3 X107 - motor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7.14.4 PE connections BM3200, BM3300 rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

8.1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

8.2 Bridging charge resistance BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.3 Operating concept BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.3.1 Enable signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.3.2 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.3.3 Service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

8.4 DC-link load / switch-on frequency of power supply . . . . . . . . . . . . . . . . . . . . . . . . . 150

8.5 Optional safety function STO of BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8.5.1 Safety notes according STO function (Safe Torque Off). . . . . . . . . . . . . . . . . . . . . 151

8.5.2 Safety levels and safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

8.5.3 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.5.4 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.5.5 Supply with separate power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.5.6 Examples for input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8.6 Fieldbus communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

8.6.1 EtherCAT®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

8.6.2 VARAN.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

8.6.3 CANopen®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

8.6.4 POWERLINK®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9.1 Safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9.2 Environmental conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9.3 Inspection intervals - maintenance notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

9.3.1 Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

9.4 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

10 Troubleshooting and Fault Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

10.1 Behavior in case of malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

10.2 Monitoring functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

10.2.1 Monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

10.3 Error detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.4 Troubleshooting/error acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

5

of 218

Table of contents

11 Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11.1.1 Cable power supply-device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11.1.2 Cable device-motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

11.1.3 Hybrid cable device-encoder-motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

11.1.4 Cable DC-link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

11.1.5 Cable control power supply / signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

11.1.6 Cable signal bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

11.1.7 Cables - EtherCAT®, VARAN, POWERLINK® . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

11.1.8 Accessories - CANopen®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

11.1.9 Cable service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

11.1.10 Encoder cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

11.1.10.1 Connecting cable for Resolver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

11.1.10.2 Connecting cable for encoder with HIPERFACE® . . . . . . . . . . . . . . . . . . . . . . . . . 186

11.1.10.3 Connecting cable for encoder with EnDat® or SSI. . . . . . . . . . . . . . . . . . . . . . . . . 187

11.1.10.4 Connecting cable for encoder with EnDat® 2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

11.1.10.5 Connecting cable for sine/square-wave incremental encoder . . . . . . . . . . . . . . . . 190

11.2 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11.2.1 Cable protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11.2.2 Device protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

11.2.3 Cable protection and device protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

11.3 Mains filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

11.3.1 Required environmental conditions mains filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

11.3.2 Mains filter for 3-phase devices BM3XXX-XTXX. . . . . . . . . . . . . . . . . . . . . . . . . . . 193

11.3.3 Mains filter for 1-phase devices BM3XXX-XEXX. . . . . . . . . . . . . . . . . . . . . . . . . . . 195

11.4 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

11.4.1 Connectors BM3200, BM3300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

11.4.2 Accessories kit shielding BM3200, BM3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

11.4.3 Accessories kit protection cover BM3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

12 Shutdown, Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

12.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

12.2 Requirements to the executing personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

12.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

12.4 Demounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

12.5 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

12.6 Recommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

13 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.1 Safety regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

13.2 Disposal facilities/authorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Appendix A - Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Appendix B - Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Table of figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Overview of Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

6

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

1.1 Information on this Instruction handbook

This Instruction handbook provides important information on handling the device. A prerequisite for safe work is compliance with all specified safety notes and procedural instructions.

Additionally, the valid accident prevention regulations and general safety regulations applicable to the scope of application the device must be complied with.

Read this Instruction handbook, particularly the safety notes chapter, completely before

beginning any work on the device. This Instruction handbook is part of the product and

must be kept accessible to personnel at all times in the immediate vicinity of the device.

1.2 Key to symbols

Warning notes

Warning notes are identified by symbols in this Instruction handbook. The notes are introduced by signal words that express the extent of the danger.

It is imperative that these notes be complied with and are conscientiously regarded in order to prevent accidents, personal injury and material damage.

1GENERAL

DANGER!

....points out a directly dangerous situation, that will lead to severe injuries or death,

if not avoided.

WARNING!

....points out a potentially dangerous situation, that could lead to severe injuries or

death, if not avoided.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

of 218

7

1.3

Recommendations

Limitation of liability

CAUTION!

....points out a potentially dangerous situation, that can lead to minor or slight injuries,

if not avoided.

NOTICE!

....points out a potentially dangerous situation, that can lead to material damage, if

not avoided.

NOTE!

....highlights useful hints and recommendations, as well as information for the effi-

cient and trouble-free use.

1.3 Limitation of liability

All specifications and notes in this Instruction handbook were compiled taking into account the applicable standards and regulations, the state of the art and our knowledge

and experience of many years.

The manufacturer assumes no liability for damages due to:

m noncompliance with the Instruction handbook

m usage for other than the intended purpose

m usage by untrained personnel

The actual scope of delivery can vary in case of optional equipment, laying claim to additional order options, or on account of the latest technical changes to the explanations and

representations described herein.

The user bears the responsibility for performing service and commissioning in accordance with the safety regulations of the applicable standards and all other relevant governmental or local regulations referring to the dimensioning and protection of conductors,

grounding, disconnectors, overcurrent protection, etc.

The person who carried out the mounting or installation is liable for any damage, which

incurred when assembling or connecting the device.

8

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

1.4 Copyright protection

General

1

The Instruction handbook must be treated confidentially

personnel who work with the device. The consignment of the Instruction handbook to third

persons without the written permission of the manufacturer is prohibited.

NOTE!

he specific contents, text, drawings, images and other representations are copy-

T

righted and subject to industrial property rights. Any prohibited usage is punishable

by law.

CANopen

EnDat

EtherCAT

HIPERFACE

HIPERFACE DSL

PROFINET

speedtec

®

®

®

®

is a registered trademark of PROFIBUS International

®

is a registered trademark of CAN in Automation e. V.

is a registered trademark of Dr. Johannes Heidenhain GmbH,

83301 Traunreut, Germany

is a registered trademark of Beckhoff Automation GmbH,

33415 Verl, Germany

is a registered trademark of SICK STEGMANN GmbH,

®

78166 Donaueschingen, Germany

is a registered trademark of INTERCONTEC Produkt GmbH

94559 Niederwinkling, Germany

. It is to be used exclusively by

NOTE!

Please note, that BAUMÜLLER is not responsible to examine whether any (industrial

property) rights of third parties are infringed by the application-specific use of the

BAUMÜLLER products/components or the execution.

1.5 Applicable documents

Components of other manufacturers are integrated into the device. For these purchased

parts, hazard assessments have been performed by the respective manufacturers. The

compliance of the design construction with the applicable European and national regulations has been declared for the components by the respective manufacturers.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

9

of 218

1.6

Spare parts

1.6 Spare parts

1.7 Disposal

WARNING!

False or flawed spare parts can lead to damage, malfunction or complete fail-

ure, thus endangering safety.

Therefore:

m Only use original spare parts of the manufacturer.

Procure spare parts through an authorized dealer or directly from the manufacturer.

See also ZAccessories and Spare Parts– as from page 177.

Insofar as no take-back or disposal agreement has been made, please disassemble units

correctly and properly recycle the constituent parts.

See also ZDisposal– on page 203.

1.8 Guarantee provisions

The guarantee provisions are stated in a separate document of the sales documents.

The devices described herein may only be operated in accordance with the stipulated

methods, procedures and conditions. Anything else not presented here, including the operation of devices in mounted positions, is not permitted and must be cleared with the

plant on a case-by-case basis. If the devices are operated in any other manner than as

described within this Instruction handbook, then all guarantee and warranty rights are rendered null and void.

1.9 Customer service

Our customer service is available to provide you with technical information.

Info on the responsible contact persons is available at all times via telephone, fax, mail or

the Internet.

1.10 Terms used

The term „device“ or the item designation BM3XXX are also used in this documentation

for this Baumüller product „BM3000, BM3200, BM3300“. A list of the abbreviations used

can be found in ZAppendix A - Abbreviations– from page 207.

10

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

This section provides an overview of all of the important safety aspects for optimum protection of personnel as well as for the safe and problem-free operation.

2.1 Contents of the Instruction handbook

Each person who is tasked with performing work on or with the device must have read

and understood the Instruction handbook before working with the device. This also applies if the person involved with this kind of device or a similar one, or has been trained

by the manufacturer.

2.2 Changes and modifications to the device

In order to prevent hazards and to ensure optimum performance, no changes, additions

or modifications may be undertaken on the device that have not been explicitly approved

by the manufacturer.

2SAFETY

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

11

of 218

2.3

Appropriate use

2.3 Appropriate use

The device is conceived and constructed exclusively for usage compliant with its intended

purpose described in this Instruction handbook.

The devices of the model series BM3200, BM3300 contains of a power converter in combination with a servo controller. Devices are available in graduated design size and performance classes. The device BM3200, BM3300 is used exclusively as a converter for

controlling a motor.

The devices BM3000 are mains rectifier units to supply the DC link.

A device is considered as being used compliant with its intended purpose if all notes and

information of this Instruction handbook are adhered to.

WARNING!

Danger arising from usage for an unintended purpose!

Any usage that goes beyond the intended purpose and/or any non-compliant use of

the device can lead to dangerous situations.

Therefore:

m Only use the device compliant with its intended purpose.

m Observe all specifications of this Instruction handbook.

m Ensure that only qualified personnel work with/on this device.

m When configuring, ensure that the device is always operated within its specifica-

tions.

m Mount the device on a wall, which is sustainable.

m The device must always be operated within a control cabinet.

m Ensure that the power supply complies with the stipulated specifications.

m The device may only be operated in a technically flawless condition.

m Only operate the device in combination with components approved by Baumüller

Nürnberg GmbH.

m Only operate the devices in secondary surrounding (e.g. an industrial environ-

ment). The device has been developed in such a manner that it fulfills the requirements of the category C3 according to IEC 61800-3:2012. The device is not

intended to be connected to the public power supply. To operate the device in primary surrounding of the category C2/C1 (residential, business and commercial areas, directly on a public low-voltage power supply without an intermediate

transformer), special measures to reduce the transient emissions (line-internal and

radiated) must be provided for and certifiable by the system builder. Otherwise,

EMC interference could occur without such additional measures. Whether a device

described here can itself qualify for category C2/C1 with additional measures cannot be guaranteed.

12

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

2.4 Responsibility of the operating company

The device will be used in commercial areas. Thus, the proprietor of the device is subject

to the legal work safety regulations.

Along with the notes on work safety in this Instruction handbook, the safety, accident prevention and environmental protection regulations valid for the area of application of this

device must be complied with. Whereby:

e operating company must inform himself about the applicable work health and safe-

m Th

ty regulations and ascertain, in a hazard ass

arise from the special working conditions in the use area of the device. These must

then be implemented in the form of operating instruction for operation of the device.

is Instruction handbook must be kept accessible to personnel working with the de-

m Th

vice at all times in the immediate vicinity of the device.

e specifications of the Instruction handbook must be adhered to completely and

m Th

without exception.

e device may only be operated in a technically faultless and operationally safe con-

m Th

dition.

Safety

essment, any additional hazards that could

2

2.5 Protective devices

Mains rectifier

BM300X

Compact servo unit

BM320X, BM330X, BM321X, BM331X

All devices BM30

net to meet the IP code required in EN 61800-5-1, chapter 4.2.3.3 (BM300X: IP00,

BM3200, BM3300: IP 30: only upper horizontal surfaces; IP 20: all other surfaces).

DANGER!

Risk of fatal injury from electrical current!

The mains rectifier BM3000 protection code is IP00.

The operator is responsible for the protection against direct and indirect contact in the

switching cabinet.

IP code

IP 00

IP 20

00, BM3200, BM3300 must be installed in an appropriate control cabi-

There is an immediate risk of fatal injury if live electrical parts are contacted.

Therefore:

m The devices BM3200, BM3300 must be in operated inside of a control cabinet that

provides protection against direct contact of the devices and at least meets the requirements of EN 61800-5-1, Chapter 4.2.3.3.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

of 218

13

2.6

Training of the personnel

2.6 Training of the personnel

WARNING!

Risk of injury due to insufficient qualifications!

Improper handling can lead to significant personal injury and material damage.

Therefore:

m Certain activities can only be performed by the persons stated in the respective

chapters of this Instruction handbook.

In this Instruction handbook, the following qualifications are stipulated for various areas

of activity:

m Operating personnel

n The drive system may only be operated by persons who have been specially trained,

familiarized and authorized.

n Troubleshooting, maintenance, cleaning, maintenance and replacement may only

be performed by trained or familiarized personnel. These persons must be familiar

with the Instruction handbook and act accordingly.

n Initial operation and training may only be performed by qualified personnel.

m Qualified personnel

n Electrical engineers authorized by Baumüller Nürnberg GmbH, and qualified electri-

cians of the customer or a third party who have learned to install and maintain

Baumüller drive systems and are authorized to ground and identify electrical power

circuits and devices in accordance with the safety engineering standards of the com

pany.

n Qualified personnel have had occupational training or instruction in accordance with

the respective locally applicable safety engineering standards for the upkeep and

use of appropriate safety equipment.

-

14

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

2.7 Personal protective equipment

The wearing of personal protective equipment is required when working in order to minimize health and safety risks.

m The protective equipment necessary for each respective type of work shall always be

worn during work.

m The personal safety signs present in each working area must be observed.

Protective work clothing

should be snug-fitting work clothes, with low tearing resistance, narrow sleeves and

with no extending parts. When having longer hair use a safety hair net.

No rings or chains should be worn.

Hard hat

to protect against parts falling down and against parts, which are flying around.

Safety

2

Wear for special

work.

Safety shoes

to protect against heavy objects falling down.

Safety gloves

to protect hands against friction, abrasion, puncturing or more severe injuries, as well

as against the contact with hot objects.

Safety goggles

to protect the eyes against objects, which are flying around and against splashes.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

15

of 218

2.8

Special hazards

2.8 Special hazards

In the following section, the remaining marginal risks will be stated that have been identified as a result of the hazard analysis.

Observe the safety notes listed here and the warning notes in the further chapters of this

manual to reduce health risks and dangerous situations.

Electrical current

DANGER!

Risk of fatal injury from electrical current!

There is an immediate risk of fatal injury if live electrical parts are contacted. Damage

to the insulation or individual components can be life-threatening.

Therefore:

m Switch off the electrical power immediately in case of damage to the power supply

m Only allow work on the electrical system to be performed by qualified personnel.

m Switch off the current when any kind of work is being performed on the electrical

insulation.

system and ensure safety before switching on again.

Danger from

residual energy

DANGER!

Risk of fatal injury from electrical current!

Stored electric charge.

Discharge time of the rack system = discharge time of the device with the longest DC

link discharge time in the rack system.

Refer to ZElectrical data– from page 35.

Therefore:

m Do not touch electrically live parts before taking into account the discharge time of

the capacitors.

m Pay attention to the corresponding notes on the device.

m If several devices are connected e.g. with a rectifier unit, the DC link discharge can

take a much longer time. In this case, the necessary waiting period must itself be

determined or a measurement made to ensure the device is de-energized. This

discharge time must be posted, together with an IEC 60417-5036 (2002-10) warning symbol, on a clearly visible location of the control cabinet.

16

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

Moving components

2.9 Fire fighting

Safety

WARNING!

Risk of injury from moving components!

Rotating components and/or components moving linearly can result in severe injury.

Therefore:

m Do not touch moving components during operation.

m Do not open any covering during operation.

m The amount of residual mechanical energy depends on the application. Powered

components still turn/move for a certain length of time even after the power supply

has been switched off. Ensure that adequate safety measures are taken.

2

DANGER!

Risk of fatal injury from electrical current!

There is a risk of electric shock if an electrically-conductive, fire-extinguishing agent

is used.

Therefore:

m Use the following fire-extinguishing agent:

ABC powder / CO

2

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

17

of 218

2.10

Safety equipment

2.10 Safety equipment

WARNING!

Risk of fatal injury due to non-functional safety equipment!

Safety equipment provides for the highest level of safety in a facility. Even if safety

equipment makes work processes more awkward, under no circumstances may they

be circumvented. Safety can only be ensured by intact safety equipment.

Therefore:

m Before starting to work, check whether the safety equipment in good working order

and properly installed.

2.11 Behavior in hazardous situations or at accidents

Preventive

measures

And if something

does happen:

respond properly

m Always be prepared for accidents or fire!

m Keep first-aid equipment (e.g. first-aid kits, blankets, etc.) and fire extinguishers readily

accessible.

m Familiarize personnel with accident signalling systems, first aid equipment and life sav-

ing equipment.

m Stop operation of the device immediately with an EMERGENCY Stop.

m Initiate first aid measures.

m Evacuate persons from the danger zone.

m Notify the responsible persons of the site.

m Alarm medical personnel and/or the fire department.

m Keep access routes clear for rescue vehicles.

18

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

2.12 Signs and labels

The following symbols and information signs are located in the working area. They refer

to the adjacencies, where they were affixed.

WARNING!

Risk of injury due to illegible symbols!

Over the course of time, stickers and symbols on the device can become dirty or otherwise unrecognizable.

Therefore:

m Maintain all safety, warning and operating labels on the device in easily readable

condition.

Safety

2

Electrical voltage

Only qualified personnel may work in work areas that identified with this.

Unauthorized persons may not touch working materials marked correspondingly.

DANGER!

Risk of fatal injury from electrical current!

Stored electric charge.

Discharge time of the rack system = discharge time of the device with the longest DC

link discharge time in the rack system.

Refer to ZElectrical data– from page 35.

Therefore:

m Do not touch before taking into account the discharge time of the capacitors and

electrically live parts.

m Heed corresponding notes on the equipment.

m If several devices are connected e.g. with a rectifier unit, the DC link discharge can

take a much longer time. In this case, the necessary waiting period must itself be

determined or a measurement made to ensure the device is de-energized. This

discharge time must be posted, together with an IEC 60417-5036 (2002-10) warning symbol, on a clearly visible location of the control cabinet.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

19

of 218

2.12

Signs and labels

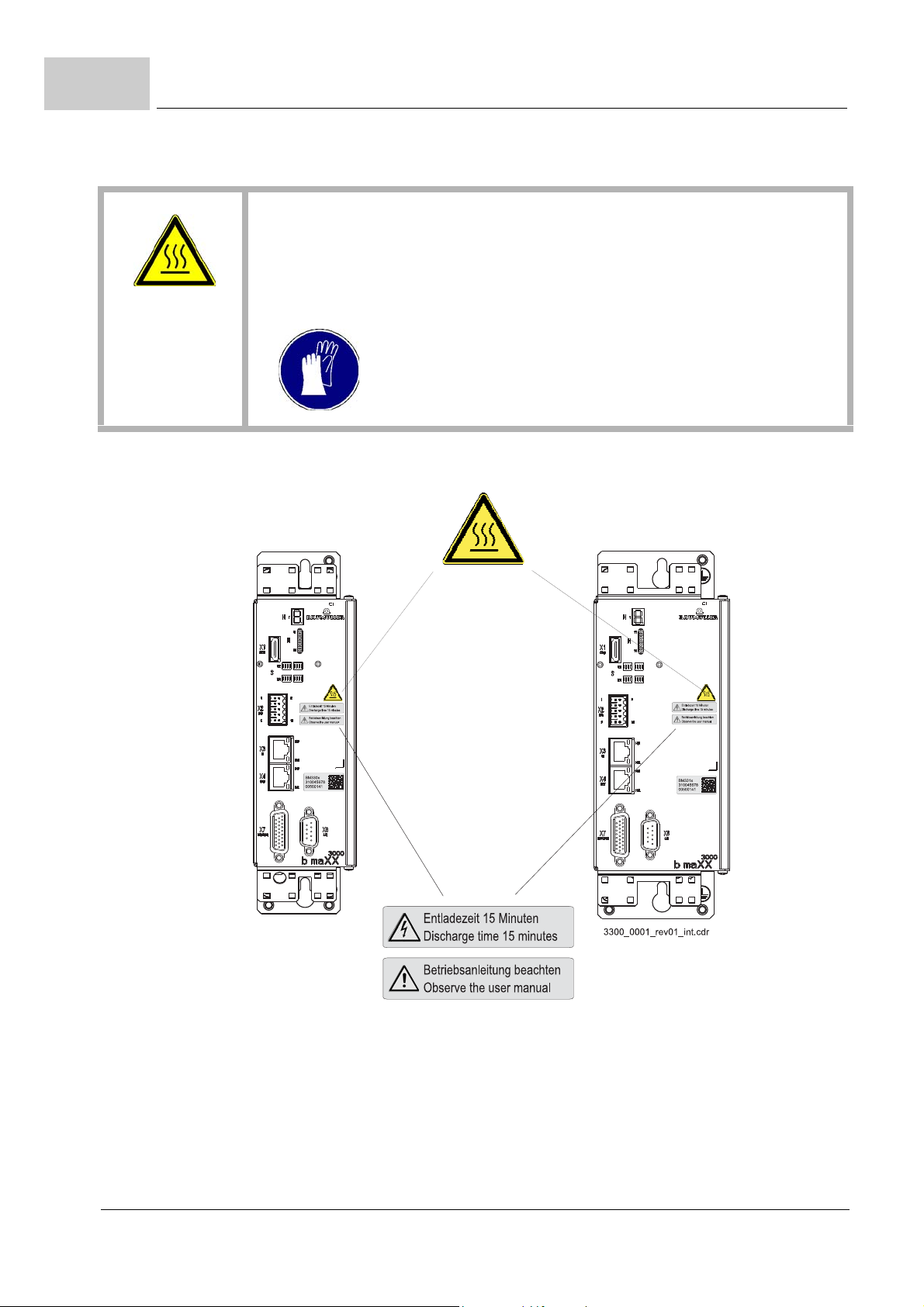

CAUTION!

Risk of injury due to hot surface!

When in operation, the top of the device can heat up to temperatures > 70 °C!

Therefore:

m Wear safety gloves

20

of 218

Figure 1: Signs and labels BM3200, BM3300

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

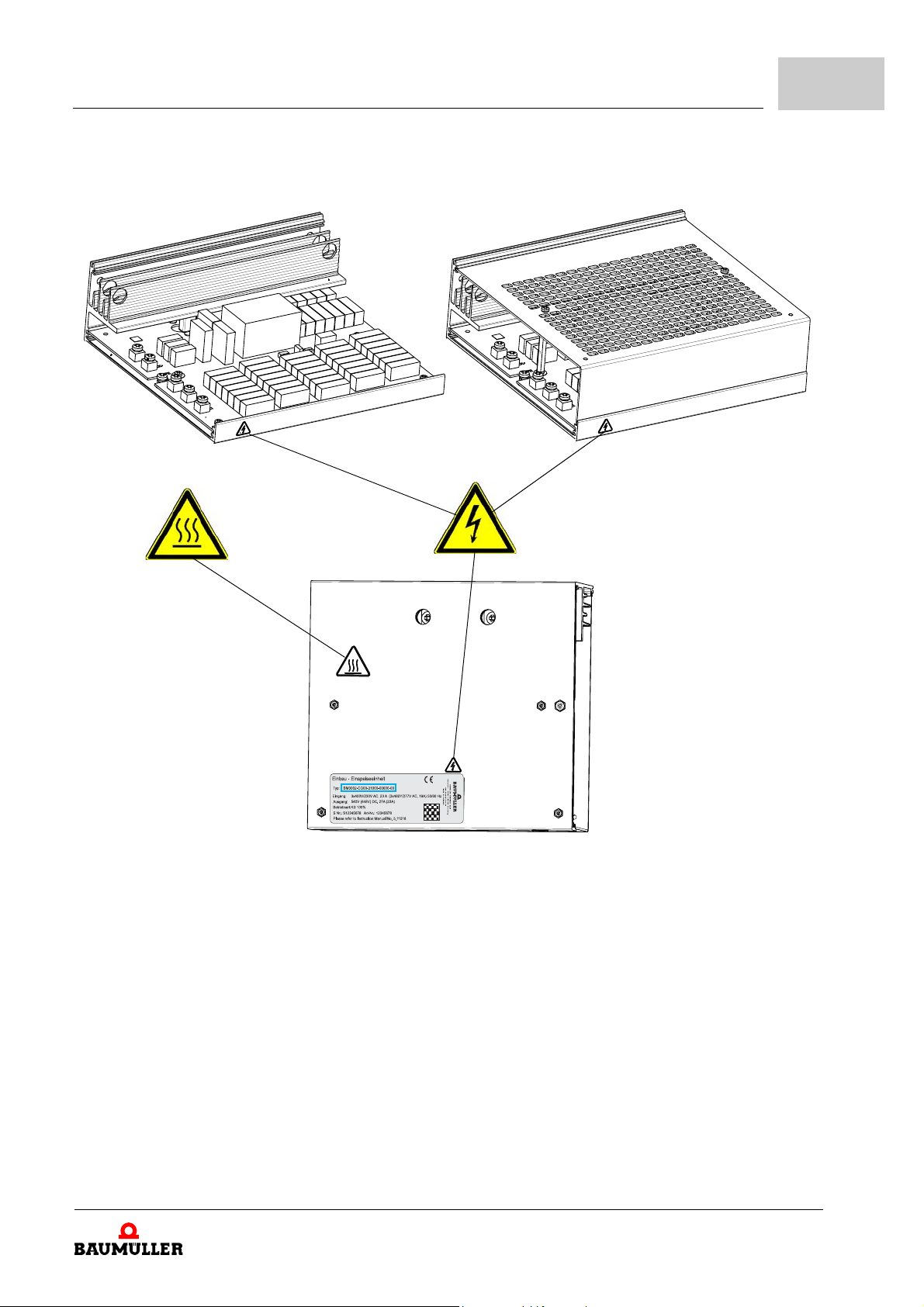

Without protection cover With protection cover (option)

Safety

2

Figure 2: Signs and labels BM3000

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

21

of 218

2.12

Signs and labels

devices

with safety level

Signs and labels

NOTE!

Only a device marked with the TÜV Rheinland certification label and the safety label

fulfills a certified safety function within the meaning of PL classification according

ISO 13849 or SIL according EN 61800.

new logo former logo

22

of 218

Figure 3: Signs and labels BM3300 with safety level

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

3.1 Dimensions

3TECHNICAL DATA

With the help of the following figures, the space requirements in the control cabinet are

determined. In order to execute the necessary drilling/section please refer to ZDrilling

templates– from page 77.

NOTE!

All dimensions in mm.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

23

of 218

3.1

70

212

Dimensions

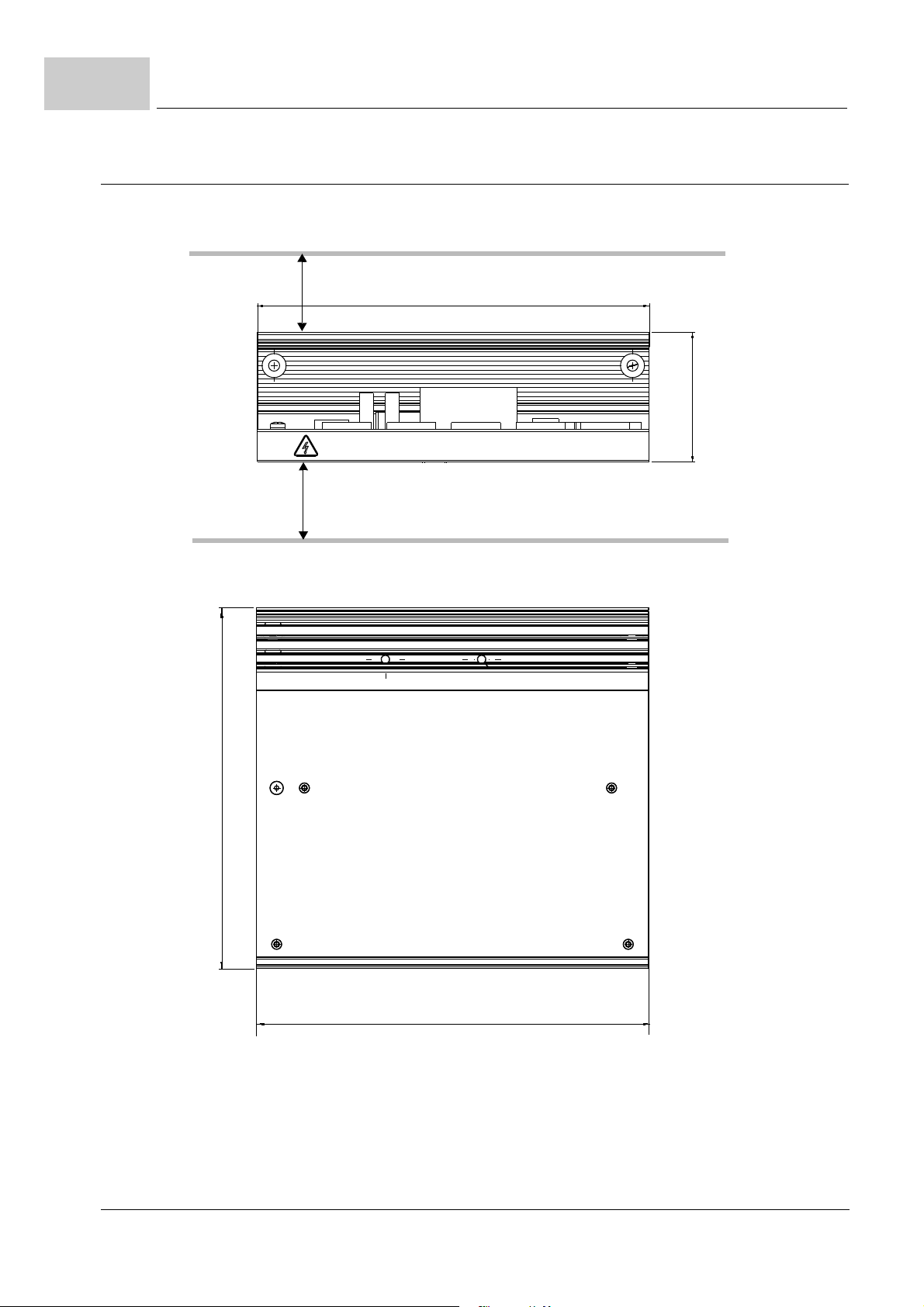

3.1.1 Dimensions BM3000

24

of 218

Figure 4: Dimensions BM3000

Instruction handbook b maXX BM3000, BM3200, BM3300

*) Consider minimum space,

ZCooling– on page 34.

Document no. 5.11018.11 Baumüller Nürnberg GmbH

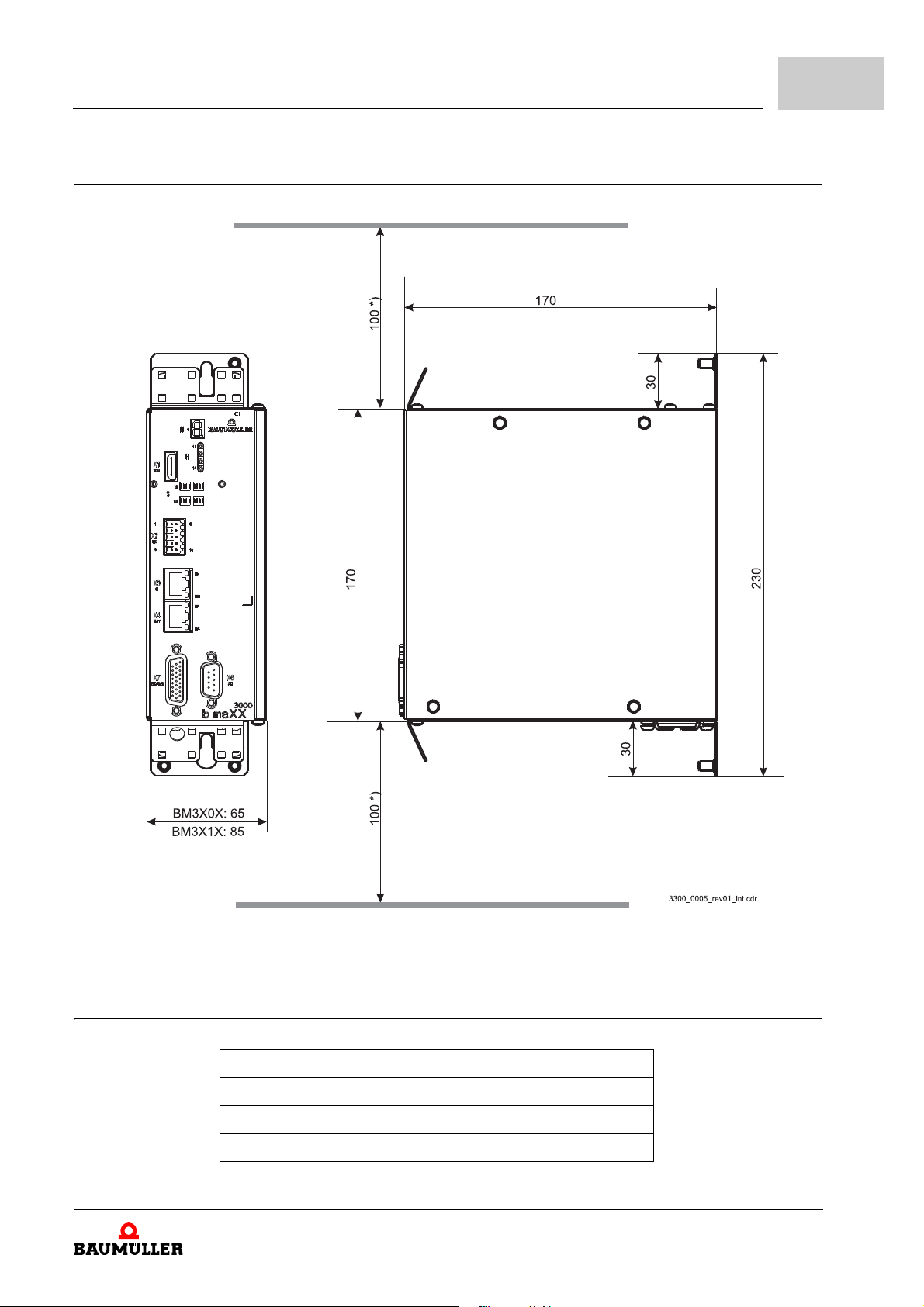

3.1.2 Dimensions BM3200, BM3300

Technical Data

3

3.2 Weight

Figure 5: Dimensions BM3200, BM3300

Device Weight

BM3002 approximately 1.15 kg

BM320X, BM330X approximately 2.2 kg

BM321X, BM331X approximately 2.5 kg

Instruction handbook b maXX BM3000, BM3200, BM3300

*) Consider minimum space,

ZCoo

Document no. 5.11018.11

ling– on page 34.

25

of 218

3.3

Operating conditions

3.3 Operating conditions

3.3.1 System types

There is a differential structure of current supply networks and it is distinguished between

three basic types, referring to their grounding, which is accordant to DIN VDE0100 part

300 and accordingly to IEC 60364:

a TN-system one point is directly grounded (main ground). The cabinet of the elec-

m In

trical installation is connected via protective conductors and accordingly PE-conductors with this point.

a TT-system a point is directly grounded (main ground). The cabinet of the electric

m In

installation is connected to ground connections, which, however, are separated from

the main ground.

an IT-system there is no direct connection between active conductors (L1, L2, L3,

m In

N) and grounded parts (PE). The cabinets of the electrical installation are grounded.

The separation is reached, by the use of an isolating transformer or with the use of an

independent current source (generator, battery).

If there is an adequate low-impedance grounding within the TN- or the TT-network, then

line-side fuse is activated. A high-impedance grounding does not activate the fuse, so

a

that the ground currents (error current) can be potentially dangerous. For this reason, circuit breakers are used for the error current monitoring.

At a short-circuit to ground, no ground current can flow and the line-side fuses cannot be

activated, by which the operation can be kept up. Only a second short-circuit to ground at

another phase would cause an current error, which can trigger a fuse. In order to detect

the first short-circuit to ground an insulation monitor and for the second short-circuit to

ground, a current error monitoring, are necessary.

Supported system

pes

ty

NOTICE!

The operation of the BM3000 devices is possible with all power supply networks.

The operation of the BM3200, BM3300 devices is possible with TT- and TN-net-

works.

The common network types in the USA are differentiate clearly from the European

networks. Besides the Solidly Grounded Wye, which is similar to the TN-S-system,

there is also a Corner Grounded Delta (this differs to the description in the IEC). The

BM3200, BM3300 may not be operated here.

An operation with DC-link connection and use of a active mains rectifier is forbidden.

26

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

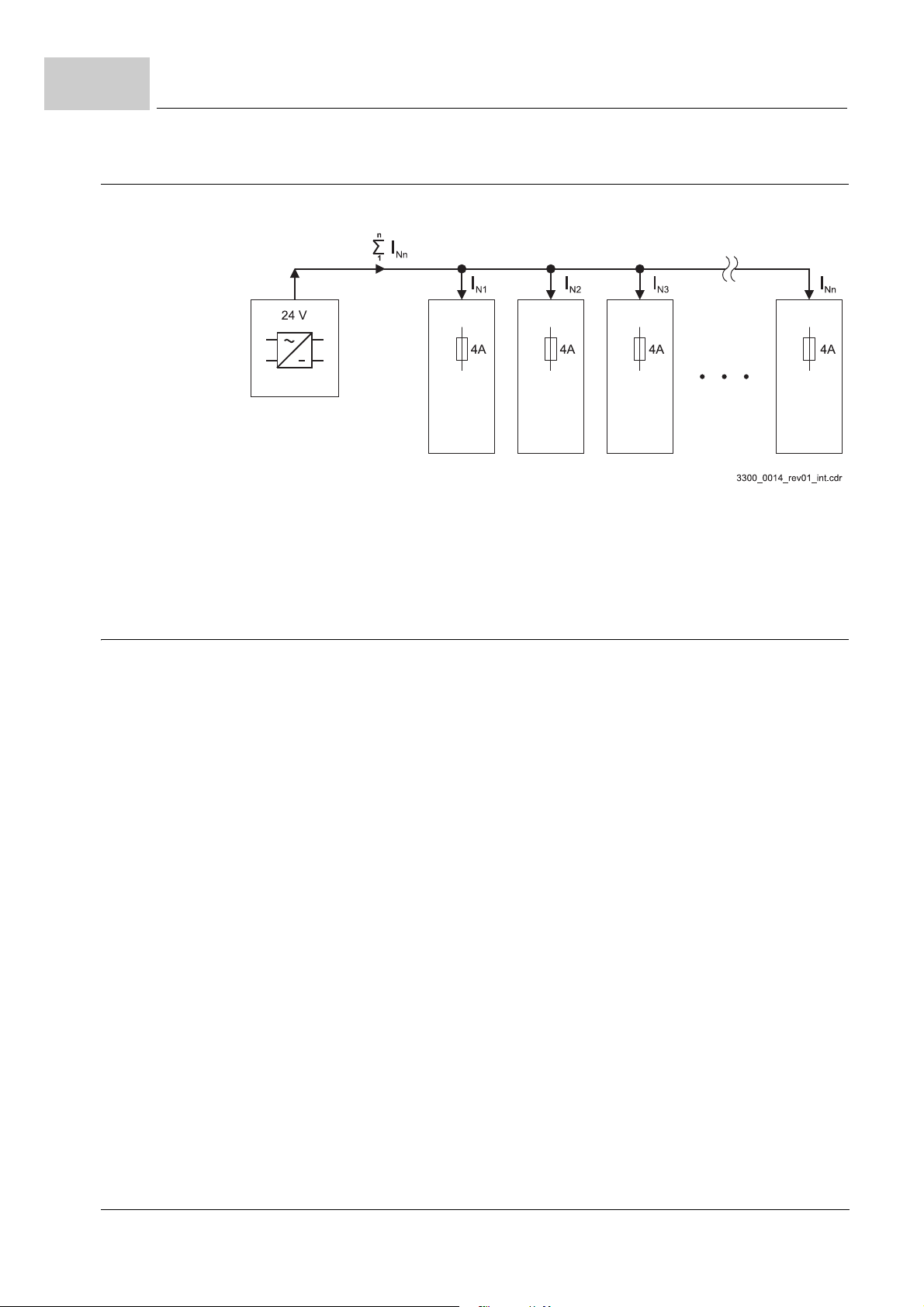

3.3.2 Requirements to the energy supply: power supply

Power supply

(also see ZSystem types– from page 26)

TN-/TT-system

Technical Data

BM3000 BM3200, BM3300

IT-system,

TN-/TT-system

3

Inductance (sum of supply inductance and the

power choke inductance)

Rated supply voltage/frequency

Absolute supply voltage minimum

Absolute supply voltage maximum

Absolute frequency minimum

Absolute frequency maximum

1) 2)

(UAC)

1) 2)

(U

ACmin

1) 2)

(U

ACmax

4)

4)

Overvoltage category

EN 61800-5-1, chapt. 4.3.6

Harmonic components (power supply voltage)

EN 61800-3, chapter 5.2.1, class 3

Power Supply voltage asymmetry

EN 61000-2-4, tab. 1, class 3

Commutation notch

EN 61800-3, chapter 5.2.1, class 3

Voltage drop

EN 61800-3:2004 and A1:2012

Voltage variations/deviations

EN 61200-2-4, Class 3

Control voltage

c

omplying with EN 61131-2:1994, table 7

3)

(UDC)

Max. short-circuit strength power supply

only necessary to comply with UL508C

Min. u

3 x 400 V, 50/60 Hz

= 0 %, max. uk = 4 %

k

1 x 230 V, 50/60 Hz

1 x 400 V, 50/60 Hz

3 x 400 V, 50/60 Hz

)

)

528 V / 50/60 Hz

/ 50/60 Hz

110 V

528 V / 50/60 Hz

47 Hz

63 Hz

III

THDU b 12 %

max. 3 %

setback depth < 40 %, area < 250 % x degree

10 % to 80 %

1)

+/-10 %

+10 % to -15 % at a time of b 1 min

-

-

+ 24 V -15 % / +20 %

5000 A

1)

If the voltage falls below U

2)

The rated voltage is 3 x 400 V

At lower supply voltages the output power of the device reduces, see correction factor at modified environmental conditions, ZSupply

voltage– on page 31.

3)

The control voltage must accord to PELV (EN 61800-5-1, chapter 3.21) and accordingly SELV (EN 61800-5-1, chapter 3.35).

At a control voltage < 24 V the ventilator power is reduced. Therefore, it can be necessary, that the output currents also be reduced.

4)

Rate of change of system frequency max. 1 Hz/s (EN 61000-2-4, class 3)

for t > 0,1 s the error „Power unit not ready-to-operate“ is generated.

ACmin

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

27

of 218

3.3

BM3200

BM3300

BM3200

BM3300

BM3200

BM3300

BM3200

BM3300

Operating conditions

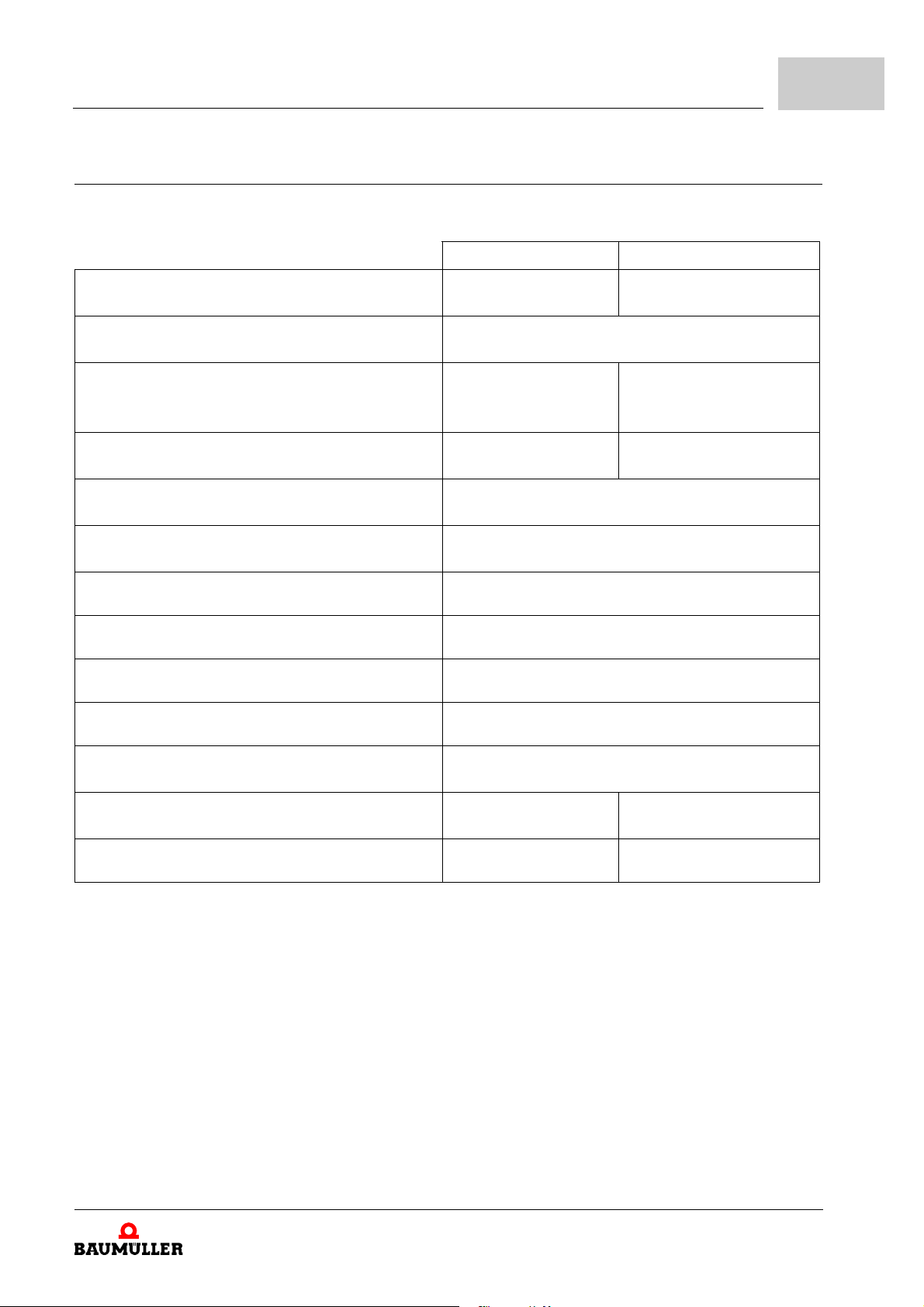

3.3.3 Requirements to the control voltage / 24 V-supply

Figure 6: Control voltage / 24V-supply

The power supply for the 24 V supply voltage must provide the rated power, at least,

which accords to the sum of the 24 V-supply voltage of all devices.

3.3.4 Requirements to the motor

The BM3200, BM3300 was prepared for the operation of three-phase motors with a motor terminal voltage of 3 x 350 V (typical for servo motors of Baumüller) or 3 x 400 V (typical for standard asynchronous motors and for customer-specific special motors of

Baumüller). The motors are to be operated wye-connected. The rated DC-link voltage is

540 V

. In braking operation it must be expected, that the DC-link voltage increases to

DC

780 V or 800 V. The connected motor must be constructed for these DC-link voltages.

The use of the devices is also possible at smaller voltages, e.g. 3 x 230 V. However, this

implies that the used three-current motors for the operation at inverters with a voltage of

up to 800 V DC-link voltage are designed, because the ballast resistor voltage threshold

remains unchanged (see ZElectrical data– from page 35). Thus, in these cases, threephase motors with U

DC rated

540 V, must be used, only.

28

of 218

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

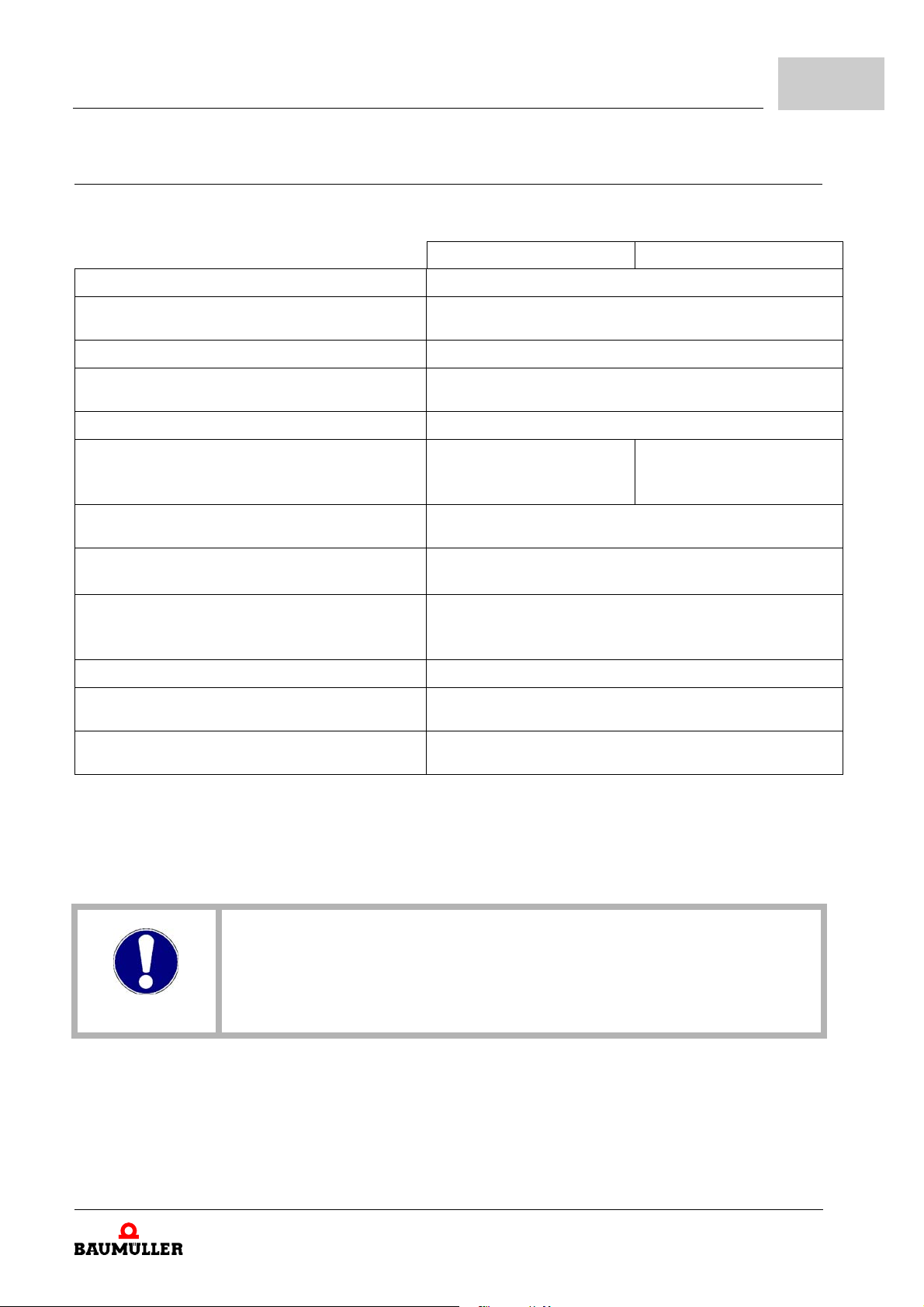

Technical Data

3.3.5 Required environmental conditions

BM3000 BM3200, BM3300

Transportation temperature range -25 °C to +70 °C

3

Transportation climate classification

EN 60721-3-2

2 K 3

Storage temperature range -25 °C to +55 °C

Storage climate classification

EN 60721-3-1

Operation environment Industrial supply network

1 K 4

1)

Operation temperature range min. 5 °C to max. 40 °C min. 5 °C to max. 55 °C

(with derating above 40 °C)

2)

Operation climate classification

EN 60721-3-3

Installation altitude up to 2000 m altitude

(with derating above 1000 m)

Humidity (operation)

EN 60721-3-3

relative humidity: 5 % to 85 % non-condensing

absolute humidity: 1 g/m

3 K 3

and

3

to 25 g/m

3)

3

Ionizing and non-ionizing radiation < measurable range

Vibration, shock and repetitive shock

EN 61800-5-1, section 5.2.6.4 vibration test

Pollution degree

EN 61800-5-1, table 6, tab. 2

max. 0.5 g operating (1 g tested)

2

1)

For an operation in an environment of category C2 according to IEC 61800-3:2012 additional measures may be required.

In this case the system manufacturer/operator must provide evidence, that these additional measures are effective and that the limit

values specified in IEC 61800-3 of category C2 are complied with.

2)

See correction factors at modified environment conditions, ZEnvironmental temperature– on page 31.

3)

See correction factors at modified environment conditions, ZInstallation altitude– on page 30.

NOTICE!

Normally, only non-conductive pollution occurs. Any conductive pollution, if for a

short-term or permanently, is forbidden and can cause the destruction of the device.

The customer is responsible for destructions, which are caused by conductive materials.

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11

29

of 218

3.3

3.3.6 Correction factors at modified operational conditions

3.3.6.1 Installation altitude

Operating conditions

If the devices BM3200, BM3300 are used at operational conditions, which cause different

correction factors, then all correction factors for the permitted output power and accordingly the output current, must be taken into account by multiplication at the same time.

The following correction factors are to be considered if nothing other is specified at the

„Technical data“ of the device:

NOTE!

The temperature of the cold plate temperature must be higher or equal to the surrounding temperature to prevent condensation.

NOTE!

It is no derating necessary while single phase operation of a three phase device

BM3201-XT, BM3301X-XT.

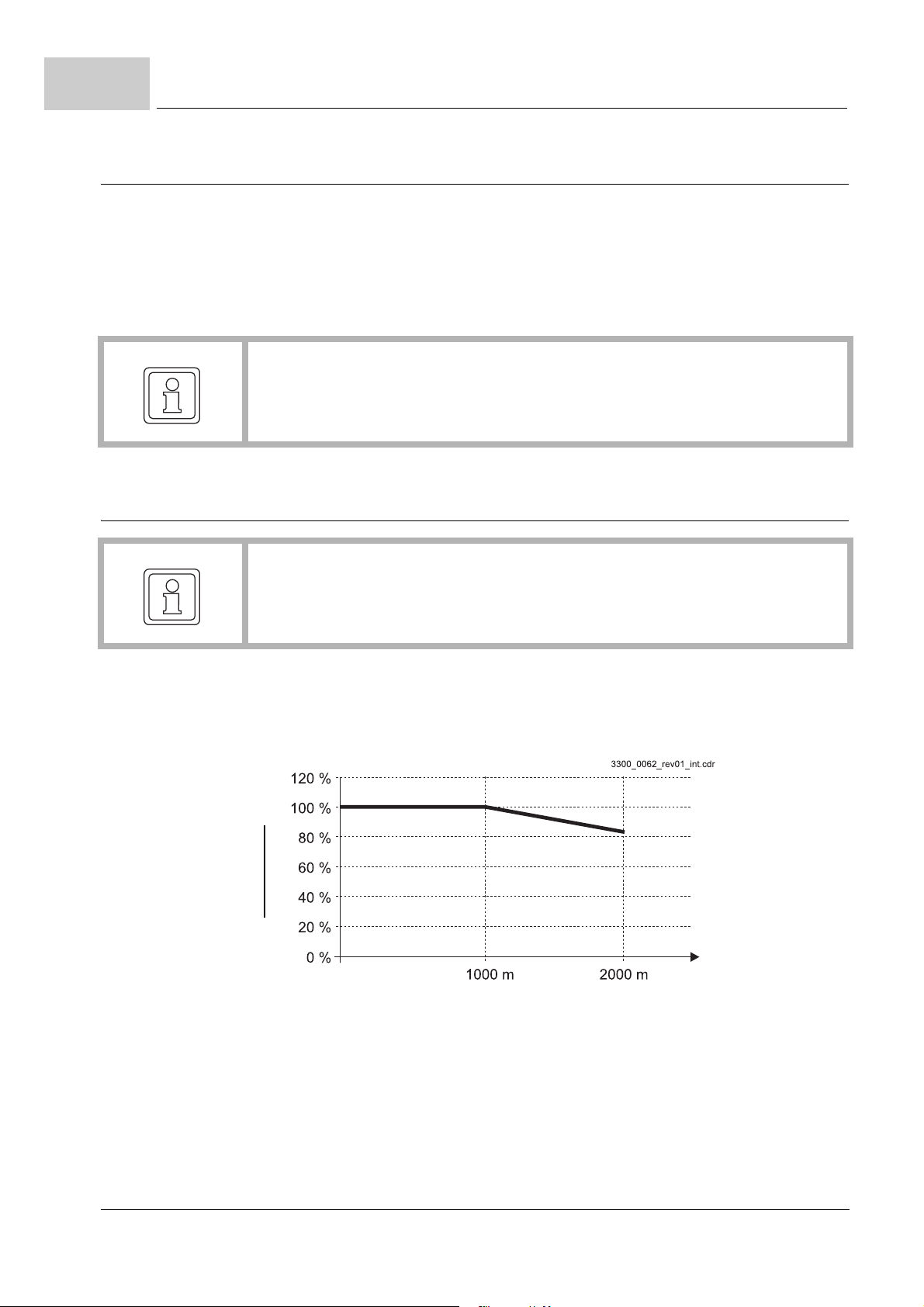

The output power must be reduced against the rated power, according to the following

figure, if the devices BM3000, BM3200, BM3300 are used above an altitude of 1000 m,

no operation is permitted above an altitude of 2000 m.

Rated Power

Output Power

Altitude

30

of 218

Figure 7: Reducing of output power in dependence of altitude

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

Loading...

Loading...